Vector 3d printer

vector 3d printer - Buy vector 3d printer with free shipping

vector 3d printer - Buy vector 3d printer with free shipping | Banggood ShoppingBrands

SEE MORE

RC Drone Spare Parts

Working Type

Plug Type

Printing Size

Printer Filament Material

3D Printer Function

Closure Type

Decoration

Hardness

Pattern Type

Bags Structure

-

Home

- "" 515 Results

Price -

OK

Ship From

1 2 3 4 . .. 9

Total 9 pages

Go to Page

Go

Confirm your age

You must be at least 18 years of age to enter this section.

I AM UNDER 18 I AM OVER 18

Vector best 3D printer files・Cults

Airsoft Chris vector body kit

€4

3D Printable Kriss Vector 9x19mm

€6.10

KRISS VECTOR Style AAP KIT

€40

kriss vector v2 (step)

€25

Chinese Peking Opera Facebook cdr dxf file format

Free

If you are looking for a laser cut wooden box vector file then this design might be for you. This file includes a downloadable laser cut wooden box vector file for CNC router/laser cutting that you can cut on your CNC today.

Free

Laser Cut Bus Wooden Layout dxf cdr,file format

Free

Laser Cut Wooden Morgan 3 Wheel Car Puzzle Kit DXF File

Free

Seashell cookie cutter

€1

Boogie Bot V1 from Poppy Playtime (Huggie Wuggy)

€2

SL_ST NAUGHTILUS SUBMARINE in progress

Free

Vector optics,Veyron parallax wheel

Free

Airsoft Krytac Vector Drum Mag Adapter

€5.17

cookie cutter Silhouette of a rhinoceros stock illustration Africa, Kenya, Rhinoceros, Vector, Head

€0.69

cookie cutter Wild African Hornbill, Outline, Vector, Animal

€0.69

cookie cutter Dachshund dog. Vector black silhouette. stock illustration Dachshund, In Silhouette, Vector, Contour Drawing, Drawing - Art Product

€0. 69

69

cookie cutter Bull Silhouette stock illustration Illustration, No People, Vector

€0.69

cookie cutter Cat, silhouette stock illustration Domestic Cat, In Silhouette, Cut Out, Profile View, Vector

€0.69

Krytac Kriss Vector wall mount

€2.99

Krytac Kriss Vector multi pack - PACKAGE DEAL - R3D

€13.82

Krytac Kriss Vector rail system pack of 3 - R3D

€4.32

Krytac Kriss Vector Display Stand - R3D

€2.88

Krytac Kriss Vector dummy mag - R3D

€2.30

Krytac Kriss Vector Battery Extension x3 sizes - R3D

€3.45

Battle Tech | Sci-Fi Tabletop Proxy Batch - K Penney Spring 2022

€6.73

Vector - cosplay mask

Free

Vector W8 1992 Printable Body Car

€8. 33

33

Vector W8 1992 Printable Car

€12.50

Krytac Kriss Vector battery storage extension

€2.99

Decorative geometric panda

€0.50

Candy Cart Model For Laser Cut or CNC Router

€5.75

3D NUMBERS DESIGNS FOR LASER CUT & CNC ROUTER

€9.88

CUTE RETRO TOASTER SOAP DISH!!! EASY TO PRINT!!!!!

€2.83

3D Number 90 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 80 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 75 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 70 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 60 Gift Box Design For Laser Cut & CNC Router

€3. 82

82

3D Number 50 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 40 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 30 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 25 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 20 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 15 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Number 10 Gift Box Design For Laser Cut & CNC Router

€3.82

3D Numbers Gift Box Designs for Laser Cut & CNC Router

€15.01

ADAM LEAF TYPE NAPKIN HOLDER

€1.24

NICE LEAF SOAP DISH - EASY TO PRINT

Free

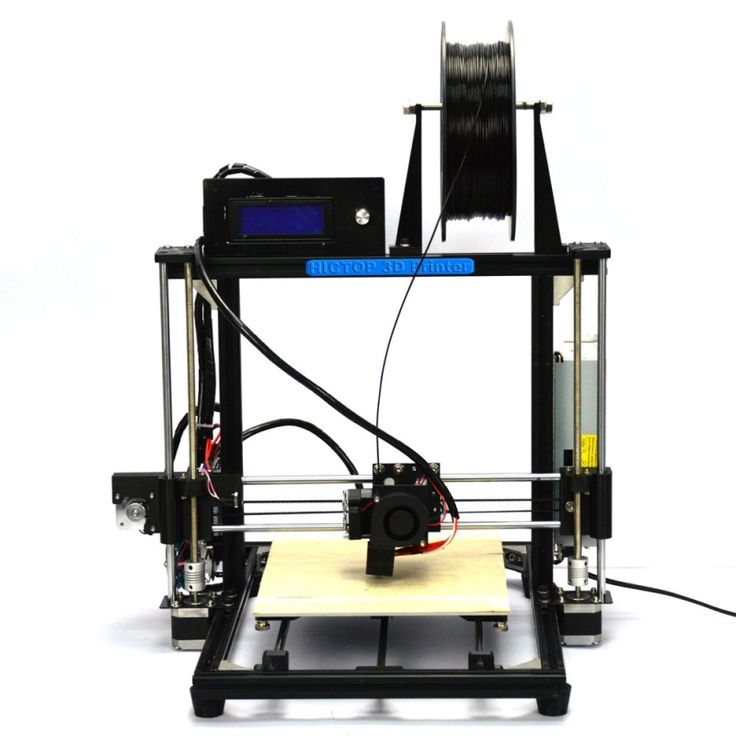

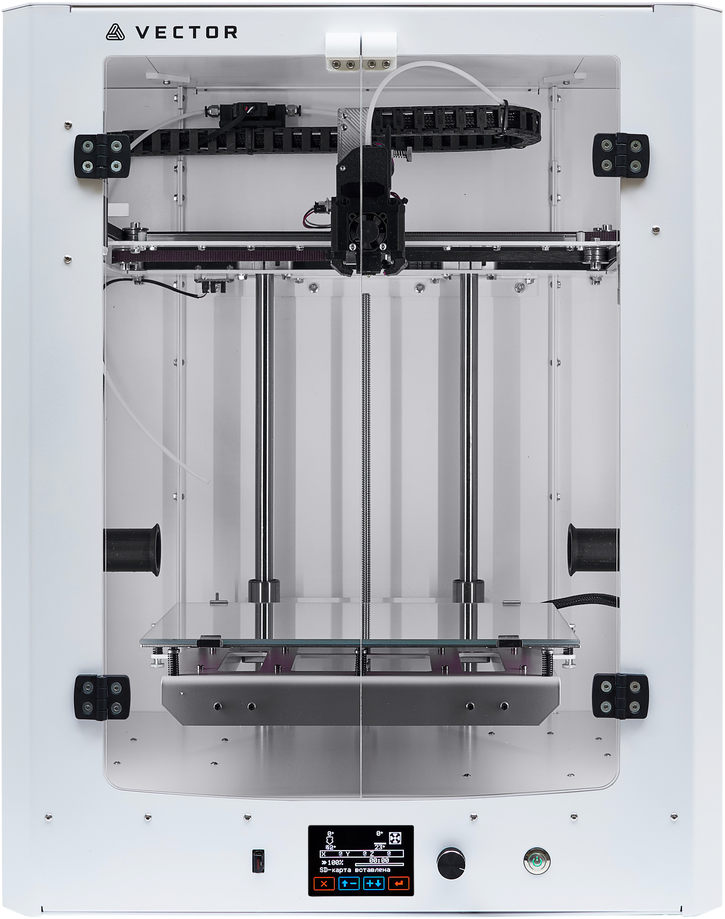

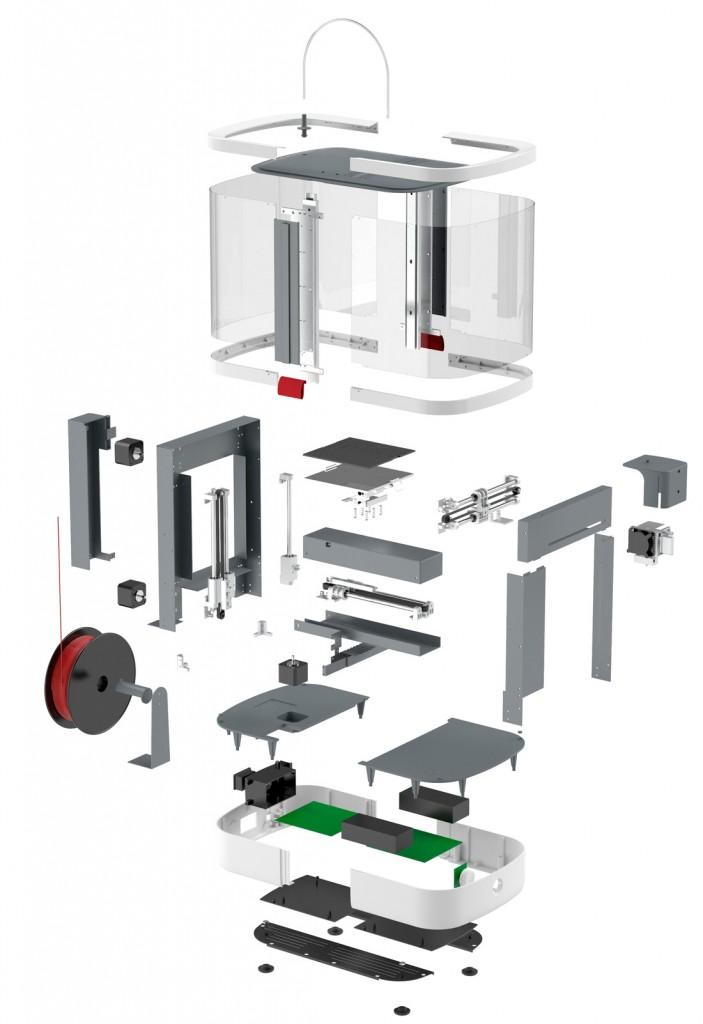

I did not expect this 3D printer Vector 200

Hello everyone!

Today I will tell you about my new acquisition, Vector 200 from Geralkom . I'll tell you about its characteristics, strengths and weaknesses. And I will also share my impressions of using the printer.

I'll tell you about its characteristics, strengths and weaknesses. And I will also share my impressions of using the printer.

By its name, you can already understand that 200 is the size of the working area of the table 200 by 200 mm. And along the Z axis, the working field is 210mm. I am one of those people who find it easier to glue a model from several pieces. Than overpaying a lot of money for a printer with a large table. To print something more once a year. Over the many years of my life with a 3D printer, my experience has shown that a 200x200mm table is enough for home printing and small businesses.

But let me start from the beginning. It all started with my friend knowing how much I dislike dark and gloomy printers. Pleased me with the news that a white printer appeared on the market.

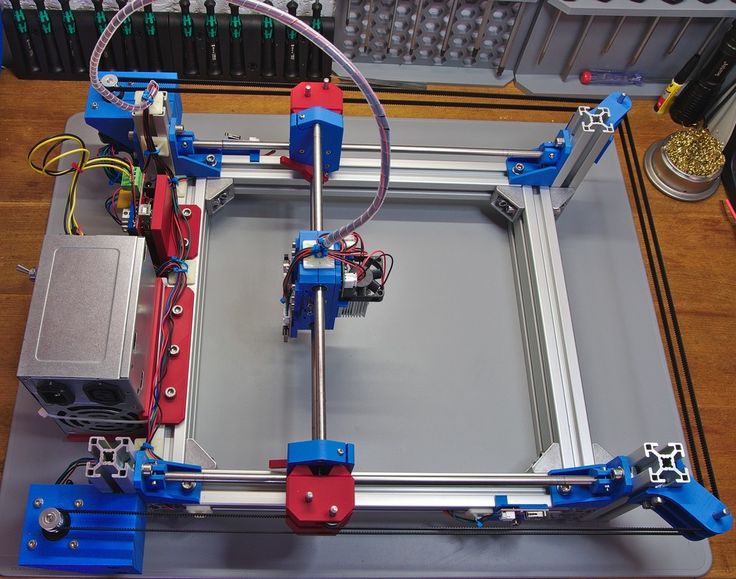

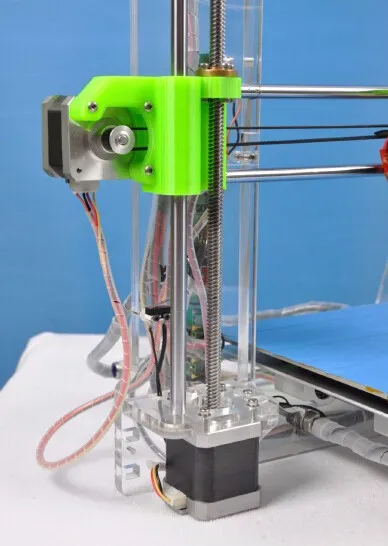

I became interested and started looking for information about him. And since the model was fresh, there was very little information. I just found out the kinematics of his H-bot extruder Direct and he is white. According to this information, not everything was clear and I wanted to fix it. Then I started asking the manufacturer to give me a printer for review. It lasted about three months, and finally the day came when I went for the printer.

I just found out the kinematics of his H-bot extruder Direct and he is white. According to this information, not everything was clear and I wanted to fix it. Then I started asking the manufacturer to give me a printer for review. It lasted about three months, and finally the day came when I went for the printer.

First look, equipment and appearance.

I won't talk about the configuration for a long time. While I am writing an article, the manufacturer is still looking for the ideal price and kit option. This may change in the future. I had the kit as pictured. Only another spool of PLA plastic 0.75 kg.

At the expense of appearance. They say it's all a matter of taste. And the taste and color of all felt-tip pens are different. So it's up to you to decide whether you like it or not. I really like it. Having brought it home and on the very first day I filled the TPU coil from FDplast (who does not know this is one of the most flexible rubber-like filaments in Russia). And about a miracle! From the box. Without any settings. On the profile from the manufacturer, I got a very high quality print. Airflow was broken on my old printer. And I have decently accumulated projects that needed airflow. And then it began! For a month, almost day and night, the printer worked without stopping the nozzle.

And about a miracle! From the box. Without any settings. On the profile from the manufacturer, I got a very high quality print. Airflow was broken on my old printer. And I have decently accumulated projects that needed airflow. And then it began! For a month, almost day and night, the printer worked without stopping the nozzle.

One simple moment can probably explain such an unbridled thirst for printing. To print something, it was enough just to change the temperature for the plastic and turn the blower on or off. Instead of digging through a pile of settings with the hope that it will be better than last time.

Here are some of the things that were printed with this printer.

Well, it would probably be logical to show you closer. What pleased me the most. So this is a flat surface with a minimum number of artifacts. To be honest, this is the first time in my life that I have such print quality. If the plastic is not damp and dumb, then the details are of amazing quality. I even almost stopped using my grinder. Pay attention to the seam that forms at the beginning of the layer. With bowden, I had big problems with this seam.

I even almost stopped using my grinder. Pay attention to the seam that forms at the beginning of the layer. With bowden, I had big problems with this seam.

And in this picture you can clearly see the difference between the printed parts on the Vector and on the Flying Bear. I used the same plastic and temperature conditions. (Not a big deviation). Last year I lived with a Bowden printer and despite the fact that the printer is good, the Bowden feed just killed me. That will loosen the tube due to which under-extrusion at the beginning of the layer. Then you have to put such retracts that the motor on the extruder goes crazy. And the advantage of a light head is negated. You try to print in flex and it's not that it doesn't print. But there are so many nuances and torments that I vowed to convert all my bowdens to direct and forget about these torments).

That's why the direct printer out of the box was like a breath of fresh air for me.

These were not all the details. Many immediately went to my friends and I did not have time to photograph them. But there was one very large project, which I took some pictures of.

Many immediately went to my friends and I did not have time to photograph them. But there was one very large project, which I took some pictures of.

A friend modeled a rider with a horse on the iPad and it was almost 40 cm long. Because of this, the whole model was cut into 13 pieces and printed with a layer height of 0.15mm. And small details in general with a layer height of 0.05mm. There were two such riders. And it took me a week and a half, almost around the clock printing. All parts of the horse were printed from ABS plastic. And on the example of the tail, it is very clearly seen that despite the ABS and the small area of \u200b\u200bcontact with the table, the tail did not fall. And all this thanks to the precise feed of the direct extruder. I couldn't print like that on a Bowden. The nozzle constantly clung to some bumps and influxes of plastic. Which led to knocking down fine details. In this photo, the infill was being printed at 80mm per second. You can judge the quality yourself.

After I printed two horses, the author of the model glued all the parts (I want to note that he had never encountered printing before and did everything for the first time). Then I applied a thin layer of epoxy and walked a little with fine sandpaper. I first applied a layer of black primer. And then covered it with paint that tries to look like bronze. The result of all these manipulations, you can enjoy in the picture below. that after the purchase I did not set up anything and did not finish it with a high-precision file. The result made me happy.

Useful printer features.

- The printer comes with an auto-off module from the box. This is an important option. Since in the event of some kind of breakdown, the printer will turn itself off and prevent fire, self-destruction or something else :). An auto-off bonus is a button on the front panel. With it, it is very convenient to turn the printer on and off. Especially when he stands close to the wall, you need to squeeze your hand and look for the button by touch.

Believe me, I know what I'm talking about.

Believe me, I know what I'm talking about. - It has a competent backlight that does not hit the eyes and illuminates the model well. This is one of the very useful things that everyone usually completes themselves. But here everything goes factory and we can only enjoy life.

- My favorite trick that not everyone understood. So it's not a bug, but a feature. The spool holder is inside the printer and only holds a 750g spool. But what if we have a kilogram? With a slight movement of the hand, open the lid, which is held on neodymium magnets and turn it over. Voila, we can fit any kilogram coil. I was also pleased with the fastening not from the back, but from the side. ( I hate rear mounting ) But if you decide to earn money and print a lot with this printer, then there are holes on the back wall for attaching a 2.5kg coil. In general, thought out for all occasions.

- The printer is fully enclosed and ready to print out of the box. Plastics such as ABS, Nylon and so on.

And since I print ABS in 95%, I accordingly paid attention to this not least.

And since I print ABS in 95%, I accordingly paid attention to this not least. - Well, then there are many little things that I will write in one paragraph.

- All coolers come with bearings.

- Head wires are connected via an adapter plate. Thanks to this, you can quickly change the heater, thermistor or fans.

- The cable channel is not simple, but tricky. With the ability to snap off the segments and lay new wires with a slight movement of the hand. A trifle, but nice.

- Table for 220v and it is grounded.

- Good two-way airflow for the model. My life tests showed excellent results on PLA plastic.

- This is my first experience with H-Bot kinematics and I had some concerns about the long strap. Like, it can stretch and affect the print. Fears were not confirmed. It turned out that Hiwin rails are a very good solution. And you do not need to change bearings every half a year. As it happens on roller printers.

- I don't even know if it makes sense to say that HIWIN's accurate MGN-9 rails are not cheap.

Which directly affects the quality and life of the printer. I am very glad that the manufacturer stopped on them.

Which directly affects the quality and life of the printer. I am very glad that the manufacturer stopped on them. - There are very few printed parts in the printer, but enough milled aluminum parts. Which adds another plus sign to karma.

- Optical end switches that do not click.

- Complete USB stick. And what a flash drive! Which does not stick out of the case.

- Proven power supply from the Taiwanese company MEAN WELL for 24 volts.

- By default there is a thermistor, which works up to 300 degrees. Optionally, you can install another one that works up to 350 degrees. As a matter of fact, I have one. Therefore, there will be more interesting videos with tests of high-temperature plastics. Don't forget to subscribe to .

- Branded motors Stepperonline.

- Motherboard Robin nano v3 with quiet drivers on all TMC2209 motors.

It may seem that my sugary review is paid. And everything that I wrote here is presented through the prism of that mountain of money that was brought to me. But let's immediately dot the "I"! (Although I still don’t understand where her dots are, I’ll still clarify the situation).

But let's immediately dot the "I"! (Although I still don’t understand where her dots are, I’ll still clarify the situation).

I took this printer for review on my own initiative. After a week spent alone with the printer, I realized that I would not return it. Therefore, I added the manufacturer to the black list and use the printer with pleasure! :D It's a joke, I just bought the printer from Geralcom and my fee for the review was a discount on the purchase.

Therefore, everything that I wrote above and will write below is my personal experience and my impressions. I really liked the printer and for two months of everyday work with it. I have not had a single skipped step or aborted prints due to the printer. (Well, I can't really blame the printer for the overlap on the spool)

So my conclusion is this. The printer is very hardworking, stable and problem-free. Who does not want to deal with finishing and alterations, but buys for work from the box. It's his choice.![]()

I was pleased with many thoughtful things and his appearance.

Shortcomings:

With all my laudatory reviews. The printer has a number of things that I didn't like.

- For all its specifications, the printer is quite noisy. Especially the hot end blower cooler. With the door closed, there is less noise, but probably you won’t be able to sleep in the same room with him. And I have something to compare with and I have slept with the printer in the same room more than once. At what printed ABS. (Here I am such a kamikaze).

- The aluminum plate of the table is only 2mm, which, according to my subjective feelings, is not enough. Sometimes you have to tighten the table at the beginning of printing, as the calibration is a little off. Not often but still. Although, in general, my table is flat and details in the entire area are printed without problems.

- The wires to the fans on the hot end are a bit inconvenient. Because of what, when you remove the cover with fans, you need to get used to putting it back.

If you do not do this carefully, you can damage the wires.

If you do not do this carefully, you can damage the wires. - I've heard complaints from people who opened the lid for the first time, which is only held on by magnets. They managed to drive this cover over the metal case. But this is only the first acquaintance. If I were the manufacturer, I would stick some kind of warning on the lid and when unpacking, a new person would not step on this rake. Because I really like this mount and it greatly expands the degree of freedom and access to the printer components.

- Someone complained about the weight of the printer. But here it is more a virtue than a disadvantage. You don't carry the printer from room to room. Install it in its place and print. I personally like its armor-piercing hull.

Well, I will end on this note. You can buy a printer HERE, and subscribe to my channel HERE.

Thanks to everyone who read to the end! I appreciate it and for this I am going to do the next project! Fortunately, there is something to print it on! ;)

Have a good mood and no problem printing!

Vector 200 from Geralkom - a 3D printer with an iron character!

Hello friends!

Recently, Geralkom sent a Vector 200 printer for me to work on, give feedback on the printer, and of course review.

Video review here!

In the video, I analyzed the printer in detail... Here I decided to briefly talk about it, list the pros and cons, in my opinion, and tell how I use it. Since very often they ask how he is to me!

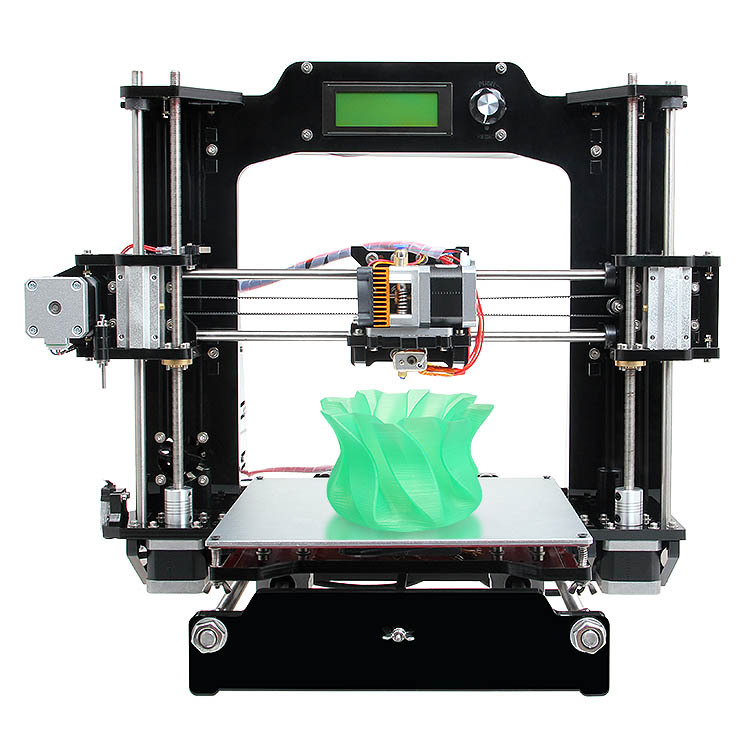

I liked the printer even before I took it out of the box, as a baby with a print area of 200x200x210 mm weighs not quite childishly. The large weight of the printer will give it greater resistance to the inertial forces that occur during printing.

The body of the printer is made of sheet steel 2 mm, and in some places 3 mm using laser cutting and bending technology.

Printer in white color, outwardly looks very good and without unnecessary design frills.

The printer body has 3 hatches on board:

- top cover with magnets for easy operation and maintenance of the printer. And also this cover needs to be removed for printing with fusible plastics;

- left hatch with filament holder. Thin coils go inside the printer, and those that are larger can be placed outside simply by turning the cover with the holder, since the cover is held on magnets here too;

Thin coils go inside the printer, and those that are larger can be placed outside simply by turning the cover with the holder, since the cover is held on magnets here too;

- and of course the transparent Plexiglas door on the front.

H-bot printer kinematics on rails and MGN-9 carriages from HIWIN along the Y and X axes. There can be no question of any twisting of the case, since the case itself is rigid from 2 mm steel and kinematics sits on a 3 mm plate.

Also attached to this plate are motors with belt pulleys on the rear and idler pulley supports on the front. The idler pulley supports are mounted in milled pieces that look very solid.

Beam X-axis steel 3 mm, heavy of course, but for such a small size tolerable.

Moreover, I will not "drive" at high speeds! I believe that speeds up to 100 mm / s are optimal, and at higher speeds, printer parts will wear out faster.

The printer table is a 3 mm plate with windows cut out for lightness and 2 corners screwed on for rigidity. On top, a sandwich of silicone heating pad, aluminum sheet and a mirror is standard on the springs.

On top, a sandwich of silicone heating pad, aluminum sheet and a mirror is standard on the springs.

220 volt heating pad 250 watts quickly heats the printer bed up to 120.

The bed is driven on 16 mm polished rollers by means of an 8 mm trapezoidal screw.

Trapezoidal nut is made of wear-resistant polyacetal plastic and has proved to be good: no play, no squeaks and noise.

Print head (extruder)

The printer's maximum print temperature is 300 degrees. The extruder is naturally direct configuration. Milled aluminum parts are screwed onto the carriage, to which a short NEMA 17 and the feeder itself are attached, here it is a BMG extruder with an E3D V6 heatsink. Pretty simple and at the same time reliable solution.

The radiator is blown by a very powerful 30 mm fan. The fan is a bit noisy. But as practice shows, noise and good airflow are better than silence and traffic jams in a thermal barrier.

2 radial fans with nozzles are responsible for blowing the print area, which I managed to shake in the first week of printing on the printer. I printed from nylon, the part came off and, touching the airflow, warped it, I had to cut off the melted parts for a while. In the future I will print from more heat-resistant plastic.

I printed from nylon, the part came off and, touching the airflow, warped it, I had to cut off the melted parts for a while. In the future I will print from more heat-resistant plastic.

All fans are mounted on a common printed housing, which can be easily removed for convenient maintenance of the hotend. I really liked this constructive solution, it's really convenient. This case is in the form of a latch and is fixed on the throat of the radiator.

There is a very steep belt tensioner underneath the motor. It is also made of aluminum and for stretching it is enough to turn the screw in the right direction.

Under the "hood" you can immediately see everything thought out and neat, all wires are crimped and where necessary in heat shrinkage. Thick bundles of wires are packed in a cable channel.

MKS Robin NANO control board version 3.0

Drivers all TMC 2209 with nice big heatsinks.

Meanwell power supply 24 volts 150 watts.![]() Nearby is a relay for the table.

Nearby is a relay for the table.

Printer auto shutdown card included. And here is my respect to the developers. I think the auto-off feature should be in every modern printer!

In the final G-CODE in the slicer, I entered the command to automatically turn off the printer. Which is very convenient and relevant leaving the print for the weekend. The printer will print and turn itself off when the nozzle cools down to 45 degrees! And all the fans in the printer, by the way, turn off when the nozzle temperature reaches 60 degrees.

All end switches are optical!

The printer has an interior light.

3.5" touch screen printer. The firmware of the Marlin printer and the screen shell are also Marlin. Which in a compartment gives a very inconvenient screen to use! And on this note, let's move on to the minuses of the printer.

Cons of the printer

The printer works in a workshop, in a separate room, so such a minus, for example, as noise, is not critical for me. But I will try to list the disadvantages not only from the point of view of a person printing parts to order in the workshop, but also remember how it is to print at home and list the disadvantages for normal home use.

But I will try to list the disadvantages not only from the point of view of a person printing parts to order in the workshop, but also remember how it is to print at home and list the disadvantages for normal home use.

1. Firmware and screen shell for Marlin. This is the main downside for me. I print a lot and a convenient printer screen is a must. I don't need a bunch of fine adjustments that the Marlin firmware gives me, I need quick access to heat profiles and start printing. Immediately, you need to press the screen a lot of times to start pre-heating, to start printing, etc. Now the manufacturer puts an encoder in addition to the touch screen, maybe it’s more convenient there, but that’s how it is for me.

Also in the firmware there is a timer for idle time, you start pre-heating and go to slice the model ... You come, and the printer is already cooling down.

It is clear that all this can be easily corrected, which I will do and the manufacturer is also working on it, but I am talking about what is now.![]()

2. The printer is noisy. The main noise is a powerful radiator fan. And also the metal case is a supporting frame and when the engine is running, the noise from it is transmitted to the case and it is audible.

3. The backlight of the printer is set below the table when it is up and there is not quite enough light from it. At least for me, for filming the printing process. But according to Geralkom, they fixed it and now the backlight goes almost to the top cover.

And the backlight is always on, there is no off button. I want to turn off the light when leaving for the weekend with a long press. Here, too, the manufacturer has made turning off the backlight from the screen, but you have to throw the wires a little.

Total

The rest of the printer is very good! I didn't think I'd like it that much. It's tough, heavy, and prints faster and better than other printers in my small fleet. In addition, the printer arrives fully assembled and ready to go, just calibrate the table, although in my case the table was already calibrated! 😱 😱 😱

The fans turn off by themselves and the printer with the full shutdown function can be put on long-term printing without fear that it will finish at the height of the weekend and turn the turntables.![]()

I have a Vector 200 for single orders that require higher precision and print quality. I installed a hardened nozzle and mostly print composite materials on it and it handles it very well. The camera inside the printer when the table is heated to 120 degrees in an hour can warm up to 55 degrees and these are excellent conditions for most plastics with noticeable shrinkage.

FAQ: Can you recommend this printer for purchase? In general, recommending an expensive device is a big responsibility! But I can recommend this particular printer, since I myself have been working on it for a long time and the flight is normal. The printer is very simple in design, which means less chance of breakdowns.

The printer can be expensive for occasional home use, but for frequent use or for custom printing like I do, this is a great reliable machine!

Almost all examples of work on this printer can be viewed on my Instagram, where I sign in the posts on which printer the product was printed.