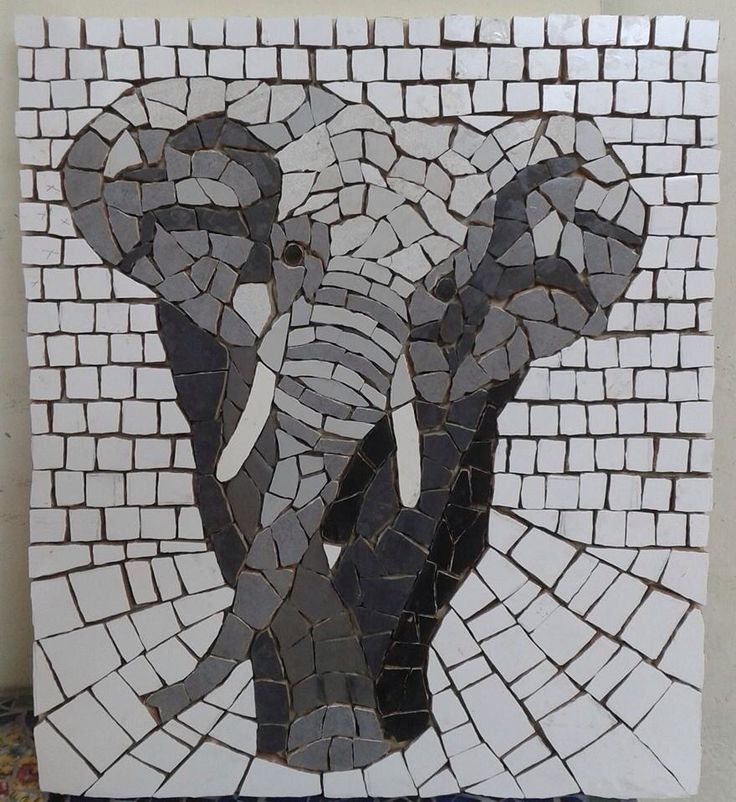

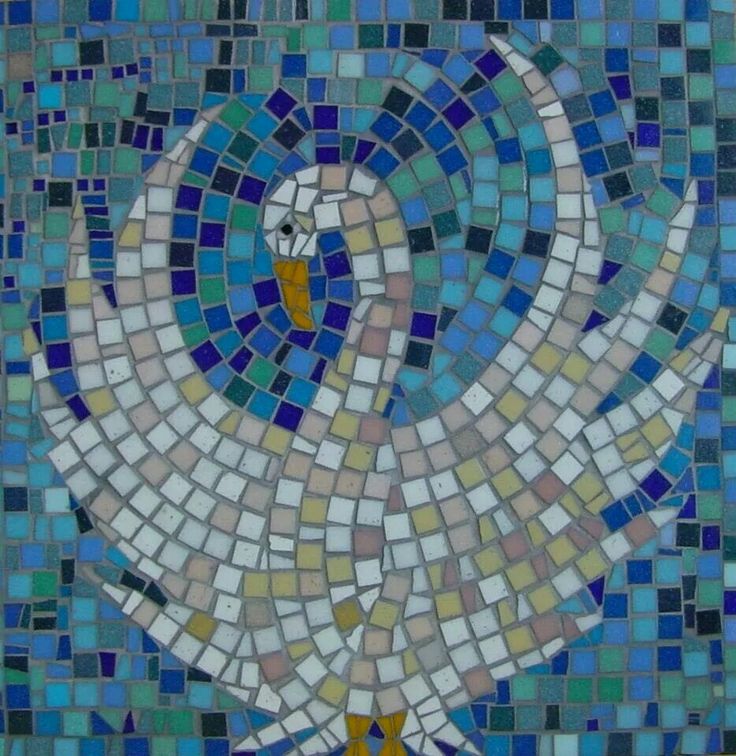

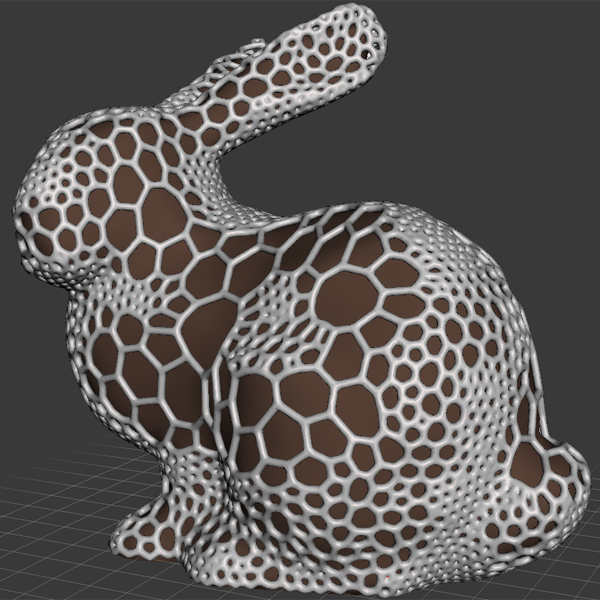

3D print mosaic

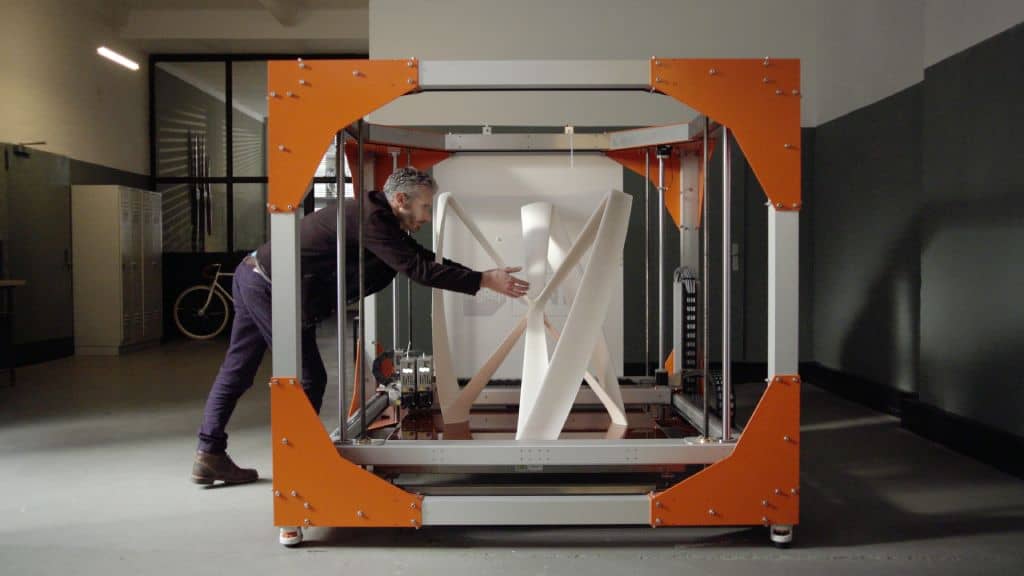

Palette 3 Pro – Mosaic Manufacturing

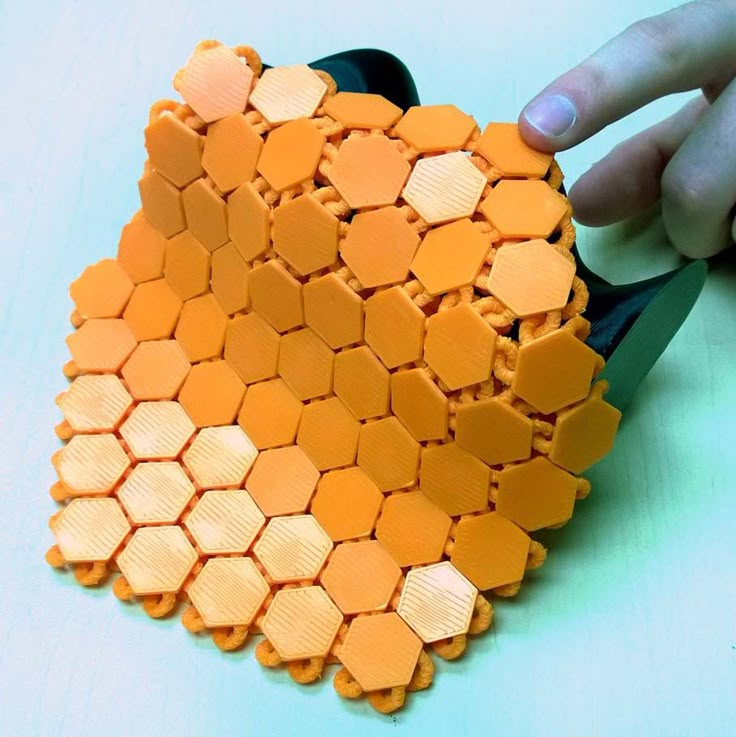

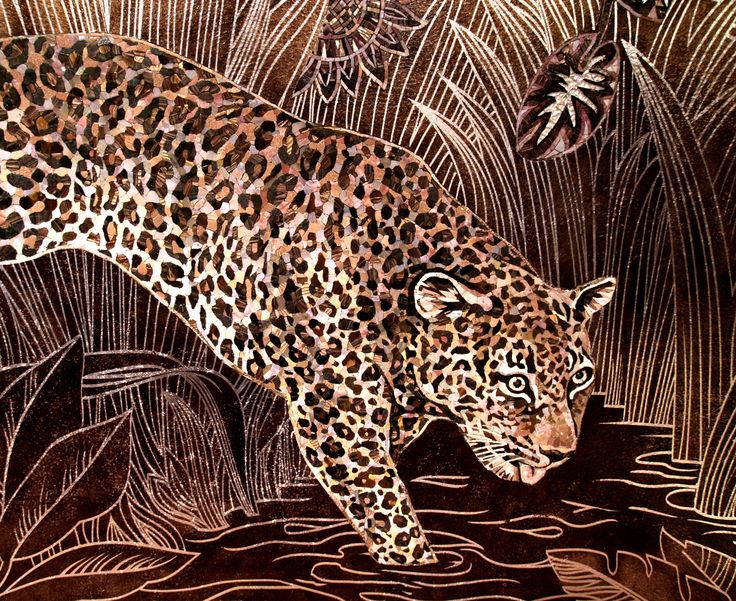

Multiple colours, infinite potential

Communicate your ideas with realistic, multi-colour prints. Palette 3 Pro enables you to achieve prints with up to 8 different colours.

Multi‑Material 3D Printing

Achieve high-quality, functional prints with flexible or rigid materials, or simplify prints with challenging overhangs using breakaway or soluble support.

3rd Generation Splice Core Pro

Engineered to strategically splice filaments, our Splice Core Pro allows your Palette 3 Pro to reach up to 10% faster splicing and cooling speeds.

Automate your filament

If a spool runs out, Palette will automatically splice to another spool and keep your print going. With 8 spools available your prints will always continue to run.

A modern 3D printing experience

To create a more seamless experience, Palette 3 Pro comes with built-in WiFi connectivity to connect your Palette, your printer and your computer.

Customize, Store and Slice

Experience a simple, powerful software suite. With our easy-to-use Canvas software you can slice, paint, stamp, and manage all your prints in the cloud.

Reliable, Plug and Play Material

While Palette 3 will work with most 1.75mm 3rd party filaments, Mosaic's tight tolerance PLA ensures the most reliable printing experience for your Palette 3 and printer.

Palette 3 Pro

With an industry leading 8 material inputs, Palette 3 Pro gives you the most flexibility when it comes to creating multi-material 3D prints

To ensure you always have the best experience, Palette 3 Pro comes with an extended 2-year warranty, Ethernet port and extra spare parts.

Experience the fastest splicing yet with 3rd Generation Splice Core Pro Technology, 10% faster than Palette 3 and 30% faster than Palette 2.

Product Comparison

Palette 3 vs Palette 3 Pro

Palette 3

Palette 3 Pro

Compatibility

Open 1.75mm filament,

.gcode/.x3g (and more)

Ultimaker and Lulzbot machines

Explore Palette Technology

Palette 3

Introducing Palette 3 and Palette 3 Pro

Learn the ins and outs of Palette 3 and Palette 3 Pro, as well as the biggest development changes when compared to previous generations of Palette.

Learn moreExplore Palette Technology

Element

Introducing Element and Element HT

Learn more about Mosaic's multi-material 3D printer line, with Palette X technology embedded inside.

Purchase

Palette

Simple multi-material 3D printing

Palette 3 Pro

$799.00 USD

Multi-material 3D printing at its best – Mosaic Manufacturing

Enabling multi-material 3D printing has been Mosaic’s mission since our early days in 2014. Since then, we’ve sold tens of thousands of Palette units to customers in over 70 countries. Introducing the latest generation of Palette:

Palette 3 + Palette 3 Pro

Design ApproachTwo of the most important aspects that Palette 3 improves on are user experience, and reliability.

Additionally, Palette 3 Pro allows for the printing of up to 8 materials on a single extruder 3D printer. This is double the 4 inputs on every other Palette to date, and more available materials than any other approach on the market.

Simple Multi-Material 3D Printing

Palette 3’s new user interface, and approach to connectivity means that you’re able to get an incredibly simple experience. One of the biggest changes when compared to Palette 2 is the integrated Canvas Hub S. This means that you’re able to connect Palette 3 (Pro) to your printer, and access easier loading, connected calibration, and a simpler printing workflow.

Alongside this, Mosaic has developed our own version of printer control and communication in Canvas, which allows you to send files directly to your Palette 3, with no USB drives or SD cards. Through this interface, you’re able to heat up your printer, start prints, and monitor your print job.

Including Canvas Hub S functionality meant the Mosaic team had more flexibility to add in additional workflows, tutorials, and walkthroughs on Palette itself. This means Palette is better able to guide you through setup and printing.

These three aspects combine to ensure your Palette printing experience will be straightforward and simpler than ever before.

Increased ReliabilityWith product feedback on thousands of Palette 2 units, the Mosaic team was able to isolate the most common failure modes and design Palette 3 to ensure these were no longer present for users.

There were two main wear points that were focused on - splice tubes and limit switches.

Re-Engineered Splicing

Each Palette Splice Core consists of a few main components, one of the important ones being the PTFE tube. This PTFE tube is where the filament is actually spliced, and re-formed to a tight tolerance in order to allow the spliced filament to feed into your 3D printer. These tubes are made through an incredibly precise manufacturing process. Based on our team’s data collection and endurance testing, we found that the typical Palette 2 splice tube would wear out between 5,000 and 10,000 splices.

This PTFE tube is where the filament is actually spliced, and re-formed to a tight tolerance in order to allow the spliced filament to feed into your 3D printer. These tubes are made through an incredibly precise manufacturing process. Based on our team’s data collection and endurance testing, we found that the typical Palette 2 splice tube would wear out between 5,000 and 10,000 splices.

This wear is very dependent on the quality of the filament used, which leads to the range seen above. Increasing the average time for a splice tube to wear is one of the primary reasons we launched Mosaic PLA last year. With tolerances of +/- .02mm, Mosaic PLA guarantees a higher average life of your PTFE tube, especially when compared to +/- .05mm filaments.

Palette 3 was designed to splice in a different way, and due to the Palette Engineering teams’ ability to modify hardware and splicing algorithms - Palette 3 splice tubes average life now ranges from 10,000 splices, up to 25,000 splices.

What that means for you is that you’ll experience a more reliable printing experience.

Filament Sensor Re-Design

One of the requirements of Palette is that it understands where filament is in the system at any given time. In order to accomplish this, Palette has a number of ‘filament sensors’ inside in order to understand if filament is present in that area of Palette (or not present).

The filament sensors on Palette 2 used an off the shelf mechanical switch that was directly in contact with the filament. Sometimes the filament would apply excessive load to the switches requiring them to be replaced leading to a less than optimal user experience.

When working through the initial designs of Palette 3, the Palette engineering team knew that these switches needed to be redesigned and optimized for longer term operation. The team took an entirely new approach to switch design, and the results came in illustrating a new lifetime of over 2,000,000 splices. The new switch features a hardened steel, bi-directiional spring loaded switch tab that activates an optical sensor when the filament displaces the tab. The filament no longer engages with the switch allowing for drastic performance and durability improvements. These switches were run for millions of cycles without fail, and have gone from one of the weaker links in the Palette system to one of the strongest.

The new switch features a hardened steel, bi-directiional spring loaded switch tab that activates an optical sensor when the filament displaces the tab. The filament no longer engages with the switch allowing for drastic performance and durability improvements. These switches were run for millions of cycles without fail, and have gone from one of the weaker links in the Palette system to one of the strongest.

Pushing the boundaries of 3D printing

CamDrive Design and 8 Material 3D Printing

One of the biggest challenges Mosaic’s engineering team faced was how to scale the number of materials Palette could print, without scaling the size and cost of the product accordingly. The Palette Engineering team came up with a cam system that would still allow for 4 inputs on Palette 3 while also enabling up to 8 inputs for Palette 3 Pro.

Building on the backbones of Mosaic’s patent pending sliding selection drive system from a 2014 application, this new rotary CAM system embodies the key benefits of 2 motors to drive any number of filament. Unlike other simpler rotary feeder systems on the market, Palette 3’s CAM is a first of it’s kind workhorse with unrivaled drive strength and consistency between all inputs.

Unlike other simpler rotary feeder systems on the market, Palette 3’s CAM is a first of it’s kind workhorse with unrivaled drive strength and consistency between all inputs.

Cam system works with one motor ‘selecting’ which material is to be driven via rotating a cylinder with a number of idler bearings. Depending on the position of the cam, a certain input’s idler bearing will be opposite the drive gear. This idler bearing pushes the filament into the gear, and the filament is driven when the gear rotates. The other 3 (or 7) materials are not pressed up against the gear so these materials do not move forward when the drive gear rotates.

Cam systems have an incredible amount of nuance to them and must be designed, tested and manufactured in a specific way in order to operate reliably. The cam system in Palette 3 has gone through torture testing of over 100,000 material changes.

Designed with a combination of metal and solid polymer components, the system is strong and rigid enough to last through the most rigorous printing processes.

Constrained Buffer System

The Palette engineering team re-imagined the buffer system inside Palette 3 in order to allow for higher print speeds, and a more constrained material path. This updated buffer system has the material staying inside of a PTFEtube, constraining the material through the buffer.

Unlike Palette 2, The lower limit buffer switch has been moved out to allow for additional movement once this switch has been triggered. In the past, if this switch was triggered it meant that there was no buffer remaining, and if the printer was pulling filament, this could lead to skips in extrusion and small gaps in your part.

With the lower limit switch moved out, there is an additional buffer below this switch, which means Palette 3 will have more time to move filament out into the buffer and continue feeding material to your printer. We also added a buffer maximum switch to further optimize buffer performance.

The constrained buffer system allows for easier automated loading and system clearing.

Additional Cooling Systems

Airflow and cooling is an understated aspect of the Palette system that most operators don’t think about. Cooling splices, and ventilating the electronics systems are incredibly important to reliable operation over longer periods of time.

With the help of some new thermal imaging equipment, we were able to collect data over tens of thousands of splices and use this data to ensure efficient cooling and airflow when Palette 3 is being run over extended periods of time.

3D Printing, Evolved.Palette 3 and Palette 3 Pro are the simplest, most reliable way to achieve multi-material 3D printing on your 3D printer. This generation of Palette is the culmination of 7 years of expertise in multi-material 3D printing, all created to allow you to get the most flexibility out of your machine.

Palette 3 and Palette 3 Pro will begin arriving as early as July 2021, check out the Palette 3 and Palette 3 Pro product page here.

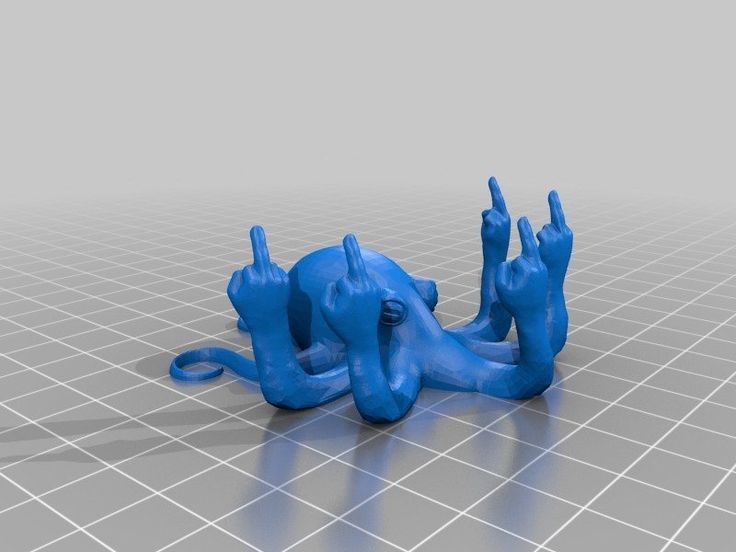

STL file Tiles, mosaic.・Model for download and 3D printing・Cults

Best 3D Printer Files in Architecture Category

BODIE ISLAND LIGHTHOUSE - N (160) SCALE MODEL SIGHTSEEING

6 €

Parametric wall shelf

3,80 €

Trullo from Alberobello, Puglia, Italy

Free

Mayak 1

0.90 €

Display Stand with Gantry for Snap-Fit Saturn 5

Free

Reims Cathedral Kitset

Free

Patrick's Star House

4. 74 €

74 €

The Impossible Castle (Ornamental Mobile)

Free

Bestsellers in the category Architecture

Elbphilharmonie Hamburg

5.90 €

Cinderella's Parisian castle at Disneyland

3.50 €

Eiffel Tower - City of Paris

1.29 €

EMPIRE STATE BUILDING - NEW YORK

€3.99

Elven High-Castle

3.98 €

Tabletop scale shipping container ASSEMBLY

6.08 €

Birdhouse -3 pieces

3,80 €

NEW YORK - CITY OF MANHATTAN

3. 99 €

99 €

WEDNESDAY Addams Merlina

11.31 €

1/64 Generic Showroom

1 € -fifty% 0.50 €

fidget spinner infinity kinetic sculpture

0,57 €

1-100th scale furniture Architecture

0,73 €

nine0007 House "Christmas holidays Lampuna"4.71 €

Good for kindergarten

0.70 €

NEW YORK - EMPIRE STATE BUILDING - MANHATTAN

1.78 €

Hole fronts for hobbits

5 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of . Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon. nine0006

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Ordering Models from a Service Desk

Ordering Models from a Service Desk

1. With a model open, click File > Print > Order 3D Print. A tray will open that contains a preview of the model, showing the model without colors. Alternatively, for remote 3D printers supported by Creo Parametric, click File (File) > Print (Print) > Prepare for 3D printing (Prepare for 3D Printing), change the settings and click Preview. preview 3D printing (Preview 3D Printing). nine0006

2. To change the tessellation of the model you want to send to the service bureau, click Tessellation Options and change the settings.

To change the tessellation of the model you want to send to the service bureau, click Tessellation Options and change the settings.

3. To export STL files, do the following.

a. To set export options, follow these steps.

a. Click File > Options. The Creo Parametric Options dialog box opens.

b. Click Additive Manufacturing. The Additive Manufacturing Settings page opens. nine0006

c. To export model bodies, lattice, and support structures as separate STL files, select the Export body, lattice, and support separately check box. When this option is selected, the following options can also be selected:

d. For models containing more than one body, to export each body as a separate STL file, select the Export each body in a separate STL file check box.

b. Click Export.

▪ If multiple STL files are being created, the Export Zip dialog box opens. All STL files created by the model are saved in one ZIP file.