3D printing in education sector

Guide to 3D Printing In Education

As professionals across almost every industry—healthcare, aerospace, engineering, manufacturing, and entertainment—continue to increase investment in 3D printing, the technology becomes an ever greater part of our daily lives. Many educational programs have recognized this and incorporated 3D printing into their curricula, but widespread integration of additive manufacturing into education programs will rely on greater awareness of the many benefits of 3D printing for education.

In the following guide, we’ll discuss the benefits of 3D printing in education, from improved student engagement and collaboration, to workforce development, multidisciplinary thinking patterns, and empowered creativity, as well as take a look at which technologies exist and how to choose between them.

From K-12 schools to post-graduate college programs, 3D printing is a way for educators to encourage more active participation in the learning process. Though research studies abound on different learning styles and the effectiveness of diverse teaching methods, so much of traditional education still relies on rote memorization of reading material. 3D printing offers a way for students to truly connect to the subject matter by physically manipulating ready-printed teaching aids or by designing tools themselves.

For K-12 students especially, this hands-on aspect of 3D printing in the classroom helps improve engagement and participation. To put this theory into practice, Formlabs partnered with Tech Boston Academy, a public high school in Dorchester, Massachusetts that focuses primarily on technology education. Over the course of a 13-week program, Formlabs employees gave lectures and guided the students through a project-based course, culminating in a ‘hackathon’ where students designed, modeled, and 3D printed a tool. The students were able to problem-solve and use CAD skills to develop a solution, then bring their ideas into reality with the Formlabs 3D printers. One student said that the aspect they enjoyed the most “was the ability to materialize physical objects inside my mind into a real thing that I could hold or touch. ”

”

FormEd program participants from Boston Tech Academy in the Formlabs Experiential Hub.

These types of in-person interactions are invaluable for developing young adults. In today’s educational environment, however, face-to-face instruction isn’t always possible. 3D printing ensures that each student has access to the hands-on tools they need and gives teachers the power to change those tools or print extra if necessary. “Our curriculum is very physical. We need machines, building tools, and laser cutters. So one of the casualties of going through the pandemic was that we couldn’t do much physical modeling or physical objects,” says Michael Silver, an architecture professor at the University of Kentucky. Relying on his previous experience with Formlabs 3D printers in the university’s labs, Silver brought a Form 2 home with him, had students send him their STL files, and printed their models out to be discussed at the final evaluation for the class. “We were able to continue to make physical objects during the period of quarantine. 3D printing gave us the ability to still physically implement a prototype during quarantine with everybody only meeting through Zoom and doing remote learning,” Silver said.

3D printing gave us the ability to still physically implement a prototype during quarantine with everybody only meeting through Zoom and doing remote learning,” Silver said.

Dental school is expensive, no matter what country you’re in. Part of that cost is due to the highly specialized tools that dental students need to learn. Dr. Gülşah Uslu, an instructor in the dental school at Canakkale Onsekiz Mart University in Turkey, began using 3D printers as a way to reduce costs and source a set of tools for each student, rather than ask students to share.

Typically, dental students go through a hands-on training program before they treat their first patient under supervision in the clinic. This training is either conducted on artificial anatomical models or on extracted teeth, both of which are expensive and difficult to procure. Dr. Uslu turned to 3D printing and produced more than 13,000 anatomically accurate artificial teeth models so each student could continue their hands-on learning uninterrupted, without relying on digital learning modules or sharing with classmates. Dr. Uslu was able to continue her high standard of teaching and students were able to focus on personalized teaching tools, increasing their knowledge retention and engagement.

Dr. Uslu was able to continue her high standard of teaching and students were able to focus on personalized teaching tools, increasing their knowledge retention and engagement.

Formlabs reseller BTech Innovation has printed 13,000 anatomically accurate teaching aids.

Hands-on learning is a major tenet of Morrison Tech’s program, which partners with local industry leaders to deliver a practical, experience-based curriculum. Morrison Tech President Chris Scott sees 3D printing as a way to accelerate a typical manufacturing process, benefiting both the students learning how to 3D print in their classes today, and the companies they’ll one day be a part of. “[With 3D printing] we can see things much more clearly, and indicate where problems may occur, or what may not work or may not feel right to the consumer,” Scott said. “A secondary goal is how can we bring products to market more quickly and more aggressively, and I think that's where additive manufacturing really starts to shine. We can shorten that design cycle.”

We can shorten that design cycle.”

As Scott sees it, hands-on learning through 3D printing allows students to identify issues with the things they’re working on much more quickly than working only in a digital medium. Morrison Tech has integrated 3D printing into their curriculum for years, and it has not only benefited students by accelerating their learning, but by preparing them for jobs in the manufacturing industry through Morrison Tech’s many partnerships with local giants like Wahl Clippers, John Deere, and Caterpillar.

The Form 3L and Form 2 printers at Morrison Tech.

Programs like Morrison Tech partner with local industry leaders for mentorship and internship opportunities. These types of ‘town and gown’ relationships are invaluable for students looking to secure references, practical experience, and real-world problem-solving skills. 3D printing is becoming an ever more important part of that practical experience as manufacturers are scaling their 3D operations and looking for skilled employees.

3D printing provides students an accessible way to meaningfully contribute to the workplace during internships and entry-level positions. Traditional large manufacturing methods rely on expensive equipment and structured workflows—students were relegated to observing the structure or were given menial tasks. With 3D printing, students can take ownership and leverage their CAD skills to design a product idea or a repair part, something the current workforce might not have the time or the knowledge base to do. The students gain valuable experience and skills, while the business gains new perspectives and practical solutions at no cost.

The Fuse Series printers are ideal for both functional prototyping and industrial quality end-use production—perfect for students to contribute meaningfully in internships and with local businesses.

It’s not just large businesses that can benefit—students at Penn State’s Innovation Hub partner with local start-ups and small manufacturers to 3D print low-volume end-use parts. One project involved students printing small widgets for a local business owner that couldn’t afford a tool made for such a small volume. The students were able to take a real-world budgetary issue, and devise a solution through 3D printing—replacing an injection molding process with a direct 3D printed part. Innovation Hub Director Ryan Mandell told us, “A local business owner wanted to print 20 plastic parts, so we looked at the array of Formlabs materials, found a match, and determined it was possible to run 20 plastic widgets in one build on the Form 3L. They had been turned down by injection molding companies because 20 parts was too small-scale, so it was the perfect 3D printing use case." Students at the Hub were able to provide tangible consulting and manufacturing services for this local business owner and by doing so, helped the local community and bolstered their resume.

One project involved students printing small widgets for a local business owner that couldn’t afford a tool made for such a small volume. The students were able to take a real-world budgetary issue, and devise a solution through 3D printing—replacing an injection molding process with a direct 3D printed part. Innovation Hub Director Ryan Mandell told us, “A local business owner wanted to print 20 plastic parts, so we looked at the array of Formlabs materials, found a match, and determined it was possible to run 20 plastic widgets in one build on the Form 3L. They had been turned down by injection molding companies because 20 parts was too small-scale, so it was the perfect 3D printing use case." Students at the Hub were able to provide tangible consulting and manufacturing services for this local business owner and by doing so, helped the local community and bolstered their resume.

At Yavapai College, Matthew Mintzmyer, Director of Aerospace Science, 3D Printing and Manufacturing, prepares students for careers in every industry—his recent graduates went on to careers in dental medicine, props work for the Mandalorian television show, and architecture, among many others. “There are tons of applications. People that aren’t in the 3D printing business in schools, they’re behind the curve. It teaches you critical thinking, math, creativeness—everything. You don’t need $100,000 to get started, these printers are affordable,” says Mintzmyer.

“There are tons of applications. People that aren’t in the 3D printing business in schools, they’re behind the curve. It teaches you critical thinking, math, creativeness—everything. You don’t need $100,000 to get started, these printers are affordable,” says Mintzmyer.

Mintzmyer leverages his 3D printers to improve Yavapai students’ experience, but also grow industry opportunities. COBOD, a concrete 3D printing construction firm, sends every new technician to Yavapai to learn how to service, operate, and maintain large industrial concrete 3D printers. This business opportunity for Yavapai is entirely because of Mintzmyer’s early investment and adoption of 3D printing technology. He uses Formlabs SLA and SLS 3D printers to print prototypes, jigs, end-use parts, and repairs for various pieces of other 3D printers. Students at Yavapai get a first-hand view of what it takes for a lucrative career in a burgeoning industry, and get to participate in the training programs alongside the COBOD engineers.

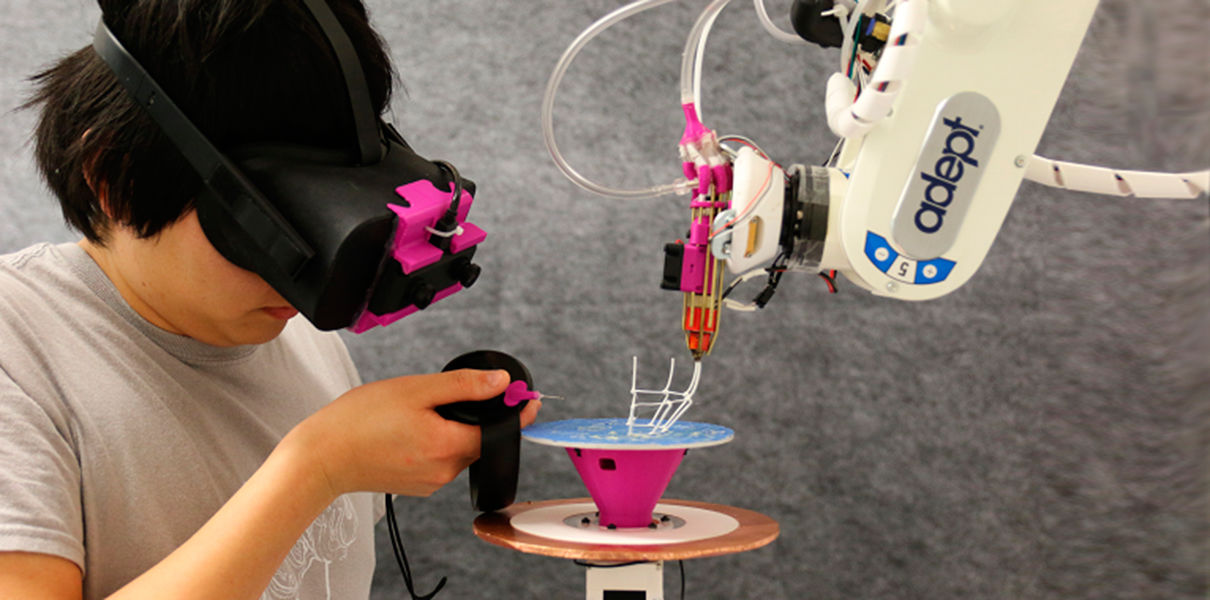

Never before have different disciplines been so interconnected. With increasing digitalization, traditionally disparate elements of a product’s lifecycle, like ideation and manufacturing, have more crossover. 3D printing is a large part of this—it speeds up product lifecycle stages to such a degree that the entire evolution can be streamlined, with disciplines blending into each other and improving upon one another. This type of collaboration within a business is also evident in educational institutions’ makerspaces and fabrication labs.

Drexel University’s Westphal College of Media Arts and Design offers programs for students hoping to pursue anything from Animation to Fashion to Virtual Reality, and their centrally located Hybrid Making Lab offers opportunities for every type of project. The Making Lab director Erik Sundquist told us, “students will use it for everything from architectural models, fashion design, accessories, hardware for garments… we have a few students interested in making fully 3D printed articulated fabrics. ”

A product design senior thesis project (left) and a sculpture class’s 3D scanned and printed fish bones (right) at Drexel’s Hybrid Making Lab. (photos courtesy of Drexel Hybrid Making Lab).

Sundquist sets up the space so that students are trained, then run the space themselves, responsible for teaching other students, no matter if the project is a different discipline than their own. “It’s more democratic that way and better for interdisciplinary learning,” says Sundquist. He sees students in fashion majors asking for help from engineering students and product design majors for articulating pieces, and vice versa. The centrally located lab is perfect for students to collaborate, share ideas, and exchange expertise, and 3D printing is the impetus behind these types of impromptu brainstorming sessions. A fashion major might see the overall picture, like a chain mail dress, but need an engineering student’s help in designing the tolerances between each chain link, or choosing which technology to use for a support-less print structure.

3D printing can empower students to try new clubs or associations and take their skills from the classroom into a new application. Students at TU Berlin rely on 3D printing to develop high-powered performance race cars for the global Formula Student competition. These cars need to be durable, resistant to high temperatures and impact, and extremely lightweight. The TU Berlin team, often composed of as many as 90 students, relies on Formlabs SLA printers for carbon fiber molding processes and end-use parts.

A mold (left picture, left hand) used for molding a carbon fiber steering wheel enclosure (left picture, right hand) and a prototype of a complex topology optimized mount (right picture), both printed on a Form 3 SLA 3D printer.

Access to accurate, reliable, and easy-to-use 3D printers has allowed the TU Berlin team to expand their output—they annually produce three cars, from design to race, within the school year. This technology has enabled a team of young students to work on something they’re passionate about, and deliver not just one, but three performance products on an international stage each year. The skills they develop and the sense of ownership and empowerment they feel wouldn’t be possible if they had to outsource much of their work, or rely on supervisors to operate more expensive machines. The affordability and accessibility of the Formlabs 3D printers empower their creativity and productivity.

Educators have a monumental task before them, and determining which technology is the best for their curriculum can be an added stress. This section will review the various 3D printers for schools and help clarify which 3D printer is best for different courses and priorities.

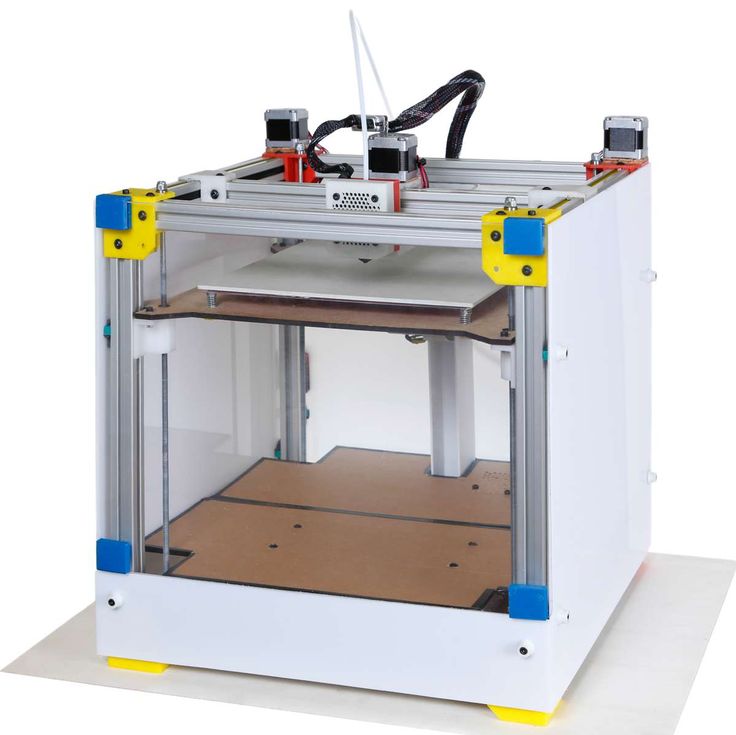

Perhaps still the most ubiquitous type of 3D printer in education, FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area. Its advantages lie in its scalability and affordability, as well as the straightforward nature of the technology, which makes it an easy concept to grasp for school children just learning how to design in CAD.

Though manufacturers do make expensive FDM printers that can cost upwards of $50,000, most units used by educators cost around $1,000-$4,000. FDM printers can deliver parts quickly and through an intuitive visual process—making them a great entry-point for younger students. Once the students begin to design functional parts and multi-part assemblies however, the lower quality surface finish and precision begins to pose a problem. The lower part quality and more narrow range of materials also means that the applications FDM printers can support are limited, especially in a research or higher educational environment. FDM 3D printers are one part of the 3D printing puzzle and a great starting point, but should be taught in concert with other, more advanced types of 3D printing.

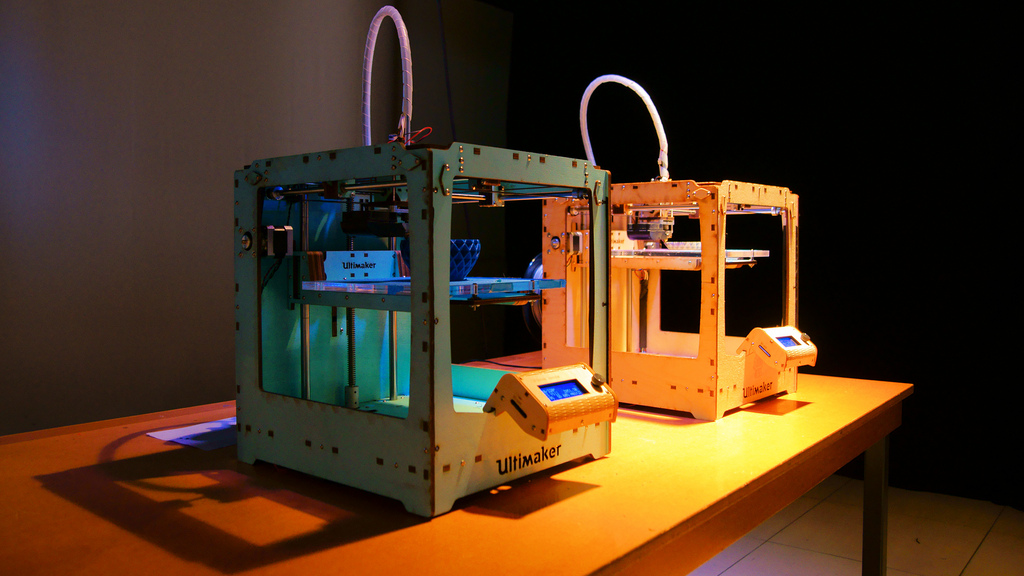

Educators were initially slow to adopt traditional SLA 3D printers when prices put them out of reach of a typical school budget. Then, as desktop SLA 3D printers like the Form 2 and Form 3 made the technology accessible and proved their reliability and professional quality, they’ve become relied-upon tools in every educator’s toolkit.

SLA printers are versatile and suitable for many applications due to their superior surface finish, range of material options, and pinpoint accuracy. The isotropic nature of SLA parts also sets them apart from other technologies, and makes SLA the front runner in watertight parts printing.

The Form 3L can fit many students’ projects into the large build volume at one time, making it a helpful addition for makerspaces during high-traffic times at the end of the semester.

For research labs, the variety of high-performance materials means that a printer can be added for a specific project, then used again and again as new projects crop up, simply by switching to whatever material is most appropriate—from high- temperature fluidics, to transparent and biocompatible cell scaffolding, to impact-resistant fixtures and casings. In open areas like fabrication labs or makerspaces, the variety of materials continues to shine along with the large build volume possible on the Form 3L. Multiple students’ projects can be fit into one build volume of the same material, then switched out for a new material and new group of students projects. The resin handling and cartridge system streamlines maintenance and operations.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Traditionally the most expensive out of the three main types of plastic 3D printing technologies, SLS 3D printers, like the Formlabs Fuse Series, create functional prototypes and durable end-use parts with high-performance mechanical properties. The technology uses a high-powered laser to selectively sinter small powder particles in the shape of a crosssection of the desired file, then repeats the process layer by layer, building the part while each layer is supported by the surrounding powder bed.

Before the Fuse Series, SLS 3D printers cost $200,000 at the minimum and often much more, putting it out of reach for most university operating budgets. Some engineering and manufacturing programs were able to secure grant funding for these units, but the large footprint, complex workflow, and expensive required infrastructure meant that very few students had the opportunity to use them.

With the introduction of the Fuse 1 in 2020, educators at every level were finally able to bring industrial quality SLS in-house, giving their students the opportunity to create end-use parts for real-world applications, and providing them with powder-bed 3D printing experience. Captain Baker at MakerSpace USNA has students use the Fuse 1 SLS 3D printer before moving on to metal 3D printing technology—in which mistakes are much costlier and more common. At the NOAA AOML lab, working in conjunction with the University of Miami’s Cooperative Institute for Marine and Atmospheric Studies (CIMAS), the Fuse 1 SLS printer is used to print rugged underwater enclosures for coral sampling equipment.

A member of the NOAA AOML lab installs a subsurface autonomous sampler to gather data on wild coral species (left). Inside the NOAA AOML lab, a coral tank monitoring device encased in a Fuse 1 printed SLS part (right).

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free SLS sample part printed on the Fuse 1+ 30W to your office.

Request a Free Sample Part

The needs of educators vary widely—from the eighth grade ‘Intro to 3D Design’ teacher to the postgraduate researcher, there isn’t one job description or role. Similarly, there can’t be one 3D printer that solves every problem. Leveraging different 3D printing solutions for different applications and environments is the best way to make sure students are engaged, encouraged and empowered, and prepared for their careers. For example:

-

FDM printers, with their simplicity and low price-point, may be ideal for K-12 schools.

-

SLA printers are the most versatile—the range of material options, prices, and sizes coupled with the high accuracy and smooth surface finish make it easy to choose an SLA printer for your project.

-

SLS printers deliver industrial power printing with proven, functional end-use materials like nylon. Models like the Formlabs Fuse 1+ 30W do so at an accessible cost, making it possible for students to master powder-bed printing without relying on grant funding.

Each educational institution will have its own preferences and abilities for making 3D printers accessible to students. For most universities, the addition of 3D printing labs is managed by department heads, while at others, large grants might be given to create a multi-disciplinary space open to all.

3D printers can improve the learning experience in any situation, whether used in small research labs for specific projects, or in large makerspaces, fabrication labs, innovation hubs, or entrepreneurial incubation centers.

Research labs vary widely in scope, size, and subject matter, but because they’re all dedicated to advancing scientific understanding, cutting-edge technology like 3D printing has been incorporated for years. At the University of Hawaii’s Nanotechnology Lab, an undergraduate student is in charge of operating and maintaining the Form 3 and Form 3L SLA printers that help undergrads, post-graduates, and doctoral candidates create research materials. The largest use-case for the printers in the lab is for sacrificial compaction molds for high-performance ceramic nanomaterials.

“We needed to have a solution where we could prototype and make molds very rapidly with structural integrity and smooth surface finish. We had the Form 3, and were very happy—it has the biggest legitimate catalog of materials to print from. As far as the Form 3L, we wanted the big form factor for big ceramic molds,” the student told us.

At the University College of London School of Pharmacy, the printers are used for visualization tools of anatomical parts. A model of a gastrointestinal tract, for example, is used to help students understand how food (and medicine) are processed and passed through the body, which helps in their understanding of how to safely medicate patients. The accuracy of the Formlabs printers allow researchers to create lifelike models of extremely complex systems in the body. “I use the Formlabs 3D printer to print molds for medical devices for a ventilation therapy project,” said Zaid Muwaffak Hassan, a PhD student in the UCL Hilton Lab. “It’s very easy to use, very accurate, and has really high details.”

In the lifesciences, accuracy and precision can mean all the difference for these students. Their projects are real life-saving devices and practices. Having accurate tools that properly represent the body, or have the biocompatibility necessary for skin or mucosal contact, is integral to their success, and therefore the health of their patients.

Makerspaces and fabrication labs are generally open to large, varied groups of students, and some also open their doors to the surrounding community, professors, or local K-12 programs. It’s because of this unpredictability in usage that planning ahead and budgeting are difficult for makerspace directors. Even when only open to university or college students, the busiest times might be limited to just the end of the semester when final projects are due. 3D printers for makerspaces have therefore traditionally been a quantity over quality consideration—directors need to make sure that when everyone comes rushing in, they can use a 3D printer with minimal oversight, scheduling, or training.

For many years, this led to large installations of FDM printers being the main (or sometimes only) technology available in makerspaces. In the past five years, however, 3D printers like the Form 3+, Form 3B+, Form 3L, and Fuse Series have gained popularity for a number of reasons.

The Formlabs suite of printers combines the industrial power and accuracy of expensive 3D printers with the ease of use and affordability of entry-level machines. Additionally, the diverse range of materials available means that a makerspace can offer one printer with multiple appropriate materials for engineering, product design, jewelry, fashion, materials science, or manufacturing students. The intuitive workflow enables students to quickly pick up the necessary operating knowledge and the reliability of the SLA and SLS print engines ensures that very little maintenance or oversight is required.

The MakerSpaceUSNA advanced section, housing Form 3 and Form 2 printers, as well as FDM printers.

At the United States Naval Academy’s MakerSpaceUSNA, every single student, regardless of major, is exposed to FDM, SLA, and SLS technologies. MakerSpace director Captain Brad Baker has added to his fleet of Formlabs machines steadily over the years, touting the reliability and consistency of the machines as major reasons for his continued investment. “The failure rate on our SLA printers is extraordinarily low. I tell [the students], ‘wait until you get to SLS.’ On SLS [Fuse Series], it’s almost 0. Virtually no failures, material properties are good, and the accuracy is really good,” says Baker.

Though many universities include entrepreneurial courses in finance or management as part of a typical business school curriculum, fewer of them offer hardware product design and development support outside of curriculum coursework. Recently, some schools have sought to set themselves apart by providing extensive support and resources for small businesses, especially hardware and product design entrepreneurs.

At the University of British Columbia in Vancouver, Canada, the HATCH Venture Builder is a collaborative institute that supports teams of students and alumni through advisory teams, office space, wet labs, and a state-of-the-art makerspace. The Hatch provides 3D printers like the Form 3 and a range of materials, as well as advice and mentorship on product design and go-to-market strategy. They rely on professional 3D printers from Formlabs to help incubator members present a high-quality, functional prototype or end-use part to potential investors and manufacturers. At Penn State, Mandell and the Innovation Hub strives to provide, “access to the best tools possible in order for individuals and groups to develop a strong proof-of-concept, to generate investment in their idea."

Education is about preparedness for the future—not just the future careers of the students, but the future of our society, which will inevitably be created by them. Investing in that future, by providing high-quality tools and resources to these students, is the best way to ensure that the future stays bright for everyone.

There is no doubt that 3D printing will have a major role to play, and we’re already seeing the benefits of the technology; there are 3D printed homes, prosthetics, surgical devices, drones, hearing aids, and electric engine components. Every educator needs to incorporate 3D printing to provide the opportunity to learn more about the technology that’s shaping the world. To speak to the Formlabs Education team and learn more about 3D printers in education, contact our team below.

3D Printing in Education - 3D Printing

Applying 3D printing in education has a wide variety of important uses in primary and secondary schools, universities, libraries, technical colleges, and other educational settings.

3D printing has changed the manufacturing world for the better. Many manufacturers use 3D printing or additive manufacturing technologies to produce airplane parts, prosthetic limbs, and even 3D-printed medications.

In education, 3D printing technologies facilitate improved learning, skills development, and increased student and teacher engagement with the subject matter. Furthermore, 3D printing sparks greater creativity and collaboration in solving problems.

How is 3D Printing Used in Education?

Broadly speaking, there are four main use cases for 3D printing in educational settings, which are:

- Teaching students about 3D printing, how 3D printing technology works, and its applications in real-world scenarios (e.

g. streamlining industrial processes)

- Informing educators about 3D printing so it can be incorporated appropriately into learning curriculums

- Improving student creativity and design skills

- Printing artifacts that aid students’ understanding of important concepts (e.g. 3D-printed anatomical artifacts)

3D Printing in Schools

Educators can include 3D printing at all school levels, from primary through to secondary (high school). 3D printing technologies enable educators to provide students with accurate physical prototypes, which provides practical, hands-on knowledge useful for understanding scientific concepts. Find out about applying 3D printing to STEM learning in the dedicated STEM learning section of this page.

Using 3D-printed objects during oral presentations and demonstrations can improve students’ public-speaking abilities. Public speaking skills become crucial when students enter the workforce. Educators can also use 3D-printed visualizations to improve spatial education. A study in China from 2014 found that 3D printing significantly improved spatial learning.

Overall, much of the research on 3D printing in education highlights how 3D-printed artifacts provide learning benefits that are not achievable with screen- or paper-based learning. Improved understanding comes through touching and physically observing 3D-printed objects. 3D printing promotes learning through exploration instead of outdated methods that only focus on learning from textbooks.

It is crucial to get a 3D printer that is suitable for how you want to use this technology to educate students. Schools need robust printers built for the demands of daily classroom use while also being affordable and user-friendly. Our expert team can advise you on a suitable 3D printer for your school.

3D Printing in Universities

At the third level of education, there is greater scope to teach students how 3D printing technology works. Many third-level universities and technical colleges now incorporate 3D printing modules and projects into engineering, applied sciences, and other courses.

Third-level 3D printing modules focus on building 3D printers from scratch in addition to fabricating 3D models using different materials. The need for explicit knowledge of 3D printing is reflected in how dedicated modules have been included in computer graphics courses, industrial engineering, and CAD.

MIT has its own graduate and advanced undergraduate course teaching the fundamentals of 3D printing. The University of Texas and Virginia Tech have followed suit with their own courses and certificates covering 3D printing and design principles for additive manufacturing.

3D printing also provides many opportunities to aid visual and practical learning across the sciences. 3D-printed components are often used as test models for scientific experiments across different disciplines, including mechanical engineering, aerospace, and robotics.

Universities have similar requirements to schools for 3D printers. Third-level educators need fast and reliable printers with an added emphasis on functionality. Get the advice you need on 3D printers suitable for use in universities and technical colleges by contacting us.

Teacher Training

3D printing can not be successfully used in education without educators who understand the design principles of additive manufacturing and how to use 3D printers and filaments. Teacher training, ongoing professional development, and 3D printing workshops can ensure students get the most from 3D printing being used in education.

3D Printing in Libraries

Libraries in the digital era are not just about books—the nature of libraries is changing to reflect how people learn about subjects using new technologies. Libraries provide an easy way to introduce 3D printing ideas and technologies to a large variety of potential users.

Having 3D printers in public libraries improves collaboration and knowledge exchange between people interested in learning about it while removing barriers to entry. Many libraries now have dedicated makerspaces with 3D printers available for use by all library members.

University libraries are one of the few cross-disciplinary areas on college campuses. Having 3D printers in a university library makes the technology available to all students rather than restricting its use to engineering or science departments.

The best 3D printer for a library is typically going to be similar to what we would recommend for classroom use. You need a printer that is affordable, durable, and fast, and we can point you in the right direction.

What is STEM Education?

STEM is an interdisciplinary approach to educating children from an early age with knowledge and skills in the four key disciplines of science, technology, engineering, and mathematics. These four core disciplines drive much of the economic development and innovation in the modern world.

People employed in STEM fields change the world through their daily work, whether by coming up with novel medical treatments for illnesses, researching cures for life-threatening illnesses, or creating new technologies.

By enabling learners to engage with STEM concepts from a young age, STEM education aims to adopt a new learning approach that goes beyond the ability to remember facts and procedures. STEM encourages people to use their creativity, critical thinking, knowledge, and skills in real-world situations.

What is STEAM Education?

STEAM education builds on the foundations of STEM education and embeds the arts into its educational philosophy. The idea behind STEAM is that it applies the arts to these four disciplines to create new ways of solving problems, innovating through creativity, and presenting information in new ways.

Applications of 3D Printing in STEM Classes

Here are some of the main ways 3D printing improves learning in STEM/STEAM classrooms:

- – Using drag-and-drop CAD programs, students can create and design simple machines by assembling the parts. Students can bring these concepts to life by 3D printing them. In this way, 3D printing provides an excellent foundation for future engineering work.

- – Building prototypes to encourage creativity and critical thinking.

- – Enable students to use CAD software to solve problems and 3D print prototypes of their models.

- – Teaching complex geometry concepts with 3D printing visualizations, which help spatial imagination.

In summary, embedding 3D printing in STEM and STEAM learning encourages the critical thinking, problem-solving, and communication skills needed for future workforces to thrive in these crucial STEM/STEAM disciplines.

Get Started with 3D Printers in STEM Education Today

3D printers are more affordable than ever and easier to use. By investing in a 3D printer, your classrooms provide the foundation for future generations to continue innovating and solving problems.

In addition to investing in a suitable 3D printer, you will need materials such as filament for printing. It is important to get a printer that fits your school’s budget and needs, and that’s where we come in with expert advice.

Project Ideas For 3D Printing in a Remote Learning Environment

Below you’ll find an overview of the ideas the derived from the aforementioned webinar.

- Collaborative or individual stop motion animations using 3D prints as components: The students are assigned a component to design for (background, characters, buildings etc) and the teacher can hit “Go” on the 3D printer to produce the needed components to create the project.

- Design Challenges to create PPE (Personal Protection Equipment) for the COVID-19 Pandemic response: The students are tasked with coming up with designs for ways to navigate through grocery stores and public spaces or create designs that will be helpful to them at home and then share those designs to an open-source community page so that others can make them too. (Examples: Shopping cart handle protectors, mask hooks for cars, hand sanitizer holsters etc.)

- Collaborative Mosaics or statues: Have each student create a piece of the puzzle for a 3D printed statue or art piece where each student is given instructions for parameters but can each use their own creativity to make it personal for them.

The students design, the teacher hits the “Go” button and the project can be assembled and displayed in the school or a local business where they can visit their creation.

- Create Distance Learning Space organizational tools or artwork: Each student has their own space at home where they are sitting to do their learning and zoom meetings. Challenge them to design something that would help them either organize or decorate their learning space at home to make it easier to participate or more personal. Expand that to ask them to interview a family member in another home to find out what they could design for their space to help them too. Encourage the class to upload their completed designs to the open-source community to help others!

- Have students build an “Engagement Box”: Teachers could deliver a kit to students to assemble and modify at home. The kit would include a particle photon, micro controller, a few buttons, a slider, some default sensors and maybe an OLED screen to assemble.

- Have the students create “Lego” or small object launchers: Send each student a few legos or small bouncy balls and have them create a prototype from cardboard for a “Flinger,” Trebuchet or Catapult. Once they have prototyped from cardboard, they design their project for a 3D printer and once the components are completed, the teacher gets the parts to the students to assemble and test. Set a day where each child gets to show what they made, launch their item, measure the distance and see who makes the design that launches the furthest!

- Design 3D models for the visually impaired: Join the e-NBLE Community in creating open-source designs for tactile learning tools for visually impaired students. How does a visually impaired child know what a specific constellation “look like?” How can they “See” the shape of a giraffe? Visit their blog from a previous design challenge for inspiration!

- Bridge Building Contests: Challenge the students to design a bridge with 3D printed parts.

The bridge has to span a certain amount of distance and the design has to hold weight. You could give the students an opportunity to not just design the bridge, but learn the slicing side of the process. By limiting how many grams of material each bridge can use, students will need to decide how much infill they want to use and what wall thickness they think they might need. The teacher 3D prints the student designs and then tests them during a bridge weight test event to see who came up with the design that holds the most weight.

- Create a class collaborative or individual diorama: Have the students design pieces for a group diorama project or characters and backgrounds for their own. The teacher could 3D print the designs and deliver them to the students in a shoe-box to assemble at home, paint and let their imaginations run wild.

- Use Makercase to create a class marble run: Have each student design a component and level for an epic 3D printed marble run and then have a viewing party to watch the marbles make their way through the design! Check out Makercase.

- Have your students design prosthetics for animals or replacement parts for broken toys: Teach 3D modeling and empathy to your students by providing them with small toy plastic animals with various limbs, fins or horns missing and have them design a replacement or prosthetic that can be printed out, painted and glued back onto their animal. Encourage them to find broken toys or games with missing pieces around their own homes and design replacements for them that can be 3D printed or laser cut! For inspiration, check out Toyrescue.com!

Helpful Links

3D Design tools (CAD)

- Tinkercad – Free, easy-to-use app for 3D design, electronics, and coding. It’s used by teachers, kids, hobbyists, and designers to imagine, design, and make anything!

- OnShape -The cross platform 3d modeling software for real word design and engineering solutions. (Compatible with Chromebook)

- Fusion 360 – A Mac or PC 3d modeling software similar to above but with a deeper toolset for fabrication and CAM

Project Inspiration

- The Secret Lives of Objects – Use a smartphone or iPad and your creative storytelling skills to document the secret lives of regular objects that you have in your home!

- Toy-rescue.

com – 3D printed replacement parts for broken toys

- MakerBot Student Virtual Prototyping Design Challenge – A fun design challenge with prizes for teachers and students from MakerBot

- Extraordinaires Cards Creative thinking game for problem solvers aged between 8 and 108

- e-NABLE 3D Printed Prosthetics – A global community of makers who are using 3D printing to make free 3D printed hands and arms for those in need of assistive devices and prosthetics

- https://www.dimensions.com/ – Accurate CAD drawings and sometimes 3d models of the most exquisitely random yet useful things!

Curriculums

- BitSpace | Prototyping with Purpose: Human-Centered Engineering Design Challenges (with e-NABLE)

- BitSpace | A Maker’s Approach to Design Thinking (3 PDH’s included)

- BitSpace | 3D Printing Prosthetics to Teach Engineering, Anatomy, and Empathy

Other Useful Links

- Particle Photon – Jeff’s go-to development board for connecting things and people together

- octoprint.

org – Remote control and viewing of 3d printers using a raspberryPi

- The Spaghetti Detective – Object recognition plugin for Octoprint which recognizes when prints have gone off the rails and sends you messages about it!

3D printers in education

3D printing is one of the main educational trends of recent years. Schools and universities in Russia and around the world clearly understand that without the use of 3D printers today it is impossible to provide students with a truly comprehensive training.

- How 3D printers can help you learn

- For techies and creators

- Use cases

- Choosing a 3D printer

- How 3D printers can help you learn

- For techies and creators

- Use cases

- Choosing a 3D printer

Just a few years ago, 3D equipment was not well represented in domestic colleges and universities due to its high cost. But now the situation has changed. First, high-quality 3D printers at an affordable price began to appear on the market. In addition, the state actively supports innovative programs in educational institutions by allocating funds for the purchase of 3D printers and 3D scanners.

A few years ago, 3D equipment was not well represented in domestic colleges and universities due to its high cost. But now the situation has changed. First, high-quality 3D printers at an affordable price began to appear on the market. In addition, the state actively supports innovative programs in educational institutions by allocating funds for the purchase of 3D printers and 3D scanners.

How 3D Printers Help Education

Educational institutions around the world are using 3D printing. 3D printers improve the learning process, develop imaginative thinking among students, accustom future specialists to automated programming and design. 3D printing greatly increases the interest in the learning process, as it allows students to feel like a real innovator.

Having created a model on a computer, a student will be able to hold it in his hands in a few hours - this is a great motivation to create something new.

![]()

Students who use a 3D printer for educational purposes have the opportunity to learn from their own mistakes. On paper or a computer, it is difficult to notice the flaws of the model, and when creating a mock-up or test part, the student, having modeled it on a computer in a 3D program, holds it in his hands after a short period of time. If something does not work, then this is not a problem, you can try again.

For the educational institutions themselves, the installation of a 3D printer will not only raise the general prestige, but also train real specialists capable of performing real design tasks. At the same time, impressive costs for the purchase of the equipment itself and for its further use will not be required.

3D printers are great for all ages. 3D modeling devices will be of interest to younger students for general development, acquaintance with technology, for use in the game mode. High school students and students will appreciate the benefits of 3D printers from a practical point of view. With their help, it will be possible to implement author's projects, print practical tasks, develop creative abilities and skills.

How 3D printers help in education

3D printing is used by educational institutions around the world. 3D printers improve the learning process, develop imaginative thinking among students, accustom future specialists to automated programming and design. 3D printing greatly increases the interest in the learning process, as it allows students to feel like a real innovator.

Having created a model on a computer, a student will be able to hold it in his hands in a few hours - this is a great motivation to create something new.

Students who use a 3D printer for educational purposes have the opportunity to learn from their own mistakes. On paper or a computer, it is difficult to notice the flaws of the model, and when creating a mock-up or test part, the student, having modeled it on a computer in a 3D program, holds it in his hands after a short period of time. If something does not work, then this is not a problem, you can try again.

For the educational institutions themselves, the installation of a 3D printer will not only raise the general prestige, but also train real specialists capable of performing real design tasks. At the same time, impressive costs for the purchase of the equipment itself and for its further use will not be required.

3D printers are great for all ages. 3D modeling devices will be of interest to younger students for general development, acquaintance with technology, for use in the game mode. High school students and students will appreciate the benefits of 3D printers from a practical point of view. With their help, it will be possible to implement author's projects, print practical tasks, develop creative abilities and skills.

Technical and creative 3D printers

In technical universities 3D technologies are the most popular. Students can design objects, parts and layouts right in the classroom, make prototypes using a 3D printer, evaluate and test them. 3D printing, already included in the curriculum of many universities, enables students to bring their design ideas and ideas to life, thereby increasing their relevance in a high-tech manufacturing environment.

3D printers that print plastic products are commonly used to teach engineering students. Such equipment allows to obtain durable prototypes and mechanisms that can withstand physical stress and be tested.

3D printers for technical and creative professions

In technical universities 3D technologies are the most popular. Students can design objects, parts and layouts right in the classroom, make prototypes using a 3D printer, evaluate and test them. 3D printing, already included in the curriculum of many universities, enables students to bring their design ideas and ideas to life, thereby increasing their relevance in a high-tech manufacturing environment.

3D printers that print plastic products are commonly used to teach engineering students. Such equipment allows to obtain durable prototypes and mechanisms that can withstand physical stress and be tested.

Robotic Prosthetic Hand Design

Parts of a Miniature Aircraft Engine

Housing for a Test Model Aircraft

Robotic Prosthetic Hand Design

Parts of a Miniature Aircraft Engine

Aircraft test case

Creative specialties is another area where 3D printing is being used. Future architects and designers with the help of 3D printers can implement the most daring projects, experiment with materials and shapes. The ability to quickly visualize and physically implement their own projects allows students to master many aspects of their future profession much faster.

Full color 3D printers are the best choice for architecture and design students. Such equipment will allow your students to quickly get bright and visual visualizations of their projects.

Creative specialties is another area where 3D printing is actively used. Future architects and designers with the help of 3D printers can implement the most daring projects, experiment with materials and shapes. The ability to quickly visualize and physically implement their own projects allows students to master many aspects of their future profession much faster.

Full color 3D printers are the best choice for architecture and design students. Such equipment will allow your students to quickly get bright and visual visualizations of their projects.

Student architectural layout

Design Chair

Design Development of shoes

Student architectural layout

Designing chair

Designer development of shoes

Examples of use of 3D printers in education

9000 3D printers today are actively used in schools and schools and schools universities throughout Russia. Their prototyping centers are open at Moscow State University, Moscow State Technical University. Bauman, MEPhI, Volga University and other universities.SISSA International School for Special Studies significantly improves its development rates >>

University students create drones using 3D printers >>

Examples of the use of 3D printers in education

3D printers are now actively used in schools and universities in throughout Russia. Their prototyping centers are open at Moscow State University, Moscow State Technical University. Bauman, MEPhI, Volga University and other universities. Here are some examples of the use of 3D printing by Western educational institutions:

An International School for Special Sissa Research significantly improves their developments >>

University students create drones using 3D printers >>

3D printers for the formation of

Stratasys F120

3DLAM 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 Total-Z AnyForm 450 PRO

3D Systems ProJet CJP 660 Pro

Stratasys F120

3DLAM Mini

TOTAL-Z ANYFORM 450 Pro

3D Systems Projet CJP 660 PRO

3D 3D in education-in which lessons is 3D printer

Anatomy

This review article will focus on the use of 3D printing in education, in particular in school education. When starting to talk about 3D printing in schools, it is important to understand that 3D printing cannot be a separate discipline, teaching 3D printing as such cannot replace any existing school subjects, such as computer science, drafting or geometry.

First of all, I would divide the teaching of 3D printing in schools into two large components, which, in principle, can exist one without the other.

The first is learning 3D modeling , because in order to print any product, you must have an object for printing. In the case of conventional printing, this any document, table, picture, photograph, presentation, etc. In the case of 3D printing, this is a 3D model that needs to be created in one of the many editors, such as a simple editor like Autodesk Tinkercad.

Learning the process of creating 3D models can be compared to a more advanced computer science lesson. Learning takes place in stages from simple to complex, you can start by creating a model like a cube, then draw a cone, a gear, a small vase, add an inscription on the cube, for example, your name or the name of the school.

Further, the lessons become more complicated, you can try to create a small car, a Lego man, etc. Depending on the direction of study - engineering, art or architecture, you can continue learning 3D modeling in programs such as 3D Studio Max, ZBrush, ArchiCAD and others. The whole process of learning 3D modeling as such is not related to 3D printing, only an insignificant part of all 3D models created today are subsequently printed. Of the models created, the vast majority exists in digital format, as does the vast majority of other digital information, such as documents and graphic content. Is teaching 3D modeling necessary in school education today, the answer is of course not. Does it help in the education of children? Of course, this makes it possible to better master the computer, as well as in the process of creating models to visualize the knowledge gained in the lessons of geometry, drawing and drawing.

So, we found out that 3D modeling is a separate discipline that can be taught in schools as an additional course or as part of computer science lessons, but it is indirectly related to 3D printing. I would compare it with photography and newspaper publishing - all newspapers have photographs and it is difficult to imagine newspapers without photographs, but at the same time a huge number of photographs do not end up in newspapers, but are used for other purposes.

Moving directly to 3D printing, it is important to note that 3D printable models come from 3 sources:

- they can be simulated,

- find ready-made models on sites such as MyMiniFactory and many others

- obtained by 3D scanning.

The first step in getting started with typing is to get familiar with the slicing software. The slicer software is usually supplied with a 3D printer and is a “translator” from the language of the 3D model to the language of the printer. With the help of this program, the model is prepared for printing with the specified parameters.

The printer needs clear commands: what to do, how to move the carriage, how thick the layer will be printed, what material, at what temperature, how voids will be filled, and much more. Thus, a novice 3D printer needs to learn how to use this software product before starting direct printing.

The second part of the 3D printing training will be learning how to interact with a 3D printer, the 3D printing process requires certain knowledge and experience, in particular about the properties of various types of plastic or resin, interlayer adhesion, plastic sintering, its supply, etc. With With an experienced mentor on the example of printing models of various shapes, with various settings, students can reach an initial level of knowledge of the printing process itself and improve them as they gain experience, taking into account the capabilities of the 3D printing equipment that they have at their disposal.

We understood how to get a 3D model, how to prepare it for printing and how to print it, but did not answer the main question, why then do we need 3D printing at school?

It is important to understand here that it is pointless to teach 3D printing at school as a subject, since this is a highly specialized discipline that a small percentage of students need to apply in future professional tasks. Such knowledge is usually obtained during the acquisition of secondary specialized or higher education. But what 3D printing is great for is embedding it into the learning process in other subjects. At first glance, a bold statement is quite easy to prove on a number of simple examples.

Mathematics

A 3D printer will help you learn the multiplication table quickly and with pleasure.

Biology

It is not necessary to dissect a live frog, you can make a 3D printed model and carry out this procedure in a humane way.

Anatomy

You can print the skull or other organs and visually study its structure.

Geography

Each student can print a square and assemble the landscape of the earth's surface together.

A separate educational area where 3D printers are indispensable tools is the area of additional education, namely the numerous and very popular today circles of robotics, modeling, prototyping and others.

3D printing is in great demand in such educational institutions as children's technoparks Quantoriums and TsMITs, which are analogous to the circles of young technicians from our childhood. These centers are equipped with everything you need, including 3D printers, 3D scanners, milling machines, mini CNC machines, and more.

This set of equipment allows not only and not so much to learn the skills of 3D printing, scanning, modeling, and so on, but also to create real design works that can be presented at olympiads, exhibitions, or even subsequently turned into technology startups. At the end of each module, a final lesson is provided, during which the team defense of scientific and technical projects, students and natural science research works takes place.

At the end of this short article, I'd like to give you some tips on choosing the best equipment for schools and further education institutions.

If your school has 3D modeling in its computer science course or as a separate additional course and the task is to print simple models of an initial or intermediate level of complexity, then I would recommend paying attention to budget models of 3D printers created specifically for this purpose.

For example, the FlashForge Adventurer 3 3D printer model has a closed housing, a safe, easily removable nozzle, a webcam for remote monitoring of printing from an application, a color touch-screen display familiar to children from smartphones and tablets.

For a more advanced level of learning, a model like FlashForge Inventor is perfect, which allows you to create more complex semi-professional models.

If the task is to provide Quantorium or TsMIT with 3D printers, then you need to choose the most versatile models that can print a wide range of different materials, preferably with an enlarged camera for large projects. Such printers are able to cope with various, sometimes very complex and, most importantly, diverse tasks. These models certainly include the Raise3D Pro2 printer, which, due to its versatility, the presence of a fully functional slicer, cloud service and a host of additional functions, is rightfully considered a leader in its segment.

If some specific areas of printer use are known in advance, then you can choose a model for these specific tasks, for example, to create detailed miniatures, printers using photopolymer printing technology are suitable, for example, the Phrozen Shuffle 4K model, which is capable of creating models of jewelry accuracy and detail.

We hope this article was useful for you, and you got a rough idea about 3D printing in education, our company's specialists will always be happy to help you with the choice of the necessary equipment.