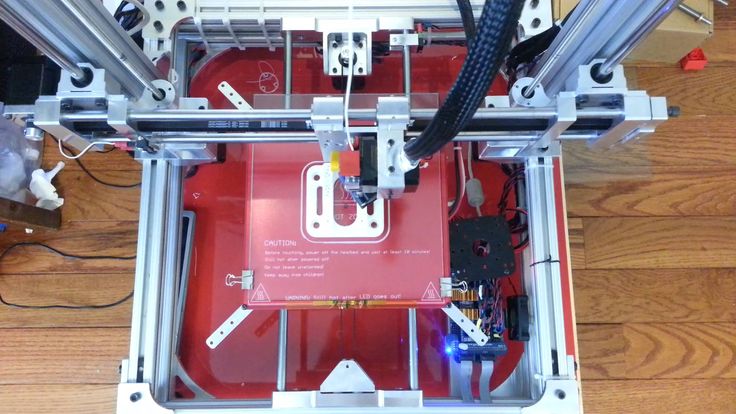

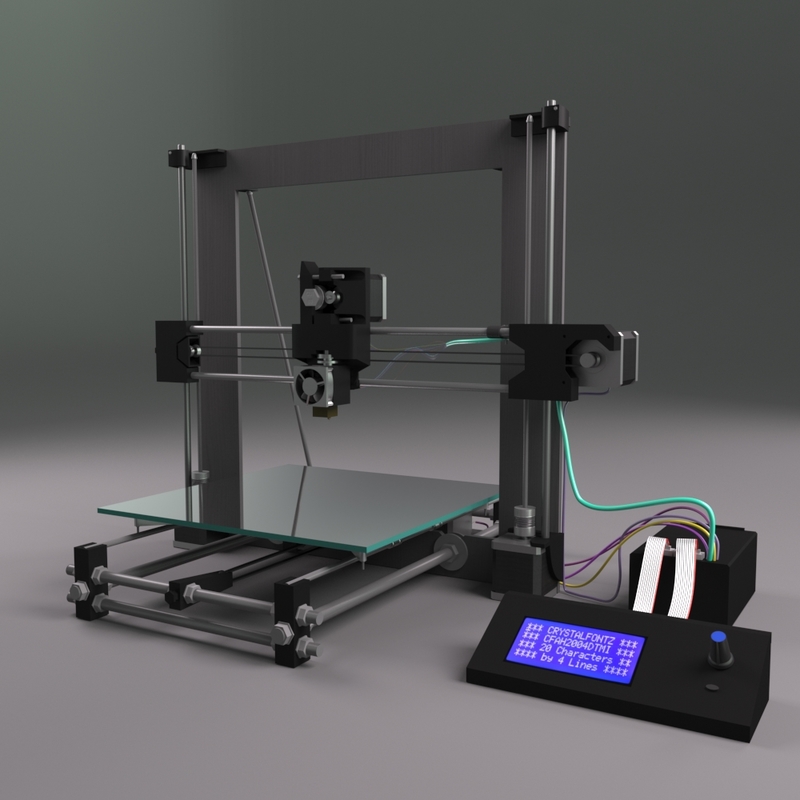

Carbide 3d printer

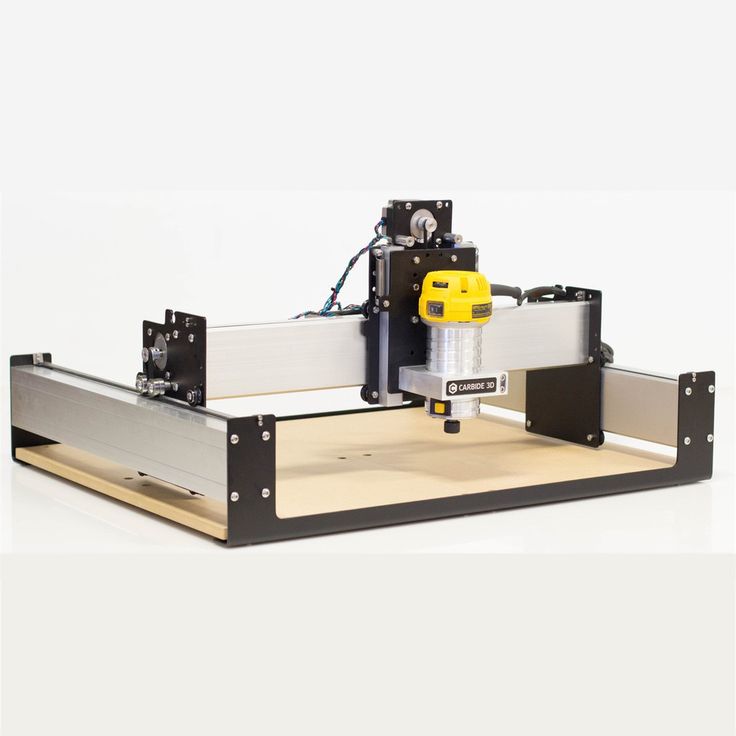

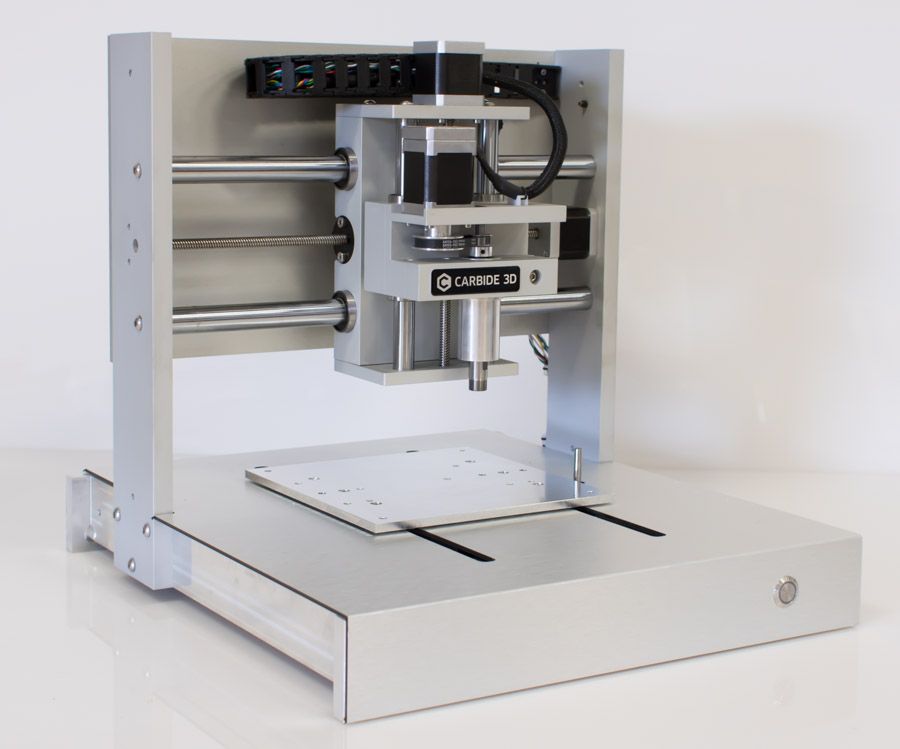

Shapeoko CNC Router, Rigid, Accurate, Reliable, and Affordable

Take Your Woodworking to a New Level

Shapeoko gives you higher precision, higher productivity, and the ability to take on projects that you can’t do any other way.

You’ll be limited only by your imagination, not by your tools.

You know what else you might make? Money.

Over half of our users make money with their Shapeoko CNC Routers.

Some people start out with the intent to sell products, others just show friends what they’ve made and answer “yes” to the inevitable question, “Can you make one for me?”

Learn to Make Money with CNC

Shapeoko Pro

Shapeoko Pro uses high-performance linear rails for added rigidity and cutting performance.

Shapeoko Pro XL

Cutting Area: 33" x 17.5"

Starting at $2600

Buy Now

Shapeoko Pro XXL

Cutting Area: 33" x 33"

Starting at $2800

Buy Now

Shapeoko 4

Shapeoko 4 uses V-wheels for lower cost and lower maintenance.

Shapeoko 4 Standard

Cutting Area: 17.5" x 17.5"

Starting at $1700

Buy Now

Shapeoko 4 XL

Cutting Area: 33" x 17.5"

Starting at $2050

Buy Now

Shapeoko 4 XXL

Cutting Area: 33" x 33"

Starting at $2300

Buy Now

Which Shapeoko should I buy?

The Shapeoko 4 is around 80-90% of the performance of the Shapeoko Pro, so there’s not a bad decision to make between the two.

-

If you’re going to use it all the time, or you’re the ultimate tool nerd, grab the Shapeoko Pro as long at the price difference isn’t a problem for you.

-

If you’re going to use it intermittently, or if you prefer a less expensive option, then grab the Shapeoko 4, the V-wheels are lower maintenance than the linear rails.

Whichever version your choose, you Shapeoko CNC Router will become one of the most productive power tools in your shop.

Believe it or not, the machine is the easy part.

Shapeoko is a rigid, accurate and reliable CNC router, but the CNC machine itself only gets you halfway there. You’re going to need a lot more than just a machine to complete a project. Luckily, we include all of that too!

Hybrid Table

Shapeoko Pro is built on our Hybrid Table, and the same Hybrid Table is available as an option for the Shapeoko 4. It acts as a rigid base for the machine and a very flexible workholding system.

Structurally, it’s made from a grid of custom-made extrusions that create a solid platform to build a CNC router on.

The Hybrid Table has a series of T-slots to hold clamps, vises, or the material being cut directly.

Between the T-slots, there are sacrificial MDF slats for your material to rest on.

Workholding Included

Shapeoko 4 and Pro come with a dirty dozen of our Teez-Nutz and six of our fiber-reinforced nylon Essential Clamps that won’t break your cutter if they get hit.

When paired with our Hybrid Table, this is everything you need to hold down many common materials but we have plenty of other options if you find that you want something more specialized.

- Tiger Claw Clamps

- Gator Tooth Clamps

- Lock Stops

- Corner-Square

Dust Collection Included

Shapeoko includes our Sweepy V2 dust boot to help keep your Shapeoko CNC router, and your shop, as clean as possible. It works with a range of hose diameters for maximum compatibility with your vacuum:

- 2.5” Direct hose

- 2.25” Shop vacuum

- 36mm Festool/Fein

Sweepy V2 also includes an additional brush-free base if you want maximum visibility at the expense of a little dust.

BitSetter Included (PRO ONLY)

Shapeoko Pro has a built-in BitSetter, our system that makes tool changes a breeze by automatically tracking changes to tool length.

Out of every accessory we’ve ever made, the BitSetter is our favorite.

BitSetter is available as an add-on for Shapeoko 4 here.

Carbide Create 2D CAD/CAM

Carbide Create is our 2D CAD/CAM computer program for your Windows or Mac. Carbide Create lets you design your projects and then define the toolpaths to actually cut them out. You can start with a blank page, load a DXF or SVG file, or load an image to trace automatically.

The best part is that Carbide Create is totally free so you can try it out today.

Carbide Motion

Carbide Motion loads gcode, the industry standard for CNC routers, and makes the machine follow that motion.

We follow common gcode standards so you can generate your projects in Carbide Create or any other CAD/CAM program that uses normal gcode. We don’t lock you into our CAD/CAM software.

CutRocket- Projects Ready-to-Cut

If you’d like to start with complete projects that others have shared, we’ve got our CutRocket CNC project sharing site.

Unlike other project sharing sites, CutRocket is only for CNC projects so you won’t find a bunch of stuff made for 3D printers.

Download projects and start cutting right away.

(We’re sure that you’ll be uploading your own projects in no time.)

A Vibrant Community of Fellow Users

The Carbide 3D community is full of other Shapeoko owners doing everything from playing around in their garage to making a full income from their machines. You’ll find the community eager to help, inspire and teach.

Once you’re up and running, jump in on our Community Challenges and compete with other members (and maybe win some free stuff)

Warranty and Support

One-year warranty

Shapeoko comes with a one-year warranty against defects. If you have any problems, we’ll take care of them.

See our warranty here.

30 Days, "Mistakes are On Us"

We want you to jump into your new Shapeoko CNC router without any fear of damaging anything so our warranty includes the following benefit:

For the first 30 days that you own your Shapeoko, we’ll replace any Carbide 3D-branded item that’s damaged, even if it’s your fault.

Details can be found here.

Unlimited US-based support

If you need help, we are available via:

- Phone

- Video Chat

- Scheduled video training session

Contact us here.

What's in the box?

Shapeoko 4 and Shapeoko Pro ship with:

- Shapeoko CNC Router

- All tools required for assembly

- 12 Teez-Nutz

- 6 Glass fiber-reinforced nylon clamps

- Sweepy V2 65mm

- Qty 1, 1/4" carbide endmill

- BitSetter (PRO ONLY)

- Carbide Create 2D CAD/CAM software

- Carbide Motion

- Free shipping in the US and Canada

What you need to provide:

- PC or Mac computer

- Shop vacuum

- Carbide Compact Router or other 65mm trim router.

- Material to cut

Customize your Shapeoko with a full range of accessories

What are people saying about Carbide 3D?

Awesome!!! Quick fix!!!! Thank you so much! Your customer service is 2nd to none, incredible.

Chad B.

Thank you so much for your assistance. I have a few friends interested in your machines I will definitely recommend you guys to them all. You guys are awesome.

Eric B.

I’ve been cncing with your product for a little over a year now and went through 2 upgrades. I’m very pleased with your product and you also have amazing customer service. I’ve recommended and will continue to recommend your products to others. Keep up the good work.

James M.

Frequently Asked Questions

Shapeoko takes 2-3 hours to assemble. Most of that time is spent on the Hybrid Table, which has a lot of screws, but the payoff is a rigid machine with great workholding.

Yes! Shapeoko can run 2D or 3D toolpaths with all motors moving simultaneously.

Shapeoko itself is very quiet. All of the noise comes from the spindle (a trim router) and the shop vacuum, if you use one.

Unfortunately, we've done the math on the and it ends up being cost prohibitive to upgrade from a Shapeoko 4 to a Shapeoko Pro.

You cannot upgrade the size of a Shapeoko 4 or Pro. Upgrading from one size to another doesn't save much money from the price of a new machine.

Shapeoko 4 and Pro and use any 65mm spindle including the Carbide Compact Router, Makita RT0701C trim router, or our 65mm VFD spindles.

We have a lot of users running Vectric software with their Shapeoko.

Fusion 360 comes with a Carbide 3D post processor that works with Shapeoko.

Shapeoko can cut any type of wood from pine, to MDF, to hard woods like white oak.

Shapeoko can cut any common plastic including ABS, acrylic, polycarbonate, Delrin, HDPE, and PEEK

Shapeoko can cut aluminum but it will cut slower than wood and plastic so you'll want to take your time with it.

Shapeoko can cut brass but it will cut slower than wood, plastic and aluminum so you'll need to take your time with it.

Shapeoko can cut brass and aluminum but harder metals, like steel or stainless steel, are not recommended. We have users that have done it, but cutting steel takes a lot more skill and experiance.

Shapeoko works with most free CNC software, but it also includes our Carbide Create so there's nothing more to buy.

Have more questions?

Get in touchReady to get your own Shapeoko?

Join tens of thousands of other Shapeoko owners.

(Yes, it might just be the best-selling CNC router of all time.)

Buy Now

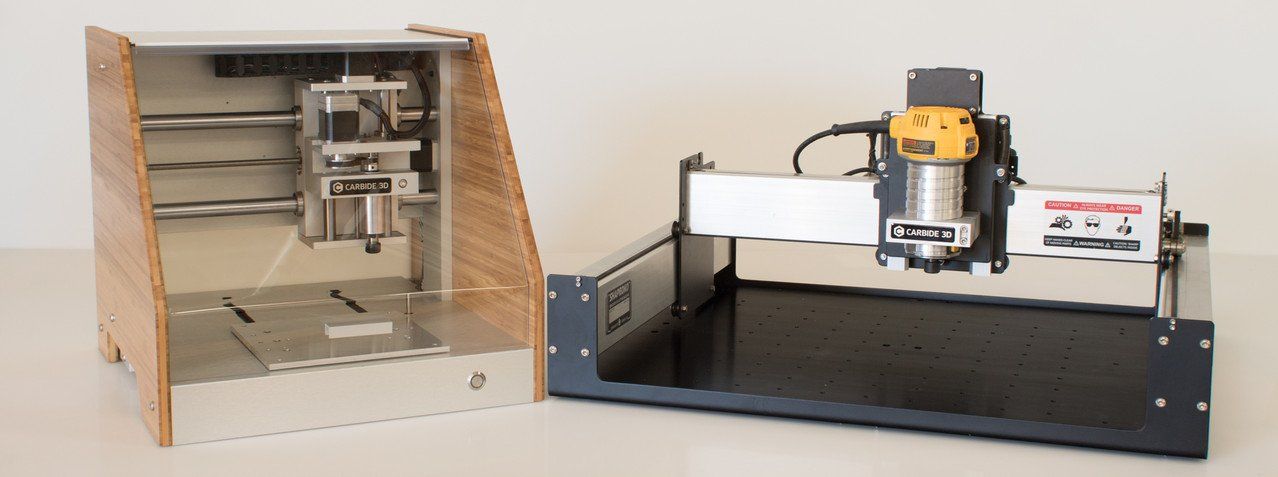

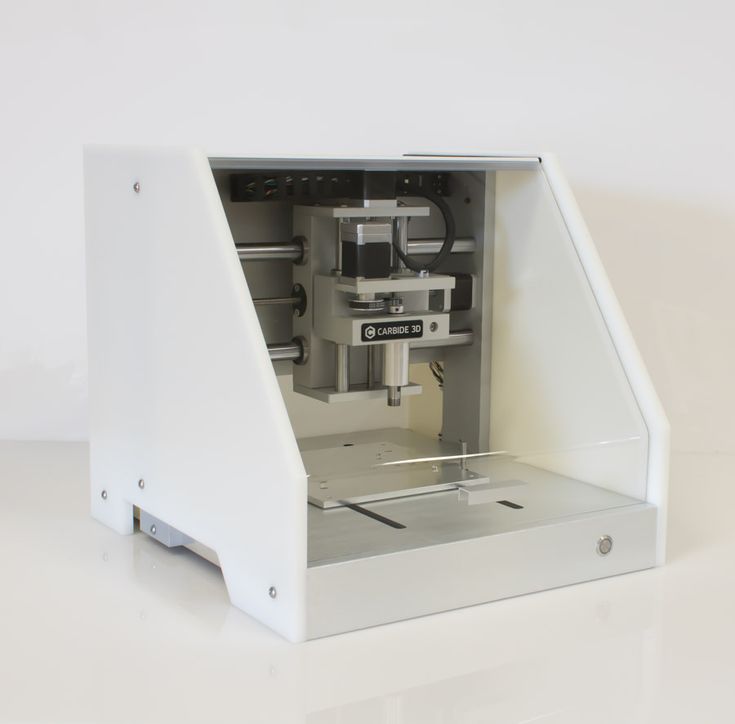

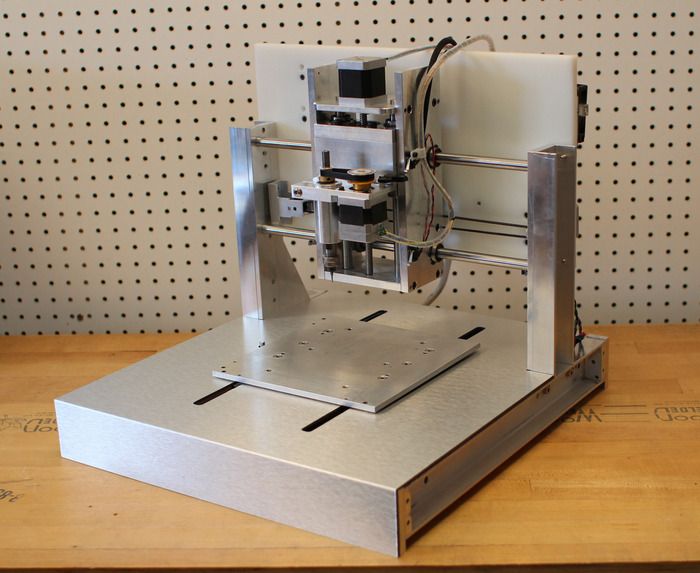

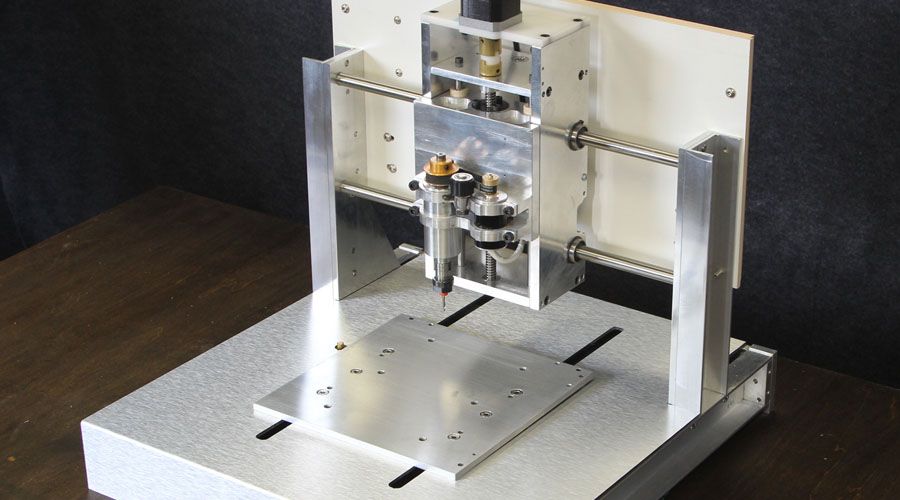

Nomad Desktop CNC

CNC machines are capable of making beautiful parts– if you know how to use them.

The Nomad 883 Pro is not just another desktop CNC machine, we designed it to make CNC machining something that normal people can do.

All of the complexity of traditional CNC machines is handled in the background.

This is only possible because of our highly-integrated hardware and software, something that isn’t possible if you have to find your own software to run the machine.

While our Shapeoko CNC Router and Shapeoko HDM have a large cutting area with a lot of power, the Nomad is built to take up minimal space and cut a wide variety of materials without making a mess.

The Nomad 883 Pro includes all of the hardware and software you need to take your 3D file and make a part. We’ve taken the uncertainty and frustration out of the equation, just open the box and get started.

Make Prototypes

Whatever materials you need to work in, whatever CAD program you use, the Nomad can do it.

Make Jewelry

Whether you work in wax or directly in metal, the Nomad is capable of the fine detail you need.

Make PCB's

The Nomad has the precision to do PCB milling with ease, even with SMT components.

Plastic is Easy

Plastic machines really well on the Nomad: HDPE, Delrin, acrylic, polycarbonate, and more.

Wood is No Problem

Any kind of wood is suitable for the Nomad, from pine to maple, oak, or the even more exotic species.

Cut Small Metal Parts

Soft metals, like aluminum and brass up to .25" thick cut well on the Nomad.

Engrave Parts

The Nomads spindle is fast and has low run out- it's perfect for engraving jobs.

Cut Inlays

The Nomad is accurate enough to cut inlays and pockets that fit together perfectly.

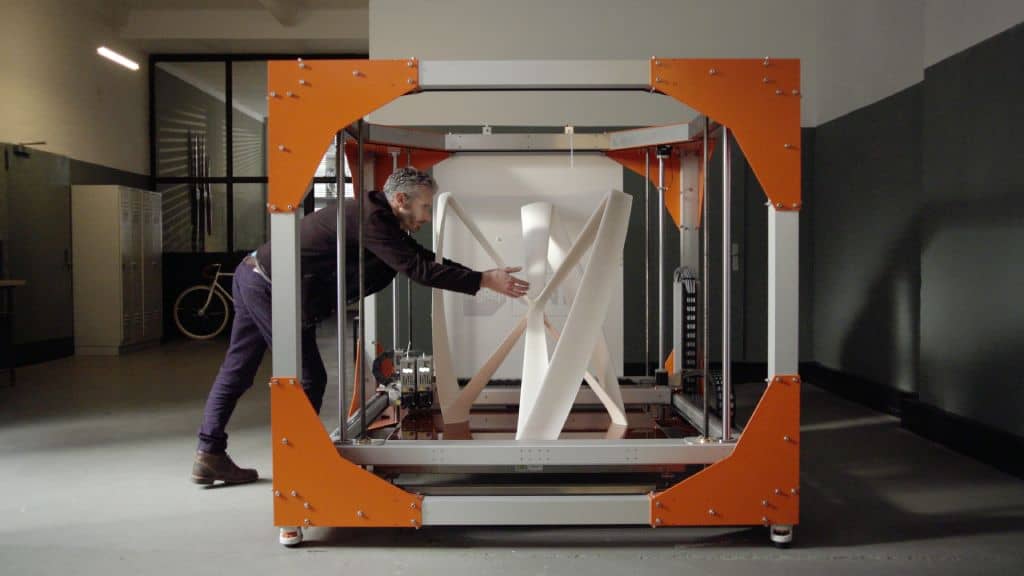

Full 3D Cutting

You're not limited to simple 2D cuts. The Nomad can do complex, flowing organic shapes with ease.

Who's it for?

- Electrical Engineers

- Mechanical Engineers

- Educators

- Industrial Designers

- Woodworkers (One more here)

- Jewelers

- Crafters

- Hobbyists

- Manufacturers of customized products

Is it for you? Ask us! There’s nothing we enjoy more than talking about CNC machines. We’d love to talk to you about your application.

We’d love to talk to you about your application.

A Big Machine in a Small Package

The Nomad 883 Pro’s small footprint means that even fully enclosed, it takes up about as much space as an inkjet printer or desktop 3D printer. Our desktop CNC turns your desktop into a workshop.

- Cutting Area: 8” (X and Y), 3” (Z)

- Weight: 65 Lbs

- Spindle Speed: 2000-10,000 RPM

- Spindle Power: 70 Watts

- Power: 110/220V, 2 Amps

- Operating Systems: Windows 7,8.1, 10, OS X 10.9, 10.10, 10.11

More Details…

A Complete Software Solution

A CNC machine is not worth much without the software to drive it, and most of them, don’t come with any software to help you complete your projects. The Nomad 883 Pro comes with all the software you need to make parts:

- Carbide Motion - Your machine controller

- MeshCAM - 3D CAM Software to help machine your existing CAD files

- Carbide Create - 2D CAD/CAM if you need to start from a blank page.

See more here

See more here

If you have a favorite CAM program and work flow The Nomad 883 will work with it. Carbide Motion can read gcode from any CAM program so you’ll never be locked into proprietary software.

MeshCAM, Carbide Create and Carbide Motion are cross-platform so you can run them on a Windows or Mac computer.

A Real Spindle for Real Work

What does that mean for you?

The Nomad 883 Pro has a durable and quiet spindle that’s capable of cutting a variety of materials without being so loud that it drives you out of the room.

Award Winning

The Nomad 883 was named “Best CNC Mill” by Make: Magazine in their “Ultimate Guide to Desktop Fabrication 2016” based on testing by 16 industry experts.

Everything is Included

The Nomad 883 Pro is ready to go the first time you power it on.

It includes:

- Windows and Mac control software

- MeshCAM 3D CAM software

- 2D CAD/CAM software

- Cutters to get started

- Material to get started

The only thing you need is a Mac or Windows computer.

Learn more

That’s just a quick introduction to The Nomad 883 but it’s full of other great features.

Show me more…

Made by Makers

We’ve spent our careers in product design and manufacturing. We’ve been on the hook to turn around prototypes and concept models in record time so we know what it takes to get that done. The Nomad 883 Pro was designed to be the machine that we wanted years ago, during those late nights and long weekends. We know that you don’t want to spend weeks learning a new tool. We know you just want to get your parts made quickly.

The Nomad 883 Pro was designed to help you complete your project now, not to become it’s own project.

3D printer in the creation of printed circuit boards (again)

Personal diaries

And I came across a curious thing that I had not seen before, I was inspired by Lamja https://www.lamja.com/?p=635

The bottom line is that a person attached a simple scriber and outlines the contours of the road on foil fiberglass, etching everything accordingly this later:

I decided to do something similar. Ato like this, the printer appeared and there is nothing to print.

Ato like this, the printer appeared and there is nothing to print.

I took the rod from an old dvd-rom, and after weighing the guides, I decided to make it from 603 bearings.

Still, I didn’t like the speed of the cutter-scriber transitions in the jerking of the table to raise and lower it. It was decided to plunge the coil from the relay and hook it onto the blower fan. Wiring prudently brought out the side of the future.

I really liked this solution for its speed. I tested it on a regular marker and was satisfied with the results. He continued his research already on the trail. day

The next day, I already bought alkyd and acrylic enamels for testing and was disappointed. The coatings turned out to be too strong, the steel scriber, even when sharply sharpened, simply glided over them. In addition, she also tore the acrylic enamel, which was not completely frozen, in shreds. I remembered that I had carbide needles for scriber with alik lying around, I decided to make them:

I remembered that I had carbide needles for scriber with alik lying around, I decided to make them:

Yes, yes, I know that it is not coaxial, that it will scroll, but surprisingly nothing scrolled when moving))

Have you ever seen a ferric chlorine homunculus left in a cupboard for two years? I see a bleach crystal for the first time o_O

The first variant in five launches with a conventional steel tip, I managed to dig through the layer, but the result is bad:

Single pass carbide scriber. Cleaning zone 0.5mm. in 5 lines. The width of the tracks for the controller is 0.2mm.

And having already dealt with the settings, I made the last two results, although while taking boards from bleach for a piece of electrical tape, I damaged part of the outlined:

In general, I am pleased with the results and I am going to do this with an auto-power board for the printer. Whatever you say, but with irons it is certainly possible. But I've always been all about printers. Very quickly, the drums fell into disrepair. Yes, and tracks thinner than 0.3mm are already a lottery. nine0003

Whatever you say, but with irons it is certainly possible. But I've always been all about printers. Very quickly, the drums fell into disrepair. Yes, and tracks thinner than 0.3mm are already a lottery. nine0003

Track insulation test with 100500kV super penetration tester

printed circuit boards sapphire pro SapphirePro

Subscribe to the author

Subscribe

Don't want

11

German scientists have developed an additive system for multi-material 3D printing with metals and ceramics

News

Subscribe to the author

Subscribe

Don't want

3

Scientists at the Fraunhofer Institute for Ceramic Technology and Systems (Fraunhofer IKTS) have designed an inkjet 3D printer, including multi-materials and metal products, capable of printing simultaneously from several materials and metal .

The pilot additive plant relies on a system of micro-dispensers that apply heated to a liquid mixture of low-melting thermoplastic with fillers of the required materials - metal or ceramic powders. The thermoplastic serves as a binder - a binder that maintains the shape of the workpieces before annealing and sintering into finished products. The experimental system is able to work with four materials simultaneously. nine0003

The equipment heats mixtures to 100°C and applies up to a thousand microdroplets with a diameter of three hundred microns to one millimeter per second, forming layers with a thickness of one hundred to two hundred microns. The linear speed of the press reaches 60 mm/s. The current version allows you to print blanks up to 200x200x180 mm.

“Currently we can work with four different materials at the same time. The critical factor here is the dosage of ceramic and metal mixtures. The correct dosage is the key to obtaining the required characteristics and functionality of the final 3D printed product after sintering, including strength, thermal and electrical conductivity,” says Uwe Scheithauer, one of the authors of the project. nine0003

nine0003

One of the options for applying the technology is 3D printing of integrated ignition systems for ceramic engines for spacecraft. The combustion chamber must be able to withstand high temperatures, so ceramics seem like a logical choice. Thanks to the possibility of 3D printing with ceramic and metal materials, it is possible to simultaneously integrate conductive elements directly into the engine design. A more “mundane” example is the 3D printing of two-tone ceramic bezels for luxury watches. Another option is the production of carbide tool blanks. Due to the sufficiently high resolution of 3D printing, this would save on the post-processing of the cutting tool to the finished look. nine0003

Microdosing system rendering

The next stage of work will be the qualification of the technology for industrial application. The team plans to present a report on September 16-17 at the online conference of the German Ceramic Society.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru .

ru .

ceramics metal Fraunhofer IKTS jet

Follow author

Follow

Don't want

3

Article comments

More interesting articles

12

Subscribe to the author

Subscribe

Don't want

Jetson One is an eight-engine electric aircraft designed for one person. The design uses...

Read more

7

Subscribe to the author

Subscribe

Don't want

An exoskeleton is being developed at the Moscow Polytechnic University to correct musculoskeletal disorders.