3D scanners for cad

The Best 3D Scanners and Scan-to-CAD Softwares

Computer-aided design (CAD) is defined as the use of computers to assist in the creation, modification, or optimization of a design. CAD software enables designers and engineers to model shapes and add features with the ultimate goal of producing parts. The CAD process, however, is a closed digital procedure, meaning that all of the functions happen digitally inside the computer. But how do we get into this process, knowing that, of course, we cannot insert a physical object into a computer?

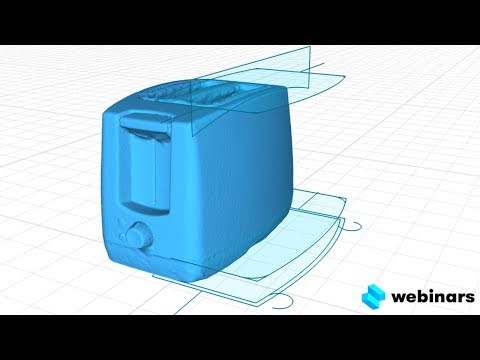

New parts can be designed entirely and directly in CAD software or they can be hand-sculpted using clay or other materials. Obsolete parts and damaged components must not be forgotten, as they often need to be updated, replaced, or fitted into a new assembly or environment. Thus, a bridge between the physical and the digital world is necessary to transition from an existing object to a CAD model. The process of converting a physical object into a virtual 3D model is called reverse engineering, and the bridge between worlds can be crossed thanks to 3D scanning.

When designing new products or adapting existing parts, engineers and designers like to use 3D scanners as a starting point for digitizing clay models or measuring physical objects in order to reconstruct their 3D models and integrate them into their designs.

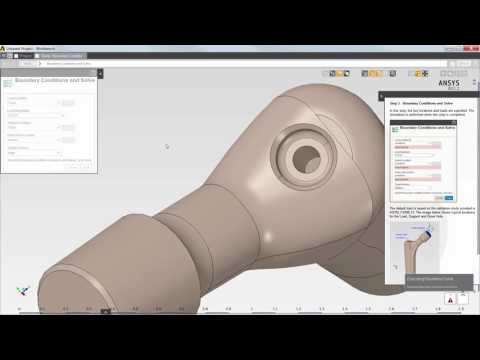

But the role of 3D scanners does not stop at the design stage. They can be used throughout the entire product development process. After manufacturing, 3D scanning participates in quality control by checking that the part is accurate and conformed to the CAD model. Next, as parts are used, 3D scanning can reveal if there are deformations, showing engineers and designers where reinforcements, improvements, or variations should be added in the next version.

In this post, “3D Scanner for CAD” we want to guide you through the process of reverse engineering and demystify the process from a 3D scan to a CAD model. We also want to address the quality of 3D models generated with 3D scanners. Finally, we wish to help you choose the best 3D scanner and Scan-to-CAD software based on your needs and budget.

- 1 The Way to CAD

- 1.1 Can a 3D Scanner Directly Output a CAD model?

- 1.2 How Good are Generated 3D Models, and is Post-Treatment Required?

- 2 Selection of 3D Scanners and Scan-to-CAD Software

- 2.1 Do You Need a Stationary or Mobile 3D Scanner?

- 3 3D Scanners for CAD and Reverse Engineering

- 4 Ways from 3D Scan to Final CAD Model

- 5 Benefits of 3D Scanning for CAD Designers

Let’s say you have to replace a damaged component or update an obsolete part for which the original CAD model is nonexistent or inaccessible. So, you have to create a new CAD model for manufacturing. You can either start your CAD design from a blank canvas, which is likely to be a long, overwhelming iterative process, or you can leverage the data you already have from the existing object and use that information as a foundation for your design, which will make your work more accurate and effective. This avenue involves 3D scanning.

This avenue involves 3D scanning.

Here are the typical steps to create a virtual 3D model from an existing physical object:

- Obtain the 3D scan mesh (STL) by 3D scanning the part.

- Extract dimensional information, such as geometries, dimensions, and cross-sections.

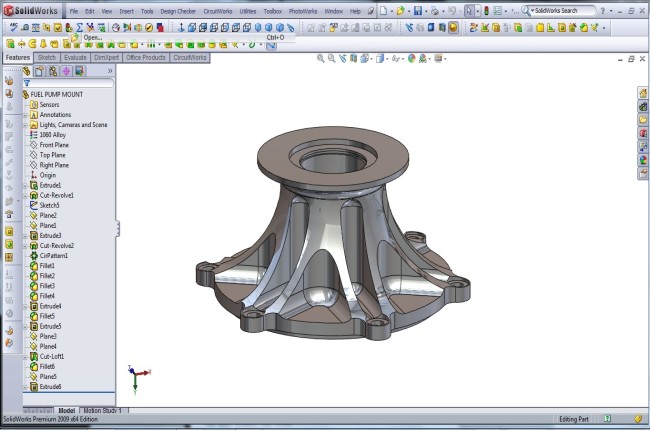

- Import models into CAD software and proceed with CAD modeling.

- Compare the resulting CAD model (STEP or IGES) with the initial 3D scan mesh.

- Analyze feedback and use the comparison to optimize the CAD reverse modeling.

- Export the final CAD model of the part for manufacturing.

Can a 3D Scanner Directly Output a CAD model?

In short, the 3D scanner produces a mesh, or point cloud, which provides all of the needed dimensional information about the part’s surface geometry. This mesh can then serve as a template to sketch the new CAD model. CAD models are usually created using non-uniform rational basis spline (NURBS), which consists of points connected by curves, while 3D scans are typically exported as meshes, which are made of millions of small triangles.

Thus, a 3D scanner does not directly output a CAD model. An intermediate Scan-to-CAD modeling stage is necessary to bridge the gap and convert non-editable triangles into editable NURBS surfaces, with which you will be able to create a solid CAD model with editable features.

How Good are Generated 3D Models, and is Post-Treatment Required?

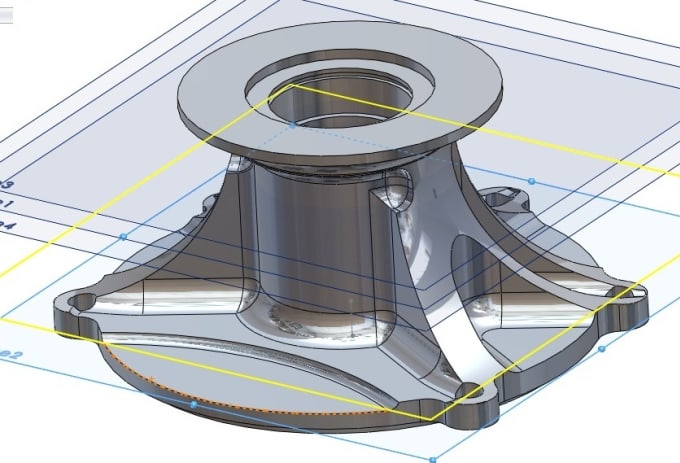

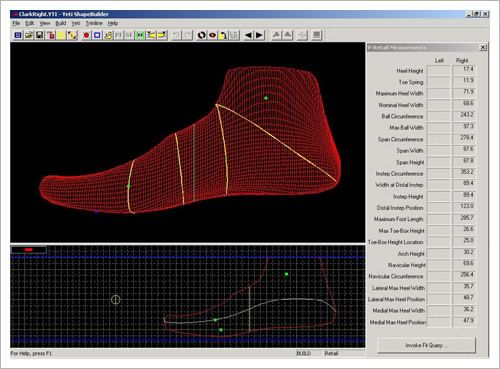

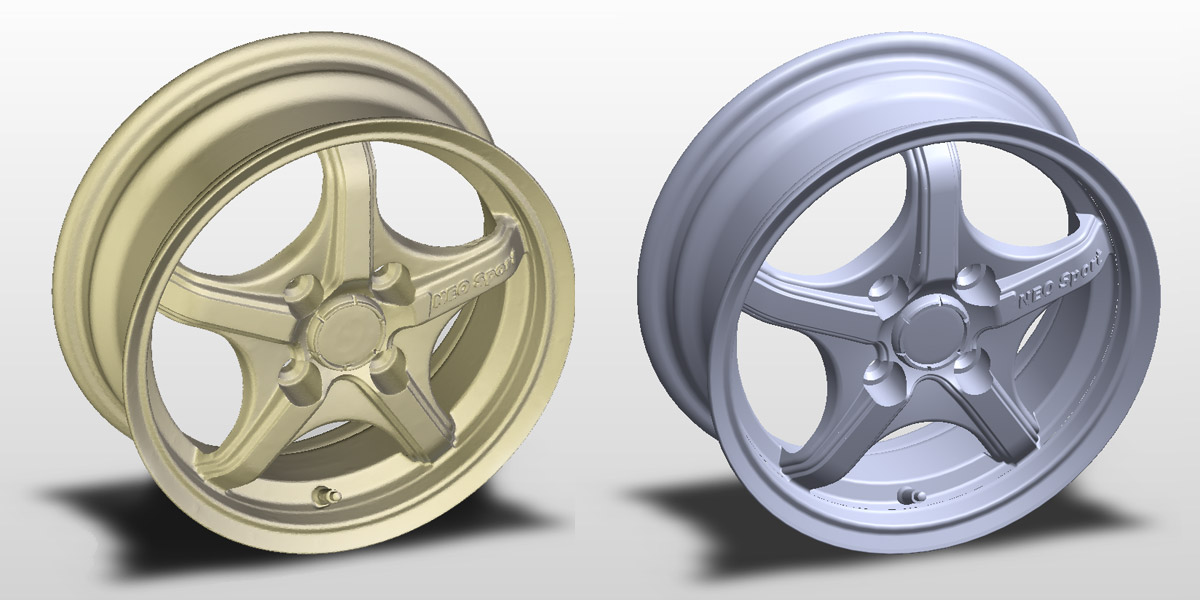

Based on your needs, there are different methodologies available to build a CAD model from an existing object. You may want to (1) reproduce a CAD model with accurate dimensions and precise angles to develop and manufacture new parts, or (2) reproduce an exact copy of a part (usually made of organic shapes) in its current condition. The first possibility creates a design intent and outputs a parametric model. The second option provides an as-is reproduction and outputs a surface model. Hybrid models also exist, which combine both methods for different areas of the object.

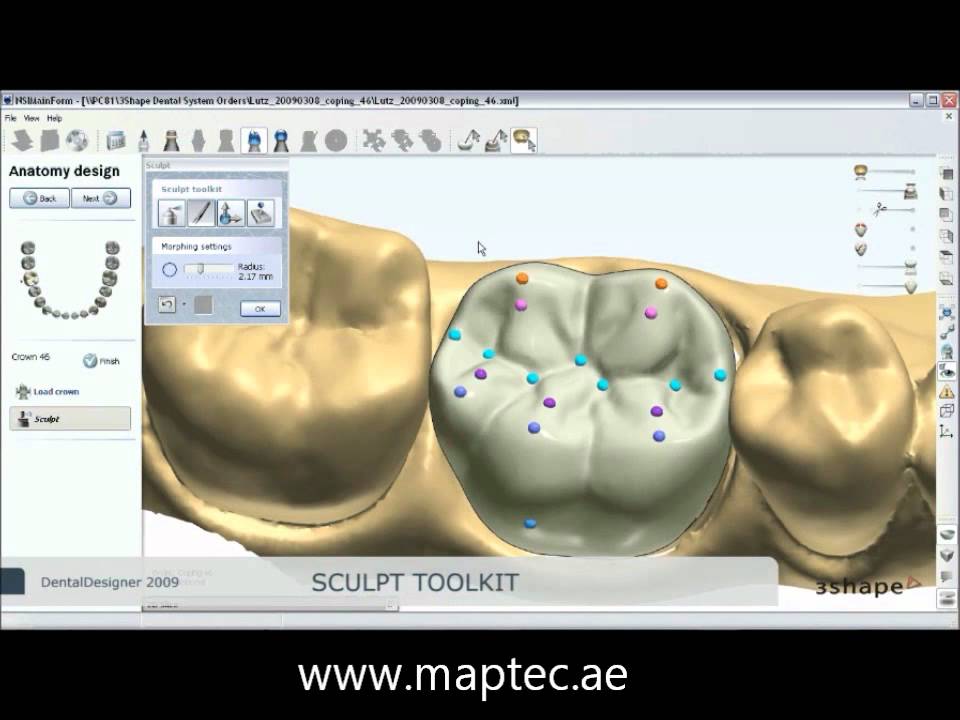

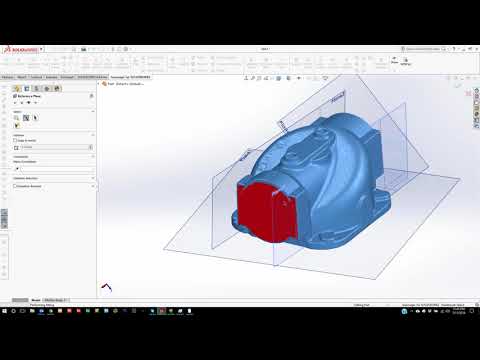

To get a parametric model from a 3D scan mesh, you first need to understand how the object was conceived. To do so, you must extract information from the scan data by creating entities, such as planes, cylinders, or cross-sections, on the mesh. These operations take place directly in Scan-to-CAD bridge software, such as VXModel. The parametric model and its entities can then be transferred to your preferred CAD software.

To do so, you must extract information from the scan data by creating entities, such as planes, cylinders, or cross-sections, on the mesh. These operations take place directly in Scan-to-CAD bridge software, such as VXModel. The parametric model and its entities can then be transferred to your preferred CAD software.

Similarly, to get a freeform surface model based on an optimized 3D scan mesh, you need to recreate the exact shape of a scanned object. To do so, you must improve and optimize the mesh by filling holes, smoothing surfaces, and trimming boundaries. Then, on the optimized mesh, you can create accurate freeform surfaces (NURBS) with control points. Again, all of these operations happen directly in the Scan-to-CAD bridge software before importing the freeform surface model into CAD software.

The 3D scanner does not generate NURBS surfaces (STEP or IGES) directly, but the Scan-to-CAD bridge software can. Nevertheless, the 3D models must then be imported into CAD software to get a parametric model for design intent.

Prior to choosing a 3D scanner and Scan-to-CAD software, you must identify your needs.

- What is the size of the part you want to scan?

- Is its geometry simple or complex?

- Can you easily move the part to the scanning session?

- What accuracy and level of detail do you need?

- What is your budget?

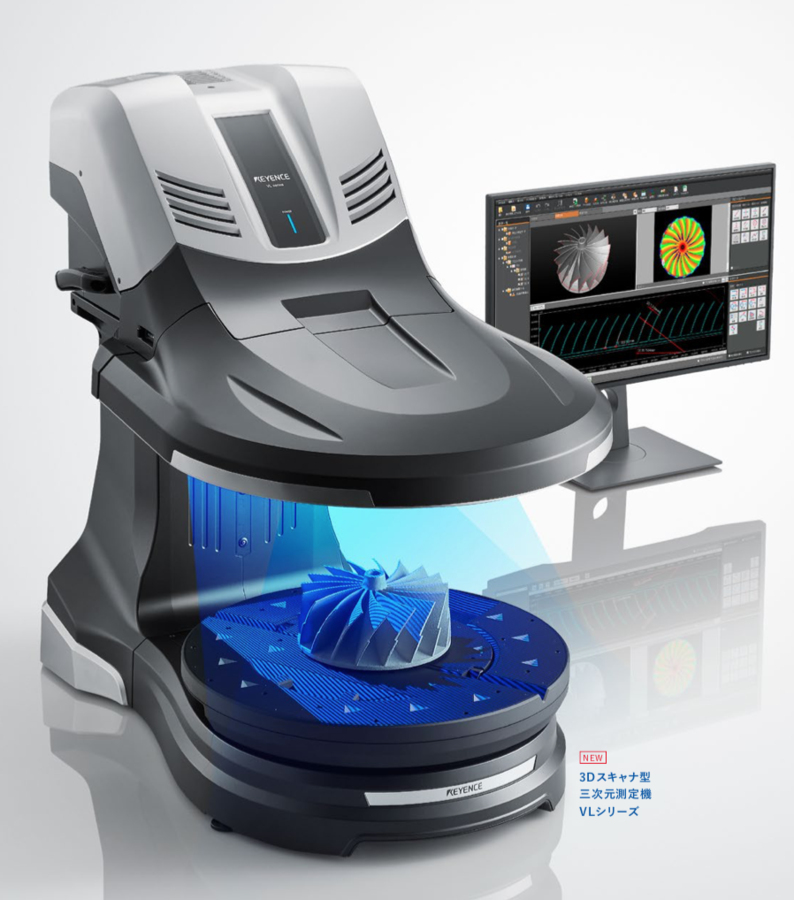

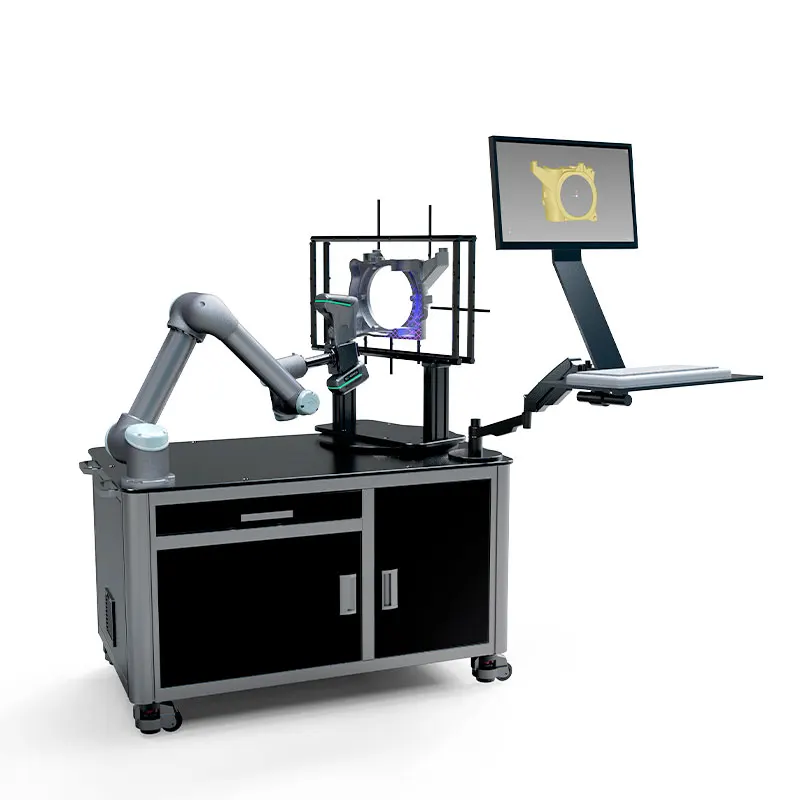

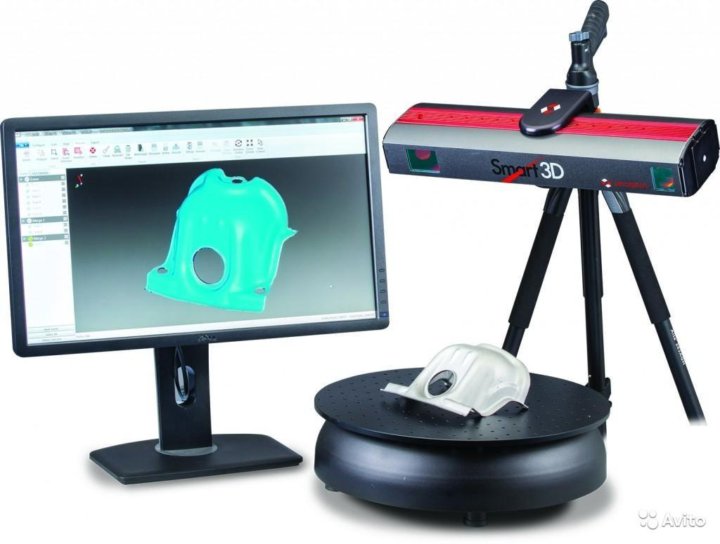

Do You Need a Stationary or Mobile 3D Scanner?

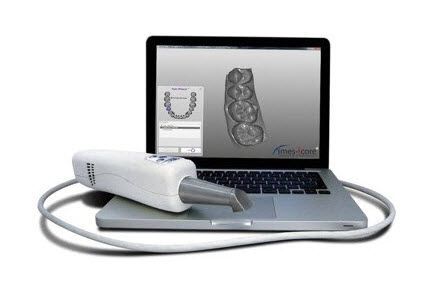

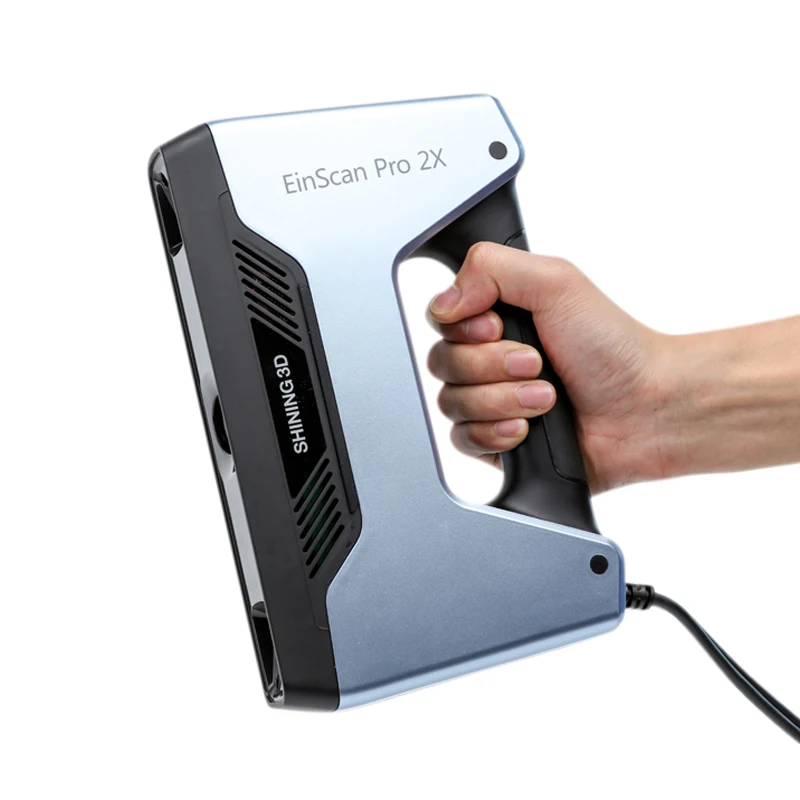

Stationary scanning systems are an option for limited budgets, but—as their name indicates—they require the part to be brought to the system, and they are mostly suitable for parts that are limited in size. Mobile scanners, which include both articulated arms and handheld scanners, are usually more accurate and better suited for large parts, and—as their name suggests—they go to the part rather than the other way around.

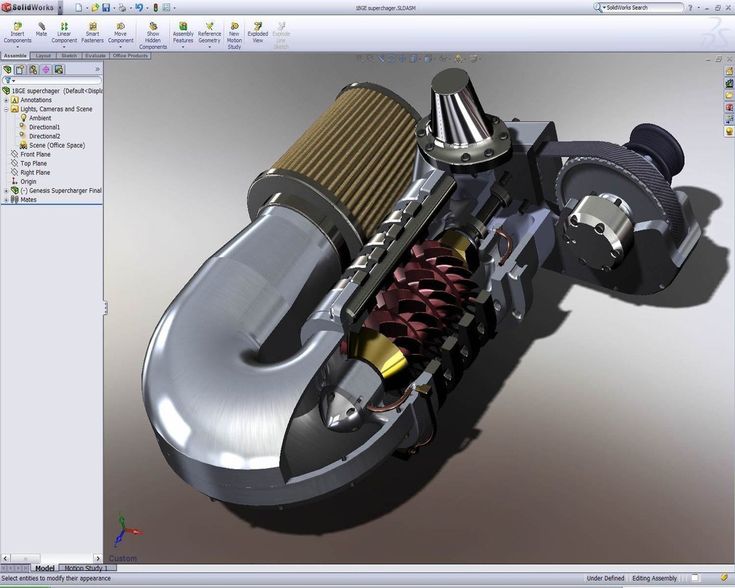

3D Scanners for CAD and Reverse EngineeringCreaform offers a variety of handheld 3D scanners, but three series stand out for product development and reverse engineering applications. Based on your budget and specific speed and accuracy requirements, a Creaform 3D scanner can certainly meet your needs.

Based on your budget and specific speed and accuracy requirements, a Creaform 3D scanner can certainly meet your needs.

The HandySCAN 3D | SILVER Series offers the best value for the money for technology innovators who wish to develop better products that are more suited to customer needs. This proven and trusted technology is accessible to low budgets and can shorten the development process.

The Go!SCAN SPARK offers the fastest and easiest 3D experience for product development, design, and reverse engineering. It enables the development of new products, with more complex shapes and designs, and gives a competitive edge by accelerating the time-to-market.

The HandySCAN 3D | BLACK Series is the most reliable and accurate ISO 17025-accredited portable 3D scanner available on the market. It can generate accurate 3D measurements and high-resolution results with the best scan quality.

Ways from 3D Scan to Final CAD ModelAs previously mentioned, 3D scanning and CAD modeling are like two different subway lines that require 3D Scan-to-CAD software to connect them efficiently.

One avenue is to opt for complete reverse engineering (RE) software, such as Geomagic Design X, which offers high-performance functionalities for alignment, information extraction, and feature modeling. Complete RE software basically replaces CAD software for reverse engineering activities. In fact, it is a ”high-end solution” for designers who do RE on a daily/weekly basis. Consequently, designers who usually feel comfortable with their preferred CAD software must learn to use new software with different features. It is also more expensive than the other options.

Another way is to start the design from a blank canvas directly in CAD software without resorting to reverse engineering. CAD software is known to be designers’ favorite place for feature modeling, but developing a sketch from nothing can be a long and tedious journey. In addition, CAD software has limited functionalities for mesh editing, alignment, and information extraction from the mesh.

A more appealing approach is to choose Scan-to-CAD bridge software, such as Creaform’s VXmodel, which includes all of the functionalities to align, clean, and optimize the mesh as well as to extract dimensional properties before transferring the entities and cross-section into CAD software, such as SOLIDWORKS, Autodesk Inventor, and Solid Edge, where designers can comfortably proceed with feature modeling. This option is more appealing because it is less expensive than complete RE software; it is also simpler to use and easier to learn.

This option is more appealing because it is less expensive than complete RE software; it is also simpler to use and easier to learn.

The benefits of using reverse engineering from Scan to CAD to create CAD models are important. It enables designers and engineers to create their 3D models from existing parts in less time, reduce the number of iterations leading to a part ready for manufacturing, and get a perfect fit of retrofit parts the first time. It can also shorten product development and time-to-market. But, more importantly, it provides an accurate foundation on which designers and engineers can build and improve their models—instead of starting from scratch—giving them more means to conceive complex geometries, modern shapes, and organic surfaces.

Scan-to-CAD bridge software is also ideal for CAD experts, as it is the shortest path back to your workflow and preferred CAD modeling software. Why learn completely new RE software when you’ve already mastered SOLIDWORKS, Autodesk Inventor, and Solid Edge?

In short, products designed through reverse engineering from Scan to CAD are not only of better quality, but also they are market-ready with fewer iterations and in less time. This is particularly valid for complex parts with intricate geometries. Creaform professional 3D scanners, such as the Go!SCAN SPARK, make reverse engineering more efficient, faster, and simpler. Scan-to-CAD bridge software, such as VXModel, leads you back to your preferred CAD software faster than any other solution, so you can get back to the joy of designing and innovating!

This is particularly valid for complex parts with intricate geometries. Creaform professional 3D scanners, such as the Go!SCAN SPARK, make reverse engineering more efficient, faster, and simpler. Scan-to-CAD bridge software, such as VXModel, leads you back to your preferred CAD software faster than any other solution, so you can get back to the joy of designing and innovating!

3 Affordable Scan to CAD Tools Not Just For CAD Specialist [With Video Demos]

News and resources on 3D scanning and measurement technologies

Published on May 9, 2022. Written by: Paul Motley

Originally published on: March 29, 2019.

Our team found an interesting Reddit post related to reverse engineering from 3D scanner data to CAD:

Affordable Scan to CAD Software (Geomagic Alternative)

Are there any other options for turning scans to usable 3D files? I have a Geomagic trial right now and it works great but it’s about $8k to purchase. I’m hoping there is a more affordable option. Thanks!

I’m hoping there is a more affordable option. Thanks!

Geomagic is known as the gold standard for converting scan data from professional 3D scanners to CAD models. We have customers who love Geomagic for SOLIDWORKS (plugin for SOLIDWORKS) and Geomagic Design X (standalone scan to CAD software) because they have extensive features for reverse engineering. They also have automated features like the Autosurfacing tool that makes it much easier to reverse engineer complicated and even organic designs.

However, if you need to do reverse engineering based off of 3D scan data and you just don’t have the budget to purchase a professional high-end package, are there any affordable alternatives to Geomagic out there?

Yes! There are more affordable options out there. Here, we’ll present you with three alternative Scan to CAD solutions that are accessible in terms of:

Mesh3Surface

Reverse Engineering Plugin for SOLIDWORKS or Rhino 3D

Plugin options that work natively inside your CAD software tend to be less expensive compared to standalone Scan to CAD software. If you are already a SOLIDWORKS or a Rhino user, Mesh3Surface is made for you. As a bonus, it empowers you to work in a CAD environment you are already familiar with, so it’s easy to pick up and learn as you go. It’s essentially an extension of the CAD software you are already using with dedicated reverse engineering toolsets.

If you are already a SOLIDWORKS or a Rhino user, Mesh3Surface is made for you. As a bonus, it empowers you to work in a CAD environment you are already familiar with, so it’s easy to pick up and learn as you go. It’s essentially an extension of the CAD software you are already using with dedicated reverse engineering toolsets.

| Mesh3Surface For Rhino | Mesh3Surface For SOLIDWORKS | |

|---|---|---|

| Software Type | Plugin (Rhino 3D sold separately) |

Plugin (SOLIDWORKS sold separately) |

| Software Compatibility | Rhino 5, 6, or 7 | SOLIDWORKS version 2017 or higher |

| Price for Single Commercial License of Plugin (in USD) |

Mechanical version: $940. What is the difference between Mechanical and Premium version?Rhino + Mesh3Surface bundle starts at just under $1,800: Learn More |

Price: $3,000 |

| Learn More | Learn More |

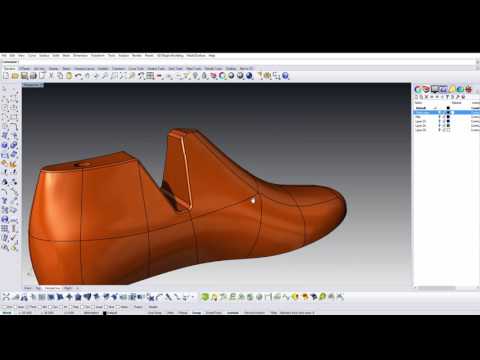

Mesh3Surface’s Approach to Reverse Engineering

Mesh3Surface is created for anyone who wants the accessibility of using 3D scanner data for CAD modeling but doesn’t have the time to learn traditional CAD systems that are often complex and challenging to use. It even excels at reverse engineering freeform and complicated surfaces.

From 3D Scanning To CAD: The workflow from capturing 3D scans using the Artec Space Spider (Top photo). The scanned data was imported into SOLIDWORKS. Then, we used Mesh3Surface for SOLIDWORKS to access the comprehensive scan to CAD toolsets inside SOLIDWORKS to design this bike frame. (Please see the photos below comparing the original scan data to the created CAD model.) Using scan data as a guide for design is much easier and faster than designing from a blank slate.

(Please see the photos below comparing the original scan data to the created CAD model.) Using scan data as a guide for design is much easier and faster than designing from a blank slate.

Every reverse engineering project is unique and the process can be time-consuming in order to achieve the right and accurate results. This inspired Mesh3Surface developers to create a universal tool that can be applied to different reverse engineering challenges while simplifying the process.

Mesh3Surface focuses on finding the fastest, most accurate, and easiest way to convert 3D scan meshes into professional CAD models. It is straightforward to use and delivers similar performance to high-end reverse engineering software.

What We Love About Mesh3Surface

- Works seamlessly with SOLIDWORKS or Rhino

- Affordable Scan to CAD plugin option

- Speed up the time for manufacturing

- Reduce costs for design

- Edit and repair CAD data for broken tools and molds

- Use existing assets to reverse engineer new parts

- Design custom products

- Export remodeled data for 3D printing

- Create complementary products or new parts to fit with existing parts

How It Works

Mesh3Surface is an affordable yet sophisticated Scan to CAD tool that extends beyond basic arcs and curves. You can take works STL, OBJ, or PLY mesh as well as PTX point cloud to create professional CAD/CAM models.

You can take works STL, OBJ, or PLY mesh as well as PTX point cloud to create professional CAD/CAM models.

What’s special about Mesh3Surface:

- You can use simple and powerful tools to create 2D sketches, extruded 3D sketches, and revolved surfaces.

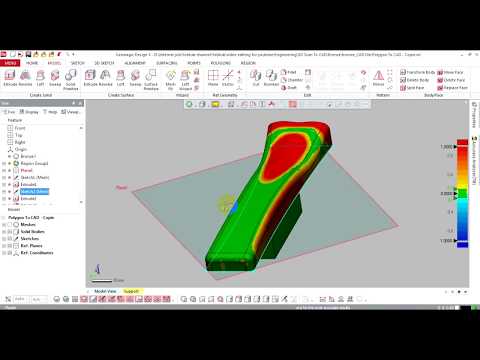

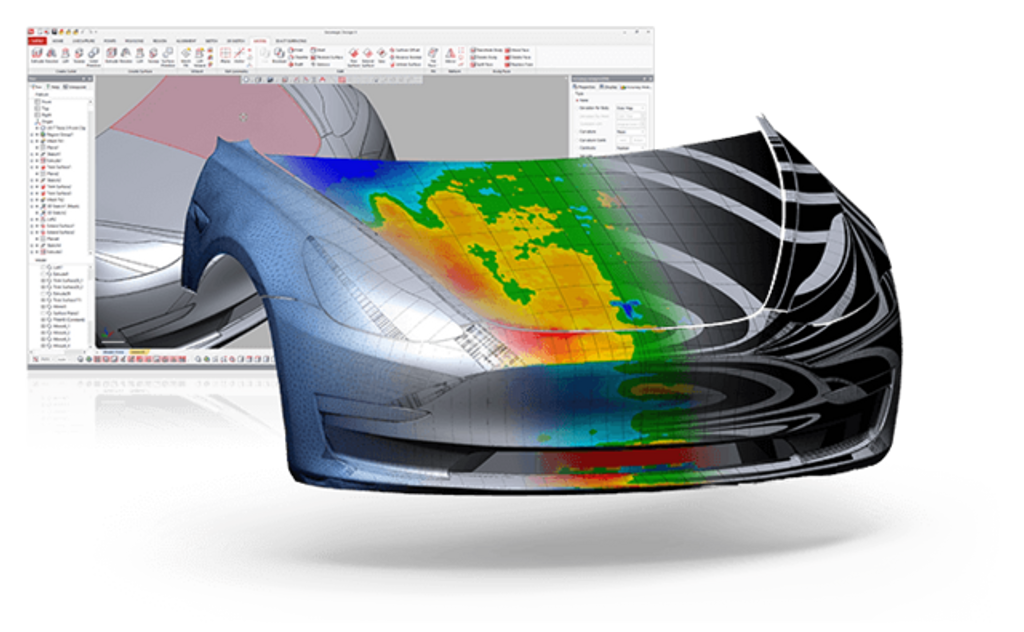

- Tolerance surfacing shows instant color map deviation from scan data and gives you full control to fix it to get the best accuracy out of your CAD model.

- It can create complex hybrid 3D models (prismatic and organic).

- Redesign your object with the best accuracy and design intent.

- Extract shapes by selecting what type of features need to be fit.

Since each CAD software works differently, here are some of the main features for Mesh3Surface for Rhino and SOLIDWORKS with video demonstrations:

| Mesh3Surface for Rhino | Mesh3Surface for SOLIDWORKS | |

|---|---|---|

| Create 2D line sketches that can revolve or extrude surfaces | ||

| 3D sketching on scan data | ||

| Freeform reverse engineering | ||

Automatic surfacing for converting freeform organic shapes just with a click of a button. |

||

| Deviation Analysis (comparing scan data to CAD) |

Video Demonstrations

Our team created videos to show what Mesh3Surface can do.

Mesh3Surface For Rhino: Reverse Engineering Basics

Mesh3Surface For Rhino: Reverse Engineer Complex Organic Surfaces

Mesh3Surface For SOLIDWORKS: Reverse Engineering An Oil Pump Series

Mesh3Surface Review

Mesh3Surface has been reviewed by its users on Trustpilot. You can read all the reviews here.

You can read all the reviews here.

Buy Now

Recommended Reading

Can A 3D Scanner Directly Output A CAD Model?

QUICKSURFACE

Standalone Scan to CAD Software

QUICKSURFACE guides you through every step of the way to help you make the best decisions in creating accurate CAD models—with user control accuracy you can trust. Intuitive to use, QUICKSURFACE helps you create designs faster and more effectively in an often labor-intensive process.

| QUICKSURFACE Overview | |

|---|---|

| Type | Standalone software |

| Price for Single Commerical License (in USD) |

Freeform: $2,195 What is the difference between QuickSurface Freeform versus Full version? |

| Learn More | |

QUICKSURFACE’S Approach To Reverse Engineering

The STL scan data of this mechanical part (left) was imported into QUICKSURFACE and then reconstructed into a fully parametric CAD model (right). View the 20 minute .

View the 20 minute .

While 3D scanners are coming down in price making the technology more accessible than ever before, 3D reverse engineering software can be expensive relative to its hardware counterpart—until now.

With plenty of scan to CAD tools at your disposal, QUICKSURFACE helps spread the use of the technology at a more affordable price point so more people can benefit from using scan data from a 3D scanner as a basis for design. QUICKSURFACE simplifies the path of converting 3D scans into usable CAD while giving users access to powerful tools.

It’s great for anyone looking for an affordable and well-rounded scan to CAD software. QUICKSURFACE has the power to work with prismatic or freeform shapes (and even hybrid), making it a very versatile reverse engineering software.

What We Love About QUICKSURFACE

- QUICKSURFACE is an affordable Scan to CAD plugin option.

- It works similar to other CAD software so the learning curve is not steep.

- You don’t have to be a CAD specialist to use it.

- It’s simple yet powerful.

- Even if you haven’t used QUICKSURFACE in a while, you just pick up where you left off.

- It offers standard CAD operations like trim, revolve, booleans, loft, sweep, extend, mirrors and patterns. Finish your work by adding fillets and chamfers.

How QUICKSURFACE Works

QUICKSURFACE helps you make the best decision in creating accurate CAD models using its proprietary best-fit algorithms. It gets the accuracy and design intent you need when building CAD models.

Similar to Mesh3Surface, QUICKSURFACE provides interactive real-time deviation maps. As you build your CAD model, you can see exactly how close or how far you are deviating from the scan data. This empowers you to correct problems immediately instead of leaving them at the end of the reverse engineering process.

This Scan to CAD software has various tool kits to take on a wide range of reverse engineering projects to perform the job. You can create parametric models, hybrid parametric modeling for both organic and prismatic shapes. Export as industry-standard STEP or IGES file format to other CAD/ CAM packages or use your results for manufacturing (3D printing, CNC machining, etc.). QUICKSURFACE offers a full parametric tree into SOLIDWORKS.

Workflow at a Glance

Here are some of the main features of QUICKSURFACE with video demonstrations:

-

Parametric Modeling

It’s a key feature of QUICKSURFACE. Parametric modeling makes it easy to modify and make changes to the parameters from solid bodies even at a later date.

-

Freeform Modeling

With Quad Surface tool, reconstruct freeform surfaces for organic 3D mesh data not normally possible with the standard surfacing methods.

Snap-to-mesh technology and real-time deviation analyzer empower you to create shapes accurately representing the scan data in no time.

Snap-to-mesh technology and real-time deviation analyzer empower you to create shapes accurately representing the scan data in no time. -

Automatic Surfacing

Load the mesh, press a button, and get desired results. Independent of the size and complexity of the object, the surface follows the natural shape of the object. You still have the ability to modify the automatic surface, if the design intent requires it.

-

Hybrid Modeling

Reconstruct parts with both organic and prismatic shapes. Starting with freeform and basic primitives, you can build a complex CAD model by trimming them and can later change the surfaces based on the design intent.

Video Demonstration

QUICKSURFACE: How To Reverse Engineer Less Than Desirable Scan Data

Reverse Engineering from Scan Data to CAD with Artec Space Spider

QUICKSURFACE Review

“…QUICKSURFACE is about taking your mesh-based data out of your scanning process and achieving the geometry you want. Whether that’s a complete part, skinned and surfaced up, or a select set of reference surfaces from which you will begin to design another part, QUICKSURFACE handles these tasks in a very efficient, clearly defined and well-executed manner.”

Al Dean Co-founder, Develop3D

QUICKSURFACE landed on Develop3D Top 30 New Technologies that give product development work a major boost. There is also an extensive QUICKSURFACE review from Al Dean, Co-founder of Develop3D you can read it here: Read the full review.

Buy Now

Recommended Reading

How Do I Reverse Engineer A Part Using Low-Quality 3D Scan Data?

Autodesk Fusion 360

Cloud-based 3D modeling with scan to CAD capabilities

Fusion 360 is not just a CAD/CAM software. You can also use 3D scanner data as a visual reference for sketching CAD models at an unbelievably low price.

You can also use 3D scanner data as a visual reference for sketching CAD models at an unbelievably low price.

| Autodesk Fusion 360 Overview | |

|---|---|

| Type | Cloud-based 3D modeling, CAD, CAM, CAE, and PCB software platform for product design and manufacturing with the capabilities of using 3D scans for CAD creation. |

| Price (in USD) | $495 per year |

Fusion 360’s Approach To Reverse Engineering

There is a growing popularity for designers, engineers, and machinists to use real-world data as the starting point for design. Fusion 360 is a powerful software at a price of just under $500 per year. With it being at the forefront and center as a CAD, CAM, CAE, and PCB software platform for product design and manufacturing, you can also edit and repair imported scans or mesh models files (STL, OBJ, and now 3MF) as well as using them for creating CAD models.

With Fusion 360, you can create custom products like eyewear, apparel, or prosthetics based on a person’s unique curvatures and measurements using 3D scan data.

Here, we have 3D scan data of a person’s leg (top photo) which can be referenced to create fitted prosthetics (bottom photo).

Source: Screenshots from .

While this article focuses on using 3D scanner data as a basis for design, it is worth noting that many users (especially hobbyists, home users, students, and educators as there is a free version of Fusion 360 available) are using the software to add their own customization for downloaded STL mesh files from websites like Thingiverse and converting them into CAD models before 3D printing them.

What We Love About Autodesk Fusion 360

- Great value for the price.

- It’s at a good price point for people who are using a low-cost 3D scanner and need complementary software for converting scan data to CAD.

- Fusion 360 is great for a full manufacturing process. It’s not just offering reverse engineering capabilities but also CAM which covers the design of a product as well as manufacturing.

How it Works

If you want to test the waters and see if CAD modeling with basic scan to CAD features is for you, give Fusion 360 a try. Fusion 360 is better at handling less complicated scan data, typically mechanical parts (as opposed to organic freeform surfaces).

Here are some videos to give you a better idea of how Fusion 360 handles the scan to CAD process.

Reverse Engineering A Scanned Part in Autodesk Fusion 360 (STL to CAD)

QUICK TIP: Mesh to Solid Reboot

Fusion 360 Review

While it’s difficult to find reviews dedicated to Fusion 360’s scan to CAD capabilities, it has favorable reviews on G2 from users as a CAD/CAM software.

Which Scan to CAD Software is Right for Me?

A quick way to determine the most suitable for your needs

If price is a major factor…Plugins are typically the best affordable solution with dedicated reverse engineering tools. Therefore, either Mesh3Surface for SOLIDWORKS or Rhino would be great options. If you aren’t using any CAD software and want dedicated reverse engineering tools, the best value we offer is Rhino with Mesh3Surface for Rhino. The combined purchase price of this package is just under $1,800 USD. Learn more >

If you are looking for a well-rounded standalone reverse engineering software…

QUICKSURFACE is a good choice.

If you already have SOLIDWORKS…

Mesh3Surface for SOLIDWORKS is the best option as you don’t need to learn another software.

If you already have Rhino3D…

Mesh3Surface for Rhino is the best option as it’s a plugin for Rhino software.

If you want to try CAD modeling and also want to test out basic reverse engineering tools…

Fusion 360 is a good choice as it’s the cheapest option that you can also do scan to CAD operations.

If budget is not an issue…

Geomagic Design X or Geomagic for SOLIDWORKS would be other options you should consider. They are considered high-end reverse engineering tools with comprehensive feature sets.

Affordable Scan to CAD Software Comparison

Here is a side-by-side comparison chart

| Mesh3Surface for SOLIDWORKS | Mesh3Surface for Rhino | QUICKSURFACE | FUSION 360 | |

|---|---|---|---|---|

| Plugin or Standalone Software | Plugin | Plugin | Standalone Software | Standalone Software |

| Required software (Sold Separately) | SOLIDWORKS | Rhino | Not Applicable | Not Applicable |

| Price |

Single License: $3,000 |

Mechanical version: $940. 50 50Premium version: $1,400 |

Freeform: $2,195 Full: $4,395 |

$495 per year |

| Reverse Engineering Tools | Dedicated scan to CAD tools that work natively in SOLIDWORKS to perform all types of reverse engineering jobs. | Dedicated scan to CAD tools to perform all types of reverse engineering jobs natively inside Rhino. | Sophisticated scan to CAD tools for reverse engineering all types of parts from basic to complex, mechanical to freeform, and even hybrid. | Good for basic scan to CAD conversion for less complicated parts that are more mechanical in nature. |

| Easy to Use | Yes | Yes | Yes | Yes |

| Great for Organic Surfaces | Yes | Yes | Yes | No |

Leave a Reply

Scroll×

Take our test and we'll email you the result directly to your inbox.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

Top Ten 3D Scanners Between $100 and $100,000 There are several ways for you: you can of course create your 3D model from scratch in a 3D modeling program or find a suitable one on the Internet, but you can also scan an existing object! The purpose of this review is to help you understand the variety of 3D scanners available and offer the best in every price segment from a photogrammetric smartphone app to professional 3D scanners.

Scanners are listed in ascending price order so you can choose the one that suits your budget and use the resulting 3D models for both 3D printing and animation.

If you are not satisfied with the proposed solutions, there is an extended overview at this link.

3D scanner in hand:

1. Best smartphone app: Autodesk 123D Catch (free)

Autodesk 123D Catch is a free photogrammetric application. It allows you to create a 3D model from photographs of an object taken from different angles. You can use it to scan objects, people, and even the landscape. For some applications, if you don't need perfect accuracy, you don't need special equipment. This application actually provides quite good detail and is easy to use. However, it will take you at least 30 minutes for the app to process your photos as the processing takes place on the server and it takes time to send them.

2. Best DIY 3D Scanner: Kinect ($99.99)

The Xbox Kinect is designed to expand your gaming experience. It is not designed for 3D scanning, but you can easily find manuals and third party software (like ReconstructMe) to turn it into a 3D scanner. If your arms are growing out of your shoulders, this is an interesting and inexpensive solution for 3D scanning.

If your arms are growing out of your shoulders, this is an interesting and inexpensive solution for 3D scanning.

Price: $99.99

Resolution: 0.051 mm

)

This scanner can be attached to your tablet or phone (generally designed for iPad, but can be adapted to other devices). Lightweight and easy to use, with a very good resolution. Suitable for large items (can scan a full-length person) and outdoor scanning. You will be able to use it with software running on Occipital's SDK. This will increase the resolution and give you access to special features like room scanning. It probably won't be something you'll use for 3D printing, but it's interesting for game development, for example.

Price: $ 379

Resolution up to: 0.5 mm

accuracy to: 4 mm

4. The best of cheap manual 3D scanners: Cubife ($ 399)

3D 3D 3D 3D 3D 3D 3D 3D 3D 3D-scanners can be quite affordable and easy to use if you choose from inexpensive portable models. Cubify fits these criteria very well and has a relatively good resolution. But still, its capabilities are not enough for texture scanning and it is better to use it for subsequent 3D printing of one-color models.

Cubify fits these criteria very well and has a relatively good resolution. But still, its capabilities are not enough for texture scanning and it is better to use it for subsequent 3D printing of one-color models.

Price: $ 399

Resolution: 0.9 mm

Resolution at a distance of 0.5 m: 1 mm

3D scanner on the table:

5. Best and cheapest table 3D 3D- 3D- scanner: Matter and Form ($519)

If you're looking to take your quality to the next level, you can purchase a desktop 3D scanner. This model is compact, easy to use, and delivers good resolution, especially considering the price (not your go-to option if you're looking for perfection, but great for educational and demo purposes). The scanning process takes place with the help of a laser and a rotating platform. The scan takes about five minutes and simultaneously reads the texture of the object.

Price: $ 519

Resolution: 0. 43 mm

43 mm

accuracy: ± 0.25 mm

6. The best device "two in one": XYZPRINTING DA VINCI 1.0 ($ 600)

is an inexpensive device combines a 3D scanner and a 3D printer. The quality of the models is not too high, but the price is very low for such a combined device. This makes the XYZprinting Da Vinci the easiest solution for beginners who want to get into the world of 3D scanning-printing.

Professional 3D scanners:

7. Best value for money portable 3D scanner: Fuel3D Scanify ($1490)

Very easy to use, intuitive, and feels good in the hand, this scanner delivers good accuracy and texture quality. The only limitation is that the size of the scanned area is limited, which is great for small objects, but for scanning a full-length person, for example, it will not work.

Price: $ 1490

Resolution: 0.35 mm

accuracy: to 0. 3 mm

3 mm

8. Best price The scanner uses a different scanning technology than others. Instead of a dual laser scanning system, it uses a structured light source and cameras for fast scanning with very fine detail down to 0.06mm! The scanner comes with DAVID Pro Edition 3 software that works with OBJ, STL and PLY 3D file formats that can be exported to other programs for further editing.

Price: $ 3995

Resolution: 0.06 mm

accuracy: 0.5% of the size of the object

9. The best desktop professional 3D scanner: SolutionIX REXCAN 4 ($ 79 900)

is a professional The 3D scanner and its price provides much better scanning quality. Solutionix Rexcan is equipped with two cameras for greater accuracy. It uses optical phase shift triangulation technology and two high-resolution CCD cameras to provide high-precision data. The scanner can be used to scan larger objects by increasing productivity with a photogrammetric system.

50

50