Dental 3d printer cost

Dental 3D Printers - What You Need to Know

Dental 3D Printers - What You Need to Know | Benco DentalAll Products

Search for:

Dental Products

Company Website

Blog Articles

3D Printers

Scan > Design > Print > Prepare

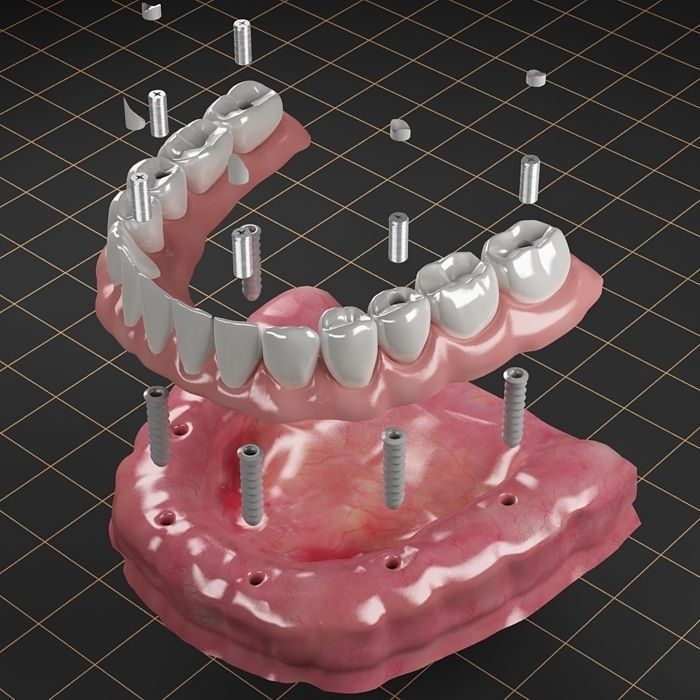

3D printing is the catalyst for digital dentistry. It’s known for reliability and high quality. Much has changed since the first desktop 3D printers became available to the dental industry. A few years ago, 3D printers were only affordable to the largest dental labs, now they are a common sight in labs and practices of any size. Dental 3D printers feature a light or laser that polymerize a liquid with the computer-guided precision required to produce small objects with intricate details.

The dental 3D printing workflow has four-steps:

- Scan – collect a digital impression with an intraoral scanner.

Send the scans to a lab or to a design station.

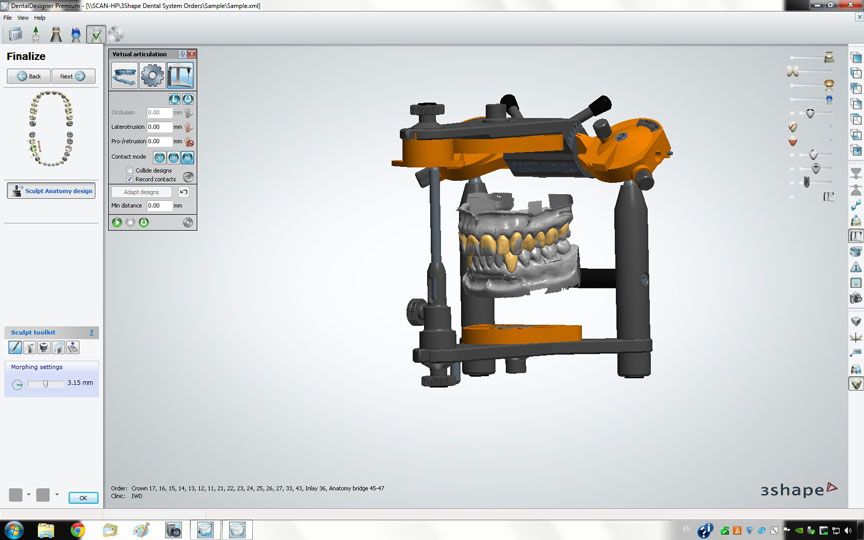

- Design – import the digital scan into design software (CAD) and design.

- Print – once designing is complete, import the file to print preparation software for print setup.

- Prepare – wash, dry and post-cure printed parts.

WHAT CAN A 3D PRINTER MAKE?

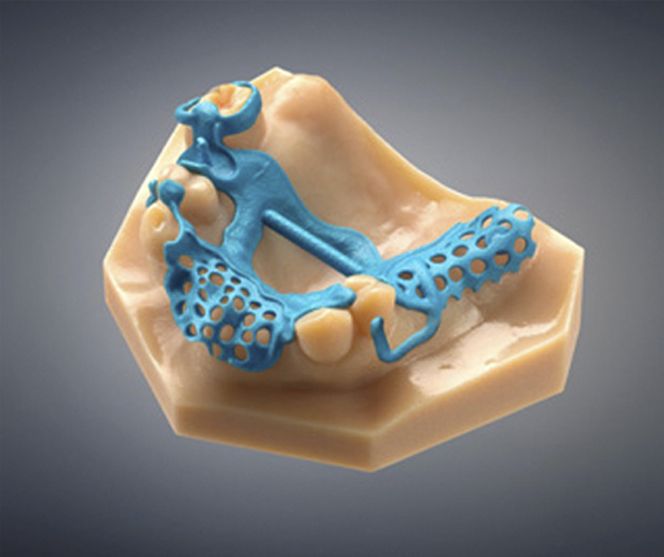

Dental 3D printers can produce applications such as:

- Crown/Bridge Models

- Clear Aligner Models

- Surgical Guides

- Splints/Occlusal Guards

- Patterns for Casting and Pressing

- Hawley Retainers

- Full Dentures

CHOOSING A 3D PRINTER FOR YOUR DENTAL PRACTICE OR LAB

Additive manufacturing is making digital dentistry a no-nonsense business choice, combining high quality and improved patient care with low unit costs and streamlined workflows.

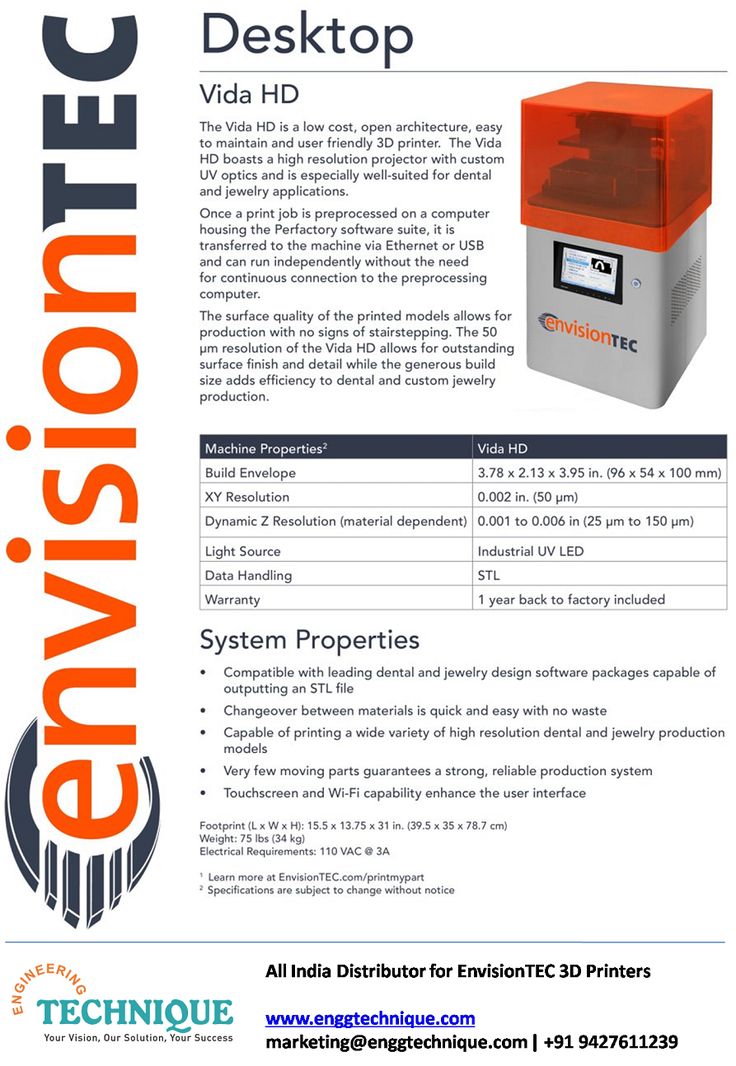

Today, three 3D printing technologies are common in dental: stereolithography (SLA), digital light processing (DLP) and material jetting. Each technology can deliver the precision and accuracy needed for dental applications, but quality can vary among different machines and systems.

Each technology can deliver the precision and accuracy needed for dental applications, but quality can vary among different machines and systems.

1. Stereolithography (SLA) – liquid resin is selectively exposed to a laser beam across the print area, solidifying resin in specific areas. Stereolithography is highly accurate and has the best surface finish of the three technologies. SLA printers offer large build volumes and a wide range of materials for various applications. Switching materials is as easy as swapping the resin tank and cartridge. The combination of small footprint, simple workflow and low price make desktop SLA printers well-suited for both dental labs and practices.

2. Digital Light Processing (DLP) – Digital light processing operates with the same chemical process as SLA but uses a digital projector as a light source to solidify the resin, rather than a laser. DLP printers have a small footprint, simple workflow and wide range of material options, but at a substantially higher cost than desktop SLA printers. DLP parts also tend to show voxel lines—layers formed by small rectangular bricks due to digital screen—and have a generally lower quality surface finish.

DLP parts also tend to show voxel lines—layers formed by small rectangular bricks due to digital screen—and have a generally lower quality surface finish.

3. Material Jetting – Material jetting (PolyJet and MultiJet Modeling) 3D printers work similarly to inkjet printing, but instead of jetting drops of ink onto paper, they jet layers of liquid resin onto a build tray and cure them instantly using light. Material jetting technologies were the most common in the dental industry a few years ago, but expansion was limited by their high cost and the large size of the machines. They require extensive post-processing and the surface finish of parts produced with this technology is generally inferior to SLA or DLP. Material jetting systems have high throughput but can only be used for a limited range of applications due to the costly, proprietary materials.

KEY FEATURES WHEN EVALUATING 3D PRINTING SOLUTIONS

- Accuracy and Precision

- Ease of Use and Reliability

- Cost and Return on Investment

- Materials and Applications

- Throughput and Scalability

HOW MUCH DO 3D PRINTERS COST

Dental 3D printers can start at a few thousand dollars for resin desktop 3D printers (SLA or DLP) ot up to tens of thousands of dollars for metal 3D printers designed for direct production. Some manufacturers only make dental 3D printers while other have developed specific dental product lines.

Some manufacturers only make dental 3D printers while other have developed specific dental product lines.

Entry-level desktop SLA or DLP 3D printers start around $1,000 and can be used to produce molds using a special casting resin. Industrial-grade dental additive manufacturing systems can cost up to tens of thousands of dollars. Dental 3D printers’ prices vary based on several factors:

- Print quality – the higher the resolution offered by the 3D printer the better, and often the more expensive the 3D printer.

- Build volume – more expensive dental 3D printers usually offer a larger print volume, allowing dental labs to optimize their production flow and increase their ROI.

- Dental 3D software – a special software is required to create custom dental implants based on a 3D scan of the patient’s mouth. The dental 3D software is an important component of the digital dentistry value chain and can be expensive.

- Reliability and repeatability – perhaps the most important factor when it comes to using 3D printing for dental appliances production. Professional dental 3D printers must be able to consistently deliver high quality prints, especially in a dental lab environment where quality controls are frequent, and a high production output is expected. Therefore, some dental 3D printers are more expensive than other because they offer this reliability.

Please select the CAD/CAM offering you are interested in: (select all that apply)

Same-day Single RestorationsBite Splints/Night GuardsSurgical GuidesDenturesLarge Span BridgesFull Arch RestorationsCustom Titanium Abutments

First Name*:

Last Name*:

Practice Name:

Phone Number*:

Email Address*:

Comments:

* Required Fields

FINANCING OPTIONS AVAILABLE FOR EQUIPMENT & TECHNOLOGY PURCHASES

100% financing means you’ll hit the ground running. Plus, your cash remains untouched and intact for savings, working capital or expenses.

Plus, your cash remains untouched and intact for savings, working capital or expenses.

You’ll get the things you need upfront, with no waiting. Click here to apply for financing.

3D Printers Available

Do you need further assistance?

We’re happy to help you with any additional questions! Please fill in the form below, and a member of our OneVisit team will reach out to you.

I need help with*:

---Intraoral ScannersSoftwareMilling MachinesBlocks & MaterialsFurnaces3D Printing

First Name*:

Last Name*:

Practice Name:

Phone Number*:

Email Address*:

Comments:

* Required Fields

Larry Cohen

CHIEF CUSTOMER ADVOCATE

Larry Cohen graduated from Wilkes College with a B.S. in Accounting in 1957 and Columbia University Graduate School of Business, earning an M.S. in Management and Finance, 1958. He served in the U. S. Army Reserve from 1958 through 1964.

S. Army Reserve from 1958 through 1964.

He is the second-generation owner of Benco Dental Company, which was founded by his father, Benjamin Cohen in 1930.

Joining Benco Dental in 1959 as manager of the Tooth Department, in 1960, Larry became an outside sales rep, a position he enjoyed full time until 1972. Beginning that year, Larry began reducing his outside sales role and increasing his managerial duties, later becoming the president of Benco Dental from 1965 – 1996.

Larry is the Founder of the American Dental Cooperative; Board, American Dental Trade Associate, plus Various ADTA committees. He sits on the Board of Wilkes University, Board of Visiting Nurses Association and the Board of Jewish Community Center.

xPRF REPORTINGENDLESS SAVINGSPRO-SYS POWER UP

Register and create an account to get started

CLICK HERE

How Much Does Dental 3D Printing Cost?

The future of dentistry and orthodontics is digital. With cutting-edge digital dental technologies for impressions, treatment planning, design, 3D scanning, and 3D printing, digital technologies are transforming thousands of dental practices and labs worldwide. As CAD/CAM continues to replace traditional workflows and become the standard of dental care, digital solutions have become a necessary consideration for any dental business.

With cutting-edge digital dental technologies for impressions, treatment planning, design, 3D scanning, and 3D printing, digital technologies are transforming thousands of dental practices and labs worldwide. As CAD/CAM continues to replace traditional workflows and become the standard of dental care, digital solutions have become a necessary consideration for any dental business.

One of the first concerns a dental professional will have about upgrading or expanding into in-house 3D printing is about costs. Does this printer make sense for my business? Will the investment break even? What’s the ROI going to be?

Dental 3D printer prices range from a few thousand dollars to $100,000 or more, with costs scaling depending on the printing process, throughput required, manufacturer, services and support, and more. However, as we’ll see, a higher price often doesn’t equal an overall better solution.

In this guide, we’ll walk you through the true cost of investing in and owning various dental 3D printers, compare outsourcing with in-house production, lay out the various factors you should account for to calculate cost per part, and look at considerations beyond cost when comparing various 3D printing solutions and other production methods.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Calculate Your Savings

When choosing a dental 3DP printer, there are a few things to consider in addition to price. In general, dental professionals should be concerned with:

- Accuracy: Guaranteeing high-quality, accurate, final parts is the most important concern for any dental professional. Accuracy and precision depend on many different factors: the quality of the 3D printer, the 3D printing process, materials, software settings, post-processing, and how well-calibrated all of these systems are.

- Reliability: Dental printers often run 24/5, if not 24/7, making print failures unacceptable and requiring practitioners to miss patient deadlines.

- Maintenance: Consider the types of everyday interactions and maintenance the printer will need once it is up and running.

Beware of compulsory service contracts that can cost as much as 20% of the upfront cost of the printer annually.

Beware of compulsory service contracts that can cost as much as 20% of the upfront cost of the printer annually. - Ease of Use: There are big differences in the software used to prepare 3D models for printing, the complexity and the number of steps to set up and operate printers, and the availability of (automated) post-processing tools.

- Materials: The ability for a single 3D printer to create prints in multiple different materials, with materials tailored-made for various dental applications, is one of the most powerful aspects of digital dental technologies.

- Production Volume: It’s important to consider production volume when investing in a dental 3D printer, not just print speed. Because a printer can finish a small set of prints quickly does not mean it will meet your business production needs. Preparing the printer, setting up the prints in your dental software, and post-processing the parts are all steps not immediately made visible in a basic print time metric.

We put together a free 3D printing buyers guide that covers these metrics in more detail. For a deeper dive into these key metrics, download our guide for Dental Labs, Orthodontics, or Dental Practices.

Sample Part

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on the Form 3B+ to evaluate.

Request a Free Sample Part

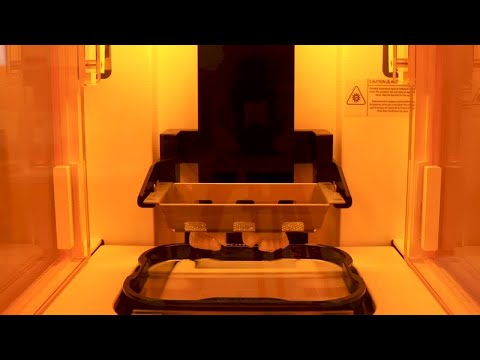

Let’s start with some basic definitions and technology overviews. Dental 3D printers are predominantly resin 3D printers. The two main processes on the market are SLA and DLP technology (defined below). Both SLA and DLP dental printers all work in similar ways: by using a resin tank with transparent bottom and a build platform that descends into the tank to create parts upside down, layer by layer, as a light source cures a thin layer of resin.

The difference in technology emerges in how light is used to cure the resin.

Stereolithography (SLA): SLA printers, such as the Form 3B+, use a laser and mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin. Formlabs has taken this process to the next level by creating Low Force Stereolithography (LFS). LFS enables SLA printers to offer incredible print quality, lighter supports, and a platform for more advanced materials and applications.

Digital Light Processing (DLP): DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

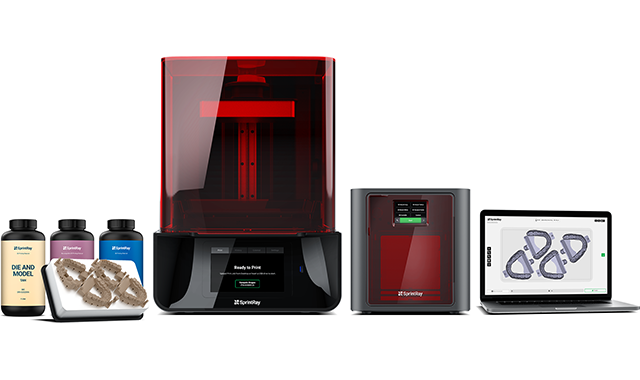

In this section, let’s take a look at some printers currently available and dive into their costs, which include both upfront costs and long term maintenance costs. When purchasing a dental 3D printer, users should consider all types of costs associated with 3D printing, which include:

| Stereolithography (SLA) | Digital Light Processing (DLP) | |

|---|---|---|

| Models and Manufacturers | Formlabs Form 3B+, Formlabs Form 3BL | SprintRay, Asiga, Desktop Health, Carbon3D |

| Equipment Ownership | Desktop printers start at $4,299, complete solution for $6,350. Large-format printers start at $13,000. Large-format printers start at $13,000. | Desktop printers start around $9,000, complete solutions around $15,000. Large format solutions start around $20,000 and go up to $100,000+. |

| Materials and Consumables | $150 per L for model resins, $250+ for biocompatible resins. | $150 per L for model resins, $250+ for biocompatible resins. |

| Labor | Low. Advanced post-processing tools are available to minimize labor needs. | Depends on the manufacturer. Advanced post-processing tools are available, but generally at a higher cost. Many solutions require manual labor to set up prints, pour resin, and more. |

| Maintenance | Minimal maintenance. | Depends on the manufacturer, some printers require extensive maintenance and calibration. |

| Service Plan | Depends on the manufacturer. For Formlabs dental 3D printers, pro service is included in the price of the complete solution. | Depends on the manufacturer, can be lacking or costly (up to 20% of the price of the printer per year). |

If you’re considering the Formlabs Form 3B+ vs. the SprintRay Pro, we put together an in-depth side-by-side comparison guide for prospective buyers to review which covers all of these costs in detail.

In terms of upfront costs to bring these printers in-house, DLP printers are generally at least twice as expensive as comparable SLA machines. And while print speeds are slightly faster, build volumes are generally much smaller, and often these printers are more expensive solely because they’re produced in lower volumes.

Both resin cartridges and resin tanks are considered consumables, and while the material itself is comparable for most manufacturers, there are bigger differences in the cost of the resin tanks—some brands’ tanks have a very limited lifetime. Labor costs are one of the areas where major differences arise. For example, Formlabs SLA 3D printers require minimal setup and can refill resin automatically, while some DLP printers require frequent calibration, lengthy setup, and a technician to manually refill the resin and pour it back into the bottle when the printer is not in use.

For example, Formlabs SLA 3D printers require minimal setup and can refill resin automatically, while some DLP printers require frequent calibration, lengthy setup, and a technician to manually refill the resin and pour it back into the bottle when the printer is not in use.

Post-processing is also more streamlined with some solutions than with others. The Formlabs Form 3B+ can be used with Build Platform 2 to quickly and easily remove parts from the build platform without tools in seconds. Automated post-processing units such as Form Wash and Form Cure also speed up the cleaning and post-curing process, meaning your dental workflows can go from print to final part as soon as possible, reducing completion times and labor costs.

Many dental professionals, labs and practitioners included, start their digital journey by outsourcing some of their indications. This makes sense for low production volumes and for dental professionals just starting out with 3D printing or dental CAD/CAM. However, the cumulative cost of outsourcing quickly climbs and can far exceed in-house production costs in just a few months. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing rapidly becomes expensive.

However, the cumulative cost of outsourcing quickly climbs and can far exceed in-house production costs in just a few months. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing rapidly becomes expensive.

Let’s take a look at a dental office that is producing 10 aligner models per day. The office’s fixed labor cost is $20 per hour, and they expect to keep the production level set all year, creating 3,650 parts in one year.

Outsourcing comes with no upfront investment costs, and each order costs $15 per part with a lead time of one week.

Under these criteria, the break even point is just seven weeks. That is, outsourcing is cheaper than in-house printing for the first seven weeks, and then becomes increasingly more expensive after that. Bringing production in-house will save this dental business $41,103 in a single year.

Formlabs Dental created an interactive ROI calculator so you can input the parts per week and labor costs and generate your own report to compare the cost of in-house production and outsourcing.

Calculate Your Time and Cost Savings Now

Some common questions dental professionals might ask when they are considering outsourcing or in-house 3D printing production:

- How many parts per week will you need? As we’ve seen, at only 10 aligner models per day, outsourcing quickly adds up to far exceed the cost of in-house production in less than two months.

- How quickly will you need your parts? If you find yourself often having to re-print models for rush cases, then long outsourcing lead times can be a deal breaker.

- Besides a 3D printer, what else do you need to get started? Both practices and labs generally require a scanning and software solution to complete the workflow, but outsourced design options are available for the latter. Learn more about it in our extensive guide.

Let’s take a look at some examples of costs per part based on dental indications created with the Form 3B+. We’ve already established that in-house 3D printing quickly becomes more affordable than outsourcing those same parts, but how much do various parts actually cost to print?

As noted above, cost per print is going to be higher on DLP printers. The costs in this table only cover the actual printing cost of materials, and not the cost of the equipment and the labor costs associated with preparing the prints.

| Dental Model | Printing Material | Cost Per Print | Print Time: Fully Packed Build Platform on a Form 3B+ |

|---|---|---|---|

| Orthodontic Models | Draft Resin | $2.10 | Nine models in one hour |

| Occlusal Splints | Dental LT Clear Resin | $3.12 | Eight models in two hours and 30 minutes |

| Temporary Restorations | Temporary CB Resin | $1. 28 28 | 15 models in one hour and 15 minutes |

| Permanent Crowns | Permanent Crown Resin | $2.10 | 58 models in four hours and 30 minutes |

| Gingival Masks | Soft Tissue Resin | $0.36 | 15 models in four hours and 30 minutes |

| Clear Aligner Models | Draft Resin | $2.50 | Nine models in three hours and 30 minutes |

There is a lot of information to consider when looking to invest in a dental 3D printer. The true cost of a printer includes the upfront investment, long-term maintenance, labor costs, and more.

What to learn more about dental printers? Explore the Formlabs Dental Academy and our free collection of dental webinars to dive into digital dentistry workflows.

If you’re interested in a dental 3D printer, evaluate parts firsthand by ordering a free sample part to your office or talk to our 3D printing experts to find the right solution for your business.

Request a Free Sample PartExplore Formlabs Dental 3D Printers

How to choose a 3D printer for dental applications

3D printing is making its way into more and more products around us. Sculptures, shoes, even food. Well, the happiest ones can already use the achievements of additive technologies for more comfortable treatment of their teeth.

The increasing popularization of new methods of treatment leads to the fact that new market niches appear, which are still very easy to occupy in our time. Accordingly, there is the prospect of a quick return on investment, obtaining a valuable asset, diversifying the sources of income for individual businesses.

In such a favorable situation, more and more investors decide to invest in this particular area - the production of dental products using 3D printing. And the question arises, how to spend these attracted investments? Or, to paraphrase, what kind of 3D printer to buy for use in a dental clinic?

Which 3D printers are in demand in dentistry

Printing multiple jaw impressions at the same time using the Phrozen Sonic 4K 9 printer0015

The situation on the market is so favorable that even those who previously were either very remotely or not at all connected with dentistry decide for themselves to enter this niche. Sometimes it is not even related to medicine at all. Therefore, I want to start with what actually needs to be made and how.

Sometimes it is not even related to medicine at all. Therefore, I want to start with what actually needs to be made and how.

Variety of in-demand dental products

Only a small part of the range of 3D printed products

Most likely I will not be mistaken if I assume that absolutely anyone reading these lines has gone to the dentist. In recent years, dentists have ceased to scare children, visiting the dentist has become less stressful. And already without negative thoughts, we can choose dental products presented in catalogs, presentations or which experts talk about personally.

There are several groups of products that can be produced with a 3D printer. The most innovative can be called products for bite correction - aligners.

Less obvious is the use of additive technologies for the creation of surgical templates, the transfer of checks.

It may seem surprising, but a temporary crown, a temporary bridge can be printed on a 3D printer.

The ability to print a prototype of the jaw, in particular, to check the fit of implants, is of great help to dentists.

For those who are familiar with jewelry, it will be clear that products that are produced by casting using a burnt model created on a 3D printer will work well. It can be crowns and bridges and liners and many other metal products.

You can also print a matrix for later use in the thermoforming process.

3D printing technologies used in dentistry

In FDM dentistry, 3D printers are used less often, but it happens. FDM 3D printer Stratasys

To a large extent, it is precisely such a wide range of products that are profitable to manufacture using a 3D printer that leads to a high demand for 3D printing in dentistry. Just by looking at this incomplete list, it becomes approximately clear which technology is used most often in dentistry.

SLA and LCD 3D printers can print with enough precision, suitable materials and are easy to use, so dentists are more likely to use them.

FDM 3D printers are less commonly used. Basically, enlarged models of jaws, presentation models are printed on them. Occasional auxiliary tools.

Let's take a closer look at the use of SLA and LCD 3D printers. The main difference between these technologies, from the point of view of application in dentistry, is that the LCD printer is designed to print small models with high resolution, while the SLA 3D printer can print a relatively large model without quality loss. Products required by dentists are not often large. The demand for SLA 3D printers, although it exists, cannot be compared with the demand for LCD models. LCD 3D printers have a printable area large enough to produce both aligners and jaw models. In terms of size, most dental products are not large. At the same time, the accuracy of such printers is sufficient - it is important to mention here that this is the case if we are talking about 4K or higher resolution print screens of such printers. LCD printers are more compact, easier to maintain, and cheaper.

In general, the choice of a printer for dentistry in 95 percent of cases will result in the purchase of an LCD 3D printer, so we will concentrate on machines using this technology.

Denote the initial conditions

Having familiarized ourselves a little with the niche that we will occupy, it is necessary to pay attention to who will use these 3D printers.

First of all, equipping a dental clinic with 3D printers should be profitable - we will pay considerable attention to issues related to the rate of return on investment and the optimal use of equipment.

Newcomers to dentistry, although they have the potential to gain a foothold in the 3D printing niche for dentists, will pick up all the bumps along the way, they are more likely to need advice about dentistry in general than advice on how to use 3D printing. Therefore, we will cover, for example, an already existing dental clinic or dental office.

At the same time, those who already use 3D printing most likely know what they lack and what is not very necessary. I suggest that such a reader go straight to the description of the advantages of individual models - most likely you will be able to find offers that are interesting to you.

I suggest that such a reader go straight to the description of the advantages of individual models - most likely you will be able to find offers that are interesting to you.

Equipment of the new 3D printing laboratory

A 3D printed lab might look like this

So, it turns out that we are discussing the choice of a 3D printer for a new 3D printed laboratory in an existing dental clinic or dental office.

The level of investment should be relatively low - for an individual dentist who runs his own practice, the investment should be minimal.

A large dental clinic will be able to afford not only to allocate a separate, well-equipped room for a 3D printed laboratory, but also to hire specialists who will serve the laboratory without combining this activity with anything else.

In addition to an LCD 3D printer, a 3D scanner, a washing and backlighting station will be useful. When creating a 3D printed laboratory in a large clinic, you can immediately plan the purchase of machines for creating products by casting according to a burnout model and by thermoforming.

Both LCD and SLA 3D printers require a separate, well-ventilated area with a desktop. If for a small office it can be a separate closet-sized room, then in a large clinic it is worth thinking about allocating an appropriate area not only for the printers themselves, but also for post-processing tables, for storage racks for materials, for service jobs.

Who is an expert in dental 3D printing

Only a doctor can be an expert in 3D printing in dentistry

A separate question is who will work directly with 3D printers.

It would be more profitable for a large clinic to immediately hire specialists with experience in using 3D printing in dentistry. At the same time, in a small clinic or in the case of a private dental practice, the dentist or dental technician himself can relatively quickly learn how to use and maintain a 3D printer.

The dentist must still evaluate and accept the products. It is quite common to hold joint seminars for dental technicians and dentists at the same clinic.

It is very important to understand that only a dentist can be an expert in dental 3D printing, evaluate the quality of printouts, and set criteria! Even the most experienced 3D printer can't do this alone.

Key criteria for choosing a 3D printer for a dental lab

When selecting any machine for commercial use, the selection criteria must be clearly defined. Often it is the clarity of such criteria that determines the payback period and the overall value of the machine.

Earlier, we touched on issues related to what exactly dentists require from the 3D printers they use. Let's cover these requirements more fully and arrange them in order of priority.

Imprint accuracy is the main criterion

Rough model of the jaw. The color shows the deviation in dimensions from the original (mm)

The main criterion for choosing a modern 3D printer for use in a dental clinic is accuracy, or rather resolution. The tasks of modern dentistry, which specialists are ready to delegate to machines, require the ability to manufacture high-precision products. For LCD 3D printers, a resolution of 2K nominally may be suitable - the accuracy of aligners, for example, is allowed up to 50 microns - but the actual quality of the resulting printouts may be lower than declared by the manufacturer of the 3D printer, both due to the characteristics of the materials used, and in connection with the presence of the human factor. Therefore, dentists use LCD printers with a print screen resolution of at least 4K.

The tasks of modern dentistry, which specialists are ready to delegate to machines, require the ability to manufacture high-precision products. For LCD 3D printers, a resolution of 2K nominally may be suitable - the accuracy of aligners, for example, is allowed up to 50 microns - but the actual quality of the resulting printouts may be lower than declared by the manufacturer of the 3D printer, both due to the characteristics of the materials used, and in connection with the presence of the human factor. Therefore, dentists use LCD printers with a print screen resolution of at least 4K.

The accuracy of the prints will be higher, with a shorter illumination time of the photopolymer. The Mono LCD screen will help reduce the time needed to expose one layer. The presence of such a screen will not only increase accuracy, but also speed up the printing process.

Print area - rate of return on investment

Even the largest laboratories use groups of identical 3D printers

A very important criterion that can be assessed by the passport of a 3D printer is the printable area. The larger the printable area, the faster you can produce a series of printouts - this is the peculiarity of using an LCD 3D printer. Due to the fact that a client of a dental clinic quite often needs to receive a series of products on hand during a visit - again, aligners, or immediately need to print a complex model with small details, the total print area will help to carry out the service faster.

The larger the printable area, the faster you can produce a series of printouts - this is the peculiarity of using an LCD 3D printer. Due to the fact that a client of a dental clinic quite often needs to receive a series of products on hand during a visit - again, aligners, or immediately need to print a complex model with small details, the total print area will help to carry out the service faster.

At the same time, the print area of one printer may not be so large - remember that products for dentistry are rarely large. To speed up the production process, most often they buy several identical or very similar printers. Most often the same manufacturer.

Such a 3D printing farm will not only be cheaper than a single printer of a comparable printing area, but will also allow you to accept multiple clients at the same time. Maintenance and repair of printers is also simplified - one or a pair can be taken out of operation without stopping all production.

The choice in favor of several printers with a smaller print area is also justified in terms of the fact that it is recommended to invest in 3D printing gradually. Buying a dozen 3D printers at once is justified only when you know for sure that you have a large flow of customers and the total workload of the 3D printing laboratory will be about 60 percent.

Buying a dozen 3D printers at once is justified only when you know for sure that you have a large flow of customers and the total workload of the 3D printing laboratory will be about 60 percent.

In general, buying multiple 3D printers will reduce your initial costs and risks, while the overall larger printable area will allow you to make more profit.

Usability, reliability, ease of maintenance

Unfortunately, most of the mistakes when choosing a 3D printer for a dental clinic are associated with underestimating the importance of the usability of a 3D printer. These machines will be serviced by a person, which means there is a human factor. You know from experience that work is more productive when you work comfortably. Research confirms the validity of this personal experience. The more convenient it is to work on a 3D printer, the fewer mistakes the operator will make, which means less money will be spent - both material and time.

The reliability of a 3D printer - design, electronics, individual elements - will be economically justified. Less breakdowns - less downtime - less costs.

Less breakdowns - less downtime - less costs.

Ease of maintenance reduces costs in the same way

Post-processing

The process of removing supports is not easy

It must be borne in mind that after printing, absolutely all printed models require post-processing. At a minimum, this is flushing and backlighting. As a maximum, a printed, washed, illuminated part, from which the supports were removed, can be a semi-finished product that has yet to be worked on. A 3D printer should provide the ability to not be a stand-alone device, but to work in an ecosystem.

What might be useful but not worth emphasizing

The standard marketing policy of any retailer is to try to convince you to buy a product based not so much on direct value as on features that sound and look good on paper, but do not greatly affect the quality of the product itself. A good example is the color of a delivery vehicle. If you do not take the possibility of applying advertising images and colors from the brand book, the delivery vehicle can be of any color. But the seller may try to convince you to buy this particular car by appealing to its color.

But the seller may try to convince you to buy this particular car by appealing to its color.

Similarly, when choosing a 3D printer for a dental clinic, some criteria are not as valuable as they sound.

Range of materials used

Most modern LCD 3D printers use ultraviolet wavelengths of 380nm-405nm to illuminate the photopolymer. The ability to use specific materials seems like a very useful feature, but in fact, you either know for sure that you will use such materials, or you will not use them. It is enough to understand what range of tasks the 3D printer will solve and choose accordingly. At the same time, it will be useful to be able to use the selected materials more conveniently, for example, a system of material profiles.

It is important to expand the range of materials used unnecessarily - it is not economically feasible.

Additional software - pros and cons

Software that helps you print. FormWare Phrozen Edition.

The whole process of creating printouts involves the use of several software products. And, if software that will allow you to facilitate or speed up printing without loss of quality is useful, then different programs for modeling or, for example, creating print timelapses will never be used. The specialist models in the environment he is used to, and time-lapses are just a beautiful feature.

Remote printing and control

When you think of 3D printing, there is often an assumption that I pressed a button, an hour later I came, and everything is ready. It's actually not that automated. In principle, it is better to keep the machine under supervision at least during the start of printing. This means that remote printing will not be so popular. At the same time, I note that after the operator of a 3D printer gets used to working with a particular machine, he will know most of its features, the ability to transfer files to the device remotely, or even remotely control printing will be useful.

Remote control will bring more benefit to an experienced operator, although a beginner in 3D printing will gain experience quickly if desired.

Top Best Dental 3D Printers

Based on what I have outlined, I will try to create a rating of the value of 3D printers for dentists.

Phrozen Sonic 4K

This 3D printer is specially designed for use in dental clinics. A good price/quality ratio makes this 3D printer an excellent choice for both a small clinic and as one of several printers in a large 3D printing laboratory. Mono LCD allows you to reduce the exposure time of the layer to 1 second, and the large area of \u200b\u200bthe 6.1” matrix allows you to print more models at the same time, making the production process even faster! With the FormWare Phrozen Edition software, post-processing can be facilitated by optimally positioning supports, and reduce printer control time by arranging more models in the same print volume. If you have a dedicated 3D printer operator, the function of remotely sending files to print will be useful.

If you have a dedicated 3D printer operator, the function of remotely sending files to print will be useful.

Phrozen Sonic Mini 4K

Mini version of the popular printer. At a lower price, it has the same resolution and matrix size - 6.1” @ 4K. It will be a good choice for a private practice dentist's office. Also one of the options for entering 3D printing for a medium-sized clinic is that it performs well both as a single 3D printer and as an additional printer, if there are several more advanced ones. A fairly high print speed is achieved due to Mono LCD, which allows you to reduce the exposure time to 2 seconds.

Peopoly Phenom

Large Format - 276 x 155 x 400mm build area - MSLA 3D printer (LCD+LED). The use of MSLA technology allows you to get high-precision prints on a 12.1” @ 4K matrix without distortion. Well suited for large clinics that want to increase their 3D printing capacity. At the same time, the extended life of the LCD panel will significantly reduce the overall cost of maintaining this machine.

FormLabs Form 3B

The LFS 3D printer is a higher priced printer. A special technology of low-intensity stereolithography and a specially designed light processing unit allows you to quickly obtain high-precision printouts up to 145x145x185 mm in size with a laser positioning accuracy of 25 microns.

Draw a line

Modern dentistry using 3D printing is not only becoming more accessible, but its demand is growing at a tremendous pace. At this stage, there is a rare opportunity to take your share of the market in the niche of dental clinics using 3D printing. I hope this material will help you to correctly assess your options and invest finances with maximum efficiency, to the delight of your patients.

Good adhesion!

How to choose the right 3D printer for dentistry

How 3D printing can be used or is already being used in medicine and, in particular, in dentistry, quite a lot of notes and articles have been written, a large number of reports and lectures have been held. Almost all participants in these disputes clearly see the advantageous prospect and inevitability of the arrival of 3D printing in most areas of dentistry.

Almost all participants in these disputes clearly see the advantageous prospect and inevitability of the arrival of 3D printing in most areas of dentistry.

But there are few places where the technical and economic specifics are voiced when choosing this equipment, and even more so, the obvious shortcomings of a particular 3D printer or 3D printing technology are pointed out.

In this article, we will try to analyze in more detail the main nuances when choosing a professional 3D printer for dentists, taking into account the most important factors - the optimal 3D printing technology, quality, reliability and, most importantly, the affordability of a 3D printer in the Russian market. We will also find out what today influences the choice in favor of 3D printing using the example of one dental clinic.

Choosing SLA

The very first professional 3D printing technology was stereolithography (SLA), which turned 30 this year. SLA remains the most versatile and cost effective 3D printing technology. In its favor speaks a large selection of photopolymers with different physical and chemical properties. The laser system has a much longer life than the similar DLP technology, which is based on light sources such as LEDs or projector lamps, which require periodic replacement and financial investment. For a long time, the main patents for the use of SLA technology (exactly in the form in which it was invented) were owned by the American company 3D Systems. Each time, making small changes, it extended the validity of patents, remaining an absolute monopolist in the market for professional and industrial 3D printers using SLA technology.

In its favor speaks a large selection of photopolymers with different physical and chemical properties. The laser system has a much longer life than the similar DLP technology, which is based on light sources such as LEDs or projector lamps, which require periodic replacement and financial investment. For a long time, the main patents for the use of SLA technology (exactly in the form in which it was invented) were owned by the American company 3D Systems. Each time, making small changes, it extended the validity of patents, remaining an absolute monopolist in the market for professional and industrial 3D printers using SLA technology.

In 2014-2015, the situation changes dramatically and after the end of all kinds of "copyrights", many manufacturers of 3D printers using SLA technology appear on the market. First of all, these are Asian analogues / clones of famous brands without any design changes. With an attractive cost from $1,000 to $4,000, but giving out completely non-profile results. Therefore, this category cannot be attributed to a professional line in any way due to the discrepancy between the print quality and the internal equipment of the equipment itself.

Therefore, this category cannot be attributed to a professional line in any way due to the discrepancy between the print quality and the internal equipment of the equipment itself.

No matter how advertising articles or online store managers convince you of the opposite, most of them read just the text of the same advertising article, you will simply lose money, time and even be disappointed in the correctness of your choice in favor of 3D printing. Therefore, we only consider 3D printers that really meet the accuracy and quality parameters declared by the manufacturer.

Price gap

And so the price range of really high-precision and reliable 3D printers (SLA) in Russia starts from $6,500. It is affordable and suitable for small-scale printing of one-off models from rigid, transparent or burn-out polymers.

But here it is important to understand that if the manufacturer of 3D printers (SLA) does not position its model as a direct 3D printer for dentistry, but presents its equipment as allowing it to be used in all production areas equally effectively and as profitably as possible, this printer , most likely has software and technical limitations. For example, such as not being able to place models vertically, but only at 45°, significantly reducing the working area of the table. To date, there simply are no multi-purpose 3D printers that are equally suitable in their starter kit for printing, for example, color building models and surgical templates for dentistry. Therefore, if you are interested in getting full-fledged performance from a 3D printer without losing quality in dentistry, we also ignore this line of 3D printers.

For example, such as not being able to place models vertically, but only at 45°, significantly reducing the working area of the table. To date, there simply are no multi-purpose 3D printers that are equally suitable in their starter kit for printing, for example, color building models and surgical templates for dentistry. Therefore, if you are interested in getting full-fledged performance from a 3D printer without losing quality in dentistry, we also ignore this line of 3D printers.

The next price range for professional 3D printers (SLA) for dentistry starts from $45,000 to $800,000.

This is no longer a small financial investment, which also requires the loading of equipment to reduce its payback period, which can reach several years.

This class of equipment has a number of disadvantages, which are sometimes ignored by the supplier:

- Binding to the use of only their own consumables.

- High cost of printing.

- Completely closed software.

- Special conditions for the operation of a 3D printer.

- Need to buy additional hardware.

- Expensive post-warranty service, long delivery time of components, etc.

3D printer Basic (Dental) - golden mean

We offer you the most optimal and cost-effective solution on the market of professional 3D printers (SLA) for dentistry.

The Basic (D) 3D printer is not positioned with well-known brands of desktop 3D printing options. This is a more affordable option for professional and expensive equipment, capable of continuously high-volume printing, while having unique control functionality and a set of excellent features. What Basic (D) offers you really doesn't fit any 3D printer (SLA).

Here are just a few of the Basic (D) justification factors:

- The Basic (D) 3D printer and its software are designed specifically for dentists.

- Vertical alignment of models without quality loss when printing at 25 microns.

- The fastest print speed in the competition.

- Not linked to consumables. A unique system for adjusting the laser illumination speed allows you to achieve high precision results using any third-party photopolymer (405 nm).

- Five print modes (25\30\50\75\100 microns).

- Low cost printing.

- Direct printing of scanned models in STL format.

- 80% of all service calls are resolved by remote connection using software, without requiring a service engineer to visit.

- The most favorable combination of price and quality on the Russian market of 3D printers for dentistry.

In addition to the above indicators, we also note the standard features of Basic (D):

- Printed in paraffin-containing photopolymer for ash-free post-casting using standard burn-in temperature.

- Rigid/ABS/Rubber/Transparent/White/Natural and many other photopolymers are also available.

- All photopolymers are non-toxic and certified to standard Class IV safety.

- Operating life of the laser system is 10,000 hours, which is confirmed by the warranty statement.

- Full service support in Russia.

The launch of the Basic (D) 3D printer on the Russian market was preceded by a lot of work by the entire 3D Osnova team. For more than a year, we have been conducting in-depth testing of this 3D printer before offering it to you. Our specialists were trained at the manufacturer's production sites, studied the experience of using this equipment among dentists in other countries, and finally, we added a number of optional changes to adapt this equipment to the requirements of Russian dentists. We really have a lot to be proud of. We also ask you to evaluate the combination of simplicity and reliability in the use of the Basic (D) 3D printer with its high-precision printing and multifunctionality of work performed in the field of dentistry. We are always ready to answer your questions, provide a full consultation and demonstration of the Basic (D) 3D printer.

We are always ready to answer your questions, provide a full consultation and demonstration of the Basic (D) 3D printer.

Let the "machines" do the work

Let's look at one specific use case for the Basic 3D printer. Meet this dentist of the highest category Alexander Nikolayevich Romankov (Clinic of Modern Dentistry, Sochi, founded in 1991), who devoted his entire conscious life to his profession, just like many colleagues, passing on his knowledge and experience to future generations, his daughter, also a dentist.

His short story about how he came to use 3D printing in his clinic

"Today, more than 2,500 people are regular patients of our clinic, plus a constant influx of new clients (1-2 daily). Over the past two years, the volume of work performed has increased significantly, taking into account the introduction of fairly new orthodontic services: correction of teeth bite without braces (system of aligners), production of our own surgical templates for implant placement. It is for this work that we planned the introduction of 3D printing. We just want to give the solution of these tasks to machines, thereby reducing the visit time of our clients and significantly saving our strength. Do not forget For example, printing one dental impression on a Basic (D) 3D printer costs us about $ 8, and soon this figure may decrease by another 1.5 times, since we may start using a photopolymer from a Russian manufacturer. we conduct remotely and one course costs about $ 170 for us. Then there is the molding and processing of the mouthguard."

It is for this work that we planned the introduction of 3D printing. We just want to give the solution of these tasks to machines, thereby reducing the visit time of our clients and significantly saving our strength. Do not forget For example, printing one dental impression on a Basic (D) 3D printer costs us about $ 8, and soon this figure may decrease by another 1.5 times, since we may start using a photopolymer from a Russian manufacturer. we conduct remotely and one course costs about $ 170 for us. Then there is the molding and processing of the mouthguard."

Tips for choosing a 3D printer supplier

1. It is not recommended to purchase equipment from companies that do not have a demo printer or print samples of this printer.

2. The company must have a full or partial service on the territory of Russia, and not a guarantee from the manufacturer.

3. When purchasing a 3D printer, you must ask the supplier to print their own 3D model for you, or to demonstrate a similar one. A conscientious supplier will not see anything strange in this, and moreover, a company that is confident in its product and has come to the market for more than one day should itself offer you a pre-sale print, albeit for a certain amount, which is deducted from its cost during the subsequent purchase of equipment.

A conscientious supplier will not see anything strange in this, and moreover, a company that is confident in its product and has come to the market for more than one day should itself offer you a pre-sale print, albeit for a certain amount, which is deducted from its cost during the subsequent purchase of equipment.

4. Ask for contacts of 1-2 customers who have already purchased this or similar equipment to form an independent opinion about this company and its product.

By following these smart tips, you will weed out unqualified suppliers and save time and money in the future.

What am I overpaying for?!

There is an opinion / practice that it is more profitable to purchase a non-industrial 3D printer directly in the manufacturer's country or order it in Europe or the States. Why overpay local suppliers and dealers when you can just pay extra for shipping. And this is a perfectly reasonable argument in favor of financial gain. But momentary gain can turn into unpleasant moments in the future.