Loctite 3d printing resin

iMakr | Loctite Resins | 3D Printing Resins

The LOCTITE 3D portfolio of resins manufactured by Henkel overcomes the limitations of conventional 3D printing materials and offers the capability of producing truly functional parts, changing rapid prototyping to rapid manufacturing. This high quality range of resins offers best in class performance for mechanical properties, flame retardancy, elasticity and temperature resistance, and is compatible with a wide range of 3D printers.

Browse the selection below, or contact us now to find out how you can transform your prototyping and manufacturing workflow.

- Show Sidebar

Sort by:

- New

$180.00

$145.00

$180.00

$37.50

$199.00

$180.00

$430.00

$430.00

$180.00

$250.00

$230.00

$360. 00

- New

$180.00

Extremely tough resin from world-leading polymer manufacturer, Henkel. This Loctite resin has been fully tested and certified to be printable on Carbon 3D printers.

$145.00

The Henkel Loctite PRO476 resin is a high Strength Tough Polymer with good surface finish designed to work on LCD Printers. Achieve results comparable to ABS.

$180.00

Henkel LOCTITE 3D IND405 HDT50 High Elongation is a tough, high impact resistant resin with a great surface finish. An extremely durable material which excels in applications such as tool production, manufacturing aids and final parts.

Black Clear

$37.50

Perfect for LCD Machines.

The Henkel Loctite PRO410 resin is a fast printing, rigid photopolymer with ultra high resolution printing. The PRO410 is formulated to produce excellent surface finish with precise print accuracy.

$199.00

Henkel Loctite 3D 8195TM is an elastomeric 3D printing resin is designed for functional prototyping via stereolithography. It is formulated to have firm compression properties with extremely quick rebound performance to emulate soft rubber materials. It can be printed with high-resolution and excellent surface finish across various SLA and DLP printer platforms.

It is formulated to have firm compression properties with extremely quick rebound performance to emulate soft rubber materials. It can be printed with high-resolution and excellent surface finish across various SLA and DLP printer platforms.

Grey Red

$180.00

The Henkel Loctite 3172 is a tough resin that allows the user to produce functional parts that require a high stiffness and durability with a good surface finish and high impact resistance.

Grey Clear

$430.00

Available in either Ultra Clear or White. The Henkel Loctite MED412 medical resin is a strong, durable material with excellent elongation, impact strength and surface finish. Ideal for single use medical devices.

White Transparent

$430.00

Henkel Loctite MED413 is a medical grade resin with excellent flexural and tensile properties. Ideal for a wide range of impact resistant medical devices such as hearing aids. Fully sterilisable and biocompatible.

White Transparent

$180.00

The Henkel LOCTITE 3D 3843 HDT60 resin is a high toughness resin created with the user in mind. This is an engineering plastic used in the production of tools.

Black White Grey Clear

$250.00

This Henkel Loctite high elongation elastomeric photopolymer has great resilience to compression. It is the ideal material for midsole and soft applications. The material is available in black.

Black Grey

$230.00

The Henkel LOCTITE 3D IND406 resin is a tough, rigid resin for the production of tools on the productions floor, industrial applications and more. The material is available in black or clear and comes in a selection of different sizes.

$360.00

The Henkel LOCTITE 3D 3955 HDT280 FST is a halogen free, high performance flame retardant 3D printing resin with excellent flexural and tensile physical properties. The material is available in black, in both 1 litre and 5 litre bottles.

Back to top

Loctite 3D Printing Resins – Adia Inc.

-

LOCTITE 3D 3172 High Impact

LOCTITE 3D 3172 High Impact

- Regular price

- $180.00

- Sale price

- $180.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 3818 High Accuracy

LOCTITE 3D 3818 High Accuracy

- Regular price

- $165.00

- Sale price

- $165.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 3820 Ultra Clear

LOCTITE 3D 3820 Ultra Clear

- Regular price

- $154.

00

00 - Sale price

- $154.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 3840 Semi Rigid

LOCTITE 3D 3840 Semi Rigid

- Regular price

- $154.00

- Sale price

- $154.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 3843 HDT60 High Toughness

LOCTITE 3D 3843 HDT60 High Toughness

- Regular price

- $220.

00

00 - Sale price

- $220.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 3860 HDT180 High Heat

LOCTITE 3D 3860 HDT180 High Heat

- Regular price

- $225.00

- Sale price

- $225.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 5010 A60 Elastomeric

LOCTITE 3D 5010 A60 Elastomeric

- Regular price

- $290.

00

00 - Sale price

- $290.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 5015 A80 Elastomeric

LOCTITE 3D 5015 A80 Elastomeric

- Regular price

- $280.00

- Sale price

- $280.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D 8195 A80 High Rebound

LOCTITE 3D 8195 A80 High Rebound

- Regular price

- $199.

00

00 - Sale price

- $199.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D IND147 HDT230 Tough Natural

LOCTITE 3D IND147 HDT230 Tough Natural

- Regular price

- $260.00

- Sale price

- $260.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D IND402 A70 High Rebound

LOCTITE 3D IND402 A70 High Rebound

- Regular price

- $300.

00

00 - Sale price

- $300.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D IND403 HDT80 High Modulus

LOCTITE 3D IND403 HDT80 High Modulus

- Regular price

- $230.00

- Sale price

- $230.00

- Regular price

-

- Unit price

- /per

Sale Sold out

-

LOCTITE 3D IND405 HDT50 High Elongation

LOCTITE 3D IND405 HDT50 High Elongation

- Regular price

- $180.

00

00 - Sale price

- $180.00

- Regular price

-

- Unit price

- /per

Sale Sold out

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

Rapid Shape joins Henkel Open Materials Platform

You are here

Home

14.00

Normal

0

false

false

false

RU

X-NONE

X-NONE

German 3D printer manufacturer DLP Rapid Shape partners with Henkel to speed up production of functional materials parts through 3D printing. As part of the agreement, Rapid Shape has become a member of Henkel's open materials platform and will handle material certification for its DLP 3D printing systems. Henkel, for its part, is integrating Rapid Shape technology into its AM ecosystem. nine0005

Henkel, for its part, is integrating Rapid Shape technology into its AM ecosystem. nine0005

To date, Rapid Shape and Henkel have already tested a range of high performance materials on Rapid Shape I30+ 3D printers. The goal is to offer users a wide and comprehensive selection of high performance materials to open mass production applications in industries such as the medical sector and others.

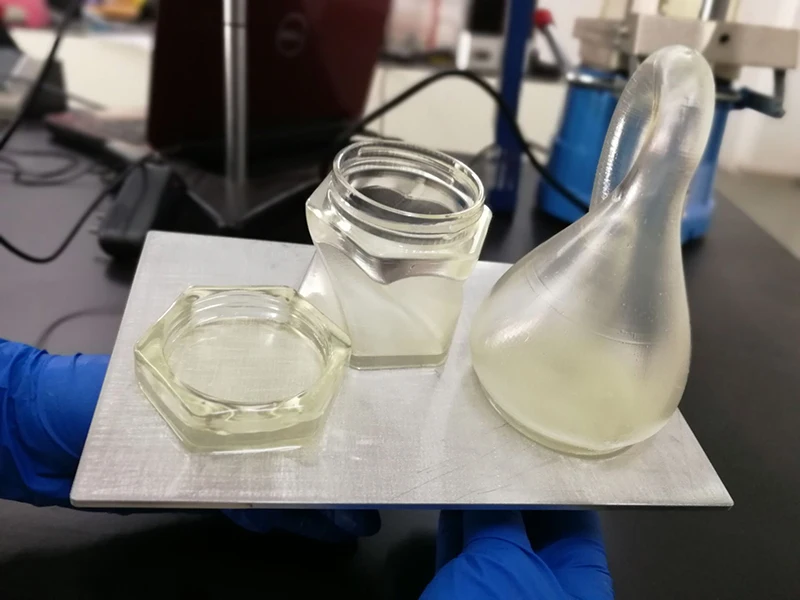

For example, Henct Loctite 3D 3820 ultra-pure resin is suitable for the production of transparent visual inspection parts, lenses, caps and other parts for the medical or industrial sectors. nine0005

DLP Rapid Shape 3D printing technology is based on the patented Force Feedback DLP process, which provides good printing speed and quality. The company's additive technology has been adopted by various industries, but especially has become a key platform for high-end dental laboratories and the medical sector.

Henkel first launched its open materials platform in May 2019 to work directly with 3D printer manufacturers to qualify new materials for the various AM platforms in the market. The company recently released a new material for use on Origin 3D printers, a 3D photopolymer material with fire, smoke and toxicity resistance properties. nine0005

The company recently released a new material for use on Origin 3D printers, a 3D photopolymer material with fire, smoke and toxicity resistance properties. nine0005

Both Henkel and Rapid Shape will be on display this week at Formnext in Hall 12.1 Stand C41 and Hall 11.1 Stand A11 respectively.

Author: Tess Buassone

Source

14.00

Normal

0

FALSE

FALSE

FALSE

FALSE 9000 RU

X-None

0 9000 9000 9000 9000 9000

Other materials:

- Lamps made from recycled CDs

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA standard resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear nine0105

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Class I biocompatibility vs Class IIa biocompatibility

- Cast SLA resins

- Cast resin for jewelry making ) , rubber -like ( flexible ) , Dental ( Dental ) ).

The information from the article will help you choose a photopolymer resin for your needs.

The information from the article will help you choose a photopolymer resin for your needs. Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail, and a smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties nine0005

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties. nine0005

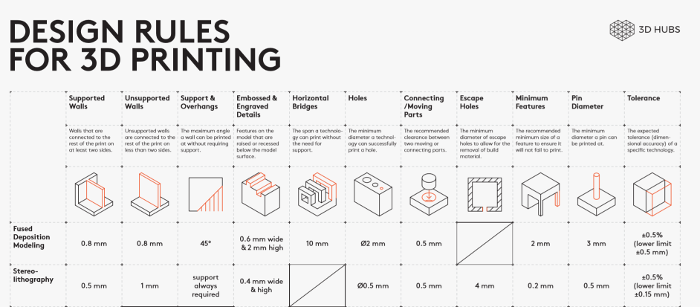

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - StandardStandard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes. nine0005

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing. nine0013

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)Tough resin was developed for models that need to withstand high loads and be durable.

nine0005

nine0005 This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

nine0005

nine0005

Refractory Photopolymer Resin - Formlabs High Temp ResinThe heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0005

Pros:

Cons:

Flexible ResinRubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0005

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0005

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0005

Ceramic photopolymer resin - Rigid ResinThis resin is reinforced with glass, which provides very high rigidity and a polished surface.

The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

The polymer is very resistant to deformation and is excellent for 3D printing thin elements. Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0005

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0005

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material.

Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon. tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0005

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0005

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media.

Image courtesy of Formlabs.

Image courtesy of Formlabs. Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0005

Comparative chart of material properties of various technical resins. Image credit: Formlabs.

Dental and medical resins

Photopolymer resin for medical devices - Custom Medical Appliances 9000 (Bi -1 BiUSTIC) Class 1 biocompatible resins can be used to make medical equipment such as surgical guides. Parts printed on this resin can be steam sterilized in an autoclave for direct use in the operating room. nine0005Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A Biocompatible) 0203These resins are specially formulated for long term dental fixtures.

Class 2A biocompatible resins can come into contact with the human body for up to a year.

Class 2A biocompatible resins can come into contact with the human body for up to a year. High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0005

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0005

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0005

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resinsThis material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Learn more

-