3D printed auger screw

STL file Archimedes screw auger・3D printer design to download・Cults

Crane hook

€1.87

Signet ring

€2.81

Canoe

€5.62

Medieval viking helmet

€7.49

Boat propeller

€7.49

Golf ball

€3.74

Next Generation Star Trek Badge

€4.68

Wireframe pyramid

€2.81

Best 3D printer files of the Tools category

SLINGA - The easy-to-print sturdy slingshot

€2.07

BIGVALLEJO ROTATING PAINT RACK

€3. 50

3D Printable Bolt Action Retractable Pen

€5.61

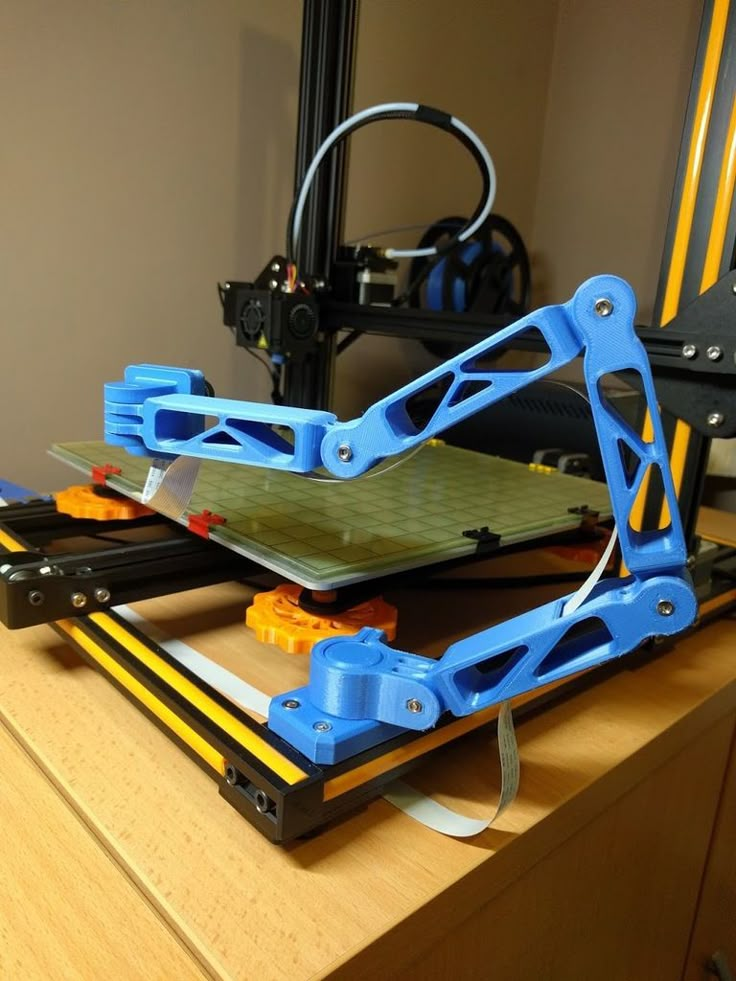

Reel unwinder - Spool Holder

Free

Bead buddy for bicycle tire installation

Free

UP! / Afinia Filament Guide

Free

Best sellers of the category Tools

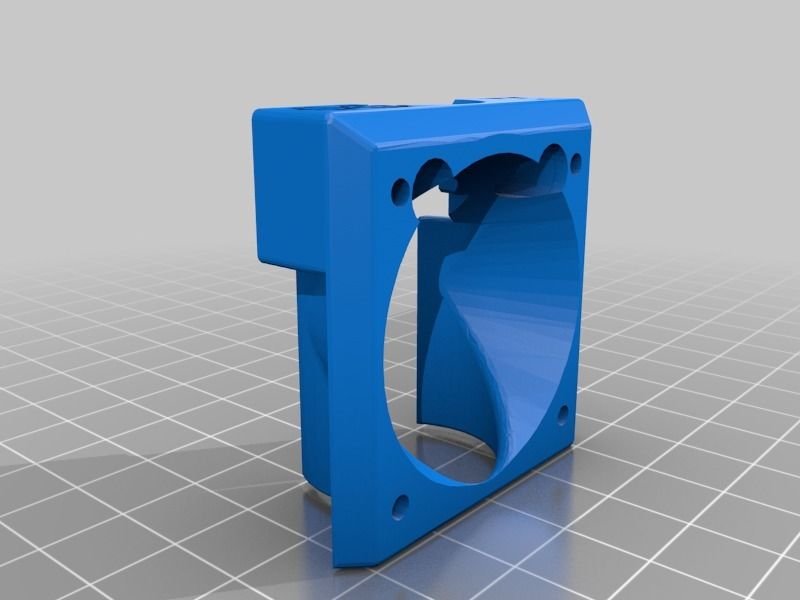

ENDER 3 S1/PRO SPRITE, HOTEND 4020 OR 5015 FAN PROBE NO Y OFFSET

€2.28 -20% €1.82

Spartan Pen Holder

€1.80

phone ring holder

€0.90

Armadillo - Flex Wire Conduit

€1. 67

67

Fast-Print Stackable Parts Bins / Storage Boxes

€2.91

Bambu AMS Stand for Placing raised 2nd Unit behind

€1.15

Fire Hydrant Stash Container

€1.87

well-engineered: Hemera fan duct

€2.50

Ender 3 S1 Fan Duct for stock Fan

€1.20 -10% €1.08

ENDER 3 S1/S1 PRO SPOOL HOLDER AND DEPORTED SPOOL

€2.13 -20% €1.70

Spartan 4mm Hex tool bit holder

€1.80

209 flash bang trainer/Ukrainian hot potato

€0. 94

94

INDICATOR FOR BEST BED LEVELING FOR ENDER 3 V2

€2.80

ARTEMIS -> Magazine for Alligator 2 || 6.5" Arrows || Repeating crossbow

€6.25

Cut-Man - PET bottle cutter with handle!

€3.49

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support needed for printing

€1.56

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

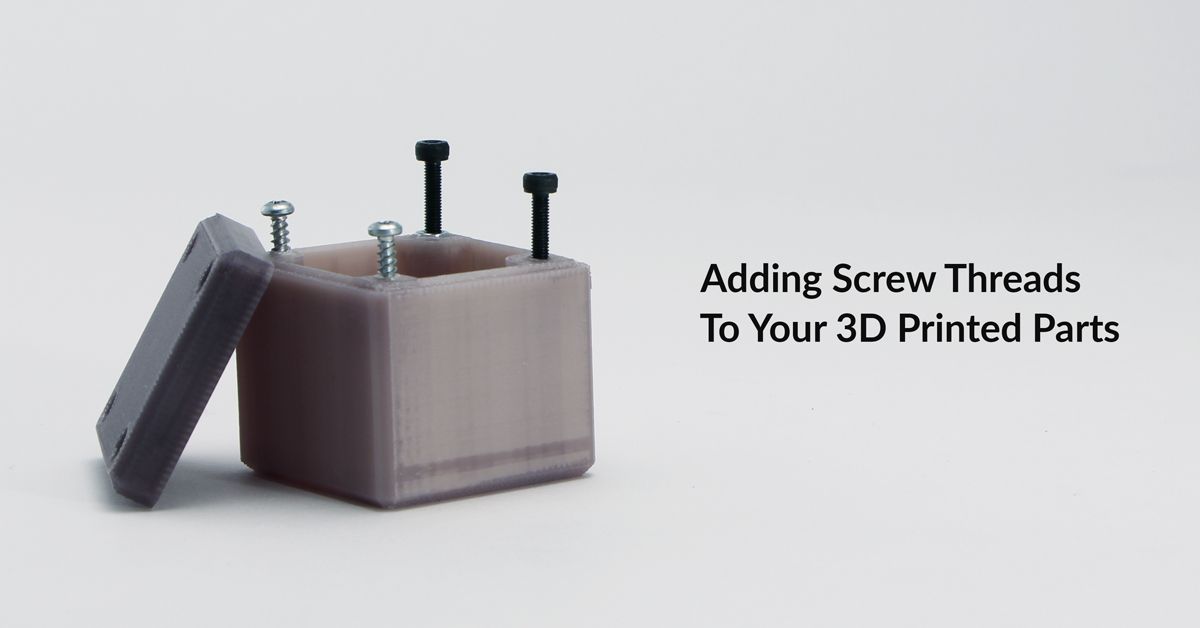

3D Printing Threads and Adding Threaded Inserts to 3D Printed Parts (With Video)

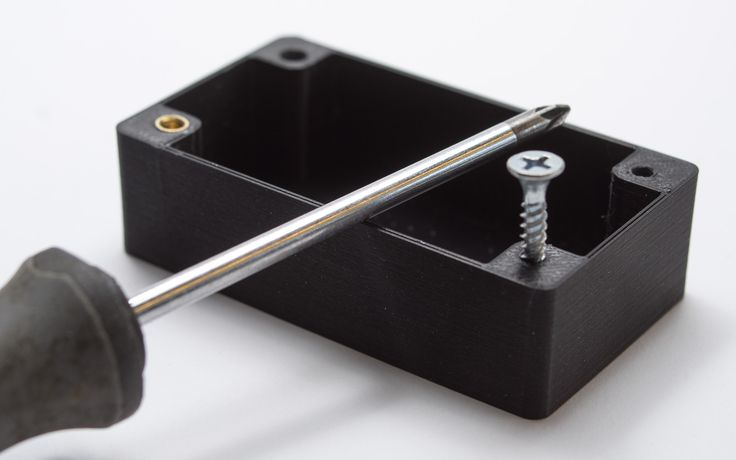

There are many ways to attach screws to 3D printed parts, including inserts, tapping, and even 3D printed screw threads.

Screws are among the most popular fasteners in any material. Can you use off-the-shelf screws with your 3D printed parts? The answer is a clear yes, for both stereolithography (SLA) and selective laser sintering (SLS) parts.

In this article, we explore different methods of using metal screws with 3D printed parts, and provide some tips for incorporating screw threads directly into your 3D design.

Watch our application video about 3D printing threads and threaded inserts for 3D printed plastics.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

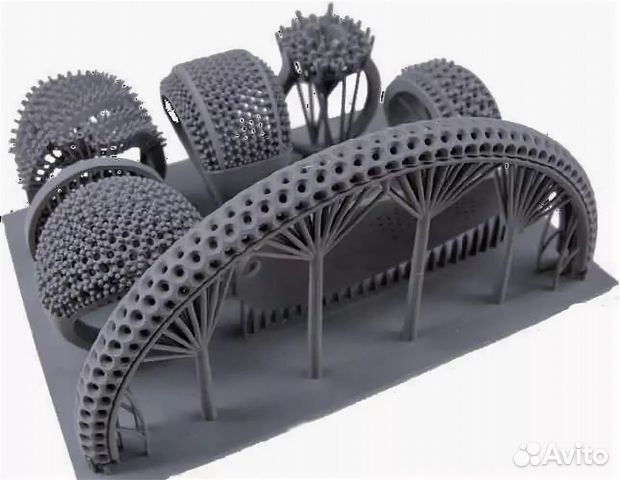

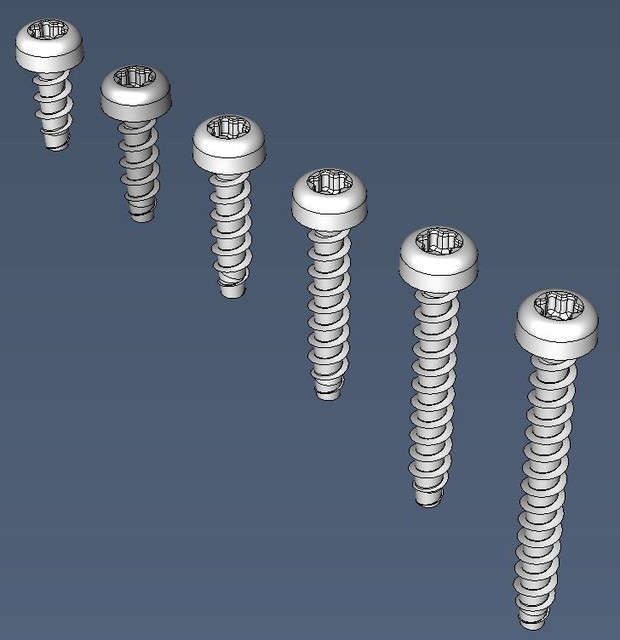

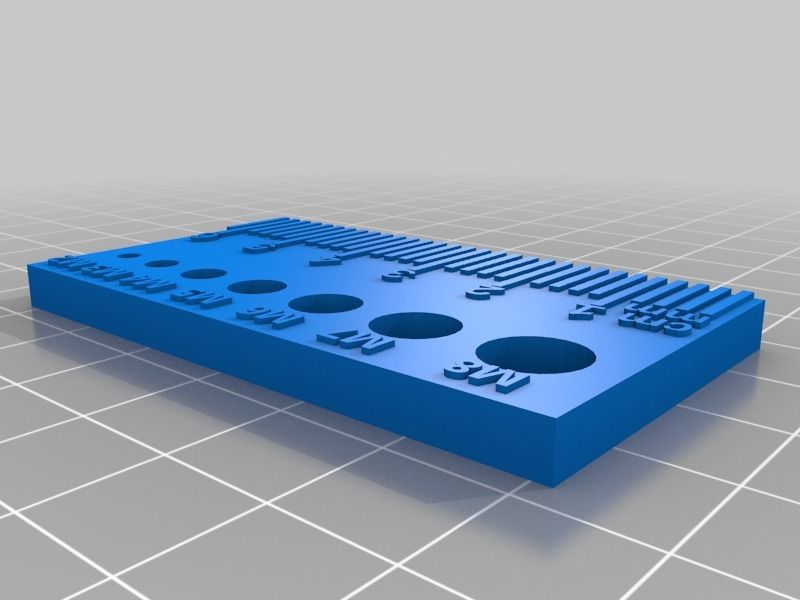

Let’s take a look at the various design options for 3D printed threads, which we’ve collected over the years within Formlabs and based on feedback from our customers. Our test part is designed to showcase all these methods at once:

We’ve grouped these options based on the type of fastening, with pros and cons of each option listed for different use cases.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part printed on an SLA or SLS 3D printer to your office.

Request a Free Sample Part

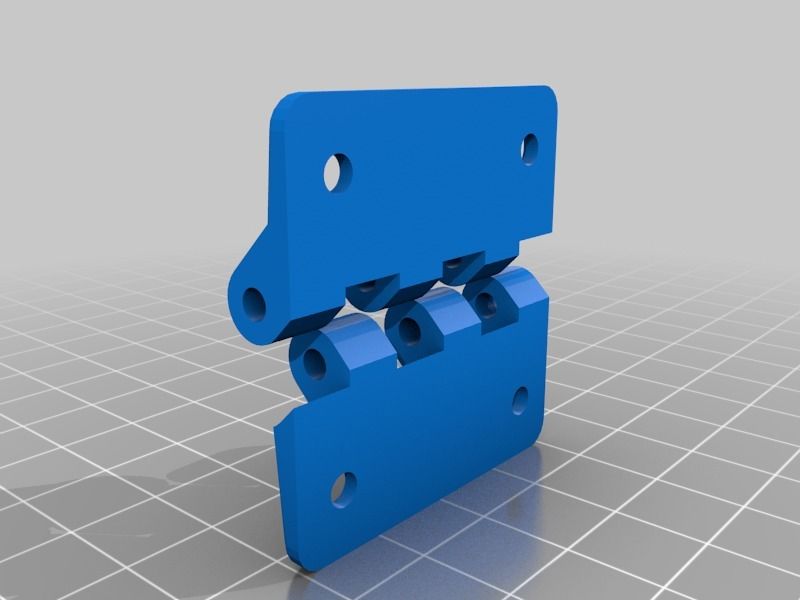

In this section, we look at three ways to incorporate inserts and nuts into your completed 3D prints for strong, long-lasting fastening that stands up to multiple cycles of assembly and disassembly.

Pros

-

Very good hold into 3D printed parts

-

Metal threads are strong and wear-resistant

-

Installs with a simple press fit

Screw-to-expand inserts are cylindrical, with a slight taper and knurling on the exterior surfaces. During the design stage, incorporate a boss with a depth and diameter based on the insert’s specs into your part. Print and post-process the part as normal, following the usual steps for SLA or SLS post-processing, taking care to make sure no extra material remains inside the cavity, and install the insert with a simple press fit. Adding a screw will press the knurled surface into the surrounding printed material, creating a strong friction fit.

Tip for using screw-to-expand inserts with 3D printed parts made with SLA 3D printing: Wash the part as normal, insert the screw-to-expand insert, install a screw, and post-cure the part with the screw in place. Saving this step for last reduces the chance that the insert will crack the surrounding material when expanded.

Heat-set threaded inserts are designed to be installed into thermoplastics using a soldering iron with an installation tip. They can also be used as glue-in inserts in thermoset materials, such as SLA parts.

To install in a thermoplastic part, like one printed with SLS Powders, follow the installation instructions for your particular hardware. The typical process is to use a soldering iron, with or without a special attachment, to heat the insert, which conducts heat into the surrounding plastic. The surrounding material softens and, by pressing down with the soldering iron, you can gently press the insert into the printed part. Be sure to allow enough time for the material to cool down and regain strength before installing a screw.

To install in a thermoset part, like one printed with SLA Resins, glue can be used to hold a heat-set insert in place. Unlike with traditional installation, make sure to design your boss to match the widest diameter of the insert, and use a bead of cyanoacrylate (CA) glue or epoxy to hold it in place when installed. Be sure to allow enough time for your glue to fully cure before installing a screw.

Be sure to allow enough time for your glue to fully cure before installing a screw.

Note: In the SLS 3D printed part photographed for this article, the boss is sized for a press-fit, as we recommend here for thermoset plastics. This also works, with a drop of glue or epoxy, for thermoplastic parts, but won’t have as strong a hold as a true heat-set installation.

Although an additional step of soldering or gluing is required, heat-set threaded inserts for both SLS and SLA parts offer improved security and strength compared to screw-to-expand inserts With either method, these are a great option to gain a little extra security and strength compared to screw-to-expand inserts, although the additional step and equipment may be inconvenient.

Cons

-

Pocket or boss needs to be designed into the part, and accessible after printing

-

Depending on geometry, may require glue and curing time

Designing a pocket or boss that securely holds a nut into the part itself is another method to get metal-on-metal contact. Hexagonal or square nuts can be used, and even locking nuts are possible to accommodate. There are many design variations for this method—just make sure your pocket or boss is easily accessible (i.e. not on an interior surface) so that the nut can be installed. For extra security, a drop of cyanoacrylate (CA) glue will hold the nut in place.

Hexagonal or square nuts can be used, and even locking nuts are possible to accommodate. There are many design variations for this method—just make sure your pocket or boss is easily accessible (i.e. not on an interior surface) so that the nut can be installed. For extra security, a drop of cyanoacrylate (CA) glue will hold the nut in place.

White Paper

Stereolithography (SLA) 3D printers such as the Formlabs Form 3+ have high accuracy and precision, and offer a wide range of engineering materials. Download our white paper for specific recommended design tolerances.

Download the White Paper

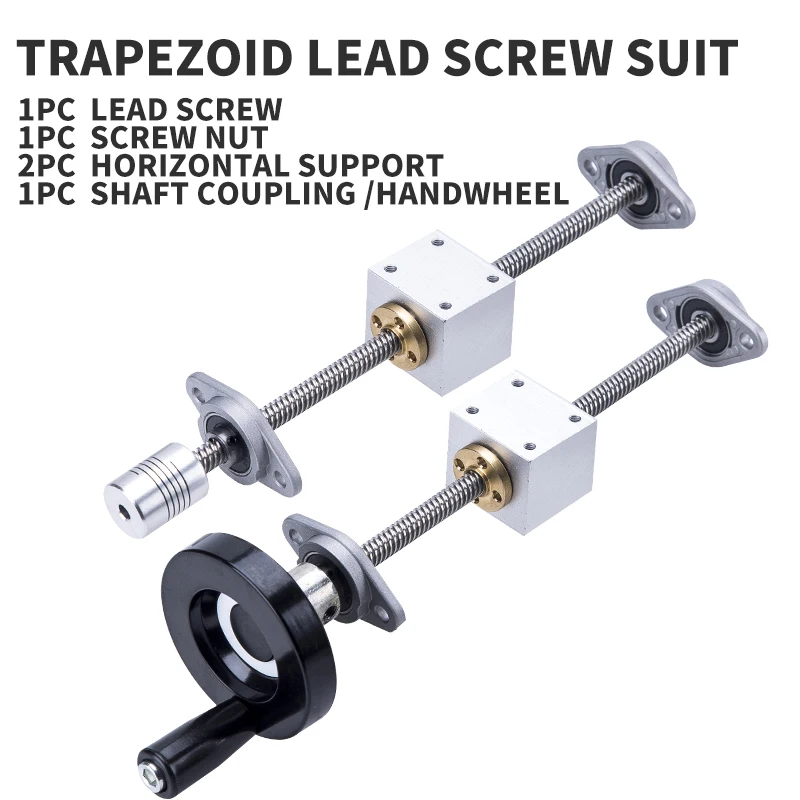

For speed and simplicity, it might be preferable to forego inserts and nuts in favor of screwing directly into a 3D printed part. Whether tapping threads or using a self-tapping screw, off-the-shelf hardware designed for use with plastics work well with 3D printed materials like resins and thermoplastic powders.

Using a thread tap designed for plastic is a quick, economical way to add screw threads to 3D printed parts. It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required.

It doesn’t require any extra design steps, and most shops that work with plastics will already have the equipment required.

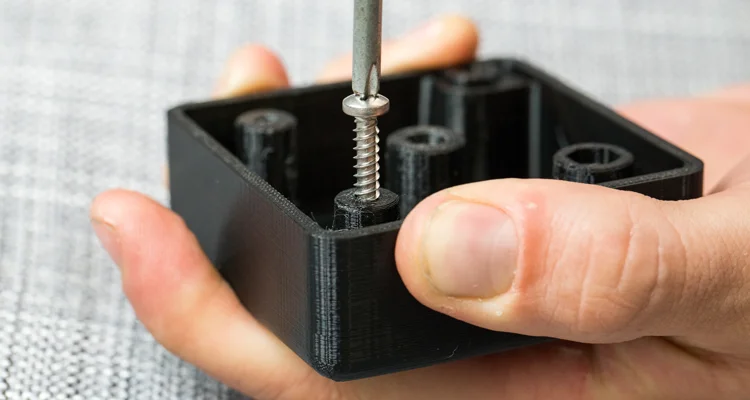

Self-tapping screws, also called thread-forming screws, can be inserted into a negative feature with no preparation work done to the part. Follow the manufacturer’s guidelines for boss dimensions.

It’s suggested to use these with materials that are ductile, or have high elongation. Formlabs Nylon 11 Powder or Nylon 12 Powder are both suitable for this, as are the Tough and Durable Resins in the Formlabs SLA material family. Brittle materials, or those with low elongation (such as the Rigid Resins in the Formlabs SLA material family), may crack when used with self-tapping screws, so take caution and wear eye protection when using these materials.

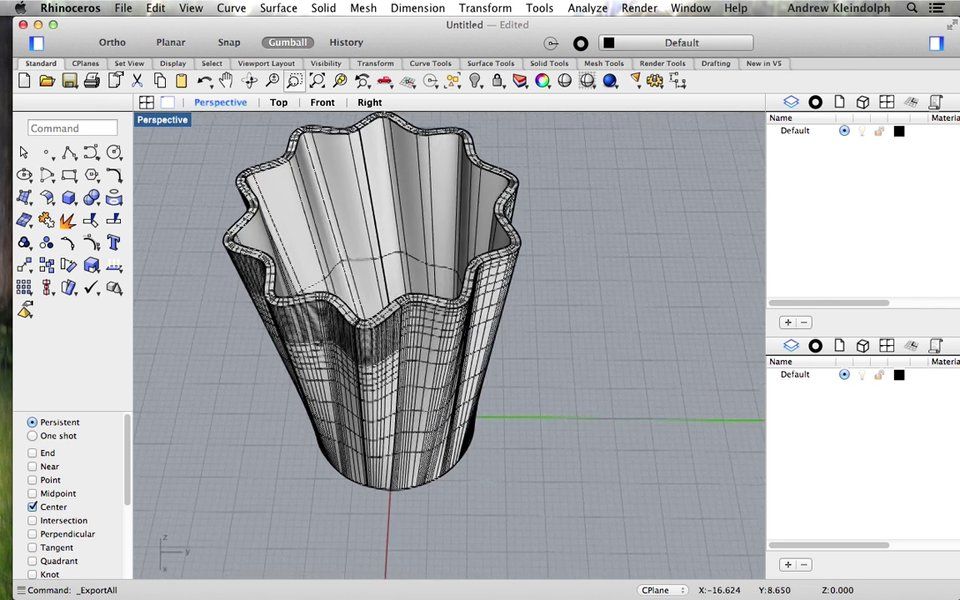

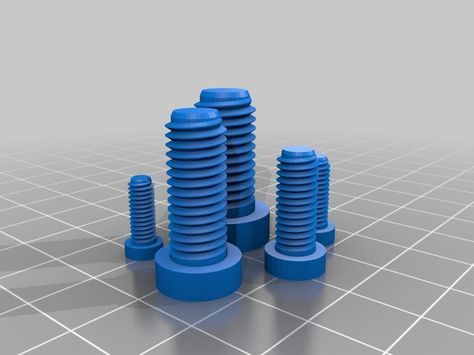

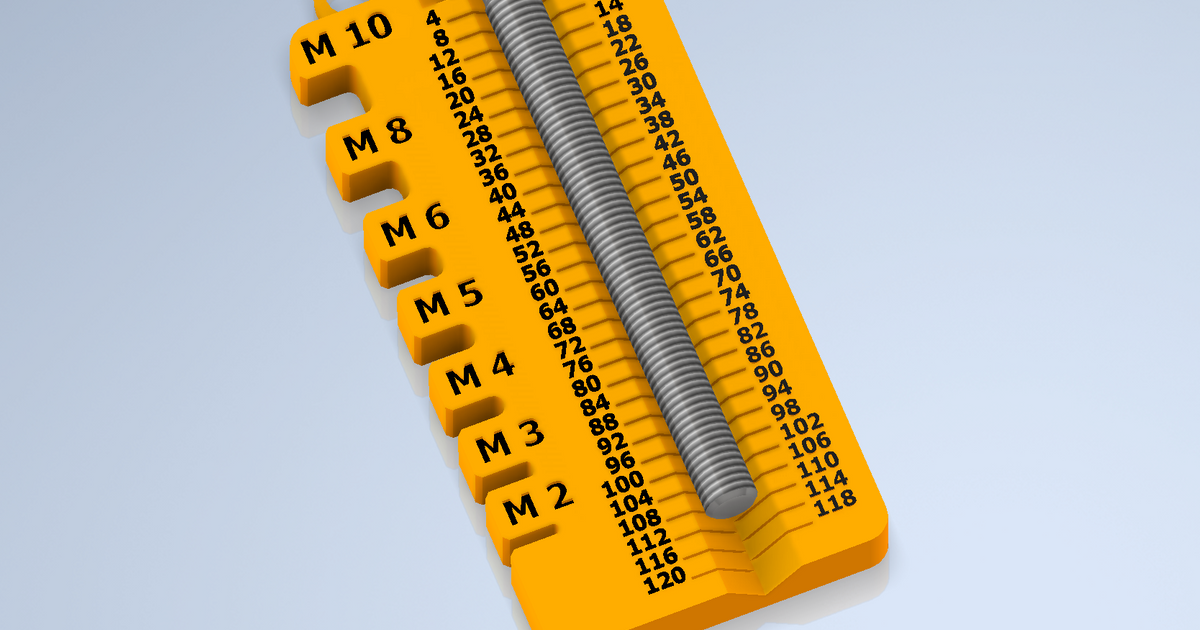

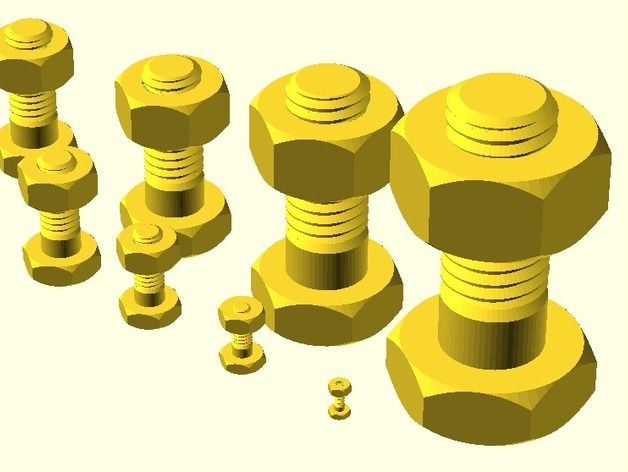

Including threaded geometries in your printed part can be effective if you follow certain guidelines. Stick to larger thread sizes, at least ¼”–20 (imperial) or M6 (metric) or larger; reduce stress concentrations with fillets; and use thread profiles that are designed for plastics. For smaller screws, the threads should be customized to create a better fastener. For example, printing a semi-circular thread profile (on screw and nut) and using a 0.1 mm offset gives better thread engagement with improved wear characteristics.

For smaller screws, the threads should be customized to create a better fastener. For example, printing a semi-circular thread profile (on screw and nut) and using a 0.1 mm offset gives better thread engagement with improved wear characteristics.

SLA and SLS 3D printing are generally preferable for this method over FDM, because they are more precise and can create parts with a smoother surface finish. Any material with particularly low surface friction, such as Durable Resin, is less likely to show wear over multiple cycles of assembly and disassembly.

When preparing your part for printing, it's important to minimize support structures on any threaded surfaces to ensure your parts will come together smoothly without additional post-processing.

There are many options for combining multiple 3D printed components using screws and threaded fasteners. From directly 3D printing threads to using off the shelf inserts, you can choose any of the methods outlined above, based on the chosen material, the number of cycles of assembly and disassembly you anticipate, the strength required, and the amount of extra steps your workflow can accommodate.

Curious to see what 3D printing material might be right for your application? Use our interactive wizard to choose the best 3D printing material or request a free 3D printed sample part to see the quality firsthand.

Explore 3D Printing MaterialsRequest a Free Sample Part

Archimedean screw STL file・3D printer design download・Cults

Crane hook

1.88 €

Signet ring

2.82 €

Canoe

5.65 €

Medieval Viking helmet

7.53 €

Boat propeller

7.53 €

Golf ball

3.76 €

New generation Star Trek badge

4.70 €

Frame pyramid

2. 82 €

82 €

The best files for 3D printers in the Tools category

Modular pegboard organizer 1.0 - early bird price

1,79 €

Y-Axis Layer Shift Test Model

Free

Multicolor Thread Configuration Disc: MCFCD

Free

Calibration Cube 20mm x 20mm x 20mm / weight: 6g

Free

Animal Crossing Lolly

Free

Sword Pin!

Free

N95 masks against coronavirus COVID19 #HackThePandemic

Free

Rear lens cap for CONTAX / YASHIKA lens mount

Free

Bestsellers in the Tools category

3D printed wave transmission (harmonic drive)

4. 99 €

99 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.55 €

Spartan pen holder

1,80 €

209Flash Bang Machine / Ukrainian Hot Potato

0.94 €

well designed: Hemera fan duct

2.50 €

Quick print stackable parts containers / storage boxes

2.86 €

Armadillo - flexible wire conduit

1.67 €

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

ENDER 3 S1/S1 PRO REEL HOLDER AND DEPORTED COIL

€2. -twenty% 1.70 €  13

13

SUPERBOX

1,50 €

Shrek Pooping Toothpaste Topper

2.82 €

ENDER 3 S1/PRO SPRITE, HOTEND 4020 OR 5015 FAN PROBE NO Y OFFSET

€2.28 -twenty% 1.82 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1,90 €

Fire hydrant storage container

1.88 €

ENDER 3 S1/PRO SPRITE, V3 AIR DUCT 5015 OR 4020, LED strip

€2.69 -twenty% 2. 15 €

15 €

PET-Machine, make your own plastic bottle filament at home!

15 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of . Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

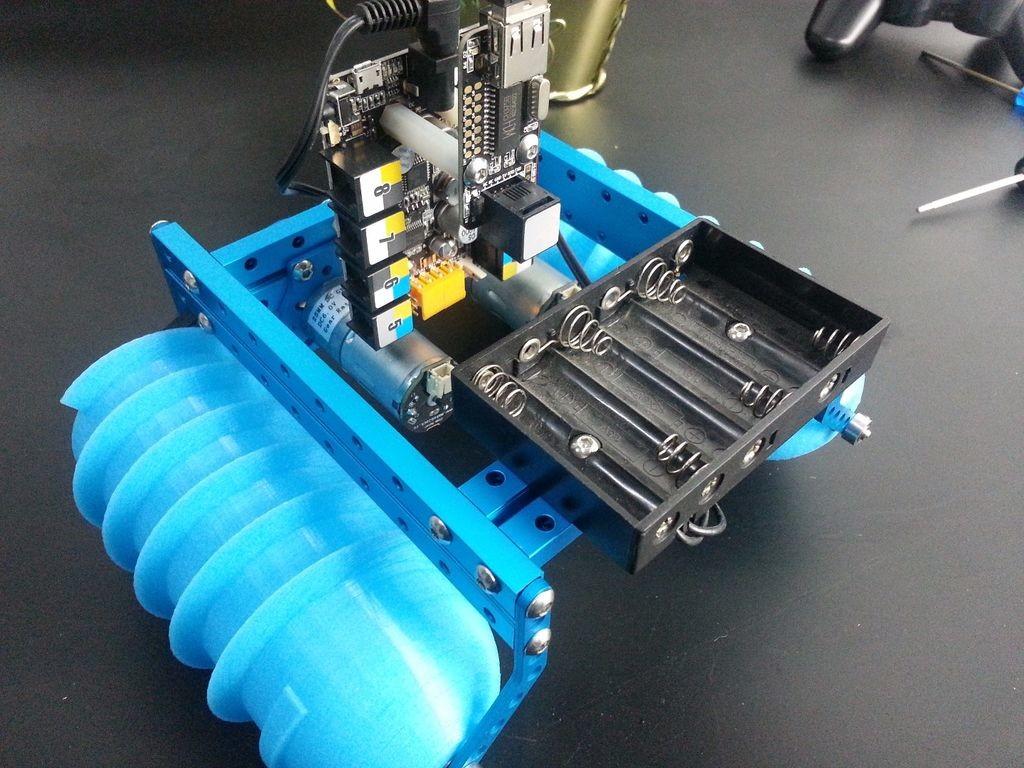

STL file (Auger) for automatic dog or cat feeder・3D printed model for download・Cults

Share Add to ? Creation quality: 0. 0/5 (0 votevotes)

0/5 (0 votevotes)

Ratings of participants on printability, usefulness, level of detail, etc.

- 👁 130 views

- ♥ 0 i like s

- 0 downloads

- 0 comments

- 0 makes

3D model description

Read carefully: (Auger) screw for automatic dog or cat feeder for designer DIY requests has two augers screw stl designs, the first design has 8. 8mm cavity diameter in the center for the name 17 stepper motor with The gear is attached insert and 2mm tension screw hole on the side, if tension is needed the second design called Augeuscrew WOGH, has no tension screw hole nor gear hole, you can attach a cross bracket or drilled a center hole if needed. The Auger screw when sit to turn counterclockwise will push the dog food out of the hopper out of the design path, such as PBC pipe or your own personal 3D design, the possibilities are endless. measurements are in millimeters just a design for DIY automatic dog or cat feeders. 3D printer settings may vary depending on the printer and slicer. Please note and be warned that depending on printer alignment and slicer settings you may have to cut 0.5 to 1mm from the bottom of the auger, but remember to cut out the tension screw hole, the tension screw hole measures approximately 2mm in diameter due to due to filament density these measurements may fluctuate be warned be sure to measure and compensate for your tension screw and eliminate the cavity located right on the bottom and centered in the middle as mentioned earlier designed for nema 17 fixed gear stepper motor most commonly used on 3D printers and can be found on eBay https://www.

8mm cavity diameter in the center for the name 17 stepper motor with The gear is attached insert and 2mm tension screw hole on the side, if tension is needed the second design called Augeuscrew WOGH, has no tension screw hole nor gear hole, you can attach a cross bracket or drilled a center hole if needed. The Auger screw when sit to turn counterclockwise will push the dog food out of the hopper out of the design path, such as PBC pipe or your own personal 3D design, the possibilities are endless. measurements are in millimeters just a design for DIY automatic dog or cat feeders. 3D printer settings may vary depending on the printer and slicer. Please note and be warned that depending on printer alignment and slicer settings you may have to cut 0.5 to 1mm from the bottom of the auger, but remember to cut out the tension screw hole, the tension screw hole measures approximately 2mm in diameter due to due to filament density these measurements may fluctuate be warned be sure to measure and compensate for your tension screw and eliminate the cavity located right on the bottom and centered in the middle as mentioned earlier designed for nema 17 fixed gear stepper motor most commonly used on 3D printers and can be found on eBay https://www. ebay.com/itm/274326752653?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=QQGdEyGhSW-&sssrc=2349624&ssuid=4sc4gxezs8-&var=&widget_ver=artemis&media=COPY has a diameter of 14mm and a depth of 10.5mm (offer) if sold and can not find the nema motor in the link provided with a gear that fits, you can also find a gear somewhat similar and heat and melt and extrude into a whole, if necessary. The nema engine diagram will be in the photos.

ebay.com/itm/274326752653?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=QQGdEyGhSW-&sssrc=2349624&ssuid=4sc4gxezs8-&var=&widget_ver=artemis&media=COPY has a diameter of 14mm and a depth of 10.5mm (offer) if sold and can not find the nema motor in the link provided with a gear that fits, you can also find a gear somewhat similar and heat and melt and extrude into a whole, if necessary. The nema engine diagram will be in the photos.

@jackpotdeals

3D Print Settings

(Read carefully) the design may have a slight imbalance depending on the slicer used and print stabilization if possible, and if necessary you may need to cut the part indicated in the description. Using the free Astroprint.com app, slicer settings are set: layer height 0.4mm, first layer height 0.4mm, perimeter minimum 2, checkboxes must be checked (generate additional parameter if needed, detect thin walls, detect overlap parameters), number of solid layers on top 1, number of solid layers on bottom 1, Sean position (aligned), internal field density 0. 2 , full angle 45, parameter speed 20, small parameter speed 20, external parameter speed 180, Infiell speed 30, upper solid Infiell speed 25 , support material speed 45, bridge speed 25, gap fill speed 20, travel speed 30, first layer speed 10, template support (Pillars), template support angle 0, do not support bridges (checkboxes must be checked), leave all extrusion parameters as yes, set all temperatures to determine what your specific filament temperature specification see production for det lei. Don't forget to run a couple of build plates and cut test prints until you are 100% sure you have the correct settings, and good luck.

2 , full angle 45, parameter speed 20, small parameter speed 20, external parameter speed 180, Infiell speed 30, upper solid Infiell speed 25 , support material speed 45, bridge speed 25, gap fill speed 20, travel speed 30, first layer speed 10, template support (Pillars), template support angle 0, do not support bridges (checkboxes must be checked), leave all extrusion parameters as yes, set all temperatures to determine what your specific filament temperature specification see production for det lei. Don't forget to run a couple of build plates and cut test prints until you are 100% sure you have the correct settings, and good luck.

3D Printer File Information

- 3D Design Format : STL Folder details close

- Auger-screw.stl

- AugerscrewWOGH.stl

Find out more about

formats - Publication date : 2022-11-21 05:32

Copyright

©

Author

Design one Subscribers 0

Contact

Best 3D Printer Files in the Miscellaneous Category

Cannabis Leaf Keychain

Free

Mate Harry Potter

Free

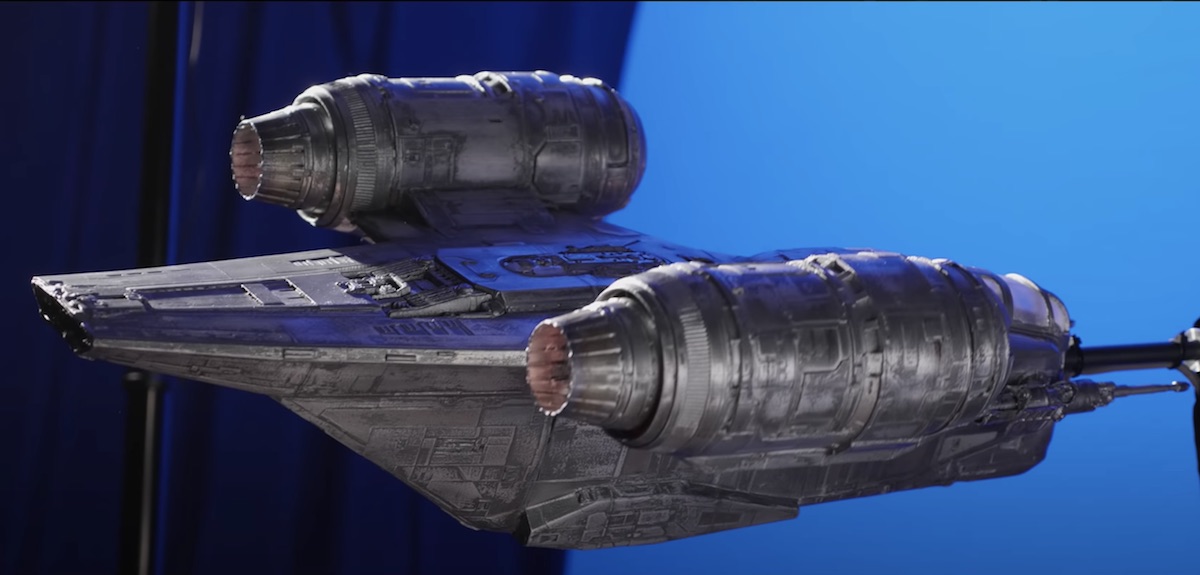

STAR WARS VINTAGE MINIONS HALLOWEEN SPECIAL R2-D2, CUSTOM UNPRODUCED KENNER, HASBRO ACTION FIGURE, 3.

75", 1/18, 5POA

75", 1/18, 5POA 1,86 €

Mate Beagle Dog

Free

Deactivated

Among us toothpaste

1.29 €

Jeep Willys - detailed 1:9 scale model kit

14 €

SCX10 Suspension with two I-beams

11.23 €

Bestsellers in Miscellaneous category

Addams Thing

1.99 €

Bunch of Christmas balls ItsLitho

7,60 €

Christmas park

4.64 €

RS-X-Bow "Government - 1911" style

6.25 €

4th planet Fighting pre-Olympic god

12 €

Dwarf Yes (No support)

2. 49 €

49 €

Christmas house

6.97 €

flexible volute

2 €

ItsLitho "Creamy" personalized Lithophane Christmas ball

1,90 €

hinged shenron

3 €

MMPR Dragon Dagger

4.68 €

ItsLitho "Drop" personalized lithophane Christmas ball

€1.90

CHRISTMAS TREE v2

1,50 €

Key holder for middle finger

1 €

Mickey Christmas night light Litophane

3,50 €

Articulated Raykuaza Flexible Dragon Pokémon

1 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of .