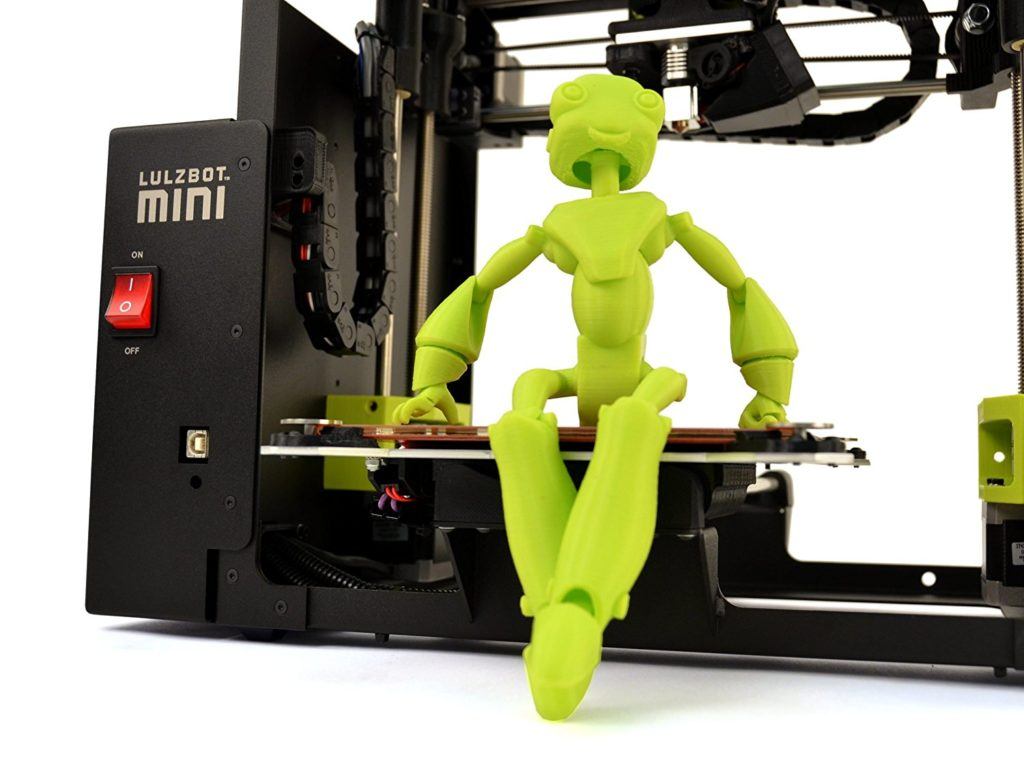

3D printing person

FAQ | Shapify

General

1. Why Artec Shapify Booth?

Artec Shapify Booth features a fully automated process for creating 3D files. Use it to set up an innovative, lucrative and scalable business.

2. What is special about your software?

It’s the only software on the market that can process full body 3D scans automatically and quickly. Just compare the Shapify’s 15 minutes of automated cloud computing to create a 3D printable file with at least 2 hours of highly skilled work spent by a 3D modeller on every file made using photogrammetry or any other scanning solution.

3. I’ve heard of photogrammetry scanning solutions, but how does Shapify Booth work?

Unlike photogrammetry the Shapify Booth uses real 3D scanners. This is what has allowed us to create software which automatically creates printable 3D files.

4. What do I need to do to operate the Booth?

I. Front office

1. Meet the customer, check he or she is wearing appropriate clothes for scanning, recommend removing shiny clothes, jewelry, black shoes and glasses. Explain the process and ask the customer to hold still for 12 seconds while being scanned. Type the customer's name (or e-mail) into the system.

2. The customer stands in the booth. You click on the "Start" button and make sure the customer doesn't move during scanning.

3. After scanning, wait with the customer until the preview picture is ready. (About 5 minutes). Meanwhile discuss delivery options with the customer.

4. Make sure the preview is good and that the customer likes it.

5. Store the customer's name (e-mail), chosen delivery address, size of figurine and number. (This can also be done during step 3)

6. Charge the customer.

7. The printable 3D file will be available to order or download on your Shapify.me online account within 15 minutes.

II. Back office, via the booth operator’s online account at www.shapify.me

1. Log in to your personal account at Shapify. me. If you want to print the figurine yourself, just select the model and press the “download” button.

me. If you want to print the figurine yourself, just select the model and press the “download” button.

2. If you want to order printing with Artec, please make sure your printing account has enough credit.

2. Go to Gallery, select the required model(s), enter the delivery address, number and size of figurine(s).

3. Click on the "order" button.

Please see the video for a visual explanation

5. If I install a Shapify Booth, will it carry your brand or mine?

The branding on the booth itself cannot be modified apart from in exceptional circumstances. However, if you decide to use an exterior pod or structure for the booth, you can create your own design or use the Shapify design. In both cases, the design should be harmonized with us for technical and marketing purposes.

6. Is the Shapify Booth portable?

Yes. Shapify Booth it is the most portable and easy to deploy automated 3D scanning solution on the market. However, the booth should be assembled and calibrated by an authorized maintenance partner; this is about 4-5 hours’ work for a two man job.

However, the booth should be assembled and calibrated by an authorized maintenance partner; this is about 4-5 hours’ work for a two man job.

7. So there are 3000 3D model files included in the Optimal business model. But what if I just need to re-scan a customer?

We don’t count scans, we count the processed 3D files you choose to print or download. You can scan your customer as many times as necessary, this will be free of charge.

8. What’s in the box? What is included in the price of the booth?

– Hardware, delivered to your address

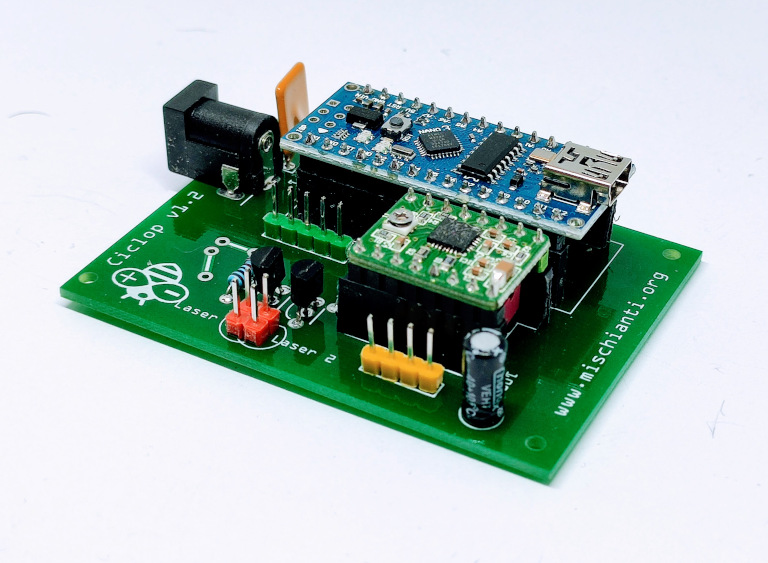

The whole scanning system - the scanning with 4 hi-res rotating scanners, lighting, and the computer to manage the process.

The first installation by our certified Maintenance Partner

- Software

There are 3 levels of software:

1. The software installed on the Booth PC for managing scanning and modelling a quick (1 min) preview so your customer can decide whether to accept the quality of the scan

2. Cloud software to process your hi-res model (3-5 min) and upload it to your personal account on the Shapify.Me web site.

Cloud software to process your hi-res model (3-5 min) and upload it to your personal account on the Shapify.Me web site.

3. The Shapify website software and interface to help you to store and manage your scans, download your files, order prints, check your scanning and printing accounts and schedules (within certain business-models)

- Warranty

1 year full warranty

With the “Optimal” business model you will also get 3000 automatically processed 3D files.

9. If I use the “optimal” model, how will I know how many files I have “spent” and what will happen afterwards?

You will have a special counter on your personal account at Shapify.me. You will always know how many files you still have left. When you have used them all, you will be able to top up your account on the website by paying $20 per extra scan.

10. Does the booth have to be connected to the internet? Can’t the file be created locally, on the booth computer?

Yes, the booth has to be connected to the internet since all the calculations are done in the cloud.

11. My client’s data will be transferred to the cloud. Is that safe?

A lot of information, from the photos on your iphone to your credit card details, is sent to and processed in the cloud. All data on the Shapify website and in the Shapify cloud is encrypted and safe.

12. Can Shapify Booth scan a couple or 3 persons together?

Yes, it can. Just remember that the more people are scanned together, the more difficult a job it is for the software, since everyone makes some slight movements even if they trying to keep totally still, and if there are several people in the booth, the volume of movements will be higher. So achieving a perfect scan of multiple people will be a little more difficult - although we have plenty of success stories!

13. What is the approximate processing time for one full body scan?

You (and your customer) will see the finished preview in about 5 minutes. Based on that, the customer can decide whether they like the scan and wish to purchase the printed 3D shapie. The hi-res fully processed file should be available in about 15 minutes on your personal account on the Shapify.me website

The hi-res fully processed file should be available in about 15 minutes on your personal account on the Shapify.me website

14. What scanners are used inside the booth?

This is the Artec L2, an enhanced version of Artec Eva, but with a wider view field and longer working distance.

15. Will we get trained to use the software and the hardware

Of course!

16. What are the installation requirements?

You’ll need a space of at least 3.3m x 3.3m, ceiling height at least 2.8 m. For electricity you should have 220V and 2500W. We recommend a fast Internet connection of 8-10M. Don’t forget you should also have a Windows laptop or a desktop to run the Shapify software. It doesn’t need to be powerful, though, all the heavy work is done in the cloud and on the Booth PC.

17. Where I can see the Booth in action?

Take a look at our map here and also keep an eye on our news.

18. Are the prices on your website in USD?

Printing

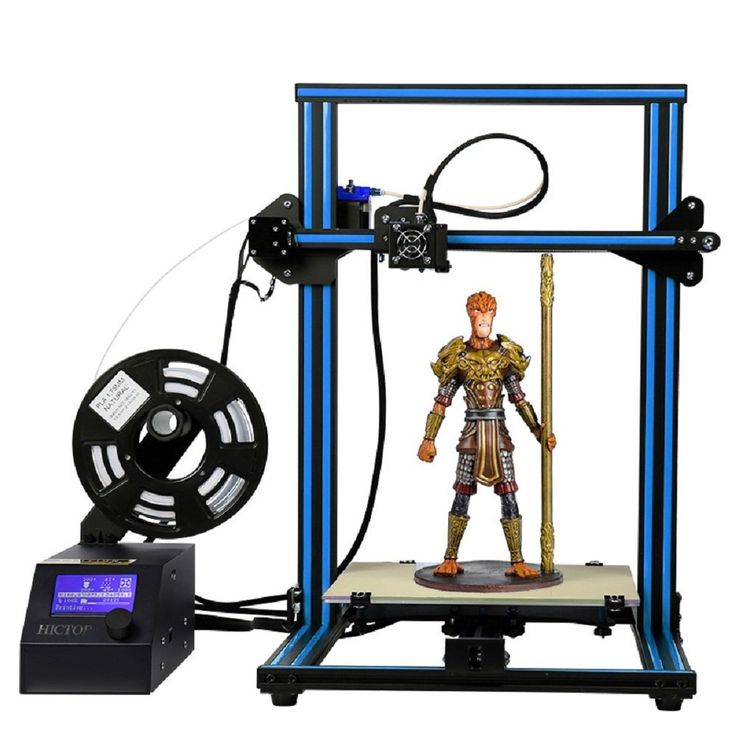

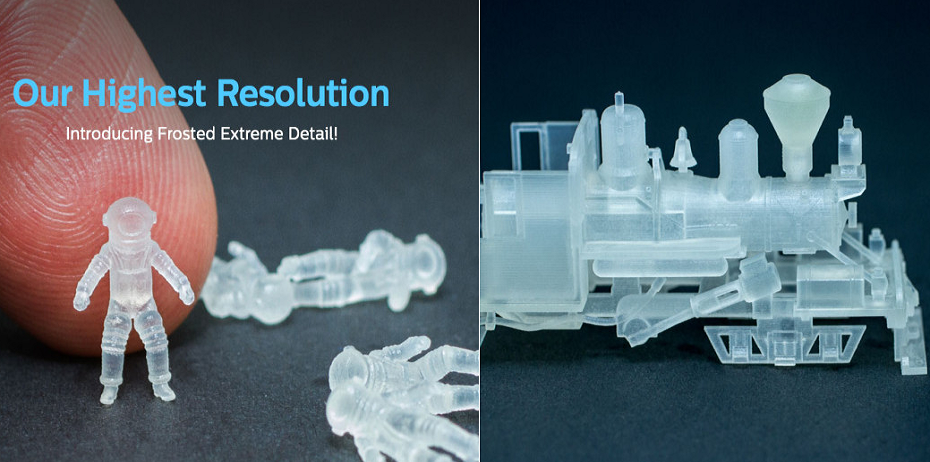

1. The Shapify Booth creates a ready-to-print 3D file. How do I turn it into a 3D printed figurine?

The Shapify Booth creates a ready-to-print 3D file. How do I turn it into a 3D printed figurine?

There are 2 options:

1. You can find your own local printing partner.

2. You own a 3D printer yourself and print the figurines on your own premises.

2. Can I order 3D prints directly from Artec 3D?

Artec 3D doesn’t offer 3D printing services.

3. What 3D file format do you support?

Our files are in .obj format (plus texture in .png) which can be easily transformed into any 3D format you need (like .ply or .stl) with free software (e.g. Meshlab).

4. What material can the figurines be printed in?

Once you have downloaded the file, you can print it out using any material you like – gypsum-based polymer, metal, plastic or even chocolate.

3D scan customers and make mini 3D figures with Artec Eva.

A present everyone will love!

What is Artec Eva

Artec Eva is the industry standard handheld 3D scanner used for capturing the human body. It was even used to make a 3D presidential portrait of Barak Obama! Using white light 3D scanning technology, it ensures safe, fast and accurate data capture. You can use this lightweight 3D scanner to make a digital portrait of adults and children, with each 3D scanning session taking around 5 minutes.

It was even used to make a 3D presidential portrait of Barak Obama! Using white light 3D scanning technology, it ensures safe, fast and accurate data capture. You can use this lightweight 3D scanner to make a digital portrait of adults and children, with each 3D scanning session taking around 5 minutes.

Start a successful 3D body scanning business

3D printed figures are a unique, fun and creative way to create fantastic memories of unforgettable moments such as birthdays, weddings, graduation, pregnancy and many others. A great and innovative gift idea, these mini figures will always be in high demand, and making them is simpler than you think. The smart combination of Artec Eva and a lightweight, portable battery pack gives you the freedom to scan absolutely anyone and everywhere. Take your 3D scanning kit to special events and capture the magic moments wherever they may happen. Creating the perfect gift has never been easier.

Click on the images below to see

shapies made by the Artec Eva

Artec Eva:

Tech specs

Another camera Camera one 30 Led Flash Texture camera twoLightweight

Only 0. 85kg

85kg

Scanning time

5 minutes

3D printable model

from 30 minutes

Polygons

Up to 1M

Throughput

Up to 30 customers

per day

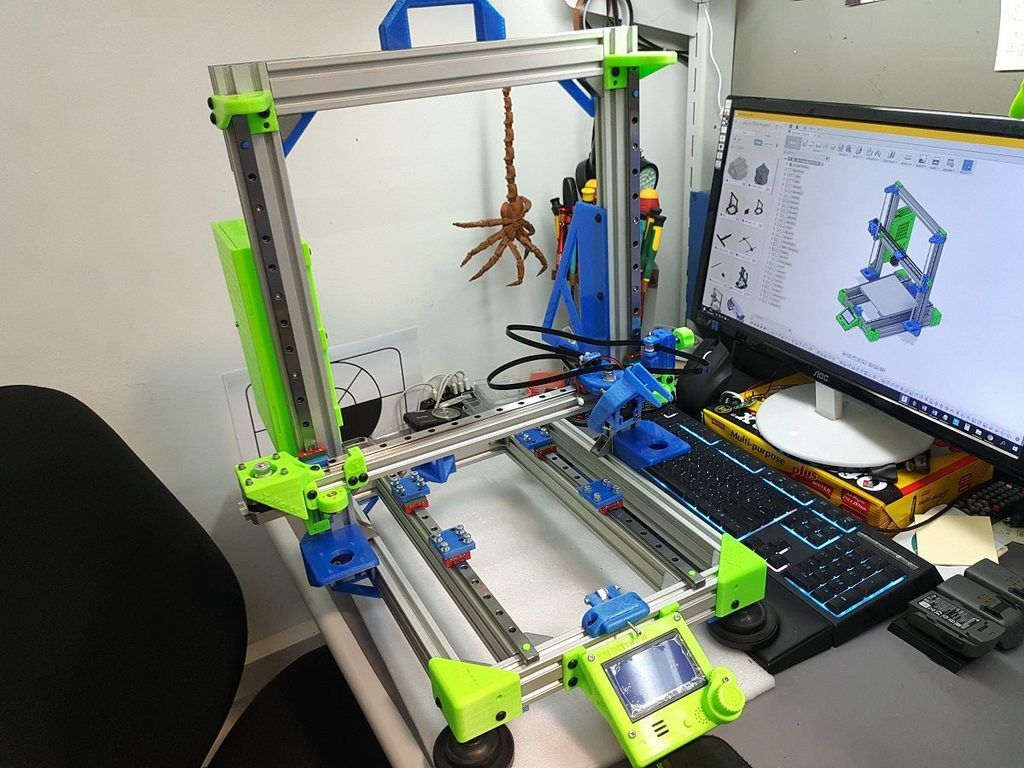

Bussiness model. What you need to get started:

Artec Eva 3D scanner

$19 800

Artec Studio 11 Professional

3D scanning and processing software

1 lifetime license of AS11 version

$1 450

Artec Studio Professional

3D scanning and processing software

1-year subscription, guaranteeing you to always

be equipped with the very latest version of Artec Studio

$600

Artec Eva:

How it works

Capture a person

or couple with the Artec Eva 3D scanner and Artec Studio 3D software

Process the 3D model

using Artec Studio

The mini 3D figure

is printed out on a 3D printer

Compatible computer

Tech requirements

Processor: Intel I5 or I7

Memory: 12 GB

Video cards: NVIDIA, AMD, or Intel

OS: Windows 7, 8, 10 – x64

Free disk space: 300 MB for installation

More on tech requirements

Want to learn more about the industry standard Artec Eva 3D scanner?

Fill out the short form below or email us at sales@artec-group. com and we will contact you as soon as we can with further information

com and we will contact you as soon as we can with further information

Name

Phone

Already making 3D figures with your Eva?

Let us know at [email protected] and we will add your business

to our scanning point map for everyone to see!

Find out more about Artec Eva on www.artec3d.com

3d printing of a person - 3d printing of figures of people on a 3d printer in Moscow

Masterpieces of fine art always amaze with filigree and liveliness of human images. It would seem that copying the human image will forever remain beyond the capabilities of ordinary people. But, nevertheless, time moves inexorably forward, sweeping away restrictions and providing opportunities.

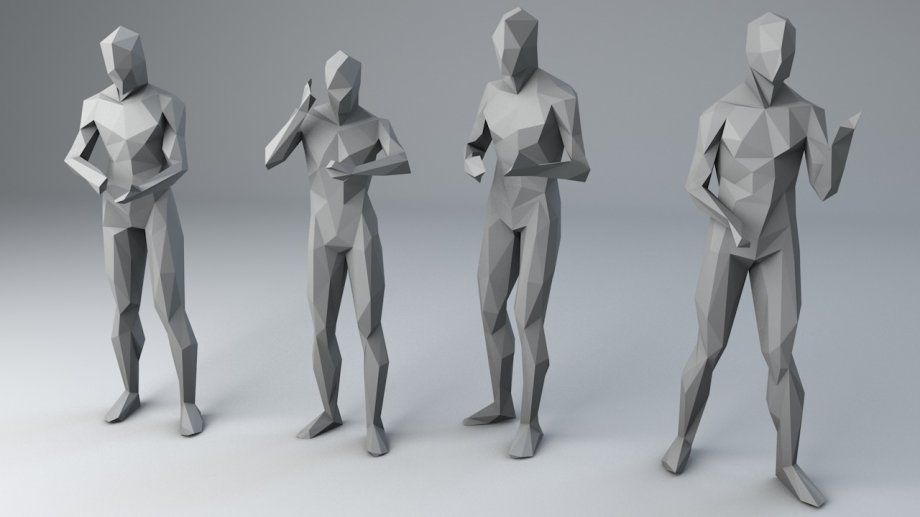

Possibilities and advantages of the masterpiece technology

Every person on the planet is unique, therefore, any copy of a person, whether it be a statuette, a model or a portrait on paper, will also have a uniqueness. 3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

And, let it sound a little cynical, but 3D printing of a person opens up incredible opportunities in various areas of our lives. Just imagine, the creation of sculptural copies of a person takes months, and sometimes years. The cost of such a sculpture is often simply beyond the reach of an ordinary person. And the chances of becoming a model of a talented sculptor are negligible.

On the other hand, getting your own exact copy a few centimeters in size is now not at all difficult and not expensive. Moreover, a real boom in the popularity of 3D printing is brewing in the world, which will soon create a significant alternative to photo printing and video chronicles. And it's not just about private ambitions and fun!

Spheres of demand for 3D printing technology of people

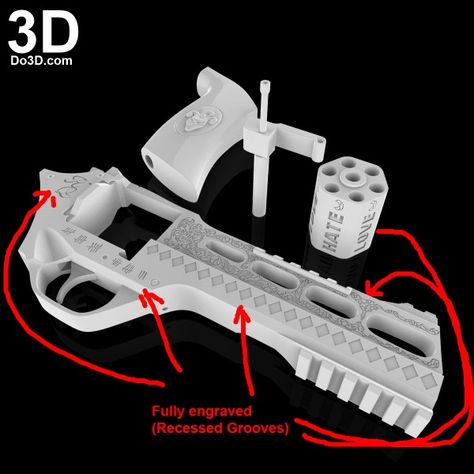

3D printing of figurines is already widespread today in:

● advertising;

● decoration of wedding celebrations;

● souvenir industry;

● prototyping of industrial and commercial facilities;

● design;

● medicine.

The noble mission of innovative technology

Moreover, the circle of people professionally interested in the service in order to develop their business is constantly growing. In addition to the persistent interest in technology, its profitability and spectacularity, 3D printing of people also serves noble purposes, for example:

● allows blind people to tactilely get acquainted with the external images of their relatives and friends, communication with which is limited to virtual space;

● allows future parents to admire their baby in the womb, not only with the help of ultrasound pictures. 3D printing of a baby figurine built thanks to innovations will allow you to get to know him visually even before he is born;

● Printing figurines on a 3D printer helps people with mental trauma and disorders to adapt to a certain social environment;

● in psychology and educational disciplines, three-dimensional models of people are involved in methods of working with children.

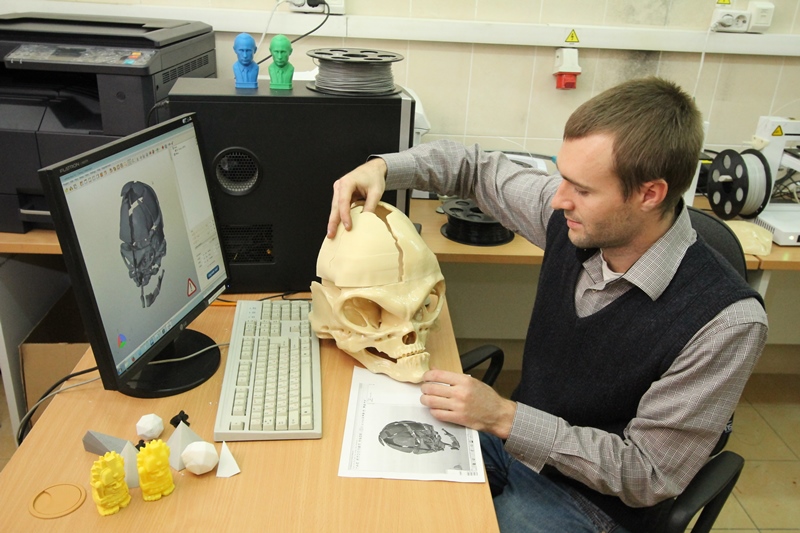

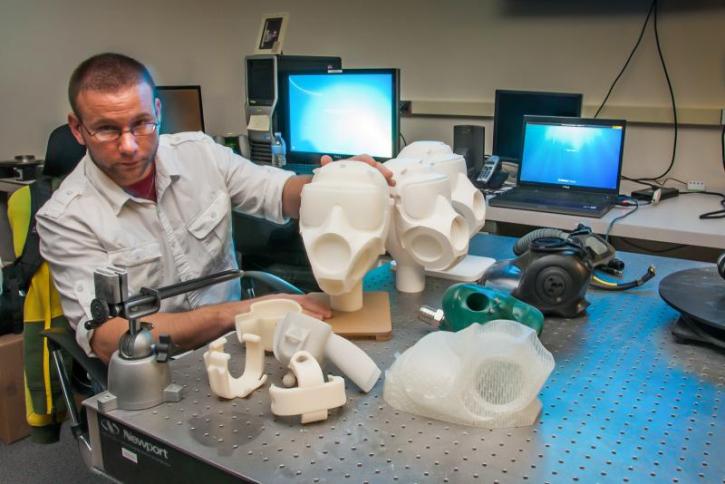

Steps for creating 3D copies of a person

High-quality and high-quality 3D printing of people actually requires several preparatory steps.

● In the first, a full-length 3D scan of a person is performed

● In the second, a copy of the 3D model is carefully processed

● In the third, the figure is scaled down and printed.

The technology also includes a number of post-press processing steps. Figures may require surface grinding, painting or tinting, freeing them from auxiliary elements - clamps, additional details, coating with protective varnishes, finishing agents.

Consumables and features of technological processes

Various materials are used for 3D printing of human figures and

even different equipment, technically and technologically different from each other. So, the result can be presented in plastic, gypsum, polymer mixtures. It can be single color or multicolor. Realistic or only in general terms reminiscent of the original.

Human 3D printing technologies are also different. The most popular and frequently used are two:

● layer-by-layer reconstruction of the model on an inkjet 3D printer;

● laser baking, stereolithography on a laser printer.

For the best and most accurate reproduction of the image of a person, it is advisable to use the method of layer-by-layer gluing of a cellulose-starch mixture.

The use of 3D printed human figures in the advertising industry

Of course, the advertising industry has traditionally been at the forefront of bringing innovation to its service. 3D printing of human figures has become the basis of several high-profile advertising campaigns in Spain, Germany, and the UK, during which passers-by on the streets and visitors to shopping centers were asked to quickly create their own miniature on a 3D printer.

But the scope of advertising use of this technology is much wider:

● Figures of real company employees in company uniforms can make up a static installation.

● May be part of a believable animated advertisement.

● Given as a souvenir, they will be a powerful motivation for a common cause and common success.

● 3D printing of human figures in addition to the presentation of 3D models of industrial, construction, social facilities can bring liveliness and dynamics to the presentation of projects.

● Using a 3D printer, you can create not only mini copies of real people, but also transform familiar replicated images of famous sculptures. For example, dress the Venus de Milo in the costume of a stewardess of the advertised airline, and use a mini copy of Rodin's sculpture in an advertisement for ladies' accessories.

The position of 3D copies of a person in souvenir production

A treasure trove of invaluable prospects 3D printer and human printing will bring to souvenir production. With the help of technology, you can make:

● popular interior figurines;

● intricate paperweights;

● gift personalized figurines;

● wedding souvenirs of the bride and groom;

● commemorative figurines of anniversaries and heroes of the occasion.

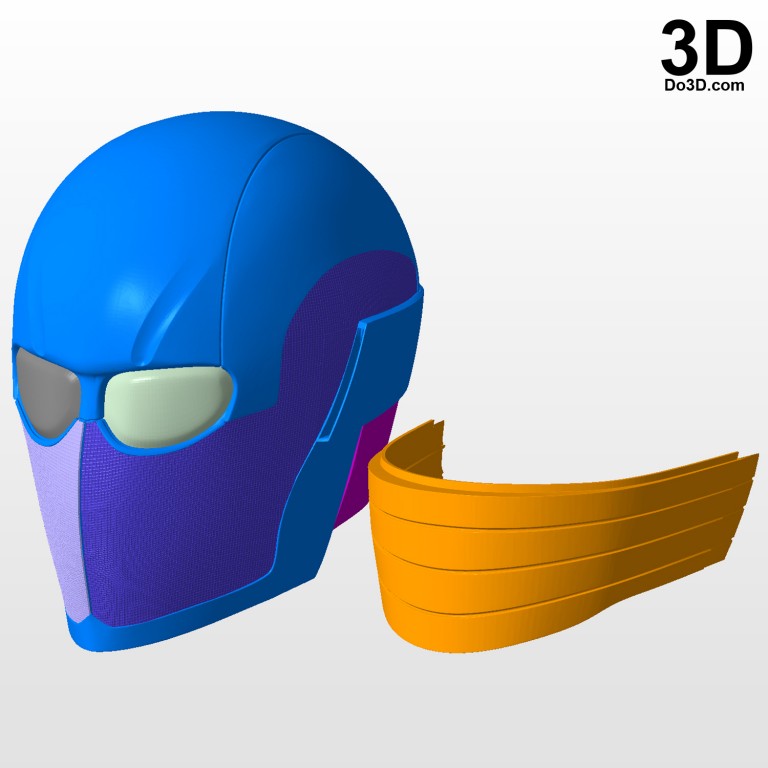

Variants of representation of the image in a three-dimensional miniature

When creating souvenir miniatures of people, you can most often find three directions for recreating the image:

● realistic or ordinary, the one that can be found in an amateur photo or in life;

● staged, when models are presented in fantasy, stylized images, for example, superheroes or characters from famous fairy tales, movies, literary works, comics;

● wedding, couple real or fictional image.

Bride and groom figurines - this is just the beginning!

The industry of wedding paraphernalia, in addition to commemorative figurines of the newlyweds, can use 3D printing of figurines to create original decorations for invitations, decorating a wedding cake, a festive table, use mini-copies as props for an original wedding photo shoot and video shooting of a romantic love-story.

Online services and their features

It is worth saying a few words about online 3D scanning services. This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

Actually, the results of scanning and allow you to remotely provide services of three-dimensional modeling of a person. The more diligently the scan is made, the more similarity will be between the model and the figurine. By the way, the service of 3D printing of people can be provided not only on the basis of a scan of a real person, but also on the basis of photographs taken from different angles.

How to obtain the necessary sources for 3D printing

To recreate the image in a 3D model, try to get pictures from eight angles in a circle, where the angle step will be 45 degrees. This information will be useful to those who plan to organize a surprise related to the secret production of a mini-copy of a person on a 3D printer. And even if a spontaneous photo session provides less information about the image than a scan, the result will still be recognizable.

Our company is ready to offer all interested people 3D human printing services, as well as business cooperation in this area. Our technical equipment allows us to implement not only our own, but also third-party projects, providing a successful launching pad for your business to take off. We will be glad to assist you in creating a three-dimensional human copy and mutually beneficial cooperation. How a bioprinter can save lives The 3D printer improves this technology in many ways, since the X, Y and Z axes are available to it. Three-dimensional printing is reduced to the layer-by-layer construction of an object specified by the operator using a computer. Already now we are able to make car parts, toys and sculptures. However, a 3D printer can not only facilitate production processes, but also save people's lives.

The fact is that a living organism is essentially a biomachine. Its success directly depends on how coordinated and high-quality the organs-details will work.

Our bodies have come a long way before becoming what they are today. Each of them has its own structure, anatomical features, and also occupies a certain place in the cascade of physiological reactions.

| The human body has evolved with a brutal reserve of strength. We are capable of living in traumatic conditions for a very long time. Contaminated air. Wrong nutrition. Toxins in food. All this slowly but surely upsets our vital activity. What to do when an organ fails? At the beginning of the 20th century, science approached the milestone at which the emergence of transplantology became possible. It would seem that everything is simple: remove the donor organ, implant it in the patient and enjoy the success. |

Only now our cells expose original antigen flags on the surface of membranes. If the immune system sees something not under its "banner", it instantly triggers an inflammatory response. T-killers produce antibody drones that swim towards foreign cells. They begin to perforate cell membranes, killing tissue.

T-killers produce antibody drones that swim towards foreign cells. They begin to perforate cell membranes, killing tissue.

In the case of the bone marrow, aggression is known not from the body towards the organ, but from the graft towards the recipient. A weakened organism is not able to withstand the conflict between its parts. This leads to the most terrible consequences up to the death of a person.

The technical execution of the operation depends on the skill and experience of the surgeon. The problem of organ engraftment is a long-standing scourge of transplantology. Modern technologies, developed in close cooperation with IT, offer a dizzying prospect of solving this difficulty - and saving thousands of lives. The fact is that it is not necessary to look for an organ that is suitable for the antigenic composition of the patient. An organ can be created artificially. This is where bioprinters and 3D printing technology come into play.

How a 3D printer works

The bioprinter does not differ from its industrial counterpart, except for the fact that it prints with living cells on a collagen matrix.

Collagen is a filamentous protein that acts as a scaffold for specialized cells. Doctors take the patient's cells and place them in an incubator where conditions are created for their reproduction. Having accumulated enough material, the operators will be ready for the actual printing.

Collagen is a filamentous protein that acts as a scaffold for specialized cells. Doctors take the patient's cells and place them in an incubator where conditions are created for their reproduction. Having accumulated enough material, the operators will be ready for the actual printing.

This process is relevant for simple fabrics like leather. Some cells, for example, blood bodies or cardiomyocytes, are at the final stages of their evolution. Propagating them in a cup is a thankless job. Such intractable comrades are much easier to make from stem cells.

On the fingers, a cell can be compared to a biological plant that produces certain substances. All cells have the same genes. The nucleus plays the role of a computer, and the DNA chains act as a hard disk on which the program is written. In molecular biology there is a dogma "gene-protein-trait". These same genes can be turned on or off, causing the cell to work in completely different ways. |

Stem cells can be considered progenitor cells from which anything grows. They can be pushed onto the road of specialization, forcing them to become the right fabric. It is she who will be the structural unit of the body.

Soft

Creation of a three-dimensional structure begins with a computer model. Speaking about the creation of organs, one should mention computer and magnetic resonance imaging. These diagnostic methods create two-dimensional sections of the anatomical structure. The model built on the basis of slices will be the reference for 3D printing.

Allevi is a major player in the bioprinting market. In September 2015, the Allevi Bioprint PRO program became available to specialists. Cloud software is available from any computer and has built-in model generation technology with integrated slicing. This allows specialists to focus on biomedical production, rather than time-consuming printer setup. |

At the same time, a new product from Cellink made a major claim to be the most flexible and advanced bioprinting software. The BIO X6 printer, which has no analogues in the world, realizes the possibility of combining a colossal array of materials, cells and other tools for the artificial creation of organs.

What can be created with a bioprinter

The human body is a complex structure that combines a huge array of living tissues. coordinate their work. Satisfy needs. Explain to each body what is required of it. All this imposes a colossal responsibility on the specialist, but saving the patient and ensuring a high quality of life is worth all the hard work.

The organs are permeated with a dense network of capillaries. Each blood vessel functions as a freeway that carries blood, oxygen, nutrients, and nerve cells. Nerve wires distribute commands from the nuclei of the brain.

Many cells sort of “know” which direction they should grow, but even so, they will need a scaffold of biological fibers.

Many cells sort of “know” which direction they should grow, but even so, they will need a scaffold of biological fibers.

| Years pass from the moment of discovery of some physiological process to understanding how to influence it. Years of clinical research, collection of statistics and processing of received information. But you still need to find out how safe the invented method of treatment is and what its long-term consequences will be. It also takes time and effort to develop specialized software. High-tech medicine is developing in close integration of mathematics, biology, cell culture and information technology. |

Programmers, doctors, engineers and biologists work day and night to ensure that people who need help can get it. Now the technology of three-dimensional printing is far from perfect, but the success is already impressive. So what can be printed on a 3D printer? Let's start from simple to complex.

Artificial leather

The skin acts as the first barrier that separates the internal environment of the body from the world. The skin can regenerate. It readily responds to stimulation of growth in the laboratory, and its structural elements tolerate the lack of oxygen well.

Skin grafting is of great importance for combustiology, the branch of medicine that deals with the treatment of burns. A burn is not just pain. Dead skin allows bacteria to enter. Moisture actively evaporates from its surface. Inflammation, which inevitably follows thermal damage, triggers very bad processes in the body.

A research team at Wake Forest School of Medicine has tested a bioprinter capable of printing skin directly onto a burn. The scanner examines the surface and depth of the wound. The printhead applies the cell culture. To effectively heal a wound, covering one tenth of the area of the defect is enough. Once on the body, skin cells begin to increase in number and heal the wound.

Cartilage

The cartilage is denser than the skin, but calmly tolerates the bioprinting procedure. The ears and eyes form the aesthetic contour of the face. Patients who have survived traffic accidents or other injuries become clients of plastic surgeons. Now there is a wide choice of silicone prostheses, outwardly barely distinguishable from the native nose. The trouble is that the body perceives silicone as a stranger.

In 2015, researchers in Zurich found a way to print a real nose in just 20 minutes. Here's what Matti Kesti has to say about it:

| “The cells of the victim are taken from the knee, broken nose or ear. We make them breed in the lab. After they are mixed with a biopolymer. From this suspension, the bioprinter makes a model of the cartilage of the nose. The surgeon implants it during the operation. Subsequently, the polymer matrix degrades, leaving only native cartilage. An additional advantage is that the implant grows with the patient, which is especially important for children.  ” ” |

Blood vessels

Blood flows through the vessel, as if through a pipe. The trophism of organs directly depends on how healthy this vessel is. Vascular accidents claim thousands of lives. The first of them is associated with atherosclerosis, when a fatty plaque clings to the vessel wall. A clot grows around her. The condition in which it comes off is called "thromboembolism". With the blood flow, the thrombus flies into the vessel of a smaller lumen and tightly closes it.

Of course, atherosclerotic plaques can be removed by vascular surgery. But why not grow a healthy vessel? Monica Moya from the Livermon National Laboratory coped with this task. Vessels made using its technology are able to independently grow into the underlying tissues. Combining the Moya technique with classical bioprinting, it is possible to create much more complex organs than skin or cartilage.

Monica Moya at work.

Bones

Fractures are managed by traumatology. The bone skeleton forms a framework on which other tissues are held. Bone articulations are different, but in the context of bioprinting, injuries of the spine and joints are of particular importance. Despite their hardness, the bones are alive, and therefore tend to become inflamed and die. Modern titanium prostheses return people the ability to move, but any metal causes rejection reactions.

Adding fuel to the fire is the need for compliance between cartilage and bone. Without it, the work of the joint will be impossible. A team from Swansea University has developed a technique for manufacturing bioprostheses.

A small bone is printed within 2 hours. So, it can be done in the operating room. The points where the implant will adhere to human tissues are covered with its own stem cells. The cell culture is supported on a gel-like alginate matrix. After implantation, recovery processes are launched in the body, the result of which will be a full-fledged bone.

Bladder

Wake Forest University in the US has made impressive strides in bladder replacements. However, the creation of American scientists is more than a bioprosthesis. This is a complete organ that is fully grown in an incubator. After implantation into the patient's body, the dissolution of the biopolymer begins, and in the end only living tissue remains.

Kidneys

Diseases of the excretory system claim many lives every year. The kidneys continuously filter the blood, clearing it of toxins. If this process is disturbed, the body literally suffocates in its own poisons. Hemodialysis and plasmapheresis technologies partially solve this problem, but the patient remains face to face with the need to regularly visit the dialysis center.

The kidney has a complex internal structure of coils and loops. It would seem that such a thing is impossible to create. Scientists from the Institute of Regenerative Medicine strongly disagree with this.

Anthony Atala, professor of urology, demonstrated a complete kidney from a bioprinter that uses an inkjet printing method. The patient's cells were placed on a matrix. The matrix is created on the basis of two-dimensional sections obtained by magnetic resonance imaging.

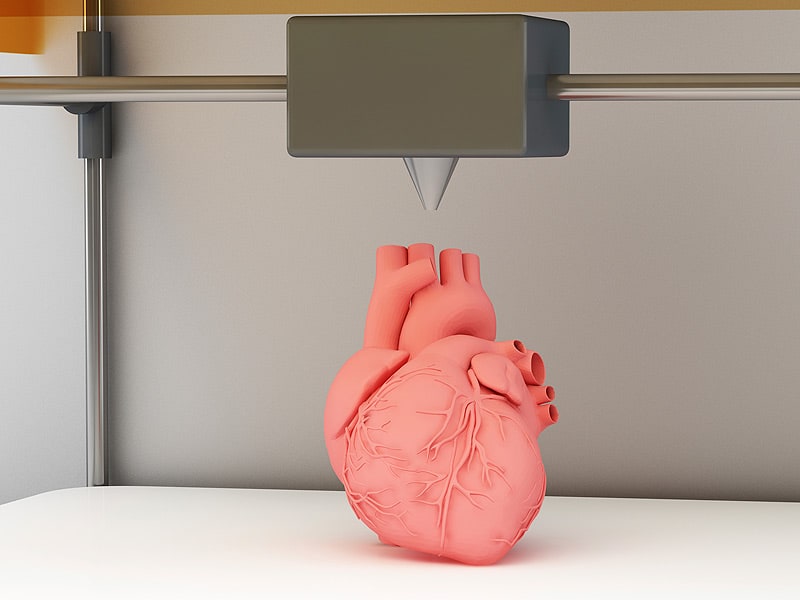

Heart

In the cohort of vital organs, the heart stands out especially. Sometimes it is compared with a pump, but such an analogy would be too rough. Let's start with the fact that the heart is made up of cardiomyocytes - special muscle cells that can contract at once. The contraction-stretch cycle is regulated through the autonomic nervous system. An electrical impulse is generated in the sinus node. It spreads through the bundle of His with its right and left crura.

It is possible to live with failed kidneys for some time. But rhythm and conduction disturbances are fatal, not to mention all kinds of heart attacks. The heart regenerates badly. If some part of it had time to die, this fact is no longer corrected. If some part of it had time to die, this fact is no longer corrected. |

An additional problem is the difficulty in heart transplantation. It is not enough to get a living organ from the body of an already dead donor: it still needs to be preserved before the operation. A heart transplant is also not easy. To do this, it is necessary to maintain the circulation of the patient in the absence of a main pump.

Bioprinting does not solve all problems, but in the future it may solve some of them.

And again, the Wake Forest Institute of Regenerative Medicine was noted here. In 2015, viable cardiomyocytes were obtained there, which fought well in unison. Israel spoke next. In 2019, they managed to produce a fully functional heart there.

The breakthrough is that Israeli scientists have created the world's first working heart, not just a part of it. The bottom line is that the heart is the same muscle, and for work it requires a continuous blood supply. Under natural conditions, this is done by the coronary vessels.

Under natural conditions, this is done by the coronary vessels.

| In the words of Professor Tal Dvir: “this is the first time that someone, somewhere, has designed, designed and printed a whole heart with all the ventricles, chambers and blood vessels.” |

Of course, scientists have dealt with this issue before. Prior to Tal Dvir's breakthrough, the technology to build an aortic valve already existed, but a part of the heart is no match for the complexity of a whole organ.

At the moment, the artificial heart is the size of a large cherry and is more of a technology demonstration. Nevertheless, the achievements of the Tel Aviv team give hope to many patients in cardiac clinics.

Conclusion

Much has been said about the advantages of bioprinting. It may seem that in the 21st century medicine has come close to creating a panacea for all diseases.

Of course, this is not true. Bioprinting puts forward huge demands on the engineering and technological part. It can be provided only in countries with a powerful industrial complex. Information technology is developing every hour, and the help of specialists in this industry is needed by doctors more than ever.

Of course, this is not true. Bioprinting puts forward huge demands on the engineering and technological part. It can be provided only in countries with a powerful industrial complex. Information technology is developing every hour, and the help of specialists in this industry is needed by doctors more than ever. In addition, bioprinting has faced legal and ethical issues. The axiom is that any promising technology will be expensive and costly not only in terms of money, but also in terms of the necessary materials. Personnel training. Providing a technical base. These aspects inevitably lead to stratification of patients. Most of the world's population will remain in line for donor organs, while wealthy people will be able to prolong their lives.

The good news is that artificial organs are rarely tested on animals. But what about patients who received printed grafts? The effects of treatment show themselves over a long period of time. The pitfalls of the methodology can only be identified through randomized and mass clinical trials. But behind every statistic is someone's life.

But behind every statistic is someone's life.

| Of course, these issues will be resolved along the way. Medicine is on the threshold of a new era, and in 20, 50 or 100 years it will be very different. Progress cannot be stopped. Soon our lives will be different. Longer, healthier and more productive. It remains only to pay tribute to the people who work for the benefit of humanity and those who need help most urgently. |

Author: Nikita Ignatenko

A UFO flew in and left here a promo code for our blog readers:

— 15% for all VDS tariffs (except for the Warming up tariff) — HABRFIRSTVDS

Materials:

1. All images are taken from open sources and belong to their authors.

2. Ken Doyle. Bioprinting: From Patches to Parts // Genetic Engineering & Biotechnology News.