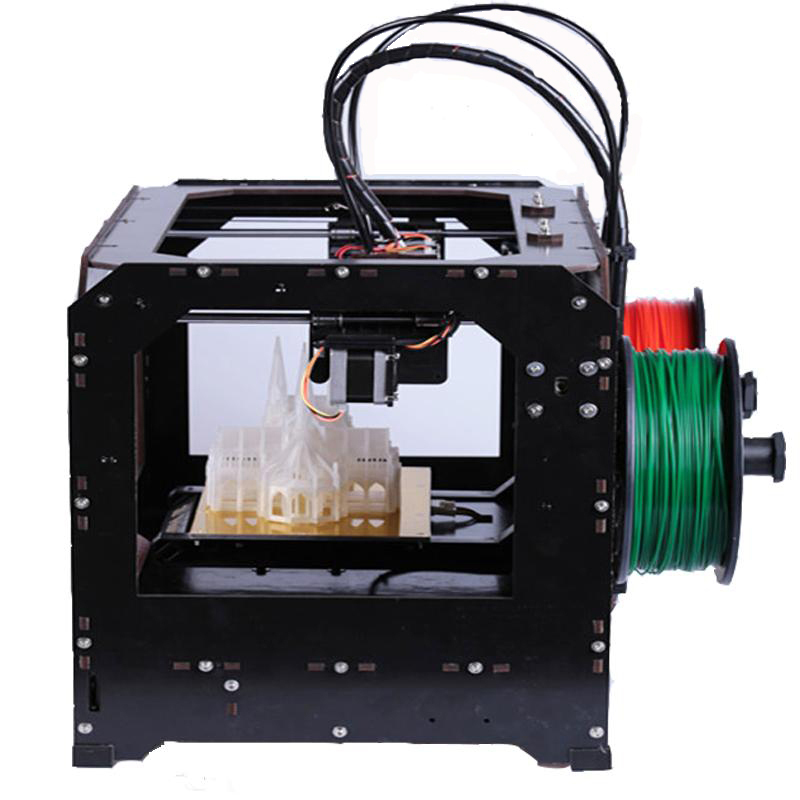

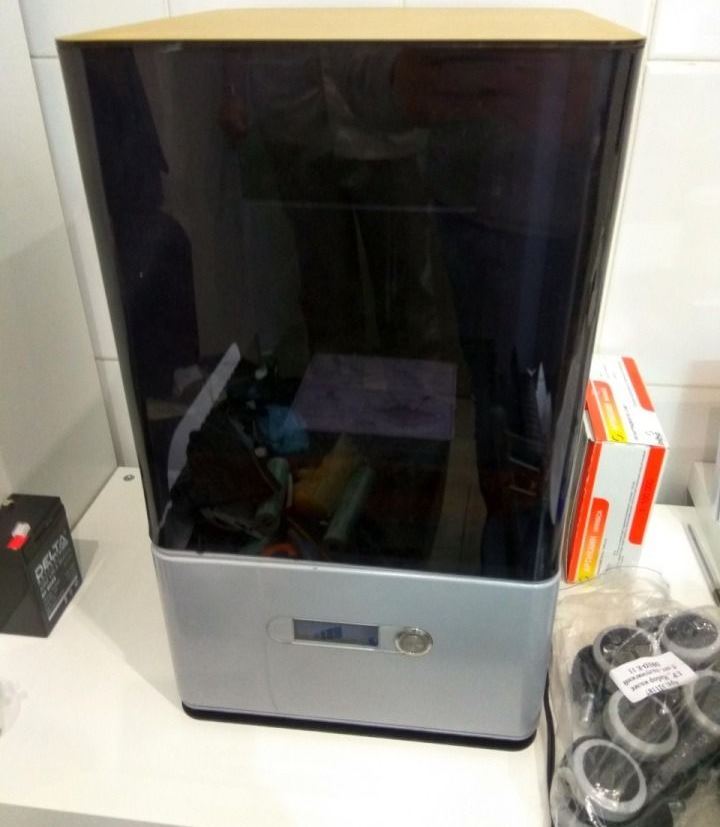

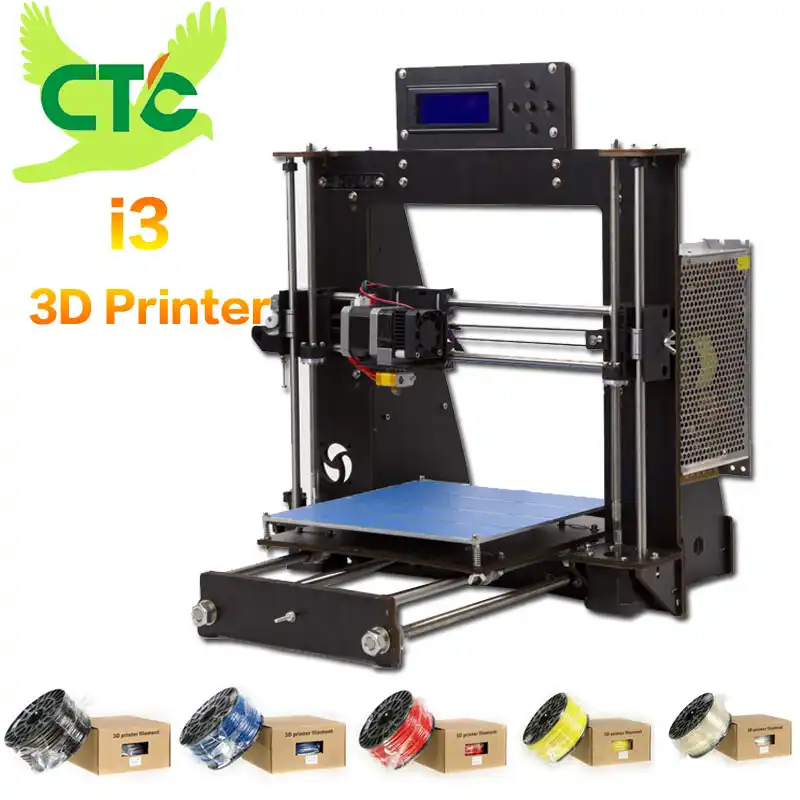

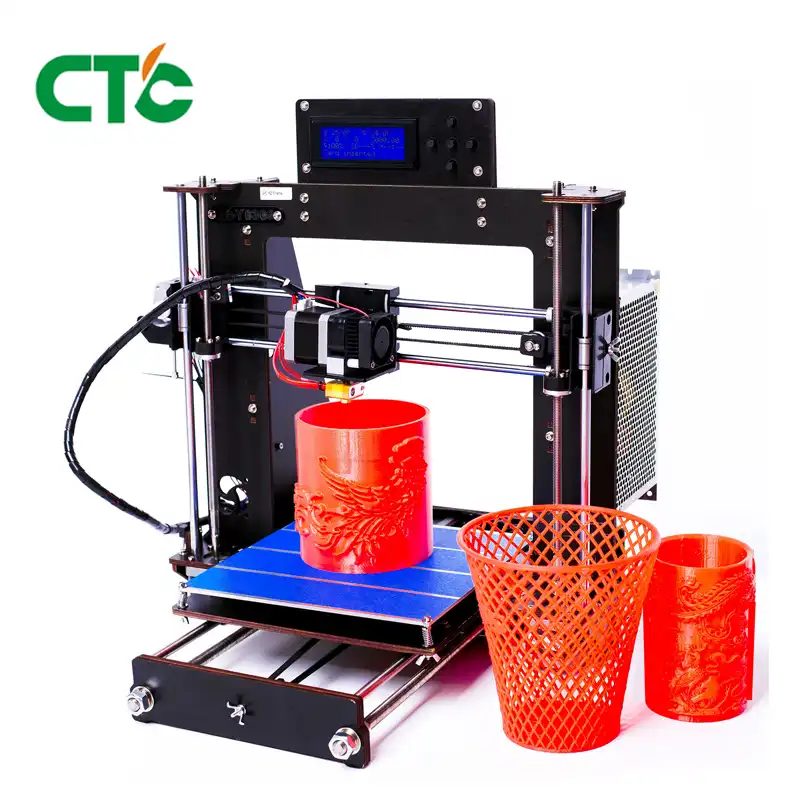

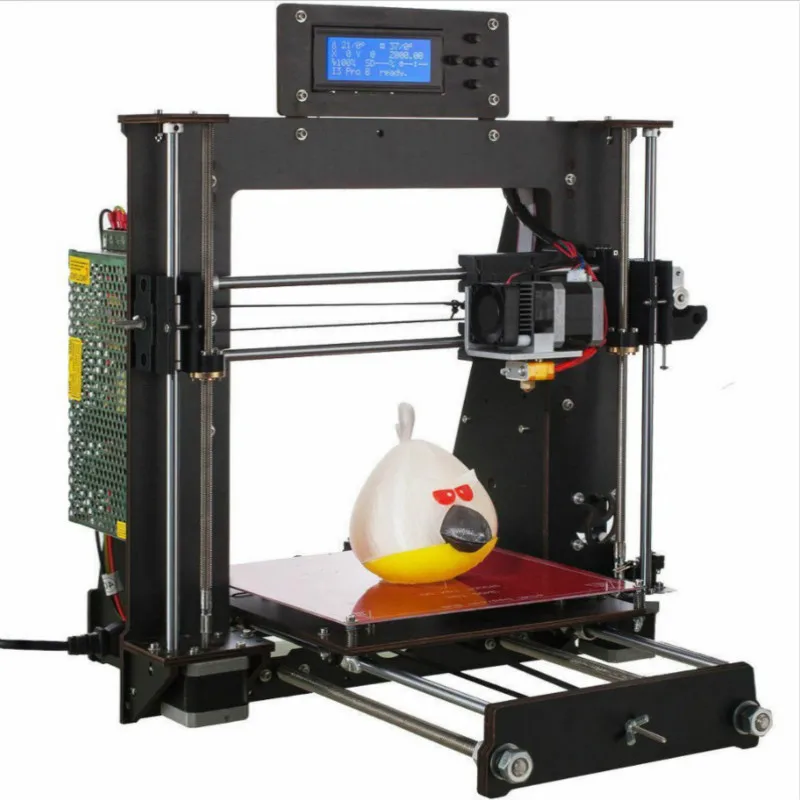

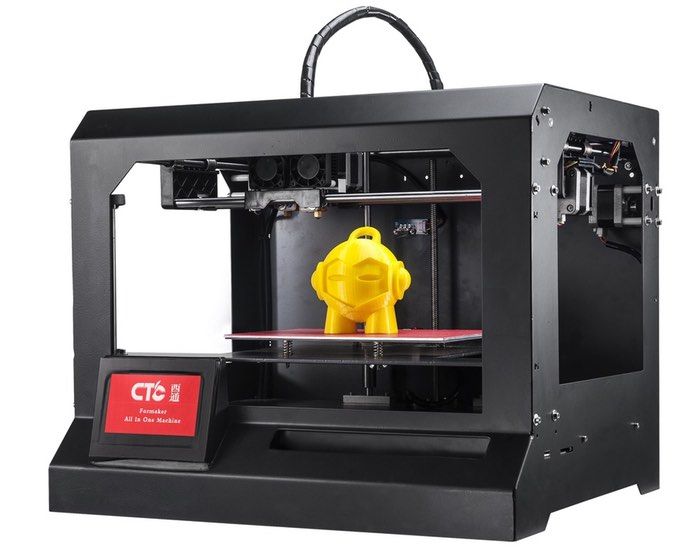

Ctc bizer 3d printer

Decent Slicing software for CTC Bizer (Dual Extruder) - 3D Printers - Talk Manufacturing

Alessandro_Jarv

#1

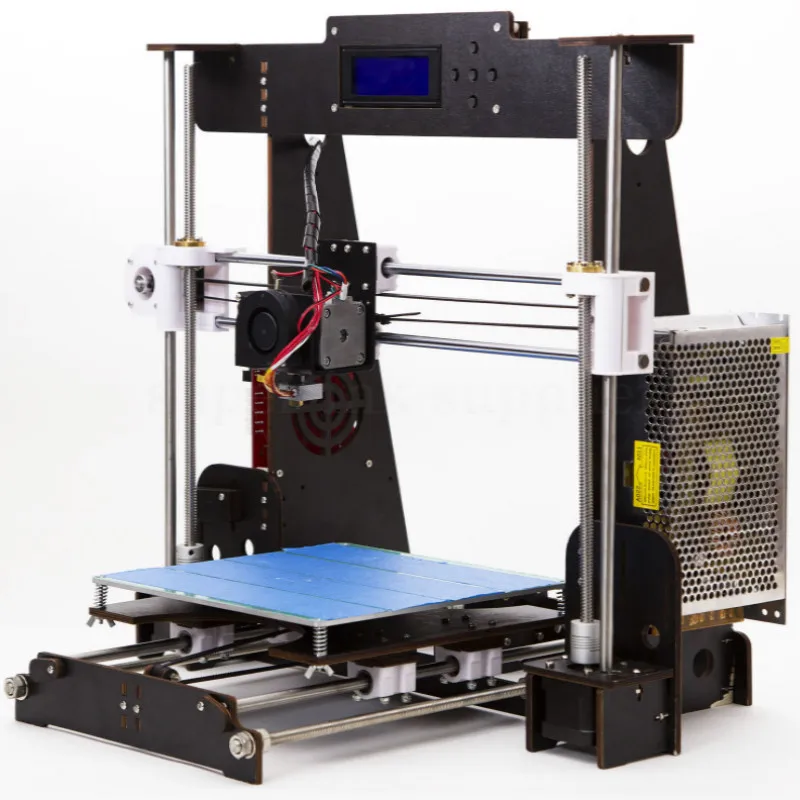

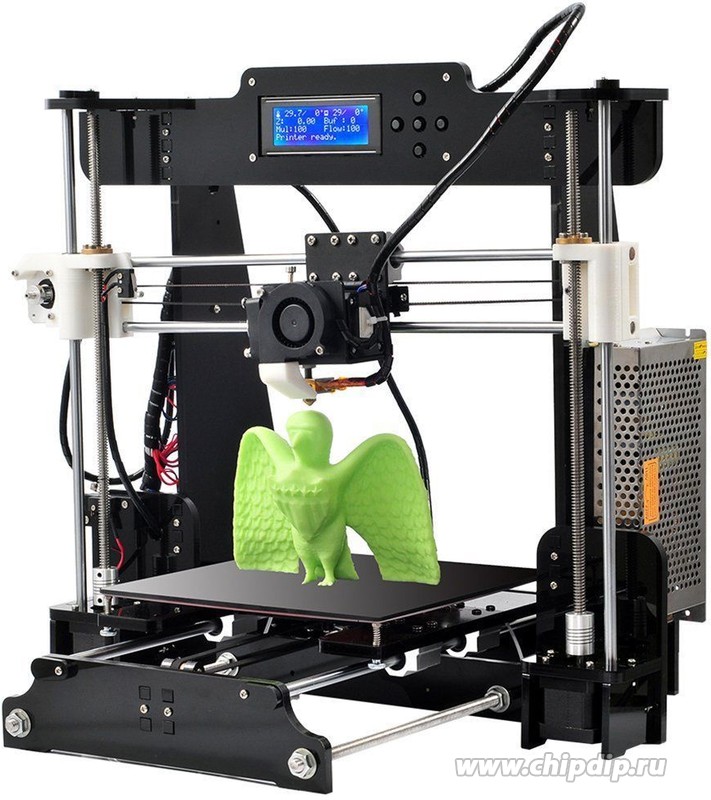

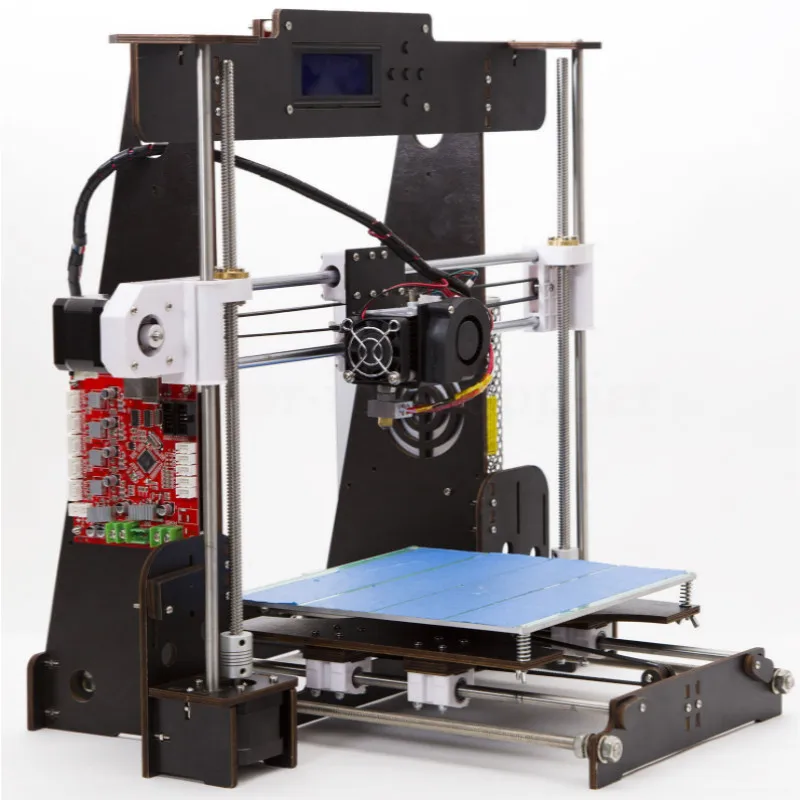

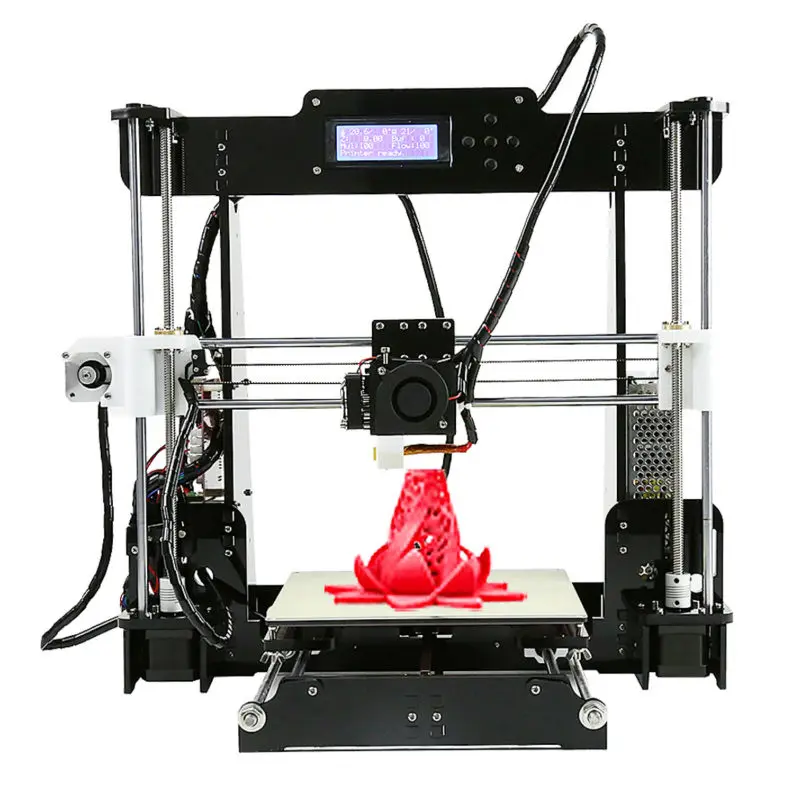

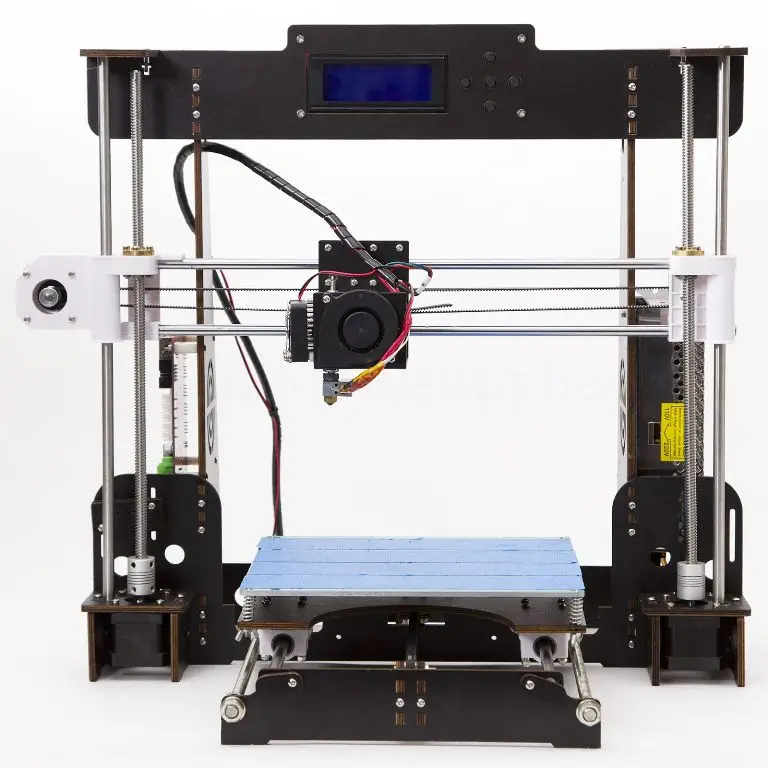

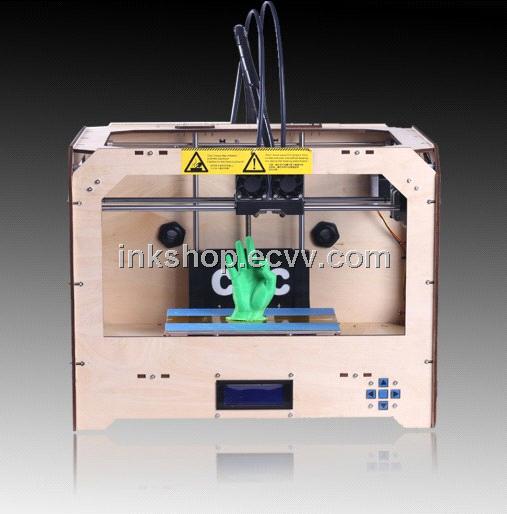

I have a CTC Bizer (Clone of Replicator 1 Dual Extruder), everything works fine, the printer works, the issue is with the slicer.

The given SD had ReplicatorG and MakerWare. MakerWare doesn’t work, it says that the background service is not running, if I try to restart it, it simply won’t start, so no slicing at all. I also downloaded MakerBot Desktop, which seems to be the latest version of MakerWare, it simply doesn’t slice files over a certain size. I tried to print the 10MB 3DBenchy.stl from http://www.thingiverse.com/thing:763622/#files - it simply won’t slice it. I have another 16MB part and it won’t slice that too. MakerBot Desktop simply shows an empty view in the “Preview” screen, stating there are 0 layers and exports a 0B (empty) x3g file. Smaller files get sliced without issues, but top and bottom layer are underextruded, so it leaves giant holes in the prints. Also, MakerBot Desktop leaves gaps between the filling and the shell.

I also tried Cura and Slic3r post-processing gcode files with ReplicatorG or GPX in order to make x3g files out of them (as that printer doesn’t read plain gcode files), I can’t get it to work, if I print something, the build plate goes down and down, then it starts vibrating as soon as it reachs the printer ground (like if it’s trying to go even further down).

I’m attaching some pictures of the Makerbot Desktop with the 3DBenchy and empty preview, and also two photos of the CTC Bizer spool holder I tried to print (which show underextrusion - so gaps of course - and gaps between shell and infill).

Is there anyone who can help?

Thank you

1 Like

Eduardo_Garcia

#2

Spend the money on simplify 3d. It’s the best thing you’re going to do. Also, update to sailfish before you burn out your board. After that look online for mod for ctc and do the main ones to get much nicer prints.

It’s the best thing you’re going to do. Also, update to sailfish before you burn out your board. After that look online for mod for ctc and do the main ones to get much nicer prints.

wirlybird

#3

I am using S3d also and even though it is for pay it was worth it to me. I can’t really comment of the other slicers since I have not used them really. RepG a bit and it was ok for what it is.

Alessandro_Jarv

#4

Does Simplify3D save to x3g? I already have Sailfish 7.7, and I was also wondering: is there any firmware capable of reading the standard gcode?

I hear lots of people telling to buy S3D but I use it for hobby, so spending $150 for a professional program is something I’d like to avoid, if not really necessary. Also, S3D doesn’t have a trial version, which would be really useful to test its potential before deciding to pay that amount.

Also, S3D doesn’t have a trial version, which would be really useful to test its potential before deciding to pay that amount.

Croft3r

#5

I use Matter Slice (Matter Control) as my slicer. However, I agree with the other posts, if you can spend the money for simplify3d then do it. With Matter Slice you can actually connect to your printer via USB if you want or export to SD card. It allows you to export straight to x3g. When I get home later tonight, I can upload my configuration file for my printer. However, for now they have a profile for the flashforge creator pro that works just fine. My profile just has a few tweaks to work better with my printer.

To get the slicer, go to mattercontrol.com.

I had the same problem that you are having right now with my prints. Again, when I get home, I will see what I can do to help you out.

Again, when I get home, I will see what I can do to help you out.

Eduardo_Garcia

#6

Yes it does. I also 3d print as a hobby aND I used makerware at first with proftweak. I learned alot then after 3 month I got s3d and it’s worth the cost even for a hobbyst. I know there is no trial, but look at YouTube videos, get familiar with it from videos and make a decision.

Alessandro_Jarv

#7

Thanks, I’ll wait! Do you have the same printer?

Croft3r

#8

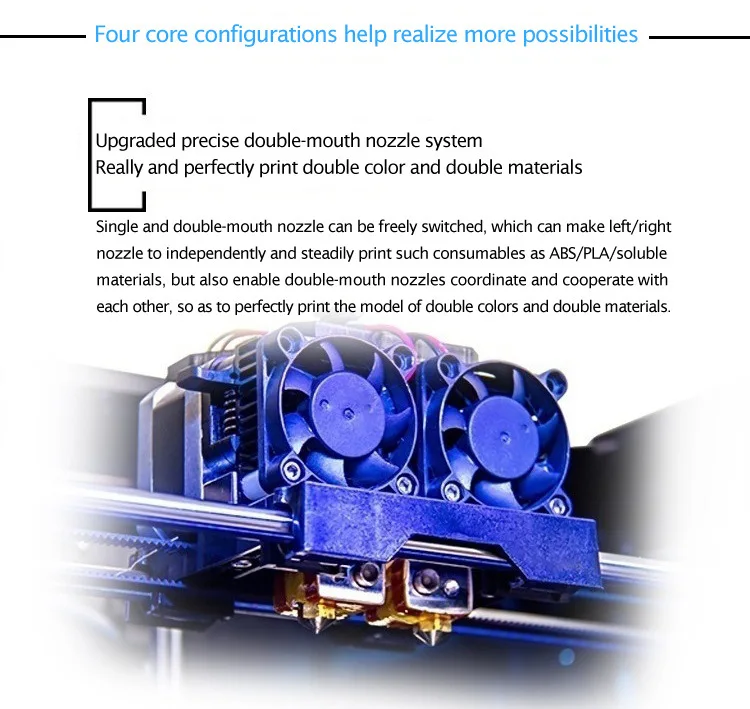

I have the same printer. However, I think I have a different version because mine is just unpainted laser cut wood and everyone else has one that is metal or painted wood. These are the settings I am using to control my printer. With this slicing software, you can use Cura, Slic3r, or Matter Slice. I use Matter Slice. I would play around the settings that I have attached. You are going to want to tune this to fit your printer better.

However, I think I have a different version because mine is just unpainted laser cut wood and everyone else has one that is metal or painted wood. These are the settings I am using to control my printer. With this slicing software, you can use Cura, Slic3r, or Matter Slice. I use Matter Slice. I would play around the settings that I have attached. You are going to want to tune this to fit your printer better.

I have been getting some pretty good prints with these settings. You may want to change around layer height to fit what you need though. If you are trying to go for something that needs a lot of detail, try lowing the speeds of the print and increasing layer height. As for layer height. The lowest I have gone so far is 50 Microns. I have printed several prints at that quality and it is difficult to see the lines in the print.

The problem you are having is that the top faces are not closing. I have this set to 8 layers on the top and bottom and that has been working. You may be able to cut down on layers if you have a cooling fan that you can blow directly on the print. You may also want to try increasing infill to support the top layer.

You may also want to try increasing infill to support the top layer.

With the configuration file, I need to let you know a few things. Under the Printer tab, and under Features. You can turn parts of the printer on and off. My heated build plate is currently not working so I have it turned off. If you have a heated build plate turn it on here. Also, please be careful on this screen. You may be able to do some damage to the printer on this screen.

Also, with the dual extrudes I am having some difficulty with them lining up. I think I have the offset set properly but I am not sure. The left extruder on my printer is jammed so I can’t really test it. However, I think I have the offset set properly. To change this got to the Printer tab, then to Extruder. Also, if you want to do an extended build plate with your printer, you can change that under the print area options.

If you have any problems with this file please let me know and I will help you out. To load this file you first need to add the FlashForge Creator Pro Dual printer using the add printer menu. Then click Settings & Controls, then click Options then import. This should change all your settings to match the file. Also, you will want to change your settings from Basic to Advanced to change some of the things I talked about previously.

Then click Settings & Controls, then click Options then import. This should change all your settings to match the file. Also, you will want to change your settings from Basic to Advanced to change some of the things I talked about previously.

For connecting to the printer, I can’t really help to much. I export my files to SD card and print directly from the printer. I do this because the USB connection on my printer does not work at all. So no Sailfish upgrade :(. Anyways, I have connected over USB with my M3D Micro and it works fairly well. You can set prints to email, and text you when they finish and you can monitor them online.

However, I would use this software to get you by. When you get a chance I recommend that you pickup Simplify3D. They do have a 30 day money back guarantee if you do not like the software. I agree though, I trial would give me a lot more trust in their software.

Also, here is the link to the config file. I had to put it in a zip because everywhere I uploaded it, it wanted to display as text instead of a file. Anyways, here is the link: https://dl.dropboxusercontent.com/u/229079674/CTC%20Bizer%20Config.zip

Anyways, here is the link: https://dl.dropboxusercontent.com/u/229079674/CTC%20Bizer%20Config.zip

Alessandro_Jarv

#9

You say I can use Cura too… How? As far as I know Cura is not capable of exporting x3g files… I have tried Matter Slice too, imported the model, clicked on “generate” button and a window saying “NullReferenceException” popped up…

Croft3r

#10

Sorry for the delay.

I am not 100% sure but I think MatterControl uses Java. Try updating your Java and see if that works. Also, the MatterControl community is very helpful. They can help you get it running if you keep having problems.

They can help you get it running if you keep having problems.

Also, for Cura you can generate the files in GCode then use ReplicatorG to convert it to x3g. However, I have never got this to work. Maybe you will have better luck.

When I mentioned Cura and Slic3r. I meant that MatterControl comes packaged with three slicing engines. Cura, Slic3r, and MatterSlice. Got into the settings of your printer, then click options, then you can change the slice engine there. Then your options will change to suite the engine.

Also, you can export x3g from Cura with a plugin but I can not find the plugin. I have found something that works along side Cura to convert Gcode to x3g but I have never got any of that to work.

Alessandro_Jarv

#11

No, a NullReferenceException comes from a . NET application, Java has a similar one but it’s called NullPointerException. I already have .NET up to date. I never got gcode to x3g conversion to work neither, as I stated in the post.

NET application, Java has a similar one but it’s called NullPointerException. I already have .NET up to date. I never got gcode to x3g conversion to work neither, as I stated in the post.

For the error: I checked the settings, fill density was set at 0.3%, I changed it to 15% and it sliced, I think this was the messy option. I also found the setting to use CuraEngine to slice, I’m trying it now Thank you! Anyway, I think we have the same printer, I have the wood one too.

Alessandro_Jarv

#12

Weird thing. I tried to slice the same model with Cura and MatterControl using CuraEngine.

Cura settings:

50mm/s print speed

50mm/s infill speed

30mm/s outer wall speed

40mm/s inner wall speed

15mm/s bottom layer speed

20% infill

MatterControl settings:

130mm/s infill speed

130mm/s inside perimeters

120mm/s outside perimeters

150mm/s travel speed

15mm/s first layer speed

20% infill

Cura says it takes 1 hour for the model to print (with lower speeds than MatterControl)

MatterControl (with CuraEngine) says it takes 2:41 hours to print - with significantly higher speeds.

Something is going wrong here, is it ignoring my settings??

Perry_1

#13

I am going to agree with the others here that simplify3d is the answer to all your ills. It is the best investment you can make in your printer.

That being said, it is so easy to put my hand in your pocket and tell you to spend the money. But sometimes folks are just not in a position to do so.

As such, I would recommend flashforges flashprint as an alternative. It will get you good prints, but not give you the control of s3d in getting to great prints.

It is free.

Daniel_Pass

#14

I can’t help with everything else, but are you using makerware on ubuntu 16. 10 by any chance? I was getting the same background service issue and after emailing makerbot they said that they support 16.04 LTS but not 16.10. Not a great help, but I have the same issue. Been dual booting into windows just for it.

10 by any chance? I was getting the same background service issue and after emailing makerbot they said that they support 16.04 LTS but not 16.10. Not a great help, but I have the same issue. Been dual booting into windows just for it.

Croft3r

#15

Sorry for not getting back to you sooner, been busy. Were you able to get x3g export working in MatterControl?

conorm125

#16

I use simplify 3d and i is a lot better than mb’s software

mbroen

#17

Could you be persuaded to reupload the settings above? (if you still have them)

I am having similar problems and can’t seem to figure out the correct settings for my printer (also a CTC Bizer Dual Extruder).

▷ ctc 2 3d models 【 STLFinder 】

CTC Replicator 2 Spool holder

thingiverse

Edit it online https://www.tinkercad.com/things/aEUrkk7hPU6 I copied the 30mm x 100mm spool holder from Thingivers, but the back plate was to big to fit through the 30mm holes on the CTC Replicator copy that i got from eBay. ...I modified to fit with...

CTC Replicator 2 (and other Makerbot Clones) Display Guard

thingiverse

(I printed mine on the CTC Makerbot Dual clone using PLA 190' and a bed temp of 57') Print Settings Printer: CTC Makerbot Dual Clone (Rep 2) Rafts: No Supports: No Resolution: Standard Infill: 10% Notes: I use PLA with a temp of 190' and a bed temp. ..

..

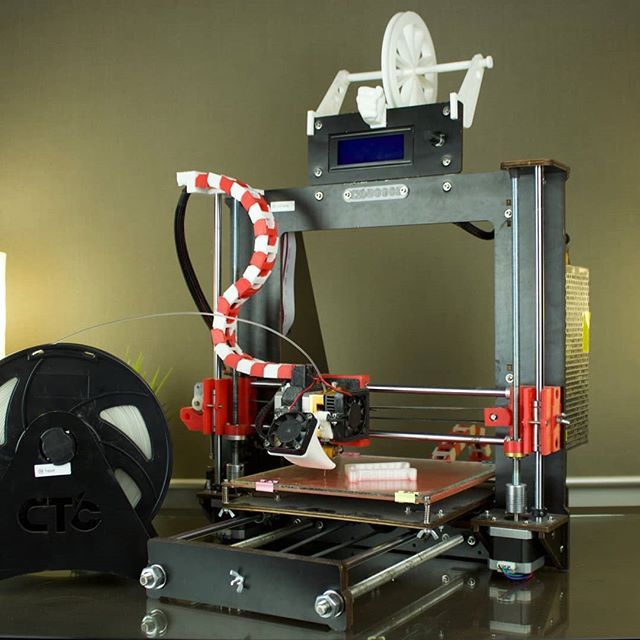

CTC Cable Chain (2 Piece Design) different radius options

thingiverse

This is another cable chain for my CTC printer. It needs no support because it is a two piece design. There are some clip of differend sizes. Each size gives another radius ot the cain. The Clip is stolen from Open Cable Chain by...

CTC Prusa i3 fan duct 2

thingiverse

CTC Prusa i3 fan duct mixed 2 version. Just print it, no need support etc.

Duct 3 version, points air flow more down away from nozzle.

5_8 version is mix from version 3 and some generic fan part. ...Using 5_8 version my self now, works ok, but needs...

...Using 5_8 version my self now, works ok, but needs...

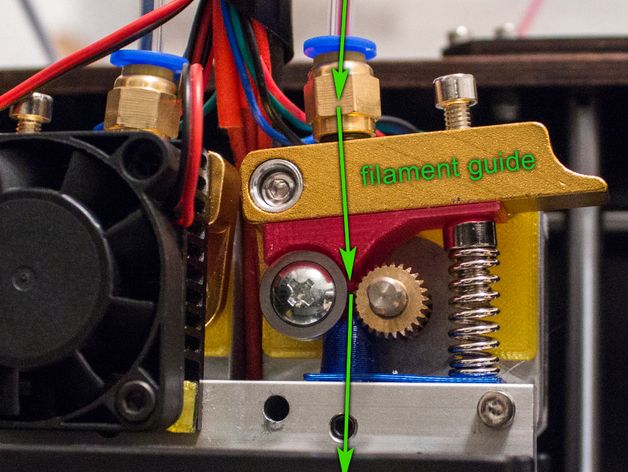

CTC Clip Adapter for Filamentguide 2.0

thingiverse

Made a version that fits the holes in the CTC dual printer. Not yet tested to see if the pole fits in, but it should edit: fixed by removing the tabs and adding a locking clip you add from the inside. ...easier to clip the top one from the bottom side...

CTC Cable Chain (2 Piece Design) _to_10x20 Chain Connector-Mountadapter ctc prusa i3

thingiverse

for the original motor mount i have remixed 2 clips thing:4311469 which are also included in the remixed motormount thing:4311585. zwei kettenglieder um die kette <a href="https://www.thingiverse.com/thing:1104664">thing:1104664</a> mit den...

zwei kettenglieder um die kette <a href="https://www.thingiverse.com/thing:1104664">thing:1104664</a> mit den...

Replicator 2, CTC, extruder upgrade compatiable with 12mm V-groove Filament Bearing (VERSION_2)

thingiverse

2) The v-groove gear now is easier to fit inside of the arm (less post-print work needed), also the V-groove hole was cut at the front to allow the smaller (3x10x4mm bearing) to be used in printers that don't use the V-groove bearing. 3) The base has...

CTC Bizer 3d printer (2.nd / 2017) Filament holder

thingiverse

Spoole holder for the CTC dual extruder 3d printer

Fan Cover for CTC A8 Fan model 2

thingiverse

So I designed this 3D printer upgrade that I call Fan Cover for CTC A8 Fan model 2. And I also I designed this 3D printed component

as a cosmetic upgrade as well, and also for the purpose of identifying

the model of this 3D printer. In the way I...

And I also I designed this 3D printed component

as a cosmetic upgrade as well, and also for the purpose of identifying

the model of this 3D printer. In the way I...

CTC Drucker Z Offsetclip 2,3, und 4mm

thingiverse

Offset Clips für die Z-Achse in verschiedenen Höhen 2, 3 und 4 mm Für die Verwendung eines dickeren Heizbetts.

CTC Bizer , Replicator , Flashforge 2 Y axis Motors

thingiverse

To Mount the Motors on the Backside you must cut out a little bit from the backplate. ...You need 2 of 16 teeth Idler Pulleys for the Idler Mounts a second nema 17 motor and a 16 teeth Pulley.

2.2Kg Spool Holder for CTC

thingiverse

... ;) Es werden hier noch 4 Kugellager (8x16x5) benötigt, sowie Schrauben und Muttern die jeder bei sich rumfliegen hat. Print Settings Printer: CTC Bizer Rafts: No Supports: No Resolution: 0,2 Infill: 15%-20% Notes: Druckzeit um die 3-4 Stunden!

Galaxy Note 2 Phoneholder for CTC 3D Printer

thingiverse

Print out this holder 2x and mount your Galaxy Note 2 in front of your CTC 3D Printer to use them as a webcam. I use the following App: https://play.google.com/store/apps/details?id=com.pas.webcam.pro Customized version of. ..

..

Replicator 2, CTC, extruder upgrade compatiable with 12mm V-groove Filament Bearing

thingiverse

-This extruder upgrade works with V Groove Filament Guiding Bearing (3x12x4mm) as well as a normal flat Bearing (3x10x4mm) -Designed to work with a CTC model 3d printers (all replicator 2 clones) the arm is very narrow at the tip. This allows it to...

Marlin 2.0.x for CTC i3 DIY GT2560A

thingiverse

I used that information with various cross-referencing online along with some trial and error to put together this Marlin configuration file for Marlin 2. 0.

The next issue I had is that this clone board didn't have a bootloader installed on it at...

0.

The next issue I had is that this clone board didn't have a bootloader installed on it at...

CTC Blende für Display und 2 Schalter

thingiverse

Schalter und Display

Schalterblende für 2 Schalter am CTC

thingiverse

Eine Schalterblende für solche Schalter ... ...https://www.amazon.de/Mini-Wippenschalter-1-polig-EIN-AUS-ECKIG/dp/B002NL3SKS/ref=sr_1_1?ie=UTF8&qid=1484775770&sr=8-1&keywords=B002NL3SKS Schraubenköpfe sind 5,5mm im Durchmesser und 3,5 mm tief und werden...

CTC Bizer Displayblende mit 2 Schaltern / Display cover with 2 switches

thingiverse

Verwendet wurden diese Schalter: http://www. pollin.de/shop/dt/NzQ3OTc1OTk-/Bauelemente_Bauteile/Mechanische_Bauelemente/Schalter_Taster/Einbau_Wippenschalter_MARQUARDT_1852_1128_2_polig.html CTC Bizer display cover with 2 switches for light and...

pollin.de/shop/dt/NzQ3OTc1OTk-/Bauelemente_Bauteile/Mechanische_Bauelemente/Schalter_Taster/Einbau_Wippenschalter_MARQUARDT_1852_1128_2_polig.html CTC Bizer display cover with 2 switches for light and...

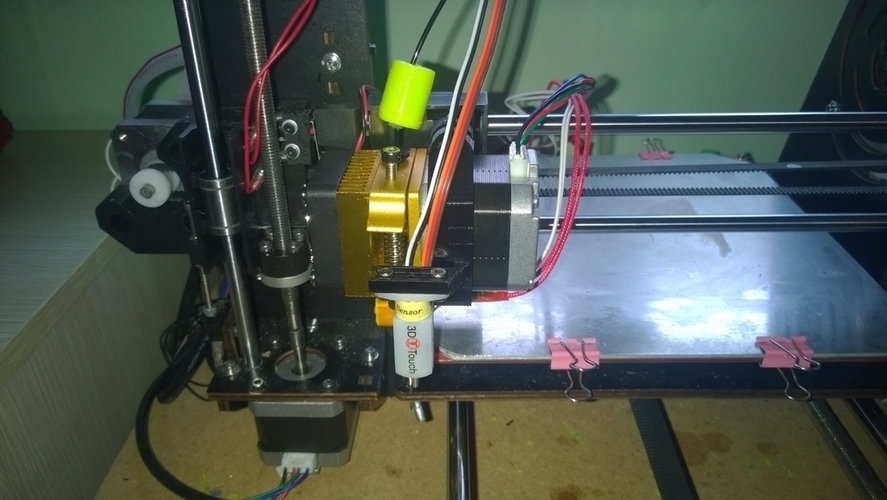

CTC Prusa i3 Pro B - E3D V6 Mount (Version 2)

thingiverse

I upgraded my thing https://www.thingiverse.com/thing:2799725 It is a E3D V6 mount for the CTC Prusa i3 Pro B. It fits the regular x-rail plate and includes: - The E3D Holder [print with support] - A sensor holder (fits the the LJ18A3-8-Z/ BX) -...

CTC Blende für Display und 2 Schalter ohne Schrift

thingiverse

Beste Ergebnisse erreicht man, wenn Frontseite direkt auf der Druckerplattform abgelegt ist. Ich habe mit 0,4er Düse und 0,2er Layer gedruckt. Support ist empfehlenswert. ...Update vom 05.07.2018 in Druckposition gedreht .

Ich habe mit 0,4er Düse und 0,2er Layer gedruckt. Support ist empfehlenswert. ...Update vom 05.07.2018 in Druckposition gedreht .

CTC Printer Z-Axis spacer in 2,3,4,5mm for glass bed

thingiverse

... thickness of the glass. Well here you are, no fixings or gluing. Just print the appropriate spacer and pop it over where the Z stop contacts your bed assembly. Easy stuff! Print Settings Printer: CTC Rafts: No Supports: No Resolution: .3 Infill: 20

My Customized Adjustable Glass Bed Bracket for CTC Dual set 2

thingiverse

Customized version of https://www. thingiverse.com/thing:1949142 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=1949142

thingiverse.com/thing:1949142 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=1949142

Marlin 2.0.5.3 for CTC Bizer/Dual/Twinmaker W/ Thermistors

thingiverse

You can view the install guide here: https://marlinfw.org/docs/basics/install.html Source code available here: https://github.com/evilexecutable/MarlinFW-2.0.5.3_CTC_BIZER I have also attached a Slic3r profile which seems to work great for...

ctc i3 ebay prusa conversion to mk 2 printer. PSU COVER/holder

thingiverse

this is for the ctc i3 ebay printer power supply, if like me you are stripping it down because of its inherient build problems in order to convert it into a prusa mk2 clone then you will need this to fit the psu as the prusa uses a different one. ..

..

Ender 2, 3, CR10, CTC A10S E3Dv6 Hotend Mount and IGUS TWE 04-12, MGN9c Rail Mount

thingiverse

The whole construction is currently being thoroughly tested on the CTC A10s (identical to the CR10). Furthermore I have integrated the E3Dv6 Hotend Mount (link here: https://www.thingiverse.com/thing:2494642 ) so that all additional fans as well as...

CTC Prusa I3 Pro B z stop foot 2 Bigger

thingiverse

the other i made was to small. i learned a few trick as i practiced with 123Design. i just drop a screw in the back hole. update 8-26-17

beefed foot up a bit in superstomper. ...using m3 lock nuts.

update 8-26-17

beefed foot up a bit in superstomper. ...using m3 lock nuts.

Marlin 2.0.0.bugfix for GT 2560 (Geeetech, CTC and more...)

thingiverse

Si tu impresora tiene las de 20 dientes, entonces tienes que modificar el fichero Configuration.h // ctc prusa i3 with pulleys 20 theet #define DEFAULT_AXIS_STEPS_PER_UNIT {80.10, 80.10, 2580.64, 105.0} // quita las dos barras de esta línea // ctc...

Geeetech / CTC Prusa I3 Pro B E3D V6 Extruder Bowden Adapter V2.2

thingiverse

This is a remix (originally by @ZooT_aLLures), improved simple E3D V6 hotend Bowden-style use adapter for Geeetech/CTC Prusa I3 Pro B, it maintains - similar Y distance as original extruder - multiple Z height hole pairs for E3D V6 with Original vs. ..

..

CTC Extruder Upgrade / Ballbearing springLever

thingiverse

CTC Springloader 2 Ballbearings 8x3x4

Filamentguide CTC

thingiverse

Filamentguide for the CTC Replicator 2 - with only one extruder in use This filter fits perfectly: https://www.thingiverse.com/thing:492067 Print Settings Printer: CTC Replicator 2 Rafts: Doesn't Matter Supports: No Resolution: 0.2mm Infill: 20%

3D food printer from Moscow scientists prints chocolate, cakes and even nuggets

A 3D food printer with a system of "smart" recipes that prints food products with specified properties was created by scientists from the Moscow State University of Food Production (MGUPP). The new device consists of 99% domestic components and can be used to design vending machines that print products according to the client's order. The 3D printer already prints with dough and chocolate, and in the future it will be able to produce even meat products - nuggets, for example, have already been successfully obtained.

The new device consists of 99% domestic components and can be used to design vending machines that print products according to the client's order. The 3D printer already prints with dough and chocolate, and in the future it will be able to produce even meat products - nuggets, for example, have already been successfully obtained.

chocolate chess

One of the goals of developing a 3D food printer was to create food rich in vitamins, micronutrients and antioxidants that would be a healthy alternative to traditional meals.

“Today, many are deficient in nutrients and micronutrients that can be replenished with elements in chemical form, but eating foods fortified with them contributes to better absorption. The main goal of creating a food printer was the ability to produce personalized functional products using a system of “smart” recipes, which will be like instructions for the printer,” says Aleksey Kuchumov, Vice-Rector for Research and Development of MGUPP.

The main difference between the development of MGUPP scientists and existing 3D printers is the units modified for the tasks of the food industry. The unique technology allows you to take a device for printing with plastic and upgrade it for printing with food raw materials.

“We made one unique extruder (a nozzle through which the raw material exits) of a revolving type. Inside it is a drum into which various raw materials are fed, which allows you to speed up the production process and use fewer parts. This is also our innovation - the use of one powerful drum extruder, into which various raw materials are fed under different pressures and temperatures, ”notes Alexey Kuchumov.

The development of MGUPP scientists allows you to make a 3D printer of any size and for any task, as well as increase the print area to one and a half meters, which is 1.2 meters more than existing analogues.

3D printer

In addition, the new device provides the ability to produce artificial meat using bioprinting technology. At the same time, the printer performs the function of a freezer - a refrigerator, and with different setting temperatures. It is designed in such a way that the necessary climatic environment will be formed for each type of raw material: its own temperature, its own humidity, etc. Among other things, a laboratory for the production of “cultured” meat is being opened together with 3D Bioprinting Solutions.

At the same time, the printer performs the function of a freezer - a refrigerator, and with different setting temperatures. It is designed in such a way that the necessary climatic environment will be formed for each type of raw material: its own temperature, its own humidity, etc. Among other things, a laboratory for the production of “cultured” meat is being opened together with 3D Bioprinting Solutions.

“The bioprinter prints a special plant-based substrate, on which live cells taken painlessly from animals are applied. This device prints according to a given digital model, using special nozzles - devices that allow you to print both cellular material and plant fibers. Such meat can be called “ethical”, and it will be in demand on the market,” comments Alexey Kuchumov.

As 3D Bioprinting Solutions Managing Partner Yousef Hesuani, 3D Bioprinting Solutions Managing Partner, added: “At this stage, it is possible to obtain the structure and organoleptic properties of the product similar to a natural product. The technology of printing with plant fibers followed by the application of a cell culture to the printed fibers has been developed, and special food bioprinters have been developed that allow automating the printing process. For example, the nuggets obtained using this technology were prepared according to a special recipe.”

The technology of printing with plant fibers followed by the application of a cell culture to the printed fibers has been developed, and special food bioprinters have been developed that allow automating the printing process. For example, the nuggets obtained using this technology were prepared according to a special recipe.”

Today, the MGUPP 3D-farm operates continuously, students and graduate students independently assemble printers and debug printing with food raw materials and living cells. The development is carried out within the framework of the MGUPP strategic project "Additive Technologies and Ingredients of the FoodNet Market" under the program of the Russian Ministry of Education and Science "Priority 2030" within the framework of the national project "Science and Universities".

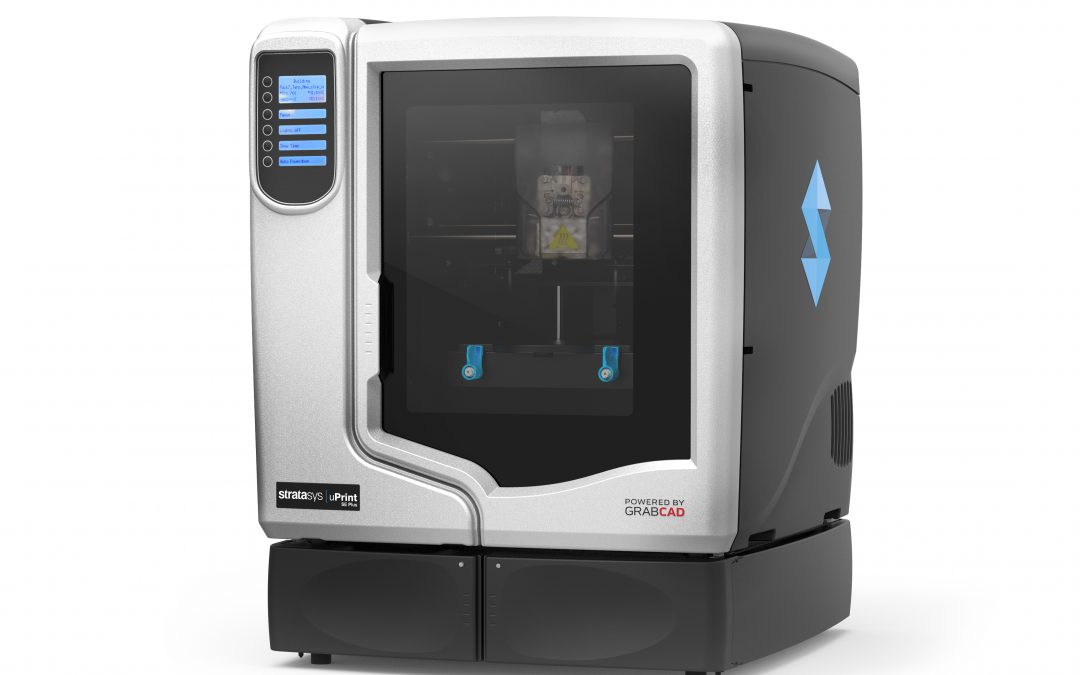

Large Area 3D Printer

Create functional plastic items up to 2.5 meters!

Find out more

Discovery 3D Printer is a range of industrial 3D printers manufactured in Spain for creating large-sized products and prototypes using FFF/FDM technology.

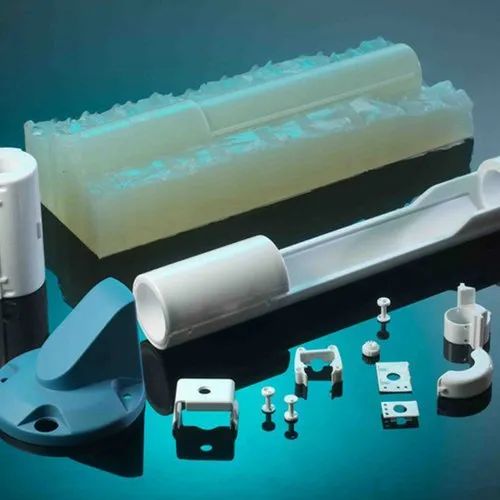

Discovery 3D Printer additive machines produce objects from high-strength thermoplastics and are designed for industries ranging from shipbuilding and automotive to architecture and medicine.

Tasks to be solved

Replacement of spare parts or lost parts at machine-building, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts

3D printing of large-sized end products, components and tooling in the automotive, shipbuilding and oil and gas industries

Creation of outdoor and interior decoration objects and design products for construction, manufacturing facing materials

Production of functional prototypes for research and development and design offices in mechanical engineering, shipbuilding and aircraft building

Manufacture of large-sized wax or burnt-out master models for metal casting and metallurgy

Creation of auxiliary fastening equipment, printing of templates for robotic equipment (robots, cobots, robotic arms or carts)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D Printers

Discovery 3D Printer 2021 9Ol000 Benefits of printing with granules and filaments in one device

Learn more

Super Discovery 3D Printer

Large build chamber and print speed up to 6 kg/h

More details

Super Discovery 3D Printer Workstation

2 in 1: unique combination of large format 3D printer and milling system

More details

Your unique 3D printer

Need to print more 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare characteristics of different models

Compare 3D printers

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and completely ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is flexible, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Benefits of Discovery 3D Printer Solutions

ISO 9001 Certified Products

World's Largest Build Chamber 3D Printers

Custom Printer Design

The only CNC-integrated 3D printer on the market to finish milling a part after printing

Accelerate the creation of new products with a dual extrusion system

Repair and replace products faster and more economically than contractors

Ability to use a large number of third-party materials

Platform self-leveling function for automatic compensation of irregularities

Application examples

FDM 3D printing of Airbus parts

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave molding of parts with a sealed surface and a low coefficient of thermal expansion.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A prototype car bumper is printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

Printed solid statue, 1. 87m high and 45kg weight.

87m high and 45kg weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

3D printed helicopter seat

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Window dressing for Dior boutiques

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles are 3D printed for the exclusive decoration of Dior brand stores.

Prototype FDM cap

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed, measuring 29 x 19 x 4.5 cm and weighing 146 g.0174

A prototype of a modular toilet is printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed ventilation grille measuring 59 x 89 x 4. 5 cm and weighing 3500 g.

5 cm and weighing 3500 g.

3D printed functional motorcycle part

| Industry: | Automotive |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | PACF |

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.0175

10cm x 9cm x 2.5cm supported prototype printed

3D printed square

| Industry: | Instrumentation |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | fireproof ABS |

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlaminar adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to the blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help optimize production?

- Features FDM-technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Explore Discovery 3D Printer Solutions - Go Virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

Best prices for this class of equipment

3D printer training

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Discovery 3D Printer solutions can be consulted by our experts free of charge.

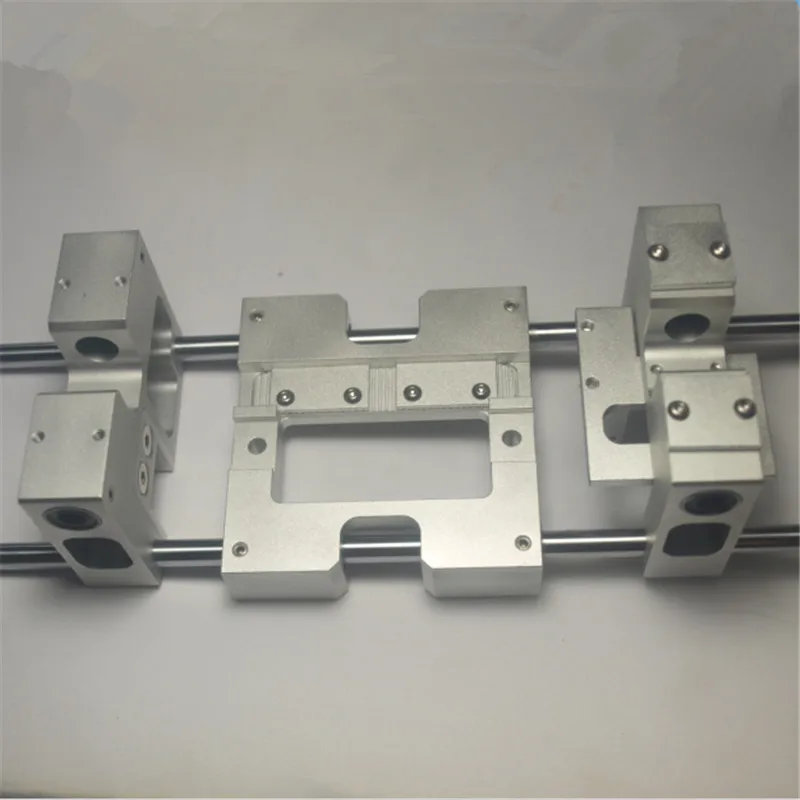

What are the kinematics and mechanics of the Discovery equipment?

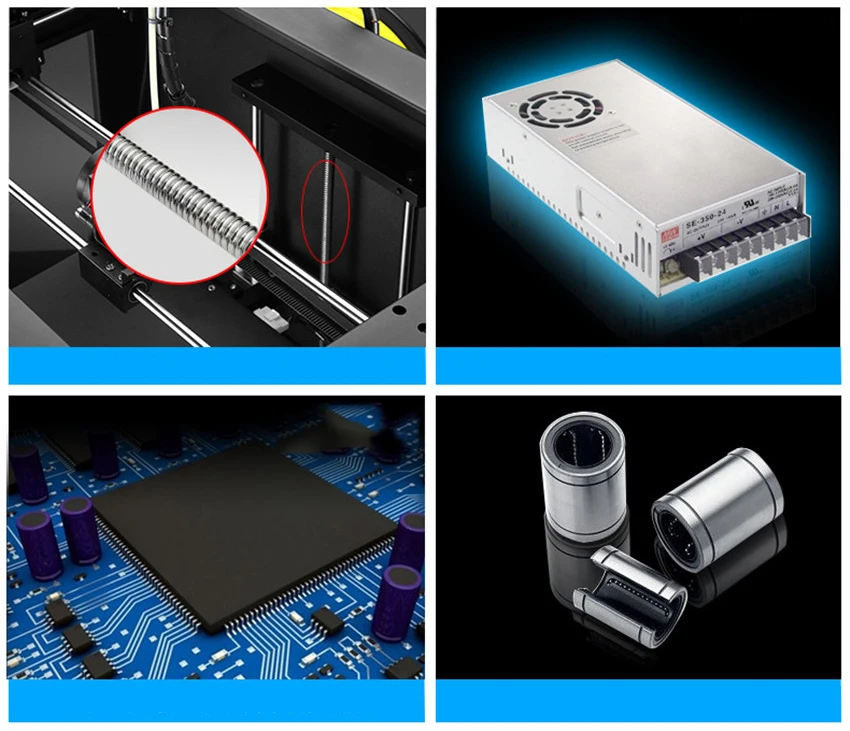

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process.