Weird 3d printing

The 10 Strangest 3D Printed Objects

Here’s a riddle for you: What’s more amazing: Technology? Or what can be made with technology?

Apply that riddle to any number of topics: medicine, the internet, nuclear armament, or engineering, and you’re in for an afternoon of philosophical pondering. But, as far as 3D printing is concerned, there’s a very clear answer to the riddle.

While 3D printing technology is amazing, the things that have been created using 3D printing are far more incredible. Let’s discuss the 10 strangest things that have been 3D-printed. But first, let’s briefly review what has been going on in the 3D printing world.

How does 3D printing work?

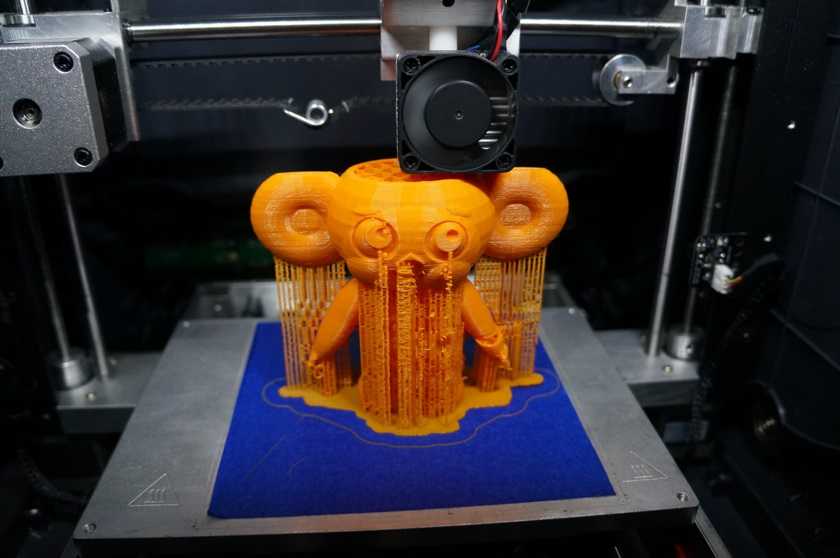

Have you ever made a sandwich? It’s simply an act of stacking layers of ingredients. The first layer is a slice of bread. The second layer is a coating of mustard. The third layer is a slice of lunch meat, and then there’s a layer of lettuce, and then tomatoes, and so on, so forth.

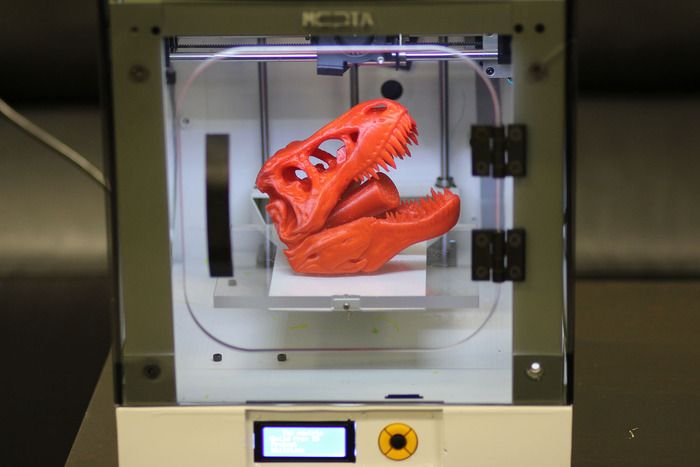

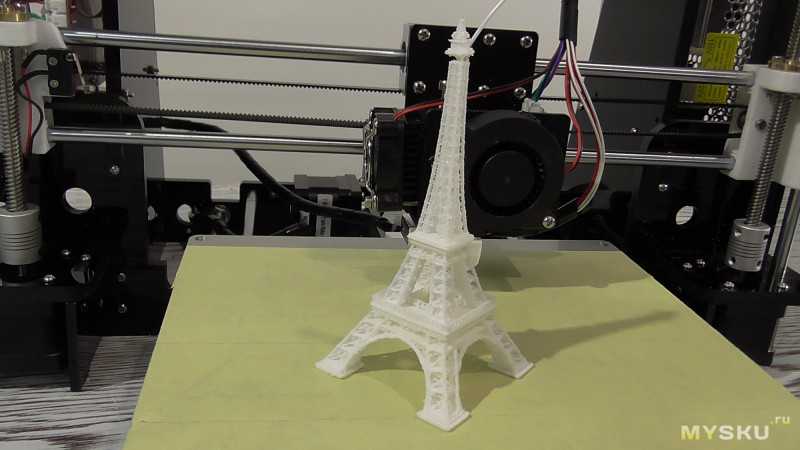

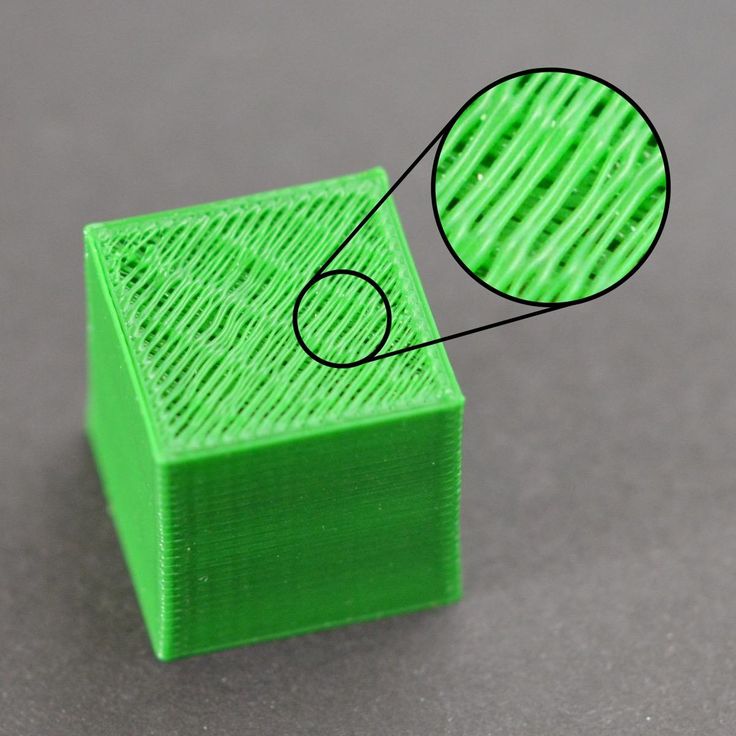

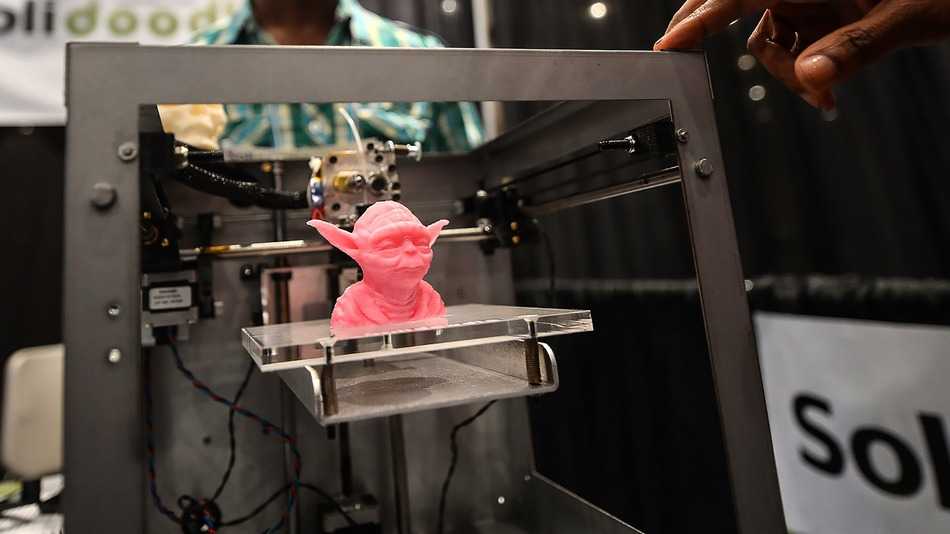

3D printing works in the same way. A 3D printer creates a physical object by stacking layer after layer of a particular substance. Each layer is poured as a liquid. Once the liquid dries or hardens, the next layer is poured on top. There are other 3D printing methods, but they work in roughly the same way.

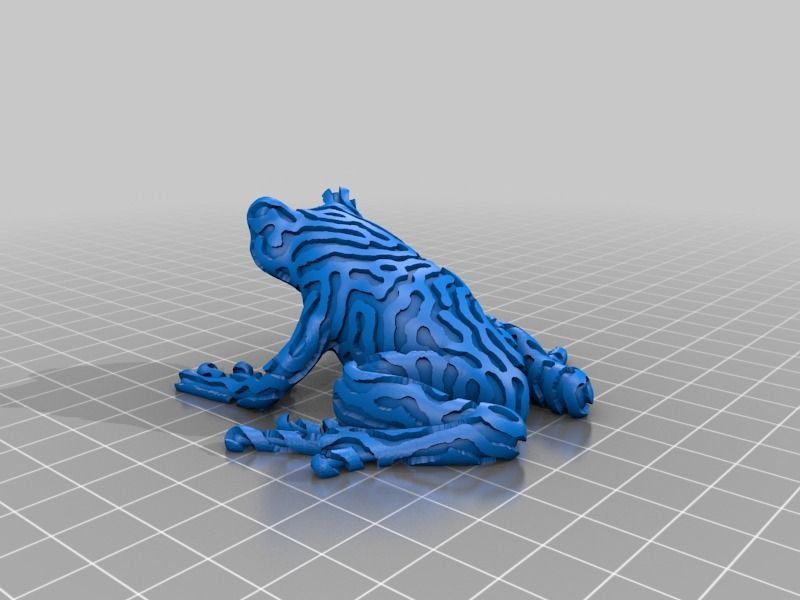

A 3D printer works off of a computer-aided design (CAD). A CAD is basically a digital model of whatever’s going to be 3D printed. The CAD provides the exact specifications of the object so the 3D printer knows what the shape and size of each layer will be. Before you 3D print an object, you’ll first have to use a design-optimized computer to create a CAD of the object.

Are there limits to 3D printing?

Yes and no. Most of the limitations of 3D printing have to do with two things: size and substance.

On a regular printer, you can’t print a document that’s larger than the printer itself. Similarly, you can’t 3D print anything that’s larger than the 3D printer. But that hasn’t stopped some of the more ambitious individuals. An entire high-rise building has been 3D printed (we’ll get to that, soon). Obviously, the building wasn’t constructed entirely within the machine. But each portion of the building was 3D printed and then assembled onsite.

But that hasn’t stopped some of the more ambitious individuals. An entire high-rise building has been 3D printed (we’ll get to that, soon). Obviously, the building wasn’t constructed entirely within the machine. But each portion of the building was 3D printed and then assembled onsite.

One of the trickier obstacles to overcome is the choice of material that’s used to print. The material must be something that can be melted and fused into a solid shape. Engineers are always working to develop 3D printers that can print using new kinds of substances, and there are now 3D printers that can print metal objects. There still isn’t a 3D printer that prints wood, but they’ve gotten close. Hilariously, there are 3D printers that can print food (yeah, we’ll get to that, too).

With enough creativity, you can overcome some of the limits of 3D printing technology and create some truly remarkable things.

Useful 3D-printed objects

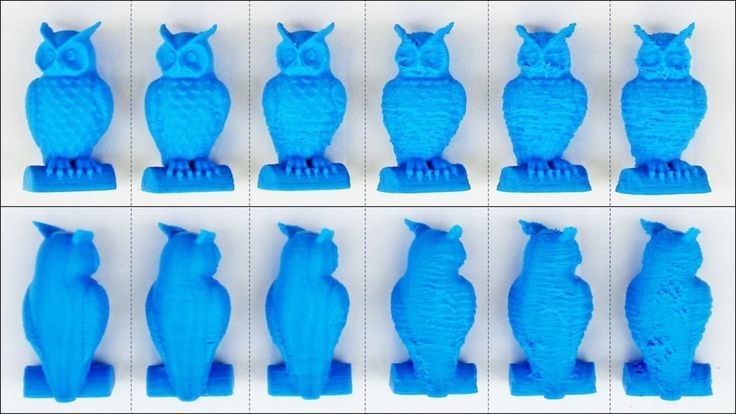

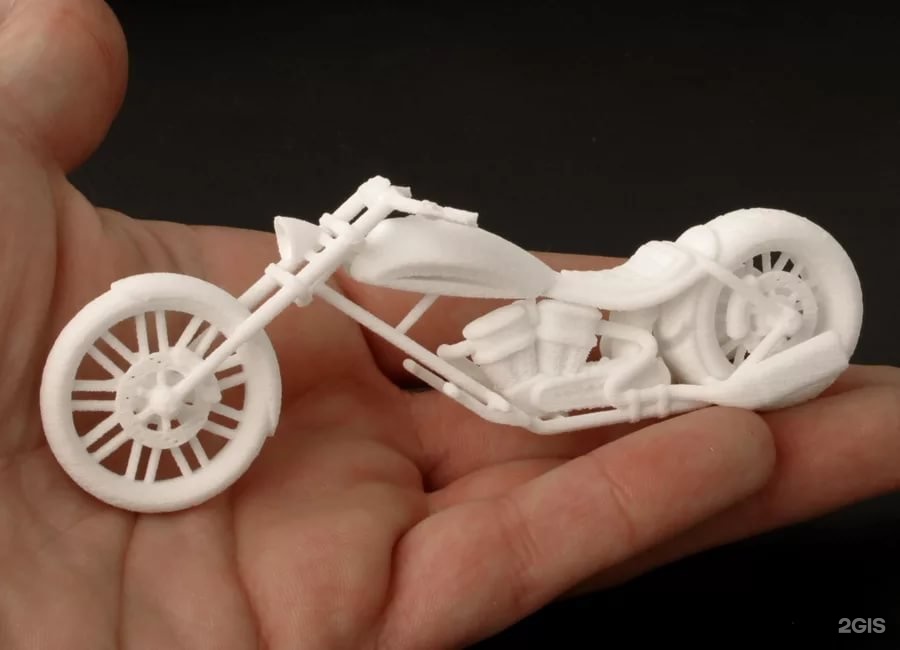

3D printing technology has been around since the 1980s. Originally, it was used to create scale models of manufacturing prototypes or assembly line parts, and that’s still largely what it’s used for today. Machine parts and scale models are commonly built using 3D printers.

Originally, it was used to create scale models of manufacturing prototypes or assembly line parts, and that’s still largely what it’s used for today. Machine parts and scale models are commonly built using 3D printers.

But in the last decade, 3D printers have become much more accessible to consumers. Media interest in 3D printers has also encouraged broader experimentation in lots of different industries, and these days both amateurs and professionals alike are printing unique 3D objects.

Strangest 3D-printed objects

Let’s discuss some of the weird objects that have been 3D printed. Some of these objects are actually quite useful. Others are not. But all of them are wonderfully weird. Here are 10 very bizarre things that have been crafted with 3D printers.

1. Mouse ovaries

Researchers at Northwestern University in Chicago created the first artificial mouse ovaries using a 3D printer. [1] Okay, so mouse ovaries aren’t technically useless - they’d be very useful for any infertile mouse. But ovaries aren’t the first thing you’d expect to be 3D printed, right?

But ovaries aren’t the first thing you’d expect to be 3D printed, right?

The mouse ovaries were created by 3D printing layers of gelatin. Then they were surgically implanted in seven infertile mice. Of the seven mice that received implants, three mice successfully gave birth to litters of pups.

There are human implications to this discovery, of course. The researchers hope that someday, they’ll be able to print artificial human ovaries for cancer patients and others who are infertile.

2. Food

Speaking of mice: researchers at University College, Cork in Ireland 3D-printed objects using cheese. [2] They filled a 3D printer nozzle with Easy Cheese and printed “cheesy” designs with it, including a small bear. The designs were mostly flat because aerosol cheese isn’t the most stable printing substance.

There are other types of foods that have been 3D printed, too, one of the most famous being 3D printed chocolate. If you think that chocolate rabbits are neat, you should see some of the nifty chocolate designs that have been made with 3D printers.

Chocolate makes for a great 3D printing substance because it can be layered while it’s melted then easily hardened. There are several companies that sell 3D-printed chocolate, including chocolate behemoth Hershey. [3]

They’ve also 3D-printed pizza. A printer was equipped with three nozzles that dispensed liquid dough, tomato sauce and cheese. In under five minutes, the pizza dough was ready for baking. Researchers said they were able to accurately control the crispiness of the bread thanks to the 3D printer.

Here are some other cool foods that have been 3D-printed:

- Quiches

- Croutons

- Candies

- Cereal

So what’s on the horizon for 3D-printed food? For one, restaurants and bakeries will be able to print large quantities of stylized foods and pastries. But the hope is that people will be able to prepare food in their own homes without having to cook. Very futuristic, indeed. “Computer...Tea. Earl Grey. Hot.”

3. Skin

Researchers at the University of Toronto created a handheld 3D printer that could apply skin cells on a pig. The pig had its cells harvested, and the cells were grown to a larger quantity. Once researchers had enough cells, they used the cells as the printing substance.

The pig had its cells harvested, and the cells were grown to a larger quantity. Once researchers had enough cells, they used the cells as the printing substance.

The 3D printer was rolled over the pig’s wound “like a white-out tape dispenser.” Success! The skin cells successfully attached to the open wound area. Scientists think that in the future, this technology could be used to replace skin grafts. It would make it much easier to treat victims with open wounds - especially burn victims. [4]

The science of printing living tissues is known as bioprinting. Researchers have printed:

- Artificial bone

- Artificial blood vessels

- Artificial bladders

Scientists are hoping they’ll be able to finally end the long - and sometimes fatal - wait for organ transplants. [5]

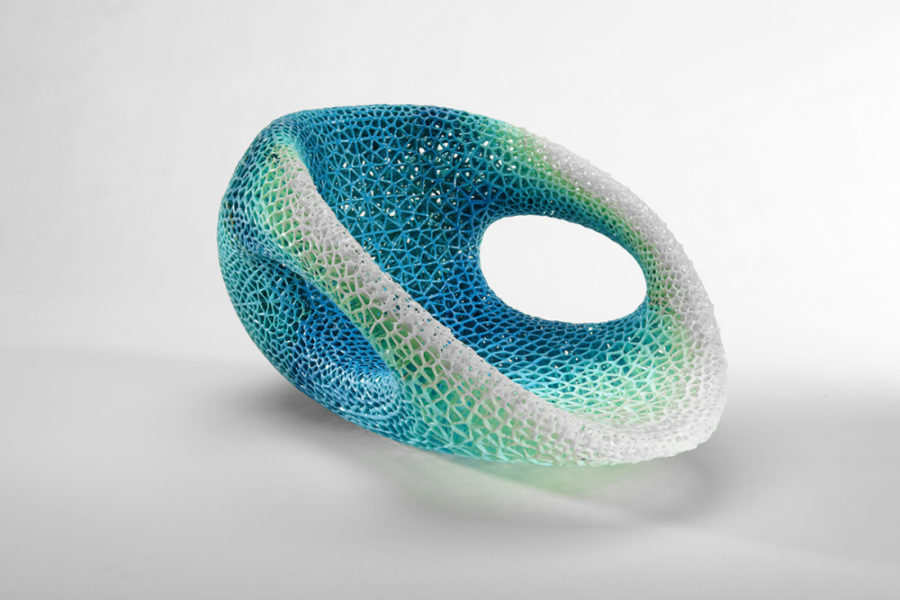

4. Bikini

Textiles are notoriously difficult to print, but a company called Continuum Fashion has created a number of cool 3D-printed fashion items. Their standout fashion piece is the 3D-printed bikini. You can hit the beach and go swimming in style and comfort.

You can hit the beach and go swimming in style and comfort.

Continuum printed the bikini using a material called Nylon 12, which is strong, flexible, and waterproof. The bikini has an awesome texture, too. It’s composed entirely of interconnected beads, a testament to the intricate kinds of designs that can be printed.

The company also produces a line of 3D-printed women’s shoes. [6]

5. Mini Power Drill

You’ve got to see it to believe it. A man in New Zealand created the world’s smallest power drill with a 3D printer. The drill measures 17 x 7.5 x 13 mm, and is equipped with a 0.5 mm drill bit. And it works! The drill is powered by a hearing aid battery and utilizes a miniature motor and headphone-cable wiring. [7]

Should we call this the world’s smallest drill, or the world’s cutest drill?

6. Microscopic race car

There’s a bizarre creation courtesy of researchers at the Vienna University of Technology. They created a 3D printer that can create near-microscopic objects. To demonstrate its abilities, the researchers printed a tiny race car that’s just about the width of a hair follicle. [8] It’s not quite built to tackle the Monaco Grand Prix, but it would make a perfect vehicle for lice.

To demonstrate its abilities, the researchers printed a tiny race car that’s just about the width of a hair follicle. [8] It’s not quite built to tackle the Monaco Grand Prix, but it would make a perfect vehicle for lice.

7. Wall-climbing robot

South Korean scientists used a 3D printer to build a robot that can climb walls. The robot mimics the movement of a gecko and is capable of climbing up vertical walls with the help of adhesion pads. The robot’s body was 3D-printed using a material called Polyamide 12. [9]

Another cool robot was 3D-printed at the University of California, San Diego. This robot has three legs and can navigate rough terrain, like sand and rocks. 3D printing was integral in building the robot. In order to crawl over rough terrain, the robot needed to be constructed of softer, more flexible materials than what most robots are made of. The researchers were able to 3D-print the robot’s soft and hard surfaces together. [10]

8. Unborn babies

Thanks to 3D printing, expectant parents can hold their baby before it pops out of the womb. A Russia-based company uses ultrasound scans to create a 3D-printed model of the unborn child. Umm… cute?

A Russia-based company uses ultrasound scans to create a 3D-printed model of the unborn child. Umm… cute?

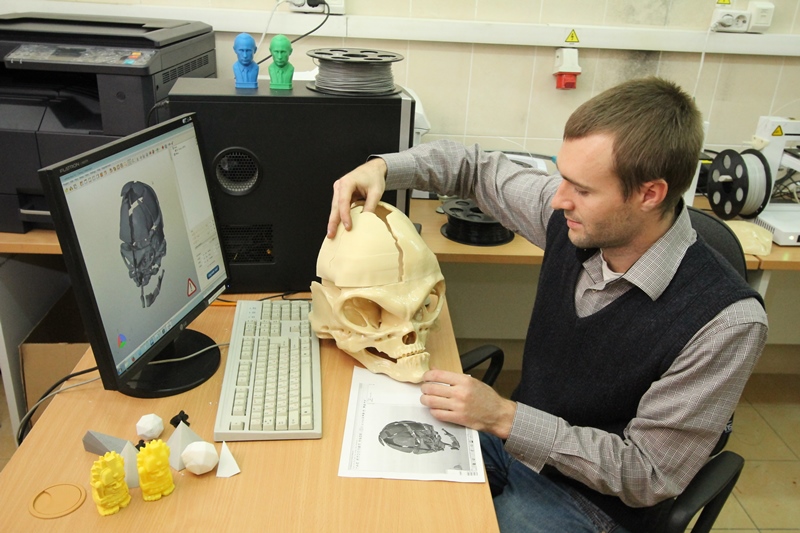

In actuality, the models aren’t made to be baby shower gifts. They help doctors evaluate the health of the developing child. The models are a bit surreal. They’re highly detailed and capture the smallest facial features of the unborn baby. [11]

Imagine the comedic possibilities of using an unborn baby model at a gender reveal party.

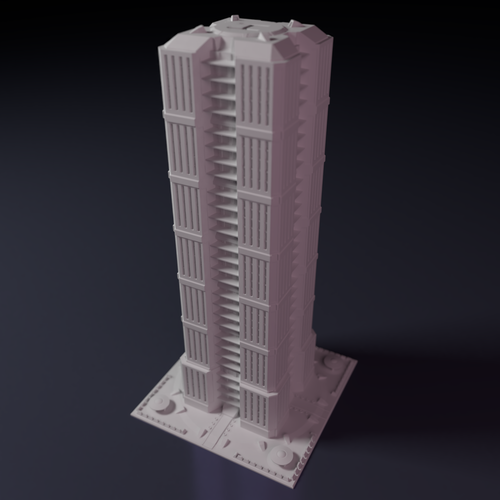

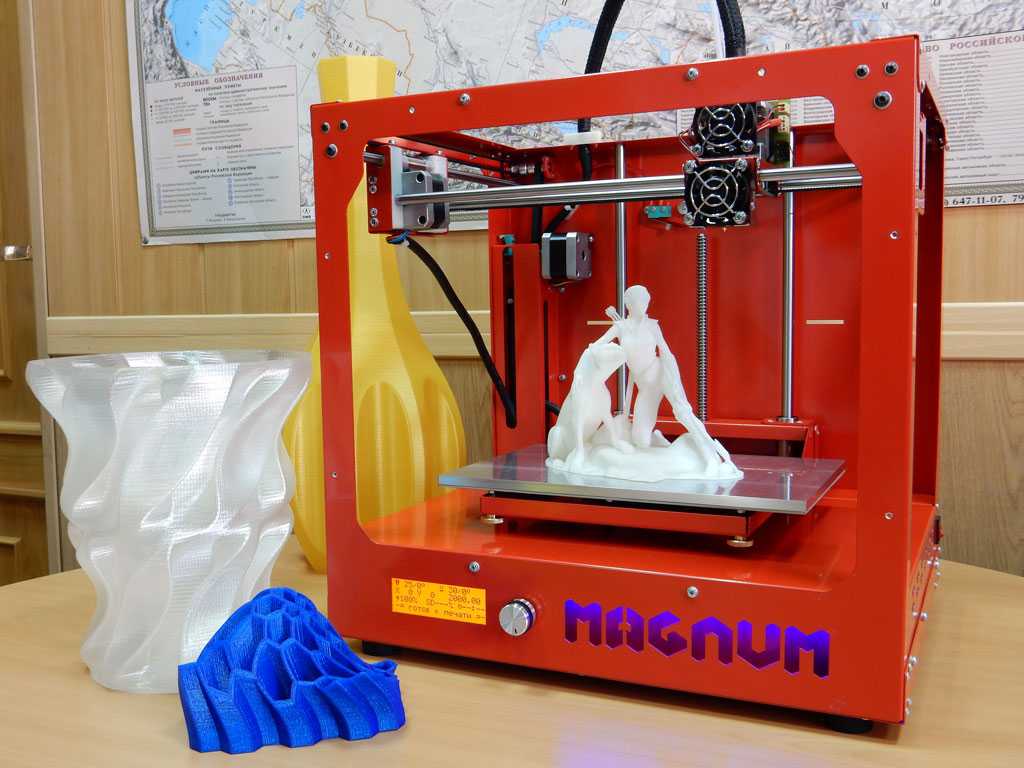

9. Buildings

Buildings aren’t strange (unless we’re talking about some contemporary architecture). But constructing a building with a 3D printer is strange. How on earth can a 3D printer construct something so gigantic?

Concrete is the main substance that’s used by a 3D printer to print a home. A crane lifts the printer nozzle above the ground and maneuvers the nozzle as it places layers of concrete. Some 3D printers can also layer insulation materials.

Most 3D-printed buildings don’t adhere to building codes, so they’re either built as temporary structures or they’re built very small. But construction firms are optimistic that they’ll be able to build more advanced structures as the technology progresses. [12]

But construction firms are optimistic that they’ll be able to build more advanced structures as the technology progresses. [12]

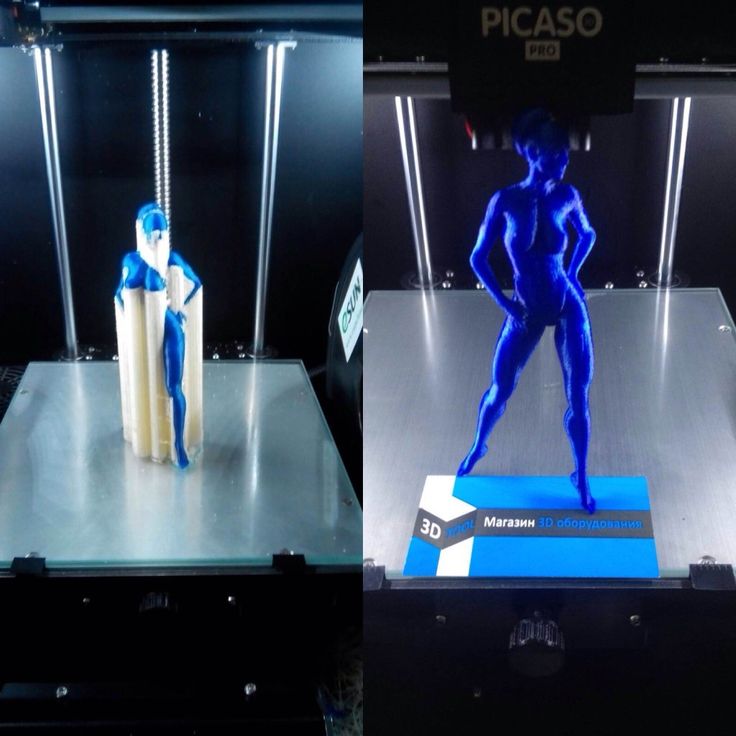

10. 3D printer

That’s right: a 3D printer has printed a 3D printer. [13] This is the most “meta” item on this list. You can’t print a 3D printer in its entirety, but people have printed all of its individual parts, and then they’ve manually assembled them.

Honorable mention: light-created objects

Researchers at the University of California, Berkeley discovered how to 3D print solid objects out of liquid and light. The researchers used a gooey liquid that turns solid when exposed to a certain amount of light. They used light beams to sculpt solid figures within the liquid. The benefit of this technique is that it’s easier to print bendable items. Objects printed in this way are also much smoother than those that are 3D-printed by traditional methods. [14]

None of the objects that they printed were uniquely “strange.” But the printing process itself is strange enough to be worthy of a mention on this list.

Your turn to contribute

What are you waiting for? You could be the next great inventor of a strange (or useful) 3D-printed object. Learn about HP 3D printing technology.

Here are some 3D printing ideas for you. You can print them on a large 3D printer or a home 3D printer. Some of these objects have been designed and 3D-printed by ordinary people!

- Musical instruments

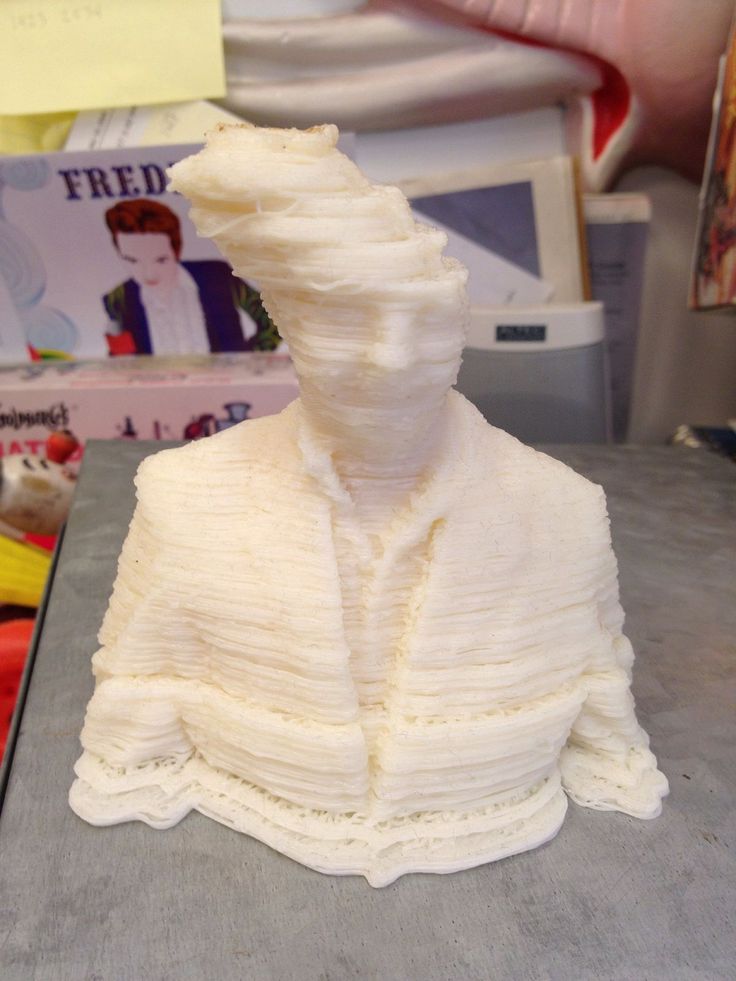

- Busts

- Makeup

- Toys

- Cable catchers

- Pen holders

- Phone docks

- Tablet stands

- SD card holders

- Garden decor

- Recycling/sustainability equipment

There are so many cool items you can make with a 3D printer, no professional assistance needed. Get out there and start creating, and be sure to share your innovative or wild ideas with the rest of us. You can change the world with 3D printing, or you can print something that’ll make all of us laugh.

[1] TheGuardian.com; 3D-printed ovaries allow infertile mice to give birth

[2] Gizmodo. com; The First 3D Printed Cheese Was as Bizarre as You’d Expect

com; The First 3D Printed Cheese Was as Bizarre as You’d Expect

[3] Fabbaloo.com; 3D Printing Is Revolutionizing The Chocolate Industry

[4] CNet.com; This Handheld 3D printer can print skin onto people

[5] Science.Org.Au; Printing the future: 3D bioprinters and their uses

[6] BusinessInsider.com; The World’s First Bikini Made Using A 3D Printer

[7] Geek.com; World’s smallest working drill created with a 3D printer

[8] UniverseToday.com; Watch This 3D Printer Make a Microscopic Car

[9] 3DPrintingIndustry.com; 3D Printed Wall-Climbing Robot Emulates Gecko By Walking Upside Down And Underwater

[10] CNNMoney.com; New 3D-printed robot can walk on sand and rocks

[11] TechTimes.com; Expectant Parents Can Have 3D Models Of Unborn Babies

[12] CityLab.com; Is the Revolution of 3D-Printed Building Getting Closer?

[13] Sculpteo.com; Can you 3D print a 3D printer?

[14] BerkeleyNews.com; New 3D printer uses rays of light to shape objects, transform product design

About the Author

Zach Cabading is a contributing writer for HP® Tech Takes. Zach is a content creation specialist based in Southern California, and creates a variety of content for the tech industry.

Zach is a content creation specialist based in Southern California, and creates a variety of content for the tech industry.

The Weirdest and Wildest 3D Printers

When you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

Most home 3D printers create small objects in simple plastic. But wouldn't you love to have a 3D printer that could print cookies? Or makeup? Or human organs? Here are 10 of the wildest 3D printers out there, proving that the devices can make a lot more than just doodads.

1. Mobile Fab trash-recycling 3D printer

Why you can trust Tom's Guide Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

(Image credit: Mobile Fab)One of the strongest criticisms of 3D printers is that they just print more useless plastic gewgaws. But what about a printer that can take old plastic trash and reuse it to make new objects? Once a futuristic dream, recycling 3D printers are quickly becoming a reality. But the best one so far is the Mobile Fab, a Taiwanese invention that's part bike, part plastic-cup recycler and part 3D printer.

But the best one so far is the Mobile Fab, a Taiwanese invention that's part bike, part plastic-cup recycler and part 3D printer.

MORE: Best 3D Printers 2014

The Mobile Fab has three parts: a machine that grinds down the plastic cups in which the popular Asian drink called bubble tea is served, a machine that takes these pieces and melts them into filament and a 3D printer that uses the filament to print objects.

The creators, who work for Taiwan-based design studio Fabraft, ride the bike around Taipei to do live demonstrations of what 3D printing can do.

2. Foodini food printer

In "Star Trek," futuristic Replicators create fully formed food. The closest thing to that here on Earth is the Foodini, a prototype 3D printer developed by Barcelona, Spain-based Natural Machines. The Foodini can print out dough, sauce, ground meat and other food materials in order to create perfectly formed pizza, chicken nuggets, ravioli and more.

In April, Natural Machines ran a Kickstarter campaign in which the Foodini was priced at $999 for a limited time and $1,300 for regular backers. The Kickstarter was unsuccessful, but the prototype works — and Natural Machines promises the commercial version is still happening.

The Kickstarter was unsuccessful, but the prototype works — and Natural Machines promises the commercial version is still happening.

3 "Made in Space" 3D Printer

(Image credit: Made in Space)Most 3D printers depend on gravity: The material drops from an extruder onto a print plate layer by layer to build objects from the ground up. But what if you wanted to 3D print something in space, where there is no gravity?

California-based engineering company Made in Space is working on a 3D printer that can print in zero gravity. And they're getting close: this August, a Made in Space prototype will be sent to the International Space Station for testing.

4. Mink cosmetics printer

Imagine if you could just print out your lipstick, eye shadow or blush, in any color or amount you desired, right from home. That's the goal of the Mink, a 3D printer designed by entrepreneur Grace Choi that launched at the Disrupt NY technology conference held in New York City this May.

Wit the Mink, people can use any photo-editing software, be it Photoshop or MS Paint, to create or select the exact color they wish. The Mink then mixes a pigment using the same basic components used in most cosmetics, and blends that pigment into makeup cream on the spot. Choi says the Mink will go on sale for less than $200 later this year.

5. 3Doodler

Most 3D printers require you to first use a computer design program to create your print object. With the 3Doodler ($99), no predesign is necessary — just pick up this 3D-printing pen and start drawing in the air.

MORE: 13 3D-Printed Halloween Costume Accessories

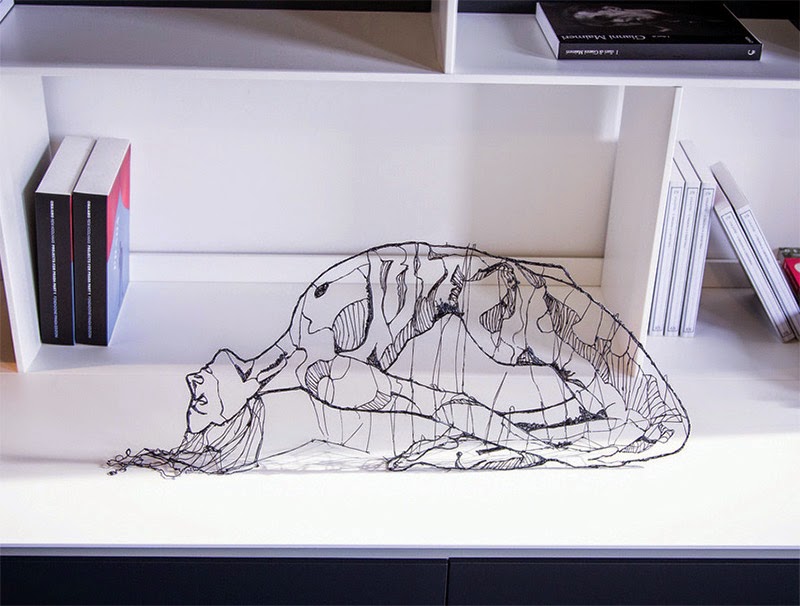

The pen extrudes hot, melted ABS plastic that quickly cools, forming lines in the shape in which you move the pen. It's similar to the way a regular 3D printer works: The pen is the extruder and filament cartridge, and you are the rest of the machine. Like a regular 3D printer, you start at the bottom and build upward, layering plastic on top of plastic as you build your object.

6. A whole-building 3D printer

(Image credit: Winsun New Materials)The 3D printers from China-based Winsun New Materials might not be as large as the one from Nanfang Ventilator, but they are still capable of printing near-complete buildings.

Printing in a combination of cement and glass fiber, the printer recently built parts for 10 656-square-foot (61 square meters) homes in Suzhou, China, that were then shipped to and assembled in Shanghai. A Winsun engineer told the Wall Street Journal that, although the process was efficient, unspecified local bureaucratic hurdles currently prevent the practice from becoming widespread.

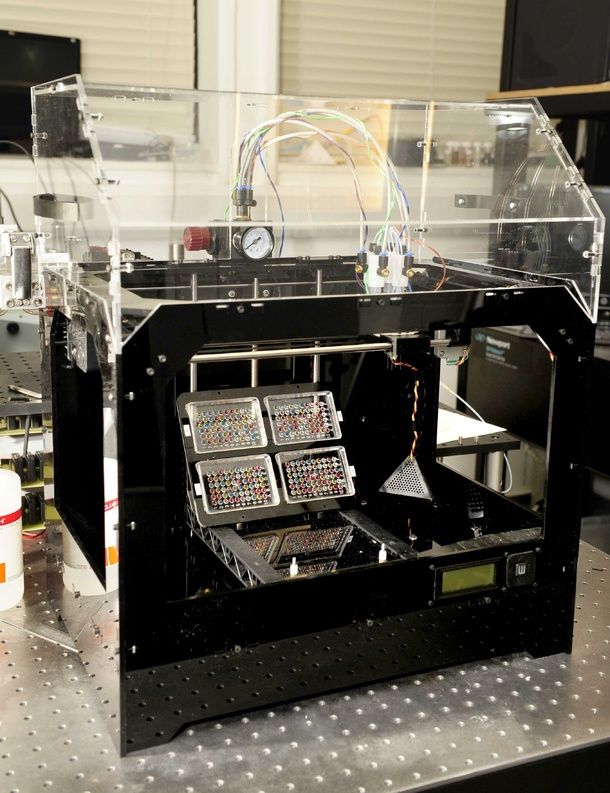

7. Human-organ printers

Need a new ear, a new lung or a new kidney? Several universities and research groups have developed various "bioprinters" that can print skin cells, organ tissue and other biological material with extreme precision, right down to the blood vessels and other fine details. They do this by laying down stem cells, which grow and differentiate into different types of cells in order to form a full organ. One of this process's main advantages is that patients' bodies are more likely to accept an organ formed of their own cells than a donor organ.

One of this process's main advantages is that patients' bodies are more likely to accept an organ formed of their own cells than a donor organ.

MORE: In Images: A 3D-Printed Liver

But the crown jewel of medical 3D printing is the ability to 3D print an entire developed, functional organ. Surgeon Anthony Atala first proposed the idea in a 2009 TED Talk, and since then, researchers at Hangzhou University in China have developed the Regenovo, a bioprinter that has successfully printed miniature, but functional, human livers and kidneys.

8. Rabbit Proto gadget printer

(Image credit: Rabbit Proto)What would it take to 3D print an electronic device — such as a cellphone — in one go? You'd need to print a circuit board, which is no easy feat. The printer would need to print a very precise pattern in multiple materials, at least one of which would have to be a conductive metal.

MORE: What Doesn't Make Sense to 3D-Print?

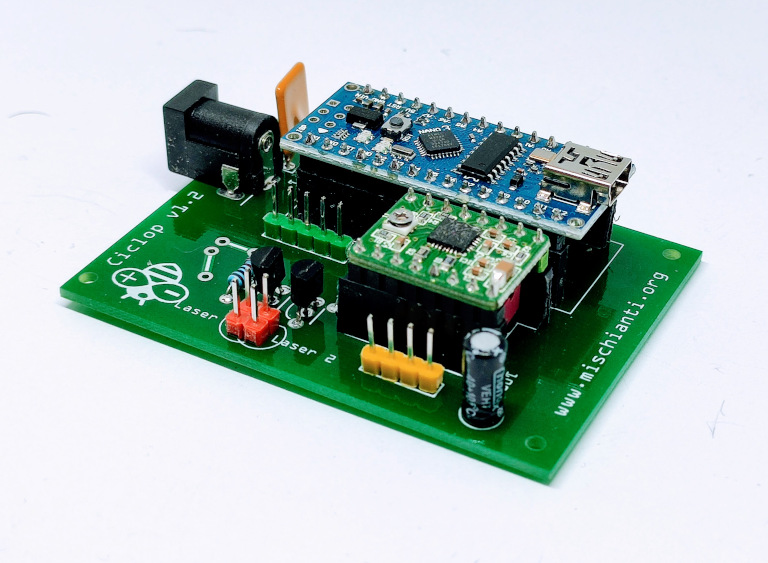

However, some 3D-printing hardware can print basic circuit boards and simple electronics. One of these is Rabbit Proto, a 3D-printer attachment that clips onto most RepRap 3D printers, creating a second extruder that lays down conductive metal alongside the main extruder that lays down plastic. This lets you print simple electronics like remote controls. It's comparatively affordable, too. One attachment is $350, sold on the company's website, but the project is open-source, so anyone with the parts and the time can build one for much less.

One of these is Rabbit Proto, a 3D-printer attachment that clips onto most RepRap 3D printers, creating a second extruder that lays down conductive metal alongside the main extruder that lays down plastic. This lets you print simple electronics like remote controls. It's comparatively affordable, too. One attachment is $350, sold on the company's website, but the project is open-source, so anyone with the parts and the time can build one for much less.

9. Chocolate 3D printer made of Legos

(Image credit: Saul, Instructables.com)3D printing in chocolate is always fantastic, but plenty of printers are now capable of this confectionary wonder. However, only one of them is made out of Legos.

With some Legos and a few simple parts, such as a funnel for the chocolate and a small heater to make it liquid, you can assemble your very own chocolate 3D printer, thanks to a user named Saul who posted the design to the online do-it-yourself website Instructables. On behalf of all humanity, Saul, we thank you.

10. World's largest 3D printer

(Image credit: Nanfang Ventilator Co. )In consumer 3D printing, the trend is to get smaller and more home-friendly. But as more industries adopt 3D-printing techniques in their manufacturing processes, printers are getting bigger, too.

In China, Nanfang Ventilator Co. is working on the world's biggest 3D printer — it measures 92 feet long, 75 feet wide and 31 feet high (28 m by 23 m by 9 m). Still nameless, it prints in metals such as carbon steel and stainless steel, and can build objects as large as 20 feet by 33 feet (6 m by 10 m). With a printer that big, Nanfang Ventilator can print parts for nuclear power plants, airplanes, ships and more.

Email [email protected] or follow her @JillScharr and Google+. Follow us@TomsGuide, on Facebook and on Google+.

- Sense Handheld 3D Scanner Review

- Make Your Barbie Battle-Ready With 3D-Printed Armor

- How 3D Printing Is Changing Etsy

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Jill Scharr is a creative writer and narrative designer in the videogame industry. She's currently Project Lead Writer at the games studio Harebrained Schemes, and has also worked at Bungie. Prior to that she worked as a Staff Writer for Tom's Guide, covering video games, online security, 3D printing and tech innovation among many subjects.

Topics

Gadgets

Top 10 Strangest 3D Printed Things / Sudo Null IT News UV radiation cures layer by layer of a polymer with certain properties), 3 years later he founded the company 3D Systems. And although 3D printing technology is the same age as CD players and camcorders, it has not achieved such popularity. However, with the advent of the RepRap project, the alignment of forces has changed, and cheap Chinese 3D printers, albeit FDM and not STL, have brought this technology to the masses in recent years.

By now, almost everyone has heard about 3D printing, and unusual methods of using these technologies constantly appear in the news. But the photo below is just the world's first 3D STL printer.

By now, almost everyone has heard about 3D printing, and unusual methods of using these technologies constantly appear in the news. But the photo below is just the world's first 3D STL printer.

So here is a list of the ten weirdest things you can 3D print.

1. Angelic shapes

Japan is the birthplace of all sorts of unusual gadgets, customs and trends. So in 3D printing they managed to excel here. The Japanese company Fasotec, or rather its Biotexture division, offers an unusual service. For future parents, not just a photograph or video of their fetus is available, but a whole printed 3D model.

Sounds a bit unusual, visually it looks even more extraordinary. Like a beetle frozen in amber, an embryo in its natural position is located in a transparent polymer crystal. It's good that the colors are chosen just contrasting and not as they are in their natural form, otherwise it would look generally creepy. This is all made possible by one of fasotec's core activities - Magnetic Resonance Body Scanning. In principle, the company “ate the dog” on such things, they have long been engaged in scanning various organs and printing them, which allows surgeons to prepare well for upcoming operations.

This is all made possible by one of fasotec's core activities - Magnetic Resonance Body Scanning. In principle, the company “ate the dog” on such things, they have long been engaged in scanning various organs and printing them, which allows surgeons to prepare well for upcoming operations.

Well, here, as it were, a "by-product", although it made quite a lot of noise and attracted additional attention to the company. It's no joke, a germ in a crystal. Such crystals with an embryo inside are called “Shapes of Angel” (angel shapes) and are not so cheap, about 100,000 yen, which is about $870 dollars (02/11/16), the price without taking into account the flight to Japan of course. The size of such a crystal is approximately 90x60x40mm, and it is issued to the customer in a nice beige box with pink silk inside.

Worth getting one to shock your future kids when they grow up.

2. Tapaburger

Oh gods, he eats sneakers! This is probably what people think when they first see a person eating a Shoe Burger. And there's really nothing out of the ordinary here. It's just a burger with a bun in the shape of your sneaker or shoe.

And there's really nothing out of the ordinary here. It's just a burger with a bun in the shape of your sneaker or shoe.

Several advanced technologies come together here: 3D scanning, 3D printing and silicone molding. That's basically the whole description of the process.

Put your shoe on the 3D scanner table, create a digital copy. Print it on a 3D printer and make a reverse mold from heat-resistant food grade silicone. Now it remains only to fill it with dough and send it to the oven.

I think this is a great way to surprise your friends who come to visit you. Just feed them slippers.

3. Nanosculptures

We live in an amazing time, we are surrounded by a colossal number of beautiful things that you can see and often even touch. But Jonty Hurwitz creates sculptures that you can't touch or even see without a microscope.

All this thanks to a special 3D printer that can create such tiny objects.

Who complained about the layered print? With such a printer, there will be no problems with layering, however, in order to create some object more or less visible to the human eye, you will have to wait a very long time.

Similar nanosculptures appeared thanks to the technologies of the Karlsruhe Institute of Technology, which are successfully used in the Weizmann Institute of Science. A similar printing method is called multiphoton lithography, which is based on the phenomenon of two-photon absorption.

This is how something new is created at the intersection of advanced technologies and art, now you can easily carry a whole museum in your pocket.

4. Weapons

3D printed weapons have long been known. When people find out that you have a similar printer, the first question is - can a gun be printed on it? All thanks to the world famous liberalator. Wow, how he made a noise on the net ... Some people even received real criminal cases for his production at home, for example: . .. Although in my opinion than using such a gun, it is easier to cut a spear from any suitable stick, it will be more effective. Moreover, when fired, there is a high chance that the barrel can simply break.

.. Although in my opinion than using such a gun, it is easier to cut a spear from any suitable stick, it will be more effective. Moreover, when fired, there is a high chance that the barrel can simply break.

But inquisitive minds do not stand still, after the liberator, a multi-shot revolver was born.

Looks good, it's getting more interesting, isn't it? Although we are not talking about a classic revolver, the design is similar to a barrelless weapon, when the bullet itself is the barrel. There is something in between - the drum itself protrudes in the rod of the trunk. It can be 6 or 8 bullet capacity. The bullets are again from the “small things” and fly at subsonic speeds.

Holes for bullets need to be reinforced with metal tubes, which, by the way, will act as a barrel. And in the case of an 8-charging drum, it is also necessary to strengthen the drum itself with metal elements.

Or, for example, from a fresh semi-automatic pistol Shuty MP-1. Now this is serious, although the caliber is still small.

Now this is serious, although the caliber is still small.

There was an article about him on Geektimes quite recently: Shuty MP-1

But RailGun can still be recognized as the crowning achievement of 3D-printed weapons (made of plastic). And although there is not the most powerful shot and it does not break through walls, this weapon looks very menacing.

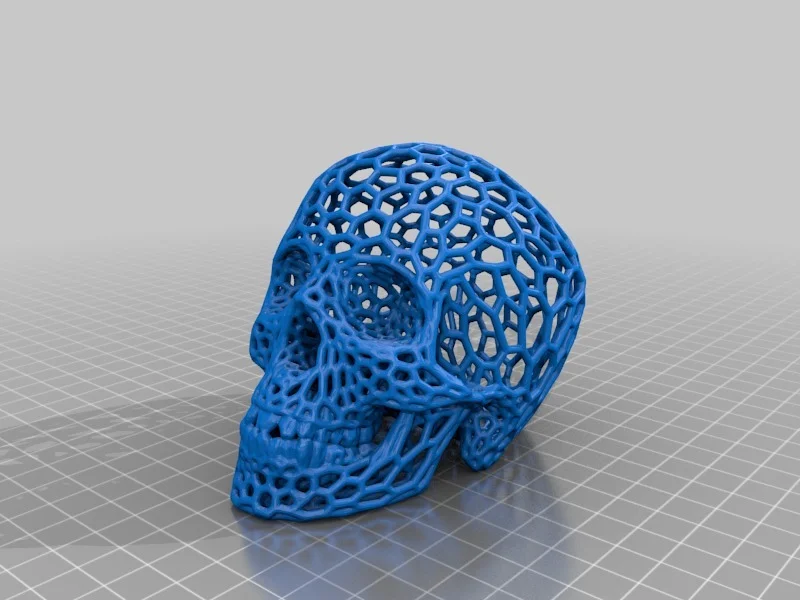

5. Human organs or their substitutes

While some people are printing tools of destruction, others are thinking about how to restore the human body, again with the help of 3D printing. For example, metal printing using SLS or SLM technology (selective laser sintering or selective laser fusion) has long been known, often, if the budget allows, prostheses or missing parts of bones are created.

But science does not stand still and it is already becoming possible to print not only metal structures for the human body, but also the basis of organs that will not be rejected by the human body.

Plastic is also used in some cases. Plastic also does not stand still, and already in some countries, fillings and dentures are being tested, which destroy bacteria and prevent caries from developing again.

It remains to wait a little longer for science fiction films where people improve themselves with the help of technology to become a reality.

6. Glass vases

Glass. Very interesting material. On the one hand, it is just sand in a large crystal, and on the other hand, it is not so easy to work with this material. It is not easy to create some complex shapes from glass. But what if you try to print with glass on a 3D printer?

Apparently, this is what MIT's Mediated Matter Group argued, the result of their research was perhaps the only 3D printer of its kind that prints with glass.

True, this technology has a number of limitations, such as printing speed and layer thickness.

In addition, the structures still turn out to be layered, which imposes certain restrictions on the use of finished products. So far, the ideal product obtained using this technology is a vase.

So far, the ideal product obtained using this technology is a vase.

A beautiful vase that gives an interesting diffused light if you shine a light bulb into it from above.

7. Bioprinting or what have you heard about B-Code?

Different types of art have always been considered amazing by some people, and strange by others. Now I'm going to talk about some really strange, hmm...probably shapes. I don't know what category it belongs to :)

This is the so-called bioprinting. Print objects with the help of bees. This is where the fantasy can play out, drawing unthinkable machines using bees. But no, everything is much simpler. Biologist Jennifer Berry once looked at wild hives and thought it looked good, and it would be interesting to control the creation of hive shapes.

As a result, after several attempts, she created a kind of bioprinter-an artificial hive in which bees live and create honeycombs under her control.

The technology is simple - you need to create a certain form limiting the outer boundaries of the created model,

And it is also necessary to set the direction of growth of the cells from a special material.

All this is placed in a transparent box, which maintains a certain microclimate and has a special valve that blocks access to the bees in the hive after they complete the creation of the object. I wonder how many finished paintings Jennifer sold? Although she definitely attracted attention to her person.

8. Giant sculptures

While some people print nanosculptures, others create giant art objects on regular FDM printers. For example, the famous artist Hong-Chi Peng from Taipei (Taiwan) realized a powerful art project in the Museum of Fine Arts - an ocean liner, supposedly twisted by the forces of nature.

The creation of this exhibit took a total of 42,000 hours of work. Printing was carried out by thirty-two FDM printers, 6000 parts were printed with a total weight of 500 kilograms. And the length of the liner turned out to be 8 meters.

And the length of the liner turned out to be 8 meters.

With his project, Pang wants to remind humanity of its impotence in the face of uncontrollable natural forces, sometimes leading to terrible disasters.

9. Cars

One of the most rewarding industries for 3D printing is the automotive industry. In addition to prototyping and creating prototypes, the automotive industry is actively testing new types of materials in the manufacture of vehicles, and new methods for their production.

For example, FORD Corporation, which owns as many as five 3D printing centers producing hundreds of parts a day. The printers at these centers print on a wide range of materials, from silicates to nylon, and even sand. One of the company's favorite examples when it comes to 3D printing is an engine intake manifold.

But these are all details. Of interest, in the context of this article, are car projects that are entirely or mostly printed on 3D printers.

A recent example of a high-tech 3D printed vehicle is the Blade supercar from Divergent Microfactories.

Blade is a frame structure made of carbon rods and special aluminum nodes. According to Blade's creators, this not only saves material, but also lightens the car by 90% compared to traditional designs. Blade is equipped with a 700 hp dual-fuel engine running on gasoline or natural gas. Thanks to the powerful engine and lightweight body, the car can accelerate from 0 to 100 km/h in 2.2 seconds.

10. Food

I remember science fiction films and stories where special food printers print any food with any taste to order almost out of thin air. This may sound fantastic, and in practice it is not yet applicable. However, some imitation of such devices already exists. The strangest thing 3D printed at number 10 is food.

The strange thing here is that this is only shaping with a 3D printer, there is no talk of any changes in the properties of materials or creation from almost nothing.

Put the minced meat into a tube and squeeze it according to the program into the desired shape, then into the oven.

Filled the dough - extruded the base for pizza or tartlets. This is more of an assistant for a cook, when it is difficult to squeeze out a drawing with your hands. The machine will do this with an accuracy of hundredths of a millimeter.

Although the artistic value is still present here. With due imagination and a little skill, you can create masterpieces of culinary art.

Conclusion

Thanks to Chinese shops, even with a rising currency, it is now possible to get a home FDM 3D printer for little money. For example, one of the most popular printer assembly kits: Sunhokey Prusa i3 (*), which was bought 1748 times from this seller alone. I personally bought this set last fall. Then it cost me a little less than 17,000 rubles, now it also costs about the same money on aliexpress. For half a year of owning this printer, I did not identify any particularly critical places, it worked for me almost immediately after assembly.

For half a year of owning this printer, I did not identify any particularly critical places, it worked for me almost immediately after assembly.

That's all, you had a simple service for choosing complex equipment Dronk.Ru. Don't forget to subscribe to our blog and YouTube channel for more.

p.s. * - You can get up to 5% back on your purchase by purchasing through these links.

Read more: dronk.ru/cashback

Our other publications:

Overview of the powerful tablet Chuwi Hi10 on a full-fledged Win10 for $180

8 devices for shooting video on a smartphone

Classes of quadcopters - what are they and what are they used for

Walkera Runner 250 video review - flight over the canyon

Our little joys or what to please yourself on a budget on February 23?

Xiaomi company. It doesn’t get cheaper without compromising quality

Chuwi Ilife V5 - a robot vacuum cleaner for $ 99 or how to turn daily cleaning into entertainment -printing originated in the 80s of the 20th century, but construction 3D printing appeared much later. The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme clearly shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov c.u. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, a regulatory framework has already been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of the formation of technology, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, an increase of 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

Now let's take a quick look at what is the construction 3D printer. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers, as well as participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

There is little that unites developed, developing and poor countries, everywhere their problems and tasks, but The lack of affordable housing is a worldwide agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards “green agenda ”, CO2 emission reduction, building with more environmentally friendly materials, etc. is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

3D printed walls. Today, when we talk about 3D printing of houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are erected as fixed formwork, which significantly saves the amount of cement used , which in turn reduces construction costs and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is currently being actively developed , the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another start-up from Russia, Mighty Buildings, headquartered in California, initially opted for a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

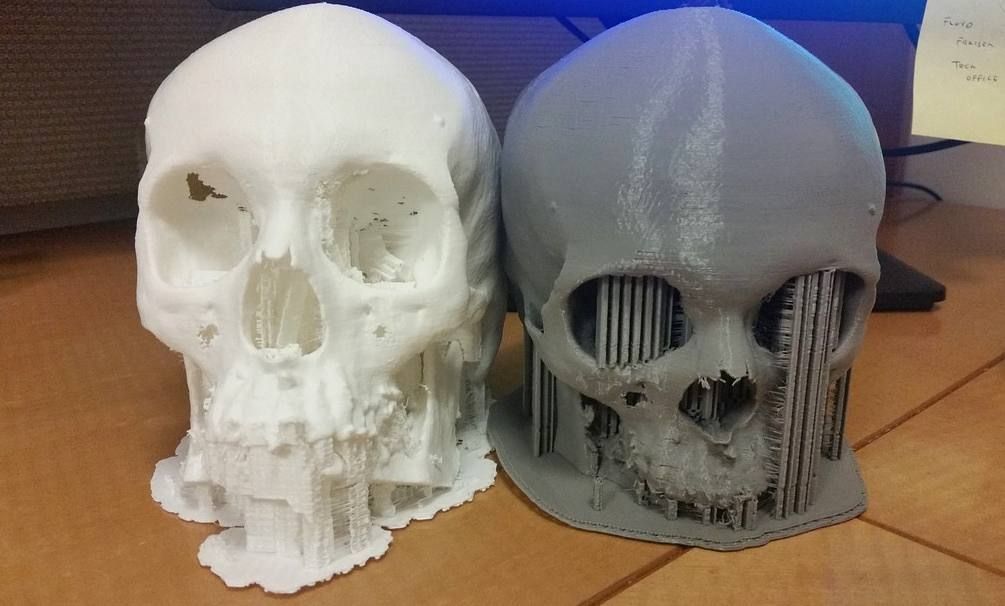

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role.