Cost of 3d printed prosthetics

The Successes and Failures of 3D Printed Prosthetics - PreScouter

The 3D printing industry has expanded rapidly over the last few years, with one of its most notable areas of application being the health and medical industry. Innovations include printing everything from medications to human organs, but perhaps the most commercially successful so far has been prosthetics. While 3D printing prosthetics allows amputees to get a hold of products for thousands of dollars less than traditional prosthetics, the methods and materials used are raising concerns.

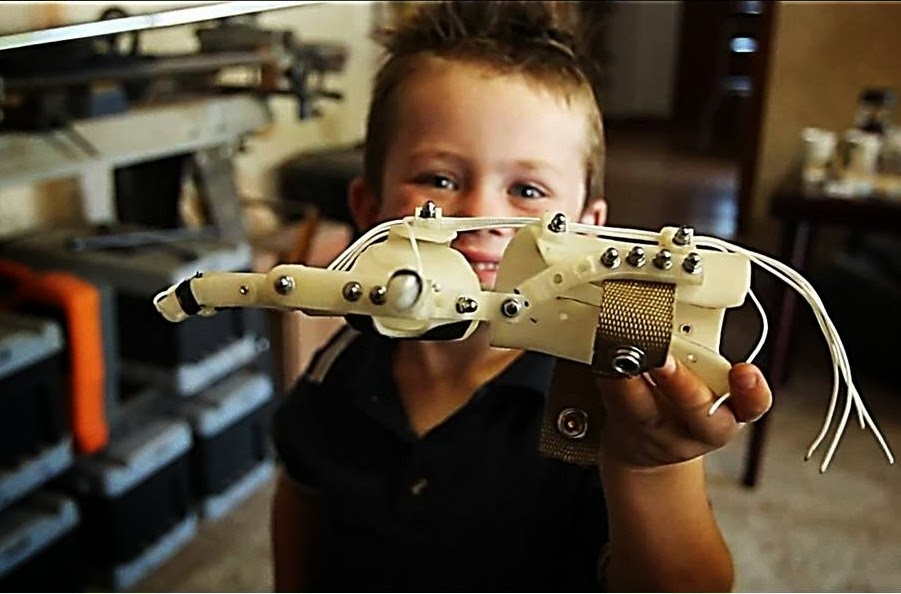

Successes of 3D Printed Prosthetics3D printed prosthetics can greatly benefit children. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. According to a statement made by the American Orthotics and Prosthetics Association, the average prosthetic costs between $1,500 to $8,000. This expense is often paid out of pocket rather than covered by insurance. By contrast, a 3D printed prosthetic costs as little as $50!

3D printed prosthetics can also be made much quicker; a limb can be made in a day. Furthermore, consumers can easily customize their purchases, which is another enticing factor for kids. Children can pick out colors and styles to fit their wants and needs.

Traditional vs 3D Printed MaterialsLike traditional prosthetics, 3D printed prosthetics are composed mainly of plastic. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum, or carbon fiber.

3D printed prosthetics use materials such as acrylonitrile butadiene styrene (ABS) plastics or for s stronger material, Bridge nylon. 3D printers are becoming compatible with other materials like lightweight titanium to increase durability and strength. A research team in Belgium successfully implanted the first 3D printed titanium mandibular prosthesis, using a laser to melt thin layers of titanium powders. The FDA approved a 3D printed polyetherketoneketone (PEKK) skull implant, which was successfully implanted by Oxford Performance Materials (OPM).

The FDA approved a 3D printed polyetherketoneketone (PEKK) skull implant, which was successfully implanted by Oxford Performance Materials (OPM).

Another company called LayerWise, now 3D Systems, manufactures 3D printed titanium orthopedic, maxillofacial, spinal, and dental implants. An anatomically correct 3D printed prosthetic ear, capable of detecting electromagnetic frequencies, was created using silicon, chondrocytes, and silver nanoparticles. Implants are even beginning to be printed with live cells.

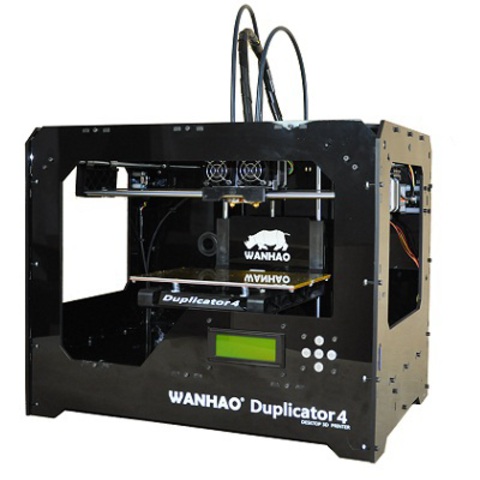

Failures of 3D Printed ProstheticsE-NABLE is a company that provides customers with affordable prosthetics through volunteers with 3D printers. Though their products are cheap, customizable, and quickly made, they have run into problems with durability. Their volunteers are not professional prosthetists, who undergo years of training, and every product is not FDA tested and approved. Therefore, the products break far more often than traditional prosthetics.

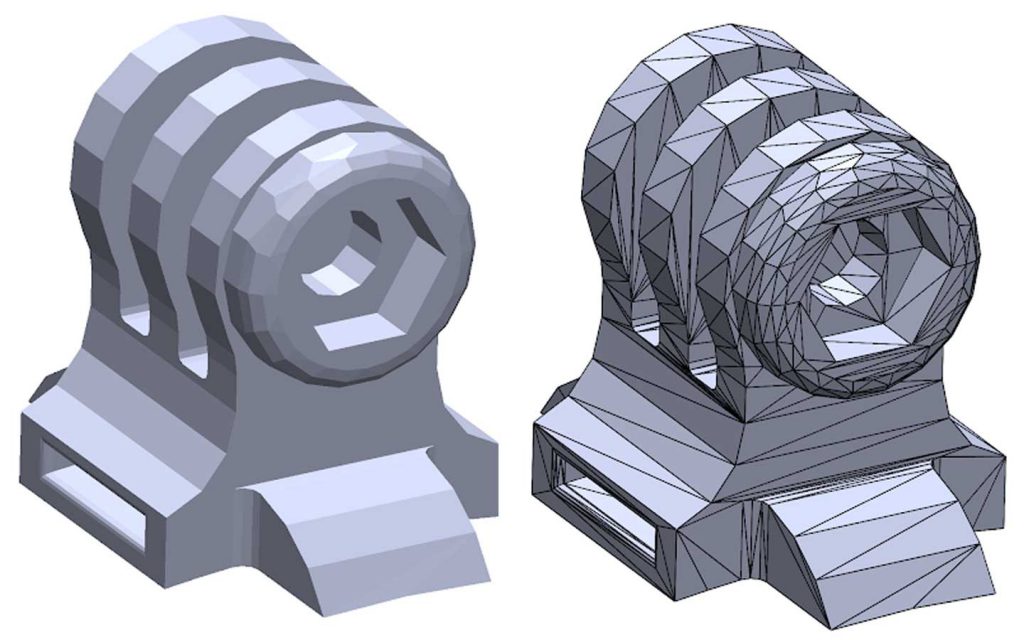

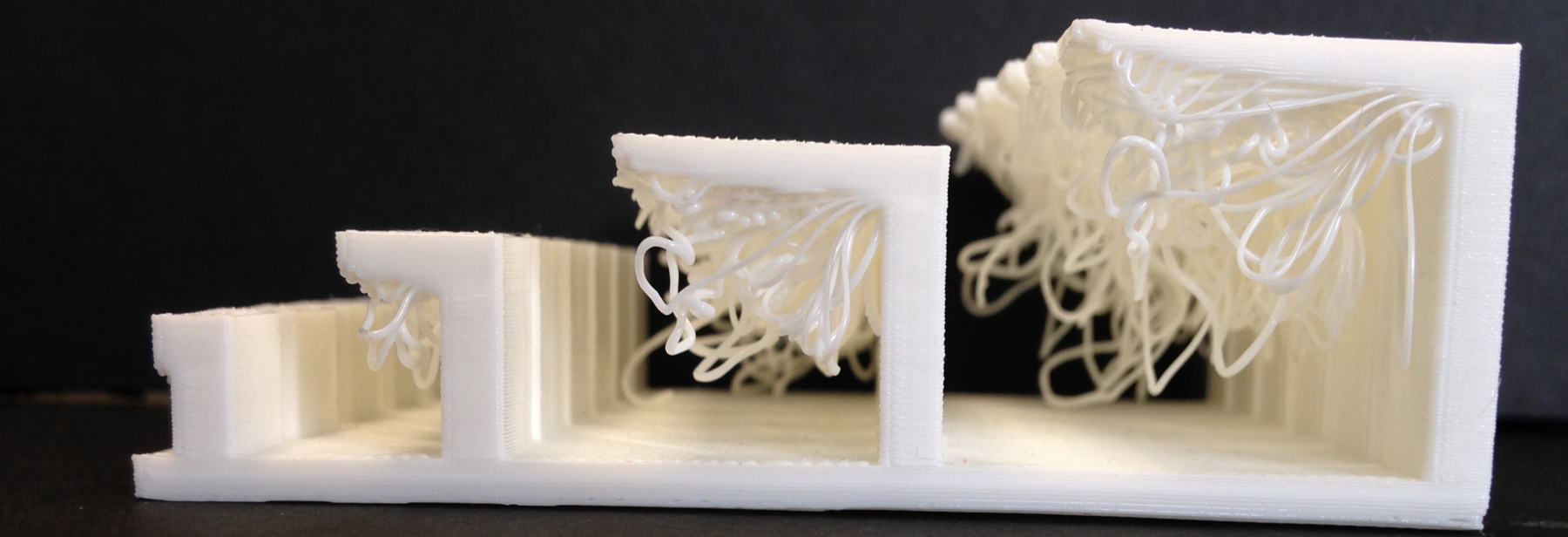

3D printed prosthetics are created by thin layers of hot plastic, so when pulled the wrong way, they can break very easily. Volunteer printers also take time to learn the proper way to regulate temperature, which can lead to cracks in the finished product.

Overcoming the ChallengesAfter running into these problems, an e-NABLE volunteer teamed up with a UK based engineer, Steve Wood, to develop something more durable and flexible. They used a material called Filaflex to create a successful prosthetic, but the finished product costs closer to $2,000, which, compared to most e-NABLE products, is a lot. However, it is still cheaper than most traditional prosthetics.

Professionals have perfected traditional prosthetic designs over many years, and will be difficult to replace overnight. Yet, 3D printed prosthetics are providing a much needed service for amputees who don’t possess the income to purchase a professionally made prosthetic, and especially for children, who outgrow prosthetics more readily. Methods and materials will be improved and refined over time and International Data Corporation (IDC) reported that 3D printing for medical implants and devices is growing market share nearly 13% in 2020 and 15% for dental.

Methods and materials will be improved and refined over time and International Data Corporation (IDC) reported that 3D printing for medical implants and devices is growing market share nearly 13% in 2020 and 15% for dental.

About the author

Heidi Reidel

Heidi Reidel is a recent graduate from Knox College in Galesburg, Illinois with a BA in Creative Writing and a minor in Psychology. She is a freelance writer and an advocate for victims of domestic violence at a local shelter.

This Startup Is 3D Printing Custom Prosthetics for a Fraction of the Standard Cost

Around 1.9 million people in the US are currently living with limb loss. The trauma of losing a limb is just the beginning of what amputees have to face, with the sky-high cost of prosthetics making their circumstance that much more challenging.

Prosthetics can run over $50,000 for a complex limb (like an arm or a leg) and aren’t always covered by insurance. As if shelling out that sum one time wasn’t costly enough, kids’ prosthetics need to be replaced as they outgrow them, meaning the total expense can reach hundreds of thousands of dollars.

A startup called Unlimited Tomorrow is trying to change this, and using cutting-edge technology to do so. Based in Rhinebeck, New York, a town about two hours north of New York City, the company was founded by 23-year-old Easton LaChappelle. He’d been teaching himself the basics of robotics and building prosthetics since grade school (his 8th grade science fair project was a robotic arm) and launched his company in 2014.

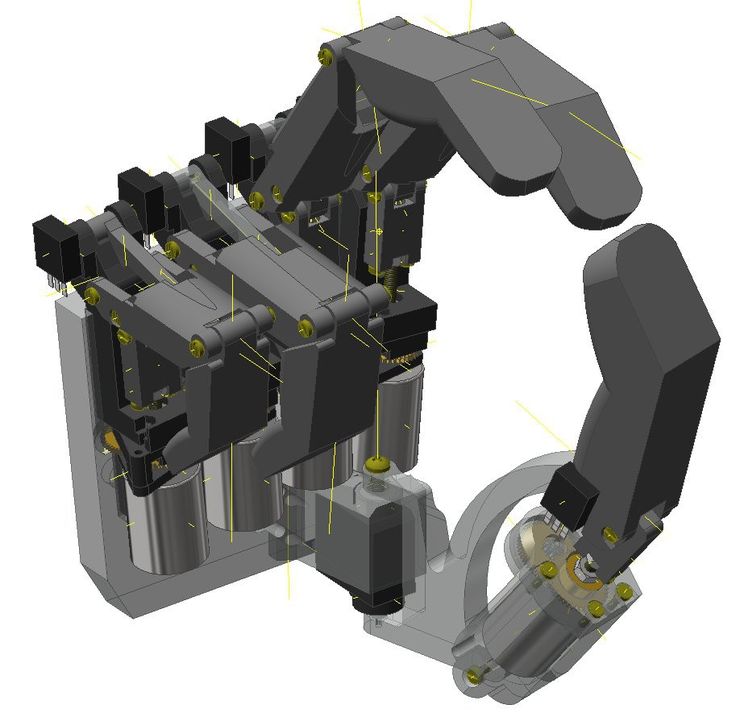

After six years of research and development, the company launched its TrueLimb product last month, describing it as an affordable, next-generation prosthetic arm using a custom remote-fitting process where the user never has to leave home.

The technologies used for TrueLimb’s customization and manufacturing are pretty impressive, in that they both cut costs and make the user’s experience a lot less stressful.

For starters, the entire purchase, sizing, and customization process for the prosthetic can be done remotely. Here’s how it works. First, prospective users fill out an eligibility form and give information about their residual limb. If they’re a qualified candidate for a prosthetic, Unlimited Tomorrow sends them a 3D scanner, which they use to scan their residual limb.

The company uses the scans to design a set of test sockets (the component that connects the residual limb to the prosthetic), which are mailed to the user. The company schedules a video meeting with the user for them to try on and discuss the different sockets, with the goal of finding the one that’s most comfortable; new sockets can be made based on the information collected during the video consultation. The user selects their skin tone from a swatch with 450 options, then Unlimited Tomorrow 3D prints and assembles the custom prosthetic and tests it before shipping it out.

“We print the socket, forearm, palm, and all the fingers out of durable nylon material in full color,” LaChappelle told Singularity Hub in an email. “The only components that aren’t 3D printed are the actuators, tendons, electronics, batteries, sensors, and the nuts and bolts. We are an extreme example of final use 3D printing.”

“The only components that aren’t 3D printed are the actuators, tendons, electronics, batteries, sensors, and the nuts and bolts. We are an extreme example of final use 3D printing.”

Unlimited Tomorrow’s website lists TrueLimb’s cost as “as low as $7,995.” When you consider the customization and capabilities of the prosthetic, this is incredibly low. According to LaChappelle, the company created a muscle sensor that picks up muscle movement at a higher resolution than the industry standard electromyography sensors. The sensors read signals from nerves in the residual limb used to control motions like fingers bending. This means that when a user thinks about bending a finger, the nerve fires and the prosthetic’s sensors can detect the signal and translate it into the action.

“Working with children using our device, I’ve witnessed a physical moment where the brain “clicks” and starts moving the hand rather than focusing on moving the muscles,” LaChappelle said.

The cost savings come both from the direct-to-consumer model and the fact that Unlimited Tomorrow doesn’t use any outside suppliers. “We create every piece of our product,” LaChappelle said. “We don’t rely on another prosthetic manufacturer to make expensive sensors or electronics. By going direct to consumer, we cut out all the middlemen that usually drive costs up.” Similar devices on the market can cost up to $100,000.

Unlimited Tomorrow is primarily focused on making prosthetics for kids; when they outgrow their first TrueLimb, they send it back, where the company upcycles the expensive quality components and integrates them into a new customized device.

Unlimited Tomorrow isn’t the first to use 3D printing for prosthetics. Florida-based Limbitless Solutions does so too, and industry experts believe the technology is the future of artificial limbs.

“I am constantly blown away by this tech,” LaChappelle said. “We look at technology as the means to augment the human body and empower people.”

Image Credit: Unlimited Tomorrow

$50 3D printed prosthesis vs $42,000 standard prosthesis

hands From war-torn Sudan, where 3D printing is helping crippled residents, to the US on the other side of the world, where 3D printing is helping cut huge medical costs, these stories help shed light on the humanitarian potential of 3D technology.

Not long ago we heard about José Delgado, who was born without a left hand. At the advanced age of 53, José got his first experience with prostheses. For a year, Jose used a $42,000 myoelectric prosthesis. This device takes signals from the muscles in the forearm and uses the resulting motor data to control the fingers of a mechanical hand that are quite similar to real ones. José was lucky: his health insurance covered the hefty costs of a prosthesis, but many people in similar situations do not have similar financial support.

3D printed Cyborg Beast prosthesis

Jeremy Simon, a doctor and 3D printing enthusiast, decided to meet Jose and print him a Cyborg Beast prosthesis. Cyborg Beast - public domain designs used in the Robohand project. These devices have already "fallen into the hands" of more than 200 people around the world, they are distinguished by versatility, convenience and, most importantly, low cost. With a $50 material cost, 840 of these devices could be printed to reach the $42,000 mark José spent on his myoelectric prosthesis.

Simon himself was somewhat skeptical about comparing an inexpensive 3D printed prosthesis to a mechanical arm for the price of a good car. After all, Delgado's job requires the ability to lift and manipulate various objects on a consistent basis. The prosthesis for $42,000 is quite functional. Will a $50 ABS artificial hand have the slightest chance of competing?

José Delgado demonstrates a 3D printed prosthesis

During the next meeting, while adjusting the device to better interact with the tendons of the patient's hand, Simon was surprised by Jose's claim that a 3D printed hand functions better than an expensive prosthesis. Although ABS plastic is not ideally strong for the task, the prosthesis turned out to be extremely comfortable, and damaged parts are easy to reprint.

Although ABS plastic is not ideally strong for the task, the prosthesis turned out to be extremely comfortable, and damaged parts are easy to reprint.

Simon is currently helping José Delgado print a new mechanical arm, but this time he intends to use more durable nylon.

Here is a video of José demonstrating both prostheses and explaining the difference: while the 3D printed prosthesis is fully functional, the two fingers on the expensive version are only cosmetic:

Article prepared for 3DToday.ru to the author

Subscribe

Don't want

Even more interesting articles

four

Follow the author

Subscribe

Don't want to

The progress of 3D printing in recent years has gained such a rapid pace that we will soon stop. ..

..

Read more

four

Subscribe to the author

Subscribe

Don't want

Alexander Gessler wrote a small handy program to convert 40+ 3D file formats (OBJ, S...

Read more

3

Follow the author

Follow

Don't want to

Not so long ago we talked about an interesting engineering and architectural project that is directly related to the use of...

Read more

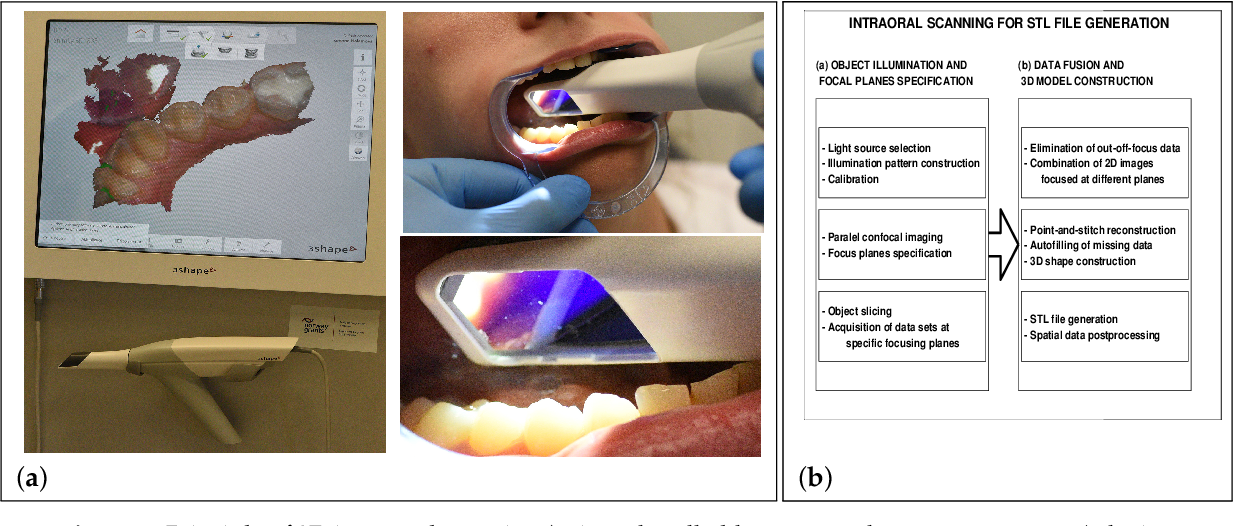

using 3D printing in dentistry to make dentures

Modern additive printing technologies allow the production of a wide variety of products for an incredible range of applications. Medicine, in particular the field of dentistry, has long been no exception and is using the achievements of technological progress for the benefit of its patients with might and main, becoming digital.

Benefits of using a 3D printer

Clinics everywhere are moving to intraoral scanning, abandoning analog, uncomfortable for the patient, methods of making an impression. Some are not limited to diagnostic manipulations at all, transferring the stages of modeling and manufacturing of single works under their own roof and partially refusing laboratory services. In this case, a 3D printer for dentistry is indispensable in the manufacture of orthodontic and temporary orthopedic structures. Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Comparison of the main 3D printing technologies used in dentistry

Laboratories are not left behind and are improving the manufacturing methods and range of dental products and services. The use of laboratory scanning eliminates the error that may occur during the manufacture of a plaster model. If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories.

The use of laboratory scanning eliminates the error that may occur during the manufacture of a plaster model. If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories.

If we talk about the main methods of manufacturing dental products on a 3D printer, then these will be:

- SLA, or the so-called stereolithography, in which the laser beam polymerizes the material, quickly passing through each point of the object;

- DLP, or layer-by-layer illumination process, in which the projector illuminates the photopolymer layer by layer using ultraviolet radiation, transforming it into a future product.

Regardless of the printing method, the final properties of the work will depend on the material from which it is made, the very "resin".

Speaking of photopolymers, one cannot but mention NextDent. The company is a subsidiary of the Dutch manufacturer of plastics for prosthetics Vertex. NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

The company is a subsidiary of the Dutch manufacturer of plastics for prosthetics Vertex. NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

With 30 unique NextDent photopolymers, the widest range of any dental material supplier. A range of aesthetically accurate colors enable dental labs and clinics to achieve a close match of finished products to the patient's teeth and gums. 3D printing materials from NextDent are biocompatible and certified in accordance with the requirements of the European Union, which makes them widely used. Photopolymers meet the requirements of the European Medical Device Directive (93/42/EEC), approved by the Food and Drug Administration (USA) and certified in many other countries.

With such a promising line of dental resins in its portfolio, 3D Systems, as the inventor of 3D printing and a recognized industry leader, could not do without using its own revolutionary technologies in a new field for itself. This is how the first 3D printer for dentists NextDent 5100 appeared, specially designed for the manufacture of products from biocompatible photopolymers.

This is how the first 3D printer for dentists NextDent 5100 appeared, specially designed for the manufacture of products from biocompatible photopolymers.

Its hallmarks are speed and ease of use. Incredibly fast in the production of dental work of any complexity, the NextDent 5100 will allow you to print more than 70 temporary crowns in 25 minutes. Or to make a whole prosthesis in front of the patient in just an hour.

NextDent Denture 3D+, a class IIa biocompatible material, was created for the fabrication of removable denture bases. This material has significantly less shrinkage than the already used, standard PMMA materials. Shrinkage can be avoided using software, resulting in a perfectly suitable base for a removable denture. Excellent mechanical properties make it possible to surpass the quality of traditional methods of manufacturing removable dentures. Available in the following shades: dark pink, light pink, opaque, reddish pink and transparent pink. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity.