3D print ice cube mold

Ten 3D Printable Things: Chocolate, Ice Cube and Jello Molds - 3DPrint.com

This week I found ten fantastic 3D printable molds that can be used to make all sort of fun treats, including chocolates, ice cubes and Jello bites. A few of these models can be used as the mold themselves, but a few of them will require you to cast the molds in food-safe silicone, which is actually a lot easier to do than you’d think. You can find more information of making candy molds with silicone here.

Here are Ten 3D Printing Things – Chocolate, Ice Cube and Jello Molds:

FILLED CHOCOLATES MOLDChocolate Mold by Dan O’Connell

Found on: MyMiniFactory

Cost: Free

This simple mold is made with a solid core, so the finished chocolate piece will have a hollow center that you can fill with just about anything. I’d recommend that you stick to fillings that don’t have to be warm to be pliable because if you try to fill the chocolates with anything warm it could actually melt the chocolate shell. I’d suggest filling them with peanut butter, nuts, caramel – or any kind of creamy filling, really.

Chocolate Bird Mold by Lawson Take

Found on: MyMiniFactory

Cost: Free

This simple bird mold is a great way to try your hand at making 3D printed candy molds because it’s pretty simple and can be printed in a wide variety of sizes depending on how big you’d like your chocolates. Unlike most of the models on this list you’ll be 3D printing the mold itself, not a solid core to be pressed into silicone, so make sure that you print it with a food-safe filament.

GUMMI BEARSGummi bear mold by jani51

Found on: Thingiverse

Cost: Free

The Gummi Bear is arguably one of the most recognizable candy shapes in the world, and with this mold you can actually make your own. And because the mold is 3D printable, you can make them in any size that you want. You can make little chocolate bears, or use the recipe on the model;s Thingiverse page and make your own Gummis. Printing a large mold would also be an ideal way to make fun bear-shaped Jello-shots without having to waste a bunch of small paper cups.

Printing a large mold would also be an ideal way to make fun bear-shaped Jello-shots without having to waste a bunch of small paper cups.

Han Solo in Chocolate! by dentikhval

Found on: Thingiverse

Cost: Free

Nerds like candy as much as anyone, so a bar of chocolate shaped like Han Solo frozen in carbonite is the perfect gift for the Star Wars fan in your life.

STAR TREK INSIGNIA MOLDStar Trek Ice Tray by MyMiniFactory

Found on: MyMiniFactory

Cost: Free

And don’t leave the Star Trek fans in your life out, this tray of Starfleet insignia badges can be used for ice, but could also make some pretty great chocolates. Just make sure that you print using a food-safe material and that it’s flexible enough to make the removal of the candy easy.

LEGO MOLDLego Ice Cube Mold by lydiac

Found on: Thingiverse

Cost: Free

This small LEGO-shaped mold was made to make ice cubes, but it would be very easy to use it to make chocolate LEGO candy. A good way to make chocolate LEGOs is to melt some white chocolate and add a few drops of food coloring so you can make a bunch of different colors. This mold will also require you to 3D print it out of a food-safe material.

A good way to make chocolate LEGOs is to melt some white chocolate and add a few drops of food coloring so you can make a bunch of different colors. This mold will also require you to 3D print it out of a food-safe material.

Chocolate Skull Mold Maker by akaziuna

Found on: Thingiverse

Cost: Free

When you make some candy skulls using this mold, make sure that you tell the goth in your life that the skull used for the mold was an actual 3D scanned skull. Trust me, it will make the candy skulls more special to them.

POKEMON MOLDSPokemon Ice / Jello Tray by Andrew Reynolds

Found on: MyMiniFactory

Cost: Free

This Pokémon mold is a little different than the others on this list as they’re really just Pokemon silhouettes, but I still think they’ll make fun chocolates. This would also be a great mold for Pokémon-shaped Jello, or large ice cubes for a party or to add to a signature drink. The mold includes Pikachu, Bulbasaur, Squirtle and Charmander.

The mold includes Pikachu, Bulbasaur, Squirtle and Charmander.

Iceberg Ice Tray by MAP

Found on: MyMiniFactory

Cost: Free

Making small icebergs for your drinks is the obvious use for this mold, but I also thought it would be fun to make “flavor bombs” with juice or crushed fruit that can be added to drinks like iced tea, lemonade, champagne, sparkling wine or soda water.

MOAI “EASTER ISLAND HEAD” MOLDMoai Head Mould (Easter island) by Peran Truscott

Found on: MyMiniFactory

Cost: Free

The Moai, aka “Easter Island Heads”, are the large stone structures carved by the long gone residents of Easter Island in Polynesia. This huge mold was designed as a way to make fun candy gifts for Easter. You can make the chocolate Moai solid by completely filling the mold, or just fill it half way, block the hole and slowly rotate the mold until the candy coats the walls and solidifies for a hollow Moai head. And just a tip if you want to make hollow chocolates: keep the mold in the fridge until it’s ready to use – when you pour in the chocolate it will start to solidify faster.

And just a tip if you want to make hollow chocolates: keep the mold in the fridge until it’s ready to use – when you pour in the chocolate it will start to solidify faster.

As always, you can email me your feedback and theme suggestions, and I always love to see what 3D printing projects you’ve been working on. You can also find me on Twitter @SJGrunewald, so say hi and feel free to show off what you printed. Tag it #103dpthings and you’ll get a RT.

Let us know if you’ll be making any of these or any other #103dpthings projects – discuss these and other 3D printing topics at 3DPrintBoard.com, or share your comments below.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: Bulbasaur • candy • candy mold • Charmander • chocolate mold • Easter Island • Han in Carbonite • han solo • ice cube mold • Moai • myminifactory • Pikachu • pokemon • Squirtle • star trek • star wars • Ten 3D Printable Things • Ten3dpthings • thingiverse

Please enable JavaScript to view the comments powered by Disqus.![]()

▷ ice cube mold 3d models 【 STLFinder 】

Ice Cube Mold

thingiverse

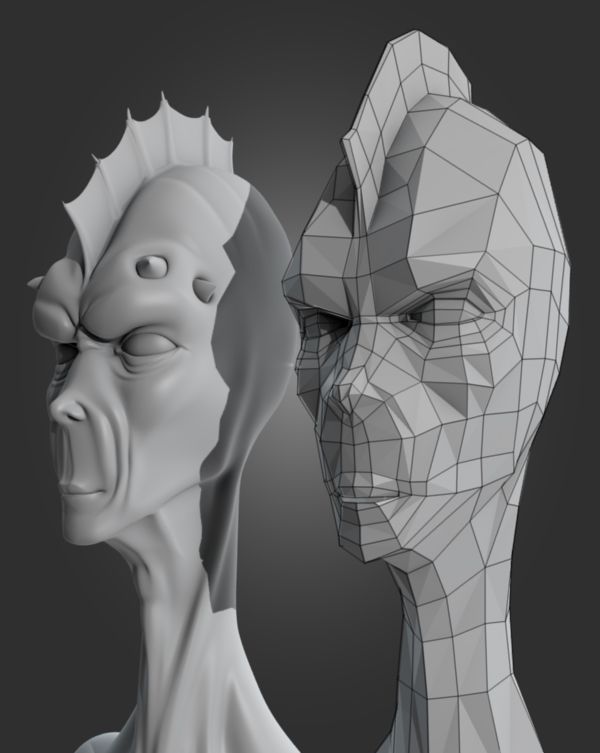

... ...To be used for self-reflection while drinking alcohol. Instructions 123D Catch for the raw mesh, processing in Meshlab to get out just the face, Rhino to create the ice cube mold from the mesh. ...Drink in a clear glass with your favorite cocktail.

silicone ice cube mold holder

thingiverse

A holder for flexible silicone ice cube mold. ...For easy freezing.

Ice cube mold for bubbler

thingiverse

Ice cube mold for bubbler Blue is TPE, clear is TPU.

Ice Cube Mold - V1.0

thingiverse

Ice Cube Mold Test with Galdhopiggen, in Norway, is the tallest mountain in Northern Europe (2,469 m) from http://www.thingiverse.com/thing:178035

.50 BMG Ice Cube Mold

thingiverse

This is an Ice Cube Mold for a .50 BMG Cartridge. It has the orginal Dimensions of a real .50 BMG Cartridge and features some Channels arround the Cavity to fill with WARM Water (DONT FILL HOT WATER IN IT MIGHT DAMAGE THE MOLD) in Order to warm the...

customisable ice cube mold

myminifactory

Modify mold_length_x to change the length of the ice cube. preview (F5), render (F6), and save as .stl

Note: if you don't want any wall text, just change the variables to empty strings (e.g. wall_text_lhs_top = "";).

Further info:Many thanks to...

preview (F5), render (F6), and save as .stl

Note: if you don't want any wall text, just change the variables to empty strings (e.g. wall_text_lhs_top = "";).

Further info:Many thanks to...

Leaf ice-cube mold

cults3d

SO if you wanted a leaf-shaped ice cube, you might be interested in this. Good for fall themed drinks. Or if you are Canadian. Or if you are into maple leaves. No judgie. Anyway, I have been using https://www.makeyourownmolds.com/shop/copyflex/...

Leaf ice-cube mold

thingiverse

SO if you wanted a leaf-shaped ice cube, you might be interested in this. Good for fall themed drinks. Or if you are Canadian. Or if you are into maple leaves. No judgie. Anyway, I have been using https://www.makeyourownmolds.com/shop/copyflex/...

Or if you are Canadian. Or if you are into maple leaves. No judgie. Anyway, I have been using https://www.makeyourownmolds.com/shop/copyflex/...

customisable ice cube mold

thingiverse

Modify `mold_length_x` to change the length of the ice cube. * preview (F5), render (F6), and save as .stl Note: if you don't want any wall text, just change the variables to empty strings (e.g. `wall_text_lhs_top = "";`). ### Further info: ...

Sphere Ice Cube mold

thingiverse

Wanted to test out the SUNLU TPU and designed a spherical ice mold to do so. printed great at 230c, 60c build plate and 30mm/sec. I use a little food safe silicone to ensure a good seal and the funnel to fill it. ...It works best if you fill it a little...

I use a little food safe silicone to ensure a good seal and the funnel to fill it. ...It works best if you fill it a little...

Titanic Ice cube mold

thingiverse

You print this, and it forms a mold that you use to create a mold using the food-safe material. I have done similar things in the past, and you have a problem getting the mold out without destroying your 3d print. This has a sleeve that you print...

Rubber duck ice cube mold

thingiverse

Small project to create a mold which can create ice-rubber-ducks. Would be fun to have those floating right up in your cola or other brew. Update2 - Just printed the mold, now need to tweak te top a bit, and the idea is now to fill it with "Vanille. ..

..

Sphere Ice cube Mold

thingiverse

I made this in blender. ...Scale the bottom piece down slightly more than the top to make sure they fit together

Round Ice Cube Mold with Pour Hole

thingiverse

This is my first project and I intend to use it. ...There isn't really much to explain, it's a mold for ice cubes, but I made it with Tinkercad and I am proud of it so here it is!

Lego 2x4 ice cube mold

thingiverse

Bullet Ice Cubes Mold

pinshape

An Ice cube tray to make bullet shaped ice cubes. 1. Resize as desired the bigger you make the ice cubes the better this works. 2. Print at .1mm2 shells 15% infill 3. Get both sides of mold wet, clamp together and put in the freezer. This will...

1. Resize as desired the bigger you make the ice cubes the better this works. 2. Print at .1mm2 shells 15% infill 3. Get both sides of mold wet, clamp together and put in the freezer. This will...

ICE CUBE TRAY/MOLD FOR BOTTLES

thingiverse

Ice Cube Mold/Tray For Making Ice That Can Be Put In Bottles

Shot Glass Ice Cube Tray Mold

thingiverse

Alphaversion: Box to create a set 0f 6 shot glasses of ice cube. ...Tray Mold Summer Drink Mixing Shooter.

Mini Ice Cube Tray Mold

thingiverse

To be used to make a silicone ice cube tray :) Video example of casting: https://youtu. be/rpu8OMzKI7M

be/rpu8OMzKI7M

3D printable Ice cube mold Christmas tree 3D print model

cgtrader

Make original Christmas ice cubes with this 3D printed mold!Merry Christmas! ...

3D printable Ice cube mold Snowman 3D print model

cgtrader

Make original Christmas ice cubes with this 3D printed mold!Merry Christmas! ...

Infinity Stones Candy/Ice Cube Mold

thingiverse

BE just like thanos

Space invader (ice cube) molds - Tiled

thingiverse

.![]() .. scaling, bottom layer sizes etc. to actually get a model that is both stable and waterproof enough to freeze through, and flexible enough to release the ice cube afterwards. ... If you manage to get one of these out in the wild, please tell us how!

.. scaling, bottom layer sizes etc. to actually get a model that is both stable and waterproof enough to freeze through, and flexible enough to release the ice cube afterwards. ... If you manage to get one of these out in the wild, please tell us how!

Silicone Ice Cubes Tray Mold

thingiverse

You can review the rest of my Silicone Mold series here: Silicone Kitchen Tongs Mold and Handle - https://www.thingiverse.com/thing:3203210 Silicone Ice Balls Tray Mold - https://www.thingiverse.com/thing:3204617 Silicone Oven Mitts Mold -...

Cube ice mold

grabcad

Plastic mold for ice blocks

cool ice cube tray/ jello mold

thingiverse

cool ice cube tray or jello mold or?

ice cube shot glass mold

thingiverse

with helper or not

Pot Leaf Ice Cube Tray Or Chocolat Mold

thingiverse

Pot Leaf Ice Cube Tray

D20 Dice Mold Set Ice Cube, Resin, Silicone

cults3d

Mold of my D20 in case you prefer to make molds instead of printed parts.

D20 Dice Mold Set Ice Cube, Resin, Silicone

thingiverse

Mold of my D20 in case you prefer to make molds instead of printed parts.

New 3D Skull Silicone Ice Mold Ice Cube Mold Box with 6

| Date | Price | |||

|---|---|---|---|---|

| 05/12/2021 | $ 11,10 | |||

| 05/13/2021 | $ 11,10 | |||

| 05/14/2021 | ||||

| 05/16/2021 | ||||

| 05/17/2021 | $ 11,10 | |||

| 05/18/2021 | $ 11,10 | |||

| 05/19/2021 | $ 11,10 | |||

| 05/20/2021 | $ 11,000 | 05/21/2021 | ||

| 05/22/2021 | ||||

| 05/23/2021 | ||||

| 05/24/2021 | 05/26/2021 | |||

| 05/27/2021 | ||||

| 05/28/2021 | ||||

| 05/29/2021 | ||||

| 05/30/2021 | ||||

| 05/31/2021 | ||||

| 06/2/2021 | ||||

| 06/3/2021 | ||||

| 06/4/2021 | 06/5/2021 | 9000 9000 | 06/20 | |

| 06/7/2021 | ||||

| 06/8/2021 | ||||

| 06/9/2021 | ||||

| 06/10/2021 | ||||

| 06/11/2021 | 06/12/20 | |||

| 06/13/2021 | ||||

| 06/14/2021 | ||||

| 06/15/2021 | 06/16/2021 | 9009 | 06/2011 06/2011 06/2011 06/2011 06/20 | |

| 06/18/2021 | ||||

| 06/19/2021 | ||||

| 06/20/2021 | ||||

| 06/21/2021 | $7,77 | |||

| 06/22/2021 | $7,55 | |||

| 06 /23/2021 | $ 7. 55 55 | |||

| 06/24/2021 | $ 7.55 | |||

| 06/25/2021 | $ 7.55 | |||

| 06/26/2021 | 9000 9000 9000 9000 9000 9 | 06/27/2021 | ||

| 06/28/2021 | ||||

| 06/29/2021 | ||||

| 06/30/2021 | ||||

| 07/1/2021 | ||||

| 07/2/2021 | ||||

| 07/4/2021 | ||||

| 07/5/2021 | $ 7,77 | |||

| 07/6/2021 | ||||

| 07/2021 | ||||

| 07/9/2021 | ||||

| 07/10/2021 | ||||

| 07/11/2021 | ||||

| 07/12/2021 | 07/13/2021 | 07/11 07/11 07/2011 07/2011 07/20 | ||

| 07/15/2021 | ||||

| 07/16/2021 | ||||

| 07/17/2021 | 07/18/2021 | 9009 | 07/11 07/2011 07/2011 07/20 | |

| 07/20/2021 | ||||

| 07/21/2021 | ||||

| 07/22/2021 | ||||

| 07/23/2021 | $ 7. 77 77 | 07/24/2021 | 0009000/25/25/25/25/25 2021 | |

| 07/26/2021 | ||||

| 07/27/2021 | ||||

| 07/28/2021 | ||||

| 07/29/2021 | ||||

| 07/31/2021 | ||||

| 08/1/2021 | ||||

| 08/2/2021 | ||||

| 08/3/2021 | ||||

| 08/4/2021 | ||||

| 08/6/2021 | ||||

| 08/2021 | ||||

| 08/8/2021 | ||||

| 08/9/2021 | ||||

| 08/11/2021 | ||||

| 08/12/2021 | ||||

| 08/13/2021 | ||||

| 08/14/2021 | ||||

| 08/2021 | ||||

| 08/2021 | ||||

| 08/18/2021 | ||||

| 08/19/2021 | ||||

| 08/20/2021 | ||||

| 08/21/2021 | ||||

| 08/22/2021 | ||||

| 08/23/2021 | ||||

| 08/24/2021 | ||||

| 08/25/25/2021 | ||||

| 08/26/2021 | 08/27/2021 | 9000 9000 9000 | ||

| 08/29/2021 | ||||

| 08/30/2021 | ||||

| 08/31/2021 | ||||

| 09/1/2021 | ||||

| 09/2/2021 | ||||

| 09/3/2021 | ||||

| 09/4/2021 | ||||

| 09/5/2021 | ||||

| 09/6/2021 | ||||

| 09/7/2021 | 9000 9000 9000 9000 | |||

| 09/9/2021 | ||||

| 09/2021 | ||||

| 09/11/2021 | ||||

| 09/12/2021 | 9 | |||

| 09/14/2021 | ||||

| 09/15/2021 | ||||

| 09/16/2021 | ||||

| 09/17/2021 | ||||

| 09/18/2021 | ||||

| 09/2021 | ||||

| 09/21/2021 | ||||

| 09/22/2021 | ||||

| 09/23/2021 | ||||

| 09/24/2021 | ||||

| 09/26/2021 | ||||

| 09/27/2021 | ||||

| 09/28/2021 | ||||

| 09/29/2021 | ||||

| 09/30/2021 | ||||

| 10/2/2021 | ||||

| 10/3/2021 | ||||

| 10/4/2021 | 10/5/2021 | 10/6/2011 10/2011 10/2011 10/20 | ||

| 7/10/2021 | $7. 77 77 | |||

| 10/8/2021 | $7,77 | |||

| 10/9/2021 | $7,77 | |||

| 10/10/2021 | $7,77 | |||

| 10/11/ 2021 | $ 7.77 | |||

| 10/12/2021 | $ 7.77 | |||

| 10/13/2021 | $ 7.77 | |||

| 10/14/2021 | $ 7,000 | |||

| 10/15/2021 | $7.77 | |||

| 10/16/2021 | $7.77 | |||

| 10/17/2021 | $ 7.77 | |||

| 10/18/2021 | $ 7.77 | |||

| 10/19/2021 | $ 7.77 | 9000 9000 9000 900010/20/20 2021 | $ 7.77 | |

| 10/21/2021 | $ 7.77 | |||

| 10/22/2021 | $ 7.77 | |||

| 10/23/2021 | $ 7,000 | |||

| 10/24/2021 | $7.77 | |||

| 10/25/2021 | $7,77 | |||

| 10/26/2021 | $7,77 | |||

| 10/27/2021 | $7,77 | |||

| 10/28/2021 | $7,77 | |||

| 10/29/2021 | $ 7. 77 77 | |||

| 10/30/2021 | $ 7.77 | |||

| 10/31/2021 | $ 7.77 | |||

| 11/2021 | .77||||

| 2/11/2021 | $7.77 | |||

| 3/11/2021 | $ 7.77 | |||

| 11/4/2021 | $ 7.77 | |||

| 11/5/2021 | $ 7.77 | 11/6/2021 | $ 7.7. | 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 900011/7/2021 | $ 7.77 |

| 11/8/2021 | $ 7.77 | |||

| 11/9/2021 | $ 7.77 | 11/10/2021 | $7.||

| 11/11/2021 | $7.44 | |||

| 12/11/2021 | $ 7.44 | |||

| 11/13/2021 | $ 7.77 | |||

| 11/14/2021 | $ 7,77 | |||

| $ 7.7,000 | ||||

| 11/16/2021 | $ 7.77 | |||

| 11/17/2021 | ||||

| 11/18/2021 | ||||

| 11/19/2021 | 11/20/20/20/20/20/20/20/20/20 | $7.77 | ||

| 21/11/2021 | $7.77 | |||

| 11/22/2021 | $ 7.77 | |||

| 11/23/2021 | $ 7.77 | |||

| 11/24/2021 | 11/25/2011 11/25/20 | |||

| 11/26/2021 | ||||

| 11/27/2021 | ||||

| 11/28/2021 | 11/29/2021 | ,000 9000 | 111/20 | $7.77 |

| 12/1/2021 | $7. 77 77 | |||

| 12/2/2021 | $ 7.77 | |||

| 12/3/2021 | $ 7.77 | |||

| 12/4/2021 | $ 7.77 | 12/5/5/5/5/5/5/5/5/5/5/5/5/5/5/5/5/5/5/5/5 2021 | $ 7.77 | |

| 12/6/2021 | ||||

| 12/7/2021 | ||||

| 12/8/2021 | ||||

| 12/9/2021 | ||||

| 12/11/2021 | $7.77 | |||

| 12/12/2021 | $ 7.77 | |||

| 12/13/2021 | $ 7.77 | |||

| 12/14/2021 | 0009 | |||

| 12/16/2021 | ||||

| 12/17/2021 | ||||

| 12/18/2021 | ||||

| 12/19/2021 | 9000 9000 9000 9000 9 ,77 | |||

| 12/21/2021 | ||||

| 12/22/2021 | ||||

| 12/23/2021 | $ 7. 77 77 | |||

| 12/24/2021 | $ 7.77 | |||

| 12/25/2021 | $ 7,77 $ 7,77 $ 7,77 $ 7. | |||

| 12/26/2021 | $ 7.77 | |||

| 12/27/2021 | $ 7.77 | |||

| 12/28/2021 | 12/29/29/2/2/2/2/2/2/2/2/2/2/A2/29/2/2/29/2/20 | $7.77 | ||

| 12/30/2021 | $7.77 | |||

| 12/31/2021 | $ 7.77 | |||

| 01/1/2022 | $ 7.77 | |||

| 01/2/2022 | $ 7,77 | 1111 $7,77 | ||

| 01/4/2022 | $7,77 | |||

| 01/5/2022 | $7,77 | |||

| 01/6/2022 | $7,77 | |||

| 01 /7/2022 | $7.77 | |||

| 01/8/2022 | $7.77 | |||

| 01/9/2022 | $ 7.77 | |||

| 01/10/2022 | $ 7.55 | |||

| 01/11/2022 | $ 7. 55 55 | 1111111 $7,55 | ||

| 01/13/2022 | $7,55 | |||

| 01/14/2022 | $7,55 | |||

| 01/15/2022 | $7,77 | |||

| 01 /16/2022 | $7.77 | |||

| 01/17/2022 | $7.77 | |||

| 01/18/2022 | $ 7.77 | |||

| 01/19/2022 | $ 7.77 | |||

| 01/20/2022 | 01/21/21/21/21/21/21/20 | $ 7.77 | ||

| 01/22/2022 | $ 7.77 | |||

| 01/23/2022 | $ 7.77 | |||

| 01/24/2022 | $ 7.7.9000 9000.9000 9000 4000 9000 4000 9000 4000 9000 4000 9000. 01/25/2022 | $7.77 | ||

| 01/26/2022 | $7.77 | |||

| 01/27/2022 | $ 7.77 | |||

| 01/28/2022 | $ 7.77 | |||

| 01/29/2022 | $ 7.77 | $ 7. 77 77 | ||

| 01/31/2022 | $ 7.77 | |||

| 02/1/2022 | $ 7.77 | |||

| 02/2022 | $ 7,000 9000 9000 9000 9000. | |||

| 02/3/2022 | $7.77 | |||

| 02/4/2022 | $7.77 | |||

| 02/5/2022 | $ 7.77 | |||

| 02/6/2022 | $ 7.77 | |||

| 02/7/2022 | $ 7,77 | 9000 9000 900002/8/8/8/8/8/8 2022 | $ 7.77 | |

| 02/9/2022 | $ 7.77 | |||

| 02/10/2022 | $ 7.77 | |||

| 02/11/2022 | $ 7.1 | |||

| 12/02/2022 | $7.77 | |||

| 13/02/2022 | $7.77 | |||

| 02/14/2022 | $ 7.77 | |||

| 02/15/2022 | $ 7.77 | |||

| 02/16/2022 | $ 7.77 | $ 7.77 | ||

| 02/18/2022 | $ 7.77 | 02/19/2022 | $ 7. 77 77 | |

| 02/20/20/2022 | $ 7,000 9,000 9,000 9,000 9,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9,000 9000 | |||

| 02/21/2022 | $7.77 | |||

| 02/22/2022 | $ 7.77 | |||

| 02/23/2022 | $ 7.77 | |||

| 02/24/2022 | $ 7.77 | 02/25/2022 | $ 7.7.000 9000.11 $ 7.7000 | |

| $ 7.77 | ||||

| 02/27/2022 | $ 7.77 | |||

| 02/28/2022 | $ 7.77 | |||

| 03/2/2022 | $7.77 | |||

| 03/3/2022 | $ 7.77 | |||

| 03/4/2022 | $ 7.77 | |||

| 03/5/2022 | $ 7.77 | |||

| $ 7.711 $ 7.7000 | ||||

| 03/7/2022 | $ 7.44 | |||

| 03/8/2022 | $ 7.44 | |||

| 03/922 | $ 7.44 | 111111 $7. 44 44 | ||

| 11/03/2022 | $7.44 | |||

| 12/03/2022 | $ 7.77 | |||

| 03/13/2022 | $ 7.77 | |||

| 03/14/2022 | $ 7.77 | |||

| 03/2022 | $ 7,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | 03/16/2022 | $ 7.77 | |

| 03/17/2022 | $ 7.77 | |||

| 03/18/2022 | 03/19/20 $7.77 | |||

| 03/20/2022 | $7.77 | |||

| 03/21/2022 | $ 7.77 | |||

| 03/22/2022 | $ 7.77 | |||

| 03/23/2022 | $ 7.77 | |||

| 03/24/2022 | $ 7,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | 03/25/2022 | $ 7.77 | |

| 03/26/2022 | $ 7. | |||

| 03/27/2022 | 9000 9000 9000 9000 | 03/28/20 $7.77 | ||

| 03/29/2022 | $7.77 | |||

| 03/30/2022 | $ 7.77 | |||

| 03/31/2022 | $ 7.77 | |||

| 04/1/2022 | $ 7.77 | |||

| 04/2/2022 | $ 7,000 | 04/3/2022 | $ 7.77 | |

| 04/4/2022 | $ 7.77 | |||

| 04/2022 | $ 7.77 | 1111 $7.77 | ||

| 04/7/2022 | $7.77 | |||

| 04/8/2022 | $ 7.77 | |||

| 04/9/2022 | $ 7.77 | |||

| 04/10/2022 | $ 7.77 | |||

| $ 7,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | 04/12/2022 | $ 7.77 | ||

| 04/13/2022 | $ 7.77 | |||

| 04/14/2022 | 9000 9000 9000 | 04/15/2015/20 $7. | ||

| 04/16/2022 | $7.77 | |||

| 04/17/2022 | $ 7.77 | |||

| 04/18/2022 | ||||

| 04/2022 | $ 7.77 | |||

| 04/20/20/20/2022 | $ | $ 7.77 | ||

| 04/22/2022 | $ 7.77 | |||

| 04/23/2022 | $ 7.77 | |||

| 04/24/2022 | ||||

| 04/25/2022 | $7.77 | |||

| 04/26/2022 | $ 7.77 | |||

| 04/27/2022 | $ 7.77 | |||

| 04/28/2022 | $ 7.77 | |||

| 04/29/2022 | $ 7,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | 04/30/2022 | $ 7. 77 77 | |

| 05/1/2022 | $ 7.77 | |||

| 05/2/2022 | $ 7.77 | 111111 $7.77 | ||

| 05/4/2022 | $7.77 | |||

| 05/5/2022 | $ 7.77 | |||

| 05/6/2022 | $ 7.77 | |||

| 05/7/2022 | $ 7,77 | |||

| $ 7.7. | 05/9/2022 | $ 7.77 | ||

| 05/10/2022 | $ 7.77 | |||

| 05/11/2022 | $ 7.77 | 11 05/12/201/20 $7.77 | ||

| 05/13/2022 | $7.77 | |||

| 05/14/2022 | $ 7.77 | |||

| 05/15/2022 | $ 7.77 | |||

| 05/16/2022 | $ 7.77 | |||

| 05/17/2022 | $ 7,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | 05/18/2022 | $ 7.77 | |

| 05/19/2022 | $ 7. 77 77 | |||

| 05/20/2022 | $ 7.77 | 11 05/21/201/20 $7.77 | ||

| 05/22/2022 | $7.77 | |||

| 05/23/2022 | $ 7.77 | |||

| 05/24/2022 | $ 7.77 | |||

| 05/25/2022 | $ 7.77 | |||

| 05/26/2022 | $ 7,000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | 05/27/2022 | $ 7.77 | |

| 05/28/2022 | $ 7.77 | |||

| 05/29/2022 | ||||

| 05/30/2022 | $ 7,1222 | |||

| 05/31/2022 | $7.77 | |||

| 06/1/2022 | ||||

| 06/2/2022 | $ 7.77 | |||

| 06/3/2022 | ||||

| 06/2022 | $ 7.77 | |||

| 06/6/2022 | $ 7.77 | |||

| 06/7/2022 | $ 7.77 | |||

| 06/8/2022 | 9000 9000 9000 9000 | 06/20 | $7. 77 77 | |

| 10/06/2022 | ||||

| 11/06/2022 | $ 7.77 | |||

| 06/12/2022 | ||||

| 06/13/2022 | ||||

| 06/2022 | 06/2022222222 | |||

| 06/16/2022 | ||||

| 06/17/2022 | ||||

| 06/18/2022 | 06/19/2022 | 06/20/20/20 | ||

| 06/21/2022 | ||||

| 06/22/2022 | ||||

| 06/23/2022 | ||||

| 06/24/2022 | ||||

| 06/25/2022 | 06/27/2022 | |||

| 06/28/2022 | ||||

| 06/29/2022 | ||||

| 06/30/2022 | ||||

| 07/2/2022 | ||||

| 07/3/2022 | ||||

| 07/4/2022 | ||||

| 07/5/2022 | ||||

| 07/6/2022 | 07/7/2022 | 9000 9000 | 07/2022 | |

| 07/9/2022 | ||||

| 07/10/2022 | ||||

| /2022 | ||||

| 07/2022 | ||||

| 07/14/2022 | ||||

| 07/15/2022 | ||||

| 07/16/2022 | ||||

| 07/17/2022 | ||||

| 07/18/2022 | 07/2011 07/2011 07/2011 07/20 | |||

| 07/20/2022 | ||||

| 07/21/2022 | ||||

| 07/22/2022 | 07/23/2022 | 000 | 07/24/2022 9001 | |

| 07/25/2022 | ||||

| 07/26/2022 | ||||

| 07/27/2022 | ||||

| 07/28/2022 | ||||

| 07/29/2022 | 9000 9000 9000 9000 9000 9000/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30/30I | |||

| 07/31/2022 | ||||

| 08/1/2022 | ||||

| 08/2/2022 | ||||

| 08/3/2022 | 9000 | |||

| 08/5/2022 | ||||

| 08/6/2022 | ||||

| 08/7/2022 | ||||

| 08/8/2022 | $ 7. | |||

| 08/922 | 08/10/10/10/10/10/10/10/10/10/10/10/AP $ 7.77 | |||

| 08/11/2022 | ||||

| 08/12/2022 | ||||

| 08/13/2022 | ||||

| 08/14/2022 | ||||

| 08/16/2022 | ||||

| 08/17/2022 | ||||

| 08/18/2022 | ||||

| 08/19/2022 | ||||

| 08/20/2022 | ||||

| 08/21/2022 | ||||

| 08/22/2022 | ||||

| 08/23/2022 | ||||

| 08/24/2022 | ||||

| 08/25/2022 | 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | |||

| 08/27/2022 | ||||

| 08/28/2022 | ||||

| 08/29/2022 | ||||

| 08/30/2022 | $ 7.77 | |||

| 08/31/2022 | /20 | |||

| 09/2/2022 | ||||

| 09/3/2022 | ||||

| 09/4/2022 | 09/5/2022 | 9000 9000 | 09/2022/20 | |

| 09/7/2022 | ||||

| 09/8/2022 | ||||

| 09/9/2022 | ||||

| 09/10/2022 | 09/11/2022 | 09/2022 | 9000 9000 9000 9 /13/2022 | |

| 09/14/2022 | ||||

| 09/15/2022 | $ 7. 77 77 | |||

| 09/16/2022 | $ 7.77 | $7.77 | ||

| 09/18/2022 | $ 7.77 | |||

| 09/19/2022 | $ 7.77 | |||

| 09/20/2022 | ||||

| 09/21/2022 | 99 | |||

| 09/23/2022 | ||||

| 09/24/2022 | ||||

| 09/25/2022 | ||||

| 09/26/2022 | 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 | |||

| 09/28/2022 | ||||

| 09/29/2022 | ||||

| 09/30/30/2022 | ||||

| 10/1/2022 | ||||

| 10/2/2022 | ||||

| 10/2022 | $ 7.7.77 $ 7,77 $ 7,77 $ 7. | |||

| 10/4/2022 | $ 7.77 | |||

| 10/5/2022 | $ 7.77 | |||

| 10/6/2022 | ||||

| 10/7/2022 | $ 7, $ 7, $ 7, $ 7, $ 7. 77 77 | |||

| 8/10/2022 | $7.77 | |||

| 9/10/2022 | $ 7.77 | |||

| 10/10/2022 | $ 6.99 | 10/11/2022 | $ 6.99 |

In which the date is the date:

05/22/2018- This date is given as an example

- 05/22/2018 - MM/d/yyyy

- 5/22/2018 - M/D/yyyy

- 05/22/2018 - dd/MM/yyyy

- 22-05-2018 - dd-MM-yyyy

- 05/22/2018 - dd.MM.yyyy

- 22/5/2018 - d/m/yyyy

- 22-5-2018 - d-m-yyyy

- 22.5.2018 - d.M.yyyy

- 2018-05-22 - yyyy-MM-dd

- 2018/5/22 - yyyy/m/d

- 2018-5-22 - yyyy-M-d

- 2018/05/22 - yyyy/MM/dd

- 2018.05.22 - yyyy.MM.dd

- 2018.22.05 - yyyy.dd.mm

- d - day, M - month (no leading zero)

- dd, MM - day and month with a leading zero for values from 1 to 9

- yyyy - 4-character year

How to display the price:

$100- $100

- 100

- 100$

- $100USD

- USD $100

- US $100

- USD 100

- US 100

What separators to use

for price:

50

50 - 1,000.50

- 1.000.50

- 1,000.50

- 1000.50

- 1,000 50

- 1'000.50

- 1'000.50

- 1.000'50

Days without a price (more about currencies):

Do not show- Do not show

- Show

In which format to download:

txt- txt

- xml

- html

- csv

- json

or

| Product name | New 3D Skull Silicone Ice Mold Ice Cube Mold Box with 6 Skull Popsicle Whiskey Ice Hockey Ice Cube Mold Press |

| Category | Home and garden |

| Subcategory | Kitchen, dining room and bar |

| Pack quantity | |

| Original price | US $11. 10 10 |

| Sales price | US $6.99 |

| Discount | 37% |

| Price in Euro | € |

| Item ID | 1005002597281607 |

| Updated | October 11, 2022, Tuesday 08:07:08 GMT |

| Current time | October 11, 2022, Tuesday 11:26:41 GMT |

More information is available on the product page on AliExpress. Go Go | |

Making Silicone Molds: A Practical Guide

Throughout history, artisans have used molds to make everything from weapons in the Bronze Age to modern consumer goods. The first molds were made of stone, but modern science has made it possible to obtain materials that are easier to work with, such as silicone.

Today, silicone mold casting is used by companies in many industries. To create a model in one copy or several batches of it, silicone molds are used by everyone from product designers and engineers to creative enthusiasts and even chefs.

In this practical guide to making silicone molds, we'll cover everything you need to know before you get started. We'll also walk you through what you'll need and show you how to use silicone molds step by step on any project.

Technical report

This report contains case studies from OXO, Tinta Crayons and Dame Products illustrating three different applications of molding in silicone molds for product development and manufacturing, including multilayer and insert molding.

Download white paper

Silicone is a reliable solution for mold making. It has many benefits. With the help of molding in silicone molds, you can create projects according to individual parameters. The molds themselves are quite strong. They can be used multiple times and won't break. Silicone is an inorganic material. Compared to rubber, its organic counterpart, it is highly resistant to heat and cold, chemicals and even mold. Silicone molds have the following advantages:

Silicone is a flexible material. This makes it easy to work with him. Silicone molds can be bent; they are light compared to tougher materials such as plastics. It is also easy to extract cast models from them. Silicone has good flexibility. Therefore, there is less chance that silicone molds or models molded in them will break. Custom silicone molds can be used to make anything from complex engineering components to ice cubes and holiday sweets.

Silicone able to withstand temperatures from -65 to +400 degrees Celsius. Depending on the formula, it has an elongation of up to 700%. It has high resistance to a wide range of conditions: silicone can be placed in an oven or refrigerator and stretched thereafter.

Depending on the formula, it has an elongation of up to 700%. It has high resistance to a wide range of conditions: silicone can be placed in an oven or refrigerator and stretched thereafter.

In most cases, one silicone mold can be used many times. However, you need to understand that the service life of different molds can vary greatly. The more often casting is performed and the more complex the shape of the model being created, the faster the mold will wear out. To maximize the life of silicone molds, they should be cleaned with mild soapy water, dried thoroughly, and stored separately without stacking.

Silicone has many advantages, but it also has some limitations:

-

Silicone is more expensive than latex or organic rubber. If you look on Amazon, you can find many offers of silicone for $100, which is almost twice the price of latex.

-

Despite good flexibility, silicone can break if stretched too hard.

-

Silicone is created using different formulas.

Therefore, it and other materials for production must be purchased from a reliable supplier.

Therefore, it and other materials for production must be purchased from a reliable supplier.

Both hobbyists and professionals use silicone molds because of their versatility and ease of use. Here are some industry examples and use cases where they are used for product manufacturing:

Silicone mold casting is used for prototyping and product development in various industries. The cost of silicone molds is significantly lower than rigid tools for traditional manufacturing processes such as injection molding. Silicone mold casting is great for prototyping product designs as well as creating samples to test customer demand for new products in the market. While 3D printing is better suited for creating one-off models, silicone and polyurethane injection molding is ideal for low-volume model production.

Webinar

Manufacture using new technologies is faster than traditional methods, and is also effective when creating products on a small scale or making changes to their design. Watch this webinar and learn how to use 3D printing to create medium-scale models using injection molding. Watch webinar

Watch this webinar and learn how to use 3D printing to create medium-scale models using injection molding. Watch webinar

Jewelers use silicone molds to duplicate handmade or 3D printed wax models. This gives them the opportunity to gradually move away from the time-consuming work of carving models in wax for each new product, while still using this material for casting. Thanks to this, it is possible to make a significant leap in mass production and use investment casting in a given scale. Because silicone molds are good at rendering detail, jewelers can create pieces with fine patterns and intricate geometric shapes.

Room temperature vulcanized silicone mold applied to a 3D printed pattern.

Technical report

3D printing with high performance materials allows designers and molders to incorporate digital technologies into their manufacturing processes. Read this article and learn how 3D printing can be used to produce small metal items.![]() Download white paper

Download white paper

Craftsmen use silicone molds to create custom handmade items such as soaps and candles. Even school supplies manufacturers use silicone molds to make products such as chalk and erasers.

For example, Tinta Crayons, a small Australian company, uses silicone molds to produce colored wax crayons with a fun shape and high surface quality.

Tinta Crayons robotic colored wax crayons molded in silicone molds (image source).

Silicone food molds can be used to create a variety of fancy confections, including chocolate, popsicles and lollipops. Since silicone can withstand temperatures up to 400 degrees Celsius, these molds can also be used for baking. They also rise well in small pastries such as buns and muffins.

Independent artists and hobbyists use silicone mold casting to create unique pieces. They can be used to shape and replicate anything from bath bombs to dog treats. The possibilities are almost endless. It will be interesting for children to create a copy of their hand using silicone molds. You just need to make sure that the silicone used is safe for the skin.

You just need to make sure that the silicone used is safe for the skin.

A sample is a model that is used to get an exact impression of it in a silicone mold. If you just want to make a copy of an existing object, it makes sense to use that as a reference. You just need to make sure that this object is able to withstand the process of creating a mold.

To get a new design or prototype, you first need to make a sample. There are several ways to do this. Among them are the following:

-

Sculpting: If you are a talented sculptor or create a relatively simple model, you can use clay to make a model. Model modeling will also be interesting for children and is an economical solution for art lovers.

-

Carving: A pattern can be created using woodcarving. Wood carved patterns are a great choice for creating tiles and flat designs.

-

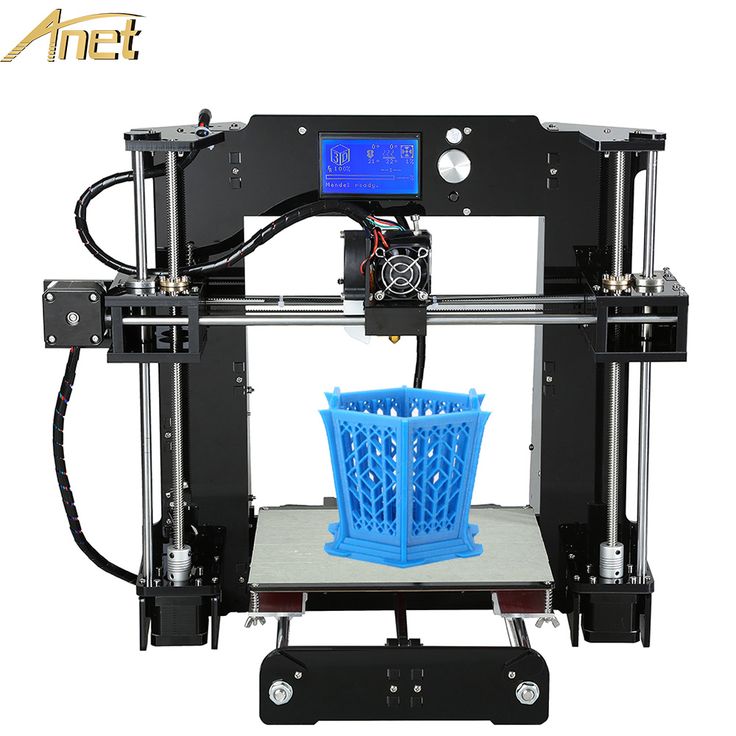

3D printing: Many professionals and designers in companies choose to print samples on a 3D printer.

Desktop 3D printers offer many benefits. They offer a wide range of design possibilities in CAD software, high detail, easy modification of prototypes, and rapid model creation.

Desktop 3D printers offer many benefits. They offer a wide range of design possibilities in CAD software, high detail, easy modification of prototypes, and rapid model creation.

Once you have a sample, you can start making your silicone mold.

To make a basic silicone mold, you will need the following:

-

Sample

-

Liquid silicone, e.g. Smooth-On OOMOO 30

-

Container or non-porous container as mold body

-

Mold release, e.g. Smooth-On Universal Mold Release

-

Wax, polymer or other end-use material

Before you start making molds, you need to decide which ones you need.

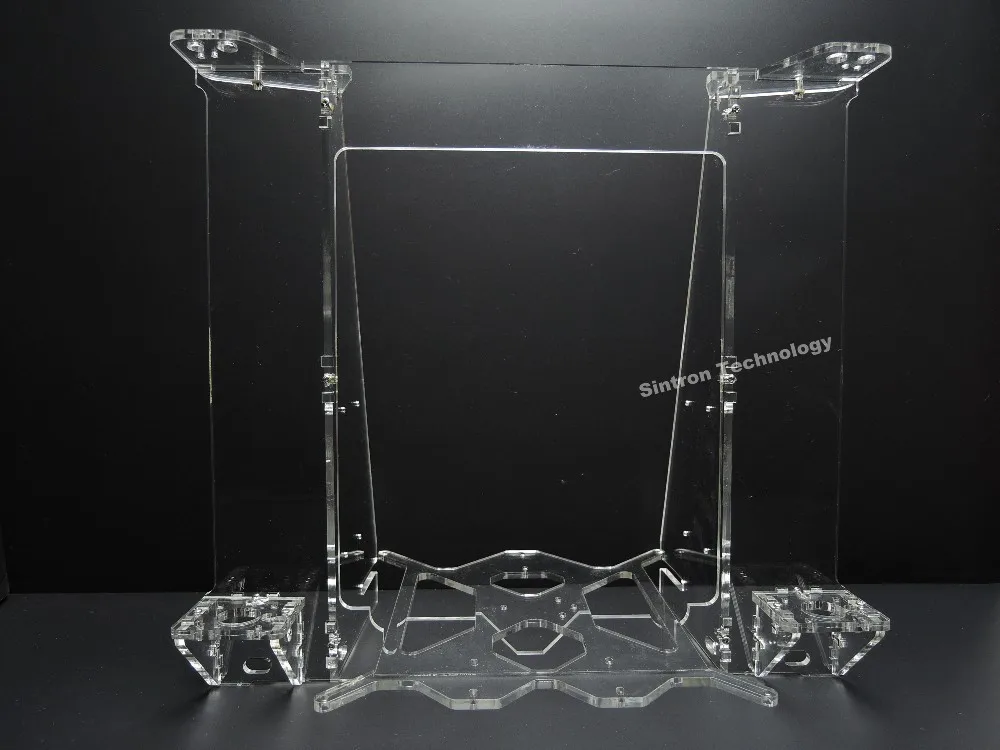

One-piece silicone molds are similar to an ice cube tray. Material is poured into them and allowed to harden. However, as with ice cubes, which have a flat top surface, one-component molds are only suitable for creating models that have a flat side. If your sample has deep grooves, once the silicone has hardened, it will be more difficult to remove it and the finished models without damaging it.

If your sample has a different design, one-piece silicone molds are ideal for continuous 3D reproduction of its entire surface.

One-piece silicone molds are the best solution for making models with a flat side and without deep grooves.

For 3D reproduction of a specimen without a flat side or with deep grooves, a two-component mold is better suited. It consists of two elements that connect and form a three-dimensional cavity (similar to how injection molding is done).

Two-component molds do not have flat surfaces and are easier to work with than single-component molds. Cons: They are a little more difficult to make. Also, seams can remain on the surface of the models if the mold components are not aligned with each other.

Two-component molds can reproduce samples with any design (image source)

First you need to decide whether to use a one-component or two-component mold. The manufacturing process is similar, but it takes a little longer to create a two-component mold. The following step-by-step instructions can be used to make silicone molds.

The following step-by-step instructions can be used to make silicone molds.

-

Sample your product: is your final design for the model to be reproduced in another material. When printing on a stereolithographic 3D printer, use standard resins with a layer height of 50 µm. The detailed surface must be free of traces of supporting structures. Rinse the models with IPS. If the surface remains sticky, it may affect the molding process in silicone molds.

-

Build a mold case: A popular solution for making a mold container is powder-coated fiberboard, but a regular plastic container will work. Materials must be non-porous and flat-bottomed.

-

Position specimen and apply mold release: Apply a small amount of release to the inside of the mold housing. Place the samples in the container with their detailed surface facing up. Apply a light coat of casting lubricant to them. Wait 10 minutes for them to dry completely.

-

Prepare the silicone: mix the silicone rubber according to package directions. Vibrating devices such as a handheld electric grinder can be used to remove air bubbles.

-

Pour the silicone into the mold body: Carefully pour the mixed silicone rubber into the container in a narrow stream. First, pour rubber into the bottom of the container (base) and gradually rise along the contours of the 3D printed sample. The thickness of the rubber layer on top of the sample must be at least one centimeter. Depending on the type and brand of silicone, the curing process will take from one hour to a day.

-

Remove the silicone from the container: After the silicone has hardened, remove it and the specimens from the container. The resulting mold will be used like an ice tray to make products for the end use.

-

Cast your model: it is recommended to apply a light coat of lubricant to the silicone mold and allow it to dry for 10 minutes.

Pour the end-use material (such as wax or cement) into the cavity and allow it to harden.

Pour the end-use material (such as wax or cement) into the cavity and allow it to harden. -

Prepare the mold for the next casting: the silicone mold can be used many times. Go to the seventh point and repeat the process.

To create a two-part silicone mold, follow the first two steps above: create a template and mold body. Then do the following:

-

Arrange the specimens in the case by placing them in the clay: use clay to form half of the mold. Clay needs to be laid out in the body for the mold. The sample must be inserted halfway into the clay.

-

Prepare the silicone and pour it: prepare the silicone by following the instructions on its packaging and carefully pour it over the clay and specimens. The poured layer of silicone is the first half of the two-component mold.

-

Remove all contents from the mold housing: After the first half has hardened, remove it, samples and clay from the mold body.

When extracting content, layers can be separated from each other.

When extracting content, layers can be separated from each other. -

Carry out clay cleaning: completely clean the first half of the mold and samples from clay. Samples and the resulting part of the mold must be absolutely clean.

-

Place the mold and specimens back into the housing: Reposition the resulting mold part with the specimens inserted into the housing so that they are facing up instead of down.

-

Apply a coat of casting lubricant: To make it easier to remove the second mold component, apply a thin layer of lubricant to the top surface of the specimen and the first mold part.

-

Prepare and pour the silicone to make the second mold part: Following the instructions above, prepare and pour the silicone into the body to make the second mold part.

-

Wait for the second part of the mold to harden: wait for the second mold component to harden before removing the second mold component from the body.

Learn more

77

77