Cost of materials for 3d printing

How much does 3D printing cost?

David Roberson21 September 2021

Guide

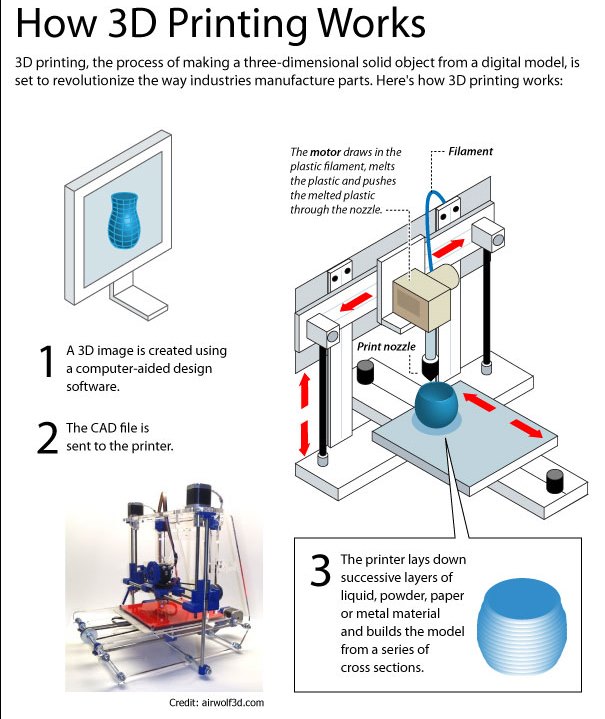

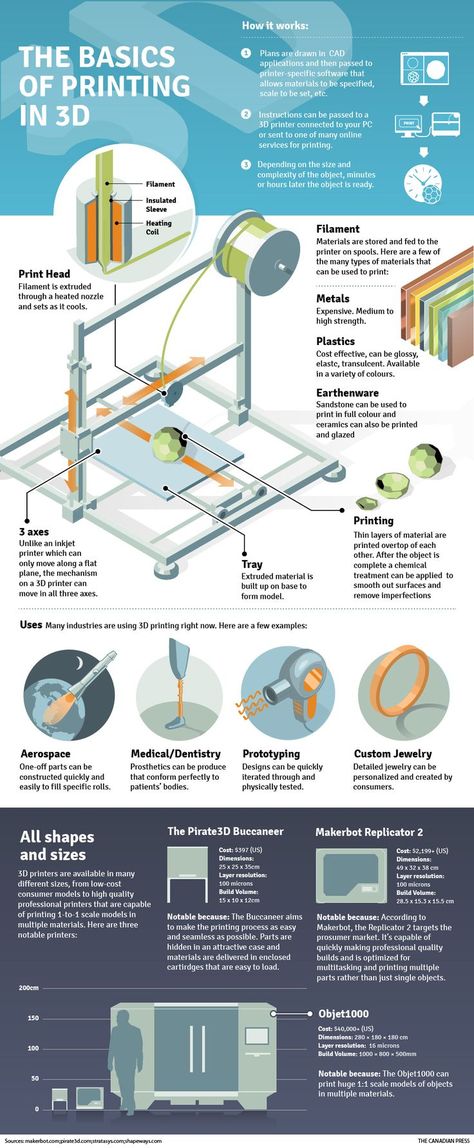

Once you understand how 3D printing works, it's important to talk money. A 3D printer should be a long-term asset for your organization that delivers value for years after you buy it. But how much does 3D printing cost?

This return on investment is a benefit that sets 3D printing apart from other solutions like outsourcing. But as with any long-term asset, it pays to be aware of all the associated costs that come with owning a 3D printer, and which expenses – including 3D printer material costs – you need to plan for into the future.

The list below should help you understand the costs involved, how they differ depending on the technology, and which are one-off or repeating. (Prices are indicative and subject to change – so we recommend doing your own research too.)

3D printer price

With products on the market for anyone from a home user to the R&D divisions of blue-chip companies, 3D printer prices vary a lot. Typically, FFF offers the greatest variation in price, from hobbyist machines costing a few hundred dollars to higher-performance desktop printers in the $2,000 to $6,000 range. Desktop SLA printers start from around $2,000 to $3,000, while an SLS printer typically costs $10,000 plus. Larger-scale industrial machines of any technology will cost significantly more.

Peripherals

These can add extra functionality, but also add extra expense your 3D printing costs. Post-processing peripherals are almost essential for SLA and SLS printers. For example, SLA prints will otherwise have to be manually washed in isopropyl alcohol and left in the sun to cure – so in practice, these printers often require purchase of post-processing stations unless that appeals to you! For FFF, peripherals can streamline workflows such as material handling, but are up to you depending on your needs.

Maintenance and service

Typically, this should only be the cost of replacing the odd consumable part over time. Check what support your seller includes as part of the price – they may offer installation and maintenance included. Some products also come with extended warranty options or an annual service plan. These plans can add certainty for some customers, but be sure to read the fine print in detail to understand the terms and exactly what support you get if something goes wrong.

Check what support your seller includes as part of the price – they may offer installation and maintenance included. Some products also come with extended warranty options or an annual service plan. These plans can add certainty for some customers, but be sure to read the fine print in detail to understand the terms and exactly what support you get if something goes wrong.

Energy

For regular use for an Ultimaker 3D printer, we calculated this to be around $50 per year. But if you want a more precise figure, check the power consumption specs of a 3D printer and make a calculation based on your likely usage and local energy prices.

Materials

Think of material costs like gas for your car. While not considerable in isolation, over the long-term it will be one of the biggest running costs. For FFF 3D printing, 3D printer filament prices (for an everyday material like PLA or PETG) are around $20 to $50 per kilogram, or $60 to $120 for specialized engineering or support filaments. Entry-level SLA resins cost around $50 per liter, and most professional options cost around $150 to $400. SLS powder can cost around $100 to $200 per kilogram.

Entry-level SLA resins cost around $50 per liter, and most professional options cost around $150 to $400. SLS powder can cost around $100 to $200 per kilogram.

Software

Most professional level 3D printers come with some software included, usually so you can prepare your prints and manage printers. Many cheaper 3D printers don’t come with adequate software, but luckily our Ultimaker Cura software is compatible with hundreds of machines and free to download. And if you really want to scale 3D printing in your business unit or even entire organization, consider an enterprise software plan with added features like direct support, online training courses, and cloud storage for your parts and projects.

You can learn more in our total cost of ownership white paper – available to download for free.

A 3D printer is part of an ecosystem that includes peripherals, materials, and software – either from the manufacturer or third parties

Need more info on 3D printing?

Explore the wider world of this incredible technology by reading our answers to these common questions:

What is 3D printing?

What can you make with a 3D printer?

How to use a 3D printer?

How Much Does 3D Printing Cost? Cost to 3D Print Objects – 3D Printerly

When it comes to 3D printing, many people wonder how much it costs to 3D print an object, whether that is a small item like a miniature figure, or a larger item like a helmet or mask that they can wear.

There are quite a few costs associated with it which can get a little confusing, so I decided to write an article about how much it costs to 3D print an object in filament or resin.

If you already have a 3D printer, your cost is just the filament and electricity for the most part. To 3D print an object that uses 100 grams of filament, it will cost around $2.50 using a price of $25 per KG of filament. The same 3D print in resin will cost around $4.50 using a price of $45 per KG of resin.

Costs don’t fluctuate too much due to a fairly constant price of materials, though you’ll want to do basic maintenance and maybe some post-processing afterwards.

Let’s go through the basic costs of 3D printing so you have a better understanding of how much it costs to 3D print an object. Keep reading for a more detailed answer.

How Much Does A 3D Printer Cost?

In order to 3D print an object, we’ll need to look at the biggest initial cost which is the 3D printer. Luckily for normal consumers, 3D printers have drastically decreased in price as time has gone on.

Luckily for normal consumers, 3D printers have drastically decreased in price as time has gone on.

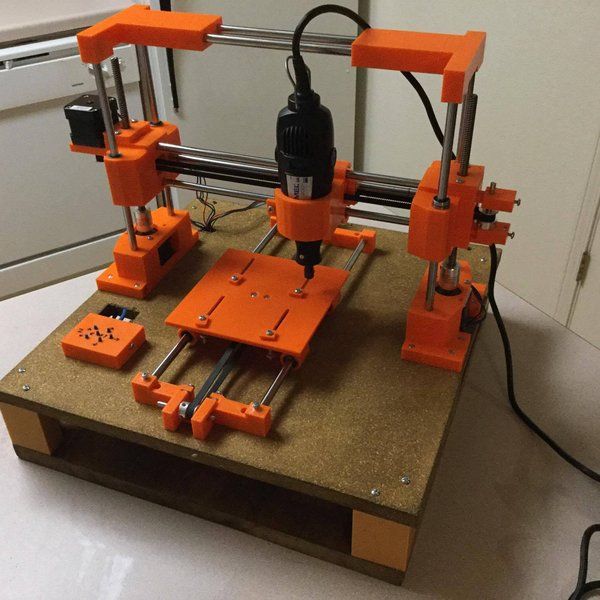

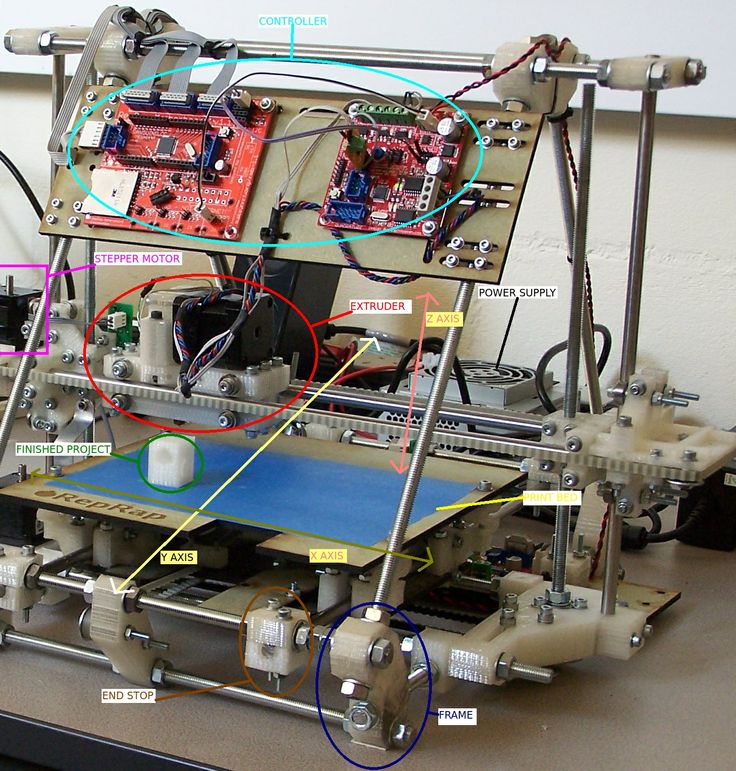

The materials that are required for creating 3D printers are increasing in supply, as well as the number of manufacturers that are competing in the space. For a standard FDM filament 3D printer like the Ender 3 (Amazon), you can get this for around $200.

The other type of 3D printer which is growing in popularity is the SLA resin 3D printer. A budget SLA resin 3D printer like the Elegoo Mars 2 Mono is currently around $230, which is a lot cheaper than what they used to be.

Previously, you would have been looking at least $1,000 for a basic version of these 3D printers, so it’s something a lot more manageable for us average users.

These are great for entry-level hobbyists, though if you want more practical features, you’ll want to spend more.

The Artillery Sidewinder X1 V4 (Amazon) is around $450 and is a great option for a filament 3D printer.

It comes 95% pre-assembled, so a beginner can put it together very easily, and comes with a much larger build volume than the Ender 3 at 300 x 300 x 400mm.

It has a touch screen operation display, as well as a direct drive extruder which makes printing some materials a lot easier.

The design is a lot cleaner, compact, and professional looking, and since it’s a long-term machine, makes sense to invest a good amount into it.

The Anycubic Photon Mono X (Amazon) is around $700 and is a great option for a resin 3D printer. It also comes mostly pre-assembled, just requiring you to place a few parts in the right places, and put in the power supply. The bed leveling process is very quick.

The main upside of the Photon Mono X over the Elegoo Mars 2 Mono is the build volume of 192 x 120 x 245 against 129 x 80 x 150mm. This is large for a resin 3D printer and with the 8.9” 4K resolution screen, it significantly increases printing speed (up to 3x).

Another key benefit is how the LCD screen in the base of the printer is designed to last about 4 times longer than the outdated RGB screens for 2,000 hours of printing. The screen is what produces the light to harden the liquid resin into plastic.

The screen is what produces the light to harden the liquid resin into plastic.

Now that we have the 3D printers out of the way, let’s look directly at the materials so we can accurately figure out how much it costs to 3D print an object.

How Much Do 3D Printing Materials Cost?

There are two main types of materials when it comes to 3D printing – filament and resin. Filament starts at around $20 per KG, while resin starts at around $35 per KG.

Filament is packaged up as a round spool of plastic which usually sits on top of the 3D printer with a spool holder for FDM printers.

Resin comes in a dark bottle with UV protection and is full of the photopolymer liquid resin that you pour into the resin vat of your SLA resin 3D printer. It has to be stored this way because the liquid hardens to UV light.

How Much Does 3D Printing Filament Cost?

A standard spool of filament will cost you anywhere from $20-$30 per KG, but there are many types of filaments that you can get.

PLA – Hatchbox PLA on Amazon goes for around $25 per KG.

ABS – Hatchbox ABS on Amazon goes for around $22 per KG.

PETG – Overture PETG on Amazon costs around $21 for 1KG.

TPU – Ninjaflex NinjaTex TPU costs around $33 for just 500g, or you can get Hatchbox TPU for around $31 for 1KG.

ASA – Overture ASA filament costs around $32 per KG on Amazon. Polymaker Polylite ASA is another popular brand of filament that costs around the same price.

Nylon – Overture Nylon filament costs around $35 per KG on Amazon.

How Much Does 3D Printing Resin Cost?

The two most popular brands of resin are the Elegoo Rapid Resin and the Anycubic UV-Curing Resin which cost around $35 per KG. These are great quality resins that can definitely produce high quality models.

They cure/harden fairly quickly, have fairly good levels of toughness and rigidity, as well as having excellent fluidity so it can be easily cured into complex and detailed shapes.

You can get more premium resins that offer characteristics such as higher durability and strength, more flexibility, mechanical-grade tough resins and even professional-grade dentistry resin.

Elegoo Water Washable Resin costs around $40-$45 per KG and it allows you to wash your resin models with just water rather than isopropyl alcohol.

Siraya Tech Tenacious Flexible & Impact-Resistant Resin costs around $65 per KG and provides users with a premium resin that works very well.

The great thing about this resin is how it can actually be mixed with other resins to increase their strength, flexibility, and even detail. One user even tested a piece printed with this resin by running over it with his truck without the 3D print breaking.

Formlabs Model Resin costs around $150 per KG and is a specialized resin that is high-precision and high accuracy. It’s specifically used in the dental field but can still be used to create high detailed models.

This is only compatible with Formlabs 3D printers such as the Form 3, Form 3L and Form 3BL.

Just to complete the knowledge with 3D printing materials, I’ll briefly mention metal powers for metal 3D printers.

A popular metal power like Aluminum Alsi7mg can cost between $24-$26 per KG, though the 3D printer itself can set you back $50,000 – $1,000,000, so this isn’t too relevant for individuals like us – rather industrial companies.

How Much Does 3D Printing Cost? Other Materials

When it comes to 3D printing, after you have your 3D printer and filament, there are other costs associated that is worth paying for.

You have the option to be as cost-effective as possible, but if you want the best 3D printing experience, I’d recommend getting some extra items.

Elmer’s Disappearing Glue

Elmer’s disappearing glue is one of the best glues to use when it comes to 3D printing purposes. It is called disappearing glue because it is usually purple when you apply it but turns clear once it dries.

This glue has been manufactured using an acid-free formula which makes its adhesive properties spectacular. You can glue different parts of your model without worrying about them coming off.

You can glue different parts of your model without worrying about them coming off.

It is also non-toxic, which makes it suitable for use when 3D printing at home, school or in a workplace.

One user found it particularly useful because it helped his prints stick to the hot bed until the print job was completed.

Check out Elmer’s Disappearing Glue on Amazon.

Sandpaper Assortment

Austor sandpaper is made from silicon carbide which provides a wet or dry sanding experience. One package of this Sandpaper assortment comes with 102 pieces of assorted abrasive sheets in different grits ranging from 60 to 3,000.

This sandpaper has been specially manufactured to be efficient with automotive sanding, and wood furnishing, but works very well with 3D prints. It is one of the toughest sandpaper out there offering high quality natural abrasion.

This makes it suitable for sanding and polishing 3D models after printing. One user said that he used it when working on his resin print and it helped him achieve an almost glass finish.

Check out the Austor Sandpaper Assortment on Amazon.

Primer/Spray Paint

Rust-Oleum primer is a water-based primer designed for exterior use in a wide range of products like furniture, laminate, PVC, railings, galvanized steel and thermoplastics.

This primer has a low odor which makes it favorable to use on 3D models before painting. It is also dries in 30 minutes. You can also spray it in humid environments and it should still work great.

One user said that she sprayed this primer to on his prints before sanding and finishing and it worked fantastically.

You can find a can of Rust-Oleum 2-In-One Filler & Primer Spray from Amazon.

Paint & Paintbrushes

Painting finished models improves their aesthetic value and enables you to add a personal touch to them. You want to use the right type of paint that works well for 3D printer objects and miniatures.

I’d recommend going with the Caliart Acrylic Paint Set with 24 Vivid Colors from Amazon.

Acyrlic paints and paint brushes are the perfect tools for coloring your printed models. They are bright and can be used on a variety of surfaces e.g. ABS, PLA, PETG and wood.

In terms of paint brushes, I’d recommend going with the Soucolor Acrylic Paint Brushes Set 20 Pcs from Amazon. They come with many fine brushes that can paint some great detail on miniature 3D prints and other 3D printed objects.

Store paints from the hardware can be too thick and even end up clumping and forming unpleasant layers. Acrylic paints are used since they cover a greater surface and are easy to use.

These aren’t necessary for 3D printing, but it will definitely give you a better overall experience with the kind of quality you can get from your models.

3D Print Cleaning Kit

Having a 3D print tool kit/cleaning kit is a great set of parts that you’ll want when you start 3D printing.

A great set is the Rustark 42-Piece 3D Print Tool Kit from Amazon.

It has several parts for 3D printing, including:

- 14-Piece Knife Set

- Scraper

- Flat File

- Pliers

- Flush Cutters

- Electronic Digital Calipers

- Cutting Mat

- Deburring Tool

- 6-Piece Deburring Blades

- 3-Piece Cleaning Brushes Set

- Glue Stick

- 10-Piece Cleaning Needles

- Zipper Bag

This set of tools helps anyone involved with 3D printing with cleaning up 3D prints to make them look closer to that professional quality. It helps with maintaining the 3D printer also with the cleaning brushes that can be used to clean up the nozzle.

You also have the cleaning needles to help with clearing out the nozzle, as well as the pliers and flush cutters to get rid of excess support material.

One user said that she had been using it for her 3D printer for close to a month now and so far, they were holding up well.

Oils & Lubricants – PTFE 3-In-One

The 3-In-One Multipurpose PTFE lubricant is designed for usage in high temperature environments to reduce friction and protect parts from wear and tear.

This lubricant can work well in temperatures ranging from -50°F to 500°F. It can be used on the Z-axis threaded rod, X-Y guide-rails, lead screws, and bearings to help parts that are in contact to move smoothly.

One user purchased it to lubricate the rails and rods on his printer and it coated better than many oils he found on the market. The only minor issue that he had with it was that the twist close cap would sometimes leak from under the cap while he was applying it.

You can find the 3-In-One Multipurpose PTFE Lubricant on Amazon today.

Cleaning Wipes & Rubbing Alcohol

When it comes to cleaning printer beds and removing dust from 3D printing machines, you want to make sure you do this on a regular basis with the right products.

You can get some pretty bad bed adhesion when you have grease and marks from handling your print bed, so you want to avoid this for more successful prints.

Most 3D printer users have either a bottle of isopropyl alcohol with paper towels, or simply some sterile alcohol wipes. I’d recommend going with Dynarex Alcohol Prep Pads (200 Count) from Amazon for your cleaning needs.

I’d recommend going with Dynarex Alcohol Prep Pads (200 Count) from Amazon for your cleaning needs.

One customer said that the Dynarex alcohol pads were very helpful in dissolving residue on his glass print bed and restoring its surface.

You can also get yourself a bottle of Solimo 99% Isopropyl Alcohol from Amazon. It’s another great cleaning solution for your print bed, and can be used with paper towels or a washcloth.

Replacement Parts

A lot of FDM printer’s parts will need to be replaced after being used for some time. The nozzles last for long when printing with PLA and ABS.

- Brass nozzles

- Hardened steel nozzles

- Stiff bed springs

- PTFE tubing

- Timing belt

Brass & Hardened Nozzles

In terms of brass nozzles, they can be used for a fairly long time when you print simple materials like PLA and ABS, but they’ll need replacement at some point. You can go with the Creality 10 Pcs Brass Nozzles Set from Amazon.

It includes 8 brass nozzles ranging from 0.2mm up to 0.6mm, along with 2 0.4mm hardened steel nozzles.

Compression Springs

A great upgrade that many 3D printer users implement with their machine are those yellow compression springs that go underneath your bed for leveling. The stock springs are usually quite weak and require regular leveling.

When you get something like the 8mm Yellow Compression Springs (20 Pcs) from Amazon, you won’t need to level your 3D printer very often. Some people have leveled it properly once and have not had to level it for months.

This upgrade is likely to save you plenty of time and frustration by giving you consistent and successful 3D prints.

PTFE Tubing

The stock PTFE tube can work fairly well on 3D printers, but after a while they can start to deteriorate. You’ll be better off upgrading it to Creality Capricorn Bowden PTFE Tubing from Amazon.

It has a much higher heat resistance and less friction to give you better successes with your 3D prints.

Timing Belt

The belts on your FDM 3D printer are one of the main moving parts, making them susceptible to wear and tear over time. These can last a good while of printing but after some time, you may need to replace these.

I’d recommend going with the Befenybay 2GT Timing Belts from Amazon when you do need to replace it.

It has a nice copper buckle that has been pre-pressed in order to lock in the belt on your 3D printer.

Although you may think there are many costs with 3D printing and maintenance, when you regularly maintain your 3D printer, it can actually decrease your overall costs because you won’t have to replace parts so often.

Beginners are more likely to have failures due to incorrect bed leveling, incorrect slicer settings, tangled filament or not adding support material. This can significantly drive up the cost of producing prints.

This cost will decrease as you gain more experience from 3D printing regularly.

How Much Does 3D Printing Cost Per Hour to Run?

With a standard flow rate of filament from a 0. 4mm nozzle, a 0.2mm layer height, along with standard electricity and maintenance costs, 3D printing costs around $0.40 per hour. Filament costs around $0.24 per hour, electricity costs around $0.09 per hour, and maintenance costs around $0.07 per hour.

4mm nozzle, a 0.2mm layer height, along with standard electricity and maintenance costs, 3D printing costs around $0.40 per hour. Filament costs around $0.24 per hour, electricity costs around $0.09 per hour, and maintenance costs around $0.07 per hour.

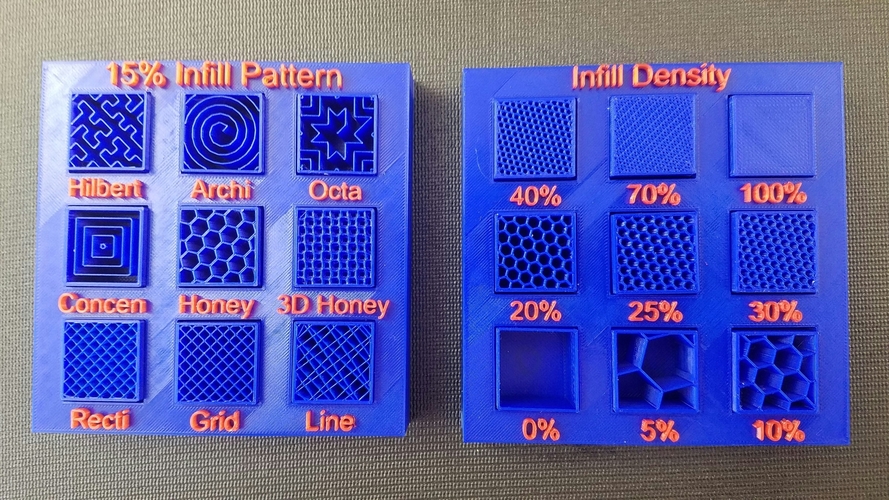

The main costs when it comes to 3D printing is the filament which goes for around $25 per KG of plastic. After doing some calculations with some standard settings, you can figure out how much filament is extruded on an hourly basis.

With the Spider-Man model below, 182g of filament gets extruded in 18 hours and 51 minutes. To calculate this on an hour basis, we take 182g / 18.85 (18 hours and 51 minutes) = 9.655g of filament extruded every hour for this specific print.

To figure out how much this is, we can take $25 per KG of plastic which is 1000g, then divide it by 1,000 to get the price per gram – $25 / 1,000 = $0.025 per gram.

Now we do 9.655 grams * $0.025 = $0.2413 or $0.24 rounded down.

Next up we got the electricity costs.

I already did an article called “How Much Electric Power Does a 3D Printer Use?” where I figured out that a standard 3D printer uses around $0.09 in electricity every hour by seeing readings of electricity use for an hour and getting an average cost in the US of electricity for a kWh.

Last but not least we have the maintenance costs. This can vary from printer to printer, but generally speaking, 3D printers don’t need a lot of maintenance if you have the right parts. You may have to replace thermistors, cooling fans, belts etc.

Once you install some durable parts and have a process, you may have to spend $30-$50 per year on items. If we take an average 3D printer user and say they use their 3D print for an average of 2 hours every day, that would be 730 hours of printing every year.

Let’s take the upper estimate of $50 per year on maintenance, then divide that by 730 hours, and we get an hour maintenance cost of $0.07.

How Much Does it Cost to 3D Print Objects?

By going to Thingiverse. com, you can download a model you like and print it. Using an average cost of $25 per KG below are the approximate prices of some common objects that people 3D print.

com, you can download a model you like and print it. Using an average cost of $25 per KG below are the approximate prices of some common objects that people 3D print.

How Much Does it Cost to 3D Print A Miniature?

A standard tabletop miniature costs around $0.12 like the Elf Ranger (28mm scale) and uses only 5g of filament. Some miniatures may use more or less filament so you adjust the cost based on the amount of filament you use.

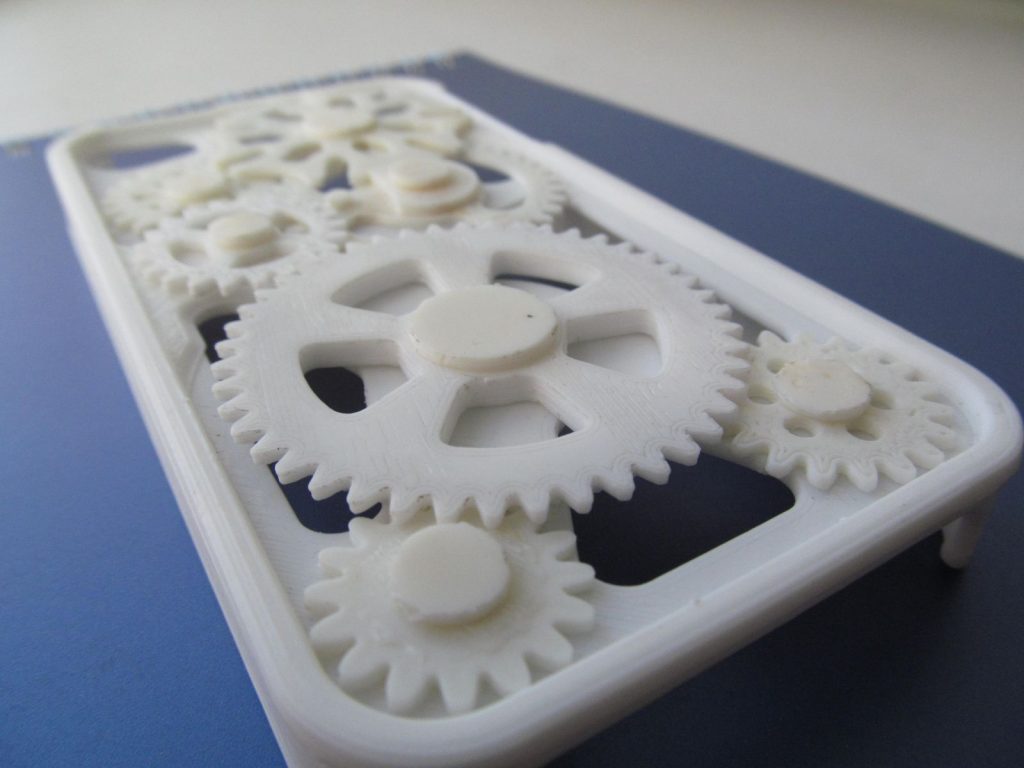

How Much Does it Cost to 3D Print A Phone Case?

A 3D printed phone case for an iPhone 6 Case (Halo Themed) costs around $0.58 and uses roughly 23g of filament. It measures at 70 x 9 x 140mm and is based on using PLA plastic which costs around $25 per KG.

How Much Does it Cost to 3D Print A Helmet (Stormtrooper Helmet)?

A Stormtrooper Helmet uses around 1.5KG of filament which would cost around $37.50 for a full-sized model. It can be printed in around 45 hours with 17 individual prints, or you have the choice to print the whole model in one if you have a big enough 3D printer.

How Much Does it Cost to 3D Print A Mask?

A Loki Mask from “The Mask” movie uses around 180g of filament and would cost $4.50 in PLA at $25/KG. Its dimensions are 165 x 87 x 220mm but can easily be scaled up or down as you desire. There are many other masks out there that can use a lot less filament which would be cheaper.

A Covid-19 Mask V2 from Thingiverse uses around 40g of filament which would cost around $1.00.

How Much Does it Cost to 3D Print A Car?

A company called XEV started the production of a $7,500 dollar electric car in 2019, which weighs 450KG. The Strati which was designed by Michele Anoé and made 3D printable by Local Motors is another 3D printed car which costs around $24,000, though not highway worthy as it doesn’t meet requirements.

One popular story about a 3D printed car is by Sterling Backus who 3D printed a Lamborghini at home with his son, costing just $20,000.

He used a Creality CR-10 to print different parts before joining them together.

Check out the full video below.

The Strati is another well-known 3D printed car that has got plenty of traction and was first printed in just 44 hours in 2014, but with a goal to get that down to just 10 hours per vehicle.

It hasn’t really have much news recently that I could see, so they could have moved onto other projects now, but it’s still a great project and insight into the potential for 3D printed cars.

How Much Does it Cost to 3D Print An Organ?

A bioprinter can reportedly create a 3D printed organ for as little as $10,000 which is likely to decrease in price as technology improves. Researchers are trying to 3D print many organs such as a pancreas, bioprinted skin, corneas, a heart, kidneys, and even bioprinted ovaries.

To 3D print an Anatomical Heart in PLA, it would cost around $3.65 and use 146g in filament.

How Much Does it Cost to 3D Print A Prototype?

For a simple prototype that requires 100g of filament to print, it would only cost $2. 50. For a more complex part that requires professional designers, the cost can range in the hundreds to thousands of dollars depending on the complexity of your prototype. The main cost would be in the design.

50. For a more complex part that requires professional designers, the cost can range in the hundreds to thousands of dollars depending on the complexity of your prototype. The main cost would be in the design.

A full Nintendo Headrest Prototype measuring 94.7 x 87.6 x 121.8mm will cost you $0.98 when using PLA filament. It was fully designed in Fusion 360 which made the locking mechanism a lot easier to use.

A prototype can be a small object which would only require 15 grams of material or a large object that consumes several KGs of material.

A prototype can cost anywhere from $30 to upwards of $30,000 without including the post-processing costs. Well, all this depends on how big the design is and its complexity.

How Much Does it Cost to 3D Print A Shoe?

A 3D printed shoe called the Pigalle Pump Shoe uses around 114g of filament and would cost $2.85 to create. Another popular footwear that is 3D printed is the Recreus Sandals which you would want to print out of TPU. It similarly uses around 115g of filament and would cost around $2.90 .

It similarly uses around 115g of filament and would cost around $2.90 .

How Much Does it Cost to 3D Print A Mug?

This 3D printed Fish Mug uses 156g of material and would cost $3.90 in PLA filament. You would want to coat this in a food safe epoxy to be able to be used safely.

How Much Does it Cost to 3D Print An Iron Man Suit?

A Full MK6 Iron Man Suit would require about 20kg of filament when using the CR-10. It would also cost about $360 when using PLA and a 15% infill rate. This is much cheaper compared to a professional Mark 43 Basic Armor Package which can cost upwards of $1,300.

How Much Does it Cost to 3D Print An FPV Drone?

The Nanolongrange V2 GPS FPV Drone is a modern and very light drone which only uses 7. 5g in filament for the frame, which is $0.18. It requires other parts like a flight controller, a motor, 4 blade propellers, a GPS antenna module, an FPV camera, M2 screws and rubber bands, all costing around $110.

5g in filament for the frame, which is $0.18. It requires other parts like a flight controller, a motor, 4 blade propellers, a GPS antenna module, an FPV camera, M2 screws and rubber bands, all costing around $110.

The cost of these parts were gathered from going on Banggood (product site) on the Thingiverse page, and adding up the relevant costs. This is a very minimal drone, only having a flight time of 20 minutes and 4.65km distance.

For a more capable drone, you’re probably looking at a much higher price, but that is due to parts rather than the 3D printing aspect of things.

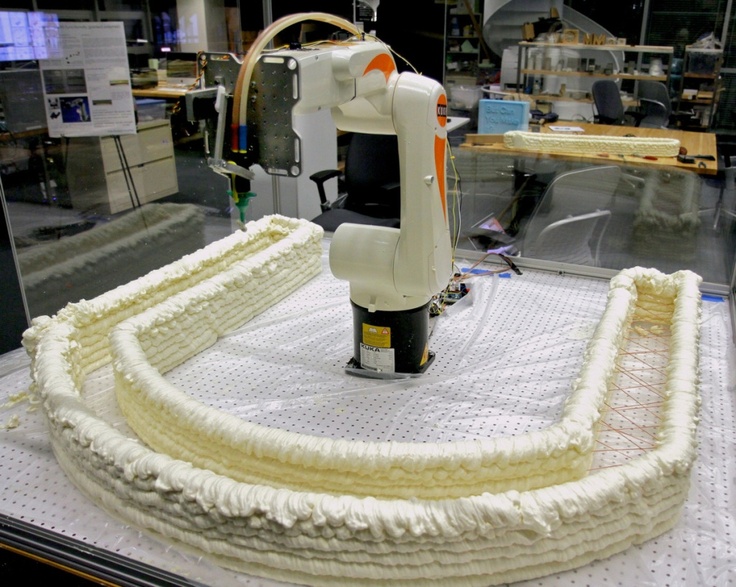

How Much Does it Cost to 3D Print A Real House?

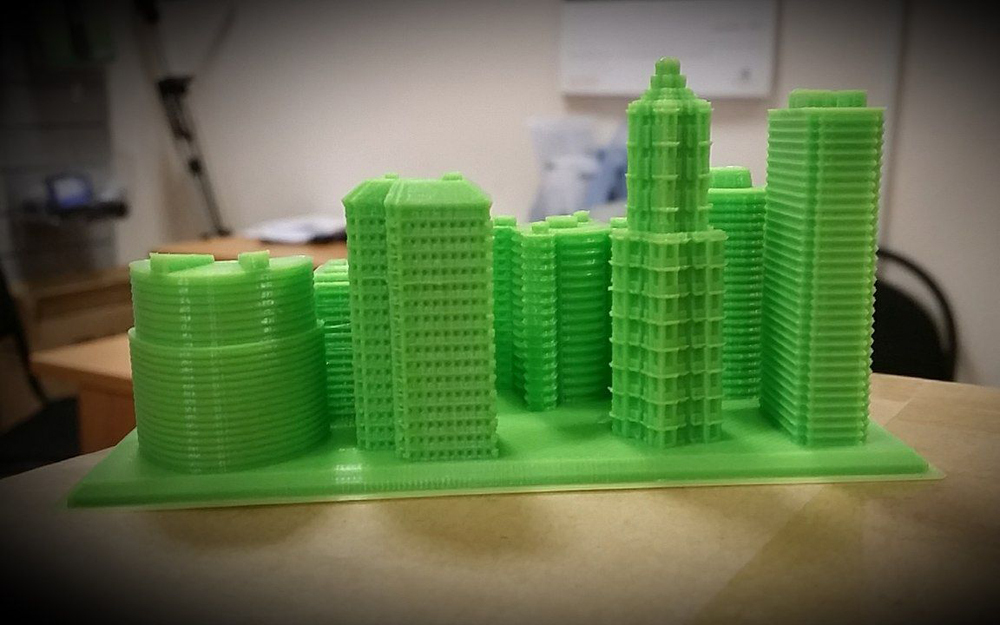

A 3D printed house can cost as low as $4,000 and only take around 24 hours to complete. SQ4D are at the forefront of the 3D printed home industry, being able to create a 1,900 SQ FT. home in just 48 hours and used less than $6,000 in materials. Costs are decreasing as times move forward.

SQ4D are at the forefront of the 3D printed home industry, being able to create a 1,900 SQ FT. home in just 48 hours and used less than $6,000 in materials. Costs are decreasing as times move forward.

Homes are being built for low-income families in Mexico, as well as throughout the US.

Large industrial grade printers extrude cement in layers to form walls. Fittings such as windows and doors are placed after the main structure is completed.

3D printing homes is still at its infancy, so we can expect to see more 3D printed homes in the market in the near future.

How to calculate the cost of printing on a 3D printer

For some ideas, 3D printing is the fastest and easiest solution. In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

Despite the fact that it is customary to indicate the price per gram of working material, simply multiplying the weight of the model by the cost of 1 gram will be wrong. In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product.

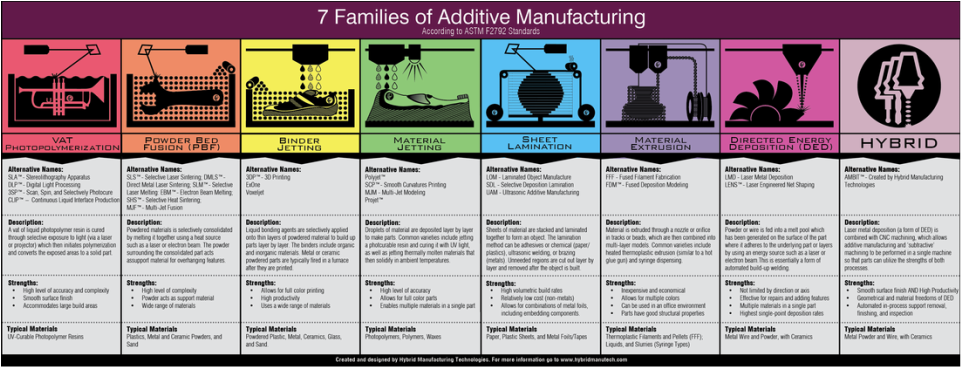

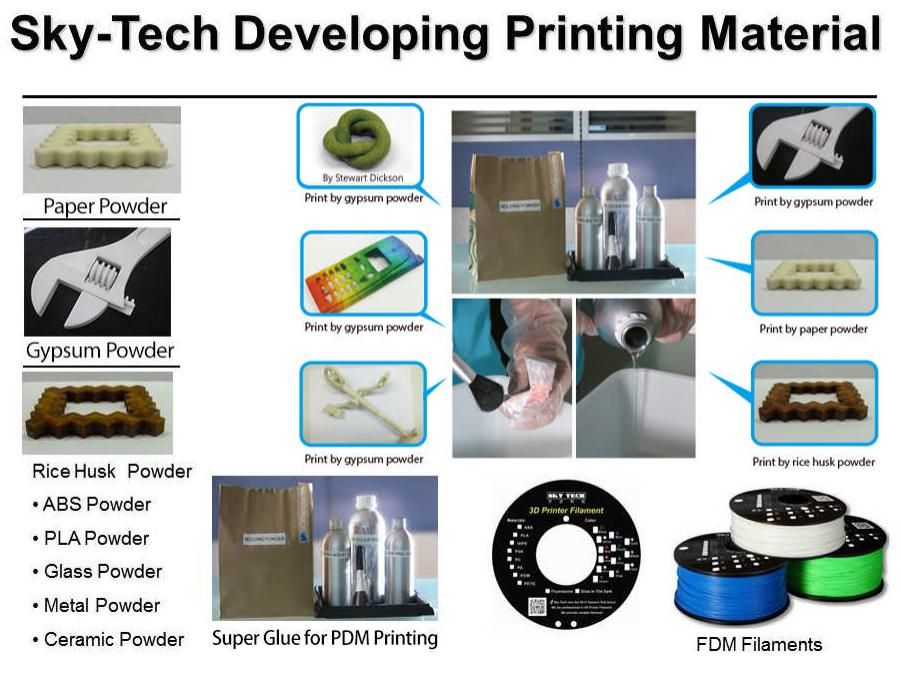

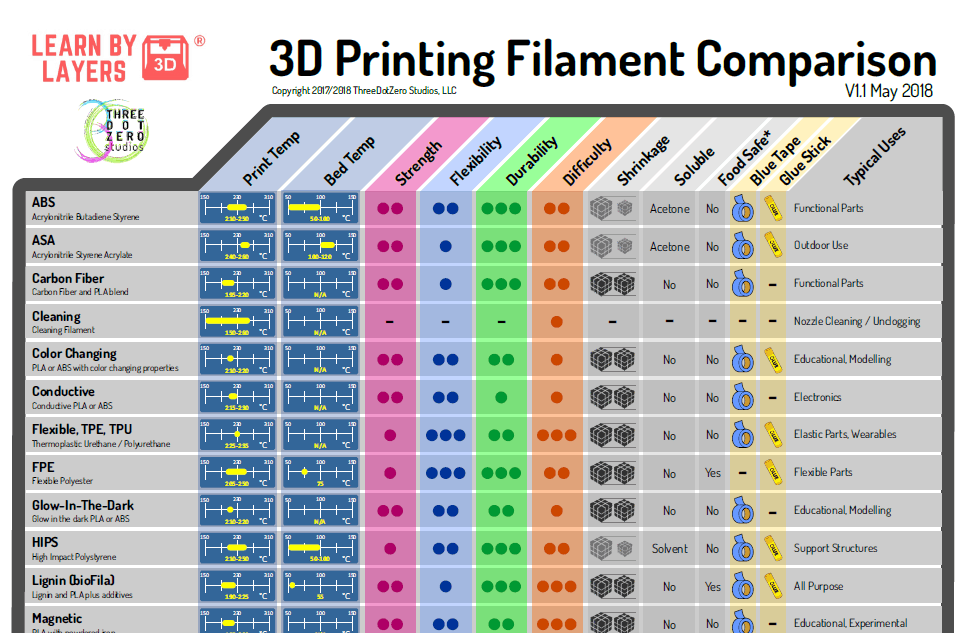

Each 3D printing technology uses its own consumables. Let's analyze the most popular and affordable of them.

Available technologies and key differences

Currently, a huge number of 3D devices have appeared, from small desktop ones that fit on the desktop to huge industrial machines. Among the most affordable, 2 technologies can be distinguished - FDM and photopolymer printers (LCD / DLP / SLA).

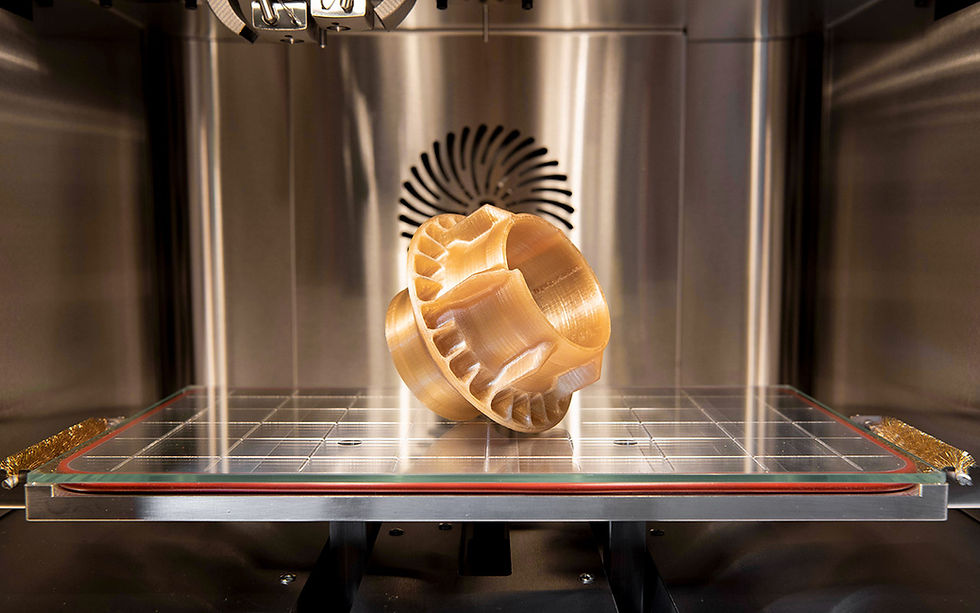

FDM 3D printing

Today, the most affordable 3D printing technology is FDM. A variety of materials and 3D printers allow FDM to be applied to a wide range of applications.

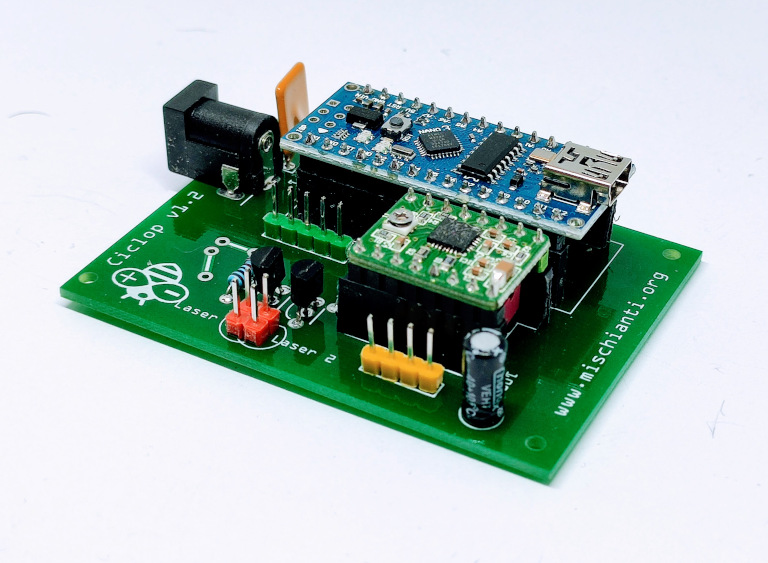

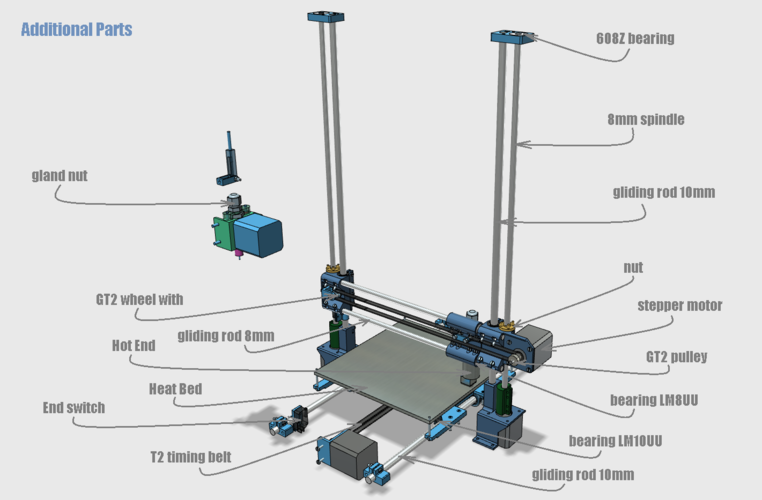

Schematic operation of FDM printer

A large selection makes it easy to choose a 3D printer for a specific task or find a universal device.

The material for printing is a plastic thread - filament. On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc.

Pros:

Cons:

Despite the fact that FDM allows you to print a wide range of plastics with different properties, the technology has some limitations. For example, it is impossible to obtain a perfectly smooth surface, to produce miniature and very thin elements, or to produce parts with very complex internal geometry with high accuracy.

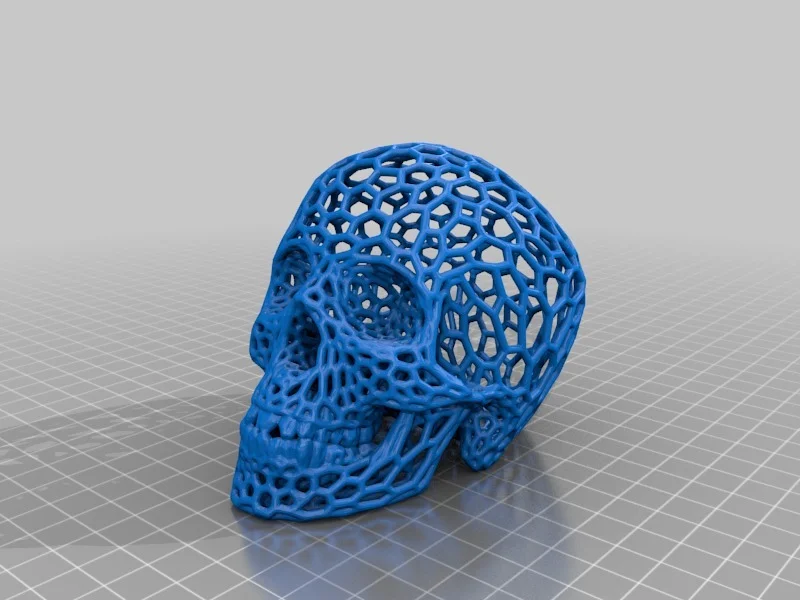

Photopolymer printing

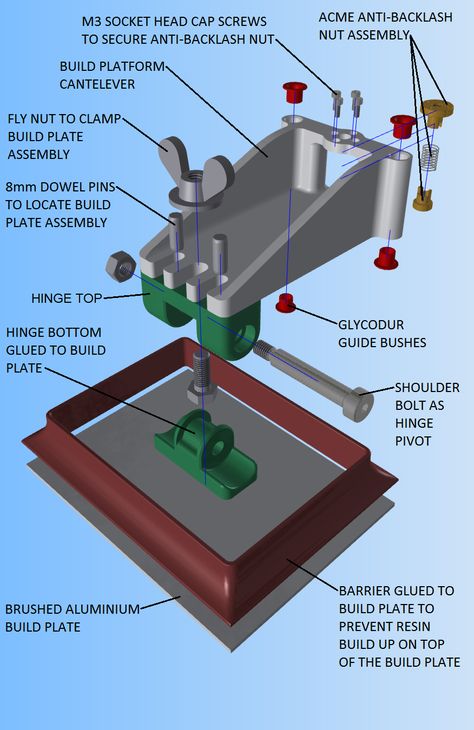

Photopolymer printers can work on one of 3 technologies - SLA, DLP or LCD. These devices will come to the rescue if you need to make a small but very detailed model with many small details.

How photopolymer printers work

As a consumable material, a photopolymer resin hardened by UV radiation is used. Now there is a wide variety of photopolymer resins for every taste. From particularly strong and precise engineering or jewelry resins to soft flexes.

Pros:

-

High print precision

-

Good surface quality

-

A wide variety of printers and consumables

Minuses:

Photopolymer printers have shown themselves well in a variety of industries that require a perfectly smooth surface and high accuracy. They are used in dentistry, the jewelry industry, for making miniature master models for casting, and much more.

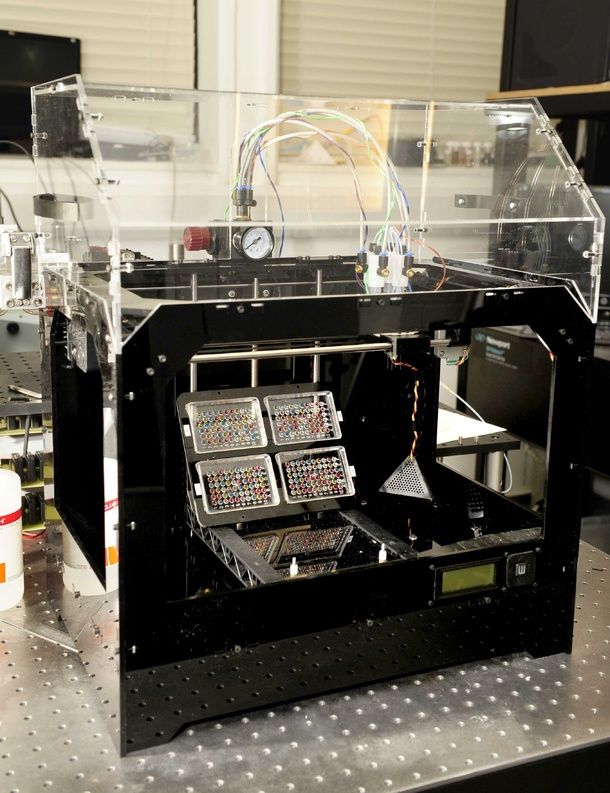

Industrial printers

These are already industrial machines, which require a separate room and sometimes certain requirements for ventilation, etc. In this article, we will not analyze these devices in detail, but briefly consider the most popular technologies.

FDM

In addition to desktop devices using FDM technology, industrial printers that work on the same principle are common.

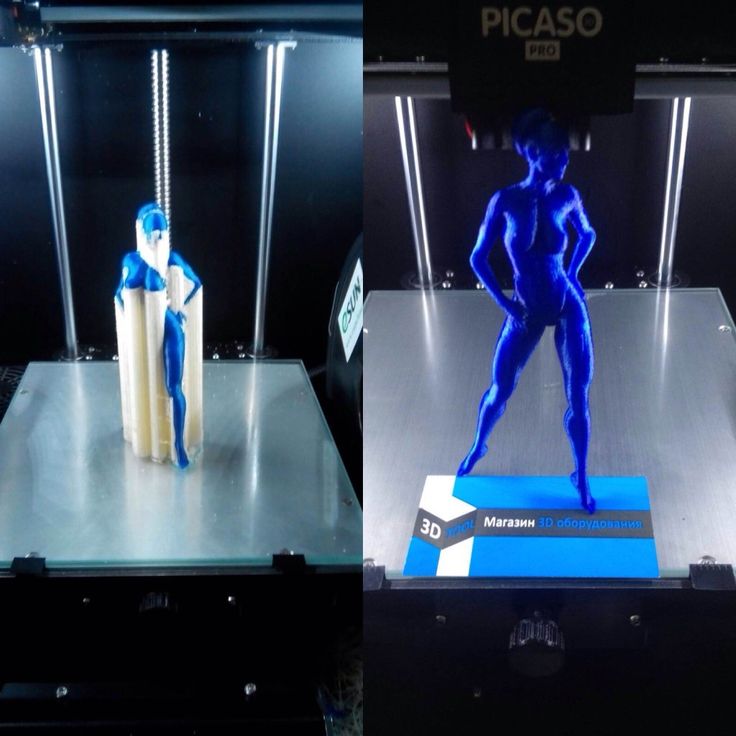

This category includes devices with a large print area (from 30x30x30 cm and more). For example, Raise Pro2 with a print area of 30x30x30 cm.

Raise Pro2

Or machines designed for printing with refractory materials (eg PEEK). Such 3D printers usually have an active thermal chamber, and the extruder can be heated above 400 degrees.

CreatBot F160-PEEK designed to work with refractory plastics

Photopolymer printers

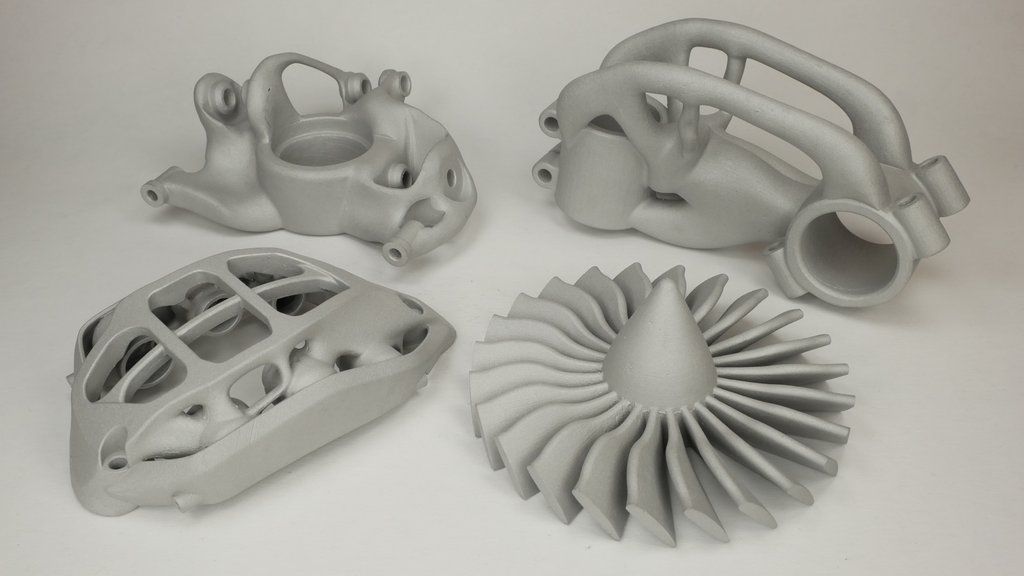

Industrial photopolymer devices usually have a much larger working area, compared to their "home" brothers. In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model.

In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model.

Prismlab Large Area Industrial Resin Printer Family

3DP

3DP - Three-Dimensional Printing (translated as three-dimensional printing) is a logical continuation of conventional two-dimensional printers. Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored.

Colored plaster model

Since the plaster model is fragile, a similar principle is used for printing with metals. Only the finished product needs to be treated in an oven to remove the binder and improve strength. But despite the processing, such metal prints will still be inferior in strength to cast products.

MJM

This is a proprietary technology of 3D Systems. MJM is a mix of FDM, 3DP and sometimes SLA (depending on material chosen). Printing is done using a variety of small nozzles (from 96 to 488) located on the head of the machine. The accuracy and quality of the surface of models made in this way is in no way inferior to photopolymer printers.

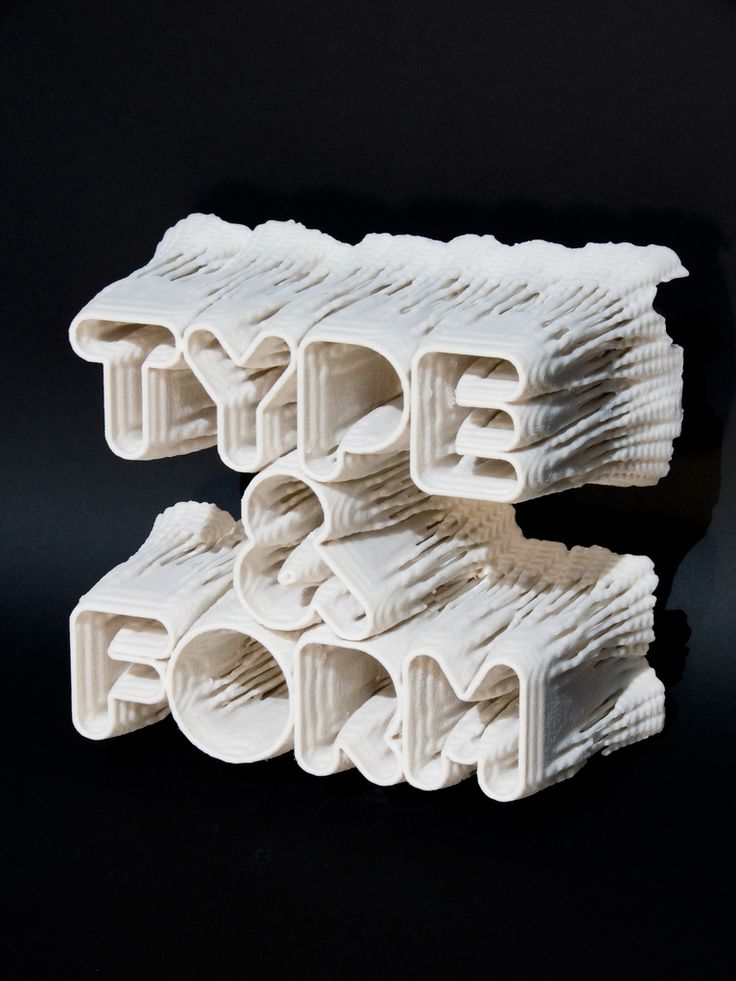

Models made with MJM technology

Such devices can work with photopolymer resins, wax or thermoplastics. You can combine several materials at once - for example, for complex models, you can use wax as a support.

SLM

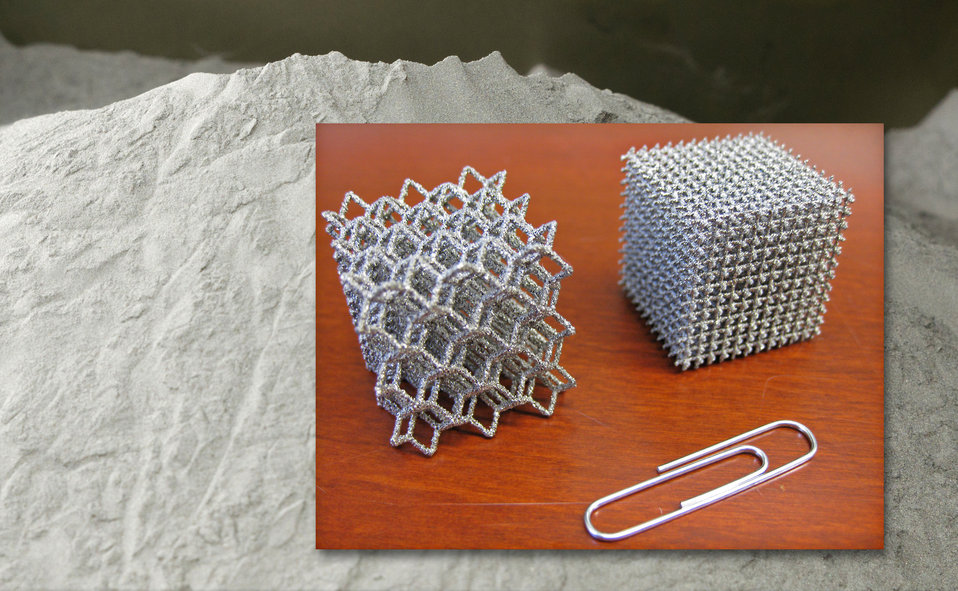

SLM is the layer-by-layer sintering of metal powder using a powerful laser. There are several similar technologies - SHS/SLS. The principle of operation is the same, only a thermal print head is used instead of a laser beam.

SLM Turbine

As a material for printing, you can use powders of various metals - gold, stainless steel, aluminum, various alloys, etc.

During printing, the working chamber is filled with an inert gas to prevent oxidation of metals. This allows printing even with titanium powder.

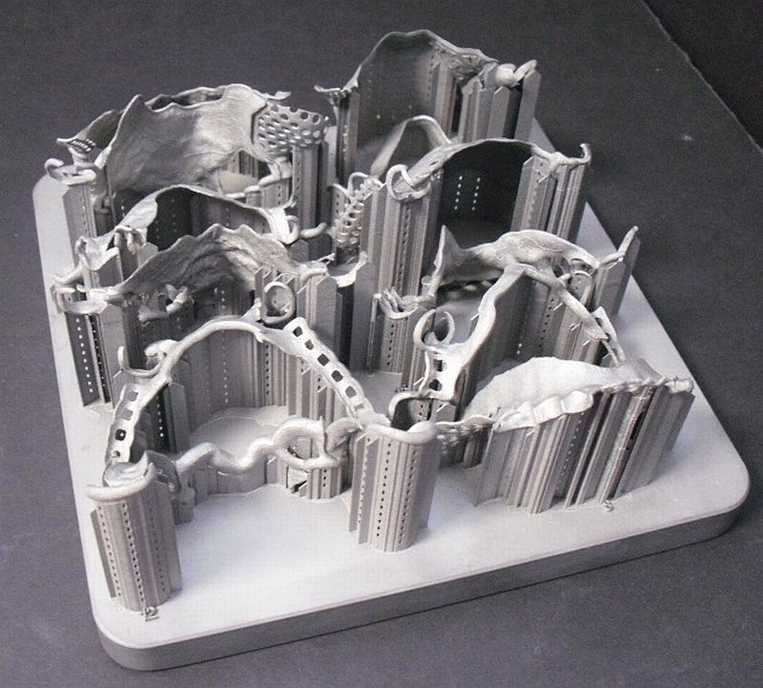

Models made by this method are in no way inferior, and sometimes even superior, to cast products. SLM allows you to produce models with complex internal geometry that cannot be produced by another method (casting or milling).

Cost of 3D printing

The cost of a model usually consists of several factors.

-

Equipment depreciation. The printer, like any machine, requires maintenance and periodic replacement of some parts. During operation, belts gradually stretch, bushings or linear bearings wear out. For example, when bushings or linear bearings are worn; shafts may wear out and need to be replaced.

Cost of materials

The main cost item for a 3D printer is, of course, the printed material.;

FDM (plastic filament)

Since FDM technology is by far the most common, the choice of filaments is very diverse.

-

Engineering plastics are usually nylon with various fillers added to improve the physical characteristics of the finished model. Special cost. plastics starts from 2000r per coil and above. It all depends on the manufacturer and filler (carbon fiber, fiberglass, etc.).

-

Decorative plastics are used to imitate various materials. Plastic can simply be unusually colored (luminous, transparent plastics) or a special filler is added to it (plastics with metal powder). The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

A big advantage of FDM is the diverse choice of materials to work with. This allows, having one printer, to produce almost any product - from a child's toy to a complex engineering prototype.

Photopolymers (resin)

Photopolymer resin printing technology is becoming more and more accessible. There are many different resins.

-

The cost of ordinary colored resin starts from 2500 rubles per 0.5 kg (volume +/- 0.5 l). You can find a smaller volume of resin (250 gr) on sale. You can buy several different resins in small containers and find out in practice which one is best for a particular model.

-

Engineering resins are resins with increased strength. They can be used not only for printing decorative items, but also for making functional prototypes and models. The cost for 0.5 kg starts from 5900r and above.

-

Special resins - burnable, dental, soft flexes, etc. Depending on the resin, the price for 0.5 kg can start from 4800 rubles and more. It all depends on the characteristics of the resin.

Photopolymer resins have not yet reached such a variety as FDM filaments, but they are surely catching up. Although due to the fact that a liter of resin costs significantly more than a spool of filament, the cost of the product is much higher.

Print examples

FDM

Mag Pull (quick release loop) for G3 magazines.

The model was downloaded for free from an open source (the file can be downloaded here). Printing with engineering carbon-filled plastic (price per spool from 4700 rubles). The weight of the model with support is about 25 grams. Post-processing was not needed. The cost of the finished model is 250 rubles.

Plastic fastener

The file was downloaded from an open source (can be downloaded here). Plastic - carbon-filled nylon (price per coil from 4700r). The weight of the finished product is about 20 grams. Print without post-processing. The total cost is 200 rubles.

Model watch

The model is modeled to order (the cost of modeling is from 1000 rubles). The product is printed on an industrial printer using soluble support. Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products).

Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products).

Traction prosthesis

The model is taken from an open source (you can download the modified version of the prosthesis here). The weight of the used material is about 600 gr, printed with ABS plastic (the cost of the coil is from 800 r). After printing, post-processing and assembly took place. The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

Pedal layout

Production of a 3D model according to the drawing (from 1000 r). The weight of the finished model is about 200 gr. The product was printed with engineering carbon-filled plastic (the cost of the coil is from 4700 r). Post-processing was not needed. The cost of the finished product is about 3000 rubles.

Photopolymer printers

Model jaws for crowns

Files for printing were obtained using a 3D scanner and finalized in a 3D editor (the cost of scanning is from 3000 r, the cost of manual revision is from 1000 r). Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Burnout resin rings

The model is made to order. Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product.

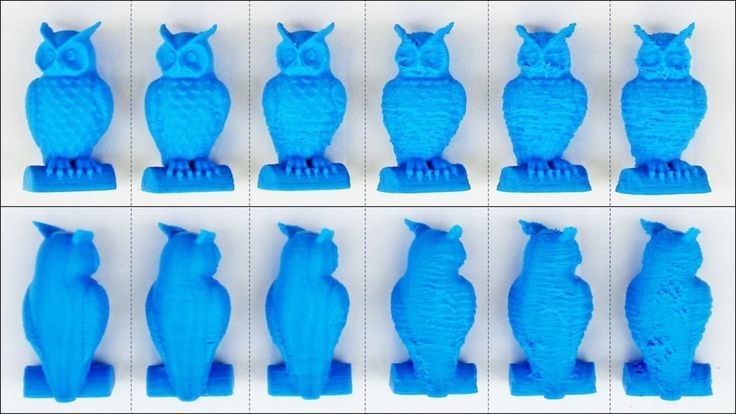

Miniatures

The models were bought on the myminifactory website (the cost of the model is from $2). Made with a desktop DLP printer. Post-processing was not required. The cost of the finished figurine is from 70 r per gram.

Custom 3D printing

Many owners of 3D printers are thinking about monetizing their hobby. But you should understand that the price of 3D printing “for yourself” and the price of commercial printing are very different.

When starting to print to order, it is better to have several printers working on different technologies.

Cost of commercial 3D printing

In addition to the cost of the model, to the commercial production of products, you can add:

-

Modeling. Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make.

-

Model post-processing. This can be simply the removal of supports, with cleaning of the place of their contact with the product, or a complete processing cycle (puttying, surface grinding, painting, etc.).

It should be borne in mind that it is not always possible to print the model the first time. Sometimes it may take several attempts. And these are additional costs.

What is unprofitable to print

Despite the wide possibilities of 3D printing, there are models that are unprofitable to make on a 3D printer. For such models, it is better to use other manufacturing methods.

For such models, it is better to use other manufacturing methods.

Commercial print examples

Jewelry for further casting

Manufacture of promotional items and souvenirs

Piece miniatures or master model for further casting

3D printed model

Profitable to print on a 3D printer:

-

If the item is only sold as an assembly. For example, a small gear broke in the mechanism, but the mechanism is sold only “assembly”. It is much cheaper to make the desired gear on a 3D printer than to buy the entire mechanism.

-

A small batch of parts. Small batches, especially models with complex geometry, are more profitable to produce on a 3D printer than by casting or other methods.

Totals

If you need several models or a small project, sometimes it will be more expedient to outsource manufacturing. After all, in addition to buying equipment and materials, you will have to understand the nuances of the settings and the characteristics of various materials.

After all, in addition to buying equipment and materials, you will have to understand the nuances of the settings and the characteristics of various materials.

Buying a 3D printer for commercial use is justified if you can fully load it with work or then it can be used for other purposes.

To print to order, you need to have several printers working on different technologies. It is better to get several devices with a smaller print area than to buy just one printer, albeit with a large working area.

FDM/FFF Consumables

FFF technology has many advantages, including the relative simplicity of the design of printers and the affordability of both devices and consumables. Moreover, the range of materials is perhaps the widest among all available technologies. As a rule, thermoplastics are used for printing, but there are exceptions - composite materials containing various additives, but based, again, on thermoplastics. In this section, we will try to talk about the most widely used materials in more detail, starting with the most popular types.

In this section, we will try to talk about the most widely used materials in more detail, starting with the most popular types.

- 1 Polylactide (PLA, PLA)

- 2 Acrylonitrile butadiene styrene (ABS)

- 3 Polyvinyl alcohol (PVA)

- 4 Nylon

- 5 Polycarbonate (PC)

- 6 High density polyethylene (HDPE)

- 7 Polypropylene (PP, PP)

- 8 Polycaprolactone (PCL)

- 9 Polyphenylsulfone (PPSU)

- 10 Polymethyl methacrylate (Acrylic, plexiglass, acrylic, PMMA)

- 11 Polyethylene terephthalate (PET, PET)

- 12 High impact polystyrene (HIPS)

- 13 Wood Simulators (LAYWOO-D3, BambooFill)

- 14 Sandstone Simulators (Laybrick)

- 15 Metal Simulators (BronzeFill)

Polylactide (PLA)

Polylactide is one of the most widely used thermoplastics due to several factors. Let's start with the fact that PLA is known for its environmental friendliness. This material is a lactic acid polymer, which makes PLA a completely biodegradable material. The raw materials for the production of polylactide are corn and sugar cane. At the same time, the environmental friendliness of polylactide causes its fragility. Plastic easily absorbs water and is relatively soft. As a rule, PLA models are not intended for functional use, but serve as designer models, souvenirs and toys. Few practical industrial applications include the production of food packaging, drug containers and surgical sutures, as well as use in bearings that do not carry high mechanical loads (for example, in modeling), which is possible due to the material's excellent slip coefficient.

Let's start with the fact that PLA is known for its environmental friendliness. This material is a lactic acid polymer, which makes PLA a completely biodegradable material. The raw materials for the production of polylactide are corn and sugar cane. At the same time, the environmental friendliness of polylactide causes its fragility. Plastic easily absorbs water and is relatively soft. As a rule, PLA models are not intended for functional use, but serve as designer models, souvenirs and toys. Few practical industrial applications include the production of food packaging, drug containers and surgical sutures, as well as use in bearings that do not carry high mechanical loads (for example, in modeling), which is possible due to the material's excellent slip coefficient.

One of the most important factors for 3D printing applications is the low melting temperature of only 170-180°C, which contributes to relatively low power consumption and the use of inexpensive brass and aluminum nozzles. As a rule, extrusion is carried out at 160-170°C. At the same time, PLA solidifies quite slowly (glass transition temperature is about 50°C), which should be taken into account when choosing a 3D printer. The best option is a device with an open case, a heated work platform (to avoid deformation of large models) and, preferably, additional fans to cool the fresh layers of the model.

As a rule, extrusion is carried out at 160-170°C. At the same time, PLA solidifies quite slowly (glass transition temperature is about 50°C), which should be taken into account when choosing a 3D printer. The best option is a device with an open case, a heated work platform (to avoid deformation of large models) and, preferably, additional fans to cool the fresh layers of the model.

PLA has low shrinkage, i.e. loss of volume on cooling, which helps to prevent warping. However, shrinkage has a cumulative effect as the dimensions of printed models increase. In the latter case, the build platform may need to be heated to evenly cool the printed objects.

The cost of PLA is relatively low, which adds to the popularity of this material.

Acrylonitrile butadiene styrene (ABS)

ABS is perhaps the most popular thermoplastic used in 3D printing, but not the most common. This contradiction is explained by certain technical difficulties that arise when printing ABS. The desire of craftsmen to use ABS is determined by the excellent mechanical properties, durability and low cost of this material. In the industry, ABS plastic is already widely used: the production of car parts, cases of various devices, containers, souvenirs, various household accessories, etc.

The desire of craftsmen to use ABS is determined by the excellent mechanical properties, durability and low cost of this material. In the industry, ABS plastic is already widely used: the production of car parts, cases of various devices, containers, souvenirs, various household accessories, etc.

ABS plastic is resistant to moisture, acids and oil, has a fairly high temperature resistance - from 90°C to 110°C. Unfortunately, some types of material are destroyed by direct sunlight, which somewhat limits the application. At the same time, ABS plastic is easy to paint, which allows you to apply protective coatings on non-mechanical elements.

Despite a relatively high glass transition temperature of around 100°C, ABS has a relatively low melting point. Actually, due to the amorphous nature of the material, ABS does not have a melting point, as such, but 180 ° C is considered an acceptable temperature for extrusion, which is on the same level as the above-described PLA. The lower temperature spread between extrusion and glass transition allows ABS to cure faster than PLA.

The lower temperature spread between extrusion and glass transition allows ABS to cure faster than PLA.

The main disadvantage of ABS plastic can be considered a high degree of shrinkage during cooling - the material can lose up to 0.8% of its volume. This effect can lead to significant deformations of the model, twisting of the first layers and cracking. To combat these unpleasant phenomena, two main solutions are used. First, heated work platforms are used to help reduce the temperature gradient between the lower and upper layers of the model. Secondly, ABS 3D printers often use closed housings and control of the background temperature of the working chamber. This makes it possible to maintain the temperature of the applied layers at a level just below the glass transition threshold, reducing the degree of shrinkage. Full cooling is carried out after receiving the finished model.

The relatively low stickiness of ABS may require additional bonding aids such as adhesive tape, polyimide film, or applying an acetone solution of the ABS to the platform just prior to printing. For more information on how to avoid warping, see How to Avoid Warping 3D Printed Models.

For more information on how to avoid warping, see How to Avoid Warping 3D Printed Models.

While ABS does not pose a health risk at room temperature, heating plastic releases acrylonitrile fumes, a toxic compound that can irritate mucous membranes and cause poisoning. Although the amount of Acrylonitrate produced in small scale printing is negligible, it is recommended that you print in a well ventilated area or use an exhaust hood. It is not recommended to use ABS plastic for the production of food containers and utensils (especially for storing hot food or alcoholic beverages) or toys for small children.

The good solubility of ABS in acetone is very useful, as it allows large models to be produced piece by piece and then glued together, greatly expanding the capabilities of inexpensive desktop printers.

Polyvinyl alcohol (PVA)

Polyvinyl alcohol is a material with unique properties and special applications. The main feature of PVA is its water solubility. 3D printers equipped with dual extruders have the ability to print models with PVA support structures. Upon completion of printing, the supports can be dissolved in water, leaving a finished model that does not require mechanical or chemical roughening. Similarly, PVA can be used to create water-soluble master patterns for molds and molds themselves.

The main feature of PVA is its water solubility. 3D printers equipped with dual extruders have the ability to print models with PVA support structures. Upon completion of printing, the supports can be dissolved in water, leaving a finished model that does not require mechanical or chemical roughening. Similarly, PVA can be used to create water-soluble master patterns for molds and molds themselves.

The mechanical properties of PVA are quite interesting. At low humidity, plastic has high tensile strength. With increasing humidity, strength decreases, but elasticity increases. The extrusion temperature is 160-175°C, which allows the use of PVA in printers designed for printing with ABS and PLA plastics.

Since the material easily absorbs moisture, it is recommended to store PVA plastic in dry packaging and, if necessary, dry before use. Drying can be done in a pottery kiln or an ordinary oven. As a rule, drying of standard coils takes 6-8 hours at a temperature of 60-80°C. Exceeding 220°C will cause the plastic to decompose, which should be taken into account when printing.

Exceeding 220°C will cause the plastic to decompose, which should be taken into account when printing.

Nylon

Nylon is attractive due to its high wear resistance and low coefficient of friction. Thus, nylon is often used to coat friction parts, which improves their performance and often allows them to function without lubrication. Following the widespread use of nylon in industry, additive manufacturing has also become interested in the material. Attempts to print with nylon have been made almost since the early days of FDM/FFF technology.

In reality, there are several types of nylon produced by different methods and with slightly different characteristics. The most famous is nylon-66, created by the American company DuPont in 1935. The second most popular option is nylon-6, developed by BASF to circumvent the DuPont patent. These two options are very similar. In terms of 3D printing, the main difference is the melting point: Nylon-6 melts at 220°C, while Nylon-66 melts at 265°C.

Many hobbyists prefer to use commercially available nylon threads such as trimmer wire. The diameter of such materials often corresponds to the diameter of standard FFF materials, which makes their use tempting. At the same time, these products are usually not pure nylon. In the case of trimmer rods, the material consists of nylon and fiberglass for an optimal combination of flexibility and rigidity.

Fiberglass has a high melting point, and therefore printing with such materials is fraught with high nozzle wear and plugging.

Recently there have been attempts to commercially develop nylon-based printing materials specifically for FDM/FFF applications, including Nylon-PA6 and Taulman 680. These grades are extrudable at 230-260°C.

Since nylon readily absorbs moisture, store consumables in vacuum packaging or at least in a container with water-absorbent materials. A sign of excessively damp media will be steam escaping from the nozzle during printing, which is not dangerous, but may degrade the quality of the model.

When printing with nylon, it is not recommended to use a polyimide desktop coating as the two materials fuse together. As a coating, you can use adhesive tape with wax impregnation (masking tape). The use of a heated bed will help reduce the possibility of deformation of the model, similar to printing with ABS plastic. Due to the low coefficient of friction of nylon, extruders with studded feeders should be used.

The nylon layers have excellent adhesion, which minimizes the chance of delamination of models.

Nylon is difficult to bond, making it difficult to print large multi-piece models. Alternatively, fusion of parts is possible.

Since nylon can release toxic fumes when heated, we recommend that you print in a well-ventilated area or use an exhaust fan.

Polycarbonate (PC)

Polycarbonates are attractive due to their high strength and toughness, as well as resistance to high and low temperatures.

The potential health risk of printing is worth noting: the toxic and potentially carcinogenic compound bisphenol A is often used as a raw material. .

The extrusion temperature depends on the printing speed to avoid cracking, but the minimum temperature at 30mm/sec can be considered as 265°C. When printing, the use of polyimide film is recommended for better adhesion to the desktop surface. The high susceptibility of polycarbonate to deformation requires the use of a heated platform and, if possible, a closed housing with heating of the working chamber.

Polycarbonate is highly hygroscopic (easily absorbs moisture), which requires storage in dry conditions to avoid the formation of bubbles in the applied layers. For extended printing in humid climates, even the print spool may need to be stored in a moisture-proof container.

High Density Polyethylene (HDPE)

Arguably the most common plastic in the world, polyethylene is relatively rare among 3D printed materials. The reason for this is the difficulty in layer-by-layer manufacturing of models.

The reason for this is the difficulty in layer-by-layer manufacturing of models.

Polyethylene melts easily (130-145°C) and hardens quickly (100-120°C), as a result of which the applied layers often do not have time to set. In addition, polyethylene is characterized by high shrinkage, which provokes the twisting of the first layers and the deformation of the models as a whole during uneven solidification. Printing with polyethylene requires the use of a heated platform and a working chamber with accurate temperature control to slow down the cooling of the applied layers. In addition, you will need to print at high speed.

Difficulties in use are more than offset by the cheapness and availability of this material. Recently, several devices have been developed for processing plastic waste from HDPE (bottles, food packaging, etc.) into standard filaments for printing on FDM/FFF printers. Examples are FilaBot and RecycleBot. Due to the simplicity of design, RecycleBot devices are often assembled by 3D craftsmen.

Melting polyethylene releases harmful vapors, so it is recommended to print in well-ventilated areas.

Polypropylene (PP, PP)

Polypropylene is a widely used plastic used in the manufacture of packaging materials, utensils, syringes, pipes, etc. The material has a low specific gravity, is non-toxic, has good chemical resistance, is resistant to moisture and wear, and cheap enough. Among the disadvantages of polypropylene, one can note the vulnerability to temperatures below -5 ° C and to direct sunlight.

The main difficulty in printing with polypropylene is the high shrinkage of the material during cooling - up to 2.4%. For comparison, the shrinkage of the popular but already problematic ABS plastic reaches 0.8%. Although polypropylene adheres well to cold surfaces, it is recommended to print on a heated platform to avoid deformation of models. The minimum recommended extrusion temperature is 220°C.

Polypropylene printing filaments are sold by Orbi-Tech, German RepRap, Qingdao TSD Plastic. Stratasys has developed a polypropylene simulant optimized for 3D printing called Endur.

Polycaprolactone (PCL)

Polycaprolactone (aka Hand Moldable Plastic, Mold-Your-Own Grips, InstaMorph, Shapelock, Friendly Plastic, Polymorph, Polymorphus, Ecoformax) - biodegradable polyester, characterized by an extremely low melting point of about 60 ° C . In practice, this property creates certain problems in 3D printing, since not all 3D printers can be configured to work at such low temperatures. Heating polycaprolactone to the usual extrusion temperatures (about 200°C) causes a loss of mechanical properties and may lead to breakage of the extruder.

Polycaprolactone is non-toxic, making it suitable for use in the medical industry and biodegradable. When ingested, polycaprolactone breaks down, which makes printing with this material safe. Due to the low melting point, there is no danger of burns when touching fresh models. The high plasticity of the material makes it possible to reuse.

Due to the low melting point, there is no danger of burns when touching fresh models. The high plasticity of the material makes it possible to reuse.

Polycaprolactone is of little use for creating functional mechanical models due to its viscosity (glass transition temperature is -60°C) and low heat resistance (melting point is 60°C). On the other hand, this material is perfect for the production of mock-ups and food containers.

The material sticks easily to the surface of even a cold working table and is easy to paint.

Polyphenylsulfone (PPSU)

Polyphenylsulfone is a high strength thermoplastic used extensively in the aviation industry. The material has excellent chemical and thermal stability and practically does not burn. Polyphenylsulfone is biologically inert, which makes it possible to use this material for the production of tableware and food containers. Operating temperature range is -50°С - 180°С. Plastic is resistant to solvents and fuels and lubricants.

Plastic is resistant to solvents and fuels and lubricants.

For all its merits, polyphenylsulfone is rarely used in 3D printing due to its high melting point, reaching 370°C. Such extrusion temperatures are beyond the power of most desktop printers, although printing is theoretically possible using ceramic nozzles. Currently, the only active user of the material is Stratasys, which offers industrial Fortus installations.

Polymethyl methacrylate (Acrylic, plexiglass, acrylic, PMMA)

Polymethyl methacrylate is a well-known organic glass. The material is durable, moisture resistant, environmentally friendly, easy to glue, plastic enough and resistant to direct sunlight.

Unfortunately, acrylic is not suitable for FDM/FFF printing for a number of reasons. Acrylic is poorly stored in the form of spools of thread, as constant mechanical stress leads to the gradual destruction of the material. To avoid bubbles, the print resolution must be high, with a precision almost impossible for home printers. Acrylic's rapid curing requires strict environmental control of the working chamber and high print speeds. Again, the print speeds of FDM/FFF printers are inversely related to print resolution, which exacerbates the problem.

Acrylic's rapid curing requires strict environmental control of the working chamber and high print speeds. Again, the print speeds of FDM/FFF printers are inversely related to print resolution, which exacerbates the problem.

However, attempts are being made to print with acrylic, and some of them are producing relatively positive results. However, when creating sufficiently strong models, it is not yet possible to avoid the formation of bubbles and achieve the usual transparency of the material. At the moment, the best results with acrylic are shown by another printing technology - multi-jet modeling (MJM) from 3D Systems. In this case, a photopolymer version of acrylic is used. Stratasys has also made significant progress using its own photopolymer acrylic simulant VeroClear on Objet Eden printers. It is hoped that the high demand for acrylic will lead to the emergence of composite materials based on polymethyl methacrylate, designed specifically for FDM/FFF printing.

Polyethylene terephthalate (PET, PET)

Polyethylene terephthalate - this complex name hides a material used for the production of plastic bottles and other food and medical containers.

The material has a high chemical resistance to acids, alkalis and organic solvents. The physical properties of PET also impress with its high wear resistance and tolerance to a wide temperature range from -40°C to 75°C. Among other things, the material is easily machined.

Printing with PET is somewhat problematic due to the relatively high melting point of up to 260°C and significant cooling shrinkage of up to 2%. Using PET as a consumable requires approximately the same conditions as printing with ABS.

Achieving transparency of models requires rapid cooling to pass the glass transition threshold of 70°C - 80°C.

The material has become the focus of attention of 3D craftsmen using used containers as raw materials for home production of 3D printing consumables. Recycling devices such as FilaBot or RecycleBot are used to make threads.

High impact polystyrene (HIPS)

High impact polystyrene is widely used in industry for the production of various household products, building materials, disposable tableware, toys, medical instruments, etc.

When 3D printed, polystyrene exhibits physical properties very similar to the popular ABS plastic, making it an increasingly popular material among 3D crafters. The most attractive feature of polystyrene is the difference from ABS in terms of chemical properties: polystyrene is quite easily amenable to the organic solvent Limonen. Since Limonene has no effect on ABS plastic, it is possible to use polystyrene as a material for building soluble support structures, which is extremely useful when building complex, interlaced models with internal supports. Compared to the convenient, water-soluble polyvinyl alcohol (PVA) plastic, polystyrene compares favorably with relatively low cost and resistance to humid climates that make PVA difficult to work with.

Be aware that some ABS manufacturers mix slightly cheaper polystyrene into their consumables. Accordingly, models made from such materials can be dissolved in Limonene along with supporting structures.

When polystyrene is heated to extrusion temperature, toxic fumes can be released, so printing in a well-ventilated area is recommended.

Wood simulants (LAYWOO-D3, BambooFill)

LAYWOO-D3 is a recent development for printing wood-like models. The material consists of 40% natural wood chips of microscopic size and 60% binder polymer. The LAYWOO-D3 is very easy to handle, being virtually warp-free and does not require the use of a heated platform. According to the manufacturers, the polymer is non-toxic and completely safe.

The unique material properties allow for different visual results when printing with different nozzle temperatures. The operating temperature range is 180°C-250°C. As the extrusion temperature increases, the shade of the material becomes progressively darker, allowing it to simulate different types of wood or annual rings.

Finished models are excellent for mechanical processing - grinding, drilling, etc. In addition, the products are easily painted, and unpainted models even have a characteristic woody smell.

Unfortunately, the cost of the material is almost four times higher than the price of popular materials such as PLA and ABS plastics. As popularity is projected to grow, the material should become more accessible.

As popularity is projected to grow, the material should become more accessible.

Alternative materials are currently being developed and tested, such as BambooFill from the Dutch company ColorFabb.

Sandstone Simulators (Laybrick)

Composite from inventor Kai Parti, responsible for the revolutionary LAYWOO-D3 wood simulant. This time, Kai set his sights on sandstone imitation, using a tried and tested method of mixing a binder with a filler, in this case mineral.

Laybrick allows you to produce objects with different surface textures. At low extrusion temperatures of the order of 165°C-190°C, the finished products have a smooth surface. Increasing the printing temperature makes the material rougher, up to a high degree of resemblance to natural sandstone at extrusion temperatures above 210°C.

The material is easy to work with no need to heat the work platform, does not show significant deformation when shrinking and does not produce toxic fumes when heated. The only drawback can be considered a rather high cost of the material, which is largely due to limited production.

The only drawback can be considered a rather high cost of the material, which is largely due to limited production.

Metal Simulators (BronzeFill)

Metals have attracted additive manufacturing enthusiasts since the early days of 3D printing technology. Unfortunately, printing with pure metals and alloys causes a lot of difficulties that are insurmountable for most 3D printing methods. Fully functional metal products can only be produced using technologies such as SLS, DLMS or EBM, which require the use of industrial plants that cost hundreds of thousands of dollars. At the same time, metal imitators are successfully used in 3D inkjet printing (3DP), where products are formed from metal powders, the particles of which are held together by an applied binder material. In FDM/FFF printing, metal simulants are just emerging.

An interesting example is BronzeFill - in fact, a transparent PLA plastic filled with bronze microparticles.