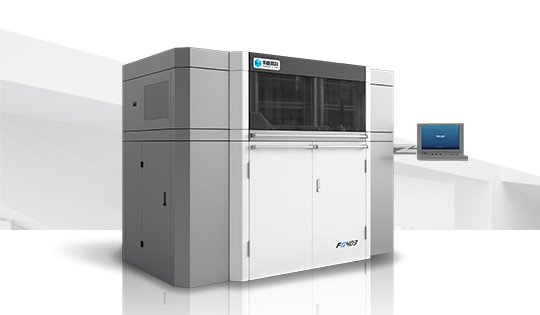

Industrial sls 3d printer

SLS 380 3D Printer | 3D Systems

Production-Grade SLS Workflow Solution

The SLS 380 is a high throughput SLS additive manufacturing solution with unprecedented levels of throughput, consistency, performance, and yield. Optimized for those who want to take the next step in integrating additive manufacturing into their factory-floor ecosystem, 3D Systems’ SLS 380 and its complementary software, material handling, and post-processing solutions answer the demand for cost-effective batch production parts.

100,000 Thermal Data Samples Per Second

The algorithm manages eight separately calibrated heaters, together with an integrated high-resolution IR camera that captures over 100,000 thermal data samples from within the build chamber per second. This data, together with the IR sensor, maintains temperature stasis for every part build-layer, for the duration of the build process. With a more consistent thermal uniformity across the build process, manufacturers can now deliver more dimensionally stable parts with better mechanical performance, higher repeatability, and greater yields – all with fewer human interventions and lower overall operating costs.

Industrial-Scale Post-Processing with AMT PostPro

3D Systems has partnered with AMT to provide a fully automated post-processing workflow, from de-powdering to vapor honing to deliver end-use parts in-hand faster and without hidden consumable or running costs of other technologies.

About this printer

-

Applications

-

Benefits

-

Tech Specs

Applications

- Impact and temperature resistant durable parts

- Covers, housings, enclosures

- Jigs and fixtures

- Reduced weight production parts

- Knobs, handles and other dashboard/interior parts

- Parts with snap fits and living hinges

- Machinery components

- Complex duct work

Benefits

- Manufacture strong end-use parts and functional prototypes faster

- Easily print any design without using supports or post-processing

- Integrated solution with expert application support

- Full automation of material handling frees valuable resource

- Streamline your workflow with automated production tools

- Lower cost of ownership with high throughput and material efficiency

- Smoothest surface finish, highest resolution and edge definition of any SLS system

Tech Specs

- Selective laser sintering (SLS) technology

- Max build envelope capacity (W x D x H): 15 x 13 x 18 in (381 x 330 x 460 mm)

- Consistent mechanical properties

- High production speed for its class of 2.

7 l/hr

7 l/hr - Streamlined production control, including 3D Sprint® integrated additive manufacturing software, fully automated powder handling and optional 3D Connect capability

- Automated 3D part nesting

- Maximized build volume and density

-

Setting the New Standard in 3D Printing

Bring increased productivity and quality to your SLS production process with this exclusive additive manufacturing software with tools for file preparation, automatic 3D nesting, quality checks for pre-build verification, and efficient build planning,

-

A new level of management in 3D production

3D Connect Service provides a secure cloud-based connection to 3D Systems service teams for proactive and preventative support, enabling better service to improve uptime and deliver production assurance for your system.

-

3D printing with plastics offers many choices for engineering grade materials, elastomers and composites. Do you need flexibility? Strength? Bio-compatibility? More?

-

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.

Interested in purchasing this printer?

You must have JavaScript enabled to use this form.

First Name

Last Name

Business Email

Company

Country -- Select Country --AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua & BarbudaArgentinaArmeniaArubaAscension IslandAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCanary IslandsCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicCeuta & MelillaChadChileChinaChristmas IslandClipperton IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCroatiaCuraçaoCyprusCzechiaCôte d’IvoireDenmarkDiego GarciaDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard & McDonald IslandsHondurasHong Kong SAR ChinaHungaryIcelandIndiaIndonesiaIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SAR ChinaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorth MacedoniaNorwayOmanOutlying OceaniaPakistanPalauPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalPuerto RicoQatarRomaniaRussiaRwandaRéunionSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaRepublic of Sudan (North Sudan)St. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

State -- Select State --Buenos AiresCatamarcaChacoChubutCiudad Autónoma de Buenos AiresCórdobaCorrientesEntre RíosFormosaJujuyLa PampaLa RiojaMendozaMisionesNeuquénRío NegroSaltaSan JuanSan LuisSanta CruzSanta FeSantiago del EsteroTierra del FuegoTucumánAustralian Capital TerritoryNew South WalesNorthern TerritoryQueenslandSouth AustraliaTasmaniaVictoriaWestern AustraliaBurgenlandKärntenNiederösterreichOberösterreichSalzburgSteiermarkTirolVorarlbergWienAcreAlagoasAmapáAmazonasBahiaCearáDistrito FederalEspírito SantoGoiásMaranhãoMato GrossoMato Grosso do SulMinas GeraisParáParaíbaParanáPernambucoPiauíRio de JaneiroRio Grande do NorteRio Grande do SulRondôniaRoraimaSanta CatarinaSão PauloSergipeTocantinsAlbertaBritish ColumbiaManitobaNew BrunswickNewfoundland and LabradorNorthwest TerritoriesNova ScotiaNunavutOntarioPrince Edward IslandQuebecSaskatchewanYukon TerritoriesAisén del General Carlos Ibañez del CampoAntofagastaAraucaníaArica y ParinacotaAtacamaBío-BíoCoquimboLibertador General Bernardo O'HigginsLos LagosLos RíosMagallanesMauleRegión Metropolitana de SantiagoTarapacáValparaísoAnhuiBeijingChinese TaipeiChongqingFujianGansuGuangdongGuangxiGuizhouHainanHebeiHeilongjiangHenanHong KongHubeiHunanJiangsuJiangxiJilinLiaoningMacaoNei MongolNingxiaQinghaiShaanxiShandongShanghaiShanxiSichuanTianjinXinjiangXizangYunnanZhejiangÎle-de-FranceOccitanieAuvergne-Rhône-AlpesBourgogne-Franche-ComtéBretagneCentre-Val de LoireCorseGrand EstHauts-de-FranceJuraNormandieNouvelle-AquitainePays de la LoireProvence-Alpes-Côte d'AzurBaden-WürttembergBayernBerlinBrandenburgBremenHamburgHessenMecklenburg-VorpommernNiedersachsenNordrhein-WestfalenRheinland-PfalzSaarlandSachsenSachsen-AnhaltSchleswig-HolsteinThüringenAndaman and Nicobar IslandsAndhra PradeshArunachal PradeshAssamBiharChandigarhChhattisgarhDadra and Nagar HaveliDaman and DiuDelhiGoaGujaratHaryanaHimachal PradeshJammu and KashmirJharkhandKarnatakaKeralaLakshadweepMadhya PradeshMaharashtraManipurMeghalayaMizoramNagalandOdishaPuducherryPunjabRajasthanSikkimTamil NaduTripuraUttar PradeshUttarakhandWest BengalCarlowCavanClareCorkDonegalDublinGalwayKerryKildareKilkennyLaoisLeitrimLimerickLongfordLouthMayoMeathMonaghanOffalyRoscommonSligoTipperaryWaterfordWestmeathWexfordWicklowAgrigentoAlessandriaAnconaAostaArezzoAscoli PicenoAstiAvellinoBariBarletta-Andria-TraniBellunoBeneventoBergamoBiellaBolognaBolzanoBresciaBrindisiCagliariCaltanissettaCampobassoCarbonia-IglesiasCasertaCataniaCatanzaroChietiComoCosenzaCremonaCrotoneCuneoEnnaFermoFerraraFirenzeFoggiaForlì-CesenaFrosinoneGenovaGoriziaGrossetoImperiaIserniaLa SpeziaL'AquilaLatinaLecceLeccoLivornoLodiLuccaMacerataMantovaMassa - CarraraMateraMedio CampidanoMessinaMilanoModenaMonza e BrianzaNapoliNovaraNuoroOgliastraOlbia-TempioOristanoPadovaPalermoParmaPaviaPerugiaPesaro e UrbinoPescaraPiacenzaPisaPistoiaPordenonePotenzaPratoRagusaRavennaReggio CalabriaReggio EmiliaRietiRiminiRomaRovigoSalernoSassariSavonaSienaSondrioSiracusaTarantoTeramoTerniTrapaniTrentoTrevisoTriesteTorinoUdineVareseVeneziaVerbano-Cusio-OssolaVercelliVeronaVibo ValentiaVicenzaViterboAichiAkitaAomoriChibaEhimeFukuiFukuokaFukushimaGifuGunmaHiroshimaHokkaidoHyogoIbarakiIshikawaIwateKagawaKagoshimaKanagawaKochiKumamotoKyotoMieMiyagiMiyazakiNaganoNagasakiNaraNiigataOitaOkayamaOkinawaOsakaSagaSaitamaShigaShimaneShizuokaTochigiTokushimaTokyoTottoriToyamaWakayamaYamagataYamaguchiYamanashiBusanDaeguDaejeonGangwonGwangjuGyeonggiIncheonJejuNorth ChungcheongNorth GyeongsangNorth JeollaSeoulSouth ChungcheongSouth GyeongsangSouth JeollaUlsanJohorKedahKelantanMelakaNegeri SembilanPahangPerakPerlisPulau PinangSabahSarawakSelangorTerengganuWilayah Persekutuan Kuala LumpurWilayah Persekutuan LabuanWilayah Persekutuan PutrajayaAguascalientesBaja CaliforniaBaja California SurCampecheChiapasChihuahuaCoahuilaColimaDurangoFederal DistrictGuanajuatoGuerreroHidalgoJaliscoMexico StateMichoacánMorelosNayaritNuevo LeónOaxacaPueblaQuerétaroQuintana RooSan Luis PotosíSinaloaSonoraTabascoTamaulipasTlaxcalaVeracruzYucatánZacatecasŚląskieŁódzkieŚwiętokrzyskieDolnośląskieKujawsko-pomorskieLubelskieLubuskieMałopolskieMazowieckieOpolskiePodkarpackiePodlaskiePomorskieWarmińsko-mazurskieWielkopolskieZachodniopomorskieAdygeya, RespublikaAltay, RespublikaAltayskiy krayAmurskaya oblast'Arkhangel'skaya oblast'Astrakhanskaya oblast'Bashkortostan, RespublikaBelgorodskaya oblast'Bryanskaya oblast'Buryatiya, RespublikaChechenskaya RespublikaChelyabinskaya oblast'Chukotskiy avtonomnyy okrugChuvashskaya RespublikaDagestan, RespublikaIngushetiya, RespublikaIrkutskaya oblast'Ivanovskaya oblast'Kabardino-Balkarskaya RespublikaKaliningradskaya oblast'Kalmykiya, RespublikaKaluzhskaya oblast'Kamchatskiy krayKarachayevo-Cherkesskaya RespublikaKareliya, RespublikaKemerovskaya oblast'Khabarovskiy krayKhakasiya, RespublikaKhanty-Mansiyskiy avtonomnyy okrug-YugraKirovskaya oblast'Komi, RespublikaKostromskaya oblast'Krasnodarskiy krayKrasnoyarskiy krayKurganskaya oblast'Kurskaya oblast'Leningradskaya oblast'Lipetskaya oblast'Magadanskaya oblast'Mariy El, RespublikaMordoviya, RespublikaMoskovskaya oblast'MoskvaMurmanskaya oblast'Nenetskiy avtonomnyy okrugNizhegorodskaya oblast'Novgorodskaya oblast'Novosibirskaya oblast'Omskaya oblast'Orenburgskaya oblast'Orlovskaya oblast'Penzenskaya oblast'Permskiy krayPrimorskiy krayPskovskaya oblast'Rostovskaya oblast'Ryazanskaya oblast'Sakha, RespublikaSakhalinskaya oblast'Samarskaya oblast'Sankt-PeterburgSaratovskaya oblast'Severnaya Osetiya-Alaniya, RespublikaSmolenskaya oblast'Stavropol'skiy kraySverdlovskaya oblast'Tambovskaya oblast'Tatarstan, RespublikaTomskaya oblast'Tul'skaya oblast'Tverskaya oblast'Tyumenskaya oblast'Tyva, RespublikaUdmurtskaya RespublikaUl'yanovskaya oblast'Vladimirskaya oblast'Volgogradskaya oblast'Vologodskaya oblast'Voronezhskaya oblast'Yamalo-Nenetskiy avtonomnyy okrugYaroslavskaya oblast'Yevreyskaya avtonomnaya oblast'Zabaykal'skiy krayCentral SingaporeNorth EastNorth WestSouth EastSouth WestA CoruñaÁlava / ArabaAlbaceteAlicante / AlacantAlmeríaAsturiasÁvilaBadajozBalearsBarcelonaBurgosCáceresCádizCantabriaCastellón / CastellóCiudad RealCórdobaCuencaGironaGranadaGuadalajaraGuipúzcoa / GipuzkoaHuelvaHuescaJaénLa RiojaLas PalmasLeónLleidaLugoMadridMálagaMurciaNavarra / NafarroaOurensePalenciaPontevedraSalamancaSanta Cruz de TenerifeSegoviaSevillaSoriaTarragonaTeruelToledoValencia / ValènciaValladolidVizcaya / BizkaiaZamoraZaragozaAargauAppenzell AusserrhodenAppenzell InnerrhodenBasel-LandschaftBasel-StadtBernFribourgGenèveGlarusGraubündenJuraLuzernNeuchâtelNidwaldenObwaldenSankt GallenSchaffhausenSchwyzSolothurnThurgauTicinoUriValaisVaudZugZürichChanghua CountyChiayi CityChiayi CountyHsinchu CityHsinchu CountyHualien CountyKaohsiung CityKaohsiung CountyKeelung CityMiaoli CountyNantou CountyPenghu CountyPingtung CountyTaichung CityTaichung CountyTainan CityTainan CountyTaipei CityTaipei CountyTaitung CountyTaoyuan CountyYilan CountyYunlin CountyŞırnakŞanlıurfaİstanbulİzmirAğrıAd?yamanAdanaAfyonkarahisarAksarayAmasyaAnkaraAntalyaArdahanArtvinAydınBalıkesirBartınBatmanBayburtBilecikBingölBitlisBoluBurdurBursaÇanakkaleÇankırıÇorumDenizliDiyarbakırDüzceEdirneElazığErzincanErzurumEskişehirGaziantepGiresunGümüşhaneHakkâriHatayIğdırIspartaKırşehirKırıkkaleKırklareliKahramanmaraşKarabükKaramanKarsKastamonuKayseriKilisKocaeliKonyaKütahyaMalatyaManisaMardinMersinMuşMuğlaNevşehirNiğdeOrduOsmaniyeRizeSakaryaSamsunSiirtSinopSivasTekirdağTokatTrabzonTunceliUşakVanYalovaYozgatZonguldakCrimeaCherkasyChernihivChernivtsiDnipropetrovskDonetskIvano-FrankivskKharkivKhersonKhmelnytskyiKirovohradKyivLuhanskLvivMykolaivOdesaPoltavaRivneSumyTernopilVinnytsiaVolynZakarpattiaZaporzhzhiaZhytomyrAberdeen CityAberdeenshireAngusAntrimArgyll and ButeArmaghAvonBanffshireBedfordshireBerkshireBlaenau GwentBordersBridgendBristolBuckinghamshireCaerphillyCambridgeshireCardiffCarmarthenshireCeredigionChannel IslandsCheshireClackmannanshireClevelandConwyCornwallCumbriaDenbighshireDerbyshireDevonDorsetDownDumfries and GallowayDurhamEast AyrshireEast DunbartonshireEast LothianEast RenfrewshireEast Riding of YorkshireEast SussexEdinburghEssexFalkirkFermanaghFifeFlintshireGlasgowGloucestershireGreater ManchesterGwyneddHampshireHerefordshireHertfordshireHighlandHumbersideInverclydeIsle of AngleseyIsle of ManIsle of WightIsles of ScillyKentLancashireLeicestershireLincolnshireLondonLondonderryMerseysideMerthyr TydfilMiddlesexMidlothianMonmouthshireMorayNeath Port TalbotNewportNorfolkNorth AyrshireNorth East LincolnshireNorth LanarkshireNorth YorkshireNorthamptonshireNorthumberlandNottinghamshireOrkneyOuter HebridesOxfordshirePembrokeshirePerthshire and KinrossPowysRenfrewshireRhondda, Cynon, TaffRoxburghshireRutlandShetlandShropshireSomersetSouth AyrshireSouth LanarkshireSouth YorkshireStaffordshireStirlingSuffolkSurreySwanseaTorfaenTyne and WearTyroneVale of GlamorganWarwickshireWest DunbartonshireWest LothianWest MidlandsWest SussexWest YorkshireWiltshireWorcestershireWrexhamAlabamaAlaskaAmerican SamoaArizonaArkansasCaliforniaColoradoConnecticutDelawareDistrict of ColumbiaFederated MicronesiaFloridaGeorgiaGuamHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarshall IslandsMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaNorthern Mariana IslandsOhioOklahomaOregonPalauPennsylvaniaPuerto RicoRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUnited States Minor Outlying IslandsUS Virgin IslandsUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Industry - None -Academic & ResearchAerospace & DefenseDentalHealthcareManufacturing & PrototypingTransportation & Motorsports

Sub-Industry - Select -Medical Device ManufacturersMedical Contract ManufacturersHospital or Medical ClinicMedical SchoolsOther HealthcareDental ClinicsDental Equipment ManufacturersDental LabsDental SchoolsOther DentalMilitary AviationCommercial AviationDefenseSpace & UAVOther Aerospace & DefenseAutomotiveTruck, Bus & RailMotorsportsAftermarket & ServiceRecreation & MarineOther Transportation3D Printing Service BureausFoundriesElectronics & ConnectorsSemiconductorTurbomachineryJewelryConsumer & Durable GoodsOther Manufacturing

Address

Postal Code

Job Level -- Select Job Level --C-LevelPresident or VPDirectorManagerProfessional StaffConsultant or ContractorIntern or StudentHobbyist

Job Function -- Select Job Function --Engineering - SoftwareEngineering - HardwareManufacturingFinanceITLegalMarketingPurchasingSalesService Technician - HardwareService Technician - SoftwareOther

Level of Interest -- Select Your Level of Interest --Beginning ResearchEvaluating Solutions and CompetitorsInterested in Buying in 1-3 MonthsInterested in Buying in 3-6 MonthsInterested in Buying in 6-12 MonthsI would like to speak with a Solutions SpecialistI have a Support Issue or Question

Area of Interest - Select -Printers• Professional Printer (ColorJet, MultiJet)• Production Printer (SLA, SLS, Metal/DMP)• Figure 4• Titan Additive• OtherSoftwareHaptics• HapticsHealthcare• Virtual Surgical Planning• Anatomical Modeling• Kumovis Additive

3D Printer - Select -MJP• ProJet 2500• ProJet 2500 Plus• ProJet 2500W• ProJet 2500 IC• ProJet 3600• ProJet 5600CJP• ProJet 260 Plus• Projet 360• ProJet 460 Plus• ProJet 660Pro• ProJet 860ProDMP• DMP Flex 100• ProX 200• DMP Flex 200• DMP Flex 350• DMP Factory 350• DMP Factory 500• ProX 100• ProX 300SLS• SLS 6100• SLS 380• sPro 140• sPro 230SLA• SLA 750• ProJet 6000• ProJet 7000• ProX 800• ProX 950Figure 4• Figure 4 Standalone• Figure 4 Modular• Figure 4 Production• Figure 4 JewelryNextDent• NextDent 5100Kumovis• Kumovis R1Atlas• Atlas H• Atlas HSMaterialsBioprinter

Software product - Select -3D Connect Manage3D Connect Service3D Modeling Services3D Sprint3D Sprint Pro for SLA3DXpertGeomagic Control XGeomagic Design XGeomagic for SOLIDWORKSGeomagic FreeformGeomagic SculptGeomagic TouchGeomagic Touch XGeomagic WrapOpenHapticsPhantom Premium

Area of Interest - Select -Medical Device Design and ManufacturingMedical SimulatorsAnatomical ModelsD2P SoftwareDental Manufacturing and Design Services

I consent to receive 3D Systems CommunicationsWould you like to receive special offers, product updates, and event news from 3D Systems? By clicking "Yes", you agree to receive follow-up communications from 3D Systems or our partners. You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

Area of Interest - None -Appearance ModelsCast UrethaneCJPCNCCNC MetalCNC PlasticDie CastingDigitalization/ScanningDMPEngineering ProjectsFDMInjection MoldingInjection ToolingInvestment CastingInvestment Casting PatternJigs and FixturesMetal CastingMJPMJP-ElastomersQuick Cast PatternsRIMSheet MetalSLASLSToolingVacuum castingVacuum forming

Custom Area of Interest

PPP

PST

Software

Healthcare

ODM

Area of interest Required

This site is protected by reCAPTCHA. The Google Privacy Policy and Terms of Service apply.

You Might Also Be Interested In

sPro 140

High repeatability and throughput of SLS production parts

sPro 230

Large capacity SLS printer for high throughput of tough and durable thermoplastic parts

Top 11 Best SLS 3D Printers 2023 (For ALL Price Ranges!)

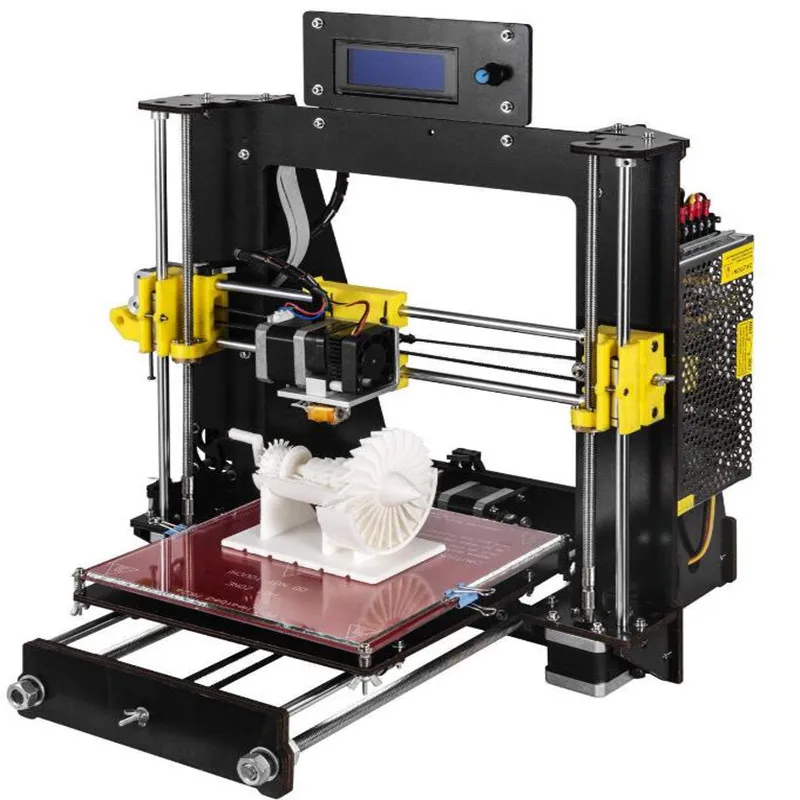

Selective Laser Sintering is one of the main plastic 3D printing technologies for creating accurate parts on demand. SLS 3D printers create accurate prototypes by sintering plastic powders using a laser. As with Fused Deposition Modeling, the part is traced layer-by-layer to gradually create the finished part.

SLS 3D printers create accurate prototypes by sintering plastic powders using a laser. As with Fused Deposition Modeling, the part is traced layer-by-layer to gradually create the finished part.

Introduction: A Short History of SLS Printing

Closely following Stereolithography as one of the first 3D printing technologies invented, Selective Laser Sintering was theorized by Carl Deckard in 1988 who filed the patent while working at the University of Texas. Instead of using a UV light as with Stereolithography, SLS involves powder 3D printers using a laser to trace and solidify layers of powder polymers to create a finished part.

Until recently, SLS 3D printers were industrial 3D printers costing tens of thousands of dollars. However, with recent patents expiring and a renewed interest in 3D printing, several more affordable SLS 3D printers have been developed, starting at a few thousand dollars.

- You can also view our in-depth Selective Laser Sintering guide here.

SLS 3D printer materials

SLS printers have a more restricted material range than technologies like FDM, mostly restricted to Nylon Polyamide powders. Some are restricted to just black PA12, whereas some can also print powders including PA11 and PA6.

Increasingly, powder mixes are compatible with industrial and desktop SLS 3D printers. These include glass mixes, carbon fiber mixes, and even food-grade powders for niche applications. Increasing numbers of SLS printers can print TPU, a flexible rubbery material.

But what is the best SLS 3D printer on the market today?

Best Desktop / Cheap SLS 3D Printers under $15,000

Firstly, we have listed the desktop SLS 3D printers. These are defined as printers under $15,000 and are appropriate for small business rapid prototyping rather than solely industrial work.

Note: we have ordered these printers by price.

Sinterit Lisa

- SLS 3D printer price: €9,995 — Available on 3DPrima here

- Company based: Poland

- Print volume: 150 x 200 x 150 mm

Pros

Affordable SLS printer.

Precise.

Compatible with Nylon and Flexa black materials.

Cons

Not portable, weighing in at 41kg.

The Sinterit Lisa is an affordable SLS printer made by Polish manufacturer Sinterit. Compatible with the usual PA12 Nylon and Flexa black materials, the Sinterit Lisa offers a 150 x 200 x. 150 mm printing volume, enough for most single-part projects.

The Sinterit Lisa is a precise powder 3D printer, with a layer thickness of between 0.075-0.175mm. Though a desktop SLS printer, it still isn’t portable, weighing 41kg. The Sinterit Lisa can be purchased for around €9,990, and comes with a 4-inch touch screen for managing printing.

While the Lisa is already an impressive machine, Sinterit have since gone one step further and released the Sinterit Lisa Pro, a premium and upgraded SLS printer. Though it’s more expensive at over €12,000, the printer has won a slew of awards and appears to be a success.The Sinterit Lisa SLS 3D printer is one of the first desktop SLS 3D printers on the market.

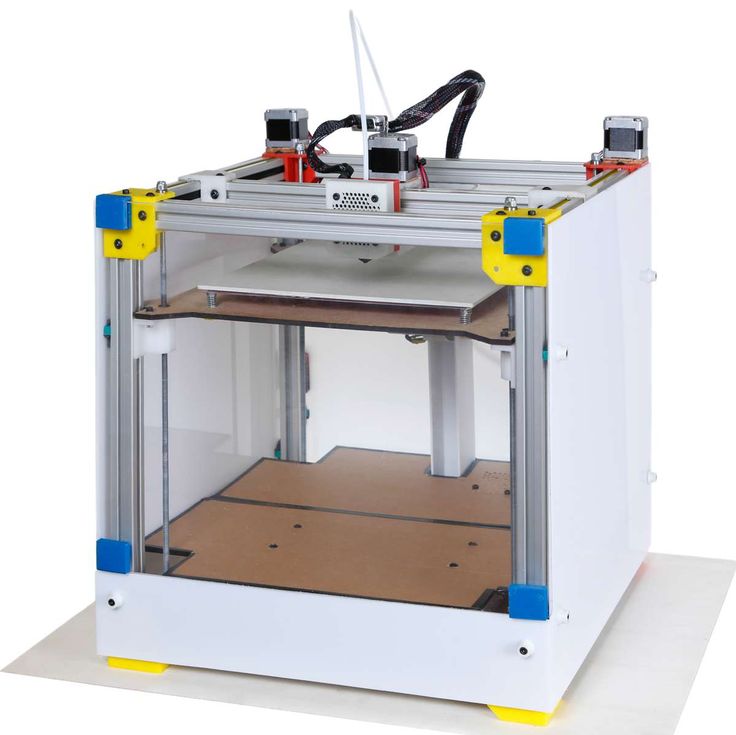

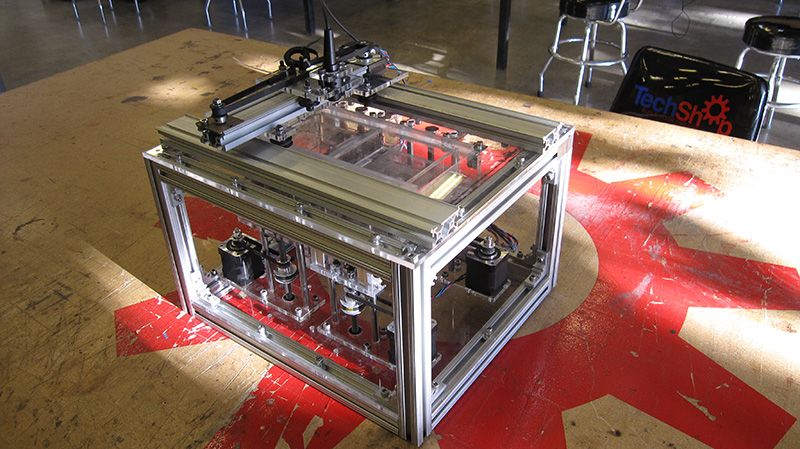

Sintratec Kit — DIY SLS 3D printer

- Cost: €4,999

- Company based: Switzerland

- Print volume: 110 x 110 x 110 mm

Pros

Only DIY SLS 3D printer on sale in the world.

No specialist technical knowledge is required.

Cheapest SLS 3D printer out there.

Cons

Cannot print many parts simultaneously.

Takes 4 days to assemble.

The Sintratec Kit is the only DIY 3D printer kit on this list, and is currently the only DIY SLS 3D printer for sale in the world! Creating an SLS 3D printer kit is a huge achievement considering how much more complex SLS is compared to fused deposition modeling, though the Sintratec takes far longer than a standard kit printer to assemble.

After successfully crowdfunding this SLS 3D printer back in 2014 — raising $213,337, more than their original $175K goal — the Sintratec DIY SLS printer kit has since been released worldwide.

With a modest 110 x 110 x 110 mm print volume, medium-sized parts can be printed without issue. For printing many parts simultaneously however, this may not be the machine for you. The Kit takes around 4 days to assemble, though Sintratec say no specialist technical knowledge is required. You can easily connect to the printer via USB to print, and Sintratec sell their own plastic powders.

For printing many parts simultaneously however, this may not be the machine for you. The Kit takes around 4 days to assemble, though Sintratec say no specialist technical knowledge is required. You can easily connect to the printer via USB to print, and Sintratec sell their own plastic powders.

If you want to try Selective Laser Sintering and don’t want to break the bank, the Sintratec Kit is also the cheapest SLS 3D printer out there, at just €4,999 — if you don’t mind building it yourself.

The only DIY kit SLS 3D printer on our list, the Sintratec Kit.Formlabs Fuse 1

- Price: $9,999

- Company based: USA

- Print volume: 165 x 165 x 320 mm

Pros

Good all-around powder printing solution.

Decent printing volume.

Can be connected via ethernet or WiFi.

Cons

Very heavy at 88kg.

Might be too expensive for some.

American 3D printer company Formlabs have grown astronomically since founding in 2011. Since taking over desktop resin 3D printing with their Form range, the Fuse 1 is Formlabs’ first foray into the SLS 3D printer market. Offering a speed of 10mm/s and a layer thickness of 100µm, the Fuse 1 is a good all-around powder printing solution.

Offering a speed of 10mm/s and a layer thickness of 100µm, the Fuse 1 is a good all-around powder printing solution.

The Fuse 1 can be connected via ethernet or WiFi, and has a very decent printing volume of 165 x 165 x 320 mm. The Fuse 1 is heavy however, weighing in at 88kg, so it’s not exactly easy to move around on a whim. Moreover, the Fuse 1 retails at around $9,999, more expensive than some printers on this list.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

The Fuse 1 is Formlabs’ first SLS 3D printer, having previously made SLA machines.Sinterit Lisa Pro

- Price: $15,000 for the base model — Available on 3DPrima here

- Company based: Poland

- Print volume: 150 x 200 x 260 mm (may be smaller maximum limit for some materials)

Pros

Great precision.

Large build area.

Smooth and accurate powder parts.

Cons

Very expensive.

The Sinterit Lisa Pro is the upgraded version of Sinterit’s original desktop SLS printer, the Lisa. The Lisa Pro comes with a number of improvements, such as better precision: 0.05 mm vs 0.175-0.75 mm. The results are noticeably smoother and more accurate powder parts — very important in industrial applications like prototype testing.

The Lisa Pro comes with a number of improvements, such as better precision: 0.05 mm vs 0.175-0.75 mm. The results are noticeably smoother and more accurate powder parts — very important in industrial applications like prototype testing.

Despite the higher price tag — starting at around $15,000 — many will consider the precision and larger build area worth it. You get their 3D printer software tool with the printer, Sinterit Studio 2019, and though Sinterit sell their own SLS printer powders, the Lisa Pro accepts third party powders.

Red Rock 3D

- Company based: Russia

- Price: Unknown

- Print volume: 180 x 180 x 180 mm

Pros

Fairly impressive print volume.

The fast printing speed of 20cm³/h.

Compact, weighing 35kg.

Cons

Can only be used with black Nylon PA12.

Red Rock are the only Russian 3D printer company on our list, having released a compact, desktop SLS 3D printer weighing just 35kg. Their printer, the Red Rock 3D, is an SLS printer developed for rapid prototyping of functional parts.

With a fairly impressive print volume of 180 x 180 x 180 mm, the Red Rock 3D is perfect for batch production. With a printing speed of 20cm³/h, parts can be created fairly quickly to be tested for their effectiveness. The Red Rock powder 3D printer is currently only able to be used with black Nylon PA12, but the Russian company plans to expand their product range in the coming months.

Best Industrial SLS 3D Printer:

Most SLS 3D printers are out of budget for all but the most industrial applications. These industrial machines are used for high-quality pre-manufacturing prototypes, R&D, and uses in sectors such as aerospace, automotives and other sectors.

Sintratec S2

- Price: $30,000 for primary parts; extra for polishing station and other add-ons

- Company based: Switzerland

- Print volume: 160 x 160 x 400 mm

Pros

Scalable compact system.

Fast and accurate.

Great to print parts in a small workshop.

Cons

Not suited for large-scale production.

After the success of both the Sintratec S1 and the Sintratec Kit, the Swiss company have broadened their range with the more industrial Sintratec S2 SLS machine. It calls itself a ‘scalable compact system’ and features a Laser Sintering Station, Material Handling Station, Material Core Unit and other key parts that make this powder 3D printer a one stop shop for SLS printing.

One of the main benefits of the Sintratec S2 is its fantastic height — you can print up to 400 mm tall parts. This opens up new possibilities for taller powder prototypes. It’s also double the speed of the Sintratec Kit, and accurate up to an astonishing 0.3 mm. It’s a huge machine however, so if you are looking to print parts in a small workshop, you need to seriously consider how viable this may be.

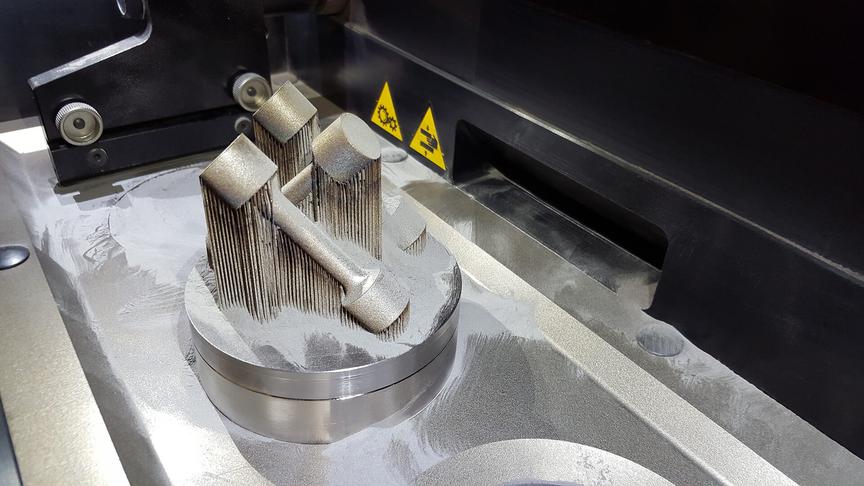

3D Systems ProX SLS 6100

- SLS 3D printer cost: over $100,000

- Company based: USA

- Print volume: 381 x 330 x 460 mm

Pros

Large build volume.

Can print metal powders like aluminum and carbon fiber.

One of the fastest SLS printers in its price range.

Cons

Expensive for an industrial 3D printer.

3D Systems are the original 3D printing firm, having been around since the mid-1980s when they commercialized stereolithography. They’ve since branched out into many other 3D printing technologies, including SLS 3D printers such as their ProX SLS 6100, taking over from the previous SLS 500 model since its release in late 2017.

- For more information on the history of 3D printing, check out our full feature story here.

This industrial SLS 3D printer offers a much larger build volume at 381 x 330 x 460 mm, as well as a layer thickness of between 0.08 and 0.15 mm. It’s fairly speedy, and also versatile, able to print nylon powders filled with other materials, including metal powders like aluminum, or carbon fiber, as well as food-grade materials.

One of the fastest SLS printers in its price range, the ProX SLS 6100 prints up to 2.7 l/h, using 3D Sprint software to maximize efficiency and manufacturing speed. 3D Systems say the ProX 6100 reaches 95% material efficiency due to the Material Quality Control (MQC) system automatically blending and recycling powder, helping lower part costs.

3D Systems say the ProX 6100 reaches 95% material efficiency due to the Material Quality Control (MQC) system automatically blending and recycling powder, helping lower part costs.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

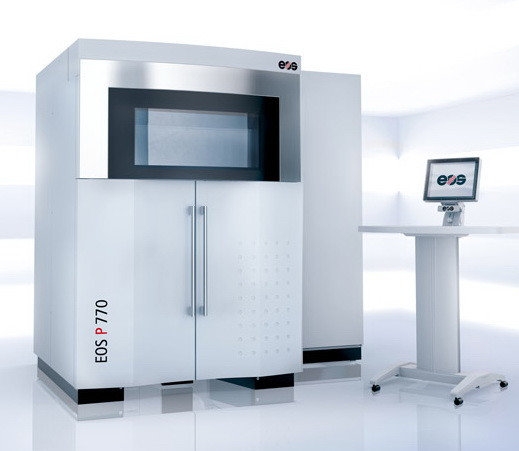

EOS Formiga P 110 Velocis

- 3D printer price: $175,000

- Company based: Germany

- Print volume: 200 x 250 x 300 mm

Pros

Considered the perfect entry-level SLS machine.

No post-processing is needed to remove the marks left by the removed supporting material.

EOS has been in the SLS game since the beginning.

Cons

One of the most expensive SLS printers.

EOS are another major 3D printer manufacturer and a leader in SLS 3D printers, based in Germany. You can trust EOS; they’ve been in the SLS and DMLS 3D printer game since the beginning, and their excellent reputation precedes them.

EOS consider the Formiga P 110 Velocis SLS 3D printer the perfect entry-level SLS machine, with a decent 200 x 250 x 300 mm build volume as well as a varying layer thickness of 0. 06/0.1/0.12 mm depending on the materials used.

06/0.1/0.12 mm depending on the materials used.

The German company sell the P 110 Velocis as the simplest SLS printer to use, highlighting the lack of any binding agent or any kind of addition — so your costs are only in the materials, and electricity. The SLS process means no supporting structures are required, and therefore no post processing to remove the marks left by removed supporting material.

Another fairly fast 3D printer, the EOS Formiga P 110 offers a speed of 1.2 l/h, and weighs approximately 600kg.

Get a quote*

*One of our trusted partners will be in touch following a quote request.EOS are pioneers of SLS technology, refining their printers over 30 years of R&D.

Sharebot SnowWhite 2

- Cost: $40,000 / €35,000

- Company based: Italy

- Print volume: 100 x 100 x 100 mm

Pros

Can print multiple powder options such as Nylon, PA11, TPU, glass, carbon and aluminum.

Designed to be simple to use.

Precis, accurate and large.

Cons

Small print volume.

Sharebot are an Italian 3D printer manufacturer that make FDM 3D printers, metal 3D printers, and have recently followed up the original SnowWhite with their fewest printer, the SnowWhite 2 SLS printer. Bringing their metal 3D printing expertise to selective laser sintering, the SnowWhite 2 is very versatile, able to print a variety of different SLS 3D printer powder options including PA12 (Nylon), PA11, TPU, as well as glass, carbon and aluminum powder mixes.

The printer is designed to be as simple as possible to operate, automating much of the printing setup. It falls in between the desktop and industrial ranges, retaining ease of use — it can be set up in just 10 minutes — while still being precise, accurate and large, with a 50-micron Z-axis resolution, 100-micron XY-resolutions, and weighing 120kg.

- We interviewed Sharebot ahead of the release of their first metal 3D printer, the metalONE. Read it here.

Despite being an industrial printer, the Sharebot SnowWhite 2 has a fairly small print volume. At 100 x 100 x 100 mm, this is not ideal for manufacturing multiple parts simultaneously, and is therefore better served for R&D and rapid prototyping of single parts. The printer costs around $40,000, or €35,000.

At 100 x 100 x 100 mm, this is not ideal for manufacturing multiple parts simultaneously, and is therefore better served for R&D and rapid prototyping of single parts. The printer costs around $40,000, or €35,000.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

XYZprinting MfgPro230 xS

- Price: $60,000

- Company based: China

- Print volume: 230 x 230 x 230 mm

Pros

Lower price than many competitors.

Great print speed at 1 l/h.

Uses specialized SLS 3D printer software.

Cons

Skilled operator required.

XYZprinting are mostly known for their desktop FDM 3D printers. They have since expanded into other 3D printing technologies, selling an SLA 3D printer and a 3D scanner, as well as their first SLS printer, the MfgPro230 xS. Weighing 360kg, it’s an industrial sized printer, but at a lower price than many competitors.

The MfgPro230 xS prints at 1 l/h speeds, great for small businesses who want to quickly prototype models for engineering and other uses. The printer uses specialized SLS 3D printer software: SLS Build for slicing and optimizing parts for printing, and SLS Ware for remote monitoring and for managing the 3D printing process.

The printer uses specialized SLS 3D printer software: SLS Build for slicing and optimizing parts for printing, and SLS Ware for remote monitoring and for managing the 3D printing process.

- XYZprinting are best known for low cost FDM printers. Check out our ranking of the best low cost 3D printers.

This professional SLS 3D printer has printing dimensions of 230 x 230 x 230 mm, easily enough to printing multiple functional parts simultaneously. Able to fulfill professional quality demands, with printable layer thicknesses of between 0.08mm and 0.2mm. At $60,000, it offers industrial SLS additive manufacturing at affordable prices.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

XYZprinting have taken over the low-cost FDM 3D printer market in recent times, and will soon release their first SLS printer.Nexa3D QLS 350 — fastest SLS 3D printer in the world!

- Price: Upon request

- Company based: USA

- Build volume: 350 x 350 x 400 mm

Pros

Prints at 4x the speed of comparable machines.

Claims to be the fastest SLS 3D in the world.

Capable of printing many parts simultaneously.

Cons

Might be too large for some people.

Nexa3D recently purchased NXT Factory, who had pioneered what they term Quantum Laser Sintering (QLS), allowing for much faster SLS 3D printing at 4x the speed of comparable machines. QLS involves splitting the printer’s laser beam into millions of micro-lasers, each sintering parts of the powder at faster speeds.

Incorporating QLS tech into their printer range, the QLS 350 claim’s to be the world’s fastest SLS 3D printer, with print speeds reaching up to 8 l/h! The QLS 350 is compatible with PA11, PA12 and tougher PA6 Nylons, as well as with food-grade, carbon and glass powder mixes.

With speeds that rival injection molding and a build volume capable of printing many parts simultaneously, many businesses will be looking on keenly to see how the QLS 350 performs when it releases — planned to be Q1 2021.

SLS 3D printer applications

As SLS printers can create strong Nylon parts, they are commonly used for:

- Strong, durable parts which need to withstand high heats and exposure to abrasive chemicals such as in the aerospace industry

- Highly impact resistant models

- Medical devices and tools

- Investment casting patterns

- Automotive design protototypes

- Engineering part prototypes

- Seals, gaskets and hoses

What is SLS 3D printing.

How does an SLS 3D printer work? Overview of additive technologies.

How does an SLS 3D printer work? Overview of additive technologies.

What is SLS?

Hello everyone, Friends! 3DTool is with you!

In this article, we will talk in detail about one of the most promising technologies 3D printing . Selective laser sintering.

Selective Laser Sintering (SLS) is an additive manufacturing process belonging to a broad family of wafer synthesis methods. In SLS, a laser selectively sinters polymer powder particles, fusing them together to create layer after layer. Granular thermoplastic polymers are used as construction material. Options for such devices can be considered in our catalog. For example, the Sintratec 3D printer.

This technology is used both for prototyping functional polymer products and for integration into small production runs, as it offers complete design freedom, high precision and produces parts with good and stable mechanical properties, unlike FDM or SLA .

Naturally, as in any other case, the possibilities of technology can be used to the full only if its key advantages and disadvantages are taken into account, so let's take a closer look at its features and principle of operation.

SLS printing process

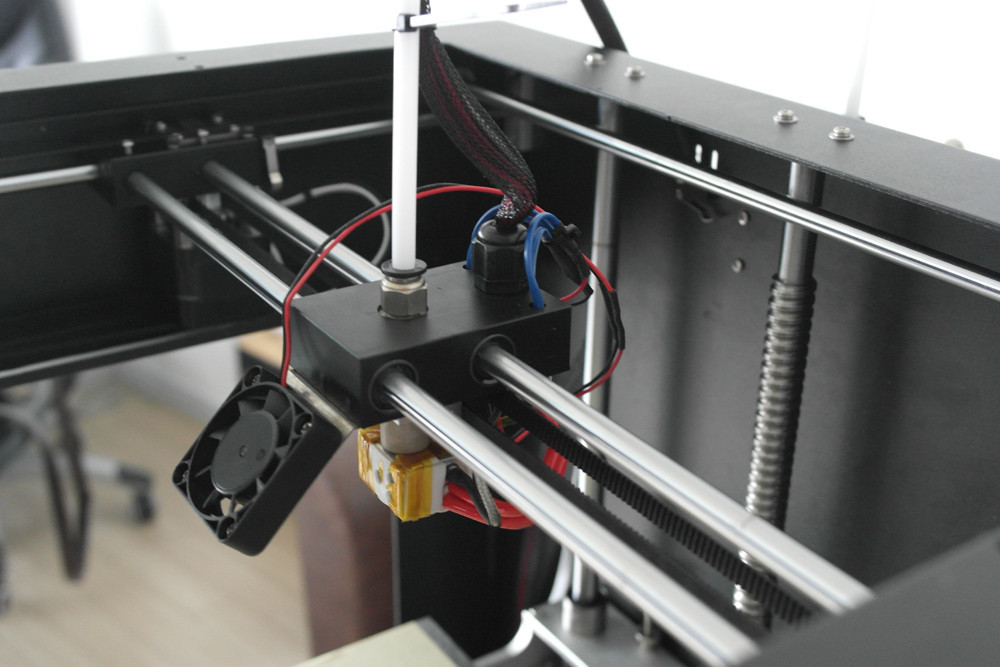

How does SLS work?

The SLS fabrication process works as follows:

I. The powder chamber, as well as the entire printable area, is heated just below the melting temperature of the resin, after which the leveling blade distributes a thin layer of powder over the build platform.

II. The CO2 laser scans the contour of the next layer and selectively sinters (melts) the polymer powder particles. The cross section of the component is scanned ( is sintered ) completely, so the part is monolithic.

III. When the layer is completed, the work platform moves down and the blade re-coats the surface with powder.

The process is repeated until the entire part is completed.

After printing, the part is completely sealed in the non-sintered powder, so the chamber and powder must cool before being removed. Cooling down can take a significant amount of time, up to 12 hours. Then the resulting part is cleaned of powder residues with compressed air. The unsintered powder is collected for further reuse.

Schematic diagram of an SLS 3D printer.

SLS printing specifications In SLS, almost all print options are set by the printer manufacturer. The default layer height for is 100-120 µm . For example, the Sintratec 3D printer we mentioned above allows you to print a much thinner layer, the layer thickness declared by the manufacturer varies from 50 to 150 micron.

The main advantage of method SLS is that the part does not need supports . In this case, the non-sintered powder plays the role of the necessary support. For this reason, the SLS method can print geometries of any shape that are impossible to print with any other additive or subtractive manufacturing method.

When printing with this method, it is very important to use as much of the printable area as possible, especially in small-scale production. Regardless of the amount of detail in the printable area, if the overall height is the same, printing will take the same amount of time. This is because it is the recoating step that determines the total print time ( the laser scanning and sintering itself is very fast ), and the printer has to cycle through the same number of layers. Also, you need to take into account the time for refilling the hopper with powder, because the same amount is poured into the chamber, regardless of the size of the printed part.

Layer sintering

When using method SLS , the sintering strength of the layers to each other is excellent. This means that printed on SLS printer parts have almost isotropic mechanical properties.

As an example, the mechanical properties of samples printed on SLS using standard polyamide powder ( PA12 or Nylon12 ), the most commonly used material in SLS printing , are shown in the table in comparison with the properties of solid nylon:

Parts printed on SLS have superior tensile strength and modulus comparable to solid material, but are more brittle ( their elongation at break is much lower than ). This is due to the internal porosity of the resulting part.

!A typical SLS part has a porosity of about 30%!

Porosity gives parts printed on SLS a characteristic grainy surface. This porosity also means that the parts can easily absorb water and are easy to paint. At the same time, such parts require special post-processing if they are to be used in a humid environment.

At the same time, such parts require special post-processing if they are to be used in a humid environment.

Shrinkage and deformation

SLS parts are subject to shrinkage and deformation: when the newly sintered layer cools, its dimensions decrease and internal stress accumulates in it, due to which the underlying layer is pulled upwards.

Shrinkage of 3 to 3.5% is typical for SLS printing of and printer operators must take this into account during model preparation.

Large flat surfaces are most prone to deformation. This problem can be mitigated slightly by orienting the part vertically on the build bed. But still, the best way to reduce deformation is to minimize the thickness of the flat areas of the part, and add cutouts to the model where the design allows. These actions will also reduce the overall cost of the part, as less material will be used.

Finished sls-part with embedded embedded elements.

Excessive caking

Over-sintering occurs when excess heat around the contour of the part melts the unsintered powder around. This is fraught with loss of detail on small objects such as slots and holes.

Excessive sintering depends on both element size and wall thickness. For example, a slot with a width of 0.5mm or hole diameter 1mm will print successfully on a wall thickness of 2mm but will not print if the wall thickness is 4mm or more. As a general rule, slits from to 0.8mm and holes from to 2mm can be safely printed in SLS without fear of excessive caking.

Powder removal

Since printing method SLS no support required, parts with hollow sections print quickly and accurately.

Hollow sections in this case reduce the weight and cost of the part, as less material is ultimately used. But you will need to make outlet holes in the part to remove unsintered powder from the internal cavities. The general recommendation in this case is to add at least 2 outlet holes with a diameter of at least 5 mm to your part.

But you will need to make outlet holes in the part to remove unsintered powder from the internal cavities. The general recommendation in this case is to add at least 2 outlet holes with a diameter of at least 5 mm to your part.

If high rigidity is required, the parts must be printed solid. An alternative here would be to make the structure hollow, with no outlets. In this way, the powder will be compacted tightly into the part, increasing its mass and providing some additional support when mechanical loads increase, without affecting print time. Also, instead of one solid internal cavity, you can add a honeycomb structure ( similar to the infill patterns used in FDM ) to further increase the rigidity of the model. Laying out the part in this way will also help reduce warping.

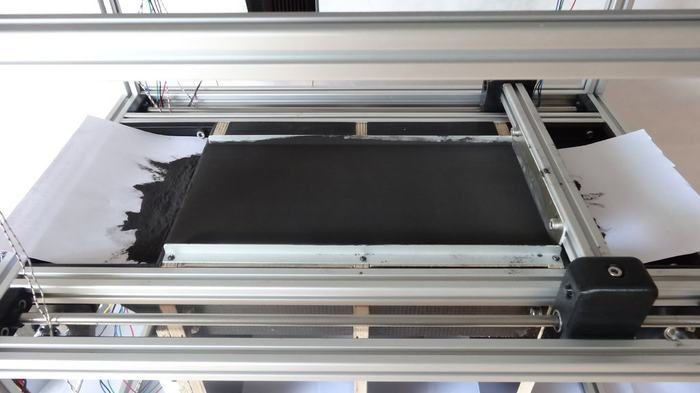

Removing powder from an SLS part

General materials SLS

The most commonly used material for SLS is Polyamide 12 (PA 12) , also known as Nylon 12 . At the moment, there are more and more materials with different properties for SLS 3D printing every day, for example, elastic polymers are represented by TPE powder and its analogues. Other technical thermoplastics such as PA11 and PEEK are also available but are not as widely used.

At the moment, there are more and more materials with different properties for SLS 3D printing every day, for example, elastic polymers are represented by TPE powder and its analogues. Other technical thermoplastics such as PA11 and PEEK are also available but are not as widely used.

As an example, you can see the list of materials used in our catalog: Sintratec Powder Sls.

Polyamide powder can be supplemented with various additives ( such as carbon fibers, glass fibers or aluminum ) to improve the mechanical and thermal properties of the printed part. Materials supplemented with additives are usually more brittle and have higher anisotropy.

Post-processing

SLS produces parts with a powdery, grainy finish that is easy to paint. The appearance of SLS printed parts can be improved to a very high standard using a variety of post-processing methods such as polishing, classic painting, spray painting and varnishing. Their functionality can also be improved by applying a waterproof coating or metal coating.

Their functionality can also be improved by applying a waterproof coating or metal coating.

Advantages and limitations of SLS

Summarizing the above, the key advantages and disadvantages of the technology are given below:

- SLS parts have good, isotropic mechanical properties, making them ideal for functional parts and prototypes.

- SLS does not require support, so parts with complex geometries can be easily printed.

- SLS manufacturing capabilities are excellent for small to medium series production.

- Only industrial SLS systems are currently widely available, so lead times are longer than other 3D printing technologies such as FDM and SLA.

- SLS parts have a grainy surface and internal porosity that may require post-treatment if a smooth surface or water resistance is required.

- SLS cannot accurately print large flat surfaces and small holes as they are prone to warping and warping.

The main characteristics of SLS technology are shown in the table below:

And that's all we have! We hope the article was useful to you.

You can purchase SLS 3d printers, consumables for them, as well as any other 3d printers and CNC machines, by contacting us:

• By email: [email protected]

• By phone: 8(800)775-86-69

• Or on our website: http://3dtool.ru

Also, don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

Industrial 3D printers for printing with nylon (polyamide) and polypropylene powder

Nylon and polypropylene powder 3D printer SLS-N

Industrial 3D Printer SLS-N Specifications

| Model | SLS-320N | SLS-420N |

| CO2 laser, Power W | thirty | 55 |

| Scanning system Dynamic focus | 4 m/s | 6 m/s |

| Print Layer Thickness | 0. | |

| Maximum melting point | 170°C, ready-to-use printing | |

| Print Accuracy | ± 0.2 mm (L ≤200 mm), ± 0.1% (L > 200 mm) | |

| Print chamber size mm | X320 Y320 Z650 | X420 Y420 Z500 |

| Powder supply | Two pistons on both sides | |

| Print material | Nylon (polyamide), PS, PP, PA6 and PA12 | |

| operating system | Windows XP | |

| Software | HUST 3DP | |

| File Format | stl, layer thickness change, scanning. | |

08-0.2mm

08-0.2mm