Inno3D 3d printer

Inno3D | 3D Printers | 3D Printing

Features

- Auto Braces Creation Technology (BCT)

- Print floating 3D objective with ease - Auto Raft insertion

- Conveniently peel off the 3D Object from bed - Auto bed level calibration

Printer Specification

- Printing Technology: Fused Filament Fabrication

- Print Nozzles: Single Nozzle (0.4mm)

- Build Volume: 100mm (L) x 100mm(W) x 100mm (H)

- User Interface: Power On Switch / Print button / Change Filament button

- Layer Resolution: 0.13mm - 0.3mm (Fine / Normal / Quick mode)

- 3D Object Supports: Fully Automated, Easy to peel off

- Filament: 1.

75mm PLA

- Filament Color Choices: Multiple colors PLA

Application software

- Free 3D Printer control software with STL to printer file format conversion

- Work with any 3D applications which can export STL file format

Weight & Dimensions

- Unit weight (without cartridge): 6.5kg

- Unit dimension: 32.5cm (length) x 32.5cm (depth) x 34cm (height - include the filament guide tube)

- Gross Weight: 10.1kg

- Carton Dimension: 40cm (length) x 39cm (width) x 53cm (height)

Order Information

- Order Part Number: I3DP-S1BK-RE01

- UPC: 83516802166-2

Minimum System Requirements

- Processor: Intel® or AMD® with dual-core processor or above

- System Memory: (Windows 98 / XP) -4GB .

(Windows 7 / 8 / 10) -8GB

(Windows 7 / 8 / 10) -8GB - Screen Resolution: 1024x768

- Disk Space: At least 20GB free space for printer application

- OS Support: Microsoft® Windows® XP or Windows® 7 / 8 / 10 (32 bit / 64 bit)

Connectivity

- USB 2.0 port for Workstation connectivity - with USB device driver

- SD-Card interface for direct file printing - support up to 32GB SD-Card

Electrical Requirements

- AC Outlet requirements: 100-240 Volts AC, 50/60 Hz

- Printer electrical rating: 24VDC

Material Storage

- Do not unpack the material if not use

- Store at room temperature: 16-29° C (60 - 85° F)

Operating Environment

- Room Temperature: 16-29° C (60 - 85°F)

- Nozzle- 270° C (518°F)

- Non-condensing Relative Humidity: 25% or above (Must higher than 25%)

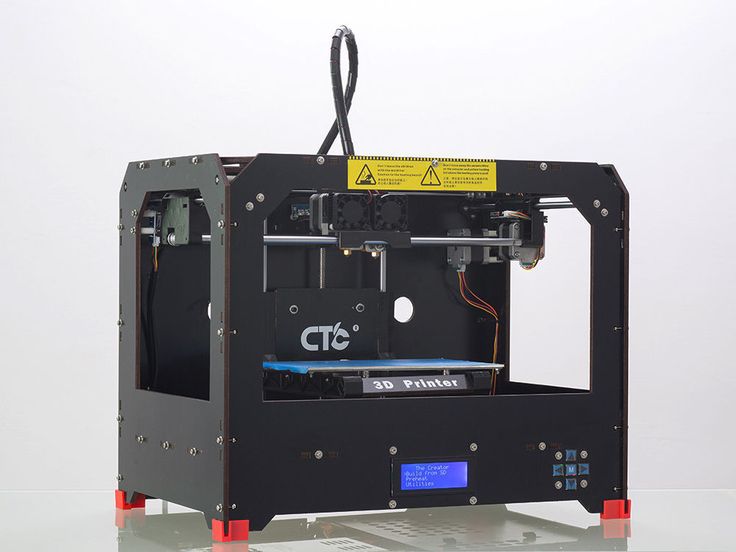

Inno3D | 3D Printers | 3D Printing

Features

- Auto Braces Creation Technology (BCT)

- Print floating 3D objective with ease - Auto Raft insertion

- Conveniently peel off the 3D Object from print platform - Auto print platform level calibration

Printer Specification

- Printing Technology: Fused Filament Fabrication

- Print Nozzles: Single Nozzle (0.

4mm)

4mm) - Build Volume: 140mm (L) x 140mm(W) x 150mm (H)

- User Interface: Touch Screen Color LCD display + Easy navigation keypad

- Layer Resolution: 0.13mm - 0.3mm

- 3D Object Supports: Fully Automated, Easy to peel off

- Filament: 1.75mm PLA / ABS

- Filament Color Choices: Multiple colors PLA / ABS

Application software

- Free 3D Printer control software with STL to printer file format conversion

- Work with any 3D applications which can export STL file format

Weight & Dimensions

- Unit weight (without cartridge): 11kg

- Unit dimension: 49cm (width) x 43cm (depth) x 52cm (height)

- Gross Weight: 16.

5kg

5kg - Carton Dimension: 56cm (length) x 52cm (width) x 60cm (height)

Order Information

- Order Part Number: I3DP-M1-BK

- UPC: 83516802051-1

Minimum System Requirements

- Processor: Intel® or AMD® with dual-core processor or above

- System Memory: (Windows 98 / XP) -4GB . (Windows 7 / 8) -8GB

- Screen Resolution: 1024x768

- Disk Space: At least 20GB free space for printer application

- OS Support: Microsoft® Windows® XP / 7 or Windows® 8 (32 bit / 64 bit)

Connectivity

- USB 2.0 port for Workstation connectivity - with USB device driver

- SD-Card interface for direct file printing - support up to 32GB SD-Card

Minimum Hardware Requirements

- Processor: Multi-core processor

- System RAM: 2 GB

- Screen Resolution: 1024x768

- Microsoft Windows XP / 7 X86 or X64

Electrical Requirements

- AC Outlet requirements: 100-240 Volts AC, 50/60 Hz

- Printer electrical rating: 24VDC, 7.

4A

4A

Material Storage

- Do not unpack until material is needed

- Store at room temperature: 16-29° C (60 - 85° F)

Operating Environment

- Room Temperature: 16-29° C (60 - 85°F)

- Nozzle- 270° C (518°F)

- Print Pad- 66-100° C (150-212°F)

- Non-condensing Relative Humidity: 25% or above (Must higher than 25%)

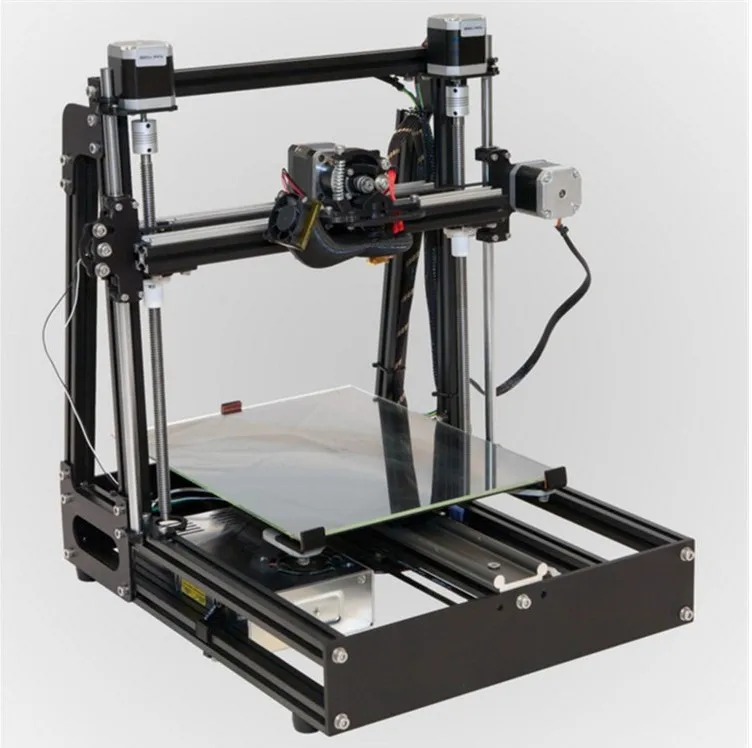

| 3DNews Technologies and IT market. News printers, print servers, scanners, copiers... Computex 2016: video cards, cooling systems... The most interesting in the reviews 06/01/2016 [17:46], Alexander Budik inno3D took part in Computex 2016. inno3D exposure inno3D M1 3D printer Among the features of the M1 model, the manufacturer notes heating temperature control during printing and quiet operation. The used printing technology is Fused Flament Fabrication (as in all other models). The printer is equipped with nozzles with a diameter of 0.4 mm and allows you to build models with dimensions up to 140 × 140 × 150 mm. The layer resolution is 0.13–0.3 mm. For ease of use, a touch color display and navigation buttons are offered. inno3D S1 3D printer The S1 version is positioned as a compact 3D printer with easy one-touch operation. This novelty is characterized by a print area of 100 x 100 x 100 mm, equipped with a color OLED display. inno3D D1 3D Printer The D1 has the same working area as the M1, but features an open design and high quality workmanship. Accelerators at the inno3D booth At one of the booths, visitors can get to know the GeForce GTX 1080 X3 and X4 accelerators "live". The X4 version uses the Active Power Cooling Solution (A.P.C.S) cooling system, which features a large heat sink for memory and other components, and two heat pipes for efficient heat dissipation. The X3 model is equipped with the Power Direct Cooling System (P.D.C.S.), which provides, in addition to heat pipes, direct heat transfer to aluminum plates. The radiators on the power circuits and the video chip are connected. Active Power Cooling Solution It is interesting to note the GPU load indicator, which tells the user about the operating mode of the video card in color (red - full game load, green - light load, blue - idle mode). The iChill X3 system uses three fans, while the X4 also uses a fourth 50mm fan to improve heat dissipation efficiency. Power Direct Cooling System The GeForce GTX 1080 Black model with the Accelero Hybrid S cooler is also presented. Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/933894 Headings: News Hardware, cooling systems, printers, print servers, scanners, copiers, MFPs, video cards, Tags: computex 2016, inno3d, graphics card, 3d printer, geforce gtx 1080 ← В past To the future → |

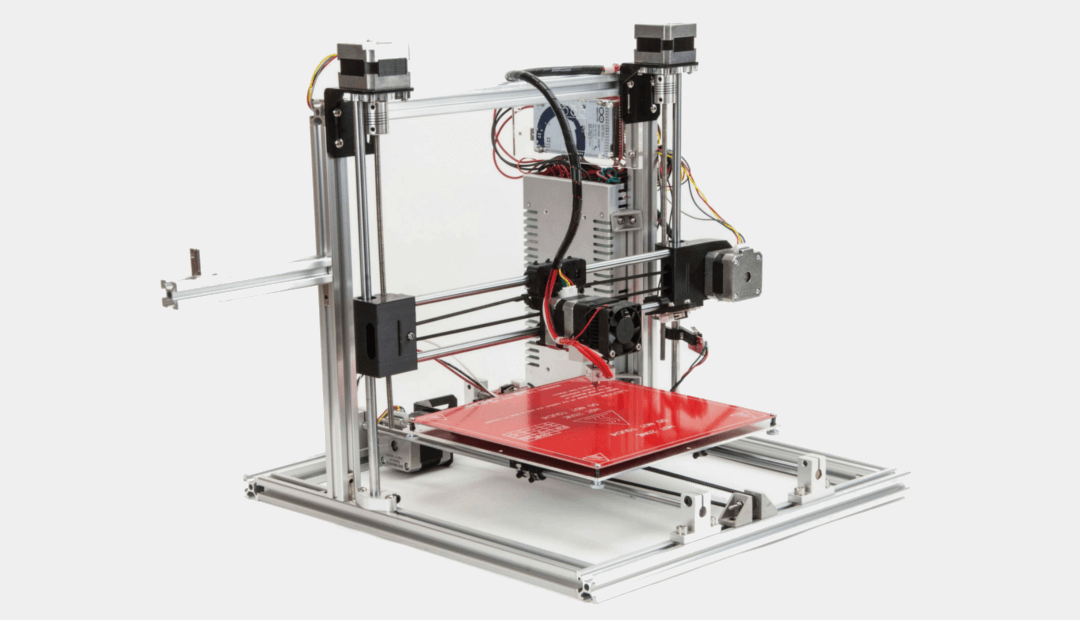

Quick Test & Review: Inno3D D1 – An Affordable 3D Printer

3D printing has long been the preserve of specialized companies that need to quickly prototype or produce products in small batches. The benefits were that a 3D print made it possible to quickly evaluate the design of the finished product without resorting to expensive molds and production equipment. But not only: the production of small batches without machines and customized work equipment has become a classic area of application for 3D printers. At the same time, 3D printers continued to get cheaper, so they also interested ordinary users who like to create ready-made solutions with their own hands. Our test lab received a preliminary sample of a 3D printer, which we tested. In the near future, it will appear in retail sales.

At the same time, 3D printers continued to get cheaper, so they also interested ordinary users who like to create ready-made solutions with their own hands. Our test lab received a preliminary sample of a 3D printer, which we tested. In the near future, it will appear in retail sales.

3D printers are one of the hottest topics on the internet today. And a month does not pass when a new model of a 3D printer appears on one of the crowdfunding platforms, collects money, and then goes into the development and production stage. Large companies such as Inno3D also do not want to miss out on a potentially successful market, so they develop their own solutions - like the D1 that entered our test lab. The potential of 3D printers is huge, some experts and analysts predict a new industrial revolution. You can argue about this for a long time, but we got a very interesting 3D printer worthy of attention.

» Photostrecke

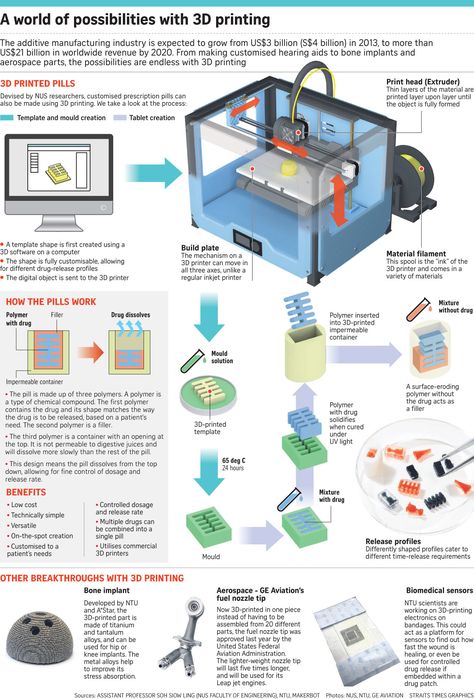

3D Printing Basics

Some 3D printers are built using a stereolithography or laser fusion process. The laser beam illuminates the UV-sensitive liquid photopolymer pixel by pixel at the right places on the layer. At the same time, the material hardens, sinks one layer to create the next layer, and the desired detail gradually appears in the bath.

The laser beam illuminates the UV-sensitive liquid photopolymer pixel by pixel at the right places on the layer. At the same time, the material hardens, sinks one layer to create the next layer, and the desired detail gradually appears in the bath.

Laser melting works in a similar way: the laser melts metal or plastic granules layer by layer in the contour of the future part. After completing one layer, work begins on the next.

Another way is Fused Deposition Modeling (FDM). This uses a filament made of plastic (thermoplastic such as ABS, PLA, PC) or other materials that is melted, after which the liquid material is applied to the desired areas of the layer of the part.

In recent years, 3D printers have become increasingly cheaper, which attracts many enthusiasts to this topic. As a rule, they use FDM printers, such as we received for tests.

Printer

Technical specifications

- Dimensions: 36x35x37 cm

- Weight: 8 kg (without filling)

- Working space: 140x150x150 mm

- Accuracy: 0.

15 mm

15 mm

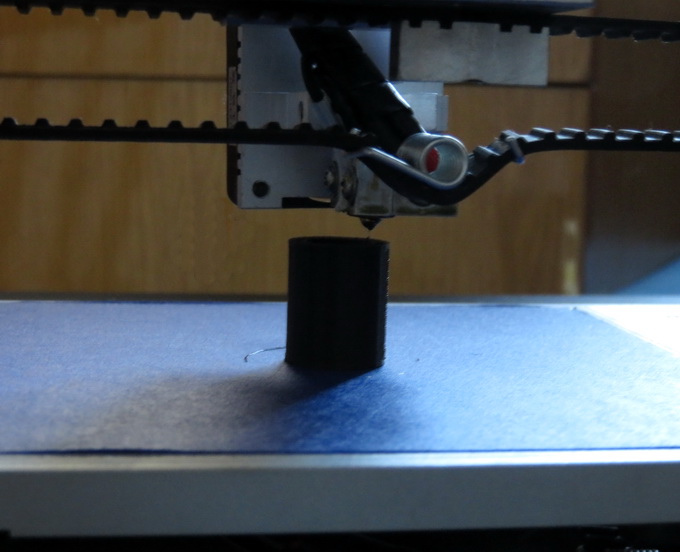

We've tested a preview of the Inno3D D1 printer, and it performed quite well. The control electronics is enclosed in a case made of steel with a thickness of 0.8-1 mm, it is made with high quality. We did not find gaps or distortions, but let's move on to the main thing: the printing mechanism.

The printer works on a similar principle to other models that enthusiasts build by hand: the print head, called an extruder, heats up a thermoplastic filament and then extrudes it through a nozzle - it just largely determines the quality. The smaller the nozzle diameter, the thinner the printed layers will be, and the thinner the structure of the finished object will be. Inno3D drives a motor to the extruder, the entire mechanism rests on an aluminum structure to minimize inaccuracies during operation.

The print head moves along the X and Z axes. Movement is provided by two step servos that are connected to the head unit by belts.

Molten plastic printing is carried out on an 8 mm aluminum plate (Hot Plate), which is specially heated. Heating is important to prevent deformation of the model when the plastic cools. The plate provides a shift along the Y axis. In general, the mechanism turned out to be of high quality: the drives through the belts accurately position the head over the entire area of the plate.

Heating is important to prevent deformation of the model when the plastic cools. The plate provides a shift along the Y axis. In general, the mechanism turned out to be of high quality: the drives through the belts accurately position the head over the entire area of the plate.

Our test model did not have the "illnesses" of many self-assembly printers, which are too large gaps and tolerances, everything worked exactly like a clock.

Of course D1 will have to be serviced. Bearings and joints must be constantly lubricated to keep them running without vibration. Dry lube would be more reasonable here. I was somewhat disappointed with the drive of the plate on one side, which, due to the mechanical stress created, led to jerks. They can blur the result a bit.

The printer has an embedded microcontroller that is controlled via the touch screen.

After calibration is complete, you can start printing. Sample print data can be transferred via an SD card or directly from a computer. In the latter case, the computer must be connected during the entire printing process.

In the latter case, the computer must be connected during the entire printing process.

Software

Inno3D includes a software package that is quite easy to use. You upload a model in *.stl format, which is then placed on the substrate. You can rotate the model and scale. The software package then splits the model into layers and then writes a gcode file to control the printer.

The predicted print time matches reality fairly well. After preparing the model, you can send data via USB to the printer or transfer via SD card, printing from it can be started using the printer's display.

As you can see, everything is quite simple. See our gallery for more photos.

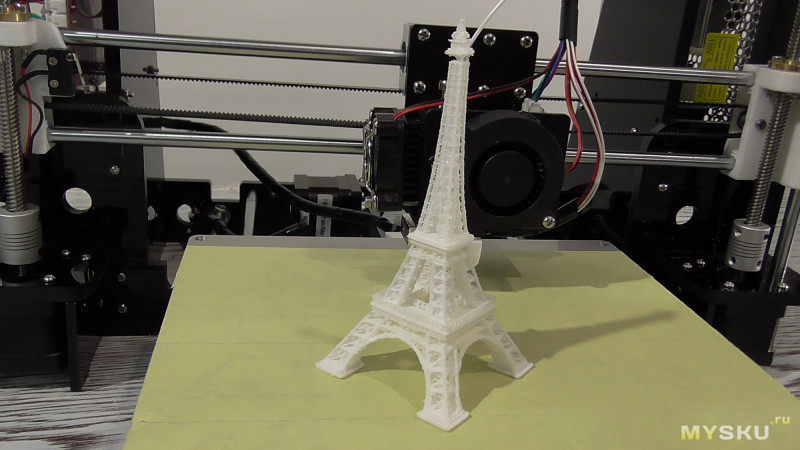

Test prints

Conclusion

The software is aimed at general users, so enthusiasts may find it too simple. But the printer can also be used with the Sli3r package, which gives more room for experimentation.

During printing, we were a bit frustrated by the slight jerking of the hot plate, which could be minimized with lubrication.

At her booth, she presented a lot of video cards and cooling systems for them. This is her main area of work. But there is also a highlight in the exposition - inno3D Printer M1, D1 and S1 3D printers.

At her booth, she presented a lot of video cards and cooling systems for them. This is her main area of work. But there is also a highlight in the exposition - inno3D Printer M1, D1 and S1 3D printers.

revealed.

revealed.