Best 3d printer for tpu filament

The 7 Best 3D Printers for Flexible Filaments – TPU/TPE – 3D Printerly

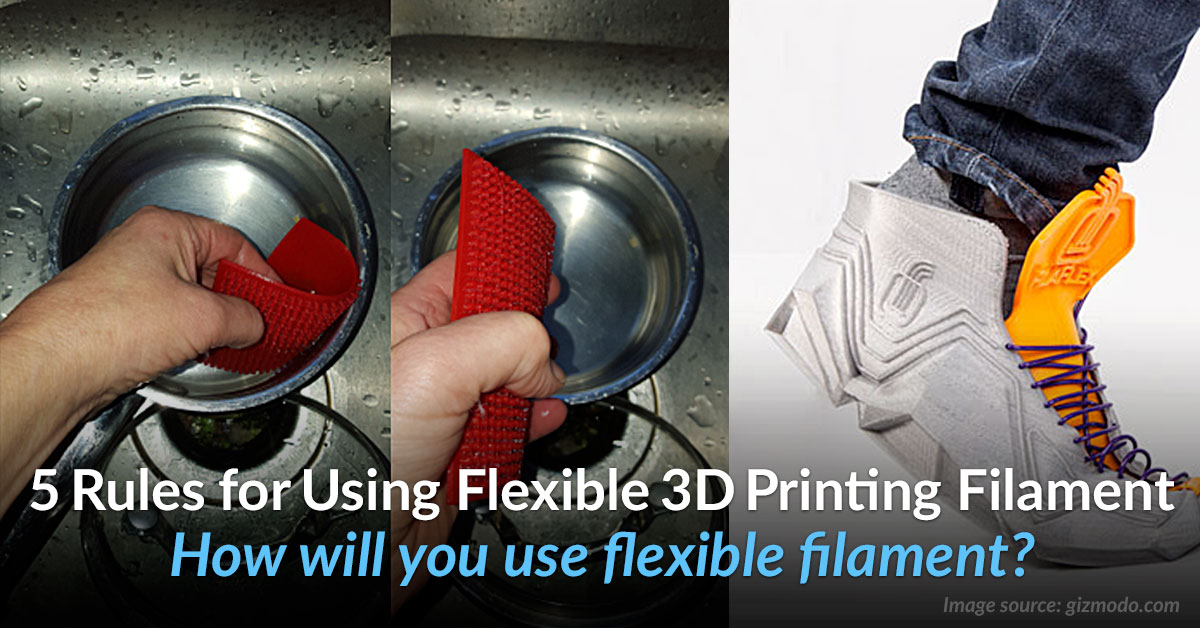

There are tons of amazing materials you can print with and enjoy when 3D printing. One of those materials that are well-loved is flexible filaments known as TPU and TPE.

There is a certain level of ability your 3D printer needs, however, to be able to print with these flexible materials. Rather than purchasing any 3D printer, you’re better off choosing a specific 3D printer which prints flexible material straight away, without any upgrades and tinkering.

This article will list 7 of the best 3D printers out there for printing with TPU/TPE so stay tuned for some great options. But first, let’s take a look at how you can choose the best 3D printer for the type of filaments in question.

QIDI Technology is widely known for its production of premium range 3D printers, and the X-Pro (Amazon) kicking off this list, is no exception to their far-flung excellence.

This machine has a price tag of somewhere around $499 if bought from Amazon and quite honestly has measured to be very affordable for the number of features it has.

First off, there’s a unique Dual Extrusion system that has been mounted on the X-Pro.

This means that instead of one nozzle, you get two at your disposal, both of which are highly suited for the likes for flexible materials like TPU and Soft PLA.

The X-Pro works with the standard 1.75mm filament which is fed to the printhead using the Direct Drive extrusion system – another favourable quality trait for flexible thermoplastics.

Features of the Qidi Tech X-Pro

- Dual Extrusion System

- 4.3-inch Touchscreen

- QIDI Tech One-to-One Service

- Aluminum Build Platform

- Power Recovery

- QIDI Slicing Software

- Magnetic Build Plate

Specifications of the Qidi Tech X-Pro

- Build Volume: 230 x 150 x 150mm

- Layer Resolution: 0.1-0.4mm

- Extruder Type: Dual

- Nozzle Diameter: 0.4mm

- Maximum Extruder Temperature: 250°C

- Maximum Print Bed Temperature: 120°C

- Frame: Aluminum

- Print Chamber: Enclosed

- Bed Levelling: Semi-automatic

- Display: LCD Touchscreen

- Built-in Camera: No

- Print Recovery: Yes

- Filament Sensor: No

- Filament Diameter: 1.

75mm

75mm - Materials: PLA, ABS, PETG

- Third-party Filament: Yes

To help cool the print down, this 3D printer has an Airblow Turbofan which covers all four sides of your printed model.

Although it does require a bit of manual setup, this handy addition pays off well to enhance print quality.

Moreover, the X-Pro arrives at your doorstep with a modernly designed, fully enclosed print chamber. This allows the printer to better maintain the temperature settings while keeping itself free from dust.

An enclosure also helps drastically when printing materials like TPU could really use constant temperature maintenance inside the chamber.

Besides, there’s a swing-open acrylic door where inside resides the heated and magnetic build plate.

The magnetism of the build plate is a catchy feature. It’s capable enough to grasp the prints well and doesn’t turn out to be a hassle when it’s time to remove them.

In fact, all you have to is bend the removable plate a bit outward from both sides, and off comes your print popping.

Specs-wise, the X-Pro’s extruder temperature can go easily up to 250°C which is more than enough to accommodate flexible materials. The heated bed can also heat up to 120°C so TPU adheres even better.

Besides all that, when it comes to the print quality, this beast from Qidi Tech is all about dimensional accuracy.

It might, however, lack some detailing here and there, but it’s still very consistent and printing slow can yield even better results.

Get yourself the Qidi Tech X-Pro from Amazon today.

Creality’s Ender 3 V2 is an inexpensive way of introducing yourself to 3D printing and getting close to the very best out of it.

It replaces its predecessor Ender 3 in many ways, both trivial and significant, and measures up to its worth for sub $250.

Some of its prominent features include an appealing new design, a tempered glass print bed, noiseless printing and a spacious build volume of 220 x 220 x 250mm.

Features of the Ender 3 V2

- Carborundum Coated Glass Print Bed

- Quiet Printing

- Coloured LCD Screen

- Belt Tensioners

- Mean Well Power Supply

- Power Recovery

- Built-in Toolbox

- Bowden-style Extrusion

Specifications of the Ender 3 V2

- Extrusion System: Bowden-style

- Extruder Type: Single

- Nozzle Diameter: 0.

4mm

4mm - Build Volume: 220 x 220 x 250mm

- Maximum Extruder temperature: 255 °C

- Maximum Bed temperature: 100 °C

- Maximum Print Speed: 180mm/s

- Enclosure: No

- Bed Levelling: Manual

- Print Bed: Heated

- Connectivity: SD card, USB

- Built-in Camera: No

- Power Recovery: Yes

- Filament Diameter: 1.75mm

- Third-party Filaments: Yes

- Compatible Materials: PLA, ABS, PETG, TPU

The Ender 3 V2 uses a Bowden-style extrusion system which might be questionable when it comes to printing flexible filaments with it.

Usually, a Direct Drive extruder is much more preferred when you have to print materials like TPU or TPE. Bowden tubes are notorious for their incapacity to print with flexible thermoplastics.

However, things could really work out for you and your V2 if you’re using a more manageable type of flexible filament, which some people have had great results with.

One of these is the Semiflex TPU filament, wherewith a slower printing speed and good retraction settings can definitely produce a quality print.

Ninjaflex, on the other hand, would be a little too flexible for an Ender 3 V2 to handle, so I would steer clear from that if you have the stock, single hot end that the printer ships with and the Bowden setup.

It’s all about the hardness ratings of the filament.

A hardness of 95A will do you justice and it’s still pretty flexible, even with 20% infill but only in the direction of the infill itself.

Moving on, there’s also an automatic resume function that allows the printer to pick right where it left from in case of an accidental shutdown or a power outage.

Apart from that, the Ender 3 V2 comes ready for action right out the box and requires a mediocre amount of assembly.

It’s a Cartesian-style printer that has the extruder temperature reaching well above 240°C – a fair extent for printing flexible materials.

To talk about the print quality, the V2 delivers beyond expectations, making its sub $300 price tag hard to believe.

Buy the Ender 3 V2 from Amazon today.

The Anycubic Mega-S is a highly refined upgrade over the original, immensely popular i3 Mega. With both the printers, the Chinese company has surprised everyone with the price point and amazing value for money.

The fundamental reason why the Mega-S deserved to be on this list is because of its Titan extruder.

Unlike the Ender 3 V2, this essential component has received a quality overhaul, making it fit for flexible filaments like TPU, not to mention the added potential with ABS and PLA.

This perhaps is the most important functional improvement over its original counterpart. Therefore, the Mega-S is truly capable to handle flexible printing materials, despite the fact that it has a Bowden drive setup.

Features of the Anycubic Mega-S

- Easy Assembly

- Sturdy Aluminum Frame

- Heated Print Bed

- Fully Colored Touchscreen

- Power Recovery

- Titan Extruder

- Filament Spool Holder

- Filament Run-out Sensor

- Anycubic Ultrabase Build Platform

Specifications of the Anycubic Mega-S

- Build Volume: 210 x 210 x 205mm

- Print Technology: FDM

- Layer Height: 100 – 400 microns

- Extrusion System: Bowden-style Extrusion

- Extruder Type: Single

- Nozzle Size: 0.

4mm

4mm - Maximum Extruder Temperature: 275 °C

- Maximum Heated Bed temperature: 100 °C

- Frame: Aluminum

- Connectivity: SD Card, Data Cable

- Compatible Materials: PLA, ABS, HIPS, PETG, Wood

- Bed Levelling: Manual

The Mega-S is adorned with the latest features like automatic power recovery and a filament run-out sensor that alarms you before your material finishes up and leaves you helpless during a crucial print.

Anycubic has another well-renowned feature that sets it a class apart as compared to 3D printers from other manufacturers. Also prominent in the Mega-S, the Anycubic Ultrabase is what we’re talking about here.

This highly refined, durable build platform has a textured surface that’s able to help thermoplastic filaments with bed adhesion, thus improving the print quality and catering to better user experience.

It’s really something that the Mega-S can brag about.

Furthermore, this 3D printer is a no brainer to fully assemble. Taking about 10-15 minutes at best, setting this machine up is no worry for newbies and professionals alike due to a clear-cut instructions guide.

Taking about 10-15 minutes at best, setting this machine up is no worry for newbies and professionals alike due to a clear-cut instructions guide.

Apart from the assembly, the Mega-S is a treat to have in terms of print resolution. While a lot of 3D printers stand strong between 100 microns of layer resolution, this bad boy kicks it up a notch and works perfectly down to 50 microns. Talk about detail.

I wrote a complete review of the Anycubic Mega-S by going much more in-depth. Be sure to check that out if you want more information on this high-performance 3D printer.

Buy the Anycubic Mega-S directly from Amazon today.

The Creator Pro (Amazon) has been developed by the Chinese 3D printer manufacturer giant known as Flashforge. The company has a knack for producing affordable machines with a bulk of hefty features.

While the Creator Pro is nothing to be taken lightly, let’s briefly review how it takes a robust stance among fellow 3D printers.

First and foremost, the Creator Pro is built with a Dual Extrusion system, just like the QIDI Tech X-Pro. On top of that, it also has a fully enclosed print chamber that allows it to print an extensive array of filaments, let alone flexible ones like TPU and TPE.

On top of that, it also has a fully enclosed print chamber that allows it to print an extensive array of filaments, let alone flexible ones like TPU and TPE.

Unlike the Ender 3 V2, it uses a Direct Drive system that combines ideally with the dual extruder. It’s customary for the Creator Pro to handle flexible filaments like a breeze, as it also has its very own adjustable cooling fan that helps streamline the process even more.

In addition, a heated build plate makes a well-grounded impression for the Creator Pro while adding more to the prospect of using TPU with this 3D printer. You also have to implement a little bit of effort to assemble it up as the printer comes almost ready for action out the box.

Features of the Flashforge Creator Pro

- Dual Extrusion System

- Noiseless Printing

- Enclosed Print Chamber

- Rigid Metal Frame

- Aluminum Build Platform

- Beginner Friendly

- Heated Build Plate

- Direct Drive Extrusion System

Specifications of the Flashforge Creator Pro

- Build Volume: 225 x 145 x 150mm

- Materials: ABS, PLA, and Exotic Filaments

- Printing Speed: 100mm/s

- Resolution: 100 microns

- Maximum Extruder Temperature: 260ºC

- Print Technology: FDM

- Open-Source: Yes

- Filament Diameter: 1.

75mm

75mm - Nozzle Diameter: 0.40mm

- Extruder: Dual

- Connectivity: USB, SD card

By consistent evaluation, the Creator Pro’s print performance has turned out to be quite decent for a printer at its price range. As a matter of fact, you’ll become quite fond of the intricate details this Flashforge workhorse produces.

To talk about the build platform, it’s heated and also consolidated with a 6.3mm thick aluminium alloy. Moreover, its sturdiness allows for an increased thermal conductivity which prevents filament deformation.

While the print bed doesn’t calibrate automatically, there is, indeed, a three-point bed levelling system which makes it comparatively easier to adjust the bed.

Unlike many of the printers listed on here, the Creator Pro is fully open-source, allowing you to experiment with different slicing software and see what suits best.

Also in comparison with the 3D printers above, the Creator Pro reaches the highest extruder temperature of 260°C and that figure bodes very well for flexible filaments like Soft PLA. Like what this printer is packing?

Like what this printer is packing?

Buy the Flashforge Creator Pro it directly from Amazon today.

Enter and embrace the royalty of the MakerGear M2 – a high-end, deluxe 3D printer that settles only for professionals and hobbyists. Beware, you’ll have a very hard time with this beast if you’ve just started out with 3D printing.

Priced at around $1,999, you can expect that the quality of the M2 is going to be nothing short of excellence. It looks like a divine shard of full-metal heaven sitting on your workstation, boasting a sophisticated yet dazzling design with a powder-coated steel frame.

It has its build mostly comprising of steel, but you’ll also observe plastic parts around the extruder. Speaking of the extrusion, the M2 consists of only a single extruder but that’s more than enough to deal with a wide variety of filaments.

From Nylon and ABS to TPU and flexible PLA, multifaceted filament compatibility is not a problem for this 3D printer.

Additionally, it has the maximum extruder temperature going up to a whopping 300°C and as you can comprehend, that’s the highest of all the printers here on this list.

Features of the MakerGear M2

- Fully Open-source

- Spacious Build Volume

- Easy Bed Levelling

- Exceptional Build Quality

- Truly Reliable

- Robust Design

- Very Versatile

Specifications of the MakerGear M2

- Build Volume: 200 x 250 x 200mm

- Nozzle Diameter: 0.35mm (rest are available on the market as well)

- Maximum Print Speed: 200mm/sec

- Maximum Extruder Temperature: 300°C

- Filament Compatibility: ABS, PLA, PETG, TPU

- Built Plate: Heated

- Open-Source: Yes

- Extruder Type: Single

- Minimum Layer Height: 25 microns

- Connectivity: USB, SD Card

- Print Area: Open

This 3D printer doesn’t come with an enclosure and there is a decent amount of learning to pursue if you’re very new to 3D printing.

Furthermore, the M2 might not have the easiest usable interface at all. This aspect of this printer does require a considerable amount of effort.

Nonetheless, it does feature a Quick Start software that makes for an easier time levelling the bed.

If you still don’t get something right, MakerGear has amazing customer support that reaches back shortly, and apart from that, a lot of tutorials teach the essentials of MakerGear 3D printers comprehensively.

With a reliable and precise 3D printer like the MakerGear M2, you simply cannot hope to go wrong when printing flexible filaments.

Get yourself the MakerGear M2 from Amazon today.

The Dremel DigiLab 3D45 (Amazon) 3D printer is another contestant in the first-rate range. It’s priced around $1,900 but it’s safe to say that those figures only do justice to this machine’s remarkable ability and style.

This 3D printer due to its diligent reliability and handiness makes itself very suitable for classrooms and professional usage as well. There’s a reason why it’s regarded so highly in those areas and I’m going to tell you why.

First off, The DigiLab 3D45 works great with demanding filaments such as ABS and Nylon, not to mention the brilliant quality when using thermoplastics like PETG and EcoABS, which is an eco-friendly alternative of ordinary ABS.

Features of the Dremel DigiLab 3D45

- Built-in HD Camera

- Heated Build Plate

- 5-inch Coloured Touchscreen

- Direct Drive Extrusion System

- All-metal Hot End

- Fully Enclosed Build Chamber

- Easy Assembly

Specifications of the Dremel DigiLab 3D45

- Print Technology: FDM

- Extruder Type: Single

- Build Volume: 255 x 155 x 170mm

- Layer Resolution: 0.05 – 0.3mm

- Compatible Materials: PLA, Nylon, ABS, TPU

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Bed Levelling: Semi-Automatic

- Max. Extruder Temperature: 280°C

- Max. Print Bed Temperature: 100°C

- Connectivity: USB, Ethernet, Wi-Fi

- Weight: 21.5 kg (47.5 lbs)

- Internal Storage: 8GB

Focusing on its extrusion sstem, the 3D45 uses a Direct Drive setup. This feature allows the 3D printer to handle flexible filaments extremely well, no matter the brand you’re using.

However, many veteran users of the 3D45 advise starting with Soft PLA. This is because it has a little bit hardness value than TPU, making it easier to print.

This is because it has a little bit hardness value than TPU, making it easier to print.

In addition, you have to watch out for some important settings like speed, extruder temperature, and retractions.

Beginning your print slow and maintaining a constant speed somewhere between 15-30mm/s (even though the 3D45 goes up to a massive 150mm/s) will get you going in the right direction with flexible filaments.

Apart from that, your retractions have to be short and unrushed.

Next, filaments like TPU should be printed with an extruder temperature that lies between 220-230°C and with the DigiLab 3D45 going up to 280°C, this shouldn’t be a problem for you or this 3D printer.

Besides, the 3D45 doesn’t fail to impress feature-wise either. It’s well-equipped with a heated and removable build platform that measures up to 10 x 6.0 x 6.7 inches – a quite decent build volume. Another noteworthy function is the ease associated with levelling the bed.

The 3D45 uses a two-point bed levelling system that’s as simple as this process could possibly be. This printer even shows you how much the turning knobs should be optimized to level the bed perfectly, all on the 4.5 inch IPS coloured screen.

This printer even shows you how much the turning knobs should be optimized to level the bed perfectly, all on the 4.5 inch IPS coloured screen.

Lastly, the 3D45 is a concise printer that can form prints of 50 microns of resolution. This makes it highly precise and keen for detail. Moreover, this 3D printer also has an enclosure which helps maintain the internal temperature right when it matters the most.

Buy the Dremel DigiLab 3D45 directly from Amazon today.

Concluding our list of the best 7 3D printers for printing flexible filaments is the critically acclaimed TEVO Tornado.

This 3D printer is famous for the number of possibilities it presents you to extend, customize, and modify its parameters and tinker around to achieve the best results.

In truth, the TEVO Tornado has drawn motivation and is actually based off of Creality’s CR-10 model, which is already quite popular in the printing community.

However, the addition of an E3D Titan extruder made by TEVO themselves just like the Anycubic Mega-S, and an AC-powered heated bed are two features that set it apart from its competition.

With this enhanced extruder, the TEVO Tornado faces no difficulty in printing flexible filaments and numerous Amazon reviews can vouch for this statement as well.

Features of the TEVO Tornado

- Heated Build Plate

- Bowden-Style Titan Extruder

- LCD Control Panel

- Sizable Build Platform

- Effortless Assembly

- AC Heated Bed

- Tight Filament Pathway

- Stylish Colored Design

Specifications of the TEVO Tornado

- Frame material: Aluminum

- Nozzle Diameter: 0.4mm

- Build Volume: 300 x 300 x 400mm

- Connectivity: SD card, USB

- LCD Screen: Yes

- Maximum Print Speed: 150mm/s

- Compatible Materials: ABS, Carbon Fiber, TPU, PETG, PLA

- Filament Diameter: 1.75mm

- Minimum Layer Thickness: 50 microns

- Maximum Extruder Temperature: 260°C

- Maximum Bed Temperature: 110°C

It also hosts a larger than normal build platform that’s about 300 x 300 x 400mm in dimension.

Moreover, Tornado has an all-metal hot end to brag about too. Combine that with the Titan extruder’s constricted filament pathway feed, filaments like TPU and TPE are exceptionally easy to deal with for this 3D printer.

This could be the reason why TEVO Tornado is well-liked among the community.

The AC-powered heated bed is ready for use in less than a minute, which is just a welcome addition to Tornado’s quality of life upgrades. Moreover, you get a maximum print speed of 150mm/s with a very detailed 50-micron layer resolution.

All that for a bit under $350? Seems too good to be true.

Another loveable quality about the TEVO Tornado is its assembly. According to the manufacturers, it arrives “95%” assembled, meaning that you just have to implement a bit of effort here and there and get to printing in under 15 minutes or so.

To speak of the design, it’s obvious how the TEVO Tornado borrows the idea from the famous Creality model, but the South African company has given its own touch of glaring colour apparently.

The Tornado’s frame is as sturdy as they come and feels solidly built too, so the 3D printer gets a good score in this aspect.

You can also get the TEVO Tornado at a really competitive price from Banggood.

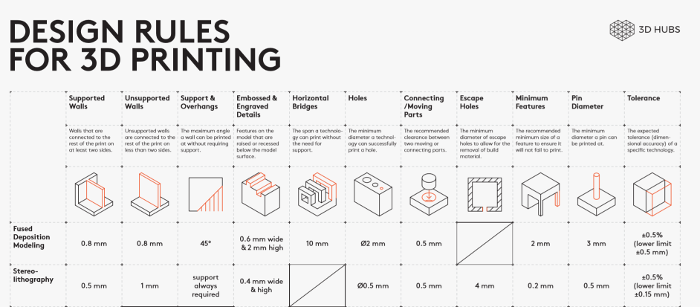

How to Pick the Best 3D Printer for Flexible Materials

Flexible thermoplastics can be difficult to print considering their hygroscopic nature and particular sensitivity to rapid movements. This is why the 3D printer you’re going to choose must be well-equipped to handle flexible filaments.

The best 3D printer for flexible materials should comprise the following attributes:

- A print bed that comfortably reaches 45-60°C. Could be a desirable addition if it’s a heated print bed as well.

- A modern extruder system that can handle high temperatures around 225-245°C.

- A Direct Drive extruder is more recommended but a Bowden setup can still get it done!

- A PEI coated print surface for good bed adhesion – although a standard plate with glue stick works wonders

Types of Flexible Materials

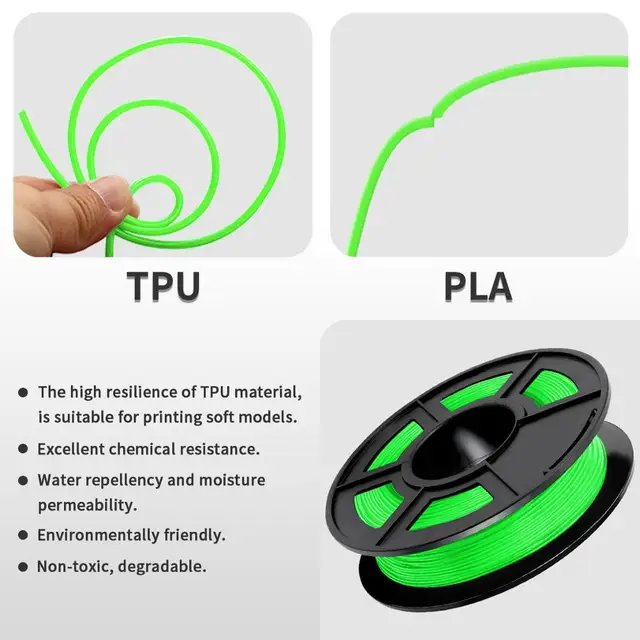

Thermoplastic Elastomers (TPEs) are a group of 3D printable materials that are further divided into a few different types.

TPU: Thermoplastic Polyurethane (TPU) is probably the most popular of all flexible printing materials out there that’s highly admired for its exclusive hardness, allowing it to be printed with ease as compared to other filaments of the like. TPU also boasts fairly strong prints with decent durability.

A good example of popular TPU filament is the 1KG Spool of PRILINE TPU that you can get straight from Amazon (rated 4.5/5.0 at time of writing). You might think that this flexible material is much more expensive than standard filament like PLA, but you’d be surprised by the prices!

PRILINE TPU is a top-grade option from a noteworth brand if you have to print with a flexible filament. It can print easily with a nozzle temperature of 190-210°C, which is what most 3D printers can comfortably handle.

The dimensional accuracy of this spool comes in at ±0.03mm, and is backed with a standard 30-day refund guarantee, so you’re sure to be happy.

TPA: Thermoplastic Polyamide (TPA) is a blend of nylon and a co-polymer of TPE. This dual-natured flexible filament exhibits super smooth prints with shining texture. This combination allows it to feature immense durability from nylon and awesome flexibility from TPE.

This dual-natured flexible filament exhibits super smooth prints with shining texture. This combination allows it to feature immense durability from nylon and awesome flexibility from TPE.

TPC: Thermoplastic Copolyester (TPC) isn’t very noticeable around 3D printing enthusiasts and hobbyists, being more suited as an engineering-grade flexible filament. To talk in terms of its physical properties, TPC does, however, feature high-temperature resistance and utterly strong print jobs.

There’s also one more type of flexible material and it’s widely known as Soft PLA. This refers to the blends of PLA in order to make it flexible yet durable and strong.

As a bonus point, you can print Soft PLA similarly as you would with regular PLA. However, you might have to print slowly and opt for a higher bed temperature to rock this flexible filament.

The Soft PLA from Matter Hackers does get relatively pricey!

Flexible Filament Hardness Measures

Flexible filaments, generally, are measured using a Shore Hardness scale. This sets them apart in terms of how much flexibility or hardness they can offer.

This sets them apart in terms of how much flexibility or hardness they can offer.

Relatively softer materials fall in the Shore A scale for 3D printing. Therefore, most of these thermoplastics have a range between 60-90 Shore A hardness.

The higher the value on this scale, the harder the material, while a lesser value will amount to more flexibility.

Lets take a TPU-70A flexible filament.

As the name depicts, this filament would have a Shore A hardness of 70, which means that it is almost in the middle of flexible and rigid, but a little more on the flexible side.

Perfect for the average 3D printer.

The less rigid and more flexible a filament, the harder it is going to be to print with because there is more work and precision needed in controlling that flexible filament.

Rigid filament like standard PLA prints pretty easily, so the further away from that, the harder it will be to print.

How to Print Flexible Filament Effectively

There’s no doubt about the trickiness of printing thermoplastics like TPU and other flexible filaments, but there are approachable workarounds and a little bit attention paying to get this ordeal sorted for you. I’m going to list a bunch of things you can start with today to print flexible filament effectively.

I’m going to list a bunch of things you can start with today to print flexible filament effectively.

Take it Slow

Even when a flexible filament is not concerned, if one hopes to get the best possible results with a lot of detail, printing slowly can’t be overlooked.

This is why a slow speed is recommended for every thermoplastic filament, and not just flexible materials. But for TPU and TPE, there’s no other way if you want to be successful when printing with them.

Slow print speeds prevent pressure from building up largely inside the extruder nozzle and helps negate a plethora of potential problems. When printing TPU, your optimum speed should be no more than 30-40mm/s.

Some people even go as low as 10-20mm/s.

Prefer a Direct Drive Setup

Though it’s not really impossible to print flexible filament with a Bowden-style extruder, it’s definitely more challenging.

Direct Drive setups reduce the distance that a filament has to travel from the extruder to the hot-end. This allows for unmatched convenience when printing with TPU and other flexible thermoplastics. Moreover, the pathway that usually follows is also constricted and narrow, providing for a clear passageway.

On the other hand, we have Bowden-style extruders that simply cannot work well with a flexible filament. This is because these types of filaments tend to bind inside the Bowden PTFE tubing, making the whole process much more difficult and tiresome.

However, there exists an upgrade you can get if possible on your Bowden-style 3D printer. It’s known as Capricorn PTFE tubing.

This upgrade can increase the ability of Bowden setups to print flexible filaments because it just has better control on the filament as it passes through the tubing, preventing it from buckling up.

Additionally, it also has higher tolerance levels over regular PTFE tubes so your Bowden extruder 3D printer is much better off with a premium Capricorn tubing system.

Calibrate Temperature and Retraction

Temperature and retraction both are equally essential when it comes to achieving the desired outcome with flexible filaments. Temperature makes for the smooth sailing of the print operation while retraction helps keep the pressure down to a minimal level.

However, we’re basically oversaturated with different brands of flexible thermoplastics, with each having their own particular properties. The appropriate temperature and retraction settings are mandatory, but we recommend reviewing the guide of your filament to see how your 3D printer can be optimized for it ideally.

Normally, you’re recommended to keep low retraction settings with slight temperature adjustments. Some people have even reported success with 0 retractions, so that’s definitely an area to experiment with as well.

Use Painter’s Tape or Glue Stick

Is material not adhering properly to your non-heated print bed? Try using Blue Painter’s Tape or a standard glue stick and watch how things change for you.

It turns out that TPU and similar filaments can adhere quite wonderfully to these adhesive substances.

In addition, if you have a heated bed, a temperature between 40-50°C should give you the best results. Many people have seen good success with some standard glue on their build plate.

Difficulties in 3D Printing Flexible Materials

Flexible thermoplastic filaments have driven 3D printing into even more far-reaching applications. They’re able to produce strong, ductile prints with terrific resistance to mechanical wear and tear. However, all that comes at a cost, and let’s take a brief look at how.

Problems During the Filament Feed

This is an issue that becomes quite apparent in mainstream Bowden setups that use PTFE tubing. Flexible filament due to its soft physical composition becomes quite a bother to push along the extruder nozzle. Oftentimes, it jams, clogs and gets stuck somewhere in between, causing the print process to fail.

Oftentimes, it jams, clogs and gets stuck somewhere in between, causing the print process to fail.

The only way to proceed is by unclogging and cleaning your nozzle out. Of course, this is not a problem with common filaments like ABS and PLA just because of their hardness, but it is indeed something to attend to with TPU and TPE.

Formation of Bends Due to Pressure

Flexible filament tends to buckle up sometimes, all due to the pressure build-up in the nozzle. This mostly occurs when there’s an absence of a narrow pathway to feed through to the hot end or when you’re printing too fast for your 3D printer to handle the flexible thermoplastic.

This again causes jams in the nozzle where you have to begin everything from scratch.

Follow the video below by Ch4P for a great method to fix this with a standard Bowden extruder.

Stringing

Stringing is one of the most notorious problems with printing flexible filaments. Even if you’ve got all the settings correctly calibrated, you can always expect stringing to come reaping in around the corner. Even the slightest of errors in temperature, speed, and retraction settings could lead to stringing easily.

Even if you’ve got all the settings correctly calibrated, you can always expect stringing to come reaping in around the corner. Even the slightest of errors in temperature, speed, and retraction settings could lead to stringing easily.

This also comes by as a result of the pressure build-up. Stringing will usually create a mess when the extra filament is thrust out the extruder unnecessarily.

Print Bed Adhesion Difficulties

Temperature plays a key role in maintaining the success rate of printing flexible filaments throughout. Flexible filament is known for its difficulties in adhering to the print surface, primarily when the bed isn’t heated or even when the surface isn’t properly levelled.

5 Best 3D Printers For Flexible Filament In 2022

- Last Updated: December 25, 2022

Everyone loves a fun 3D print, but what if it wasn’t so… boring?

It’s no doubt that flexible 3D prints have an “awe” effect, but they also prove to be very practical in some scenarios, like for a phone case, due to their bend-ability and impact resistance. You can 3D print flexible parts with flexible filament, like TPU or TPE, but you’ll also need the right 3D printer to ensure your prints are high quality.

You can 3D print flexible parts with flexible filament, like TPU or TPE, but you’ll also need the right 3D printer to ensure your prints are high quality.

So, are you ready to take a less rigid approach to 3D printing? If so, read on for our review of the best 3D printers for printing flexible filaments!

Creality Ender 3 S1

Build Volume: 220 x 220 x 270 mm

Get Discount Now

Check Latest Price

Flashforge Creator Pro

Build Volume: 230 x 150 x 140 mm

Get Discount Now

Check Latest Price

Dremel DigiLab 3D45-01

Build Volume: 254 x 152 x 170 mm

Check Latest Price

Table of Contents

- Best 3D Printers for flexible filament At A Glance

- Why Is a Direct Drive Extruder ideal for Flexible Filament?

- 1. Creality Ender 3 S1 (best Value)

- 2. Flashforge Creator Pro (Best Choice)

- 3.

Dremel DigiLab 3D45-01 (Premium Choice)

Dremel DigiLab 3D45-01 (Premium Choice) - 4. Sovol SV01 (Best for Beginners)

- 5. Creality CR-10 V3 (Best for Large Prints)

- What are the Benefits of Using 3D Printers with Flexible Filaments?

- What are the Flexible Filaments?

- What are the Challenges in Printing Flexible Filaments?

- Best 3D Prints for Flexible Filament? What Can You Print?

- Conclusion

Best 3D Printers for flexible filament At A Glance

1. Creality Ender 3 S1 (Best Value)

2. Flashforge Creator Pro (Best Choice)

3. Dremel DigiLab 3D45-01 (Premium Choice)

4. Sovol SV01 (Best for Beginners)

5. Creality CR-10 V3 (Biggest Build Volume)

Why Is a Direct Drive Extruder ideal for Flexible Filament?

Before we dive into the printers and reviews, you might be wondering what makes a printer good for printing flexible materials. Well, there are a few factors, such as the machine’s temperature capabilities, the quality of the parts used, and the typical quality of prints made with the printer. However, the most important feature a printer for flexible filaments must have is a direct drive extruder.

However, the most important feature a printer for flexible filaments must have is a direct drive extruder.

Direct drive extruder configurations involve placing the extruder stepper motor directly over the hot end, where the filament is melted. This gives the inserted flexible filament less room to stretch or bend, reducing the chances of a nozzle jam, so your prints don’t fail. This type of extruder is the alternative to the Bowden-drive extrusion system, which involves the extruder motor separated from the hot end by a PTFE tube.

Most consumer-grade 3D printers have Bowden-drive extruders as its cheaper to manufacture and less complicated to work with. The less precise extrusion associated with Bowden-drive extruders makes it the inferior extruder configuration for printing flexible filaments.

Now, lets’ get into the best 3D printers!

3D Printer Type: FDM | Materials: PLA, TPU, PETG, ABS | Build Volume: 220 x 220 x 270 mm

First up, we have an all-around hard hitting 3D printing machine: the Ender 3 S1. Developed by Creality, one of the most popular 3D printer manufacturers, the Ender 3 S1 is the latest interaction in the Ender 3 series. The printer has many new features that were previously optional upgrades on older versions of the Ender 3 (original, Pro, V2), making it a great printer for flexible filaments.

Developed by Creality, one of the most popular 3D printer manufacturers, the Ender 3 S1 is the latest interaction in the Ender 3 series. The printer has many new features that were previously optional upgrades on older versions of the Ender 3 (original, Pro, V2), making it a great printer for flexible filaments.

Most important, the Ender 3 S1 is the first printer to feature Creality’s new Sprite extruder. The Sprite is a powerful and compact direct drive extruder with a 3.5:1 gear ratio that allows it to precisely and forcefully push filament through the hot end. The Sprite has dual drive gears that put a tighter grasp on the inserted filament, further improving the pushing power and precision of the extruder, while preventing the filament from bending around the extruder and causing a print failure.

The Ender 3 S1 has a spring-steel build plate that offers both flexibility and magnetism for easy part removal and bed re-attachment to the printer. The build plate’s surface has a PEI coating too for its top surface layer, and your TPU prints, especially the first layer, should adhere to this surface very well.

The build plate’s surface has a PEI coating too for its top surface layer, and your TPU prints, especially the first layer, should adhere to this surface very well.

The S1 also has Creality’s new CR-Touch device, an automatic bed leveling sensor that can help keep your nozzle an equal distance above the bed, so your first layer comes out great. Other important features on the printer include belt tensioners to prevent layer shifting on prints, an easy-to-use LCD and interface, an onboard filament runout sensor to detect if your flexible filament has run out or isn’t flowing, and more.

Despite having as many, or more, features than some above-$1,000 printers, the Ender 3 S1 comes with a pretty affordable price tag of just $429, making the printer a total bargain and an obvious choice for the best value printer when it comes to printing flexible filaments. Of course, at this price, the Ender 3 S1 isn’t the cheapest printer on the list, but, we recommend it for those with a little extra in their 3D printer budget who want the biggest bang for their buck.

- Compact and powerful direct drive extruder

- Good bang for your buck

- Automatic bed leveling with a very accurate CR-Touch sensor will ensure a good first layer

- Onboard filament sensor for ensuring filament is flowing properly and has not run out

- Spring-steel bed for good adhesion and easy part removal

- Belt tensioners, tool drawer, good cable management, and included filament spool

- ABS might not work due to low maximum bed temperature

- Filament runout sensor placement prevents you from using larger spools

Get Discount (Official Store)

Check Latest Price

3D Printer Type: FDM | Materials: PLA, ABS, TPU, TPE, PETG, Wood, Copper | Build Volume: 230 x 150 x 140 mm

Need to print two filaments at once or simply don’t want to go through the annoying process of changing out your filament every time you want to print a different filament? Well, one company has forged (hint, hint) the ultimate machine for you: the Flashforge Creator Pro. This machine is the Pro version of the standard Creator printer from Flashforge and is packed with features that make it deserving of our pick for the best printer for printing flexible filament.

This machine is the Pro version of the standard Creator printer from Flashforge and is packed with features that make it deserving of our pick for the best printer for printing flexible filament.

As we mentioned, this machine allows you to print two filaments at once and this is possible through its dual-extruder system. Moreover, the Creator Pro has a wider printhead that has not one, but two hot ends and a separate extruder for each to allow you to print dual-color models without any extra attachments of manual filament swaps. Alternatively, you can take advantage of the dual extruders to avoid having to switch filaments every time you want to print a flexible material.

On this note about the flexibles, the Creator Pro is well suited for printing this type of filament due to its dual direct drive configuration. Moreover, both hot ends have their own extruder directly above which makes printing flexibles easier and reduces the risk of print failure.

Now, you may be thinking “with two direct drive extruders and hot ends, the printhead is probably too heavy to move fast”. Well, don’t you worry because Flashforge has used lightweight components on the printhead to allow for print speeds around 100 mm/s (super fast).

Well, don’t you worry because Flashforge has used lightweight components on the printhead to allow for print speeds around 100 mm/s (super fast).

It’s also worth mentioning that the Creator Pro has a moderately-high maximum nozzle temperature of 240 °C with a maximum bed temperature of 120 °C. These temperatures are easily enough to print most flexible filaments, but another added benefit is that the Creator Pro has an integrated enclosure. This should keep the ambient temperature around prints consistently warm, which often yields higher-quality prints and will allow you to print temperature-sensitive materials like ABS and ASA.

One of the best parts about the Creator Pro is its cost of just $450, which is surprisingly low for a dual-extruder printer. Because designing and preparing models for dual-extrusion 3D printing can be difficult, we think the Flashforge Creator Pro is best suited for users with some experience with 3D printing or those really wanting dual-color or dual-material prints. However, as the printer has a single extruder mode and many other great features like an integrated enclosure, it’s also a great option for beginners.

However, as the printer has a single extruder mode and many other great features like an integrated enclosure, it’s also a great option for beginners.

- Dual extrusion system enables multi-filament printing

- High maximum bed temperature will allow for printing with ABS and ASA

- Capable of fast print speeds of up to 100 mm/s

- Direct drive extruder for printing flexible filament easily

- Enclosure for keeping a consistent ambient temperature and improving print quality

- Maximum nozzle temperature may not work with some ABS filaments

- Dual extrusion isn’t independent so dual-color prints will take longer

- Dual extruders on single printhead makes repair difficult

Click For Official Website

Check Latest Price

3D Printer Type: FDM | Materials: PLA, ABS, PETG, Nylon | Build Volume: 254 x 152 x 170 mm

Our premium choice for a 3D printer for printing flexible filament is the DigiLab 3D45-01, developed by Dremel, the manufacturer of rotary tools and other power tools. The machine costs a pretty penny with a price tag of around $2,000 but has some features not typically included on consumer printers.

The machine costs a pretty penny with a price tag of around $2,000 but has some features not typically included on consumer printers.

First off, the printer is enclosed with a transparent acrylic panel at the front to trap heat while still letting you monitor your printer. The enclosure should increase the print quality of models and it will allow you to print temperature-sensitive filaments like ABS. On a related note, the printer can also hit a maximum bed temperature of 100 °C, which is suitable for these materials.

When it comes to printing flexible filaments, the DigiLab 3D45 is a great choice due to its compact printhead assembly, comprised of a direct drive extruder above a high-temperature hot end. Moreover, the nozzle goes up to 280 °C, which is more than enough for flexibles like thermoplastic polyurethane (TPU). Additionally, it’s worth mentioning that the printhead has a few fans and a well-designed fan duct pointed towards the nozzle to provide excellent part cooling that can significantly improve the quality of prints.

One of the more unique features of the 3D45 is the camera located in the top corner of the printer’s frame. The camera is hooked up to DigiLab’s onboard computer so you can monitor your printer’s ongoing print jobs remotely to ensure everything is running smoothly.

The DigiLab also has a built-in NFC chip reader on the filament spool holder that monitors and tracks your filament usage. While your printer knowing extra information about the spool you’re using, like how much is left or the color, can be helpful, this system also forces you to use only filament spools manufactured by Dremel. Dremel sells a variety of high-quality filaments, including a flexible material, and there are also available slicer profiles for each filament that are fine-tuned to the 3D45 for maximum print quality.

Overall, the Dremel DigiLab 3D45 is an amazing machine for printing flexible filaments, especially if you have a little extra dough to spend for the added features on the printer, like the webcam, enclosure, and high-temperature hot end.

- NFC chip reader on filament spool holder prevents you from using third-party filaments

- Low maximum bed temperature can reduce the ability to print high-temperature materials like ABS

- Large and heavy printhead assembly

- No automatic bed leveling sensor

Check Latest Price

3D Printer Type: FDM | Materials: PLA, ABS, TPU, HIPS, PETG, Wood | Build Volume: 280 x 240 x 300 mm

Sovol is a lesser-known manufacturer of 3D printers that started to gain popularity with their hit printer, the SV01. The SV01 is a mid-to-large-size 3D printer boasting a generous build volume of 280 x 240 x 300 mm.

The reason we included the SV01, though, isn’t only for its decent print size and direct drive extruder that should make printing flexible filaments a breeze. The main reason the SV01 performs well with flexibles is due to its Titan-style extruder, inspired by E3D’s Titan extruder. The Titan extruder features a quick-release lever for speedy filament changes and uses a standard NEMA-17 stepper motor attached that makes the assembly rather large, but ensures a lack of extruder power is never an issue.

On this note about extrusion power, the SV01’s Titan extruder has a 3:1 gear ratio that should forcefully push filament through the hot end underneath the extruder. Onboard the printhead is also a large 5050 part cooling fan with a fan duct pointed towards the nozzle for maximum cooling of the filament flowing out of the nozzle. The high pushing force from the extruder combined with the direct drive configuration and powerful cooling fan all make for an ideal machine for printing flexible filaments.

Besides the extruder and printhead assembly, the SV01 has many small features that are very desirable among 3D printing enthusiasts, such as a filament runout sensor. This sensor, while very small, can be a lifesaver at times because it will pause your current print once it detects that you’ve run out of filament. Then, you can load a new spool in, looping it through the sensor, and resume your print right where it left off.

Sovol used two Z-axis stepper motors for reliable motion across the Z-axis, which will make the printer more precise in its movement and also prevent certain printing issues like Z-axis sagging. We also can’t forget about the tempered glass build plate, which parts will stick to when heated and pop off from when cooled.

The SV01 also has a wide, two-color LCD display with a Marlin-based graphical user interface that should make operating the machine easy. The screen is powered by Sovol’s own 3D printer motherboard which has a few additional ports for the optional upgrades that Sovol offers, such as an automatic bed leveling device. Other optional upgrades that are very easy to install on the SV01 are:

Other optional upgrades that are very easy to install on the SV01 are:

- A full-color LCD screen

- Amagnetic flexible build plate

- A silent motherboard with better stepper motor drivers for decreased noise.

The SV01 is a great option for a flexible filament printer for many reasons like its powerful Titan extruder and filament runout sensor. On top of this, the easy-to-use LCD and interface along with the many optional upgrades that Sovol offers for the printer make the SV01 a great option for beginners.

- Powerful Titan direct drive extruder for maximum pushing force and high print quality for flexible filaments

- Optional upgrades, such as silent motherboard, full-color LCD, and magnetic flexible build plate, are easy to install

- Filament sensor that pauses prints when filament stops flowing

- Dual Z-axis lead screws for more precise and stable motion

- Decent size print volume

- Direct drive extruder isn’t compact and takes up a lot of space

- Optional upgrades aren't included

Check Latest Price

3D Printer Type: FDM | Materials: PLA, ABS, TPU | Build Volume: 300 x 300 x 400 mm

Another hit classic from Creality is the CR-10 V3, the third version of their popular original CR-10 printer. While the V3 is packed with some great features, the most obvious benefit of the printer is its MASSIVE build volume of 300 x 300 x 400 mm. With this much space, you can print basically any model you want, from small gadgets to ginormous cosplay items.

While the V3 is packed with some great features, the most obvious benefit of the printer is its MASSIVE build volume of 300 x 300 x 400 mm. With this much space, you can print basically any model you want, from small gadgets to ginormous cosplay items.

- Read this article if you’re looking for the best 3D printer for cosplay

After you find the right place to put this huge 3D printer, you may be worried if the printer is stable enough to function properly and safely. The answer is a big yes and Creality has added support rods that connect the different gantries on the printer to ensure it doesn’t ever tilt or become unstable. This not only keeps the printer and the room it’s located in safe but also improves the print quality of the CR-10 V3 because there will be less interference with the printing process (e.g. vibrations).

The CR-10 V3, like Creality’s Ender 3 S1, has a direct drive extruder, but it’s closer in design to the extruder on the Sovol SV01 than the Sprite extruder on the Ender 3 S1. Moreover, the CR-10 V3’s printhead is fairly large and uses a Titan extruder turned by a beefy stepper motor. Due to the Titan extruder’s 3:1 gear ratio and direct drive configuration, flexible filaments should print like a charm with minimal extrusion defects like stringing.

Moreover, the CR-10 V3’s printhead is fairly large and uses a Titan extruder turned by a beefy stepper motor. Due to the Titan extruder’s 3:1 gear ratio and direct drive configuration, flexible filaments should print like a charm with minimal extrusion defects like stringing.

The V3’s motherboard is another important feature on the CR-10 V3, equipped with TMC2208 drivers that quiet the machine’s noise. There are also many extra ports on the board to support the machine’s wide array of electronic features. For example, there’s an extra stepper motor port to allow the V3 to use two Z-axis motors, ensuring more precise and stable motion across the printer’s large frame.

Additionally, there’s a port for a BLTouch sensor, which is an automatic bed leveling sensor. The sensor measures the distance between the nozzle and the build plate and adjusts the printhead’s height so that every print’s first layer comes out well. There are also ports for a filament runout sensor and dual cooling fans so the machine can pause a print when filament runs out and layers will solidify faster once extruded so models turn out more detailed.

As for the build plate, the CR-10 V3 has a standard Creality tempered glass bed. The bed isn’t flexible or magnetic, but it has a slightly bumpy glass surface that plastic adheres to easily when heated. However, once the build plate cools, prints pop right off without the need for hot water or much pushing on the print.

The Creality CR-10 V3 is an obvious choice if you’re looking to print large flexible models. But the CR-10 V3 is much more than just a large-format 3D printer and its Titan direct drive extruder, onboard BLTouch device, filament runout sensor, and dual Z-axis motors yield exceptional print quality, especially for prints in flexible filaments.

- Powerful Titan-style direct drive extruder that provides excellent extrusion for materials and prints flexible filaments very well

- Onboard automatic bed leveling BLTouch sensor for the high-quality first layer and easy print preparation

- Dual Z-axis motors for precise and stable component motion

- Textured glass build plate for great surface adhesion and low-effort part removal

- Filament sensor that temporarily stops prints when filament runs out

- Supports rods for stable motion and safety

- Large build volume for printing large items

- Large glass build plate can be fragile

- No enclosure, making it harder to print high-temperature filaments

- Direct drive extruder isn’t very compact

Get Discount (Official Store)

Check Latest Price

What are the Benefits of Using 3D Printers with Flexible Filaments?

There are many benefits to 3D printing with flexible filaments, but the most obvious one is that flexible models are simply cooler and more fun than traditional, rigid models. With the right 3D printer, you can make custom models that can bend and stretch while still being decently strong.

With the right 3D printer, you can make custom models that can bend and stretch while still being decently strong.

However, fun and games aren’t the only benefits of using flexible filaments and this type of material also has many more professional applications. Due to their semi-flexibility, flexible filaments are naturally great impact resistors. As such, flexible materials are great for printing components that travel at high rates of speed and face a lot of stress, such as a GoPro mount on a drone.

Flexible filaments are also useful for printing parts that interact with electronics. As a thermoplastic, flexible filaments aren’t conductive and won’t put any physical stress on most electronics parts, like circuit boards, because the printed model can easily bend.

Finally, another benefit of printing with flexible filaments is that they are not too challenging to print as long as you have the right type of printer (direct drive), which we talked about earlier. Flexible filaments don’t require super high temperatures (nozzle and bed), meaning they can work on most direct drive machines.

Flexible filaments don’t require super high temperatures (nozzle and bed), meaning they can work on most direct drive machines.

What are the Flexible Filaments?

As you probably guessed, flexible filaments are like a typical filament (a plastic in a stringed form), but are less tense and can stretch and bend easier. For consume-grade 3D printers, there are two main flexible filament materials, including TPU and TPE.

First, thermoplastic polyurethane, commonly abbreviated as TPU, is the most popular flexible filament material. Out of TPU and TPE, the former is the newer material and it’s also a better option for 3D printing because it’s easier to print, requiring lower nozzle and bed temperatures than TPE.

As for the flexibility, TPE filaments tend to be more bendable and stretchy than TPU filaments, but this can depend on the specific spool and manufacturer of the filament. When choosing what filament to use, make sure to look at the Shore hardness level of the filament. The lower the number and closer-to-the-beginning (lower) the letter in the rating, the more flexible the filament. Lastly, both TPU and TPE filaments cost about the same, ranging from $30-60 per kilogram spool.

The lower the number and closer-to-the-beginning (lower) the letter in the rating, the more flexible the filament. Lastly, both TPU and TPE filaments cost about the same, ranging from $30-60 per kilogram spool.

What are the Challenges in Printing Flexible Filaments?

As we’ve explained, printing flexible filaments aren’t too difficult, but it’s definitely more challenging than using more traditional filament materials, like PLA or PETG. The first challenge with printing flexible filament is the extrusion system. To point out yet again (because it’s so very important), you basically need a direct drive printer to be able to print flexible filament while maintaining decent print quality.

However, there are a few other challenges with printing materials like TPU or TPE too. For example, you have to disable retractions on your slicer profile. In turn this usually results in some stringing and over-extrusion on models, but it’s necessary because any retraction moves on the extruder will cause the hot end to jam.

Another disadvantage is that flexible filaments need to be printed with a very slow print speed. That’s because the stretchy filament is sensitive to its extrusion and pushing it out of the hot end too fast will result in significantly reduced print quality. A speed around 20-30 mm/s should work, but you might have to go even lower than 20 mm/s to achieve high-quality prints.

Best 3D Prints for Flexible Filament? What Can You Print?

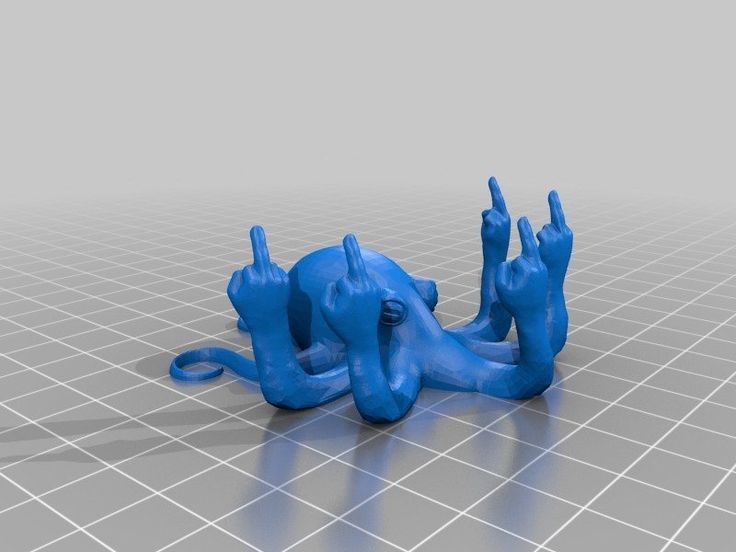

So, let’s say you’ve got your 3D printer, some flexible filament, and are ready to print a few flexible models. If you’re wondering what to print, look no further!

There are many great models you can 3D print in a flexible filament that will leave you astounded by how useful and fun flexible filaments really are. Below, we’ve listed a few different 3D models and projects that you work great with when printing a flexible material:

- Wallet: Need a place to store some cash or cards? This wallet is a great option and you can print it in a flexible filament to make it easily foldable and portable.

- Vibration Damper: 3D printers, and other machines, can be pretty loud. Take advantage of the vibration absorption of flexible filaments by printing these vibration dampers that go on the bottom of your 3D printer.

- GoPro Case: If you’re into flying drones, then you probably have a GoPro camera attached to your flying machine. You can 3D print this GoPro drone case in a flexible filament to surround your expensive camera in an impact-resistant material so it stays safe and secure.

- Pet toy: Want a fun way to play with your furry friend? This toy can be printed in a flexible filament and will keep you and your pet entertained for hours on end!

Conclusion

There are hundreds of different 3D printers on the market, but not everyone is best for printing flexible materials. If you want to be able to print bendy, stretchy, flexible 3D models, make sure you get a printer that’s more than capable of printing these materials. The 3D printers we’ve reviewed on this list are some of the best options out there, but each one is best for a certain type of user.

The 3D printers we’ve reviewed on this list are some of the best options out there, but each one is best for a certain type of user.

First, if you’re looking for a good deal on a 3D printer that’s packed with features, the Ender 3 S1 is the one for you. However, if you have some extra money and want even more operation and printing performance features, we suggest the Flashforge Creator Pro, which is a dual-extrusion printer that allows you to print with multiple filaments at once.

Next, if you’re not worried about the budget, then the Dremel DigiLab 3D45 is an excellent choice that brings together a compact printhead assembly with some extra features like a camera. And, if you’re just getting into 3D printing and want a printer that’s easy to operate and pretty reliable then the Sovol SV01 is a great choice. Finally, if none of the other printers fit your liking, the Creality CR-10 V3 is always an option, boasting a large print space.

No matter what printer you have, don’t forget to have some fun when printing flexible filaments. And, if you ever run into an issue, remember that help is just a few clicks away!

And, if you ever run into an issue, remember that help is just a few clicks away!

All you need to know about TPU for 3D printing

You are here

Home

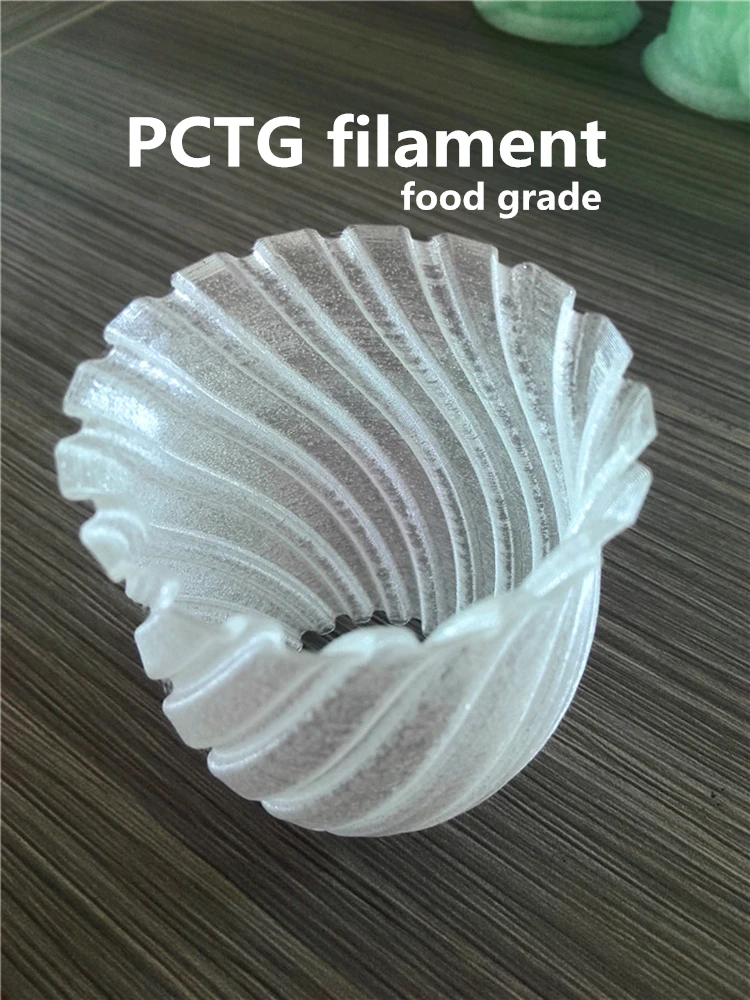

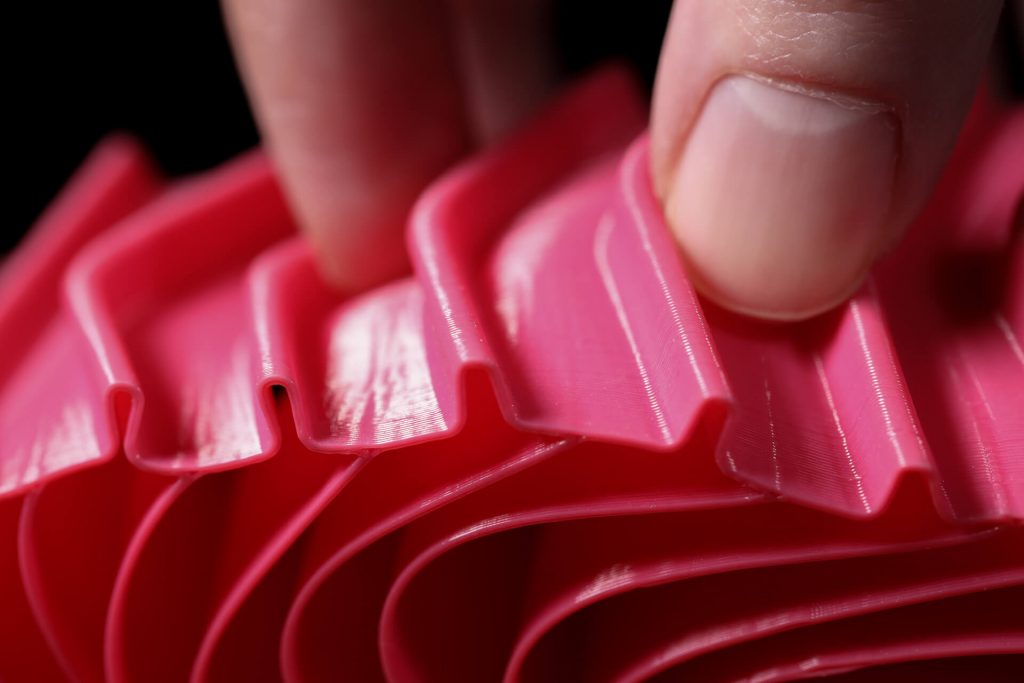

So-called thermoplastic polyurethane (TPU) is a type of elastomer that is highly flexible and durable when processed. Its properties are due to the presence of alternating sequences of hard and soft segments, that is, by varying the proportion of these segments, we can change the hardness and flexibility of the material. It also affects the transparency of the final parts, the softness to the touch or the adhesion of the parts. In general, we can say that TPU is a very diverse polymer that provides a very interesting set of part characteristics. In addition, this makes it possible to apply it to create 3D printed flexible models. But what should we consider when using TPU? nine0005

In the additive manufacturing industry, this material opens up many opportunities for different markets such as footwear, elastic soles, or the automotive industry for tires and shock absorbers. TPU is ideal for end-use parts, functional prototypes, concept models and custom components. This type of material is widely used to make mobile phone cases, for example, as it protects the device from bumps and cracks. Let's now look at the outstanding properties of this flexible material. nine0005

TPU is ideal for end-use parts, functional prototypes, concept models and custom components. This type of material is widely used to make mobile phone cases, for example, as it protects the device from bumps and cracks. Let's now look at the outstanding properties of this flexible material. nine0005

Due to its flexibility, TPU can be used to make phone cases.

Features of TPU in 3D printing

In terms of properties, we need to know that these polymers have many advantages, such as high resistance to impact, wear, abrasion and cuts. In addition, they have a fairly high adhesion to the layer, which provides excellent mechanical uniformity of the manufactured parts, making them isotropic. However, this type of material has certain limitations that we must take into account. TPU does not adapt well to hot conditions. This factor is remarkable in that, despite the wide operating range, it does not withstand high temperatures. In addition, print settings should differ depending on the technology used. nine0005

In addition, print settings should differ depending on the technology used. nine0005

When printing parts with TPU using FDM, we suggest applying a thin layer of adhesive to the print bed to facilitate adhesion of the material. It is also recommended that the extrusion nozzle reach a temperature between 210 and 235°C to melt the filament (although this will vary by manufacturer). These are general tips, however, the success of a TPU will depend on each 3D printer's configuration and proper calibration; therefore it is recommended to perform small tests with this material before starting more complex prints. nine0005

Good layer adhesion results in excellent mechanical homogeneity.

In terms of stereolithography, TPU is not recommended for small, thin-walled models or models simulating high elongation materials. When setting up a model, it is recommended that the models have their final shape and be oriented close to the production platform, but not more than 20º. Thinner and taller parts will be more difficult to print, although additional supports can always be used for optimal results. nine0005

Thinner and taller parts will be more difficult to print, although additional supports can always be used for optimal results. nine0005

Which companies provide these materials?

In today's additive manufacturing market, we can find major players offering TPU for flexible parts. The giant Ultimaker has a filament called TUP 95A that is compatible with its Ultimaker S5, Ultimaker 3 and Ultimaker 2+ 3D printers. According to the company, the material can withstand up to 580% elongation at break; this thread is available in 4 different colors. Another big company is Formlabs, which introduced its so-called "elastic resin" for SLA technology last year. This resin has a hardness of 50 Shore A, in addition to high elongation and energy return. The elasticity and durability of this material allows it to be used in several cycles. In addition, the technology allows you to reduce costs and delivery times by printing directly on soft parts. nine0005

Source: Formlabs

There are other companies that mainly develop these materials, such as Recreus, which offers a variety of 3D printing filaments. In particular, her famous thread FilaFlex.

In particular, her famous thread FilaFlex.

Source

Tags:

thermoplastic polyurethane (TPU), additive manufacturing, 3D printed flexible modeling, 3D printing filament, Recreus, FilaFlex filament, Ultimaker, TUP 9 filament5A, Formlabs, "Elastic Resin" for SLA Technology

Other materials:

- Researchers determine the impact of powder processing on stainless steel 316L

- Scientists at ITMO University, as part of Megagrant’s work, the Toronto University

- advantages of Materialise Magics when creating supports for 3D printing

- Vladimir Cheverikin: We register the patents of our own .

- How we taught the 3D printer to print with metal casting wax

Attention!

We accept news, articles or press releases

with links and images. [email protected]

SUNLU TPU 1.

75mm Filament 0.5kg 1 Roll 11 Colors High Tenacity 3D Printer Filament Reviews SUNLU TPU 1.75mm Filament 0.5kg 1 Roll 11 Colors High Tenacity 3D Printer Filament Reviews - Banggood UK Online -the shops nine0094 Customer reviews

75mm Filament 0.5kg 1 Roll 11 Colors High Tenacity 3D Printer Filament Reviews SUNLU TPU 1.75mm Filament 0.5kg 1 Roll 11 Colors High Tenacity 3D Printer Filament Reviews - Banggood UK Online -the shops nine0094 Customer reviews - 5 star187 (96.9%)

- 4 star4 (2.1%)

- 3 star1 (0.5%)

- 2 star0 (0%)

- 1 star1 (0.5%)

Write a review You'll get double Banggood points for a review if you're one of the first 3 to leave it!

- All reviews (193)

- Image (31)

- Video (0)

- All Stars

- All sprockets (193)

- 5 Star (187)

- 4 Star (4)

- 3 Star (1)

- 2 Star (0)

- 1 Star (1)

Sort by:

evaluation

- utility nine0172 date

Reviews only from your country (Russian Federation)

|

Show original

Part of the review is translated automatically.

- nine0191

- nine0203

General 0 page

Go to page

Go

Recommended

-

425.

10€

10€ Artillery® Sidewinder X2 and Sidewinder X1 3D Printer Large Print Size Support Kit 300*300*400mm0005

(2204)

-

311.49€

Creality 3D® Ender-3 V2 Upgraded 3D Printer Kit 220x220x250mm Print Size TMC2208 / Ultra Quiet 32-bit Motherboard / Carborane Platform

nine0004 (2535) -

64.

37€

37€ iFlight TITAN XL5 HD Replacement Part 250mm 3K Carbon Fiber Frame Kit Compatible DJI Air Unit for RC Drone FPV Racing

(52)

-

75.73€

30.5*30.5mm HAKRC F722 DJI Stack 45A F7 3-6S Flight Controller Betaflight_4.1.0_MATEK722se with BLHeliSuite ESC for RC FPV Racing Drone

(79)

nine0072 -

18.

93€

93€ Eachine TX805 5.8G 40CH 25/200/600 / 800mW FPV Transmitter VTX LED Display Support OSD / Power Mode / Smart Audio

(4152)

nine0071 - nine0004 9.

46€

46€ 6 Pairs iFlight Nazgul F5 5.1 Inch 3 Blade Propeller with 5mm Bore CW CCW for RC Racing FPV Drone

(444)

-

13.25€

BlitzWolk® BW-S20, 20W, 2 Ports, PD3.0, QC3.0, Wall Charger, FCP Support, AFC, Quick Charge Adapter, EU AU Plug for iPhone 13 13 M

(405)

-

10.

41€

41€ ESP32-CAM-MB-WiFi MICRO USB ESP32 Serial to WiFi ESP32 CAM Development Board Ch440G 5V Bluetooth + OV2640 Camera + 2.4G Antenna IPX

nine0004 (243) -

20.82€

5Pcs URUAV 3.8V 300mAh 40/80C 1S HV 4.35V Ph3.0 Lipo Battery for Happymodel Mobula6 Eachine TRASHCAN Snapper6 7 Mobula7

(974)

nine0072 -

302.

96€

96€ SKYZONE SKY02O FPV Goggles OLED 5.8GHz SteadyView Diversity RX Built-in HeadTracker Video Recorder HDMI AVIN/OUT for RC Racing Drone

(36)

nine0071 -

13.

nine0350 34T 38T 42T 44T 52T Bike Chainring Bike Mid Central Motor Single Chain Ring Cycling Bicycle Accessories 25€

25€ (1)

-

23.66€

Portable DIY Spot Welding Machine with Auto Touch Mode Welding LCD Display for 18650 Battery 12V Auto Super Capcitor Battery

(467)

-

189.

35€

35€ RadioMaster TX16S Hall Sensor Gimbals 2.4G 16CH Multiprotocol RF System OpenTX Mode2 Radio Transmitter for RC Drone

(3179)

-

330.42€

Artillery® GeniusPro and Genius 3D printer Print size 220*220*250mm with silent stepper TFT motor Touch screen support Filament failure

(1672)

-

37.

86€

86€ Creality 3D® CR-Touch Auto Leveling Kit Compatible with Ender-3 V2/Ender-3/CR-10/Ender-3 pro 3D Printer

(269)

nine0071 - nine0004 39.

76€

76€ Creality 3D® Ender-3 V2 Double Rod Bolt Upgrade Kit Double Bolt with Nut for 3D Printer Part

(446)

-

90.88€

JumperRC T-Pro 2.4GHz 16CH Hall Sensor Cardan 1000mW ELRS/CC2500/JP4IN1 Multiprotocol Remote Controller OpenTX2 Firmware Mode Radio Front

(387)

-

9.

46€

46€ 10 Pairs URUAV XT60 Male Female Bullet Power Plug Connectors with Heat Shrink Tube for Lipo Battery

(1386)

-

7.56€

URUAV XT30 K Ph3.0 1S Lipo Battery Charging Cable Wire For Happymodel Mobula6 Mobula7 EMAX Tinyhawk II D6

(316)

nine0071 - nine0004 66.26€

SCULPFUN 400x400mm Laser Cutting Honeycomb Worktable Platform for CO2 or Diode Laser Engraving Cutting Machine

(110)

-

61.

nine0482 TWOTREES® 400*400mm Laser Engraver Honeycomb Desktop Platform for Laser Engraving Cutting Machine 400x400x22mm 53€

53€ (27)

-

90.88€

ULTRA POWER UP9 AC 100W DC 200W LCD Battery Balancer Charger Discharger

(8)

-

16.09€

HXSJ M103FGS Mouse Multimode 2.4GHz Wireless Bluetooth 5.1 Adjustable 800-1600DPI Silent Button Rainbow LED Breathing Light Rechargeable Slim

nine0004 (51) -

28.39€

AC 220V 4000W AC Voltage Regulator Step Down Voltage Converter Transformer Motor Speed Controller vein

(135)

-

21.

77€

77€ 220V 4000W Universal Motor Speed Controller Speed Controller LED Display Motor

(200)

nine0071 - nine0004 €85.

20

20 Drillpro 3 in 1 Adjustable Woodworking Dowel Set Pocket Hole Drill H

(84)

-

22.71€

nine0559 5 pcs. URUAV 3.8V 350mAh 50/100C 1S Lipo Battery Ph3.0 Connector for RC Racing Drone(82)

-

9.99€

Extruder with double toothed pulley and double drive Set + 3 pcs. MK8 1.75/0.4mm Brass Nozzles Accessories Kit for 3D Printer

(163)

-

40.70€

Kexcelled PLA K5Silk 1.75mm / 1kg spool of 3D printer filament

(0)

nine0072 -

17.98€

iFlight XING-E Pro 2207 1800KV 3-6S / 2450KV 2750KV 2-4S Brushless Motor for RC Drone FPV Racing

(839)

nine0071 - nine0004 58.69€

Creality 3D® Filament Dry Box Dust / Moisture / 3D Printer Protection Kit to Protect Print Materials

(23)

-

490.

nine0625 3D Printer Creativity 3D® Ender-3 S1 Build Size 220*220*270mm w/Sprite Direct 2-Stage Extruder/Auto Layer Leveling 42€

42€ (76)

-

90.88€

DarwinFPV Baby Ape/Pro 142mm 3" 2-3S FPV Racing RC Drone PNP 1104 4300KV Brushless Motor

(331)

-

47.33€

eSUN® PLA-LW 3D Printing Material 1.

nine0004 (18) 75 mm 1 kg 2.2 lbs 3D Printing Filament Light Aircraft Model Foam

75 mm 1 kg 2.2 lbs 3D Printing Filament Light Aircraft Model Foam -

9.46€

Creality 3D® 8*25mm Regulating Spring for Extruder for CR-10S PRO/CR-X 3D Printer Heated

(134)

nine0072 -

7.56€

Spare Part DarwinFPV Baby Monkey 3'' Frame Set/Bottom Plate/Top Plate/X Plate/Arm/LED Strip for FPV Racing RC Drone

(64)

nine0071

17.60€

Smallest Mini Dual GLONASS+GPS BN-180 Micro Double GPS Module UART TTL Antenna for CC3D F3 RC Airplane Drone

(1464)

5.67€

Creality 3D® 5PCS 0.4mm Copper M6 Thread Extruder Nozzle for 3D Printer

(1470)

7.85€

Creality 3D® New Upgraded Bowden Red Block Solid Metal Extruder Kit for Ender-3/Ender-3 Pro/Ender-3 V2/CR-10 Pro V2 3D Printer

(402)

312. 43€

43€

New SCULPFUN S9 Laser Engraving Machine Ultrathin Laser Beam Forming Technology High Precision Wood Acrylic Laser Engravers

(696)

13.91€

Audew 16PCS T10 C5W T15/912/921 LED Canbus Auto Dome Domestic License Map Light Plate Lamp

(8)

21. 46€

46€

BIQU® 310*310*4.0mm Carbon Crystal Silicone Glass Plate for B1 SE PLUS 3D Printer Upgrade Accessories

(11)

265.