3D glass printers

Glass 3D Printing

3D printed glass manufacturing

Research team (Glass I): John Klein, Michael Stern, Markus Kayser, Chikara Inamura, Giorgia Franchin, Shreya Dave, Daniel Lizardo, Peter Houk. Prof. Neri Oxman

Research team (Glass II): Chikara Inamura, Michael Stern, Daniel Lizardo, Tal Achituv, Tomer Weller, Owen Trueblood, Nassia Inglessis, Giorgia Franchin, Marianna Gonzalez, Yinong Liu, Kelly Egorova, Peter Houk. Prof. Neri Oxman

Year: 2015-present

Location: MIT Media Lab, 2015, Cambridge, MA

Projects: Glass I, Glass II

Position

Glass 3D Printing 2 (G3DP 2) enables an entirely unique means of digital design and fabrication with glass. It is a high fidelity, large-scale, additive manufacturing technology for 3D printing optically transparent glass structures at architectural dimensions.

This novel additive-manufacturing platform includes a digitally integrated thermal control system to accompany the various stages of glass forming. It also includes a novel 4-axis motion control system permitting flow control, spatial accuracy and precision, and faster production rates with continuous deposition of up to 30kg of molten glass.

Process

G3DP2 uniquely enables the additive manufacturing of optically-transparent glass by restructuring the machine’s architecture and process control operations as informed by material properties and behaviors of silicate glass to 3D print building components with tunable, predictable mechanical and optical properties.

This enabling technology builds upon our previous efforts to 3D print optically transparent glass for product scale applications.

Age of Glass Manufacturing in Years

4500

Ancient yet modern, enclosing yet invisible, glass was first created in Mesopotamia and Ancient Egypt 4,500 years ago. Glass can be molded, formed, blown, plated or sintered; its formal qualities are closely tied to techniques used for its formation.

Glass can be molded, formed, blown, plated or sintered; its formal qualities are closely tied to techniques used for its formation.

From the discovery of core-forming process for bead-making in ancient Egypt, through the invention of the metal blow pipe during Roman times, to the modern industrial Pilkington process for making large-scale flat glass; each new breakthrough in glass technology occurred as a result of prolonged experimentation and ingenuity, and has given rise to a new universe of possibilities for uses of the material.

Micro CT scan SEM image of a printed glass wall SEM image of the interface between 2 layers of glass Micro CT scan in cross section SEM image of a printed glass wall in cross section SEM image of the interface between 2 layers of glass The tunability enabled by geometrical and optical variation driven by form, transparency and color variation can drive, limit or control light transmission, reflection and refraction, and therefore carries significant implications for all things glass.

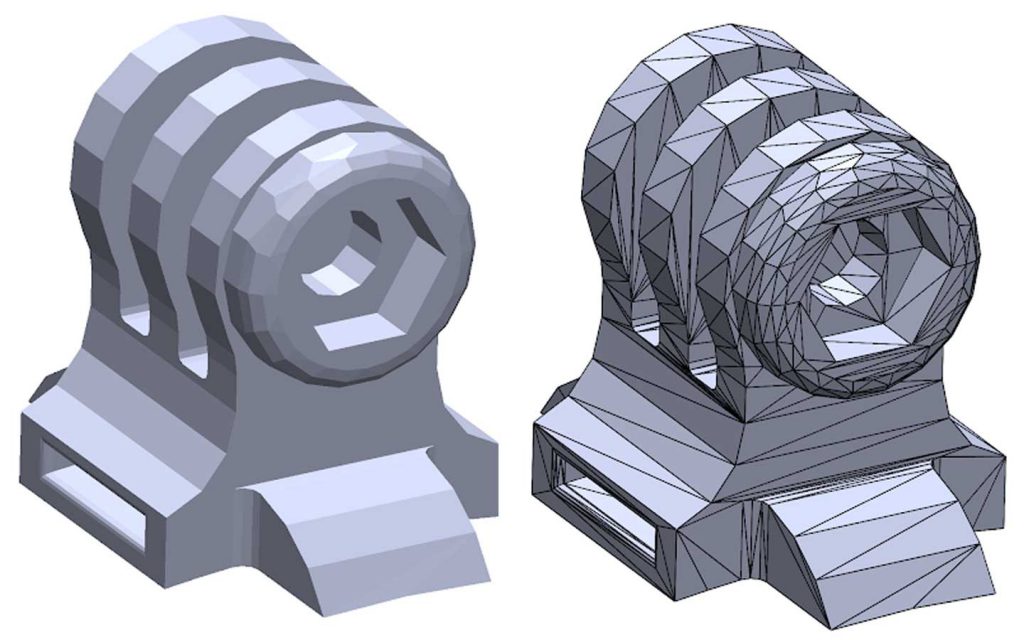

The computational methodology used by G3DP2 is designed to interact intelligently with the constraints of the manufacturing with glass. A wide range of shapes determined by desired mechanical and optical properties can be printed through feedback-enabled control systems.

Internal temperatures and feed rate are precisely regulated in order to ensure the precise deposition and cooling rate of molten glass that enables not only the high-fidelity realization of designed geometries, but the preservation of optical transparency and superior strength.

The worlds first molten glass 3D printer named G3DPPublications

Additive Manufacturing of Optically Transparent Glass (2015)

High-Fidelity Additive Manufacturing of Transparent Glass Structures (2018)

Patents

Methods and Apparatus for Additive Manufacturing of Glass

Methods and Apparatus for Additive Manufacturing with Molten Glass

Credits

Collaborators & Contributors: Mary Ann Babula, P. T. Brun, Jeremy Flower, Wyss Institute at Harvard University, Rubix Composites, Skutt Kilns, The Glass Art Society, MIT Center for Bits and Atoms, MIT Edgerton Center, MIT Central Machine Shop, MIT Mechanical Engineering Department, MIT Glass Lab, MIT Media Lab

T. Brun, Jeremy Flower, Wyss Institute at Harvard University, Rubix Composites, Skutt Kilns, The Glass Art Society, MIT Center for Bits and Atoms, MIT Edgerton Center, MIT Central Machine Shop, MIT Mechanical Engineering Department, MIT Glass Lab, MIT Media Lab

All images and videos courtesy Neri Oxman and The Mediated Matter Group

Scientists develop rapid new method of 3D printing glass into parts with "the thickness of hair”

0Shares

Researchers at the University of Freiburg have worked with colleagues at the University of California, Berkeley to come up with a novel means of rapidly 3D printing complex glass parts at a microscopic scale.

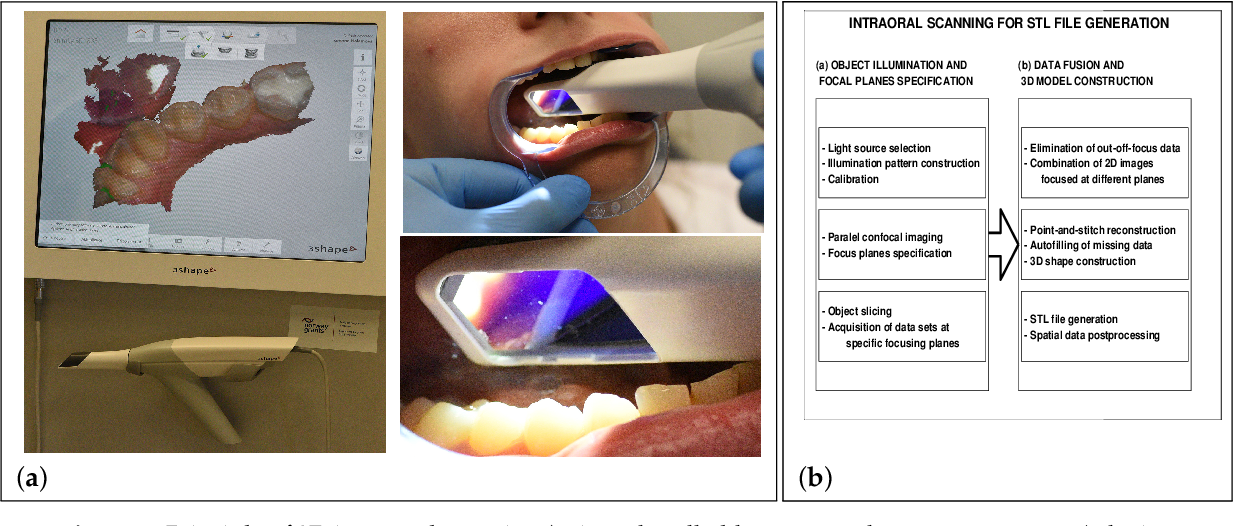

Known as ‘ Microscale Computed Axial Lithography’ (Micro-CAL), this approach involves exposing resin to 2D light images of a desired shape from multiple angles, which when they overlap, trigger polymerization. When used to print the Glassomer material previously honed at Freiburg, the team say their layer-free process has the potential to unlock devices with new microfluidic or micro-optical functionality.

“For the first time, we were able to print glass with structures in the range of 50 micrometers in just a few minutes, which corresponds roughly to the thickness of a hair,” explains the University of Freiburg’s Dr. Frederik Kotz-Helmer. The ability to manufacture such components at high speed and with great geometric freedom will enable new functions and more cost-effective products in the future.”

The researchers’ ‘Micro-CAL’ 3D printing process. Image via the University of Freiburg.‘CAL’ vs serial deposition 3D printing

According to the scientists, glass has “innumerable uses” thanks to its high level of optical transparency, as well as its thermal and chemical resistance, and low coefficient of thermal expansion. Given these qualities, it’s hardly surprising that the material is sometimes used within 3D printing as well, however, the researchers say that layer-by-layer deposition can “induce defects” and “limit geometric freedom.”

Though many 3D printing processes rely on serial deposition, one alternative that does exist is Computed Axial Lithography (CAL). Rather than build up objects in layers, CAL polymerizes light-sensitive resins into 3D structures by exposing them to iteratively optimized projections, which in turn, cause them to hit a threshold at which their entire volume hardens simultaneously in a precursor material.

Rather than build up objects in layers, CAL polymerizes light-sensitive resins into 3D structures by exposing them to iteratively optimized projections, which in turn, cause them to hit a threshold at which their entire volume hardens simultaneously in a precursor material.

As there’s no relative motion between this precursor and the object being printed, it’s possible to utilize high-viscosity nanocomposites as part of the process. Another benefit of CAL over layer-by-layer techniques, is that supports aren’t required to hold builds in place, hence the process is potentially better suited to creating intricate microstructures.

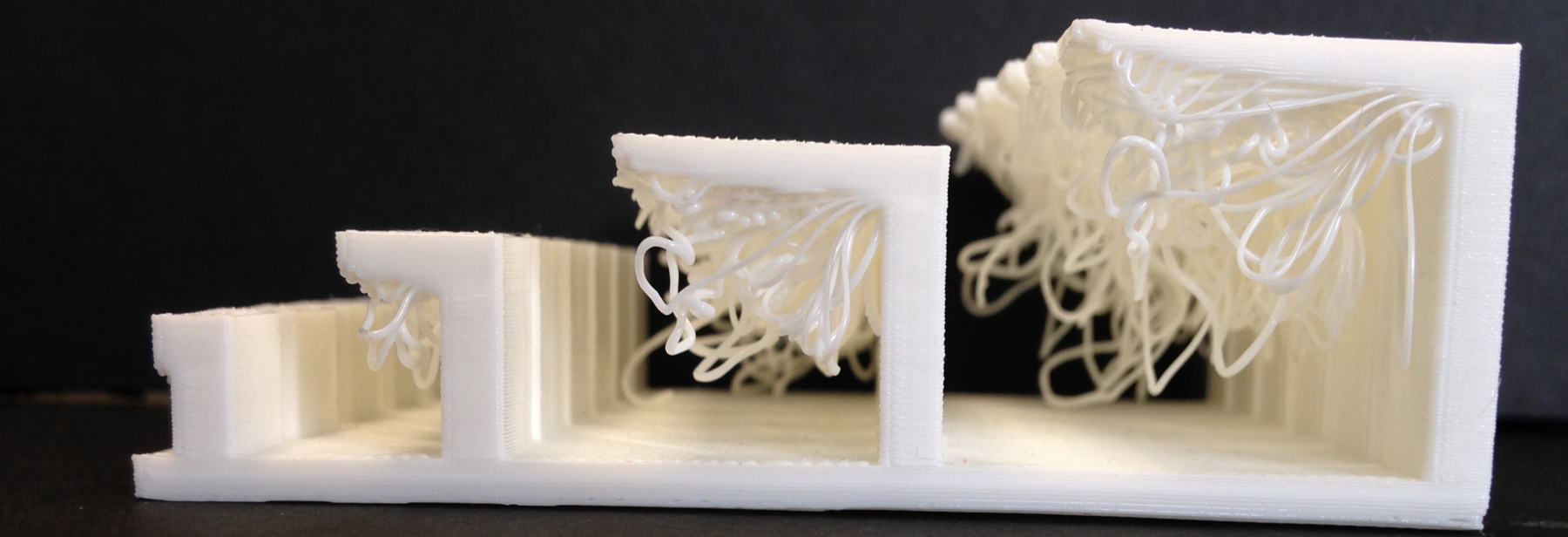

Some of the team’s 3D printed glass samples and imaging results. Image via the University of Freiburg.‘Micro-CAL’ printing ‘Glassomer’ objects

In order to assess the potential of CAL for producing glass structures at a microscale, the researchers have built their own Micro-CAL system. Equipped with a laser light source combined with a low numerical aperture optical fiber, the prototype has proven capable of demagnifying the light pattern emitted by a digital micromirror device across several tests.

In these experiments, the scientists polymerized a nanoparticle-loaded material inside a nanocomposite resin, which served to suitably support the build, before it was removed and reused in the creation of further objects. Once ready, the resulting green parts were then debinded and sintered, in a process which caused their nanoparticles to bond together, yielding a fully-dense glass component.

This process was made possible by a revised version of the polymer-based silica glass developed by the University of Freiburg and its spin-out Glassomer, tweaked to be both highly transparent, and harden quickly at a predetermined threshold.

In practice, Micro-CAL 3D printing the material enabled the team to produce microstructures in the space of 30-90 seconds, with features down to sizes of 20 µm and 50 µm in plastic and glass respectively. Compared to traditionally-manufactured silica glass, the researchers’ prototypes also featured a higher tensile stress at failure of 187. 7 MPa, as their process was found to limit the formation of microcracks and indentation.

7 MPa, as their process was found to limit the formation of microcracks and indentation.

With these benefits in mind, the team behind the project believe that Micro-CAL could soon be used as a means of producing various micro-optical parts, ranging from those used in VR headsets to modern microscopes. Given that most lab-on-a-chip devices also rely on the precise integration of complex microfluidic channels, the scientists believe their method can be used in clinical diagnostic tools too.

A set of Micro-CAL 3D printed glass prototypes. Image via the University of Freiburg.The emerging field of glass 3D printing

Despite the Freiburg-led research team’s critique of many existing approaches to glass 3D printing, a number of these are now starting to show commercial potential. Formnext 2021 start-up challenge winner Nobula, for instance, told 3D Printing Industry last year that it aimed to bring a dedicated glass 3D printer and feedstock to market in 2022.

On a similarly commercial note, Optiswiss installed Luxexcel’s VisionPlatform 7 platform in November 2021, with the aim of using it to 3D print lenses for eyewear customers. After the deal was signed, Optiswiss CEO Samuel Frei claimed that it gave his firm “a clear path towards the large-volume manufacturing of prescription smart glasses.”

At an experimental level, scientists at the University of Freiburg have also worked with Nanoscribe in the past to 2PP 3D print glass silica microstructures. Again, through the use of Glassomer materials, the project participants found they were able to create complex objects with a surface roughness of just 6 nanometers, significantly less than the 40-200 nanometers seen in many other glass parts.

The researchers’ findings are detailed in their paper titled “Volumetric Additive Manufacturing of Silica Glass with Microscale Computed Axial Lithography.” The study was co-authored by Joseph Toombs, Manuel Luitz, Caitlyn Cook, Sophie Jenne, Chi Chung Li, Bastian Rapp, Frederik Kotz-Helmer and Hayden Taylor.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a set of ‘Micro-CAL’ 3D printed glass prototypes. Image via the University of Freiburg.

Tags Frederik Kotz-Helmer Glassomer Luxexcel Nanoscribe Nobula Optiswiss Samuel Frei University of California Berkeley University of Freiburg

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

glass 3d printer | 3d-daily

Pelevin N. 0 Comments 3d printing, 3d printers, Neri Oxman, Equipment, Technologies

The number of materials that 3d printers can work with is growing every day. The extrusion process itself conquers new heights and, in addition to plastics, food and various metals, can use glass as a filler.

Previously, quartz sand or glass powder was used to 3D print with glass, but a team of researchers led by Neri Oxman has developed a 3D printer capable of working directly with molten source material. The technology used by the 3D printer is called G3DP (Glass 3D Printing).

G3DP is a first-of-its-kind method that allows you to create completely transparent products, and here glass is used as the main material. This technology allows you to open new frontiers in the field of glass processing, which appeared more than 4. 5 thousand years ago, and approach the process itself from a new, technological point of view.

5 thousand years ago, and approach the process itself from a new, technological point of view.

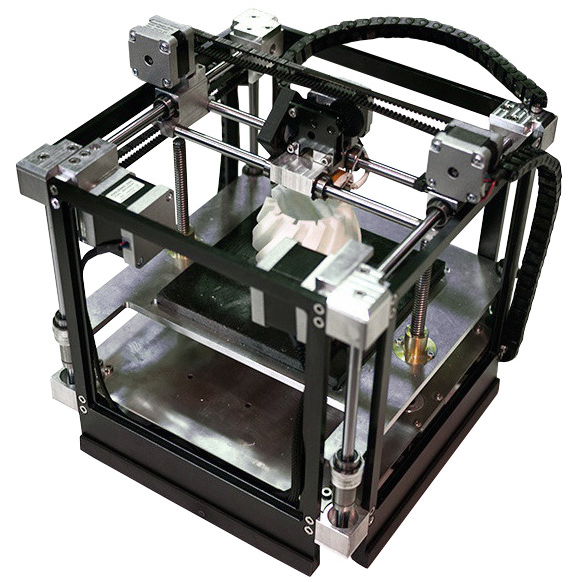

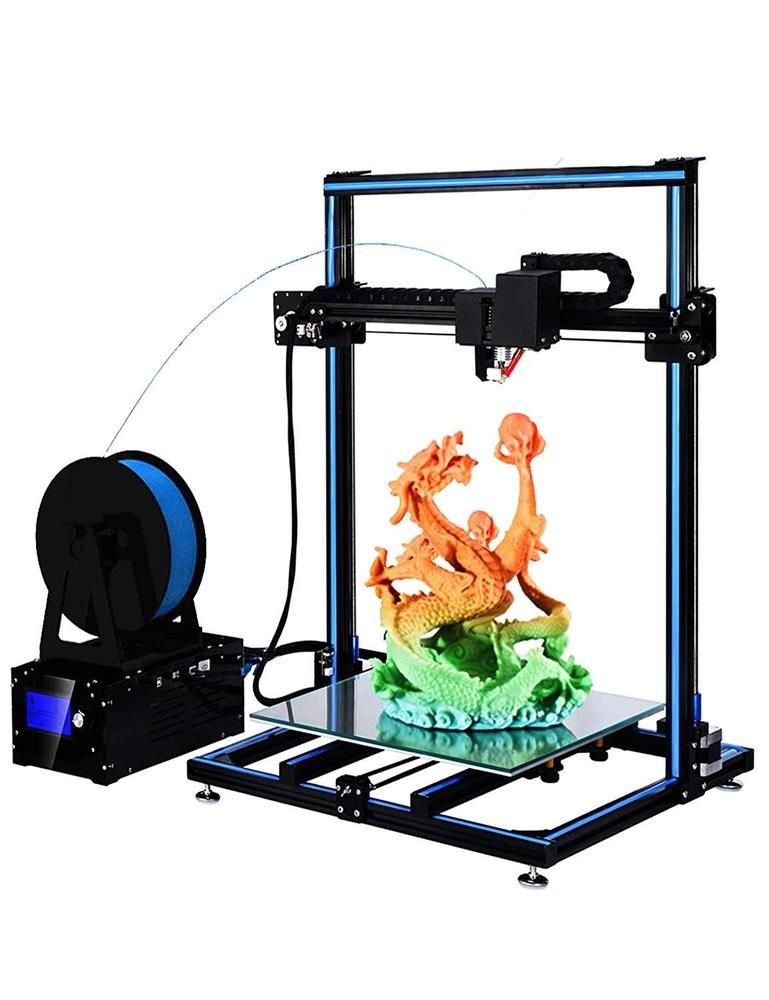

The operation of standard FDM printers is limited by the amount of materials that can be used for printing, as well as the way they are fed to the print head. As a rule, this is plastic, which is stored on special coils and before getting on the platform for the product, it is preheated to the desired temperature and cooled. In addition, the cost of some types of fillers is quite high due to their properties, which sometimes simply does not allow beginner 3d lovers to use it.

Against the background of these factors, glass has its own number of advantages, among which are the strength of the material, its optical properties and the availability of quartz glass, soda ash and other ingredients.

During the creation of a 3d printer for working with glass, the developers faced a number of problems. Glass objects must be slowly cooled to room temperature, and the cooling process itself must take place in several stages, each of which has its own temperature range. This reduces the chance of destruction of the product from a sharp temperature drop.

This reduces the chance of destruction of the product from a sharp temperature drop.

The group originally used hand propane torches, but their use caused cracks in the printed object. The solution was found with the addition of heating to the annealing chamber, which made it possible to set the correct temperature algorithm during the printing process.

Glass filler is fed into the 3d printer in the form of glass beads, which are placed in a special chamber. From there, it enters the heating area, where the temperature ranges from 1040 to 1165 degrees Celsius. It can be adjusted depending on the desired power, print speed, height of the future object and material feed speed. The glass filler is fed under standard pressure through a hole with a diameter of 10 mm. The product is built up in layers on a ceramic platform, heated with a 300-watt heater to a temperature of 1000 degrees.

The size of printed products is currently limited by the dimensions of the annealing chamber, which is 25 x 25 x 30 mm. It is additionally equipped with ceramic windows that allow you to observe the printing process.

It is additionally equipped with ceramic windows that allow you to observe the printing process.

3D printing with glass is an opportunity to solve many problems when working with many products. Such printers can be used in many industries ranging from printing laboratory equipment to spare parts for the aerospace industry.

New features of 3d printers - glass printing: characteristics, pictures and description.

Contents:

- 3d printed glass

- A little history of Glass 3D Printing

- G3DP extrusion technology

- Video

3d printing with glass

3D printing technologies are developing rapidly, becoming in demand in all spheres of human life. The first materials that allowed the creation of three-dimensional models were different types of plastic. Today, devices that reproduce products made of metal, ceramics, wood, food products, imitating fabrics, and paper are successfully operating in the world.

One of the latest developments in this area is the 3D printer, which has opened up new possibilities in the production (extrusion) of glass products. The technology, which is called Glass 3D Printing (G3DP), allows you to print objects of various shapes, designs, purposes, individual elements and structural details.

A bit of the history of Glass 3D Printing

A research team led by Neri Oksman has developed a new type of dual-chamber 3D printer. It was decided to use molten glass as a raw material for production in such devices. This made it possible to obtain three-dimensional objects of simple and complex shapes that differ:

- as transparent as traditional glass;

- color and texture variety;

- high strength;

- optical properties.

The first problem that the developers faced was the appearance of a crack due to the rapid cooling of the resulting surfaces. As a result of the experiments, a solution was found - to add heating to the annealing chamber in order to be able to set the desired temperature regime during the extrusion process.

G3DP extrusion technology

An innovative solution was to replace the material used by previous generations of machines. The 3D printer developed by Neri Oksman prints glass using glass beads. Sitall glass is used to obtain products of impeccable quality.

The initial material goes through several technological stages:

- heating and primary melting takes place in the first chamber;

- through the second liquid raw material enters the tip of the print head;

- at the outlet, the mass is squeezed out through a ten-millimeter hole and falls on a ceramic platform - a table, where a gradual, layer-by-layer build-up of the object takes place.

Modern technology is distinguished by the availability and low cost of raw materials. This allows you to reach a new level in the production of glass, which is in demand in various areas of human life and activity, may differ in aesthetics and technical characteristics.