Cutting edge 3d printing technology

Army scientists develop cutting-edge, durable 3D printing technology | Article

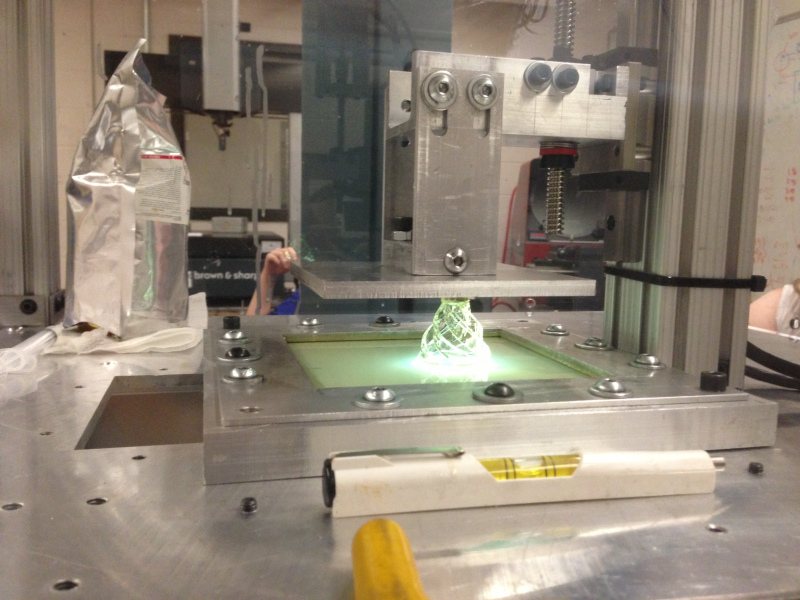

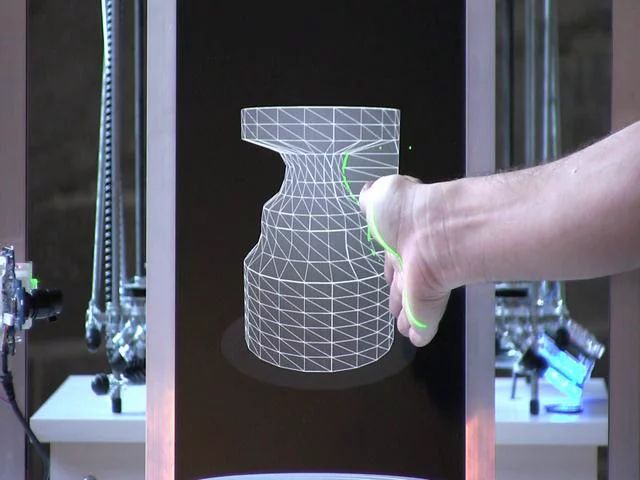

1 / 3 Show Caption + Hide Caption – Dr. Eric Wetzel demonstrates dual-polymer filaments at the U.S. Army Research Laboratory on Feb. 10, 2020, at Aberdeen Proving Ground, Maryland. The technology is capable of delivering heavy-duty printed parts for Soldiers in remote locations from ea... (Photo Credit: U.S. Army) VIEW ORIGINAL 2 / 3 Show Caption + Hide Caption – Dr. S. Army) VIEW ORIGINAL

S. Army) VIEW ORIGINAL ABERDEEN PROVING GROUND, Md. -- Army scientists are on the brink of a pioneering additive-manufacturing technology to help Soldiers quickly swap out broken plastic components with durable 3D printed replacements, says a top Army researcher.

In the past, troops have either lugged replacement parts around or ordered them from warehouses thousands of miles away, only to wait weeks for them to arrive.

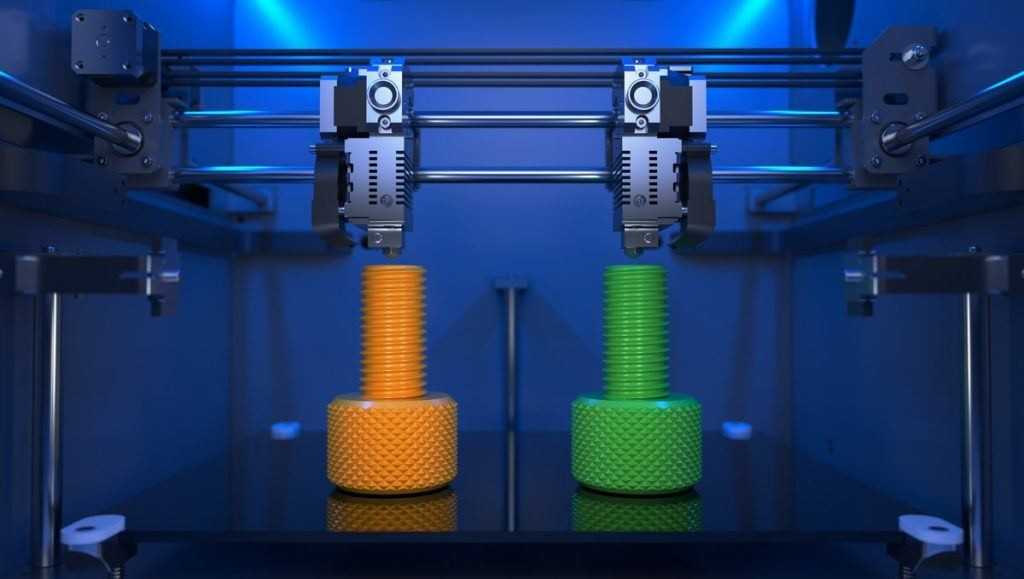

But with dual-polymer 3D printed parts -- developed by scientists at the U.S. Army Combat Capabilities Development Command Army Research Laboratory, or ARL -- Soldiers could be a few clicks away from swapping out broken pieces and heading back to the fight within hours.

"We're crossing a threshold where low-cost, easy-to-operate and maintain printers will be proliferated on the battlefield -- and able to produce engineering parts of very good quality with short turn-around times," said Dr. Eric Wetzel, ARL's research arealeader for Soldier materials.

"In order to do that, we need printing technologies that can print parts that are accurate geometrically and have mechanical properties that are sufficiently robust to survive conditions in battle," he added.

The printing technology comes on the heels of Secretary of the Army Ryan McCarthy pushing an advanced manufacturing policy last October, intended to enhance supply chains in the field.

Until this point, 3D printing technologies that produce mechanically robust parts have required printers and print technologies that are not suitable for austere environments, while the printers suitable for austere environments produced poor-quality parts, Wetzel said.

That's where the ARL scientists come in. For the last few years, they have delved into this issue, Wetzel said. For the first time, ARL scientists have developed a cutting-edge filament capable of being used in off-the-shelf, low-cost 3D printers to produce mechanically strong, battlefield-ready parts.

"By summer, we hope to have samples of the filament distributed to Army transition partners," Wetzel added. Based on their feedback, ARL could ramp up production -- with help from industry partners -- and have it in the hands of Soldiers within the calendar year.

Based on their feedback, ARL could ramp up production -- with help from industry partners -- and have it in the hands of Soldiers within the calendar year.

THE DUAL-POLYMER TECHNOLOGY

"Conventional polymer filaments for 3D printing are made up of a single polymer," Wetzel said. "Our innovation is that we've combined two different polymers into a single filament, providing a unique combination of characteristics useful for printing and building strength."

The dual-polymer filament combines acrylonitrile butadiene styrene, or ABS, with polycarbonate, or PC. A critical design feature of the filament is that the ABS and PC phases are not simply mixed together, a common approach for creating blended polymers. Instead, a special die-less thermal drawing process developed by ARL is used to create an ABS filament with a star-shaped PC core. Once coupled, the filament is used as feedstock in a desktop fused-filament fabrication, or FFF, printer to create 3D prints with a heavy-duty ABS/PC meso‐structure.

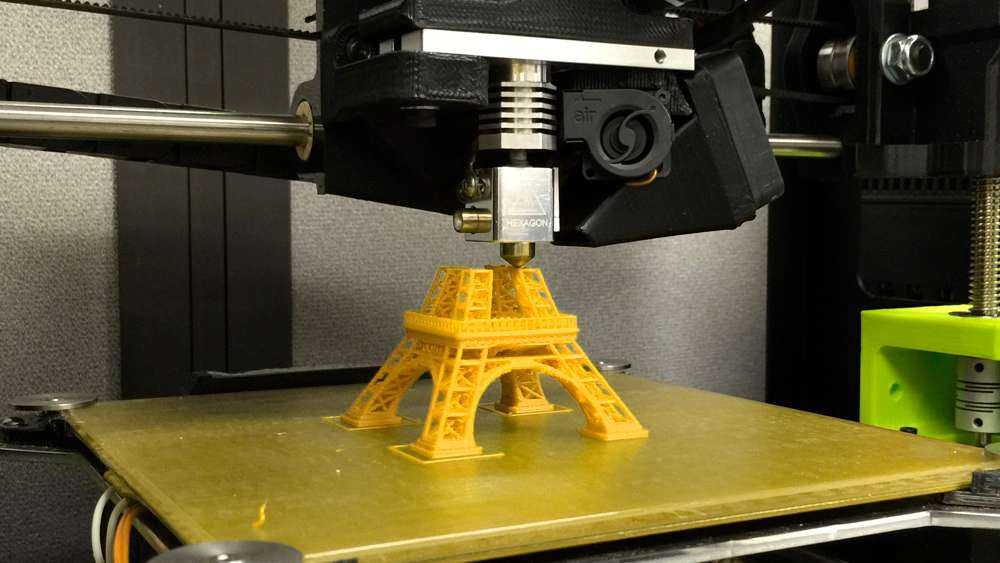

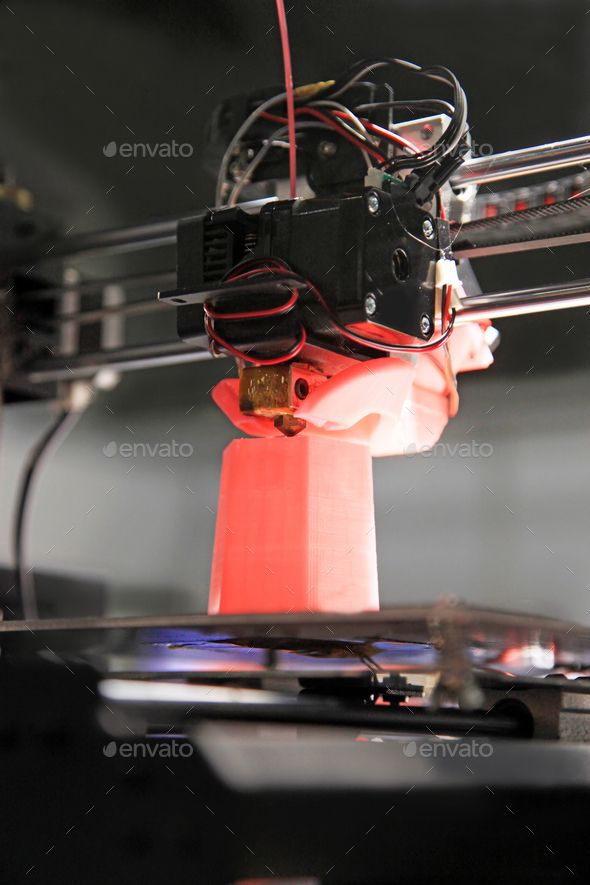

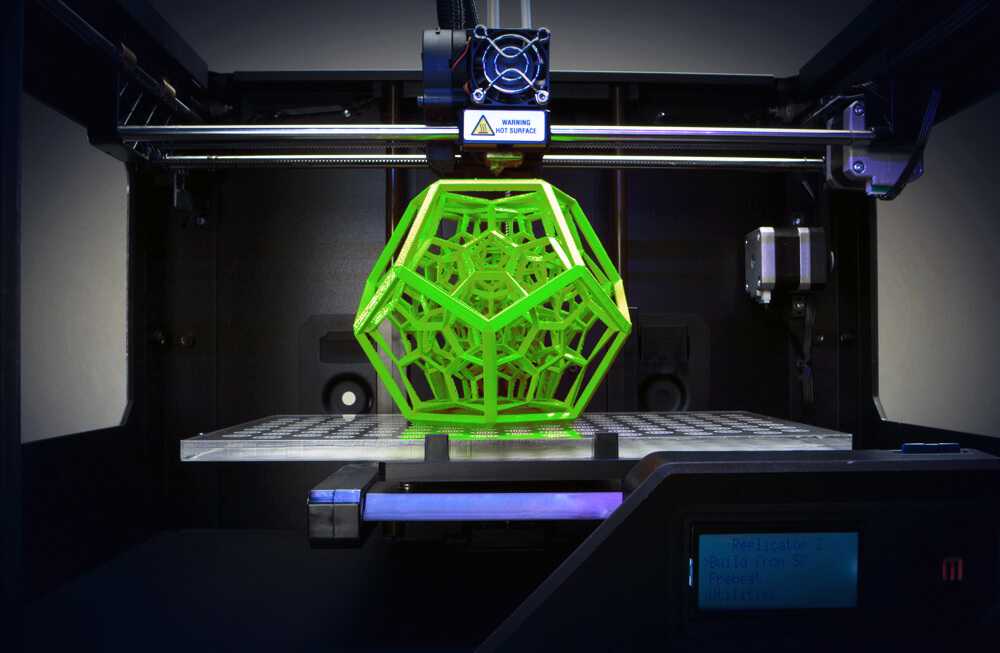

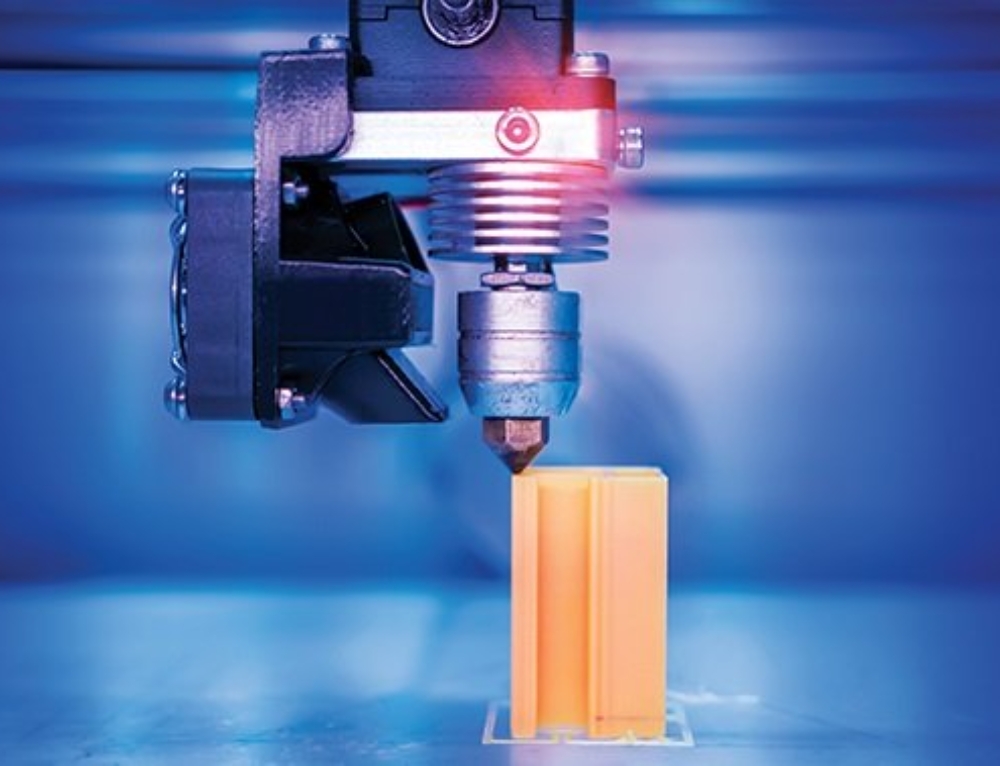

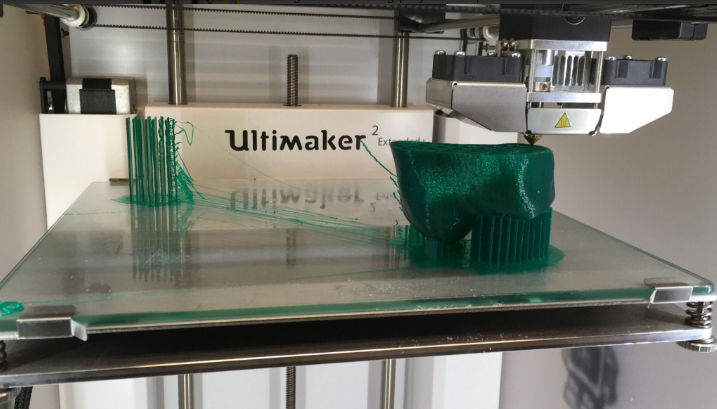

FFF printers work with a heated nozzle that emits thin layers of melted plastic, similar to molten glass. The filament is deposited onto a print bed, one layer on top of another until it forms the 3D printed part. In order to fabricate a unique part, the nozzle, print bed, or both move while the hot plastic streams down.

The two polymers found in the new filament technology have distinct melting temperatures, Wetzel said.

After the solid bodies are initially printed, they are put in an oven to build strength. During this annealing process, the deposited material layers fuse together while maintaining their geometry and form. This stability is caused by the higher temperature resistance of the built-in framework.

"The second polymer holds the shape like a skeleton while the rest of it is melting and bonding together," Wetzel said. "Through a series of filament design trials, we were able to identify that the star-shaped PC core provided a superior combination of part toughness and stability compared to other arrangements of ABS and PC in the filament. "

"

Current filaments -- traditionally consisting of a single thermoplastic -- produce parts that are brittle and weak, and would deform excessively during the annealing process, he said.

"We focused in on what can we do to improve those mechanical properties," he added. "We wrote a series of papers getting very fundamentally down to the details of exactly why conventional single-polymer parts are not sufficient, what's happening in the physics of the polymer -- really at a molecular level -- that prevents conventional printed polymer parts from meeting these requirements."

The legacy thermoplastic deposits like a hot glue gun, he said. As the layers build, they don't stick very well to the previous layer because by the time the second layer adds, the first one is cooled off.

"So, you're not melting the layers together, you're just solidifying material on top of one another, and they never really bond between layers," Wetzel said. "Our technology is an approach that allows us to use these conventional desktop printers, but then apply post-processing to dramatically improve the toughness and strength between layers. "

"

"Manufacturing at the point-of-need provides some exciting possibilities," Wetzel said. "In the future we can imagine Soldiers deployed overseas collaborating with engineers in the United States, allowing new hardware concepts to be designed and then sent as digital files to be coverted into physical prototypes that the Soldiers can use the same day. This paradigm shift could allow us to innovate at a much higher speed, and be keenly responsive to the ever-changing battlefield."

Fused Filament 3D Printing

Army News Service

3D printing technology enhancing logistics for Army

Army looks toward future of additive, advanced manufacturing

ARNEWS Archive

STAND-TO! Additive Manufacturing

STAND-TO! 2019 Army Modernization Strategy

3D Printing at the Cutting Edge: What AM Brings to Cutting Tools - 3DPrint.com

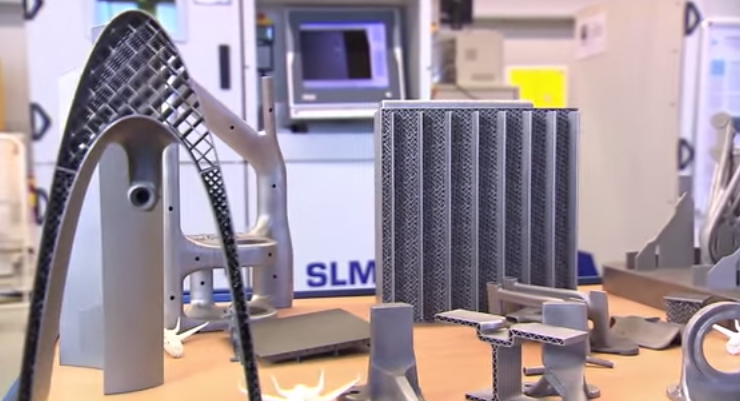

According to the “Market Opportunities for Additive Manufacturing in the General Industry and Tooling Sector 2020-2029” report from SmarTech Analysis, 3D printing for industrial manufacturing is expected to generate $5. 48 billion in total revenue by 2029. One application that is continuing to gain traction is the additive manufacturing (AM) of cutting tools. So, why is 3D printing shaking up the world of cutting tools?

48 billion in total revenue by 2029. One application that is continuing to gain traction is the additive manufacturing (AM) of cutting tools. So, why is 3D printing shaking up the world of cutting tools?

One of the downsides of manufacturing large components, such as those for the automotive and aerospace industries, is that bigger parts require bigger cutting tools. However, since the tools are also heavier, there’s a risk of spindle damage or that the tool may fall out of the machine during use.

At least one company has found a workaround for that issue by relying on 3D printing. Star SU Neher uses 3D printing to make the cutting tools weigh less, perform better and last longer than their non-3D-printed counterparts.

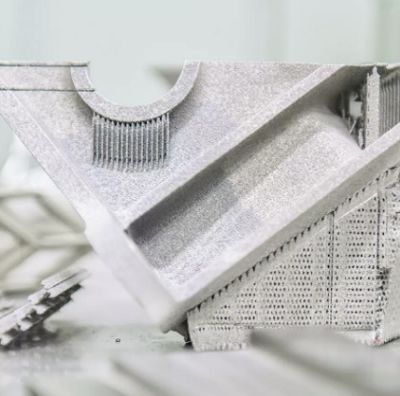

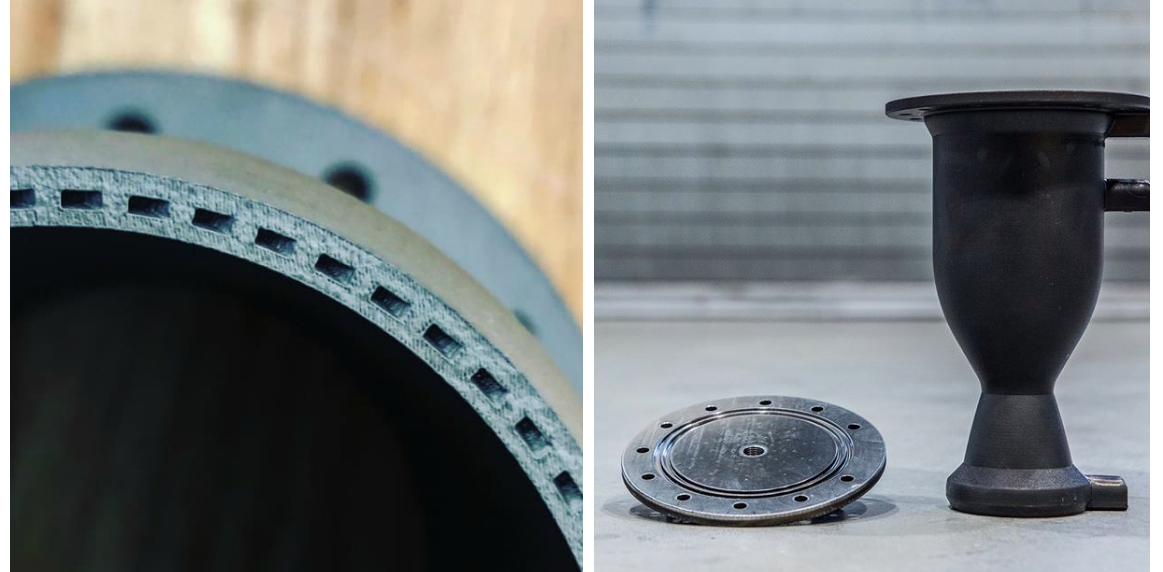

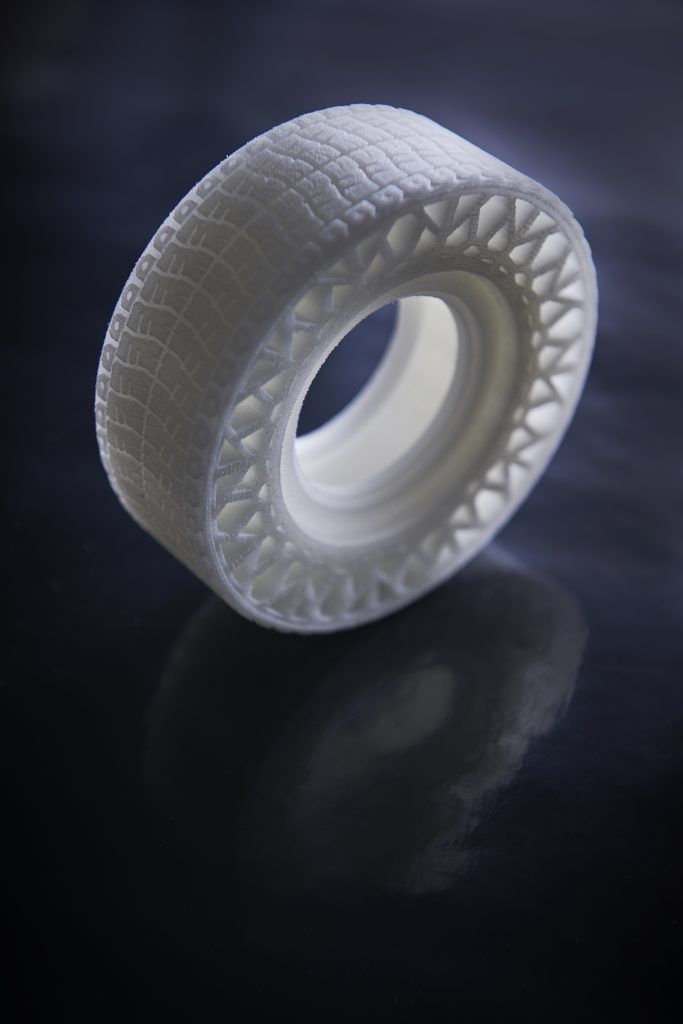

By designing in lattice structures, the weight of the tool can be cut by as much as 30 percent. Image courtesy of Star SU Neher.

One of the company’s tool designers mentioned that adding internal lattice structures cuts their products weight by 30% without adversely affecting torsional strength. Plus, company representatives custom-make most of their cutting tools to meet individual components’ needs. 3D printing enables that flexibility.

Plus, company representatives custom-make most of their cutting tools to meet individual components’ needs. 3D printing enables that flexibility.

One of the reasons why the company’s 3D-printed cutting tools last longer is through the incorporation of a cooling channel, a technique that is increasingly used in 3D printing cutting tools. Typically, such channels are created via drilling, a method with limited effectiveness. With AM, channels can be designed directly into the part, improving the tool’s overall effectiveness. The increased flow of coolant can raise metal removal rates by as much as 30%.

3D printing makes it possible to reduce the weight of large cutting tool heads to limit the changes of damage or slippage in a machine tool part. Image courtesy of Star SU Neher.

The 3D printing of large cutting tools is not necessarily faster than creating them through more conventional methods. It can still take up to 24 hours to produce a component that takes up the whole print bed with its size. However, given the other advantages, it can often make good business sense to pursue 3D printing.

However, given the other advantages, it can often make good business sense to pursue 3D printing.

Cutting tool manufacturers working with clients in certain industries, such as oil and gas and defense, often need to satisfy the need for wear-resistant tools. Cutting tool maker Kennametal specializes in products made from tungsten carbide. The company has an in-house line of products crafted from that material. Similar to Star SU’s application, the printing process allows for the formation of fluid cooling channels within the tools. Due to the design freedom of AM, 3D those pathways can be curved or branched in ways that other manufacturing methods could not accomplish.

Kennametal is able to 3D print drill bodies with interior cooling channels. Image courtesy of Kennametal.

While Kennametal relies on both metal binder jetting and powder bed fusion (PBF), some of the cutting tools are 10 millimeters or smaller in diameter and require PBF. Representatives say it gives them an economical way to produce tools and meet client needs. Weight reduction is also a possibility. In one instance, a 3D printed boring device used for electric vehicle parts production was 15 to 20 pounds lighter than those made with conventional methods.

Representatives say it gives them an economical way to produce tools and meet client needs. Weight reduction is also a possibility. In one instance, a 3D printed boring device used for electric vehicle parts production was 15 to 20 pounds lighter than those made with conventional methods.

3D printing made it possible to cut the weight of this boring tool for manufacturing electric vehicle parts by 15 to 20 pounds. Image courtesy of Kennametal.

3D Printing Helps Revolutionize Cutting ToolsCutting tools featuring 3D printed components is not yet a widespread practice, but it’s a technology worth exploring. As of now, 3D printing is often less expensive and sometimes faster than conventional methods, depending on the application.

AM won’t replace common methods for producing most cutting tools anytime soon. Many ongoing efforts are still in the early stages and manufacturers will almost certainly find instances where 3D printing is not an appropriate way of producing specific cutting tool types.

The technology is a particular good candidate for tools that have complex shapes. However, when the pieces are large parts with comparably regular geometries, it may make more sense to buy those off the shelf than to use 3D printers to produce them.

Another thing to remember is that, since 3D printing as a tool-manufacturing method is relatively new, decision-makers may want to see how it has paid off for similar companies before giving the go-ahead to invest in it. Once they see the results, they may be more willing to gradually scale up the process.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D printed cutting tools • cutting tools • general industry • industrial 3d printing • Kennametal • Star SU

Please enable JavaScript to view the comments powered by Disqus.

Modern 3D printing technologies

5 - 2016

Nikolai Dubina

info@prodtp. ru

ru

3D printers that exist at this stage of their development are capable of creating not only delicious meals and all sorts of pleasant little things. For example, it turned out that it is economically advantageous to obtain rocket engines by this method. Similar projects have a place to be - for example, NASA already has such a printer. However, the 3D printer is used so far only to create the components of such engines. Nevertheless, experts unanimously argue that in four to six years such printers will be used everywhere.

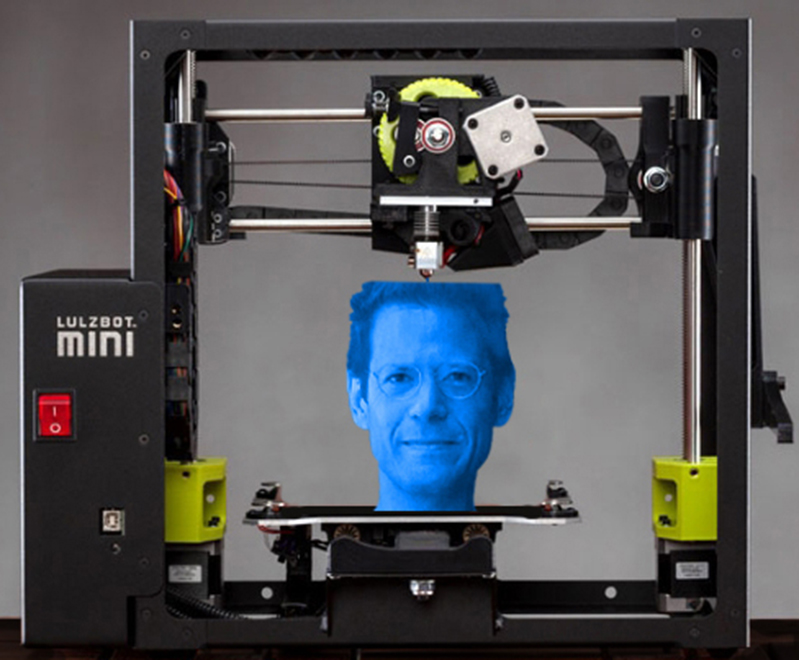

Japan is currently experiencing a real boom in 3D printers and printing - the ubiquity of printed photographs is gradually being replaced by 3D printing. For example, in Tokyo, Osaka, there are 3D photo booths that allow instead of the usual paper photography to get a voluminous, three-dimensional figurine of photography with excellent precise execution of even small details.

The “3D photoshop” service is also gaining popularity, when you are “dressed up” in virtual clothes of some historical era or portrayed as a brave knight, having received a three-dimensional model of your appearance during preliminary scanning.

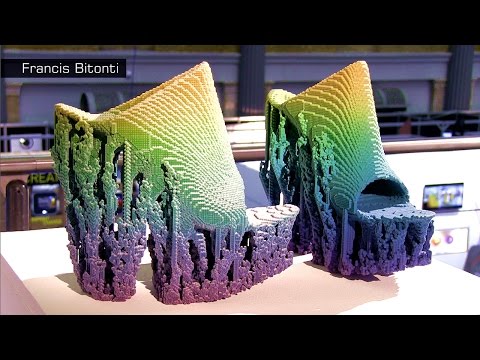

This symbiosis is gaining more and more space in art. So, at the 3D Print Show exhibition, the most incredible exhibits obtained as a result of 3D printing were demonstrated: from unusual musical instruments to amazing furniture solutions, computer gadgets, and even human organs.

Hollywood is experiencing a real boom in connection with the use of 3D modeling technologies. For example, in the film "Agent 007" the protagonist's car is so perfect that it simply does not exist. This is another brainchild of 3D printing and related technologies (Fig. 1). Traditional production is many times more expensive, more knowledge-intensive and slower than 3D printing.

Fig. 1. James Bond 3D printed machine

The possibilities of 3D printing are endless. At the Farnborough Airshow, a large unmanned aircraft was presented, most of which was reproduced by 3D printing. The Polecat aircraft is a flying prototype capable of demonstrating the performance of new 3D printing technology. The advantages of such obtaining parts include not only speed, but also the low price of such parts, and this is the main goal.

The advantages of such obtaining parts include not only speed, but also the low price of such parts, and this is the main goal.

According to IDC, shipments of 3D printers will increase 10 times by 2017, and the annual sales growth rate will be 29%. In connection with the positive statistics, many companies and firms are beginning to master 3D technologies.

3D printing in advertising and marketing

A person perceives the world spatially, that is, in three dimensions, where perception is fixed on one object at different angles, the image is processed based on the distance between the eyes and thus a three-dimensional effect is formed.

3D printing has found practical application in advertising. The main objective of advertising is to inform consumers about goods and services and create demand for products. Whatever the type of advertising (informational, reminder, reinforcing or prestigious), it is becoming more and more difficult today to hold a person's eye by traditional means.

3D advertising is used by such world famous companies as Coca Cola, Adidas, Cavalli, Ferrero, McDonalds and others.

The main advantages of 3D advertising are a high degree of visibility, novelty form, memorability, long service life without loss of appearance. It has been proven that even with peripheral vision, the buyer will notice the unusual shape and turn his attention to the advertised object.

Industrial 3D printers open up a lot of new opportunities for the implementation of non-standard projects in various business areas, in particular in marketing and the fashion industry. With the help of 3D printers, you can create all kinds of non-standard gifts, figurines, awards, promotional materials, decorative items, and hold high-profile promotions.

Fig. 2. Cups to the authors of the tweet about Belvita crackers

World practice already has many interesting examples of the use of 3D printing in marketing. Here are some of them:

- To promote their new mini-bottles in Israel, Coca-Cola teamed up with marketing agency Gefem TelAviv to jointly develop a special mobile application where users could create their own virtual mini-bottle and treat it like a Tamagotchi.

Among all users of the application, several people won a trip to the Coca-Cola factory, where they underwent 3D scanning and received as a gift their mini copy printed from full-color gypsum on a 3D printer. A video was made about the campaign, which gained a huge number of views and helped Coca-Cola Mini to become extremely popular.

Among all users of the application, several people won a trip to the Coca-Cola factory, where they underwent 3D scanning and received as a gift their mini copy printed from full-color gypsum on a 3D printer. A video was made about the campaign, which gained a huge number of views and helped Coca-Cola Mini to become extremely popular. - To promote Belvita crackers, American creative agencies Droga5 and Fake Love invited Twitter users to post morning tweets with a special hashtag. Then, specially invited actors took a pose that vividly characterizes the events described by one or another user. The actors were scanned using a 3D scanner, and the resulting model was printed on a 3D printer in the form of a kind of cup and presented to the author of the tweet (Fig. 2). After that, a witty video about this campaign was posted on the Internet. The video received more than 80 million responses on various social networks, and Belvita increased its sales by 100%.

- To generate interest in 3D design software, Loft sent out informational brochures to users, complete with a 3D printed mini sofa.

As an interior for sofas, a box was used in which the parcel was packed. And the Munich furniture company AerisImpulsmöbel GmbH & Co. KG, along with promotional brochures, sent out 3D printed samples of its chairs to customers.

As an interior for sofas, a box was used in which the parcel was packed. And the Munich furniture company AerisImpulsmöbel GmbH & Co. KG, along with promotional brochures, sent out 3D printed samples of its chairs to customers. - British charity Barnardos and advertising agency BBH London launched the Home for Xmas campaign on Christmas Eve to raise awareness of the homeless and remind everyone of the importance of having a roof over their heads. As part of the campaign, every day they chose the house of one of the philanthropists and printed a plaster miniature of him on a 3D printer, which was then placed in a glass ball and sent to the “owner” with words of gratitude. A video of this action went viral, and the amount of money transferred to the Barnardos fund increased several times.

- The Volkswagen Group and DDB Copenhagen launched The Polo Principle campaign. Buyers were asked to design the car and place the project on the manufacturer's website. Forty of the best ideas were 3D printed and presented at an exhibition in Copenhagen, after which they were handed over to their developers.

The winning design was used in the production of the VW Polo.

The winning design was used in the production of the VW Polo.

Fig. 3. Sofas from Loft

Pic. 4. One of the models submitted to The Polo Principle

Benefits of using 3D printers in advertising and design

First of all, with the help of 3D printing you get the opportunity to create products of any geometry, your imagination is not limited by anything. Any whim of the customer can now be visualized in a few hours. At the same time, thanks to modern 3D printers, you can create bright full-color products that convey any color scheme.

The production and promotional stage plays a critical role in building a brand image and marketing strategy. That is why the product is not immediately brought to the market - first, a visual analysis of the trial model, an analysis of ergonomics, and a study of the focus group are carried out. During development and testing, the model may change several times, so it will be more economical and practical to create a product layout on a 3D printer.

3D printers make it possible to produce mock-ups of packages, vials and bottles of original shape, designer products, furniture, prototypes of electrical appliances and much more. At the same time, finished products can include all design elements, including labels, barcodes, brand names. The advantages of 3D prototypes are obvious: the customer can hold the project in his hands, evaluate its texture, texture, color scheme and other characteristics.

Prototype materials can be gypsum, photopolymers or ABS, depending on the properties of the product. With the help of 3D printing, you can not only convey the shape of a future object, but also show its best sides and hide its flaws. Color printing, high detail and quality surfaces allow you to quickly get the desired result.

3D Printing Technologies

Currently, there are many technologies for materializing real objects from created virtual 3D models. The most common and affordable technology is plastic printing.

The following is a classification of printing technologies and a description of each.

Currently, 3D printing technologies are divided into four main categories:

- Extrusion - extrusion of molten material.

- Photopolymerization - UV or laser curing of a polymer.

- Printing by sintering and melting materials.

- Lamination - bonding layers of material with subsequent cutting.

In addition, there are other technologies that are intermediate or do not fall into the above categories for one reason or another.

Extrusion

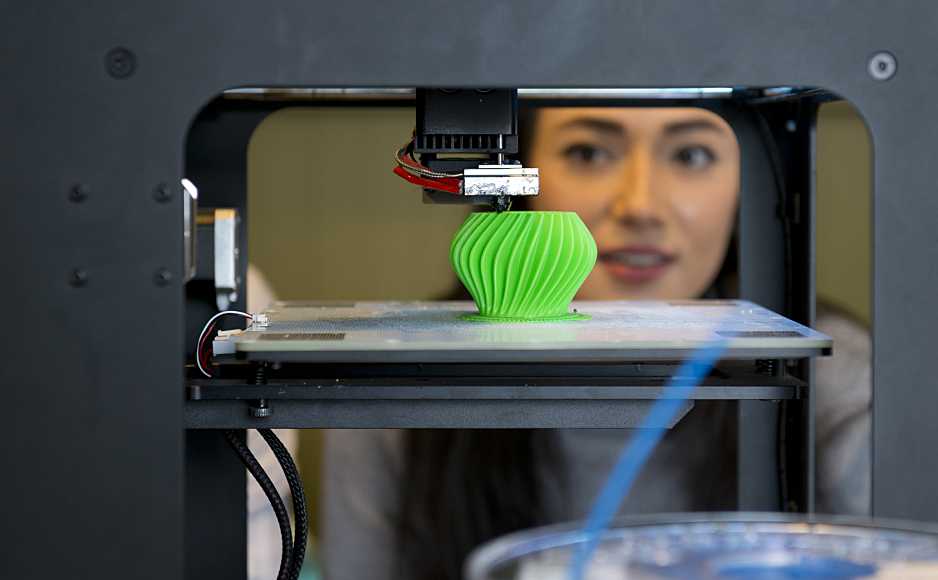

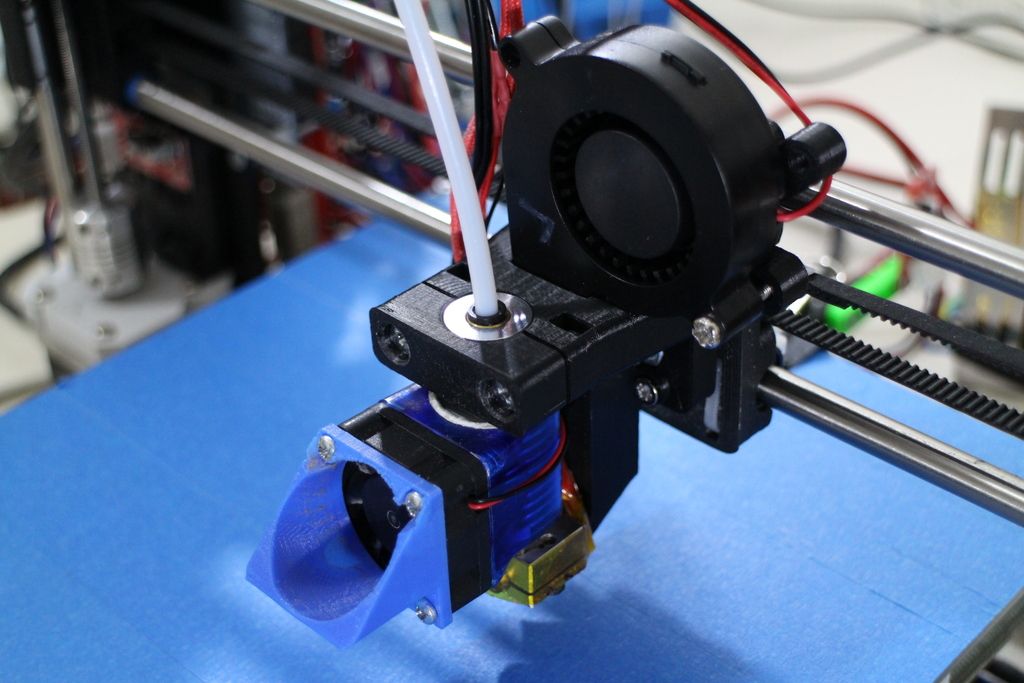

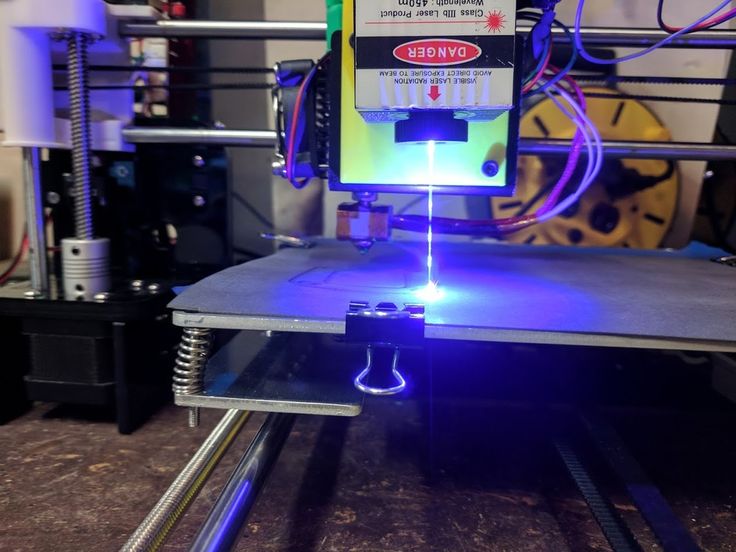

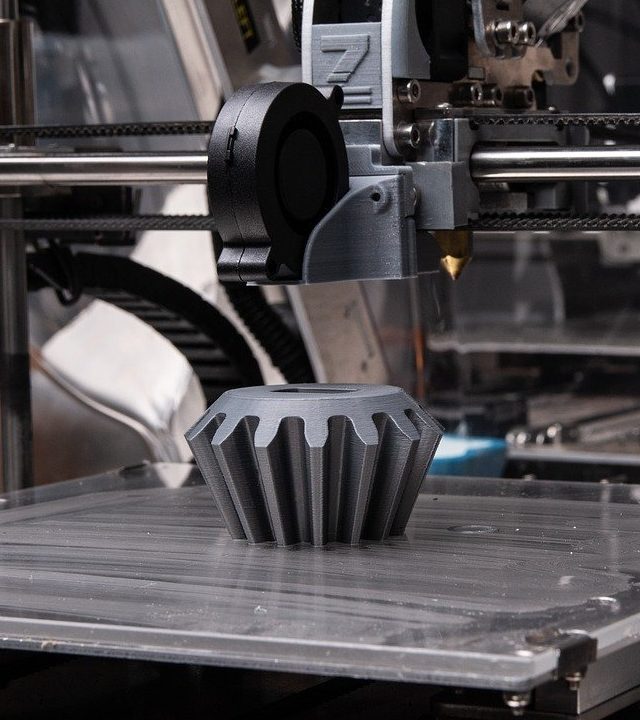

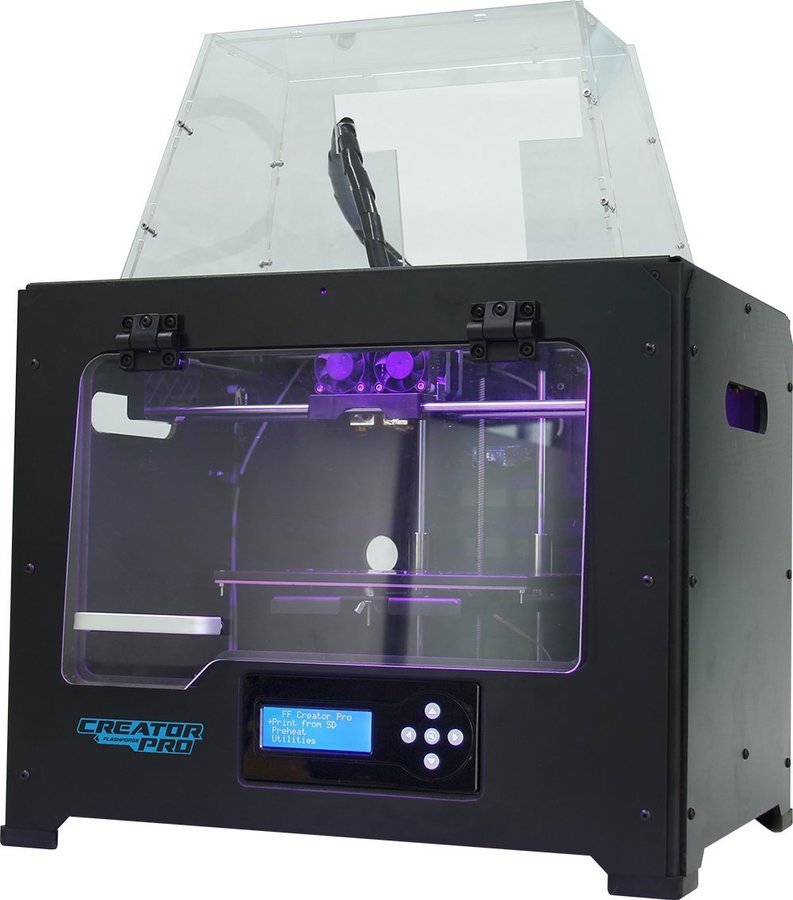

Fused Deposition Modeling (FDM)

The most common 3D printing technology, especially among personal and desktop 3D printers.

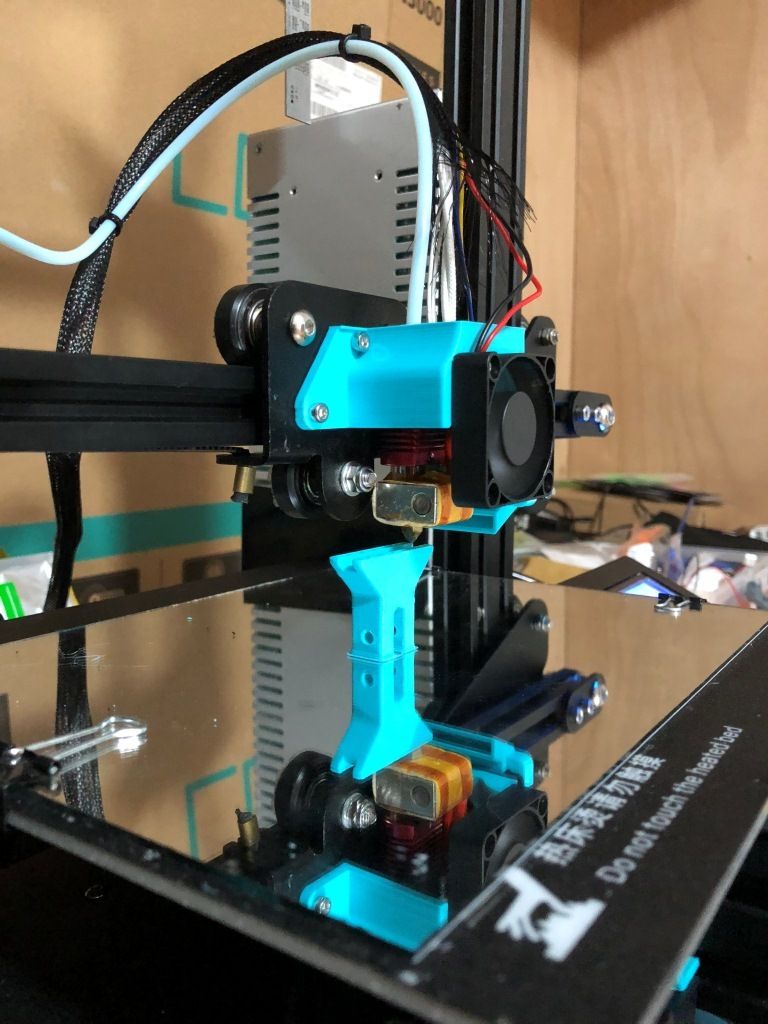

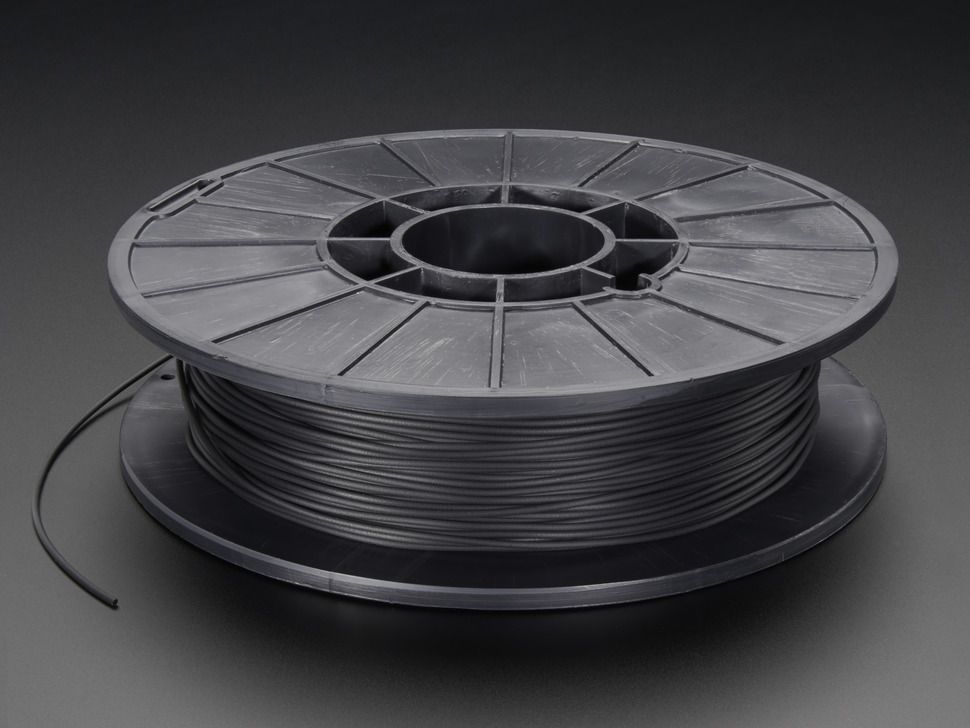

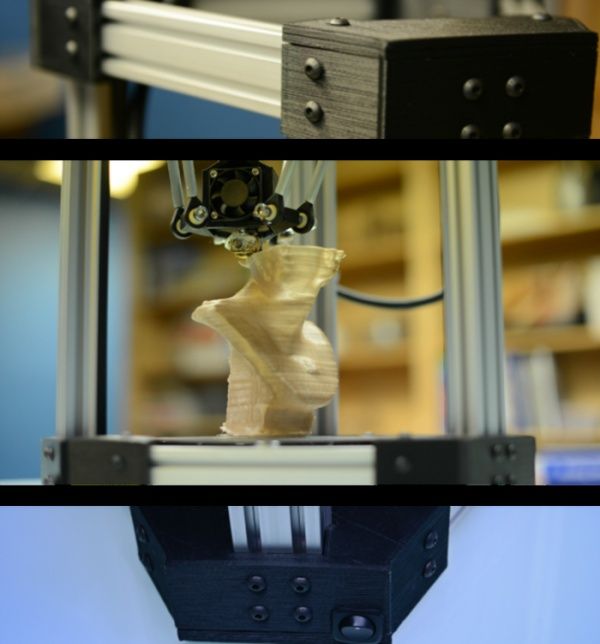

The technology works on the principle of material deposition in layers. Plastic or metal threads are unwound from a roll (cartridge) and fed into the print head (extruder). The extruder heats the filaments to a liquid state and extrudes the material through the nozzle, moving in the horizontal and vertical directions, forming the object layer by layer.

Benefits of FDM 3D printing:

- speed and ease of model making;

- availability;

- safety, environmental friendliness and non-toxicity of most materials;

- building accuracy;

- ease of use and maintenance;

- parts strength;

- easy disposal.

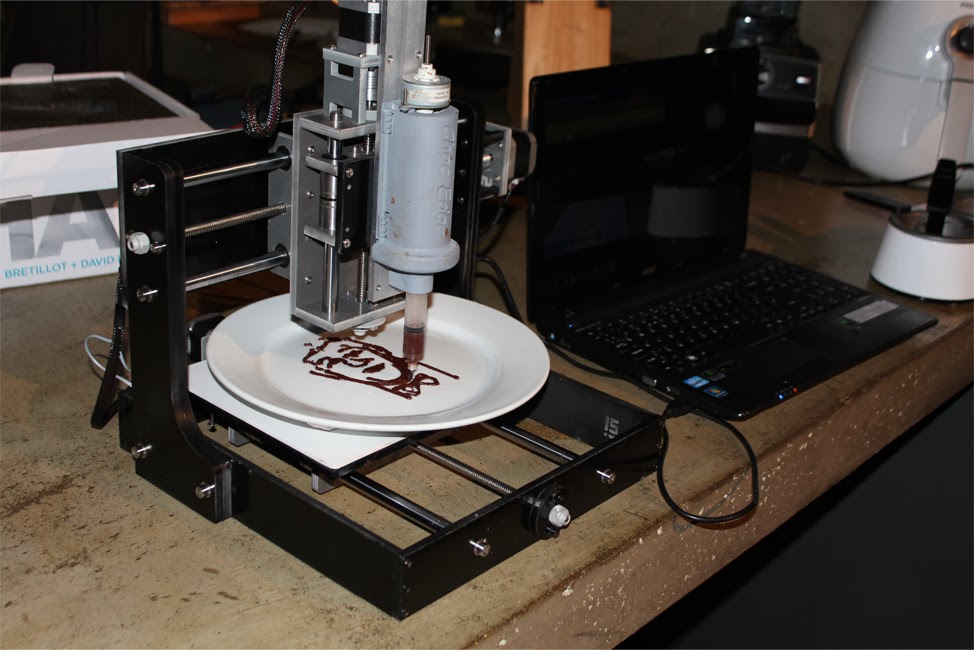

Media: Thermoplastics (PLA, ABS, PVA, HIPS, etc.), fusible metals and alloys. Plus, various culinary printers that use icing, cheese, dough, as well as medical printers that print with “living ink” (a set of living cells is placed in a special medical gel).

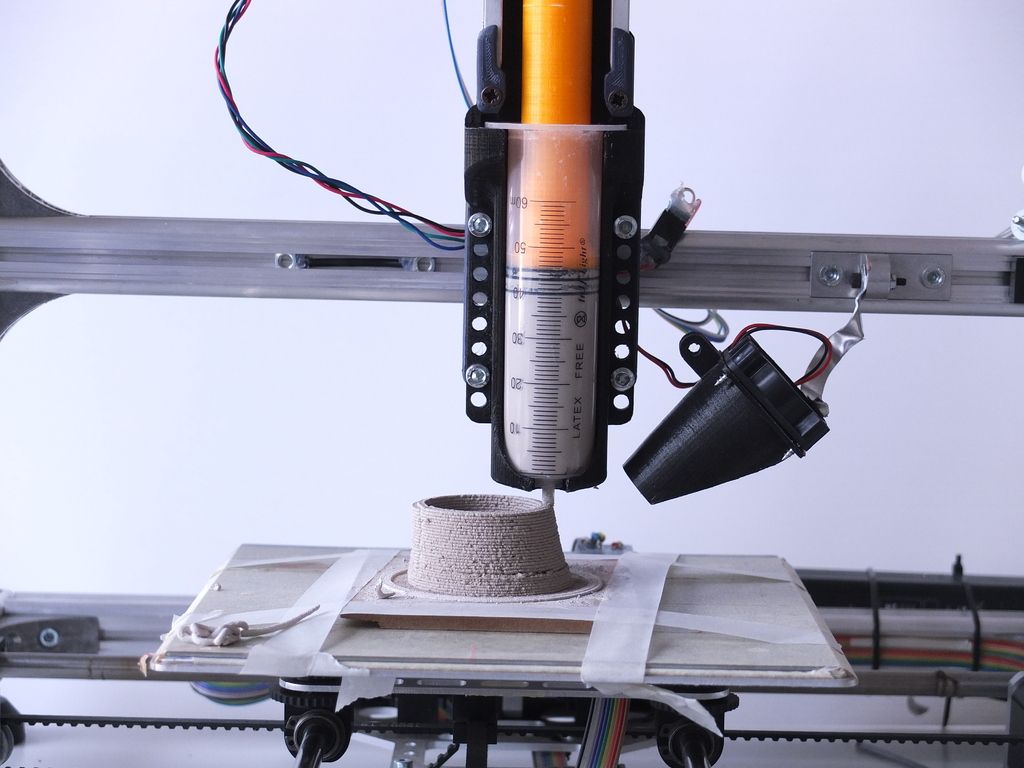

Spray On Demand Jet (DODJet)

This 3D printing technology uses two types of materials: model material and support material.

Printhead sprays both consumables at the same time. Then a special milling head cools the sprayed layer and mechanically processes it. DODJet technology allows you to build high-precision models with an absolutely smooth surface. Since the spraying of the working layer occurs due to a mechanical moving head, the speed of manufacturing a prototype largely depends on the complexity of the printed model.

Printing material: casting wax.

Fig. 5. Fused Deposition Modeling

Photopolymerization

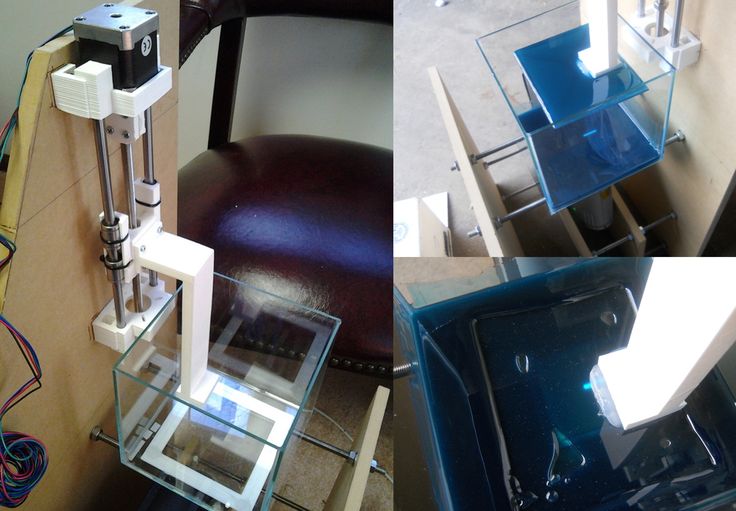

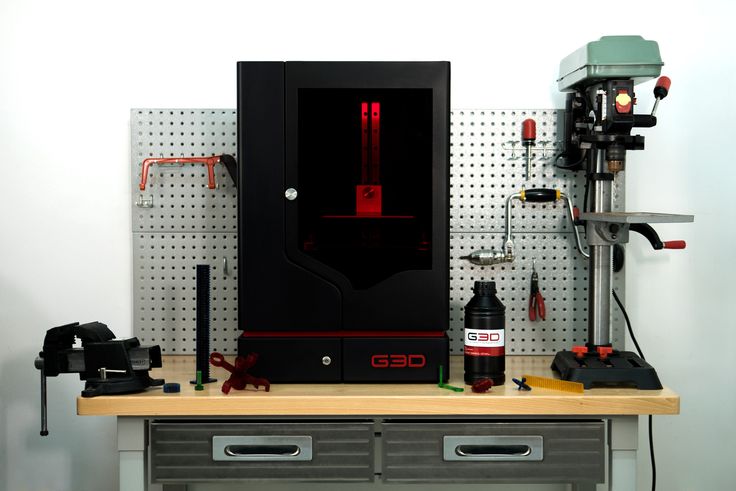

Laser Stereolithography (SLA)

The technology was invented by Charles Hull. After receiving a patent for it, Hull founded 3D Systems, which today remains the leading manufacturer of SLA machines.

The technology involves the use of a special photopolymer - photosensitive resin as a model material. The basis of this process is an ultraviolet laser, which sequentially transfers the cross-sections of the model to the surface of the vessel with photosensitive resin. The photopolymer cures only in the place where the laser beam has passed. Then a new layer of resin is applied to the cured layer and a new contour is drawn with a laser. The process is repeated until the completion of the model building.

Fig. 6. Stereolithography

Stereolithography is the most popular rapid prototyping technique for high precision models. It covers almost all branches of material production, from medicine to heavy engineering. SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of the surfaces depends on the construction step. Modern machines provide a construction step of 0.0250.15 mm.

It covers almost all branches of material production, from medicine to heavy engineering. SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of the surfaces depends on the construction step. Modern machines provide a construction step of 0.0250.15 mm.

Materials in 3D printingFiberglassGRP is a composite material consisting of glass filler and a special synthetic polymer binder. As a rule, glass fibers in the form of fabrics, mats, tows, threads or chopped fibers serve as a filler. Binder components - epoxy, phenol-formaldehyde, organosilicon, polyester resins, as well as polyamides, polycarbonates, polyimides, etc. The characteristics of fiberglass are a combination of high dielectric and strength properties with relatively low density and thermal conductivity. In this list, it is also necessary to add a significant moisture, thermal and weather resistance of this material.

Examples of fiberglass products include boat and yacht hulls, car bodies and tanks, rocket engine parts and radio-transparent fairings, swimming pools and much more. Polyurethane foamPolyurethane foam is a refractory, thermosetting, rigid mass with a pronounced cellular structure. The solid base of this material is only 3% of its volume and forms a rigid frame of walls and ribs. Such a crystal structure gives polyurethane foam significant mechanical strength. The remaining 97% are cavities and pores filled with fluorochloromethane. Fluorochloromethane gas is characterized by low thermal conductivity, and the proportion of closed pores in which it is contained reaches 95%. zp131 zp131 is a 4th generation high-composition material based on gypsum. zp131 was created based on the zp130 material, which has proven itself in the 3D printing industry. But the zp131 compares favorably with the zp130 with 50% more durability and 115% more color gamut. Testing of the composite material zp131 clearly showed that parts with rod elements with a diameter of 0. A simple example of how the zp131 can be used is to model a residential building with white interior walls. When using the zp130 material, the walls will definitely acquire a beige-yellowish tint or ivory color, which is not a marriage, but, nevertheless, looks “sloppy” in the project. zp131 allowed to solve this problem, because its composition, in addition to the powder base, includes a new adhesive mass, which provides a wide choice of colors and is capable of transmitting them as accurately as possible in finished form. ABS plastic The most popular consumable is ABS plastic. The special structure of this type of "consumable" allows you to withstand strong mechanical stress. Such plastic belongs to the impact-resistant group, and if we compare ABS with ordinary polystyrene, then it is significantly superior to other analogues in terms of mechanical strength and rigidity. Among the huge list of advantages can be noted resistance to alkali, grease, acid, hydrocarbon, grease and even gasoline. However, it is highly soluble in acetone, ether, benzene, ethyl chloride, ethylene chloride, aniline and anisole. The main disadvantage is sensitivity to ultraviolet rays and precipitation. This material is characterized by a low level of electrical insulation. Practically does not absorb moisture. It ignites at a temperature of 395 °C. PLA PLA plastic, or polylactide, is the most environmentally friendly and suitable consumable for 3D printing. This type of plastic is a thermoplastic polyester, which is created from biological waste (sugar beet or corn silage). This material is most commonly used in children's toys because PLA has minimal toxicity. The only drawback of polyactide is the fragility and gradual decomposition. Note that if you do not touch the printed product, then it can stand for about 20 years (if the temperature of the material does not exceed 50 ° C). However, if you subject it to constant use, then soon the object will lose its original appearance. The material is excellent for large and small prints. It is worth noting that polyactide can be mixed with ABS plastic to increase the strength of the product, especially since they have a relatively similar cost. If you want to melt PLA plastic, then just place the model in an ultrasonic tank with a small amount of caustic soda. An easier way to melt is to put the object in water heated to 80°C. PVA plastic PVA-plastic appeared on the Russian market in 2012. PhotopolymersPhotopolymers are another popular consumable for modern printers. In fact, this material has a lot of varieties, but they all have a common feature - photopolymers change their shape under the influence of sunlight. This consumable is used for printing on SLA and PJET printers. Such "consumables" can be liquid or solid. Objects that have been printed using photopolymers are highly durable, resistant to sunlight and water. Metal powder Metal powder is also commonly used in 3D printing. NylonNylon is very similar to the most popular consumable material, ABS plastic. However, it has better resistance to high printing temperatures and is able to absorb moisture. The disadvantage of nylon is a longer curing time and the need to evacuate air from the extruder. Nylon is considered a toxic material. This type of consumable is great for printing gears, levers, and even spare parts for medical devices. It is worth noting that today most printer owners use material such as Nylon 618, which has much less toxicity. * * * * * Modern types of consumables for 3D printers have the necessary margin of safety. As an example, we can mention a new material from the company Filamentarno, which offered users two filaments imitating ceramics. New consumables for 3D printing are called CERAMO and CERAMO-TEX (relevance of the news is the end of September this year). CERAMO is a high-density, smooth version reminiscent of earthenware - right down to the weight and impact sound. The material lends itself well to sanding, has low shrinkage on cooling and sets well between coats. CERAMO-TEX has high hardness at low density. According to the company, the density of products printed with 100% infill can be 0.75-0.8 g/cm³. |

SLA technology gives the best result in the manufacture of master models for the subsequent production of silicone molds and casting polymer resins in them, and is also used for growing jewelry master models.

Depending on the desired properties of the final object, the model is baked in so-called ultraviolet ovens.

Fig. 7. A brush printed entirely in one session using PolyJet technology

Photopolymer is often toxic, so when working with it, you need to use protective equipment and respirators. Maintaining and maintaining such a printer at home is difficult and expensive.

Benefits: Fast and accurate (accurate down to 10 microns). To sinter the photopolymer, a laser from a Bluray player is enough, thanks to which cheap and at the same time accurate printers using this technology appear on the market.

Media: photopolymer resin.

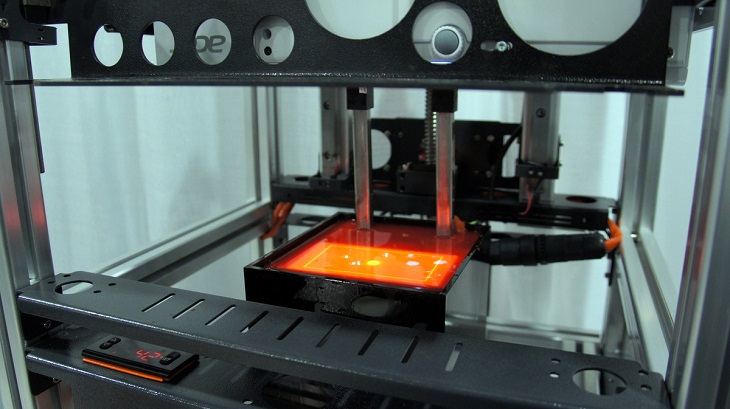

Digital Light Processing (DLP)

Similar to SLA technology. Unlike traditional stereolithography technology, which uses a scanning ultraviolet laser to solidify a liquid material, a DLP printer works on a similar principle, but uses a DLP projector that affects each layer. Once the first layer has set on the platform, it sinks a little deeper into the resin tank and the spotlight illuminates a new image to harden the next layer.

Media: liquid resin.

MJM Technology (Multi-Jet-Modeling)

Technology developed and patented by 3D Systems. MJM 3D printing technology is based on a layer-by-layer section of a CAD file into horizontal layers, which are sequentially sent to a 3D printer.

Each layer is formed by a printhead which, through groups of nozzles, releases melted (temperature around 80 °C) photopolymer or melted wax onto a horizontal moving platform. The material is melted in the supply system before it enters the print head.

If 3D printing is made from photopolymer, then after each layer is printed, the platform on which the layer is grown moves behind the print head under an ultraviolet lamp. A flash of an ultraviolet lamp causes a reaction, due to which the material hardens. After that, the platform moves back under the print head and the layer formation cycle is repeated. The print head forms a new layer.

MJM technology features the ability to reproduce 3D models with high fidelity. The 3D printing process uses a support material - wax (supplied in separate cartridges). If 3D printing is made from photopolymer, then the support material is removed by means of high temperature: the supported part is placed in an oven with a temperature of ~60 °C. If 3D printing is made from wax, then the support is removed using a special solution.

The 3D printing process uses a support material - wax (supplied in separate cartridges). If 3D printing is made from photopolymer, then the support material is removed by means of high temperature: the supported part is placed in an oven with a temperature of ~60 °C. If 3D printing is made from wax, then the support is removed using a special solution.

It is also important that dyes can be added to the glue, and therefore, it is possible to obtain not only a three-dimensional model, but also a multi-colored one.

Print media: photopolymer resin, acrylic resin, casting wax.

Polyjet technology (PolyJet, PJET)

Technology introduced in 2000 by Objet, then acquired by Stratasys in 2012.

PolyJet 3D printing is similar to document inkjet printing, but instead of inkjet on paper, PolyJet 3D printers emit jets of liquid photopolymer that forms layers on the build tray and is instantly fixed with UV light. Thin layers are laid down sequentially and form an accurate three-dimensional model or prototype. Models are ready to use immediately upon removal from the 3D printer, and no additional fixation is required.

Models are ready to use immediately upon removal from the 3D printer, and no additional fixation is required.

In addition to the selected build material, the 3D printer also jets a gel-like support material designed to support protrusions and complex geometries. It is easy to remove by hand or with water.

PolyJet 3D printing technology has many advantages for rapid prototyping, producing stunningly fine details and smooth surfaces quickly and accurately.

An important feature that distinguishes PolyJet from stereolithography is the ability to print with various materials. The technology uses a wide range of materials, including rigid opaque materials in hundreds of vibrant colors, transparent and colored translucent tones, flexible elastic materials, and specialized photopolymers for 3D printing in the dental, medical, and consumer goods industries.

Advantages of the technology: layer thickness - up to 16 microns (blood cell - 10 microns), high printing speed, since the liquid can be applied very quickly. Disadvantages of the technology: prints only using photopolymer - a highly specialized, expensive plastic, usually sensitive to UV and quite fragile.

Disadvantages of the technology: prints only using photopolymer - a highly specialized, expensive plastic, usually sensitive to UV and quite fragile.

Media: photopolymer resin.

Fig. 8. Laser sintering process using Selective Laser Sintering

Continuous Liquid Interface Production technology (CLIP)

A team of chemists led by Joseph DeSimone (University of North Carolina at Chapel Hill) has created an enhancement to photolithography printing that speeds up the process of layer-by-layer creation of UV-cured liquid polymer parts by a factor of ten.

With SLA or Polyjet in 3 hours and SLS in 11 hours, the CLIP printer takes only 6 minutes per object. Speed up from 30 to 100 times!

Fig. 9. Printing with LENS technology

It is obvious that the profitability of such a printer will grow fantastically, and the cost of products will immediately fall. At the same time, the improvement is not something particularly complicated or expensive. The essence of the invention is to create at the very bottom of the polymer bath, on top of the projection window, the thinnest layer of liquid, inhibited by oxygen and not hardened by ultraviolet radiation. Thus, curing takes place above, in a layer that does not touch the bottom of the bath and is separated from it by a layer of liquid polymer. The classic SLA technology cures the layer lying on the bottom of the bath, and therefore it can be lifted to the next step not earlier than it has completely hardened, that is, there is a long unremovable pause on each layer. In the CLIP technology, the rise of the platform occurs immediately, as soon as the next layer is exposed, which creates such a speed of construction. Oxygen, which inhibits the reaction in the bottom layer, is supplied by diffusion directly through the material from which the bottom of the bath is made. Actually, this oxygen-permeable bottom is the main innovation in the design of the SLA printer.

The essence of the invention is to create at the very bottom of the polymer bath, on top of the projection window, the thinnest layer of liquid, inhibited by oxygen and not hardened by ultraviolet radiation. Thus, curing takes place above, in a layer that does not touch the bottom of the bath and is separated from it by a layer of liquid polymer. The classic SLA technology cures the layer lying on the bottom of the bath, and therefore it can be lifted to the next step not earlier than it has completely hardened, that is, there is a long unremovable pause on each layer. In the CLIP technology, the rise of the platform occurs immediately, as soon as the next layer is exposed, which creates such a speed of construction. Oxygen, which inhibits the reaction in the bottom layer, is supplied by diffusion directly through the material from which the bottom of the bath is made. Actually, this oxygen-permeable bottom is the main innovation in the design of the SLA printer.

MultiFab is working with a record number of materials Although 3D printing technology is developing by leaps and bounds, it still needs additional human intervention. Another major issue with additive manufacturing is the limited number of materials a single printer can handle. Models that exist today are capable of working with three different materials, and the cost of such a multifunctional machine can reach $250,000. However, a team of scientists from the Computer Science and Artificial Intelligence Laboratory (CSAIL) at the Massachusetts Institute of Technology has introduced a new 3D printer, which, according to the creators, is better, cheaper and more convenient than all existing analogues. The device works with ten different materials at once and uses a 3D scanning technique that saves time and money during production. The print resolution is 40 micrometers, which is half the thickness of a human hair. The MultiFab system is equipped with self-calibration technology, which eliminates the need for a person to make adjustments himself. By overlaying each new layer into the design, the device compares it with a 3D model in the computer and generates so-called correction masks. This approach allows the use of inexpensive hardware while maintaining high print accuracy. In addition, MultiFab allows users to embed complex components such as circuits and sensors directly into the body of an object. And this means that the new 3D printer will be able to print entire devices with moving parts and built-in electronics. Unlike conventional 3D printers that rely on extrusion, the new technology relies on a slightly more sophisticated process. Extrusion in conventional 3D printers is the extrusion of material from special syringes - much like squeezing decorative icing or cream onto a cake from a pastry syringe. This results in details being printed at a fairly low resolution, resulting in a rough end product. (The diameter of the hole cannot be reduced to microscopic values, since the surface tension will not allow a drop of substance to be squeezed out). The MultiFab system works differently. It mixes microscopic droplets of photopolymers, which are then sent through inkjet print heads, similar to those built into the design of a typical office printer. This ensures high resolution of layer-by-layer deposition of materials and the quality of the final product. The total cost of materials used to construct the MultiFab printer was only $7,000, which is almost 20 times cheaper than existing counterparts. |

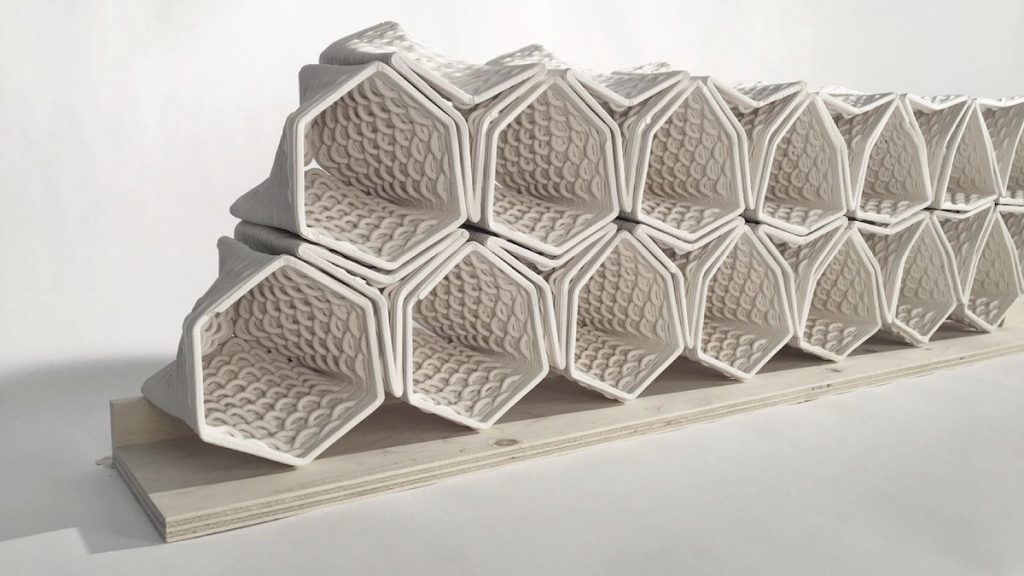

The technology makes it possible to use a huge range of consumables for applications ranging from sports shoes to the automotive and other industries.

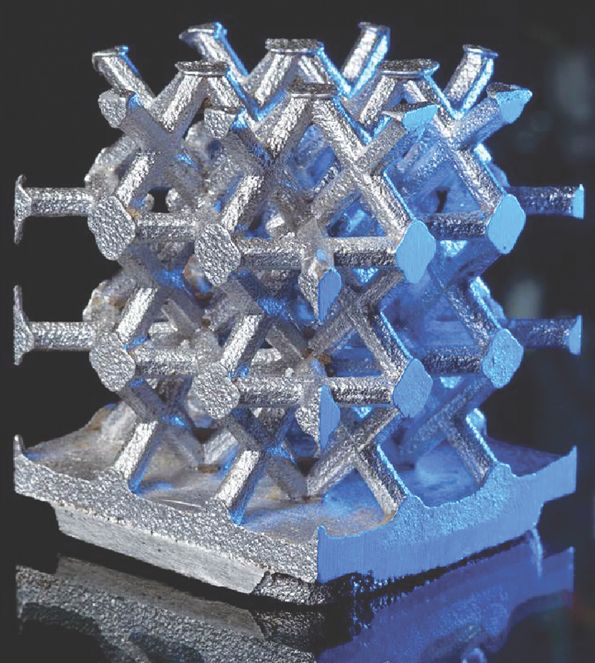

Material sintering and melting printing

Selective Laser Sintering (SLS)

The SLS method was invented by Carl Deckard in 1986. Using this technology, models are created from powder materials due to the effect of sintering using the energy of a laser beam. Unlike the SLA process, in this case the laser beam is not a light source, but a heat source. Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass in accordance with the geometry of the part. Polyamide, polystyrene, sand and some metal powders are used as materials.

Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass in accordance with the geometry of the part. Polyamide, polystyrene, sand and some metal powders are used as materials.

A significant advantage of the SLS process is the absence of so-called supports when building a model. In the SLA and MJM processes, when building overhanging elements of a part, special supports are used to protect freshly built thin layers of the model from collapse. In the SLS process, such supports are not necessary, since the construction is carried out in a homogeneous mass of powder. Once built, the model is extracted from the powder array and cleaned up.

The leading manufacturers of SLS machines are Concept Laser (Germany), 3D Systems (USA) and EOS GmbH (Germany).

Print material: thermoplastic, metal powder, ceramic powder, glass powder.

Direct Metal Selective Laser Melting (SLM)

SLM is a variation of SLS technology. This technology is similar to SLS, they are sometimes even confused, but at the same time they have cardinal differences. But, if in the SLS technology the powder particles are sintered with each other, here the metal particles are brought to a state of melting and welded together, forming a rigid frame.

But, if in the SLS technology the powder particles are sintered with each other, here the metal particles are brought to a state of melting and welded together, forming a rigid frame.

Materials are metals and alloys in powder form. The following metals and alloys are available for printing: steel, stainless steel, tool steel, aluminum, cobaltchromium alloy, titanium.

Fine layers of quality metal powder are spread evenly using a special coating mechanism. The platform on which the powder is located can be lowered vertically. The whole process takes place inside a chamber that maintains tight control of atmospheric inert gases such as argon, nitrogen, oxygen, the level of which does not exceed 500 ppm. Each layer is then formed by selectively exposing the powder surface to lasers using two high-frequency X and Y axis scanners. The focusing system directs a high power laser at the metal particles, melting and welding them together. Solid welding takes place along the contours of the section, and the insides of the walls of the object can be welded in accordance with the filling pattern. By the way, the powder left from the manufacture of the part can be reused to print the next model.

By the way, the powder left from the manufacture of the part can be reused to print the next model.

Printing material: almost any metal alloy in the form of granules, crumbs, powder.

Electron Beam Melting (EBM)

This technology was developed by Arcam AB in Sweden. The technology is the manufacture of parts by melting metal powder, applied layer by layer, with a powerful electron beam in a vacuum. Unlike some methods of metal sintering, the parts are obtained without voids, very strong.

EBM is the most advanced 3D printing technology available.

The technology allows to produce parts of any geometric shape with the parameters of the material used. The EBM machine reads data from a 3D model, usually in a CAD file, and builds it up layer by layer. These layers are fused together using a computer controlled electron beam. In this way he builds whole parts. The process takes place in a vacuum, which makes it suitable for the manufacture of parts from materials that are highly susceptible to oxygen, such as titanium.

An important advantage is that the powder is a pure final material without any fillers, and therefore the printed part does not need to be subjected to additional heat treatment.

EBM operates at temperatures typically between 700 and 1000°C. Parts are ready almost immediately after cooling.

The combination of vacuum and general high temperature results in the phenomenon of so-called internal stress relief. Steelmakers are obviously familiar with this term, but for everyone else, let's just say that the final product gets a strength comparable to forged alloys.

Titanium alloys, as noted above, are easily machined with this technology, making it a suitable choice for the medical implant market.

Print material: titanium alloys.

Selective Heat Sintering

SHS is similar to Selective Laser Sintering (SLS) but uses directed heat instead of a high-precision laser. A special lamp is covered with a mask, due to which it becomes possible to selectively act on the source material.

This technology uses special UV lamps to control the heat flow.

One of the main advantages is that for a given wavelength of infrared radiation it is possible to choose two types of material: one will transmit heat, and the other will reflect. Also, one of the main properties of IR radiation is the ability to choose a wavelength at which a particular material will absorb or reflect all radiation.

Interestingly, one 100 micron (0.1 mm) thick layer is printed in just 12 seconds. This technology is a real breakthrough in high-speed printing. It is important to emphasize that the model is formed from powder, and all unused powder can be reused.

This technology allows you to make models of the most complex geometric shapes, as well as print several parts at the same time.

Media: thermoplastic powder.

Laser Engineered Net Shaping (LENS)

Powder material is blown out of a nozzle and hit by a focused laser beam. Part of the powder flies past, and the part that falls into the focus of the laser is instantly sintered and layer by layer forms a three-dimensional part. This technology is used to print steel and titanium objects.

This technology is used to print steel and titanium objects.

Since before the advent of this technology only plastic objects could be printed, 3D printing was not taken very seriously, and this technology opened the door for 3D printing to the “big” industry. Powders of various materials can be mixed and thus alloys can be obtained, as they say, on the fly.

Application: eg titanium blades for turbines with internal cooling channels. Equipment manufacturer: Optomec.

Layer-by-layer distribution of adhesive on gypsum powder (Powder bed and inkjet head 3d printing, Plaster-based 3D printing, 3DP)

3DP is a specific additive manufacturing technology based on the use of a powder and a binder. This technology was patented in 1993 at the Massachusetts Institute of Technology (MIT) and sold in 1995 to Z Corporation, which in turn was acquired by 3D Systems in January 2012.

3DP uses a powder manufacturing method similar to SLS, but instead of sintering or melting the powder, a binder (adhesive) is added to the powder. For these purposes, a print head is used, similar to the head of an inkjet 3D printer.

For these purposes, a print head is used, similar to the head of an inkjet 3D printer.

The technology is very simple: there is a layer of powder, a print head passes over it and selectively (according to the shape of the section) applies a special binding liquid. A fresh layer of powder spreads over the entire surface of the model and the process is repeated. When the model is ready, unbound powder is automatically removed.

Advantages:

- since it uses glue, it can add ink and print colored objects;

- technology is relatively cheap and energy efficient;

- can be used at home or office;

- can be printed with glass powder, bone powder, recycled rubber, bronze, and even sawdust.

Edible objects such as sugar or chocolate powder can be printed using a similar technology. The powder is glued together with special food glue, dye and flavoring can be added to the glue.

Disadvantages:

- the output is quite rough, with a low resolution - ~ 100 microns;

- material must be post-processed (baked) to give it the necessary properties.

Printing material: gypsum, gypsum-based composite, gypsum powder, etc.

Full color 3D printing . Coloring occurs immediately during construction. This technology makes it possible to obtain photorealistic objects, so it is very interesting for designers, as it can be used in the development of decorative models and design prototypes.

Gypsum-based powder is used as starting material. Special rollers and brushes first form a thin, even layer of powder. Then the movable head moves in a horizontal plane and applies microscopic drops of a glue-like substance to the desired areas, resembling cyanoacrylate in composition. But beforehand, the substance is colored in accordance with the exact value of the color at a given point. This builds up layer by layer. The platform gradually lowers until the object is ready to the very top. The desired color is usually achieved by mixing from four possible colors - almost like in home inkjet printers. At the end, the object is dipped entirely in cyanoacrylate to give strength and shine.

Objects created using color 3D printing are not durable and therefore are not used as machine parts. Another feature is that objects are afraid of water: when in contact with moisture, the colors fade. Therefore, when choosing a material, it is important to consider the purpose of the subject.

Fig. 10. An example of color 3D printing

Laminated Object Manufacturing (LOM)

In this technology, the model is made from thin layers of polymer film. Previously, each layer of the future product is cut out of the working material with a laser or a mechanical cutter. The finished forms of the layers are placed in the prescribed order and glued together. Layer-by-layer bonding can occur in many ways - using local heating, pressing under pressure or conventional chemical bonding.

Print media: paper, metal foil, polyethylene film.

3D Printing by Mcor Technologies

A recent technology that allows you to print products from plain A4 paper. A carbide steel cutter cuts out each layer of the future model from a sheet of paper. Then the layers are glued with ordinary water-based clerical glue. This printing technology is used by the innovative MATRIX 3000 3D printer.

A carbide steel cutter cuts out each layer of the future model from a sheet of paper. Then the layers are glued with ordinary water-based clerical glue. This printing technology is used by the innovative MATRIX 3000 3D printer.

Print material: standard office paper.

Contour Crafting (CC)

Invented by Professor Behrokh Khoshnevis of the University of Southern California. CC is a building technology, and equipment for "printing" can only be called a 3D printer by some stretch.

Printer looks more like a gantry crane. Instead of a multi-ton hook, there is a concrete spraying head with built-in pneumatic surface formers. Instantly hardening concrete mortar layer by layer is applied to the base of the house. Walls, along with openings, vents, chimneys in the truest sense of the word, are growing before our eyes. The construction of a hollow "box" of one cottage with an area of 100 m2 takes about eight hours of continuous work.

Print material: concrete mixture.

All about 3D printing. additive manufacturing. Basic concepts.

- 1 Technology

- 2 Terminology

- 3 Fundamentals

- 4 Printing Technologies

- 5 3D printers

- 6 Application

- 7 Domestic and hobby use

- 8 Clothes

- 9 3D bioprinting

- 10 3D printing of implants and medical devices

- 11 3D printing services

- 12 Research into new applications

- 13 Intellectual Property

- 14 Influence of 3D printing

- 15 Space research

- 16 Social change

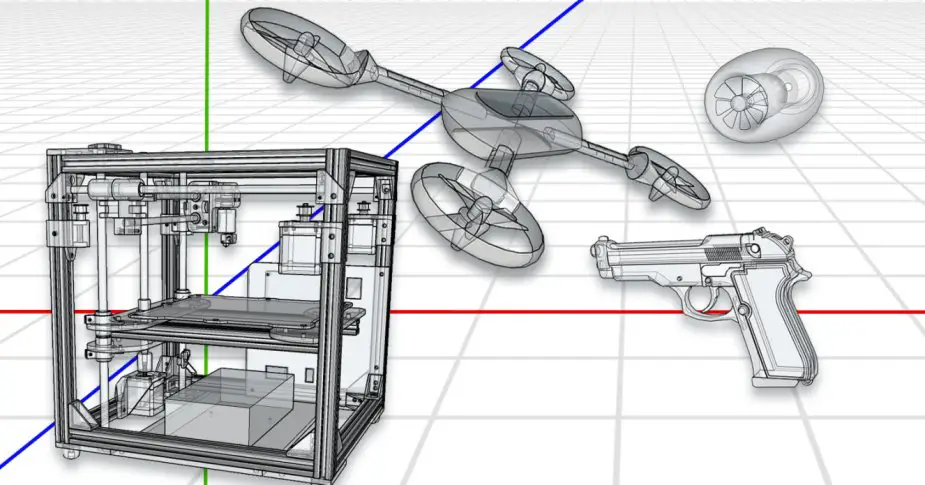

- 17 Firearms

Technology

Charles Hull - the father of modern 3D printing

3D printing is based on the concept of building an object in successive layers that display the contours of the model. In fact, 3D printing is the complete opposite of traditional mechanical production and processing methods such as milling or cutting, where the appearance of the product is formed by removing excess material (so-called "subtractive manufacturing").

In fact, 3D printing is the complete opposite of traditional mechanical production and processing methods such as milling or cutting, where the appearance of the product is formed by removing excess material (so-called "subtractive manufacturing").

3D printers are computer-controlled machines that build parts in an additive way. Although 3D printing technology appeared in the 80s of the last century, 3D printers were widely used commercially only in the early 2010s. The first viable 3D printer was created by Charles Hull, one of the founders of 3D Systems Corporation. At the beginning of the 21st century, there was a significant increase in sales, which led to a sharp drop in the cost of devices. According to the consulting firm Wohlers Associates, the global market for 3D printers and related services reached $2.2 billion in 2012, growing by 29%.% compared to 2011.

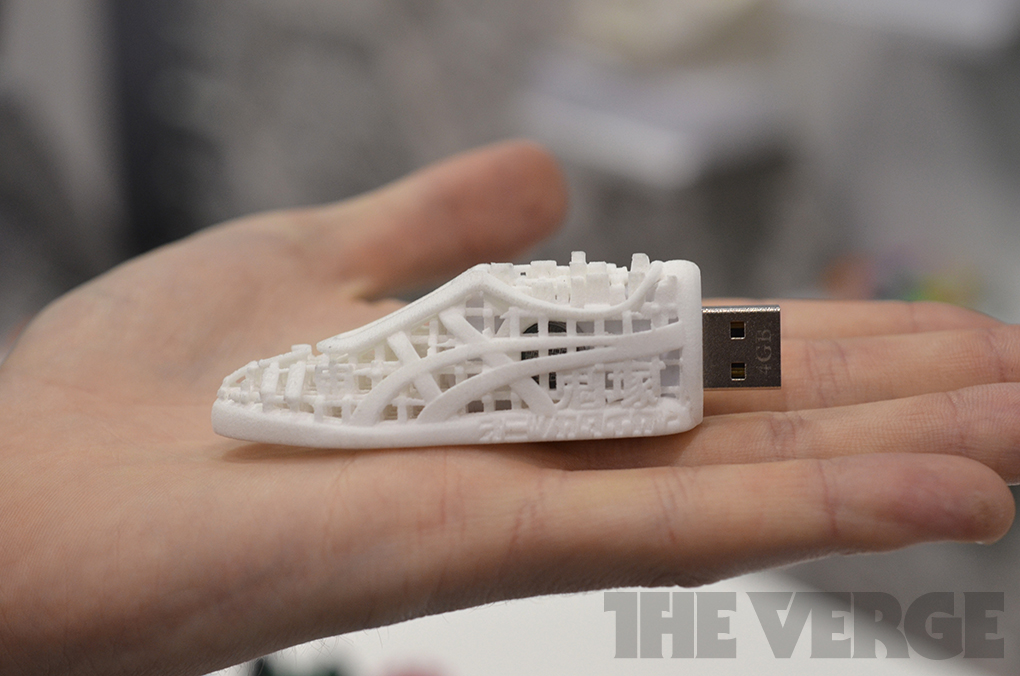

3D printing technologies are used for prototyping and distributed manufacturing in architecture, construction, industrial design, automotive, aerospace, military, engineering and medical industries, bioengineering (to create artificial fabrics), fashion and footwear, jewelry, education, geographic information systems, food industry and many other areas. According to research, open source home 3D printers will allow you to win back the capital costs of your own purchase through the economy of household production of items.

According to research, open source home 3D printers will allow you to win back the capital costs of your own purchase through the economy of household production of items.

Terminology

Additive manufacturing involves the construction of objects by adding the necessary material, and not by removing excess, as is the case with subtractive methods

The term "additive manufacturing" refers to the technology of creating objects by applying successive layers material. Models made using the additive method can be used at any stage of production - both for the production of prototypes (so-called rapid prototyping) and as finished products themselves (so-called rapid production).

In manufacturing, especially machining, the term "subtractive" implies more traditional methods and is a retronym coined in recent years to distinguish between traditional methods and new additive methods. Although traditional manufacturing has used essentially "additive" methods for centuries (such as riveting, welding, and screwing), they lack a 3D information technology component. Machining, on the other hand, (the production of parts of an exact shape), as a rule, is based on subtractive methods - filing, milling, drilling and grinding.

Although traditional manufacturing has used essentially "additive" methods for centuries (such as riveting, welding, and screwing), they lack a 3D information technology component. Machining, on the other hand, (the production of parts of an exact shape), as a rule, is based on subtractive methods - filing, milling, drilling and grinding.

The term "stereolithography" was defined by Charles Hull in a 1984 patent as "a system for generating three-dimensional objects by layering".

Fundamentals

3D printed models

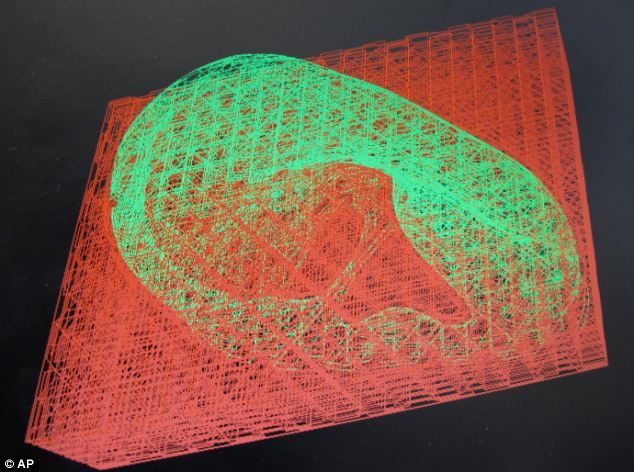

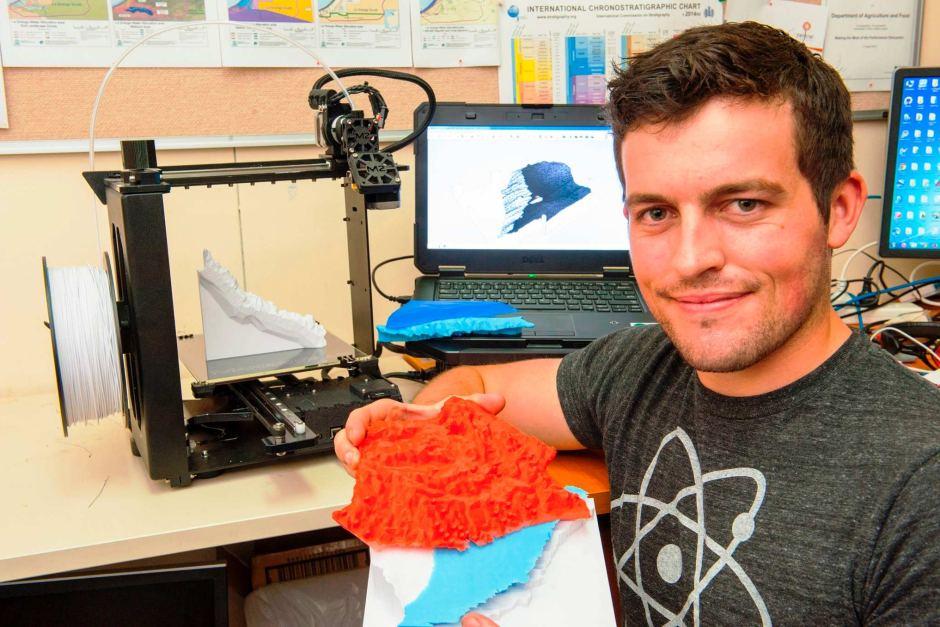

3D models are created by hand-held computer graphic design or 3D scanning. Hand modeling, or the preparation of geometric data for the creation of 3D computer graphics, is somewhat like sculpture. 3D scanning is the automatic collection and analysis of data from a real object, namely shape, color and other characteristics, with subsequent conversion into a digital three-dimensional model.

Both manual and automatic creation of 3D printed models can be difficult for the average user. In this regard, 3D printed marketplaces have become widespread in recent years. Some of the more popular examples include Shapeways, Thingiverse, and Threeding.

3D printing

The following digital models are used as drawings for 3D printed objects , powder, paper or sheet material, building a 3D model from a series of cross sections. These layers, corresponding to virtual cross-sections in the CAD model, are connected or fused together to create an object of a given shape. The main advantage of this method is the ability to create geometric shapes of almost unlimited complexity.

"Resolution" of the printer means the thickness of the applied layers (Z axis) and the accuracy of positioning the print head in the horizontal plane (along the X and Y axes). Resolution is measured in DPI (dots per inch) or micrometers (the obsolete term is "micron"). Typical layer thicknesses are 100µm (250 DPI), although some devices like the Objet Connex and 3D Systems ProJet are capable of printing layers as thin as 16µm (1600 DPI). The resolution on the X and Y axes is similar to that of conventional 2D laser printers. A typical particle size is about 50-100µm (510 to 250 DPI) in diameter.

Typical layer thicknesses are 100µm (250 DPI), although some devices like the Objet Connex and 3D Systems ProJet are capable of printing layers as thin as 16µm (1600 DPI). The resolution on the X and Y axes is similar to that of conventional 2D laser printers. A typical particle size is about 50-100µm (510 to 250 DPI) in diameter.

One of the methods for obtaining a digital model is 3D scanning. Pictured here is a MakerBot Digitizer

3D Scanner Building a model using today's technology takes hours to days, depending on the method used and the size and complexity of the model. Industrial additive systems can typically reduce the time to a few hours, but it all depends on the type of plant, as well as the size and number of models produced at the same time.

Traditional manufacturing methods such as injection molding can be cheaper for large-scale production of polymer products, but additive manufacturing has advantages for small-scale production, allowing for higher production rates and design flexibility, along with increased cost per unit produced. In addition, desktop 3D printers allow designers and developers to create concept models and prototypes without leaving the office.

In addition, desktop 3D printers allow designers and developers to create concept models and prototypes without leaving the office.

Machining

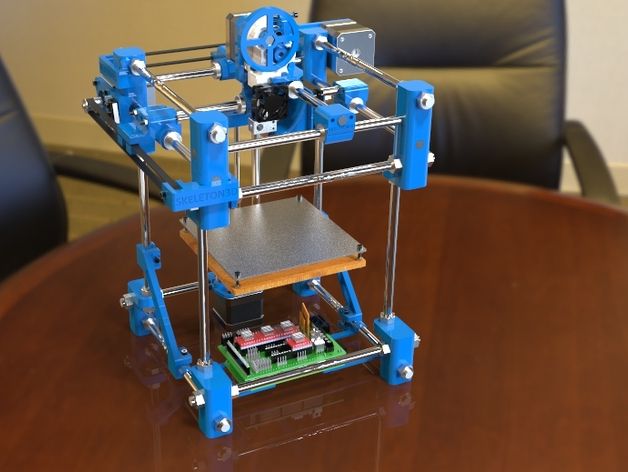

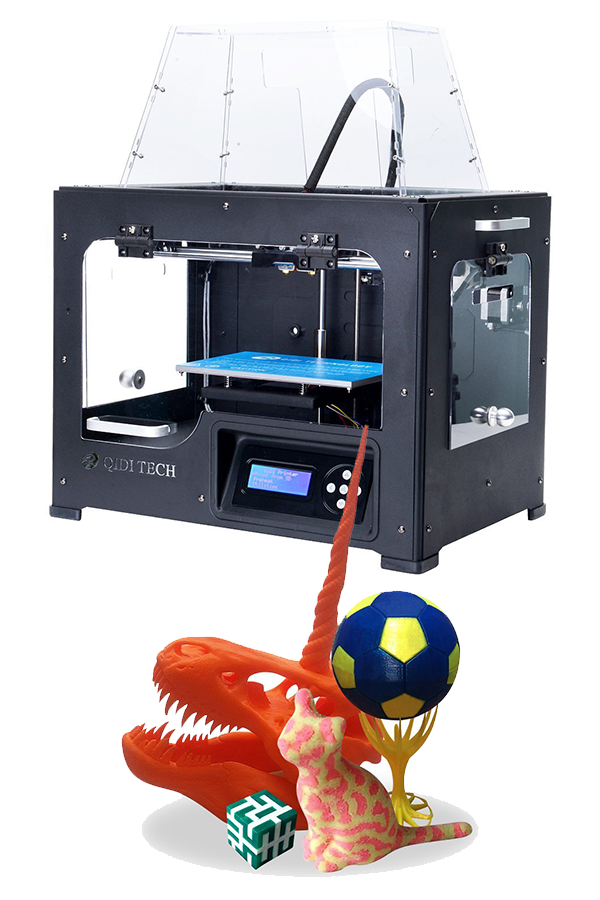

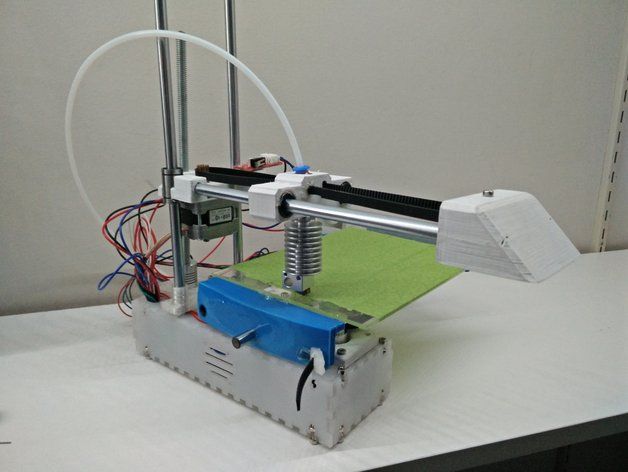

FDM Type 3D Printers

Although the resolution of the printers is sufficient for most projects, printing slightly oversized objects and then subtractively machining them with high precision tools allows you to create models of increased accuracy.

The LUMEX Avance-25 is an example of devices with a similar combined manufacturing and processing method. Some additive manufacturing methods allow for the use of multiple materials, as well as different colors, within a single production run. Many of the 3D printers use "supports" or "supports" during printing. Supports are needed to build model fragments that are not in contact with the underlying layers or the working platform. The supports themselves are not part of the given model, and upon completion of printing, they either break off (in the case of using the same material as for printing the model itself), or dissolve (usually in water or acetone - depending on the material used to create the supports). ).

).

Printing technologies

Since the late 1970s, several 3D printing methods have come into being. The first printers were large, expensive and very limited.

Complete skull with supports not yet removed

A wide variety of additive manufacturing methods are now available. The main differences are in the layering method and consumables used. Some methods rely on melting or softening materials to create layers: these include selective laser sintering (SLS), selective laser melting (SLM), direct metal laser sintering (DMLS), fusing deposition printing (FDM or FFF). Another trend has been the production of solid models by polymerization of liquid materials, known as stereolithography (SLA).

In the case of lamination of sheet materials (LOM), thin layers of material are cut to the required contour, and then joined into a single whole. Paper, polymers and metals can be used as LOM materials. Each of these methods has its own advantages and disadvantages, which is why some companies offer a choice of consumables for building a model - polymer or powder. LOM printers often use regular office paper to build durable prototypes. The key points when choosing the right device are the speed of printing, the price of a 3D printer, the cost of printed prototypes, as well as the cost and range of compatible consumables.

Each of these methods has its own advantages and disadvantages, which is why some companies offer a choice of consumables for building a model - polymer or powder. LOM printers often use regular office paper to build durable prototypes. The key points when choosing the right device are the speed of printing, the price of a 3D printer, the cost of printed prototypes, as well as the cost and range of compatible consumables.

Printers that produce full-fledged metal models are quite expensive, but it is possible to use less expensive devices for the production of molds and subsequent casting of metal parts.

The main methods of additive manufacturing are presented in the table:

| | ||

| Method | Technology | Materials used |

| Extrusion | Fused deposition modeling (FDM or FFF) | Thermoplastics (such as polylactide (PLA), acrylonitrile butadiene styrene (ABS), etc. ) ) |

| Wire | Manufacture of arbitrary shapes by electron beam fusing (EBFȝ) | Virtually all metal alloys |

| Powder | Direct Metal Laser Sintering (DMLS) | Virtually all metal alloys |

| Electron Beam Melting (EBM) | Titanium alloys | |

| Selective laser melting (SLM) | Titanium alloys, cobalt-chromium alloys, stainless steel, aluminum | |

| Selective heat sintering (SHS) | Powder thermoplastics | |

| Selective laser sintering (SLS) | Thermoplastics, metal powders, ceramic powders | |

| Inkjet | 3D Inkjet(3DP) | Gypsum, plastics, metal powders, sand mixtures |

| Lamination | Lamination Object Manufacturing (LOM) | Paper, metal foil, plastic film |

| Polymerization | Stereolithography (SLA) | Photopolymers |

| Digital LED Projection (DLP) | Photopolymers |

Extrusion Printing

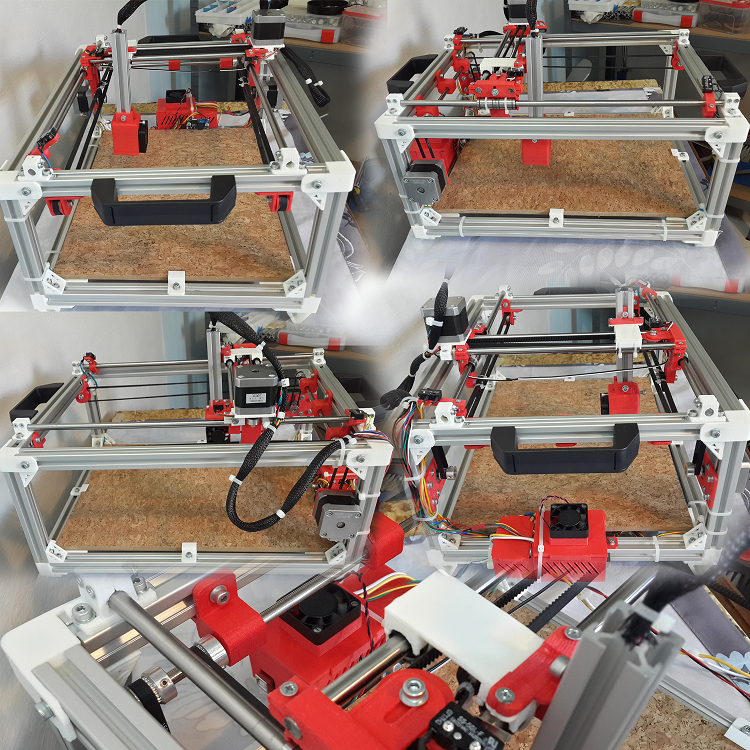

Fused Deposition Modeling (FDM/FFF) was developed by S. Scott Trump in the late 1980s and commercialized in the 1990s by Stratasys, of which Trump is one of the founders. Due to the expiration of the patent, there is a large community of open source 3D printer developers as well as commercial organizations using the technology. As a consequence, the cost of devices has decreased by two orders of magnitude since the invention of the technology.

Scott Trump in the late 1980s and commercialized in the 1990s by Stratasys, of which Trump is one of the founders. Due to the expiration of the patent, there is a large community of open source 3D printer developers as well as commercial organizations using the technology. As a consequence, the cost of devices has decreased by two orders of magnitude since the invention of the technology.

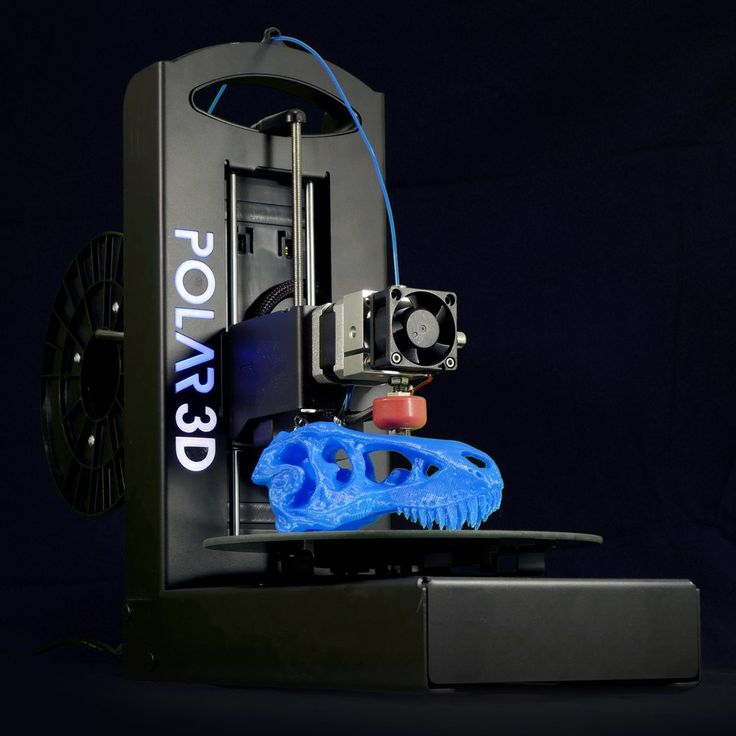

3D printers range from simple do-it-yourself printers to plastic...

Fusion printing process involves the creation of layers by extrusion of a fast-curing material in the form of microdrops or thin jets. Typically, consumable material (such as thermoplastic) comes in the form of spools from which the material is fed into a printhead called an "extruder". The extruder heats the material to its melting temperature, followed by extrusion of the molten mass through a nozzle. The extruder itself is driven by stepper motors or servomotors to position the print head in three planes. The movement of the extruder is controlled by a manufacturing software (CAM) linked to a microcontroller.

The movement of the extruder is controlled by a manufacturing software (CAM) linked to a microcontroller.

A variety of polymers are used as consumables, including acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polylactide (PLA), high pressure polyethylene (HDPE), polycarbonate-ABS blends, polyphenylene sulfone (PPSU), etc. Typically, polymer supplied in the form of a filler made of pure plastic. There are several projects in the 3D printing enthusiast community that aim to recycle used plastic into materials for 3D printing. The projects are based on the production of consumables using shredders and melters.

FDM/FFF technology has certain limitations on the complexity of the generated geometric shapes. For example, the creation of suspended structures (such as stalactites) is impossible by itself, due to the lack of necessary support. This limitation is compensated by the creation of temporary support structures that are removed after printing is completed.

Powder print

Selective sintering of powder materials is one of the additive manufacturing methods. Model layers are drawn (sintered) in a thin layer of powdered material, after which the work platform is lowered and a new layer of powder is applied. The process is repeated until a complete model is obtained. The unused material remains in the working chamber and serves to support the overhanging layers without requiring the creation of special supports.

The most common methods are based on laser sintering: selective laser sintering (SLS) for working with metals and polymers (e.g. polyamide (PA), glass fiber reinforced polyamide (PA-GF), glass fiber (GF), polyetheretherketone) (PEEK), polystyrene (PS), alumide, carbon fiber reinforced polyamide (Carbonmide), elastomers) and direct metal laser sintering (DMLS).

... to expensive industrial plants that work with metals

Selective Laser Sintering (SLS) was developed and patented by Carl Deckard and Joseph Beeman of the University of Texas at Austin in the mid 1080s under the auspices of the Defense Advanced Research Projects Agency (DARPA). A similar method was patented by R. F. Householder in 1979, but has not been commercialized.

A similar method was patented by R. F. Householder in 1979, but has not been commercialized.

Selective laser melting (SLM) is characterized by the fact that it does not sinter, but actually melts the powder at the points of contact with a powerful laser beam, allowing you to create high-density materials that are similar in terms of mechanical characteristics to products made by traditional methods.

Electron Beam Melting (EBM) is a similar method for the additive manufacturing of metal parts (eg titanium alloys) but using electron beams instead of lasers. EBM is based on melting metal powders layer by layer in a vacuum chamber. In contrast to sintering at temperatures below melting thresholds, models made by electron beam melting are characterized by solidity with a corresponding high strength.

Finally, there is the 3D inkjet printing method. In this case, a binder is applied to thin layers of powder (gypsum or plastic) in accordance with the contours of successive layers of the digital model. The process is repeated until the finished model is obtained. The technology provides a wide range of applications, including the creation of color models, suspended structures, the use of elastomers. The design of models can be strengthened by subsequent impregnation with wax or polymers.

The process is repeated until the finished model is obtained. The technology provides a wide range of applications, including the creation of color models, suspended structures, the use of elastomers. The design of models can be strengthened by subsequent impregnation with wax or polymers.

Lamination

FDM 3D printers are the most popular among hobbyists and enthusiasts

Some printers use paper as a material for building models, thereby reducing the cost of printing. Such devices experienced the peak of popularity in the 1990s. The technology consists in cutting out the layers of the model from paper using a carbon dioxide laser with simultaneous lamination of the contours to form the finished product.

In 2005, Mcor Technologies Ltd developed a variant of the technology that uses plain office paper, a tungsten carbide blade instead of a laser, and selective adhesive application.

There are also device variants that laminate thin metal and plastic sheets.

Photopolymerization

3D printing allows you to create functional monolithic parts of complex geometric shapes, like this jet nozzle

Stereolithography technology was patented by Charles Hull in 1986. Photopolymerization is primarily used in stereolithography (SLA) to create solid objects from liquid materials. This method differs significantly from previous attempts, from the sculptural portraits of François Willem (1830-1905) to photopolymerization by the Matsubara method (1974).

The Digital Projection Method (DLP) uses liquid photopolymer resins that are cured by exposure to ultraviolet light emitted from digital projectors in a coated working chamber. After the material has hardened, the working platform is immersed to a depth equal to the thickness of one layer, and the liquid polymer is irradiated again. The procedure is repeated until the completion of the model building. An example of a rapid prototyping system using digital LED projectors is the EnvisionTEC Perfactory.

Inkjet printers (eg Objet PolyJet) spray thin layers (16-30µm) of photopolymer onto the build platform until a complete model is obtained. Each layer is irradiated with an ultraviolet beam until hardened. The result is a model ready for immediate use. The gel-like support material used to support the components of geometrically complex models is removed after the model has been handcrafted and washed. The technology allows the use of elastomers.

Ultra-precise detailing of models can be achieved using multiphoton polymerization. This method is reduced to drawing the contours of a three-dimensional object with a focused laser beam. Due to non-linear photoexcitation, the material solidifies only at the focusing points of the laser beam. This method makes it easy to achieve resolutions above 100 µm, as well as build complex structures with moving and interacting parts.

Another popular method is curing with LED projectors or "projection stereolithography".

Projection stereolithography

This method involves dividing a 3D digital model into horizontal layers, converting each layer into a 2D projection similar to photomasks. The 2D images are projected onto successive layers of photopolymer resin that harden according to the projected contours.

In some systems, the projectors are located at the bottom, helping to level the surface of the photopolymer material when the model moves vertically (in this case, the build platform with the applied layers moves up, rather than sinking into the material) and reduces the production cycle to minutes instead of hours.

The technology allows you to create models with layers of several materials with different curing rates.

Some commercial models, such as the Objet Connex, apply resin using small nozzles.

3D printers

Industrial plants

Industrial adoption of additive manufacturing is proceeding at a rapid pace. For example, US-Israeli joint venture Stratasys supplies $2,000 to $500,000 additive manufacturing machines, while General Electric uses high-end machines to produce gas turbine parts.

For example, US-Israeli joint venture Stratasys supplies $2,000 to $500,000 additive manufacturing machines, while General Electric uses high-end machines to produce gas turbine parts.

Home appliances

LOM takes papier-mâché to the next level The development of 3D printers for home use is being pursued by a growing number of companies and enthusiasts. Most of the work is done by amateurs for their own and public needs, with help from the academic community and hackers.

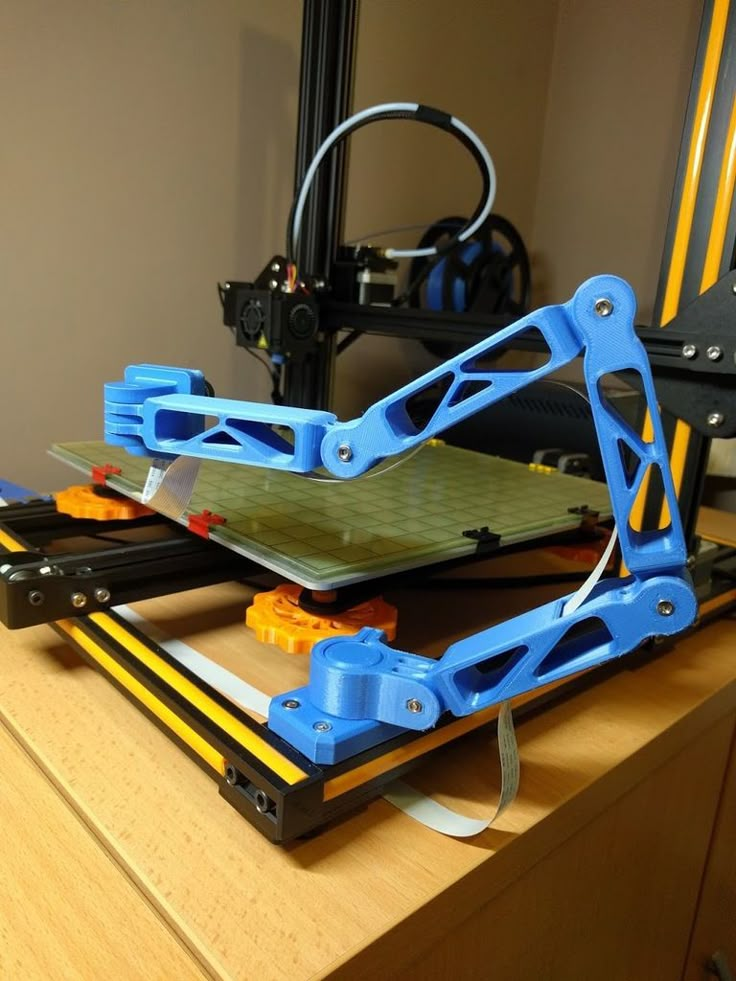

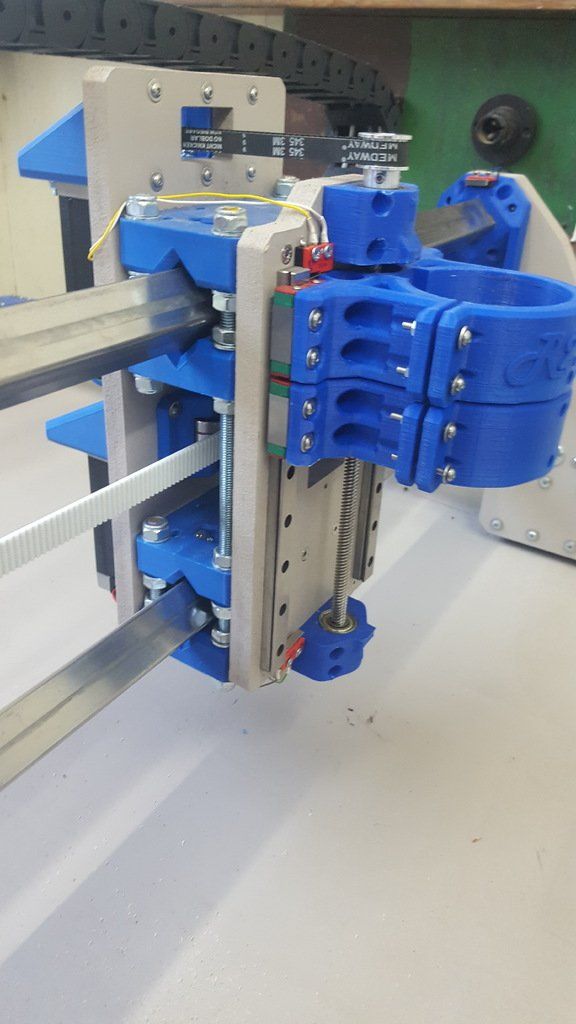

The oldest and longest running project in the desktop 3D printer category is RepRap. The RepRap project aims to create free and open source (FOSH) 3D printers provided under the GNU General Public License. RepRap devices are capable of printing custom-designed plastic components that can be used to build clones of the original device. Individual RepRap devices have been successfully applied to the production of printed circuit boards and metal parts.

Due to open access to drawings of RepRap printers, many of the projects adopt the technical solutions of analogues, thus creating a semblance of an ecosystem consisting mostly of freely modifiable devices. The wide availability of open source designs only encourages variations. On the other hand, there is a significant variation in the level of quality and complexity of both the designs themselves and the devices manufactured on their basis. The rapid development of open source 3D printers is leading to a rise in popularity and the emergence of public and commercial portals (such as Thingiverse or Cubify) offering a variety of printable 3D designs. In addition, the development of technology contributes to the sustainable development of local economies through the possibility of using locally available materials for the production of printers.

The wide availability of open source designs only encourages variations. On the other hand, there is a significant variation in the level of quality and complexity of both the designs themselves and the devices manufactured on their basis. The rapid development of open source 3D printers is leading to a rise in popularity and the emergence of public and commercial portals (such as Thingiverse or Cubify) offering a variety of printable 3D designs. In addition, the development of technology contributes to the sustainable development of local economies through the possibility of using locally available materials for the production of printers.

Stereolithographic 3D printers are often used in dental prosthetics

The cost of 3D printers has been declining at a significant rate since about 2010: devices that cost $20,000 at the time are now $1,000 or less. Many companies and individual developers are already offering budget RepRap kits under $500. The Fab@Home open source project has led to the development of general purpose printers capable of printing anything that can be squeezed through a nozzle, from chocolate to silicone putty and chemicals.

Printers based on this design have been available as kits since 2012 for about $2,000. Some 3D printers, including the mUVe 3D and Lumifold, are designed from the ground up to be as affordable as the Peachy Printer is priced around $100. .

Professional Kickstarter-funded printers often perform well: Rapide 3D printers are quiet and fumes-free at $1499. 3D Doodler's '3D Printing Pen' Raised $2.3M in Kickstarter donations, with a selling price of $99 for the device itself. True, it is difficult to call the 3D Doodler a full-fledged 3D printer.

3D Systems Cube is a popular consumer 3D printer

As prices fall, 3D printers are becoming more attractive for home production. In addition, home use of 3D printing technologies can reduce the environmental footprint of industry by reducing the volume of consumables and the energy and fuel costs of transporting materials and goods.

Parallel to the creation of home 3D printing devices, the development of devices for processing household waste into printed materials, the so-called. Recyclebot. For example, the commercial model Filastrucer was designed to recycle plastic waste (shampoo bottles, milk containers) into inexpensive consumables for RepRap printers. Such methods of household disposal are not only practical, but also have a positive impact on the ecological situation.

Recyclebot. For example, the commercial model Filastrucer was designed to recycle plastic waste (shampoo bottles, milk containers) into inexpensive consumables for RepRap printers. Such methods of household disposal are not only practical, but also have a positive impact on the ecological situation.