Hp 3d printer pricing

How much does an industrial 3D printer cost?

How much does a 3D printing machine cost?

As we’re sure you can imagine, this question is a little like asking, ‘how long is a piece of string?’ The answer, realistically, depends. 3D printers are available from small, low-cost home machines to large-scale industrial printers. Some require a limited setup, others are extremely technical and demanding. Some are good for single items, others are good for industrial quantities—some good for plastics, others good for metals.

Working out how much a 3D printing machine will cost

The best way for you to work out how much you can expect to pay is to come to as full an understanding of your needs as you can, then try to base your quote specifically on those needs. To help you understand the things you need to consider, continue reading, and we’ll guide you through the rough costs of 3D printing machines and what you can expect to pay.

What is the price of the different 3D printing technologies and manufacturing processes?

To help you get a better understanding of 3D printing machine prices, here is a guide to what you might expect to pay, depending on your requirements. Remember though, these 3D printer costs and price ranges are only rough outlines, and the final costs will depend on your specific applications and operations needs.

Back to menu

A guide to 3D printing machine price ranges

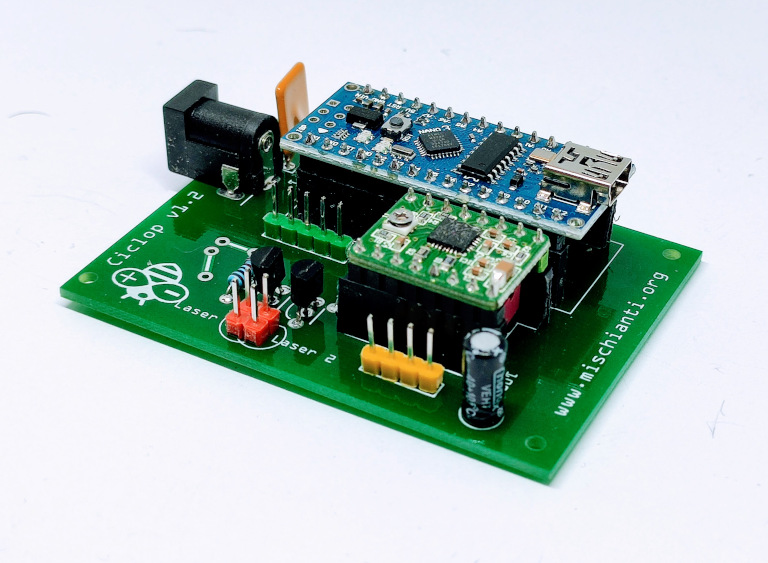

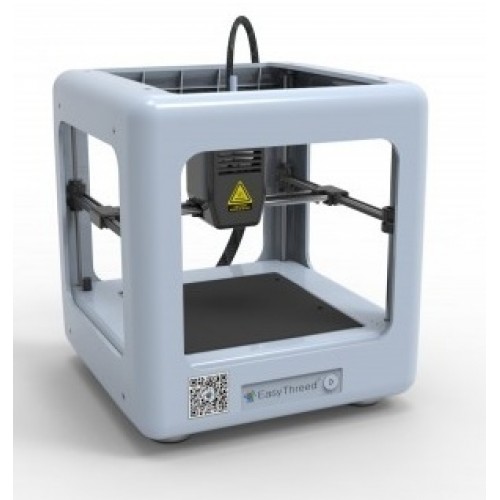

Entry level 3D printers

Approximate price range: $100-$500

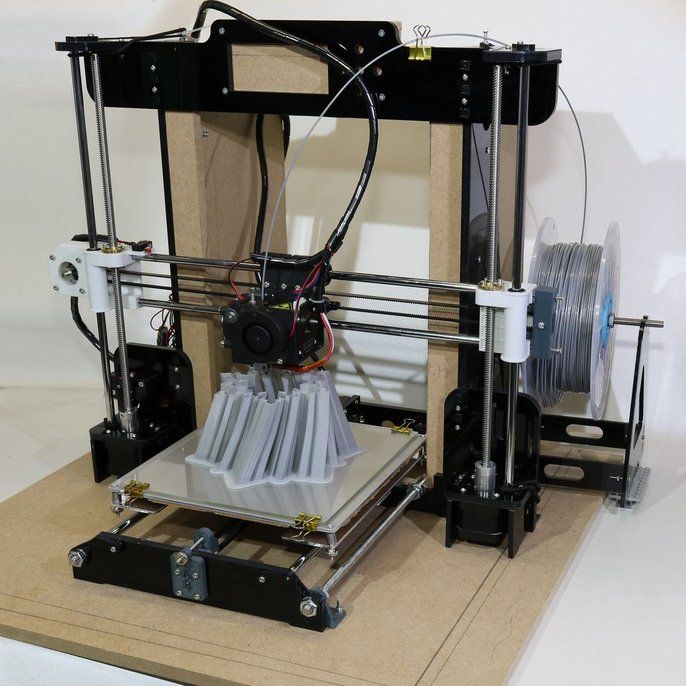

3D printing may not seem like something that can be done at home, but it most certainly is. In fact, all over the world, people are 3D printing in their homes, garages, and even workshops to make new products, decorative items, and more.

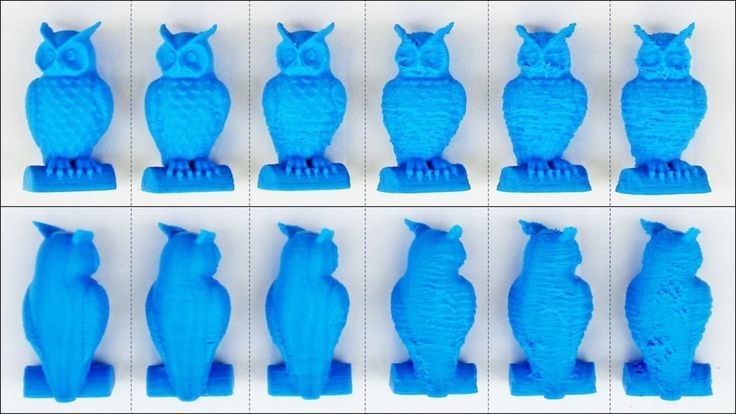

This is possible because of a generation of low-cost, entry-level 3D printers that sell for under $500. These printers are small and often simple, so they can only print small and elementary designs, often from easily obtainable materials. With that in mind, they’re not suitable for most industrial operations but can be a useful asset for individual or low-end prototyping needs on a tight budget.

These printers are small and often simple, so they can only print small and elementary designs, often from easily obtainable materials. With that in mind, they’re not suitable for most industrial operations but can be a useful asset for individual or low-end prototyping needs on a tight budget.

Be aware, though these printers can be slow, noisy, error-prone, and can typically only print in a single material. Unless you’re on a budget, it’s usually wiser to spend a little more and open a higher level of performance.

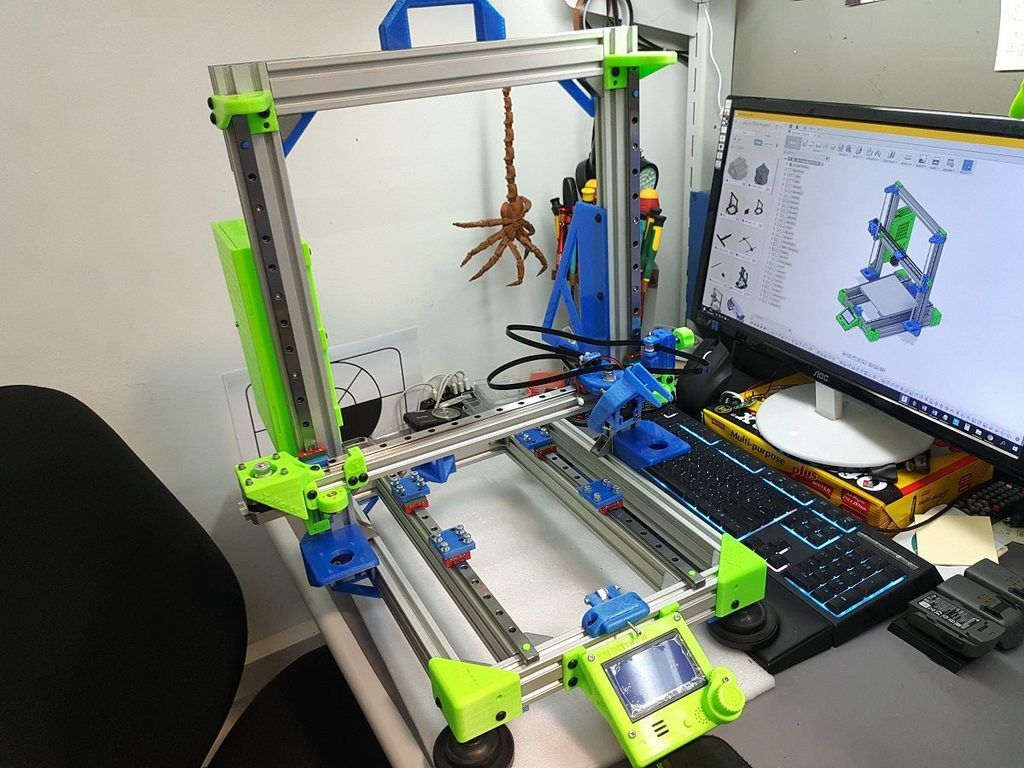

Intermediate 3D printers

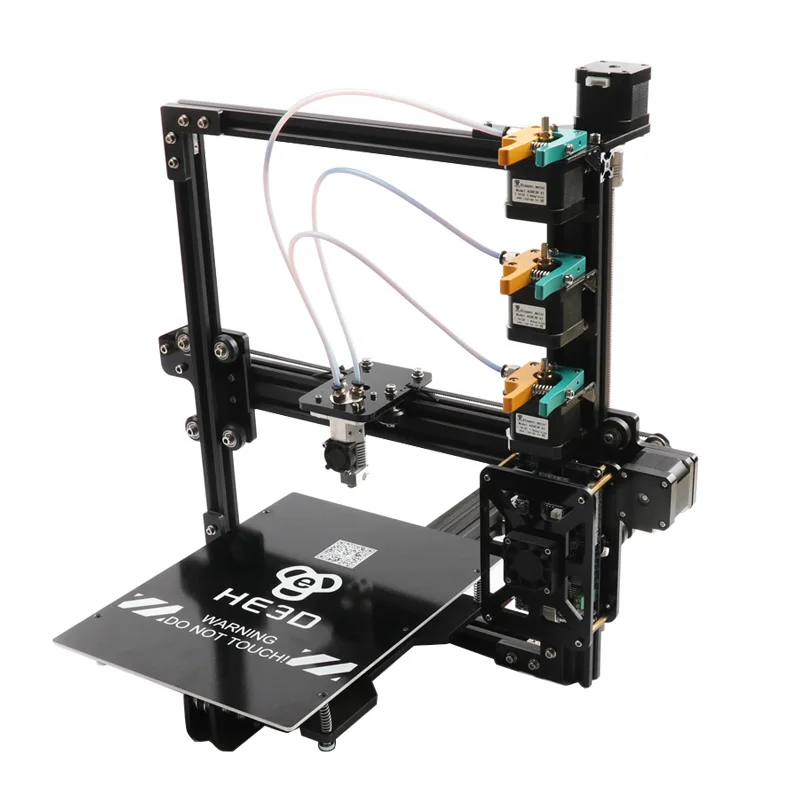

Approximate price range: $400-$1500

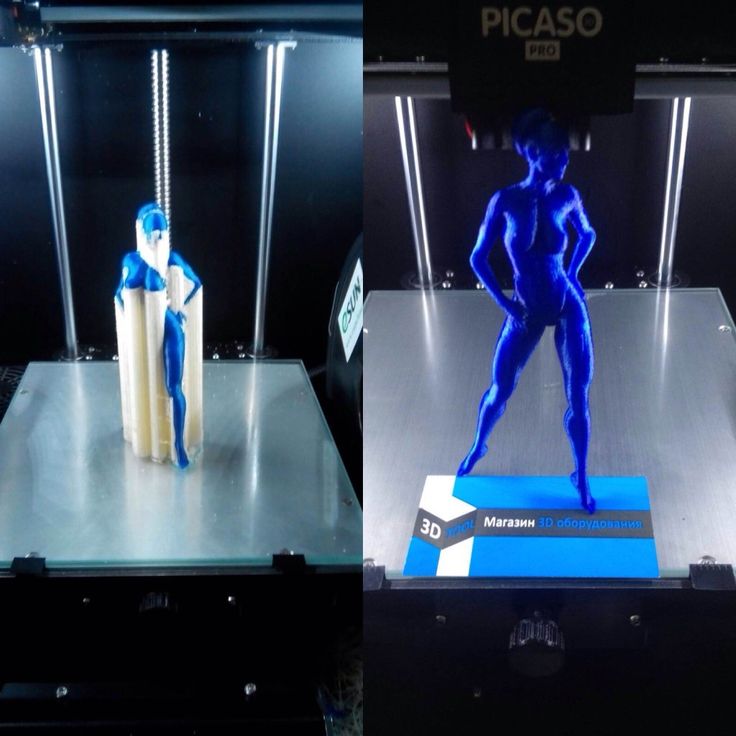

Spending a little more money will often have great returns. The next category of printer will allow you to print bigger objects, often in a range of materials and at better quality. There might be some more time spent assembling, calibrating, and testing before you start printing and the print speeds are often slower than more expensive machines, but typically these machines are useful for testing out designs or for use as teaching tools. Another limitation here is likely the length of run, as printers in this range are only suitable for single items, and not for lengthy print runs.

Another limitation here is likely the length of run, as printers in this range are only suitable for single items, and not for lengthy print runs.

On the software front, you’ll find plenty of open-source software available to experiment with designs, but you should expect limited support, so you’ll have to spend a lot of your own time tuning, troubleshooting, and maintaining your machines. Material choices are typically low-temperature plastics like PLA, PETG, and ABS.

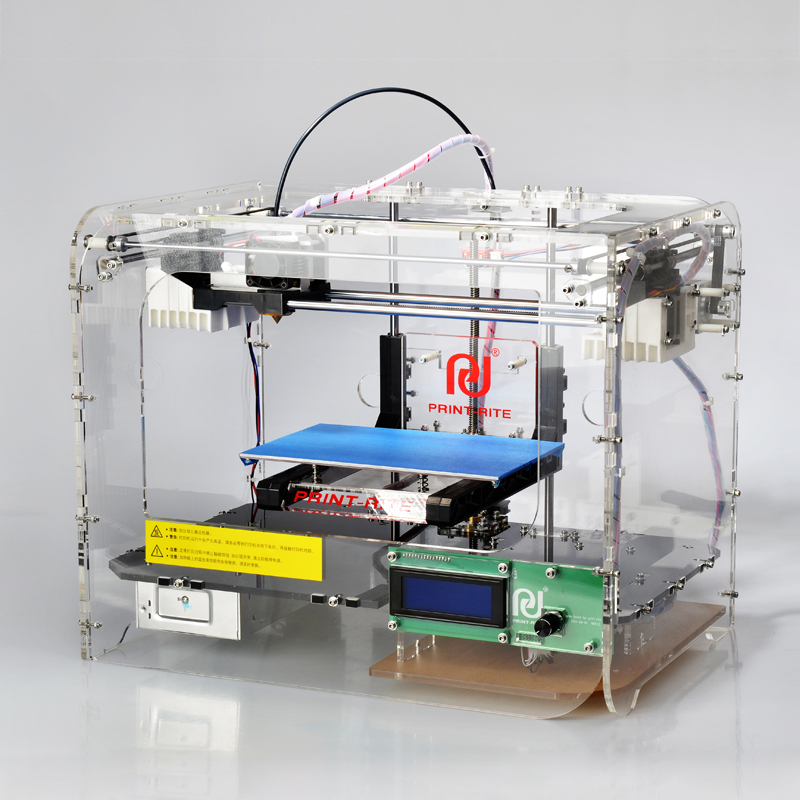

Enthusiast 3D printers

Approximate price range: $1,000-$4,000

If you’ve tried 3D printing and have seen the difference that it can make, then you might want to consider upgrading to a more capable and robust machine. 3D printers in this category can often print items as large as 12 inches in each dimension and do so at a reasonable speed and print quality. In this category, you’ll also get a wider selection of printable materials.

However, many printers in this price range are still not very durable and might even need significant maintenance and repairs if they’re used constantly. These printers should be considered at the highest end of the home or non-professional category. Some businesses might find them suitable, but if 3D printing is going to form a significant part of your workflow, it is usually advisable to make an investment in the professional category, which typically starts just above this bracket.

These printers should be considered at the highest end of the home or non-professional category. Some businesses might find them suitable, but if 3D printing is going to form a significant part of your workflow, it is usually advisable to make an investment in the professional category, which typically starts just above this bracket.

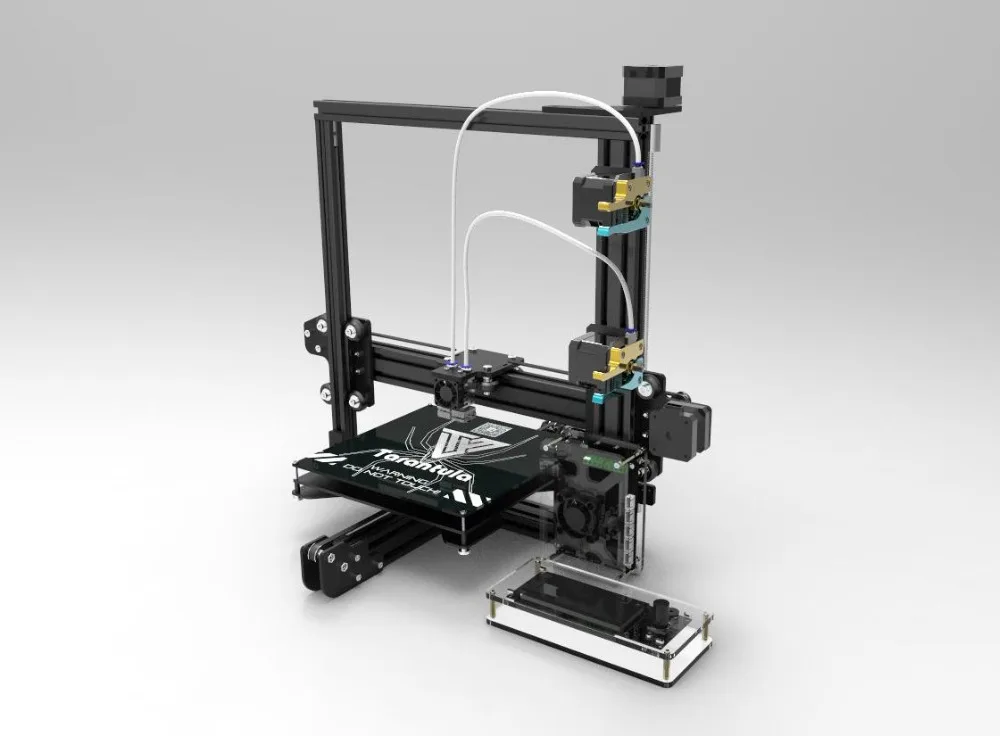

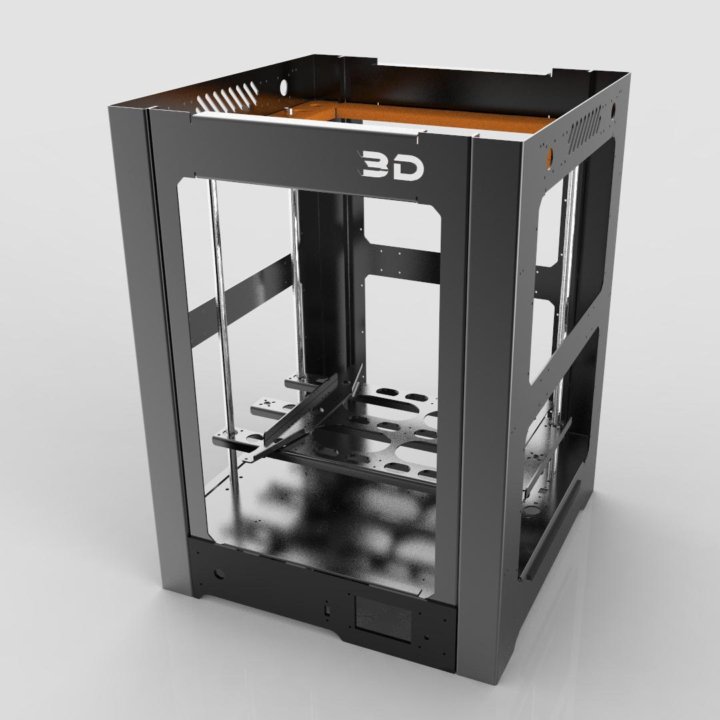

Low-end Professional 3D printers

Approximate price range: $4,000-$20,000

If you’re a professional organization approaching 3D printing, this is where you will want to start. Printers in this price range can deliver significant benefits, mainly for prototyping.

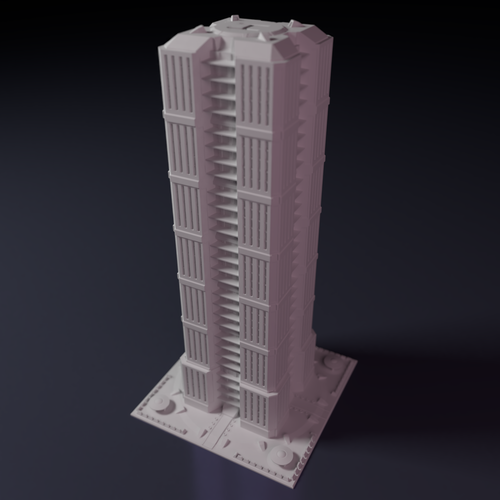

The build areas are bigger, the overall quality is better, and the range of materials expands to include 3D print materials like nylon, carbon fiber, and polycarbonate.

Here you will also experience faster print speeds compared with lower priced 3D printing machines, with better quality output. 3D printer manufacturers in this price bracket typically offer more support and better warranties. While it may seem like a significant investment upfront, if you’re planning on using 3D printing to its full potential, it is often more cost-effective to spend upfront on your machine rather than buying a smaller machine that you might quickly outgrow.

While it may seem like a significant investment upfront, if you’re planning on using 3D printing to its full potential, it is often more cost-effective to spend upfront on your machine rather than buying a smaller machine that you might quickly outgrow.

High-end Professional 3D printers

Approximate price range: $20,000-$100,000

As you move further along in your 3D printing adoption curve and define how important a role 3D printing plays in your overall business model and if you are looking to increase the number of parts in your 3D print—you may want to look into higher price brackets, as these types of 3D printers can offer greater build volume and throughput translating into higher productivity and therefore lower cost per part versus the lower-end 3D printer price categories. 3D printing equipment in this price range also tends to be designed for more specific applications and materials.

Enterprise/Industrial 3D printers

Approximate price range: +$100,000

If you’re now familiar with 3D printing or have decided to make it a permanent part of your manufacturing workflow, then industrial-level 3D printers are where you should be looking. These 3D printers can print quality parts at high speeds, and so will return investment faster, even if the initial outlay is more significant. Higher-end 3D printing equipment, like for example the HP Jet Fusion 5200 Industrial 3D Printer have user-friendly interfaces and reliable, durable construction, important for repeated use. They are typically designed for rapid, volume part production combined with manufacturing predictability, reliability, and productivity. The yield combined with throughput, productivity, and cost per part that you would get from one of these manufacturing-ready industrial 3D printers is of course a world away from entry-level 3D printers.

These 3D printers can print quality parts at high speeds, and so will return investment faster, even if the initial outlay is more significant. Higher-end 3D printing equipment, like for example the HP Jet Fusion 5200 Industrial 3D Printer have user-friendly interfaces and reliable, durable construction, important for repeated use. They are typically designed for rapid, volume part production combined with manufacturing predictability, reliability, and productivity. The yield combined with throughput, productivity, and cost per part that you would get from one of these manufacturing-ready industrial 3D printers is of course a world away from entry-level 3D printers.

Printers at this size are versatile, durable, and reliable, but they do typically require an operator, so the investment makes them more appropriate for businesses who are certain about the role 3D printing plays in their supply chain.

Bear in mind that in this high-end range, the price may be calculated as a solution made up of different elements that the 3D printer vendor recommends as the best fit for your needs—e. g., 3D printer hardware, post-processing equipment, services, and other elements that support your manufacturing workflow.

g., 3D printer hardware, post-processing equipment, services, and other elements that support your manufacturing workflow.

Back to menu

Is a 3D printing machine worth the price?

This is really the key business question. Unfortunately, like most important business questions, it's also quite a complicated one to answer. A lot of it boils down to part cost, i.e., will the return on investment be worth the outlay once you go into significant production of parts? Does 3D printing bring additional value to your parts or products that you cannot achieve via other manufacturing methods? Do you want to keep control of your IP and have full control and flexibility in-house over the design and manufacturing process - or do you prefer to outsource your design and/or manufacturing operations to a 3rd party?

Understanding the benefits and detractions of both options versus your business model and priorities will help you come to the right decision for your organization.

Back to menu

Should I consider 3D printing in-house?

Manufacturing parts in-house will give you more control and agility in the design and overall production process and over time can lead to considerable cost savings. If keeping your Intellectual Property safe is a concern, then this is another important consideration. However, this will also come with running costs, material costs and maintenance costs, on your chosen machine. Most of these costs can be factored into the purchase price of the object, part, or product you eventually create, but as you will have seen the initial outlay to buy an industrial 3D printing machine can be significant and should be factored in into your overall decision.

That said – financial and consulting services can help ease any budget or operational concerns about 3D printing that you may have:

HP Integrated Financial Solutions

Provide you with the flexibility to meet both your technology and financial plans, and allow you to allocate your cash budget for other priorities:

- No large up-front payment

- Align payments with revenue by leveraging step payments or deferred payments

- Simplify your administration: bundle hardware and services into a single agreement

- Agility to change as your requirements evolve, refresh every 3–5 years

HP 3D as a Service

In this business climate, there are many advantages to a “pay-as-you-go” business model when the focus is on outcomes. Paying on a usage basis puts the focus on your business results rather than equipment or transactions.

Paying on a usage basis puts the focus on your business results rather than equipment or transactions.

- Avoid up-front investment—and help align your costs directly with your revenue by paying monthly.1

- Usage-based price per successful 3D printing build2 gives you certainty around your variable costs.

- Gain new operational efficiencies by simplifying supplies ordering and inventory management.3

HP 3D Professional Services

HP’s team of Additive Manufacturing consultants can offer expert guidance at every step of your additive manufacturing adoption journey, from concept to product development to production—helping you identify viable strategic opportunities, optimize design for breakthrough applications, and streamline manufacturing processes, and setting up a factory to enable you to scale production.

Back to menu

Should I outsource to a 3D parts supplier?

Depending on a variety of considerations—for example, how many parts you plan to produce in a year and your level of 3D printing expertise - it may make more sense to have your 3D printing needs met by a third-party supplier, though there can be disadvantages to this too. While it may reduce the cost per part if your volumes are still too low to justify investing in a 3D printing machine, it also gives you less control over of the design and development phase, and can come with extended lead or production times, not to mention shipping, which could slow down your process. It's important to consider whether the cost-saving outweighs the loss of control and longer lead times.

While it may reduce the cost per part if your volumes are still too low to justify investing in a 3D printing machine, it also gives you less control over of the design and development phase, and can come with extended lead or production times, not to mention shipping, which could slow down your process. It's important to consider whether the cost-saving outweighs the loss of control and longer lead times.

That said, if you know you are early on in your 3D printing adoption curve and aren’t quite ready to step into full ownership of a 3D printing machine – maybe your expertise is not there yet, or you don’t yet want to manage operations, maintenance and manufacturing processes – then partnering with a 3D printing service provider can be the ideal solution. 3D printing service providers and parts suppliers can add a lot of value, as they typically have solid experience with different types of 3D printing technologies and expertise in applications development across different industries.

Take a look at the HP Digital Manufacturing Network—a global network and directory of 3D parts suppliers that can help accelerate your business’ digital transformation with 3D printed parts—enabling rapid innovation, fast time-to-market, distributed manufacturing, and a lean supply chain.

HP Digital Manufacturing Network partners have been evaluated and qualified based on their end-to-end 3D printing service capabilities for production at scale, as well as their manufacturing and quality processes. HP Digital Manufacturing partners offer:

- Advanced Additive Manufacturing processes

- Industry standard certifications

- Robust quality management

- Volume job production

Search the HP Digital Manufacturing Network directory to connect with a wide network of HP certified 3D parts suppliers around the world.

Back to menu

Overall business impact

It’s important to remember that costs aren’t everything. 3D printers can provide your company with value-add part production capabilities, that translate into significant business benefits that may not show up on your short-term bottom line, but will provide your business with key long-term advantages over competitors in the rest of your industry. Many industries – you can see some examples in our “What can you make with a 3D printer?” article - are witnessing a complete transformation in traditional business models thanks to the new possibilities that 3D printing helps to unlock.

3D printers can provide your company with value-add part production capabilities, that translate into significant business benefits that may not show up on your short-term bottom line, but will provide your business with key long-term advantages over competitors in the rest of your industry. Many industries – you can see some examples in our “What can you make with a 3D printer?” article - are witnessing a complete transformation in traditional business models thanks to the new possibilities that 3D printing helps to unlock.

3D printing is enabling design teams around the world to get functioning prototypes and final parts faster than ever, these parts can often be printed same day, iterated, and developed within weeks, instead of months. If it helps you to think in terms of metaphors, imagine the typewriter and the inkjet printer. There was a time when the cost of an inkjet printer might have seemed prohibitively expensive, but today does anyone still use a typewriter?

Back to menu

Want to continue learning?

Footnotes and disclaimers

- HP 3DaaS: defined usage-based price applies for a one-year term.

- A successful build is a printed job that ends with the exit code “job_completed_successfully.”

- HP Supplies and Automatic Replenishment is currently available in the US, Canada, Austria, Belgium, Check Republic, Denmark, Finland, France, Germany, Ireland, Italy, Netherlands, Poland, Portugal, Spain, Sweden, UK and South Korea. HP 3DaaS Service Only (HP Supplies not included) is available in Mexico, Brazil, Israel, Hungary, Romania, Slovenia, Turkey, United Arab Emirates, Greece and South Africa (China, Singapore and Taiwan availability in May 2022).

HP 3D Printer Price - How Much HP 3D Printers Cost

Table of Contents

HP is a name that is not new for anyone who hears it. Starting in a garage as an electronic test and measuring equipment manufacturers, HP has grown like a tree from a single root into many branches of green leaves.

Currently, this tree-like company is well-known in its surrounding to give its fruits regularly in the field of manufacturing printers, software products, cloud products, digital cameras, scanners, tablet computers, mobile phones, pocket computers, desktop calculators and computers, business notebooks, personal notebooks, workstations, servers, and a lot more.

In this article, we are going to talk about HP’s products in the field of manufacturing 3D printers. And about each of the HP 3D printer price.

For people who do not know about HP’s venture into the field of 3D printer manufacturing, it must be surprising to hear about the transition and expansion of this “electrical equipment” manufacturing company devising 3D printers.

The company started walking along the road of additive manufacturing long ago but produced its first checkpoint in the year 2016.

This checkpoint was new even for the companies which started before HP. It is what is currently known today as HP’s trademark 3D printing technology.

What is Multi Jet Fusion?

Based on Powder Bed Fusion 3D printing technology, Multi Jet Fusion aims to use plastic for creating parts and functional prototypes.

Technically this technique is known as a mixture of two older existing powder bed fusion technologies: SLS and Binder Jetting.

As mentioned above, this technology, based on powder bed fusion, starts working by laying a bed of powdered material that you have chosen to 3D print parts and functional prototypes.

Let’s understand a little bit about the two technologies of which Multi Jet Fusion is said to be a mixture.

- Binder Jetting: A printed adhesive/ binding agent is sprayed successively on layers of powder giving the geometry of a part or functional prototype.

- Selective Laser Sintering: Starting out with a powder, SLS uses tiny volumes of nylon powder that are also known as voxels. These voxels play the part of connecting the complete part together as does binding agent in the Binder Jetting.

Combining Binder Jetting and Selective Laser Sintering

The benefit of HP in the field of 3D printer manufacturing is its lessons from 2D printing.

3D printing technology has 2D printing as its base ideas, and since HP has done it for years and extensively unlike many other companies, it knows the best of heavy-duty 2D printing.

Multi Jet Fusion, like binder jetting 3D printing technology, uses inkjet printing for defining part geometry, but that’s all it takes from binder jetting.

Then the technique diverges in the way it fuses the powdered material into a part or functional prototype.

In printers based on Multi Jet Fusion technology, each fraction of part or functional prototype is created in a specific manner.

- After the layer of powder is spread uniformly over the print bed of the 3D printer, the Inkjet print head spreads across the print bed, uniformly, millions of drops of light-absorbing ink. The voxels that can successfully keep up even after distribution of this light-absorbing ink keep up, while the rest fall away as powder. Surplus inks, in this case, helps mark a boundary of parts and functional prototypes that can then provide other properties such as color.

- The work of sweeping is now shifted from the print head of the printer to the heater that sweeps across the complete print bed. The areas of the voxel that are ink-marked absorb enough of the infrared energy for sintering the underlying part or functional prototype while the rest remains fully-colored.

Using this technology parts and functional prototypes are printed in an HP 3D printer. To date HP has three 3D printers to its name:

- Jet Fusion 5200 Series.

- Jet Fusion 4200.

- Jet Fusion 500/300 Series.

HP 3D printer price for all three of these printers is different from each other in the terms of their features and service offering.

We’ll now look at each of these printers one by one, giving you a brief idea about each one of them.

Jet Fusion 5200 Series

While the other two on the list are known for short runs and short production, the Jet Fusion 5200 Series is HP’s offering to the world of long runs and longer production needing manufacturers.

The hardware of this 3D printer system comes with a number of significant improvements and upgrades that enable the user to take advantages like higher productivity, accuracy as well as consistency in the quality of each part or functional prototype that is manufactured.

Insights that led to the improvement of features in this 3D printing system were a gift to the company by its previous Multi Jet Fusion technology users. Three main categories include:

- 3D Printer cost.

- 3D printer productivity.

- 3D Printer applications.

Notable Features of this printer

The single-pass configuration is noted to be the most notable feature of the Jet Fusion 5200 Series.

This new system effectively is able to travel in the center of the operation from two-pass mode to a single pass mode.

An even more powerful lamp and a higher degree of productivity compared to HP’s previously employed MJF systems fuels this process for all its users and creating opportunities for working with materials that achieve glass transition temperature at a greater number than others.

The thermal imaging system of this printer is developed with more sophistication and five times the resolution of the Jet Fusion 4200.

A new cooling module that enables faster and safer operation, streamlining and automating the complete production process.

Jet Fusion 5200 Series features a low-cost cooling unit that sits on top of the build unit and is hot even after the completion of the printing process.

The liberation of the build unit for the next job is completed when the “still-hot parts” are automatically transferred into the cooling boxes.

The complete system of Jet Fusion 5200 Series consists of three 3D printer models: The Jet Fusion 5200, 5210, and 5210 Pro.

Jet Fusion 5200 series HP 3D printer Price

The 5210 and 5210 Pro are of more economic value than Jet Fusion 5200 because they are more conducive for industrial applications and they enable manufacturers to see the status of their machine even from a distance.

You need to Get a Quote from the company to know the exact price of any of these 3D printers. However, estimations of the price of Jet Fusion 5200 Series is around $ 250,000.

Jet Fusion 4200

Able to produce parts and functional prototypes of medium-range, the Jet Fusion 4200 is considered ideal for industrial prototyping and final part production for manufacturers who do not wish to spend as much as the HP 3D printer price 5200.

The printer allows you to choose between print modes that are tuned for mechanical, or functional, or aesthetic properties, printer accuracy, and speed.

Jet Fusion 4200 has a size of 2210 mm * 1200 mm * 1448 mm and weighs 750 kilograms. The layer thickness of this machine is 80 whereas its print speed is 4115 cubic centimeters per hour.

An XY precision of 1200 dpi and can print file types such as 3MF, STL, OBJ, and VRML.

When the printer reaches your place, you can plug and play it directly, it needs no further assembling or installation.

The maximum build volume offered by this 3D printer is 380 mm * 284 mm * 380 mm.

Notable Features of the printer

Calibration which is one of the most important things to achieve before starting any 3D print is an area where more experienced hands are needed.

By providing an auto-calibration feature in the printer, HP has thinned out the line between experienced hands and first-timers.

The nozzle to print bed height will be automatically leveled depending on the part or functional prototype that you are 3D printing.

A highly effective and functioning control screen that not only lets one monitor but also operate various parts of the printer, makes it easier for people to manufacture parts and functional prototypes with lesser human intervention.

Ensuring the temperature needed to melt the powder, a closed chamber is designed by the manufacturers of this printer that lets users print parts and functional prototypes with uniformity.

And once the parts or functional prototypes are prepared, they can be cooled instantly using the processing station of this printer.

Jet Fusion 4200 series HP 3D printer Price

For knowing the HP 3D printer price of this printer, one needs to get a quote from the company. However, estimations of the price of this printer are around $268,000.

This 3D printer has featured many lists of best 3D printers that one should buy for this year. Jet Fusion 3D 4210 such an option that users can ...

Add to wishlistAdded to wishlistRemoved from wishlist 0

Add to compare

|

HP Jet Fusion 3D 4210 3D Printer In-Depth Review

Jet Fusion 500/300 Series

Being the most compact 3D printer in its offering, HP Jet Fusion 500/300 series printers are designed by cost-effective small to medium-sized product development teams.

Primarily designed for design firms that need professional 3D printing, as well as universities that want to teach their students with this amazing new manufacturing technology, HP Jet Fusion 500/300 series can increase your productivity by producing multiple design iterations at the same time, it takes for printing a single print.

The size of this printer is 1565 mm * 955 mm * 1505 mm, whereas its weight is 650 kilograms.

Like the previous 3D printer series on the list, this one too manages to offer a layer thickness of 80.

The speed of the 3D printing part and functional prototype offered by printers in this range is 2340 cubic centimeters per hour and the precision along the XY axis is 1200 dpi.

HP Jet Fusion 500/300 series offers a build volume of 190 mm * 332 mm * 248 mm. File formats that can be printed using this 3D printer are 3MF, STL, OBJ, and VRML.

Notable Features of the printer

Engineers would love to tweak and tinker with this printer because it has the ability to produce accurate functional parts that require intricate detailing.

Also as a user, it is fun to operate on this printer which promises to produce engineering-grade thermoplastics with optimal mechanical properties.

Whether your part is to be manufactured in black, white, or fully colored, you would always be able to stay ahead of the competition because of a technology that is completely ready and supportive.

As mentioned in the above section of this article, using 3D printers in this series you would be able to increase your productivity.

There are two 3D printers available in this series: HP Jet Fusion 580 Color, and HP Jet Fusion 540.

Jet Fusion 500/300 series HP 3D printer Price

You can buy the 3D printer from a reseller near you or from any website that functions as e-commerce for 3D printers.

These printers are known to be available anywhere in between the price range of $20,000 to $120,000.

All the series of HP 3D printers use HP Smarstream 3D Build Manager, HP Smarstream 3D Command Center as software to build a 3D design file of the part or functional prototype you wish to 3D print with.

The Conclusion

HP’s Multi Jet Fusion has a very positive review to print parts and functional prototypes with unmatched accuracy.

Users of these printing systems recommend adjusting a little with the cost of getting a higher quality of products.

HP 3D printer price may seem on a higher-end, but they are only because of their proprietary 3D printing technology.

One should always remember before buying a product of HP, the immense amount of experience it possesses in the making of 2D printers. Also, to remember is that HP also acts as a 3D printing service provider.

So, if you wish to get parts straightway from the company, without purchasing its printers, it is possible.

You can check out the website of the company for more information regarding the HP 3D printer price, as well as HP 3D printing services.

Hope this article serves you the aim with which it started and provided you insights that were new and curiosity-raising.

3D PRINTER FOR SERIES PRODUCTION HP JET FUSION 5200 series

Go digital

plastic parts

See more Watch video

ADVANTAGES OF HP

- Fast production of plastic parts with repeatable precision

- Best isotropic properties among 3D printers0017

- Integrated solutions for the production of parts and processing of construction materials

contacts

Complex solutions for

digital production

Unique software

To manage production

processes

Solution for serial production

of any geometrically and functionally

complex plastic parts

Simple and intimate work

against conventional technologies

production

The highest resolution of the thermal chamber,

High efficiency of melting

AMP and the highest savings of materials

Uses the entire

volume

10 s.

SAME PRODUCTION TIME

DOES NOT AFFECT PRODUCT COMPLEXITY

80 %

USES

POWDER AND 20% FRESH MATERIAL0003 FOR QUALITY PRINT

HP JET FUSION 5200

3D PRINTER

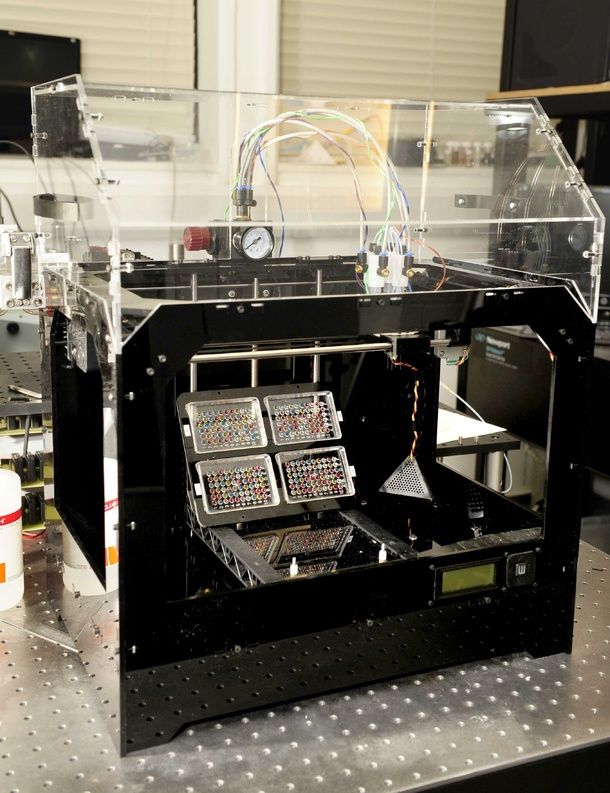

The HP Jet Fusion 5200 Digital Manufacturing Solution consists of the 3D Printer, Interchangeable Build Unit and Processing Station. For greater productivity in the production of functional parts, the assembly has been supplemented with a replaceable cooling unit. Together with dedicated software (HP 3D Process Control) for continuous process control to ensure repeatable precision, reliability and production consistency, the HP Jet Fusion 5200 is the solution for the medium volume production of plastic parts.

Print material is filled automatically into the process equipment. Then insert the filled device into the 3D printer and start printing. After printing, you install the cooling unit on the device, into which the still hot printed parts are automatically transferred. Thus, the construction device is immediately ready for further production of parts. After the parts have cooled, the unmelted building material is removed from the cooling block in the process block and used for a new build. powerful software with the necessary tools for preparing data and further manufacturing parts.

After printing, you install the cooling unit on the device, into which the still hot printed parts are automatically transferred. Thus, the construction device is immediately ready for further production of parts. After the parts have cooled, the unmelted building material is removed from the cooling block in the process block and used for a new build. powerful software with the necessary tools for preparing data and further manufacturing parts.

The whole technology is based on the precise and at the same time fast application of building materials and special solutions for further interaction with temperature. 3D printing a single layer is permanent, no matter how complex the part you are printing. You can print a 380 x 284 x 380 mm building space on the HP Jet Fusion 5200 in just 9.5 hours.

USING 3D PRINTING

HP IN PRODUCTION

Multi Jet Fusion offers a unique growth opportunity for manufacturing companies. You can quickly create both rapid prototypes and thousands of functional final parts on a single device. Thus, HP enters the arena of traditional plastic parts manufacturing technologies such as injection molding.

You can quickly create both rapid prototypes and thousands of functional final parts on a single device. Thus, HP enters the arena of traditional plastic parts manufacturing technologies such as injection molding.

Injection molding of plastics unrivaled with high production volumes and low unit costs. However, production often needs to start quickly, and you can't afford to wait while the mold is produced. Or you need to be flexible in redesigning products for which mold making doesn't make economic sense. In these cases, the HP Jet Fusion 3D printer is a great alternative even for simple parts.

CASE STUDIES

Show examples

Gallery

HP Jet Fusion 5200 3D printers produce thermoplastic parts in large batches with fine details and optimal mechanical properties.

BUILDING MATERIALS

FOR HP 3D PRINTER

In terms of further cost savings, the HP Open Material Platform is a revolutionary innovation in the 3D printing industry - the rapid release of new materials and the natural competition in the market between several manufacturers. The cost of purchasing building materials will rapidly decrease and at the same time their quality will increase.

The cost of purchasing building materials will rapidly decrease and at the same time their quality will increase.

BUILDING MATERIALS FOR HP JET FUSION 5200 3D PRINTER

| HP 3D High Reusability PA 12 Durable thermoplastic for functional prototypes and final parts with high density and optimum technical properties. |

|

| VESTOSINT® 3D Z2773 Similar to PA 12 in black Evonik. | |

| Polypropylene and other materials

|

Learn more

SEE PA 11 STABILITY AND FLEXIBILITY TEST

CERTIFICATIONS & OTHERS

DOWNLOAD INFORMATION

Hewlett Packard is committed to providing information about the safety of 3D printing and the technical and other specifications of printed parts. If you do not find the information you need here, please contact us.

If you do not find the information you need here, please contact us.

BIOINTELLIGENCE OF BUILDING MATERIALS AND PRINTED PARTS

| The Material Modes Pa 12 | Download |

| Declaration on the fitness of parts printed from the material 000PA 12 for toys | Download |

| Biocompatibility Information TPU Estane

| Download |

Water resistance information for parts

Download

pdf

Flammability information for parts printed in PA 12

Download

pdf

Flammability information for parts printed on PA 12 GB

Information on exposure to UV radiation and other external influences

mechanical properties of printed parts

Information on the chemical resistance of printed parts PA 12 to technical

liquids (lubricants, fuels)

Information about smoothing the surface of parts by vibration processing

pdf0016

If you want to realize the full potential of 3D printing, you need quality 3D modeling. Modern software solutions can not only create 3D models, resize and convert them to the appropriate format, but also provide tools such as topological optimization and full color texture. Before modeling for HP Multi Jet Fusion 3D printing, it's a good idea to review a few basic guidelines.

Modern software solutions can not only create 3D models, resize and convert them to the appropriate format, but also provide tools such as topological optimization and full color texture. Before modeling for HP Multi Jet Fusion 3D printing, it's a good idea to review a few basic guidelines.

DOWNLOAD RULES FOR PREPARING 3D MODELS

Various software tools can be used to create 3D models for 3D printing, including the most commonly used CAD software. If you are already working with CAD software, you can easily use it to prepare data for 3D printing.

View 3D printing software

FINANCING THE PURCHASE

OR OPERATION

We offer financing solutions for HP Multi Jet Fusion. We have an experienced financial team who will recommend an appropriate financial proposal, an attractive grant application, or a combination of the two.

We have an experienced financial team who will recommend an appropriate financial proposal, an attractive grant application, or a combination of the two.

VIEW FINANCING INFORMATION

POST

All 3D powder printing technologies, including HP Multi Jet Fusion, require some further processing of the printed parts. Namely, the removal of residues of unbound printing material from the surface of parts. This is best achieved by sandblasting or using a mixture of fine plastic powder. Other processing may be, for example, painting or coating. We offer functional and cost-effective options for post-processing equipment.

BUSINESS DATA

Overview of 3D printer manufacturers

3D printing appeared in the late 1980s, but 2020 became a breakthrough year for the technology. The pandemic disrupted supply chains, and it was 3D printing that made it possible to quickly obtain the necessary items and spare parts, ranging from consumables for hospitals and clinics to parts for medical, industrial and other equipment.

The pandemic disrupted supply chains, and it was 3D printing that made it possible to quickly obtain the necessary items and spare parts, ranging from consumables for hospitals and clinics to parts for medical, industrial and other equipment.

The prospects and pace of development of the sector in recent years have significantly increased its investment attractiveness, however, there are certain risks that should not be discounted.

Vadim Kizimov

private investor

Author profile

Buy

Buy

Buy

Buy

Service in partnership with Investment. Quotes are updated every 15 minutes

Technology Brief

3D printing is the process of converting a computer-generated model into a real three-dimensional object. Printing occurs due to the successive layering of thin layers of material. These are mainly thermoplastics of various types, but ceramic, biocompatible and other composite mixtures can also be used. That is why this technology is called additive.

That is why this technology is called additive.

3D printing technologies differ depending on the materials and equipment used, but the general scheme of the process is always the same:

- A virtual model of the object is created on the computer, and in order to make a model, you do not need to have 3D modeling skills. A special scanner photographs a real object from different angles, creating a digital copy of it.

- The program is slicing - splitting the model into many thin horizontal layers.

- The template is loaded onto the 3D printer, the device reads the diagram and prints it layer by layer in volumetric form.

Application

Using a 3D printer, you can copy any object or create your own. The possibilities for additive printing are almost limitless. Now the technology has already found application in various industries:

- health care: the creation of orthopedic orthoses, dentistry, transplantology, the manufacture of prostheses;

- industrial production: parts of machine tools and equipment;

- space, aviation and automotive industry;

- robotics;

- construction: models of buildings or individual structural elements;

- food production: figured chocolate, jellies and other desserts;

- household items: from smartphone cases and collectible figurines to shoes and interior items;

- jewelry.

At the moment, additive technologies are most in demand in medicine — 3D printing makes it possible to create consumables, prostheses, orthoses, mouthguards, and even absolutely accurate models of human organs — and in industrial production when creating parts and equipment elements.

But the field of 3D printing is constantly expanding, opening up new opportunities for both large companies and small start-ups.

Industry Prospects

While 3D printing is not yet able to achieve fast and large-scale results, the technology has proven itself in areas that require precision and uniqueness.

The increased availability of equipment and the absence of the need for long training of personnel to work with 3D printers also played a role. Over the past six years, the number of global and specific industries that use 3D printing technology has increased, and this market is truly limitless:

- large companies or organizations may refuse to purchase the necessary consumables or parts, producing them on their own in the volumes they need;

- the role of additive printing in medicine has already been mentioned above, and there are also broad development prospects here;

- 3D solutions lower the barrier to entry for new players.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity.

At the end of 2021, the additive printing market was worth $15 billion, based on 3D printing and printer and component costs. In the coming years, the expert agency Business Insights predicts an annual growth of the segment by more than 24%. At this pace, by the beginning of 2029, the size of the 3D printing market will grow at least five and a half times.

Technology deficiencies and company risks

Despite the promise of 3D technology development, 3D printing cannot yet be unequivocally called a profitable industry. There are a number of difficulties that do not allow you to fully rely on additive technologies.

Still high cost of equipment. Cheap 3D printers can print small objects. To create parts of large dimensions, it is necessary to purchase expensive equipment, which may turn out to be unprofitable.

To create parts of large dimensions, it is necessary to purchase expensive equipment, which may turn out to be unprofitable.

Poor performance. This disadvantage should be considered in conjunction with the previous one: now the speed and cost of 3D printers do not allow them to be used in mass production, making a tangible profit.

Insufficient strength of manufactured parts. The layered structure is more brittle in the direction of the layers than the monolith and cannot withstand heavy loads.

Lack of stability. The use of additive technologies on an industrial scale requires equipment and materials that can provide higher production reliability. At the moment, 3D printing is most often used for prototyping, quality control, or for the production of single parts.

The need for post-processing , which increases the cost and time of production of each unit.

Unpredictability. Additive manufacturing is constantly evolving, new materials and printer models are emerging, and there is always a risk that equipment that has been heavily invested in will suddenly become obsolete.

Additive manufacturing is constantly evolving, new materials and printer models are emerging, and there is always a risk that equipment that has been heavily invested in will suddenly become obsolete.

3D printing companies on the St. Petersburg Stock Exchange

There are quite a few companies associated with 3D printing on the St. Petersburg Stock Exchange, and it is not their main activity. This industry is so young that at the moment it does not even have a benchmark significant index.

But the global trend of increasing demand for additive technologies in various areas of life can open up new prospects for industry pioneers.

Proto Labs (NYSE: PRLB). Capitalization - 2.56 billion Proto Labs was founded in 1999 in Minnesota, and by 2022 it already has more than ten branches in seven countries of the world. The company specializes in the creation of prototypes and finished parts for individual orders. In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity.

Since 2014, Proto Labs has been using additive technology for manufacturing parts. In total, the company operates in four areas:

- Injection molding, revenue growth +4% year-on-year.

- CNC machining, +41%.

- 3D printing, +17%.

- Sheet metal production, +24%.

While 3D printing still only accounted for 14.8% of the company's revenue as of the end of 2021, growth trends in the technology's popularity may bring more tangible profits in the future.

Source: Tinkoff Investments Source: Tinkoff Investments3D Systems Corp (NYSE: DDD). Capitalization - 1.88 billion. The company was founded in 1986, headquarters - in Rock Hill, South Carolina.

3D Systems manufactures and sells equipment, software and materials for additive manufacturing. Most often, the company's products are used in the aerospace, automotive, semiconductor and healthcare industries.

In 2021, 3D Systems announced two separate acquisitions. The company has agreed to acquire Titan Additive LLC, a developer and manufacturer of large-format industrial 3D printers, and Kumovis, a German provider of additive manufacturing solutions for personalized medical applications.

The company has agreed to acquire Titan Additive LLC, a developer and manufacturer of large-format industrial 3D printers, and Kumovis, a German provider of additive manufacturing solutions for personalized medical applications.

After the announcement of the results for the fourth quarter of 2021, the company's quotes increased by 15%. This positive reaction was driven by double-digit revenue growth of 13.1% yoy, excluding sales of part of the business. In addition, 3D Systems reduced its net loss by almost three times, and the revenue forecast for 2022 was increased by 10%.

Source: Tinkoff Investments Source: Tinkoff Investments Align Technology (NYSE: ALGN). Capitalization - 32.4 billion American company Align Technology is a manufacturer of medical equipment for dentistry and orthodontics. The patented Invisalign bite treatment system is based on the use of transparent removable orthodontic caps, which are printed on a 3D printer individually for each client.

The company is headquartered in Silicon Valley and has a rapidly growing branch network covering Russia, Mexico, Costa Rica, the Netherlands, Australia and Japan.

Digital orthodontics is rapidly evolving and Align Technology is not going to give up just yet. The percentage structure of revenue for 2021 is distributed as follows: 80% - sales of Invisalign products, 20% - sales of intraoral scanners and other dental equipment.

Source: Tinkoff Investments Source: Tinkoff InvestmentsHP Inc. (NYSE: HPQ). Capitalization - 39.7 billion. The company does not specialize in the production of 3D printers, but is still one of the leaders in the additive printing market.

In 2014, HP developed Multi Jet Fusion 3D powder printing technology to lower the price and speed of industrial 3D printers, and two years later, the first HP Multi Jet Fusion models went on sale.

In 2017, Hewlett Packard introduced the world's first 3D lab for testing various types of additive printing raw materials. And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products.

And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products.

HP Metal Jet Printer is 50 times more productive and significantly lower cost of finished parts than other technologies.

On April 7, 2022, investors were shocked by the news that Warren Buffett had bought $4.2 billion worth of shares in the company. Immediately after the announcement of the deal, HP shares grew by 14.75%.

Compare companies by multiples, growth rates, and R&D spending.

Source: Tinkoff Investments Source: Tinkoff InvestmentsCompany multiples

| Capitalization, billion dollars | P/E | Forecast P/E | P/S | Debt to equity | |

|---|---|---|---|---|---|

| PRLB | 2.56 | 38.00 | 28.00 | 2.81 | 0.01 |

| ALGN | 32.40 | 41.00 | 32.00 | 8.18 | 0.04 |

| DDD | 1. 88 88 | 5.30 | 5.00 | 2.88 | 0.60 |

| HPQ | 39.70 | 6.80 | 8.70 | 0.69 | −3.58 |

Capitalization, billion dollars

PRLB

2.56

ALGN

32.4

DDD

40002 HPQ

39.7

PRLB

38

Algn

41

DDD

Algn

32

HPQ

8.7

PRLB

2.81

Algn

8,18

DDD

2.88

HPQ

0.69

DEBT TO equity

PRLB

0.01

Algn

0.04

DDD

4%)

4%) 2019

458 (+2.69%)

2020

434 (−5.24%)

200004

488 (+12.44%)

2019

2406 (+22 %)

2020

2471 (+3%)

2021

3952 (+60%)

2019

636 (−8%)

2020

557 (−12%)

2021

615 (+10.4%)

2019

58 760 (+1.3%)

2020

56 630 (−3.62%)

2021

63 000 (+11.25%) 9000

2019

63

2020

50

2021

35

2019

442

2020

1775

2021

772

2019

−69

2020

−149

2021

322

2019

3152

2020

2884

2021

6503

R&D costs, as a percentage of revenue

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | 7. 2% 2% | 8.5% | 9.0% |

| ALGN | 6.5% | 7.1% | 6.3% |

| DDD | 13.1% | 13.3% | 11.2% |

| HPQ | 2.6% | 2.6% | 3.0% |

2019

7.2

2020

8.5

2019

6.5

20200004

7.1

2021

6.3

2019

13.1

2020

13.3

200004

2019

2020 9000 9000

2.6

Summarizing the data, several conclusions can be drawn:

- All companies are profitable, with the exception of DDD, which received a one-time profit in 2021 through the sale of non-core assets.

- ALGN and PRLB have the lowest leverage.

- All companies are growing.

- DDD has the highest R&D spending and the lowest revenue growth rate. Investors should pay attention to this.

Bottom line

Modern 3D printers can significantly reduce the time and cost of solving geometry control and reverse engineering problems in the automotive, aviation, mechanical engineering, shipbuilding, jewelry and medicine industries.

build size

build size