Creality3D cr 10s 3d printer upgrade version

Upgrades | Creality 3D Printers

Filters

- In stock (81)

- Out of stock (24)

- 3D Printer Accessories (9)

- Accessories/Upgrades (62)

- Hotends (2)

- Nozzles (1)

- Replacement Parts (6)

- Upgrades (9)

- Bondtech (33)

- Creality (14)

- E3D (1)

- LDO Motors (1)

- Mean Well (2)

- Micro Swiss (9)

- Printed Solid (1)

- SeeMeCNC (1)

- Slice Engineering (2)

- Tiny Machines 3D (31)

Showing 1 - 24 of 95 products

View

Filters

- In stock (81)

- Out of stock (24)

- 3D Printer Accessories (9)

- Accessories/Upgrades (62)

- Hotends (2)

- Nozzles (1)

- Replacement Parts (6)

- Upgrades (9)

- Bondtech (33)

- Creality (14)

- E3D (1)

- LDO Motors (1)

- Mean Well (2)

- Micro Swiss (9)

- Printed Solid (1)

- SeeMeCNC (1)

- Slice Engineering (2)

- Tiny Machines 3D (31)

The Best Creality CR-10/S/V2 Upgrades & Mods – Creality 3D

The CR-10 series has great 3D printers, but they aren't perfect. Check out the best Creality CR-10/S/V2/Mini upgrades and mods to pimp your 3D printer.

Out of the box, a CR-10 is good. With a few tweaks, it becomes even better. Give it an upgrade, and it’ll be among the best. So what are we looking for in an upgrade?

We’ve chosen the best upgrades for the CR-10 and all CR-10S-variants (S, S4, and S5), the CR-10 Mini, and the CR-10 V2. Each upgrade provides a useful function on the printer and is proven to work. For example, yes, a “hood ornament” is cool, but no, we don’t consider that an upgrade.

We split the upgrades and mods into four sections:

- Ease of use upgrades are aimed at making the user experience better. These range from making the bed easier to level to making it easy to mount cameras for time-lapses and video streaming.

- Functional improvements are upgrades that allow the printer to perform better and allow for improved printing results. Some such improvements are fan ducts and support braces.

- Extended upgrades are things that must be bought rather than printed, for instance, vibration dampeners or a Raspberry Pi to run OctoPi software.

These upgrades do not directly impact performance, but rather improve your printer with extended features and perks.

These upgrades do not directly impact performance, but rather improve your printer with extended features and perks.

For the most part, all of these mods are compatible with the complete list of the above-mentioned variants, unless stated otherwise. So what are we waiting for? Let’s get to it!

- Build Plate

- MicroSD Extender Cable

- Metal Extruder & Direct Drive

- Capricorn Bowden Tubing

- Enclosure

- Supporting Rod Set

- BL Touch Leveling Sensor Kit

- Stepper Dampers

- TL Smoothers

- Raspberry Pi

If you’ve been into 3D printing any decent amount of time, you know that bed adhesion is one of the most important factors in whether a print will turn out or not. Also, having a good build plate makes your printer much easier to use, no more fiddling around with scrapers and blades trying to get that one fragile print off without breaking it.

If you’re on a quest for better adhesion, Creality offers some enticing upgrade options. Their Tempered Glass build plate features a special carbon-silicone coating, similar to Anycubic’s Ultrabase, that reportedly has fantastic adhesion while hot, but breaks free easily when cold.

Their Tempered Glass build plate features a special carbon-silicone coating, similar to Anycubic’s Ultrabase, that reportedly has fantastic adhesion while hot, but breaks free easily when cold.

If glass isn’t your thing, you could always opt for the Cmagnet flexible build plate. Essentially a floppy magnetic version of a Buildtak-like surface, this product allows you to peel prints off without a scraper, by nature of being both highly flexible and easily removable from the printer.

These products are primarily available for the CR-10 and 10S, or their variants with a 310 by 310 mm surface area. If you have a larger build area but still want to upgrade, it may be worth looking into 3rd-party alternatives.

If you’ve ever worried about losing the tiny little microSD card that came with your printer, then this upgrade is for you.

Essentially, this is an extension cable for your microSD slot, converting it to a full-sized SD card reader. It also allows you to reposition your SD slot, so you are no longer dependent on having the side of the control box always accessible.

Ah, the gripping fear of a filament jam, a true classic in the 3D printing world.

Creality’s Official Bondtech Double Gear extruder kit should make your filament jamming days a distant memory. This upgrade comes stock on some of Creality’s newer CR-line printers, but for those of you with older models, this dual-drive extruder is available for sale as an upgrade. All you have to do is swap it out and re-calibrate your E-steps, and you’ll be ready to roll!

Alternatively, if you are the lucky owner of a CR-10 V2, you can also purchase a Genuine E3D Titan extruder. Designed to slot into the Cr-10 V2 as a seamless transition into direct-drive 3D printing, this upgrade facilitates the use of flexible filaments and relieves some of the common issues of Bowden tubes.

The Titan extruder can also be used in place of the stock extruder on the other CR-10 models, but this may require more work to install.

Note that for any extruder upgrades, it is a good idea to calibrate your extruder (also known as E-steps calibration) to make sure your printer is pushing the right amount of filament while printing.

If you have a fancy new extruder, why not make sure what comes after has the same quality and precision?

This Capricorn tubing, in its iconic dark blue color, has much tighter tolerances than a standard PTFE Bowden tube. What this means is there is less room for the filament to wiggle around on its way to the nozzle, resulting in smoother, more precise and consistent extrusion throughout your print.

Printing with PLA might be all fine and dandy, but when it comes to ABS and nylon, the CR-10 printers really struggle. A combination of an open-air frame and a massive heated bed makes it difficult to maintain a draft-free printing environment at the right temperatures.

Taking note of the issue, Creality released a printer enclosure kit that allows you to seal off your printer from the woes of an open workshop. Sized to fit the original CR-10 and the popular Ender printers, this enclosure should fit most of the CR-series machines, aside from the much larger S4 and S5 variants.

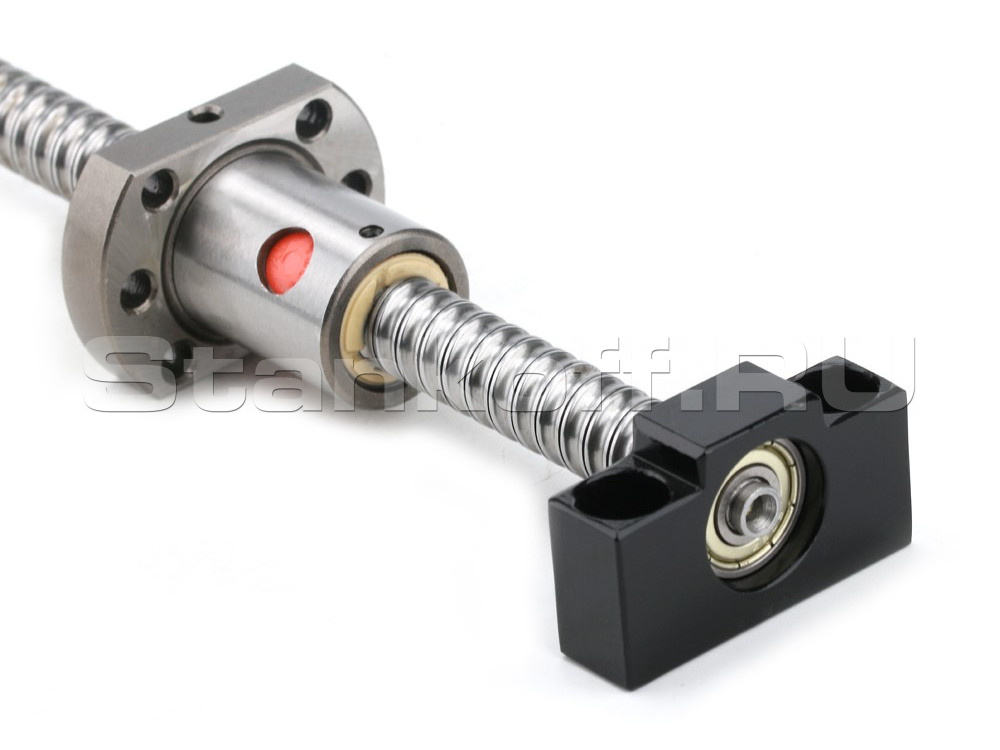

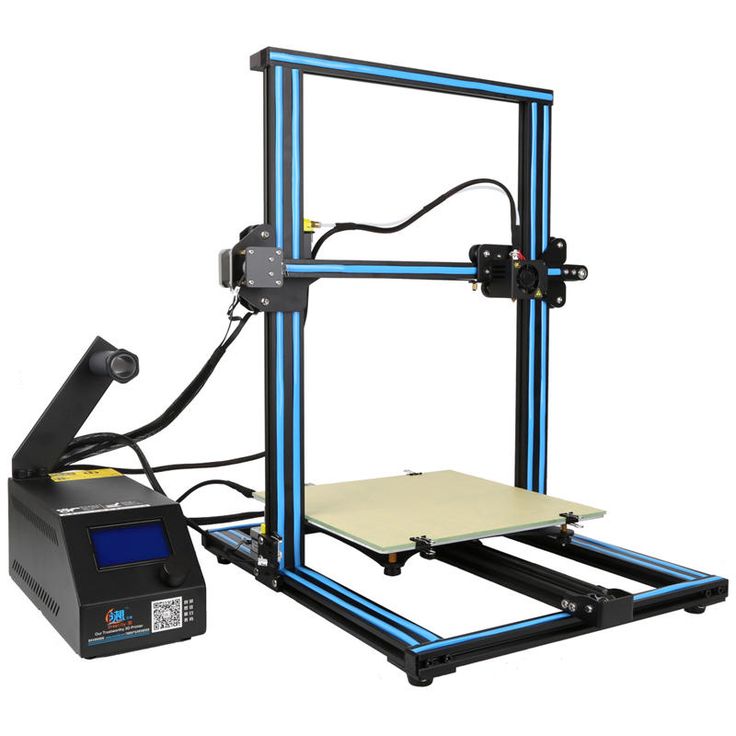

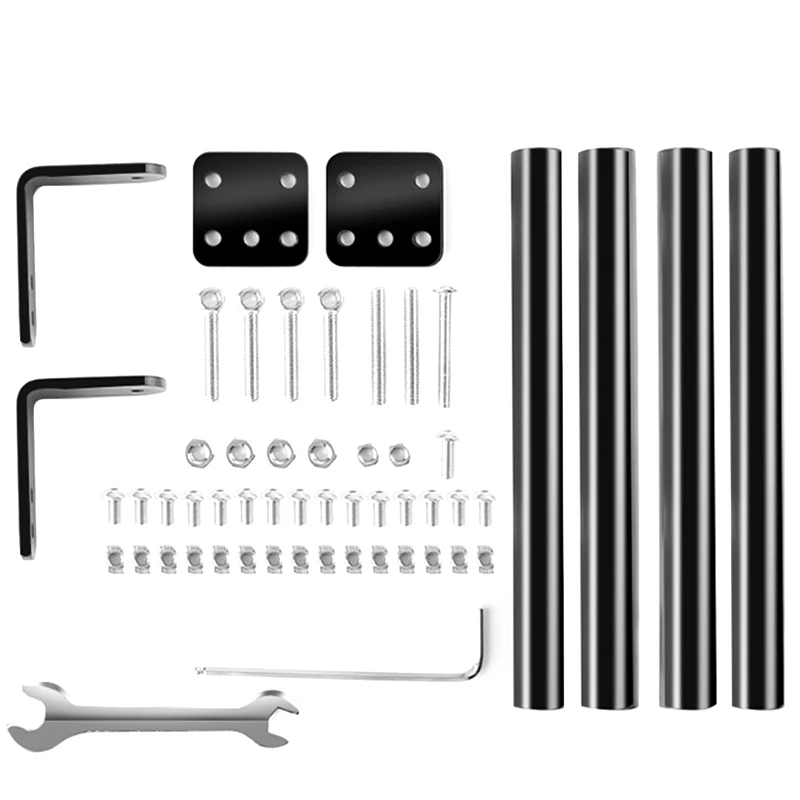

Many users have noted that the tall vertical extrusions in the Z-axis of the CR-10 aren’t the most stable, which leads to wobbling and inconsistent layers in taller, larger prints.

However, to mitigate this problem, Creality offers a set of supporting rods, the same ones included with the CR-10 V2. The rod set includes a tapping kit, allowing you to thread the core of the front-most aluminum frame extrusion, to which the rods are then bolted.

This kit is advertised as compatible with the CR-10 and 10S, but should also fit on the S4 variant. The other CR-10 models have different frame sizes, and as such would likely benefit more from the DIY version of this upgrade, mentioned further on in our list.

One of the main issues with the CR-10 series of printers is that the beds are so large that keeping a good level across the entire surface can be difficult. A classic solution to this is to add an auto-leveling sensor.

In the case of the original CR-10 series, Creality offers their own BL Touch kit, including everything you need to get going with a BL Touch sensor, including a mounting bracket.

For owners of the CR-10 V2, a simplified kit is available at the same price, featuring a different mounting bracket to fit your X-gantry.

A relatively cheap but more time-consuming Creality CR-10 upgrade is adding stepper dampers to your printer. This decreases the vibrations caused by the stepper motors and significantly reduces noise levels while printing and, in some cases, can help the quality of your prints.

TL Smoothers are relatively cheap add-ons for your CR-10’s stepper motor drivers, which essentially help smooth your print and remove artifacts like “salmon skin”. They can be bought for a couple of dollars and are super easy to install thanks to plug-and-play setup and zero software. Cheap and easy, a no-brainer Creality CR-10 upgrade.

Adding a Raspberry Pi to your CR-10 can be useful for a number of reasons, but the most popular one is for using the free OctoPi software. OctoPi allows you to monitor and control your printer remotely or over WiFi, so that you can check on your print, ensure against failures, and perhaps even run a printer farm. Another cool feature of OctoPi is that it will auto-record the entire print with a connected camera.

Another cool feature of OctoPi is that it will auto-record the entire print with a connected camera.

The Raspberry Pi itself is of course the only essential component, however you can also add on a Pi camera or webcam. And don’t forget to print yourself a cool case.

Source: ALL3DP.com

We resume deliveries of Creality3D 3D printers

Miscellaneous

We are resuming supplies of 3D printers from the world famous company

Creality3D .

Creality3D has been designing and manufacturing 3D equipment since 2014. Creality3D desktop 3D printers have gained immense trust among users around the world. Due to the reliability of the equipment and its affordable cost, 3D printers can often be found in the ratings of the best, which once again proves the popularity of the company.

Already in August we expect the most popular models Ender 3, Ender-3 V2, Ender 5 Pro, Ender 5 Plus, CR-10S Pro V2 and a novelty - photopolymer printer LD-002R.

Creality3D Ender 3 3D Printer is one of the most popular budget models today. With a fairly large build area for its category, the Ender 3 delivers consistently high print quality. Supplied as a kit for assembly, due to which its cost is always lower than similar models on the market.

Learn more about the Creality3D Ender 3 3D Printer

The Creality3D Ender-3 V2 3D Printer is an updated version of the Ender 3 printer. during work.

Learn more about Creality3D Ender-3 V2 3D Printer

Creality Ender 5 Pro 9 3D Printer0014 is a more modern version of the Ender 5 printer. A model with an extruder heating temperature of up to 260 C easily copes with high-temperature durable and flexible plastics. Compared to the Ender 3 version, Ender 5 Pro has a larger build area and print speed.

Learn more about the Creality Ender 5 Pro 3D Printer

The Creality Ender 5 Plus 3D Printer is built for large scale printing. It has the largest build area of any Creality3D 3D printer. The rugged cubic design ensures stable printing for a long time, allowing you to create large projects with high quality.

It has the largest build area of any Creality3D 3D printer. The rugged cubic design ensures stable printing for a long time, allowing you to create large projects with high quality.

Learn more about Creality Ender 5 Plus 3D Printer

The Creality3D CR-10S Pro 3D printer is a model of the CR series for professional printing, equipped with intelligent sensors and automatic platform calibration, which greatly simplifies the operation of the device. A large build area will allow you to print large models as a whole or batches of small models.

More about Creality3D CR-10S Pro V2 3D Printer

The Creality LD-002R LCD 3D printer is Creality3D's only photopolymer model. A budget LCD printer is perfect for users who are new to photopolymer printing. At a fairly modest cost, the printer is equipped with a 2K resolution matrix, which shows high print quality. For complex models, Creality3D offers 4X and 8X Uniform Smoothing.

Learn more about Creality LD-002R LCD 3D Printer

Experience Creality3D 3D printers first by pre-ordering in our online store!

Follow us on social. networks to keep abreast of the latest events:

VKontakte

YouTube

cvetmir3d.ru

setup and calibration instructions, print examples

In modern times, technology does not stand still. So, 3D printers are widely included in our daily life and simplify it. In this article, we will take a closer look at the Creality CR-10 brand representative. We will present the reader with a brief overview of the functionality, technical characteristics, analyze the advantages and disadvantages. We hope that the information received will easily solve the issue of choice.

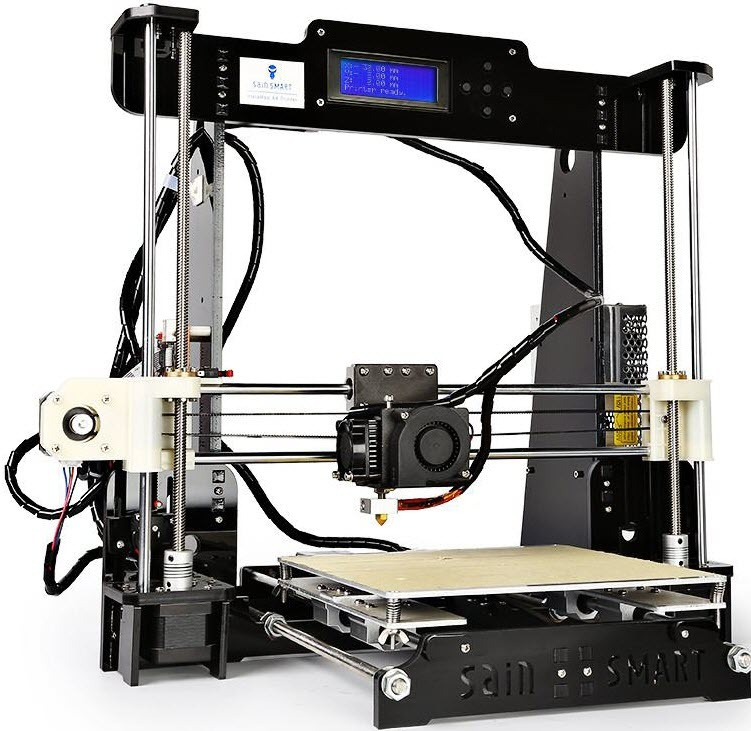

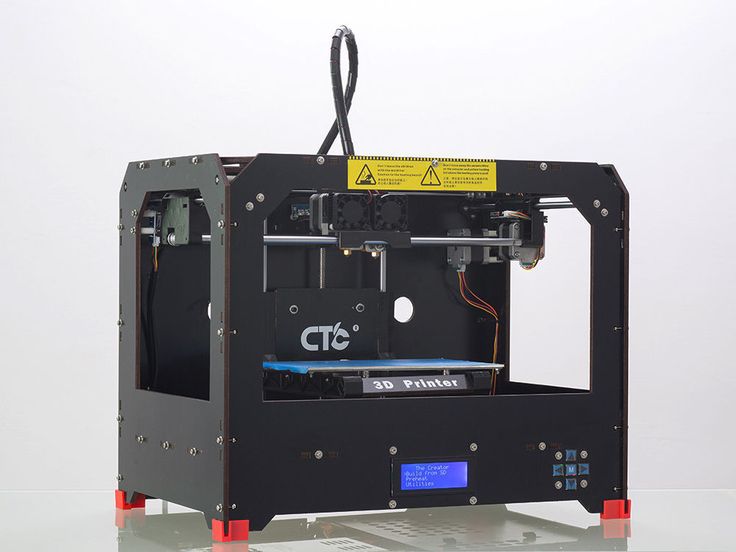

Creality CR-10 3D Printer Overview

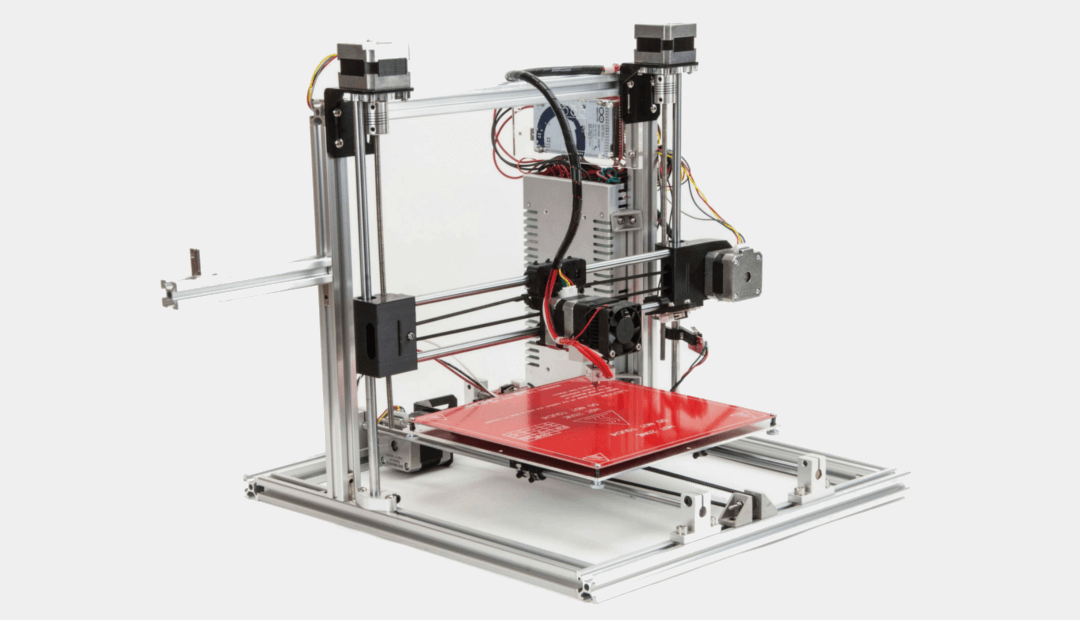

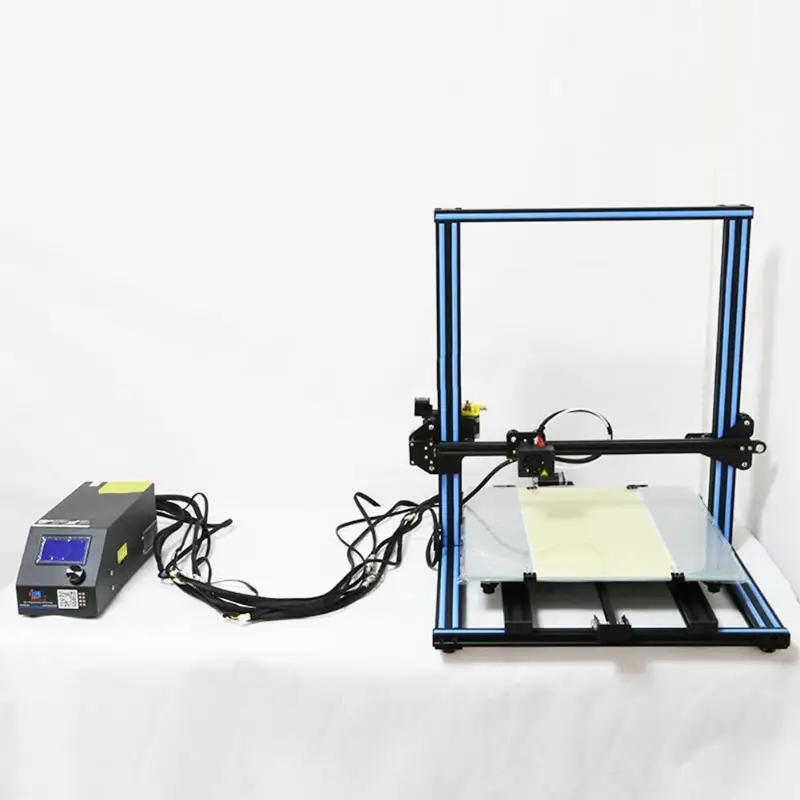

The Creality CR-10 3D printer is small enough to fit on a small desk. This will provide an opportunity to realize all your creative desires even at home. The design of the three-dimensional printer consists of a durable aluminum housing, which will allow the printer to last for quite a long time. Another positive criterion is the ease of assembly and further configuration.

The design of the three-dimensional printer consists of a durable aluminum housing, which will allow the printer to last for quite a long time. Another positive criterion is the ease of assembly and further configuration.

Description

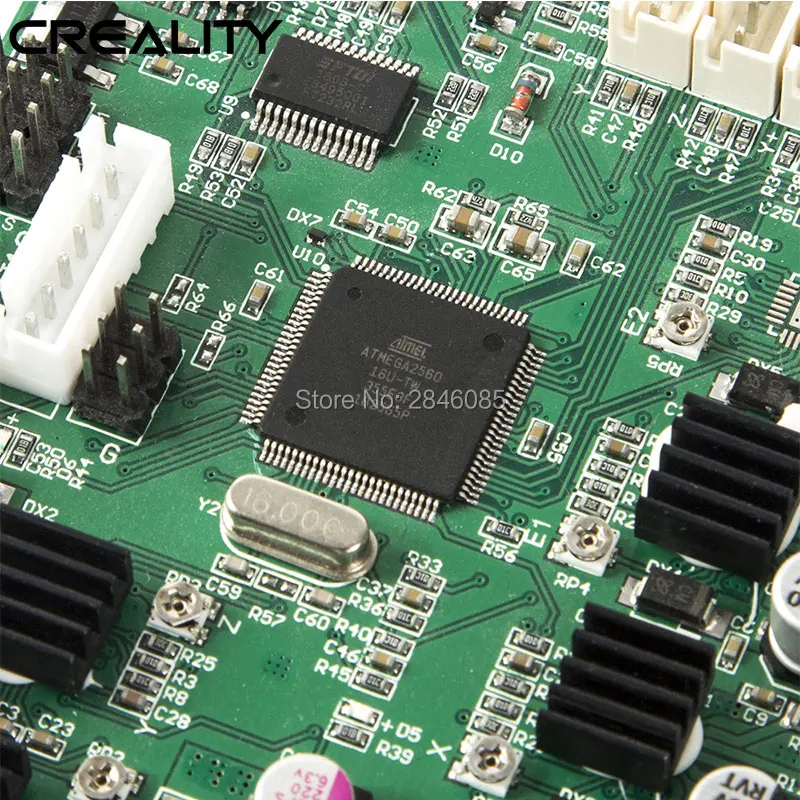

The printer was invented in 2017 by the Chinese company Creality 3D, which in turn was founded in 2014. Despite its rather impressive dimensions of 540 × 640 × 310 and a weight of about 10.3 kg, assembly time takes an average of only 20 minutes. The device is equipped with an industrial printed circuit board, which is capable of continuous operation for 200 hours. The linear pulley system is a patented technology: V-profile and precision pulley with ideal smoother running is considered to be wear resistant. With these characteristics, the printer works almost silently.

Loading filament for printing is quick and easy, and the filament prints smoothly and well. The display is bright and spectacular, equipped with contrast adjustment and easy to manage. The screen displays the temperature of the bed and nozzle both in a given format and shows the current value and flow rate.

The screen displays the temperature of the bed and nozzle both in a given format and shows the current value and flow rate.

For reference . On the information board, you can find out data on excessive extrusion (we are talking about the fact that a lot of material is loaded) or too low extrusion (too little material), as well as the speed of the fan.

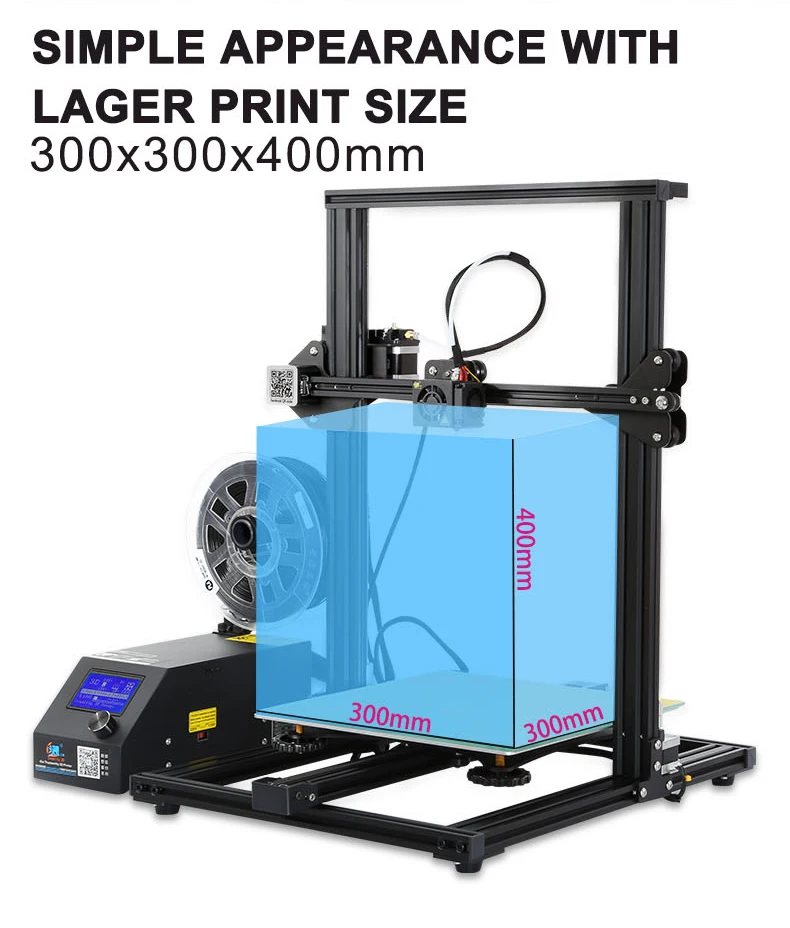

The 3D printer in its original assembly requires a heated platform. The kit comes with an extruder in a single quantity. The Creality CR-10 is also equipped with the ability to use several types of plastic in printing at once, such as ABS and PLA. The thickness of the plastic wire must be 1.75 mm. Printing can be done from both USB and SD cards. When building three-dimensional models, Cura software is used, which is also included with the printer. The maximum temperature that the nozzle produces reaches 270 degrees. The printable area of the printer is 300 × 300 × 400 mm.

The manufacturer recently released an updated version of the CR-10S. The parameters of the machine are almost the same, but some of the functionality has been significantly upgraded. The following are a number of upgrades:

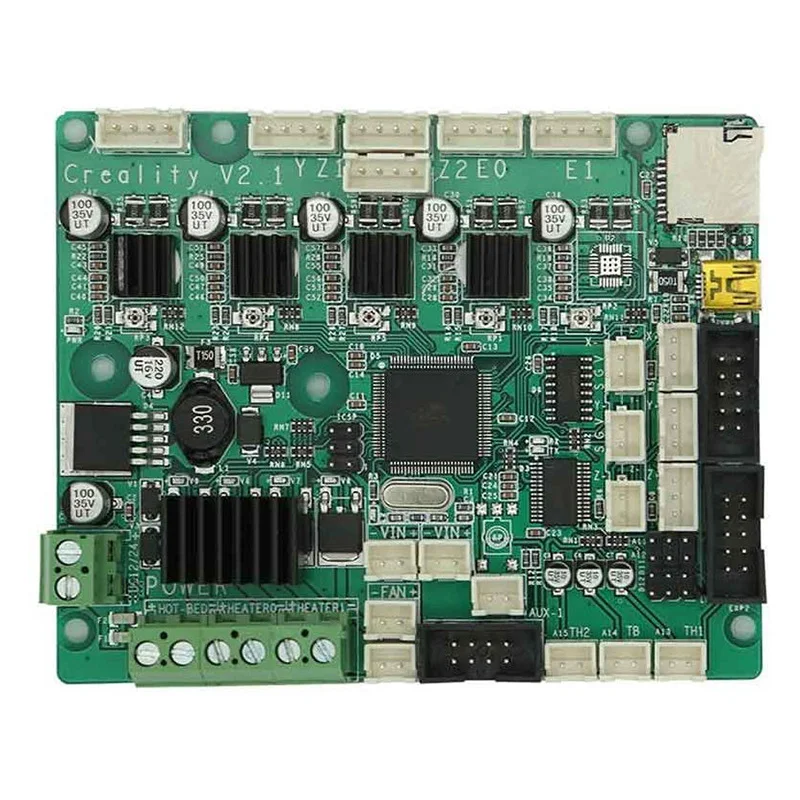

- Upgraded CR-10S Motherboard - Equipped with Creality 3D V2.1 board, can print 200 hours of high quality non-stop without interrupting the production process.

- Print Resume Feature - The printer can resume printing when there is a power outage. The motherboard has been completely redesigned and supports permanent power outage monitoring.

- Thread break sensor - the printer is equipped with a special device that allows you to monitor the process. When the filament runs out or breaks, the printer will automatically stop to ensure smooth and continuous printing of the model.

Creality 3D printer CR-10

- Dimensions, mm 615x600x490 mm

- Seal FDM

- Extruder temperature Up to 250 °C

- Working chamber area 300x300x400 mm

- Speed ≤200 mm / s

- Layer thickness from 100 µm

- Nozzle diameter, mm 0.

4

- Thread diameter, mm 1.75

Go to product

Pros and cons

Like any technique, the printer has both advantages and disadvantages.

Let's start with the positives:

- Has a large printable area.

- Easy to use.

- Easy to assemble.

- Silent operation.

- No software update required.

- 3D printed, easily removable platform.

- Sustainable power supply.

- Quality build.

Cons:

- It takes quite a long time to warm up the platform.

- The room temperature rises due to the high temperature of the platform.

- The cable from the motor to the extruder is relatively heavy, which can affect print quality.

- The touch screen does not display all saved model files.

- Layer displacement when changing plastic filaments.

Package contents

The 3D printer comes semi-assembled and in a modest cardboard box. It is obvious that at first glance the package looks cheap. But in fact, this model is made of quality materials. Of course, the manufacturer should have placed an image of a 3D printer on the packaging, but apparently he did not consider this necessary.

Opening the Creality CR-10 box you will find two foam trays with a small number of parts including tool kits and spare screws.

Installation instructions included in the package, at first glance, incomprehensible and vague. To avoid assembly errors, use the information on the Internet.

Creality CR-10 3D Printer includes the following parts:

- 3D printer,

- two spools with ABS and PLA consumables,

- tool kit,

- power cable,

- SD memory card with software,

- packing box,

- warranty card.

Print quality and product examples

If the printer is set up correctly, the finished part is good and of good quality. The Creality CR-10 3D printer prints models with a minimum layer thickness of 100 microns.

Next, consider the samples that the device can print. 9

The Creality CR-10 3D Printer can be used in various fields such as education, design and architecture. But that's not all. Also, the device is capable of printing on fabric with a plastic filament - this opens up new horizons for the use of a 3D printer.

Consider how 3D printing can be used in jewelry. With its high level of detail, the Creality CR-10 is capable of realizing any jewelry design. The main thing here is to understand that the printer does not print finished products for wear. In other words, 3D printers don't print gold rings and earrings.

The Creality CR-10 is able to create a high quality, detailed model of a piece of jewelry that will later be used to make molds.

The benefits of using a 3D printer in the jewelry industry:

- Improving the skills of making unique products.

- Creating a plastic model of a piece of jewelry will save time and provide an opportunity to coordinate the product with the customer at the modeling stage.

What materials are used?

The printer uses 0.75 mm filaments such as ABS and PLA as consumables for operation:

- ABS - Acrylonitrile Butadiene Styrene, an impact resistant thermoplastic. This material is used in the automotive, medical and souvenir industries, as well as in the manufacture of sanitary ware, credit cards, toys, furniture, etc. Due to its low cost and strength, ABS has become popular among 3D printing enthusiasts. The melting point is about 105 degrees.

- PLA (polylactide) is a plastic whose structural unit is lactic acid. It is made from corn or sugar cane. Potato and corn starch, soy protein, cassava tubers and cellulose are also used as a material for producing plastic. To date, polylactide is most often used as a consumable for printing on 3D printers. This material is absolutely harmless to human health.

The melting point of such plastic is 173 degrees.

A big advantage of this printer is the fact that the Creality CR-10 uses open spools. Thanks to this, you are not tied to one manufacturer. So, many companies produce consumables in special cartridges, which are much more expensive. A thread with a diameter of 1.75 mm is ideal, since such a sample is produced by a sufficient number of companies. At the same time, the color palette pleases with a huge assortment.

Initial setup and preparation instructions

We present to your attention a quick guide to setting up and preparing the printer for work.

- Remove all parts from box and remove protective tapes and gaskets from parts.

- Inspect each item for shipping damage.

- Proceed with the installation of the structure, based on the enclosed instructions, or use information from the Internet. Assembly will take no more than 20 minutes.

After installation, the first step is to calibrate. The build plate should be level and the nozzle approximately 0.1-0.2mm from the platform at all locations. You need to adjust the height so that you can barely slide the paper between the nozzle and the assembly.

Set up carefully and follow the steps below:

- Turn on the printer first.

- Choose Select Control > Temperature > Bed. The heating temperature should correspond to 55 degrees.

- Select Prepare > Preheat PLA. This will heat up the nozzle and melt any hardened plastic that may be on the nozzle and interfering with the alignment process.

- Select Prepare > Auto home. This will move the nozzle to its original position in the front left corner of the slab.

- Select Prepare > Disable steppers. This will allow you to move the nozzle in the X-axis and in the Y-axis manually.

- Wait until platform temperature reaches 55 degrees and nozzle temperature reaches 195 degrees. Temperature information is displayed on the screen.

- Insert a piece of paper between the nozzle and build plate.

- Adjust each of the four screws so that the gap is the same everywhere and the sheet of paper moves with little resistance.

- Select Prepare > Auto home then Prepare > Disable steppers and check several places again. It is important to do this to make sure that the Z-Axis lead screw is not loose while adjusting the clearance.

Important! You may need to adjust the platen level during printing. The first layer of detail will show if the correct distance is selected between the nozzle and the pastel.

Let's summarize. The Creality CR-10 3D printer is a worthy Chinese representative that will easily fit into both home and production environments. We list the main points that you should pay attention to when buying:

- The 3D printer is easy to operate and assemble.

- The model has many advantages, including silent operation, large print area and quality assembly.

Learn more