Fullmetal alchemist 3d print

Buy Professional 3D Models | CGTrader

Explore 3D Models

CategoriesBuy or free-download professional 3D models ready to be used in CG projects, film and video production, animation, visualizations, games, VR/AR, and others. Assets are available for download in many industry-accepted formats including MAX, OBJ, FBX, 3DS, STL, C4D, BLEND, MA, MB and other. If you are searching for high poly or real-time 3D assets, we have a leading digital art library for all your needs.

Aircraft 3D ModelsThis category covers 3D aircraft. CG airplanes will fit into simulations, visualizations, advertisements and videos. Drone bodies and parts will delight fans of tiny flying vehicles. And the rigged models are ready to be imported into game engines.

Animals 3D ModelsThe collection of 3D fauna - cats, horses, bears, rhinos, eagles, lions and more - can be found here. The CG 3D animals will satisfy the needs of advertisements or static scenes. We also have rigged animal models for games.

Stair, fireplace, 3D models as well as decorations like frame, pillow, or lamp can be found in the extensive architectural detail model library. Interior and exterior can be used to build both digital kitchens, bedrooms, castle rooms or dungeons whether you are an architect, engineer or indie game developer.

Exterior 3D ModelsBrowse architectural exteriors from facades, urban buildings to landscape objects, residential houses, industrial constructions, and full scale 3D city models. Some of the assets are low poly and could help you complete your game or VR/AR application.

Interior 3D ModelsThis category contains realistic 3D elements and details of architecture, construction and engineering interior design. You can use these 3D models for animation or games - some of them are rigged and low poly.

Car 3D ModelsCar category contains automobile 3D models, low-poly versions of which will be attractive to game designers, others - to film makers or advertisers. From classic cars to racing and track cars to the concept ones, there’s a great variety of 3D auto models.

From classic cars to racing and track cars to the concept ones, there’s a great variety of 3D auto models.

In this category you will find 3D models of human, people, sci-fi, clothing and other. From heart and hand to detailed realistic male or female models. A number of the models are rigged and could be easily added to your game or animation.

Food 3D ModelsFood helps to create realistic scenes of domestic life. 3D fruits, vegetables, beverages and meals are all here. Advertisements for restaurants, AR applications for healthier eating. Whether you were looking for 3D pizza or a wedding cake model, they’re here.

Furniture 3D Models3D tables, chairs, sofas, beds in a variety of textures (wood, metal, etc.) and styles ( retro, modern, etc.) are on-hand. This category is meant for anyone involved with architecture and interior design, as well as advertisers.

Household 3D ModelsHousehold item 3D models are used to give details to rooms. You can put a 3D dinner set on the table, or have pepper and salt containers to complete kitchen interior, maybe put some lights and flowers near the bed to create luxurious feel.

You can put a 3D dinner set on the table, or have pepper and salt containers to complete kitchen interior, maybe put some lights and flowers near the bed to create luxurious feel.

Construction materials, engineering tools, machinery and containers that provide both environmental details and interactive, rigged elements. This is perfect for simulation game developers or people building construction yard level.

Plant 3D ModelsThis category contains 3D models of flora organisms such as flowers, trees, grass, creepers, greenery, herbs, perennials, seedlings, shoots, shrubs, slips, sprouts, vines, weed. To buy or download a free 3D model, browse the categories below.

Space 3D ModelsSpace is a category full of low poly, game-ready models of sci-fi spaceships, asteroids, planets (including Earth and realistic space shuttles for the more scientifically inclined. 3D space models are useful for VR space simulator games.

Trucks, ambulances, buses, trains, tractors, bikes and motorcycles - this category is for the people who want their city streets to be filled with realistic and sci-fi vehicles, and for those making simulation games or formating posters.

Watercraft 3D ModelsWatercraft covers boats, yachts, ships and other water vehicles. The rigged 3D models will do well in video games, animation while CG models are there for your scenes or other applications where visual fidelity is more important than polycount.

Military 3D ModelsIn this category you can buy 3D models of weapons, arms, swords and artillery both modern and historical used by military forces and self defence. You can use models for games - some of them are polygons optimized and ready for game engines.

CG Textures 3D ModelsBrowse through a library of beautifully-made 3D materials and find the best suited, ready-to-use textures to prepare game-ready or photorealistic models, upgrade your asset library, and improve your 3D works.

Browse all models

▷ fullmetal alchemist arm 3d models 【 STLFinder 】

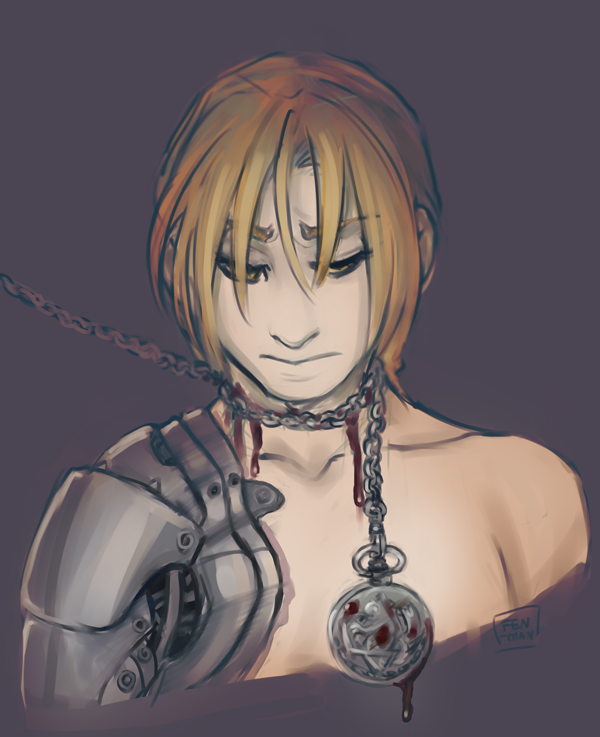

Fullmetal Alchemist Edward Elric Arm

prusaprinters

Good Luck , Cheers Jace Please note this can be found freely obe at pepakura.com https://www.pepakura.eu/full-metal-alchemist-edward-automail-arm/ Please also note, I've attempted to slice every thing in such away, it should eliminate a lot of need...

Fullmetal Alchemist Edward Elric Arm

thingiverse

Good Luck , Cheers Jace Please note this can be found freely obe at pepakura.com https://www.pepakura.eu/full-metal-alchemist-edward-automail-arm/ Please also note, I've attempted to slice every thing in such away, it should eliminate a lot of need. ..

..

Fullmetal Alchemist (KeyChain)

cults3d

Fullmetal Alchemist (KeyChain)

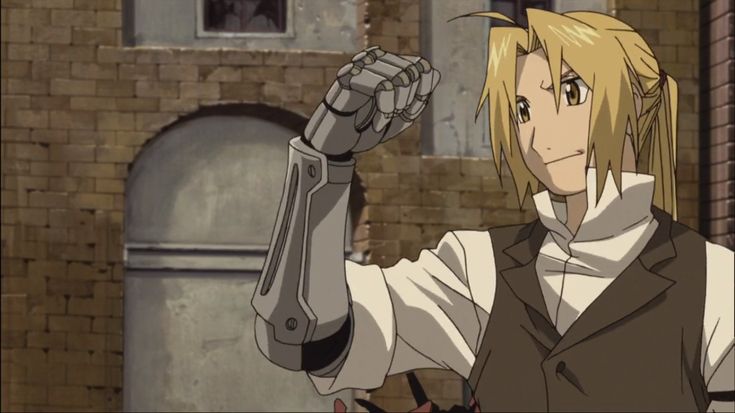

Edward - Fullmetal Alchemist

cults3d

Edward - Fullmetal Alchemist size:170 mm

Fullmetal Alchemist - Alphonse Elric

sketchfab

Fullmetal Alchemist (Japanese: 鋼の錬金術師, Hepburn: Hagane no Renkinjutsushi, lit. “The Steel Alchemist”) is a Japanese manga series written and illustrated by Hiromu Arakawa. ...free to use leave a like if u like

...free to use leave a like if u like

Edward Elric - Fullmetal Alchemist

sketchfab

3D Character Programa usado: Blender Design Gráfico _ Universidade Veiga de Almeida Fernanda Barreto Andrade Silva 20181105352 Modelagem e Texturização de Personagens Personagem: Edward Elric - Fullmetal Alchemist

Fullmetal Alchemist - Logo Keychain

thingiverse

... Alchemist Keychain : a transmutation circle as base and that famous alchimist cross ! ...So I found the Fullmetal Alchemist Logo by LittleSimba and the Magic Circle Transmutation by devonjones, mixed both of them and add an handle for the ring !

Fullmetal Alchemist Blood Seal

thingiverse

Blood seal Edward uses to save Alphonse in Fullmetal Alchemist. ...https://sketchfab.com/models/3cbf9878eabe45e89b13dadff0f224f5 How I Designed This Used blender 2.7 Made multiple mesh sections and boolean them together.

...https://sketchfab.com/models/3cbf9878eabe45e89b13dadff0f224f5 How I Designed This Used blender 2.7 Made multiple mesh sections and boolean them together.

FullMetal ALchemist symbol

thingiverse

FullMetal Alchemist is a japan serie. I've made Elric brothers (protagonists) symbol. It has been made in OpenSCAD and printed by "PADRE", a 3D printer, in the Carlos III University. ... Instructions...

FullMetal Alchemist Homunculus Keychain

thingiverse

FullMetal Alchemist Homunculus Keychain which is a little modified from the actual design so it will be intact. Hole at the top to make it into a keychain. Size is quite small and needs to be scaled when printed. ... ...

Hole at the top to make it into a keychain. Size is quite small and needs to be scaled when printed. ... ...

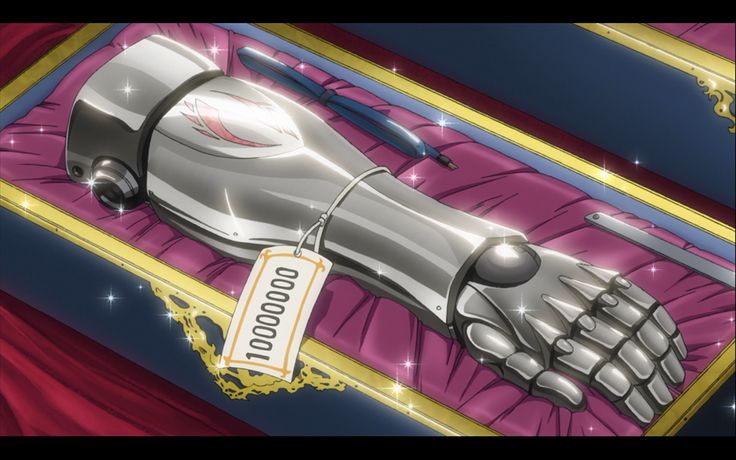

Fullmetal Alchemist- State Alchemist Pocket Watch

thingiverse

State Alchemist Pocket Watch to enhance an alchemist's capabilities! ... *Note: Some parts are missing, but you can DIY those

Alchemical circle from "Fullmetal Alchemist"

thingiverse

I did this circle of alchemist because I did not find it on the Internet

Fullmetal alchemist 2d wall art

prusaprinters

Full metal alchemist brotherhood 2d wall art , easy print

fullmetal alchemist brotherhood alphonse elric

sketchfab

This is a alphonse elric model I made based on information I found onsite. ...one of my favorite characters from the fullmetal alchemist brotherhood

...one of my favorite characters from the fullmetal alchemist brotherhood

Alex Louis Armstrong(Fullmetal Alchemist)

cults3d

亞力士·路易·阿姆斯壯(鋼の錬金術師) Alex Louis Armstrong(Fullmetal Alchemist) Follow me here:https://www.facebook.com/PatrickFanart.HK Support me:https://www.buymeacoffee.com/NrDZF9LEG

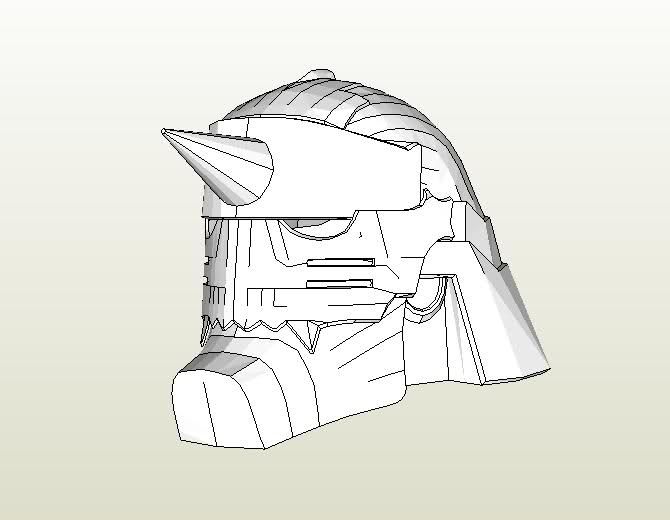

Helmet Alphonse Elric [Fullmetal Alchemist]

sketchfab

Study the metal, I need to improve a lot, I used as a guinea pig the helmet of the Alphonse elric character of the anime Fullmetal Alchemist. ...process: https://youtu.be/2GSTTwcn3Yg

Alex Louis Armstrong(Fullmetal Alchemist)

thingiverse

亞力士·路易·阿姆斯壯(鋼の錬金術師) Alex Louis Armstrong(Fullmetal Alchemist) Follow me here: https://www. facebook.com/PatrickFanart.HK ![alt text][id] [id]: https://truth.bahamut.com.tw/s01/201908/503ce54bdaf8862827523905acca4201.JPG "Title" Support me: By buying...

facebook.com/PatrickFanart.HK ![alt text][id] [id]: https://truth.bahamut.com.tw/s01/201908/503ce54bdaf8862827523905acca4201.JPG "Title" Support me: By buying...

fullmetal alchemist

thingiverse

Customized version of http://www.thingiverse.com/thing:74322 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=74322

Fullmetal Alchemist Spear head 3D print model

cgtrader

Fullmetal Alchemist spear head fits a 1/2 dowel will need a wrap a glue for a snug fit! ...

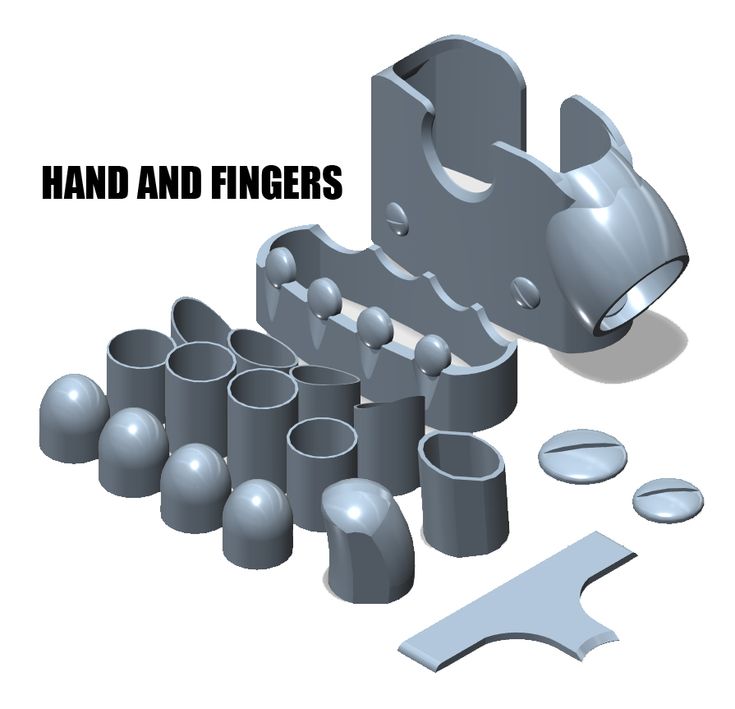

Edward Elric automail arm Fullmetal alchemist stl 3D print model

cgtrader

3D Model for 3D printing only digital files This prop is pretty simple in terms of printing. All files are ready to print and made to fit standart 20x20x20cm build volume. Brim and supports are required for most parts. Fingers are most likely will...

All files are ready to print and made to fit standart 20x20x20cm build volume. Brim and supports are required for most parts. Fingers are most likely will...

FullMetal Alchemist The Silver Pocket Watch

thingiverse

The Fullmetal Alchemist, the original 2004 version is one of my favourite anime, because at the time, manga was not finished and the production team pull ideas instead of waited, therefore it is more realistic and brutal. Or perhaps, at the time,...

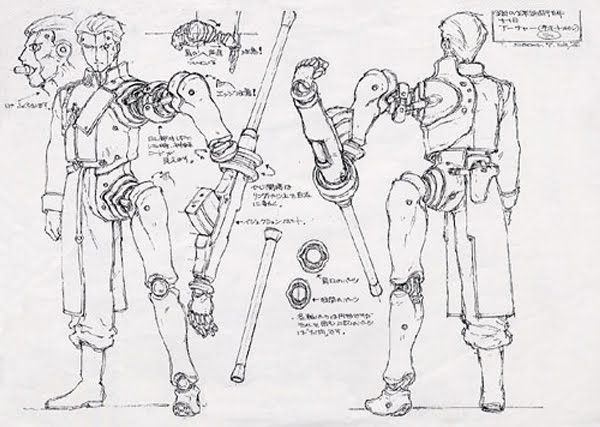

Fullmetal alchemist - Anime.

grabcad

Teachers Symbol from FMA

Fullmetal alchemist pendant

cults3d

ready to print 18k gold weight 1. 2gr please contact us for any question or different size

2gr please contact us for any question or different size

Fullmetal Alchemist Key chain

thingiverse

________________ 0.15 -- layer height 20% -- infill No supports ________________ Printed by AnetA8 enjoy

Fullmetal Alchemist Flamel Charm

thingiverse

Just a little something that I personally wear everyday! ... Enjoy!

Fullmetal Alchemist logo keychain

thingiverse

Can be either dual extruded or single extruded. I did not make this design and do not own the rights to it. Instructions For Single extrusion: Use the "Final FMA Keychain" STL file. For Dual...

I did not make this design and do not own the rights to it. Instructions For Single extrusion: Use the "Final FMA Keychain" STL file. For Dual...

Fullmetal Alchemist Keychain

prusaprinters

<p>The gcode is a 2 colors print</p>

Ling Yao - Fullmetal Alchemist Nendoroid

thingiverse

My art project for 2019, a Ling Yao Nendoroid!

This project was fully modeled in OnShape from scratch which was definitely a great learning experience - all in all there are 28 current parts making up the nendoroid, and he has fully posable limbs. ..

..

Edward's watch (Fullmetal Alchemist)

prusaprinters

<p>This is an attempt of Edward's pocket watch design.</p><p>Thank you for being indulgent, I am discovering Fusion 360 xD</p><p>Printing with Smartfil filament.</p><p><strong>Print instructions</strong></p><p>Layer: 0.05mm<br>Infill: 10%<br>Support:...

FullMetal Alchemist EDWARD (PlaKit2 Series)

cults3d

Exclusive models and contents Only on PATREON!! Visit now at: https://www.patreon.com/purakito Exclusive Packaging, Multi Material models, and more! ** NEWS UPDATE! ** EXCLUSIVE MODELS AND CONTENTS ON PATREON!!!!https://patreon. com/purakito...

com/purakito...

Full Metal Alchemist (3D Printer 3KU)

Hi all!

Finally, I got my long-suffering printer and decided to introduce you to it.

Reasons for purchase:

I won’t spread especially because they are very utilitarian, I need to print trial cases for the development of small electronic products with the subsequent order of casting in China, although at cost price I have already thought about buying a park of printers.

Choice:

The thing is that my office is a former small bedroom in the apartment, and there are already machines lying around (my bedlam will be visible in the photo) and there is simply nowhere to put another box, I didn’t want to take a small one, in the end I decided that Delta was the best way out because it grows to the top and not in width, and after reading it, I found out that they are faster, more accurate and more cumbersome in setting, and this is of some interest. It’s also not a little, it was important that the device had a standard board in order to pour other people’s firmware and choose the best. Well, the most important thing is metal, at one time I had enough plastic CNC machines, and this was probably the most important condition.

It’s also not a little, it was important that the device had a standard board in order to pour other people’s firmware and choose the best. Well, the most important thing is metal, at one time I had enough plastic CNC machines, and this was probably the most important condition.

Purchase delivery and price:

I took it on Taobao: https://world.taobao.com/item/44964552708.htm?spm=a312a.7700714.0.0.IMqdo5#detail But this seller is also represented on Ali: http://ru.aliexpress.com/store/product/2015-3KU-Easy-Install-Metal-Structure-Delta-3D-Printer-with-One-Filament-and-LCD- for-free/1373025_32364813740.html?storeId=1373025&spm=a312a.7728556.0.0.03z6fjMost of this information will be useless, since this delivery method (shuttles) is available only in the border regions with China, but still, to estimate the scale of the disaster, I will give numbers, on at the time of purchase, the Yuan cost 11.1 rubles.

yuan Rules

Printer itself

1450 16095

Warm crib 150 1668

Inductive sensor

minimum

heights at Z 50 555

Delivery for China 0 0

Delivery to Russia 13 kg per 265p per Kg 3445

Total 21763

A sad story about how I tried to bring the first time through an unverified person who promised 150 rubles per kilogram when crossing the border, the result: a printer from the moment when I had money for it until the moment when I it took 4 months to get it in hand, in general, here the fool himself trusted the untested . ..

..

Unpacking:

The whole thing arrived in one box, in which, in turn, something was in boxes and something in a bubble wrap:

The first thing I got was exactly what was in the bubble wrap, they turned out to be mounts for steppers, they just impressed me and set me up for the fact that, in my opinion, my expectations were justified.

Oh yes, 3mm of metal and even with corner reinforcement, you can pull not a belt but a metal cable, okay, okay cable ....

A power supply was also found in the center of the pimple, obviously from some kind of laptop, although 12v 10A is something cool:

Then everything was packed in boxes of different sizes, in which everything was put either just in a bubble wrap or in a bubble wrap and a vacuum bag (wire boards and other heresy).

In the first box there were plain bearings, already pressed into the structure under the guides, the fact that they were dead there upset me a little, not repairable, but the thickness of the metal pleased me again: crap . ..

..

The only thing else that was at the bottom and was without boxes is the parts of the chassis, table, and rails. But at the same time, everything was laid and wrapped in a puffy, I must say that I have not yet pulled out so much garbage, the volume of the pimp and boxes is simply cosmic ... while the Chinese did not know that he would be taken to Russia ...

All structures made of 3 mm metal, I didn't really understand what it was. but this is not aluminum, since the metal is heavier, but not iron, since it is lighter, an attempt to deform it by hand showed that the metal is very strong.

The next thing that was extracted from the next box upset me a little, since it looked like a power mount and it was printed, and even with shitty filling judging by the weight and tactile sensations:

I’ll run ahead, I’ll say that these mount in general, they don’t play any role . .. but in the future, if I find a piece of aluminum, I’ll drink myself such ...

.. but in the future, if I find a piece of aluminum, I’ll drink myself such ...

Next in the box, inside the box in foamed polyethylene were 4 steppers:

Next, I had a complete misunderstanding, I found a warm bed, but what is it ??? :

In addition to the thermistor wires, it also pulled wires to the solid state relay ????

And yes, at the end there were wires and a plug for 220v ????

Haven't turned it on yet, but I have some doubts about the 220v crib... but we'll look further.

Further in the box, there were more plastic parts for the coil holder at the bottom, and the probe itself:

Next is a box with belts and at the very bottom of the rails and other metal structures:

All the electronics were in a separate box, but more on that later.

Assembly:

I will not show the video and make a detailed photo report, since the video is on the Internet, it is very well done and detailed, and the pictures . .. you see for yourself I take a picture on a pipe six years ago and even at night ... so poke your face boldly into the basin ... I will only go through certain points in brief ...

.. you see for yourself I take a picture on a pipe six years ago and even at night ... so poke your face boldly into the basin ... I will only go through certain points in brief ...

Assembly video 3KU In general, the whole structure is assembled easily, and has a rigid fixation of each part. The process is quite simple, although if you do not watch the video clip, you can specifically blunt it a couple of times.

The fixators of the structure also act as legs, I think then I will print out covers on them and there will be cool legs:

KOTE controls all the work:

When I put on the guides of the structure for hanging the head, I realized that everything fit just perfectly. to say that from now on I am changing my rating system and all those that I gave 5 out of 5 points for quality and fit, I reduce by one. Since here the fit is just a sniper fit of less than 0.1mm. Some parts even have to be pushed through with a little effort.

Assembling the top is also not difficult:

Having put all this on, I realized that it is not very small, the bandura is gone ...

In the assembly video, the Chinese says that you don’t have to take a steam bath and set the cover evenly, they say 1mm is enough , but I achieved the ideal, 10 minutes with an accurate tape measure ... and here is the result:

I will not show the assembly of the head, there is nothing interesting there, we hang 6 rails for the head, then we twist them to those on the main chassis, and that's all ...

I will say just that, if you look at the beginning, the tension mechanism looks somehow stupid and not convenient. 4 bolts than to pull how to twist, but it turns out that everything is just tightened from one side to the second, we press as much as we want, and tighten it in the same way. The stretch is obtained simply due to the effect of the lever, although not large, but sufficient to not strain . ..

..

Well, the moment has come when you need to hang up "Active Equipment":

Yes, the end stops come in the form of end stops, although they are good OMRON but still they are only end stops, I will almost immediately replace some parts, including the end stops, but so that the review was without embellishments, I mount only what was given.

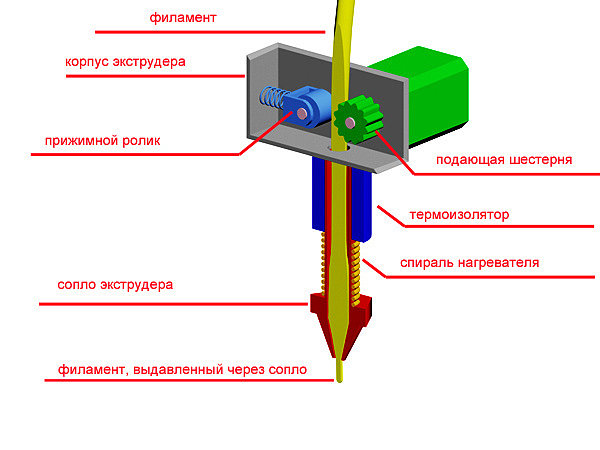

Well, now let's move on to special cases, and we will probably start with the DRIVE of the thread feed, and yes, I knew for sure that it was bad, I read, saw this model and read what they write about it:

Not spring-loaded, the upper part (movable) simply spins on a bolt without a bushing, and either you don’t tighten it and staggers, or you tighten it and the movable part turns into a fixed one, the edges of the gear are not sharp, but as if diamond-shaped, this also does not improve grip on the bar, there is a notch-channel only on the roller, which is also not very good, in general, I immediately ordered a separate set of this type:

220v, after joking on ali on tao-bao, I also didn’t find it, it happens very often and we all know about it that the Chinese brothers just throw us, but the question is why do it in general, it’s a very high-quality thing and do it at such a not very acute moment scam? especially since even a power supply with a large margin is provided. I decided to write to the Chinese and he very insistently said that yes he was at 220, but I don’t trust anyone and decided to check, first I examined the entire structure: 92/272 = 0.582 watt ... some kind of crap (from personal experience I’ll say that all heating elements plugged into a 220 socket have a resistance from 90 ohms to 150), well, now we’ll recalculate the same thing if we think that we have 220 volts and it comes out 177 Watt, but this already looks like the truth (we don’t throw slippers, the formulas are taken for direct current, they are not accurate, but the error is small, I kind of know everything, but it’s easier and clearer). I stick it directly:

I decided to write to the Chinese and he very insistently said that yes he was at 220, but I don’t trust anyone and decided to check, first I examined the entire structure: 92/272 = 0.582 watt ... some kind of crap (from personal experience I’ll say that all heating elements plugged into a 220 socket have a resistance from 90 ohms to 150), well, now we’ll recalculate the same thing if we think that we have 220 volts and it comes out 177 Watt, but this already looks like the truth (we don’t throw slippers, the formulas are taken for direct current, they are not accurate, but the error is small, I kind of know everything, but it’s easier and clearer). I stick it directly:

And it turns out that we have a current of 0.5 amperes, which gives us not very much power of 110 watts, but quite enough to boil water, which means everything is okay, the only question is why did the Chinese put such an expensive solid state relay? 10 A? and the answer is simple, he put what was at hand, or rather, his experience with printers and heating at 12 volts told him that he needed 10 amperes (110/12 = 9,2A) and 10 is just a smaller ceiling of what could be given. That's all, I will adapt the relay to another place, there is enough triac for 2 amperes with a head.

That's all, I will adapt the relay to another place, there is enough triac for 2 amperes with a head.

A video with a warm-up test will be later and if you want in the comments, I will give a link... on the side of the table, with a 3A automatic:

Well, here we come to the most important object that has not yet been illuminated here, and yes, it's not what you thought it was the power supply, the photo was higher, I see no reason to post his other photos:

Power supply 12v 10A, and he gives them to the defense, he left me only 11.2 with a smooth increase in load. That is, he answers the declared chorus.

In my case, here are the measurements:

The heating element draws: 5A, I'm shocked it comes out 60 watts, but I didn’t find more than 40 watts on sale

Brains: 0.11A

And that’s what piles on the power supply at a peak of 9.51, but as my device showed in an hour of printing, the average current was seriously more modest, only 6. 136A, in general, the power supply should be enough in any case. For 3 hours of non-stop printing, the power supply did not warm up at least a little noticeably by hand, so I don’t see the point in uploading photos with a pyrometer.

136A, in general, the power supply should be enough in any case. For 3 hours of non-stop printing, the power supply did not warm up at least a little noticeably by hand, so I don’t see the point in uploading photos with a pyrometer.

The last descriptive part will be devoted to the brains, there is nothing special to say, on board:

ARDUINO 2560

And the RAMPS 1.4 extension

The firmware in the Marlin version did not exactly get ahead of the version, but apparently about the 11th year.

I won't tell you about uploading and setting up the firmware for a long time, separately and lasts for weeks, there is no limit to perfection.

I will show you only the firmware and settings that the seller provided.

About the pouring process. I won't tell you too much either...

Startup and warm-up video: [48]

Print video: [49]

without any adjustments or adjustments.

All that day was over, I collected it at 5:30 pm and I did the first print at 1 am... , in general, a very small amount of material supplied, an article was found on the same site on how to set it up and settings were made, and accordingly a better result was obtained, in order to achieve an almost ideal, the axes and limit switches were set more accurately and evenly, actually here:

From left to right in order, stock printing, printing with set extrusion, printing with set limit switches...

As we can see the increase in quality on the face, well, then immediately began to print holders for opto limit switches, and other heresy...

Further there will be only upgrades and utilitarian use, but more on that separately ...

Conclusions: it is recommended to buy everything is very well machined, everything works, in general, there are almost no complaints.

3D Steel Printing - Quick Guide / Sudo Null IT News0001

Metal 3D printing using pure steel and alloys produces durable functional parts for mechanical and industrial products.

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts?

Let's see how a 3D printed steel part revolutionizes manufacturing and opens the door to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts.

Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal)The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes stronger, than traditionally made. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc.

It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc.

Printed steel parts are used in the aerospace industry, the military, and for example the footbridge shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Queen Maxima of the Netherlands officially opens a 3D printed metal bridge. Photo by Adriaande Groot (Source: MX3D)A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts.

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture.

The main advantage of steel printing is not only its strength, but also its unique ability to create internal channels and lattice fillings in parts, which is impossible with traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength.

MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D) Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product.

When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product.

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants.

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc. ), then all these parameters can be incorporated into the product at the production stage.

), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive)There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods.

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to gain increased corrosion resistance while being easy to machine and polish.

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties, and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast.

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

BCN3D's Epsilon Printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced.FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts.

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts.

(Source: BCN3D)While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Ideal use cases for this technology are metal prototype parts and finished parts that will not be subjected to extreme stress.

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal) Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required.

This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required.

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel.

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal tools.

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer.

LPBF 3D printers come in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Binder Jetting

Binder 3D printing technology uses powdered metal and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to parts made by injection molding metal.

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels.

HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels.

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer.

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries.

That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries.

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen, or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation.

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in automobiles can be susceptible to thermal repair methods such as welding.

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D)Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining.

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost savings. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field.

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint)Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts.