Large industrial 3d printer

Large Industrial 3D Printers - Large Format AM

BigRep's large 3D printers are your partner for industrial additive manufacturing, whether for functional rapid prototyping, tooling, or end products.

The industrial 3D printers offer a number of state-of-the-art features that enable a wide range of professional applications. Benefit from expert advice on your 3D printer purchase and the wide selection of 3D printing filaments.

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

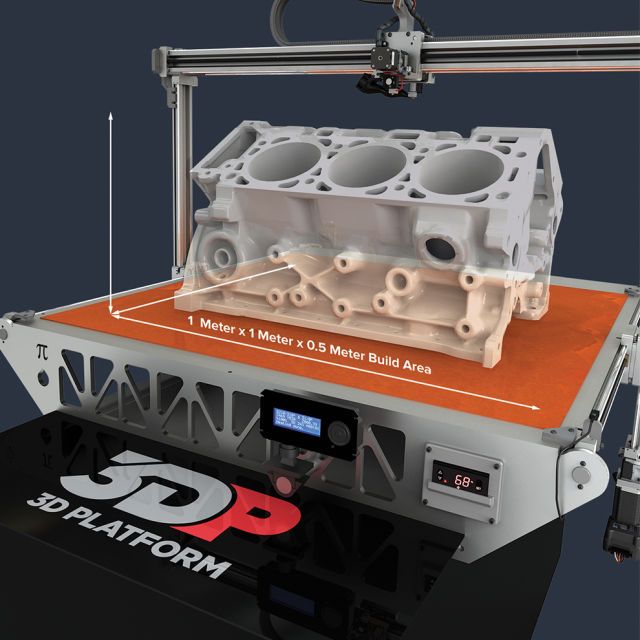

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

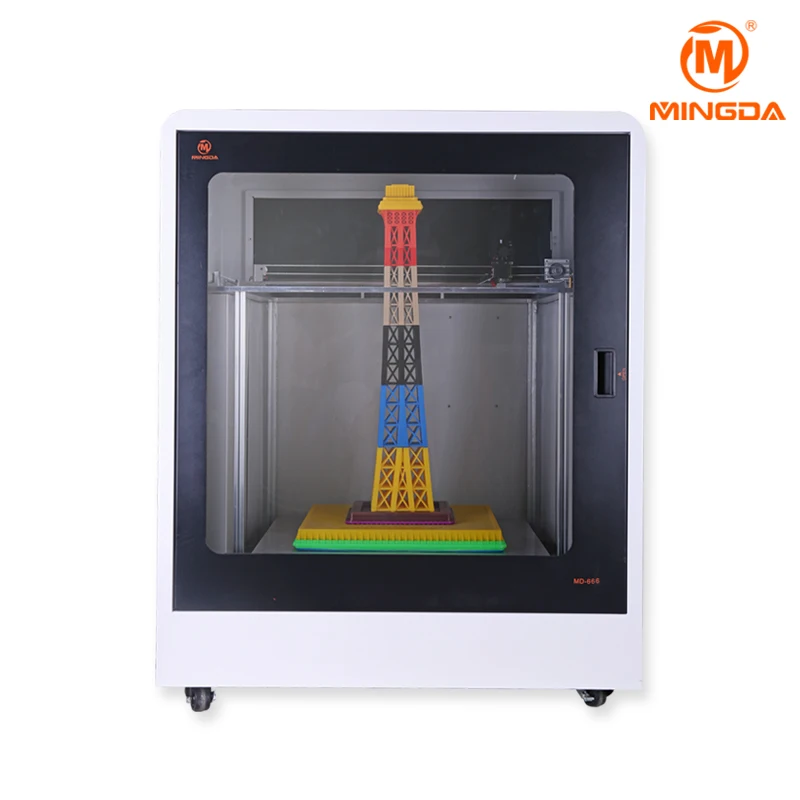

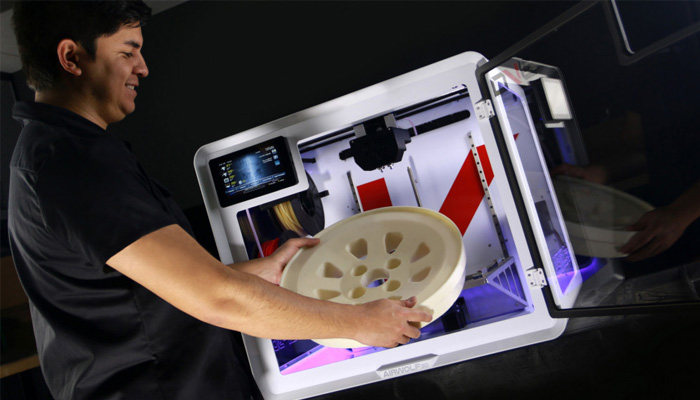

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

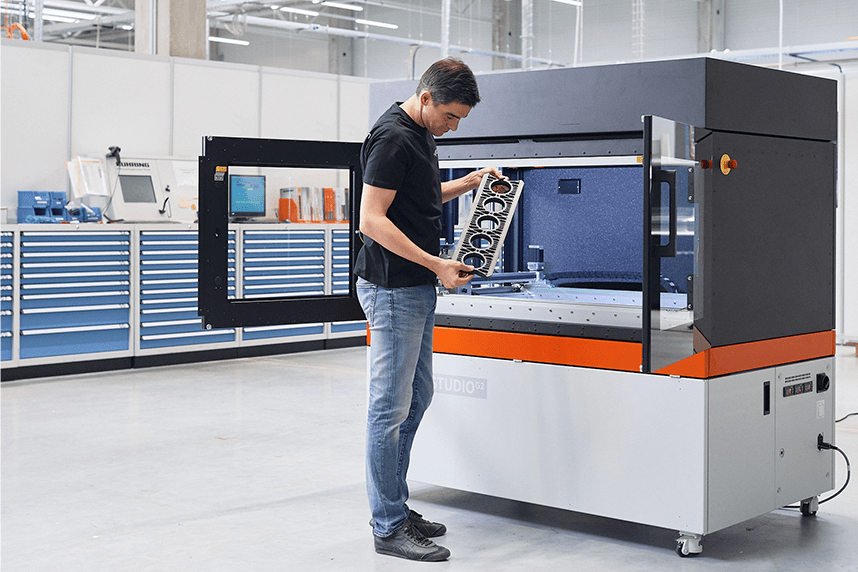

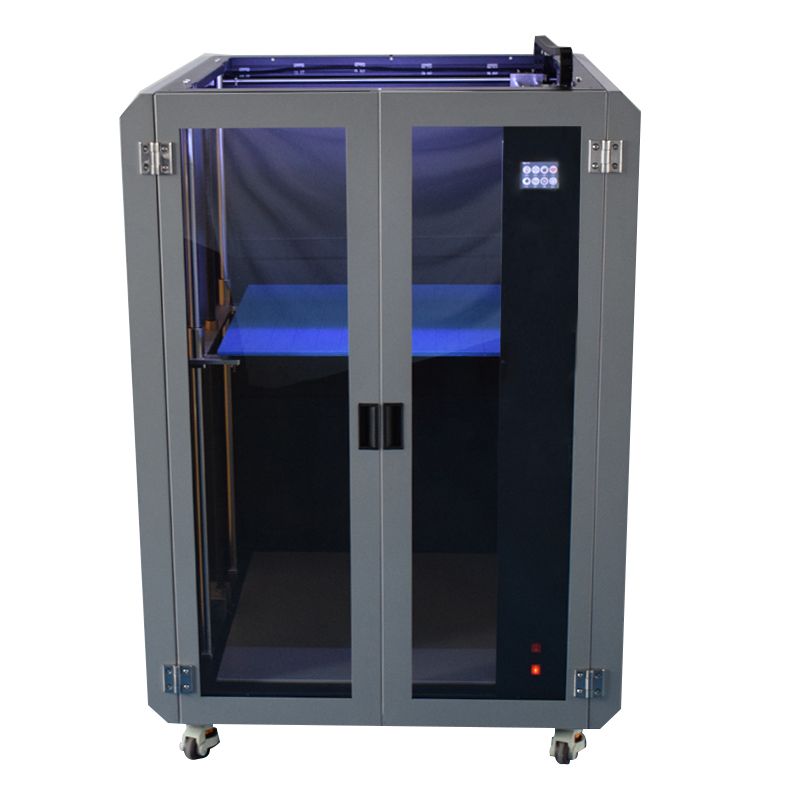

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

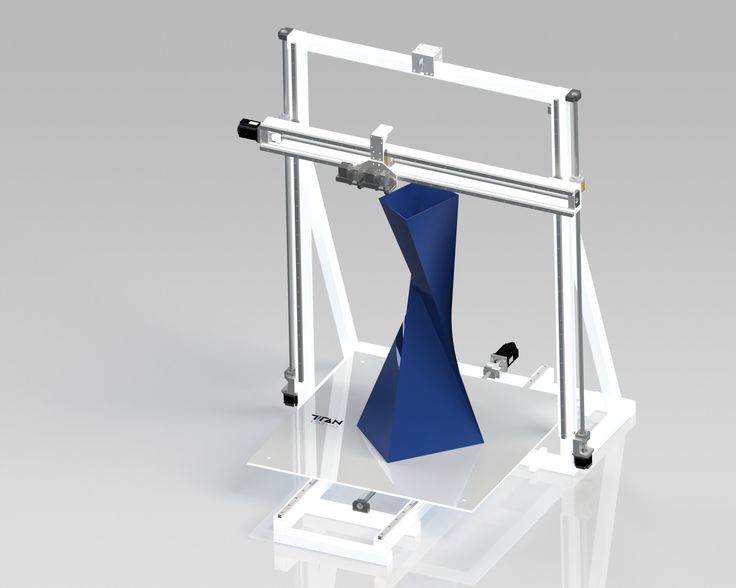

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

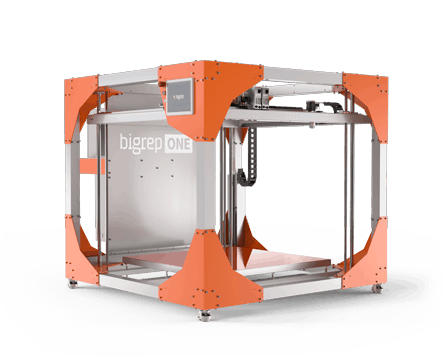

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

Request Pricing or Talk to a 3D Printing ExpertHelp Us Understand Your Needs

REQUEST PRICING

What is 3D Printing?

3D printing, also called additive manufacturing (AM), is a technology used to manufacture three-dimensional objects. 3D printers usually use plastic polymer materials (but also occasionally metal) and form objects by adhering layers to each other in succession.

3D printers usually use plastic polymer materials (but also occasionally metal) and form objects by adhering layers to each other in succession.

Like many other manufacturing technologies, a 3D printer’s production is mapped with computer-aided designs, or CAD models. Digital models are “sliced” by specialized 3D printing software (called slicers) into individual layers and accompanying support structures, then printed.

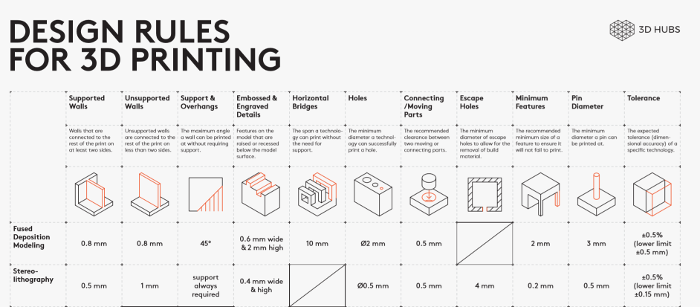

How does a 3D Printer work?How a 3D printer works depends on the specific technology it employs, the most common being FFF (FDM), SLA, and SLS in that order.

1

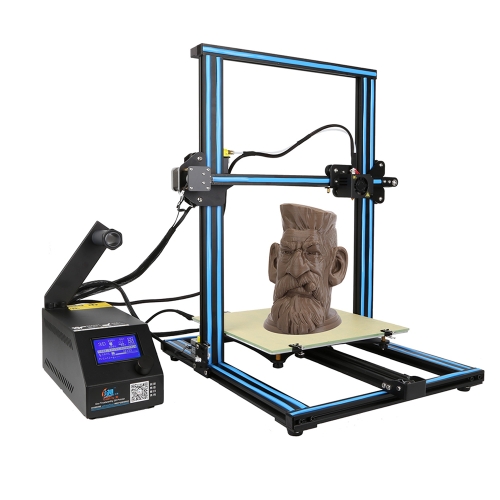

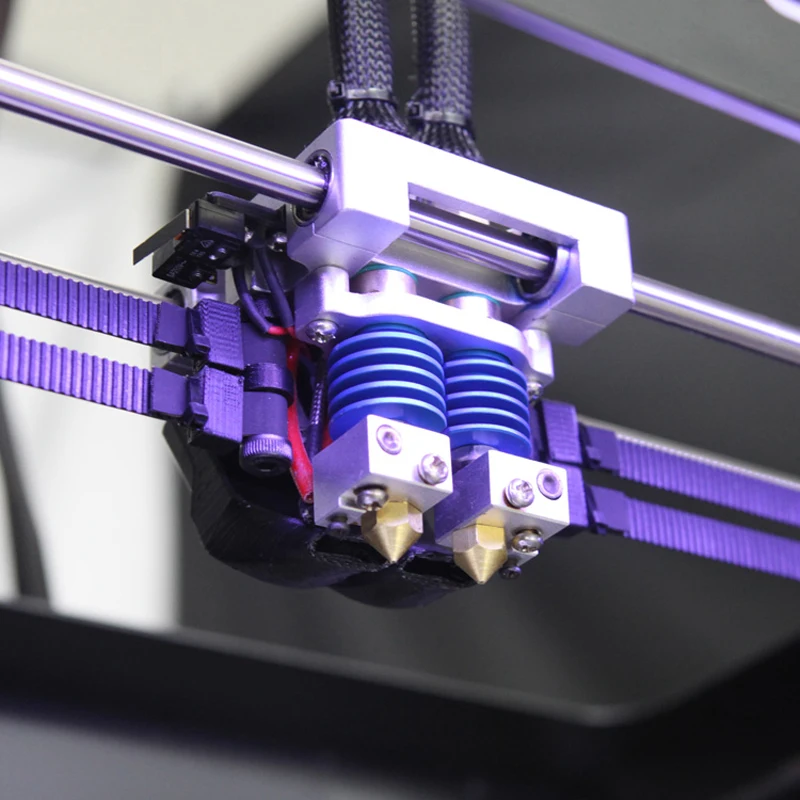

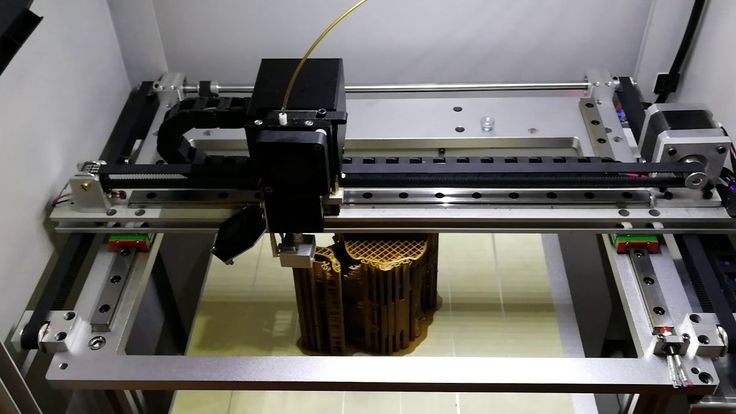

FFF - Fused Filament FabricationFused Filament Fabrication (FFF), also commonly known by its trademarked name; Fused Deposition Modeling (FDM), works by depositing molten filament on top of itself in individual layers until the desired object’s final geometry is formed. FFF is the most common – and usually most affordable – form of additive manufacturing technology available today.

In FFF 3D printing, polymer filament is pushed through an extruder that melts the material at a hot-end – similar to a hot-glue gun pushing solid glue sticks through its hot nozzle. The polymer material is then “printed” in layers as it is pushed through its nozzle, the diameter of which determines the layer size, and deposited onto a build platform (or “print bed”) or preceding layers.

There is usually minimal post-processing required for parts printed with FFF technology beyond support structure removal – if they were necessary at all.

What are some features of an FFF 3D printer?

- Usually fastest of common 3D printing technologies

- Lowest cost in both purchase price and consumables

- Extremely easy post-processing and minimal cleanup

2

SLA - StereolithographyStereolithography (SLA), the second most common additive manufacturing technology, works by curing liquid resin to itself in successive layers to form the desired object.

In SLA 3D printing, a build platform is lowered into a tray of liquid resin where it compresses the material against the bottom of a transparent tray before being cured by a mirrored UV laser. The process repeats, pushing each previous layer against the bottom of the tray until complete.

SLA is capable of incredibly detailed parts but is a material-intensive process. Significantly more of the resin material is normally required than the final object demands for the process to be effective. With excess material usually left in the tray, failed prints risk contamination. Dedicated trays are usually required for each liquid resin – which are themselves consumable as they are worn by light exposure from the UV laser.

What are some features of an SLA 3D printer?

- Capable of very small layer sizes for intricate model details

- Time-consuming process, increased exponentially with smaller layers

- Requires heavy clean up and post-processing with additional curing

3

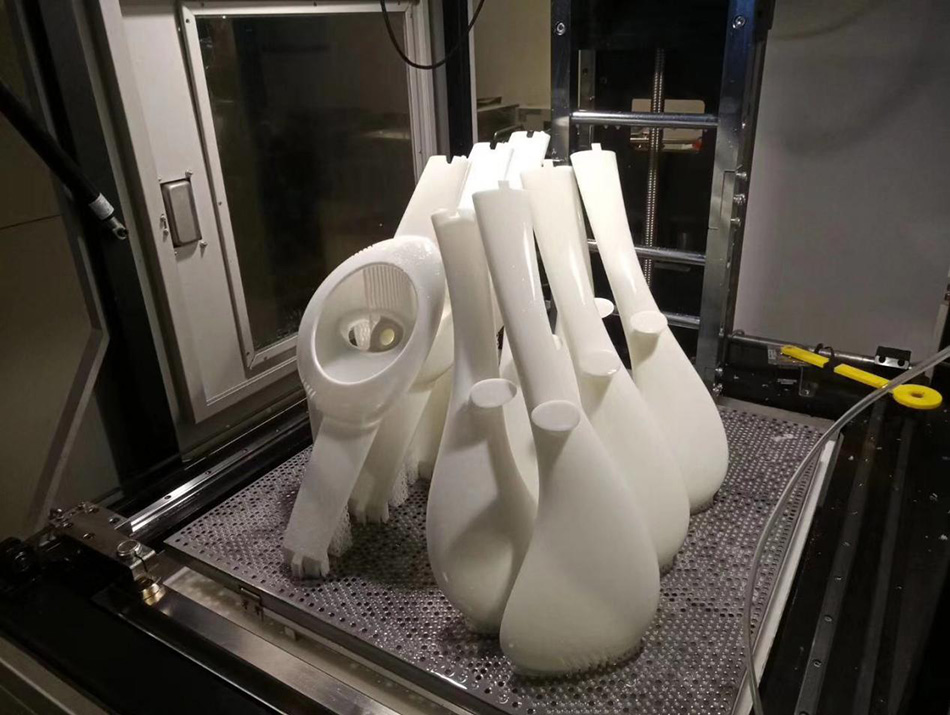

SLS - Selective Laser SinteringSelective Laser Sintering (SLS) works by curing powdered material in successive layers as it is repeatedly spread throughout a build volume until the final object is formed. It is significantly less common than the other plastic technologies listed here, but is commonly used in metal additive manufacturing.

It is significantly less common than the other plastic technologies listed here, but is commonly used in metal additive manufacturing.

Similarly to SLA technology, the SLS process requires an abundance more material than is used to form the final object. However, there is little chance of material contamination and the required excess material serves a secondary purpose as a natural support structure.

Because SLS uses its powder material as a support for printed objects, it requires virtually no post-processing after the print has completed. It is capable of intricate detail but is a relatively slow and expensive process.

What are some features of an SLS 3D printer?

- No post-processing required since excess material serves as supports

- Typically the most expensive of the common 3D printing technologies

- Time-consuming process, increased exponentially with smaller layers

DESIGN

3D printed objects are designed with computer-aided design software (CAD). Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. Increasingly, artificial intelligence and parametric design software is used to automate design processes.

Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. Increasingly, artificial intelligence and parametric design software is used to automate design processes.

3D PRINT

To be 3D printed CAD models must be broken down into individual layers and the printing process mapped with slicing software (or “slicers”). Slicers generate G-code, a computer-aided manufacturing control language, from CAD models that directs a 3D printer’s movements as it recreates the digital model as a physical object.

POST PROCESS

Depending on your design and 3D printing technology, you’ll likely want to improve your print with some post-processing. Post-processing is anything that is done to an object after the 3D printer has finished producing it. Additional curing, support removal, sanding, painting and other coatings are all examples of common post-processing used to achieve a perfect, final 3D printed object.

Advantages of 3D Printing

3D printing offers many advantages over traditional manufacturing technologies. As a uniquely disruptive technology, businesses who invest in additive manufacturing are rewarded with exceptional efficiencies in their production. As 3D printing methods improve and new polymer materials with increased capabilities are introduced to the ever-growing additive manufacturing market, the technology’s possible applications continue to increase exponentially.

3D printers work exceptionally fast to produce impressive, geometrically complex objects – often in a matter of hours, depending on the size.

Traditional manufacturing methods are notorious for long lead times that hold up dependent workflows, often for weeks at a time. As a highly reliable unattended process, 3D printing can produce even full scale objects overnight to be ready for use the next day.

FLEXIBILITY

Because 3D printing uses digital files (CAD models) instead of physical tooling like patterns and molds, it’s a highly flexible technology.

Small series or 100% personalized manufacturing and design processes with many iterations benefit greatly in both speed and cost when compared to traditional manufacturing processes that require manually machined tooling to operate.

Manufacturing costs can be determined by three metrics - material, operating and labor expenses. Unlike wasteful reductive manufacturing techniques, 3D printing is an “additive” process that uses just enough material to produce an object.

As a single unattended process, operating and labor expenses are eliminated by a consolidated process that frees staff for other tasks. Since 3D printers don’t require object-specific tooling, manufacturers also save whenever implementing product changes.

ENVIRONMENTALLY FRIENDLY

Though some forms of 3D printing are more ecological than others, the nature of additive manufacturing technologies – which use just enough material to produce an object – make them all significantly more environmentally friendly than reductive techniques.

In FFF 3D printing “closed-loop” material processes are becoming increasingly common, where polymer shredders are used to recycle filament in-house to be reused in the 3D printing process.

Advantages of Industrial 3D PrintersWith industrial 3D printers you can create functional, full-scale objects or industrial parts beyond the limitations of more standard build volumes.

In smaller build sizes large-format parts must be divided before slicing, printed separately and adhered together in an imperfect manual process. By manufacturing in full scale, you save time by not only avoiding multiple print jobs and post-processing, but also make parts exceptionally stronger. Objects printed with industrial 3D printers are often highly functional parts ranging from end-use products like furniture and recreational vehicles to high-strength industrial tooling.

What is a

large-format 3D Printer used for?3D printers are used for a wide variety of applications, with more becoming a reality every day. The three most common additive manufacturing applications are…

The three most common additive manufacturing applications are…

Increasingly, 3D printers are being used to create end-use parts and even consumer products. Because of the flexibility inherent in additive manufacturing, businesses offering highly personalized products have been using additive manufacturing to create small series or completely unique products for a long time. Today, even industrial manufacturers use 3D printing for serial production and to create affordable, industrial parts.

Tooling / FixturesThough 3D printers don’t require any tooling themselves, they’re fantastic at producing it. Manufacturers can use 3D printing technology to create molds, patterns, or even jigs and fixtures to aid other manufacturing processes.

Unlike traditional tooling production, which usually requires excessive lead times, creating tooling with 3D printing is a fast and simple process. Even larger tooling can be additively manufacturing in an unattended process and be quickly in use on the factory floor.

Because 3D printers can manufacture objects so quickly without specially designed tooling, it’s widely recognized as an ideal technology for product development. Products can be manufactured and redesigned at incredible speed allowing designers to create more iterations and perfect their product.

Later in the design process, the same technology and design files can be used to create functional prototypes, allowing a team to experience their product in the real world.

3D-Printer FAQ

What is considered a large 3D printer?

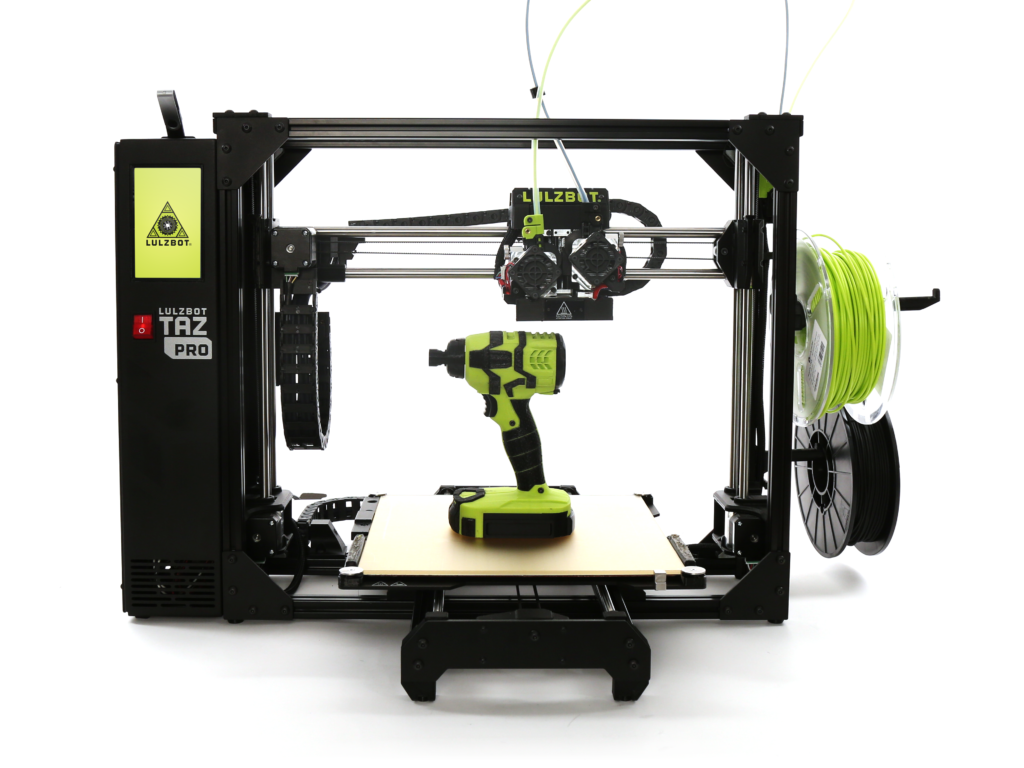

Large 3D printers are too big to fit on a desk and usually offer a build volume bigger than 500x500x500 mm.

Small or large 3D printers can be sorted into two categories:

- Desktop 3D printers

- Large-format 3D printers

BigRep 3D printers provide a build volume of up to 1000x1000x1000 mm.

Which 3D printer has the biggest bed size?

With serial production 3D printers the print bed size can be up to 1000x1000 mm like in the BigRep PRO.

However, there is no real limit to bed sizes as there are custom made 3D printers like the University of Maine's 100 feet (30,5 m) long printer.

Can you 3D print large objects?

The size of a 3D printed object depends on the size of the 3D printer. With a BigRep ONE you can 3D print large objects up to 1000x1000x1000 mm or 35 cubic feet.

What does an industrial 3D printer do?

An industrial 3D printer saves time and money in product development, engineering and manufacturing.

What sets an industrial 3D printer apart from an entry level 3D printer is:

- High reliability

- Faster 3D printing

- High repeatability

- No assembly required

- Factory service

What is 3D printing? How does it work?

3D printing is a process for generating three dimensional objects by creating a cross sectional pattern of the object to be formed. 3D printing is a subset of broader term additive Manufacturing. In loose terms technology used here is slicing CAD model of part geometry in layers using software and producing one layer at a time. Each layer sticks to previous layer and thus building the whole solid part in layers.

In loose terms technology used here is slicing CAD model of part geometry in layers using software and producing one layer at a time. Each layer sticks to previous layer and thus building the whole solid part in layers.

What technology is used in 3D printing?

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses, but choosing between the various competing 3D printing solutions can be difficult.

Which technology is suitable for your application? What materials and equipment’s are available to get started? How about costs and return on investment?

There are three most established plastic 3D printing technologies for plastic: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

How many types of 3D printing are there?

There are 7 different types of 3D printing formulated by ASTM International officially in the ISO/ASTM 52900 standard:

- Material extrusion

- Material jetting

- Binder jetting

- Sheet lamination

- Vat photopolymerization

- Powder bed fusion

- Directed energy deposition

What materials can be used in 3d printing?

Plastics are the most widely adopted 3D printed material - and it comes in filament, resin, granule, and powder forms. Most thermoplastic 3D printing materials can be used in home 3D printing technology and professional applications as well. Below materials are also used widely:

Most thermoplastic 3D printing materials can be used in home 3D printing technology and professional applications as well. Below materials are also used widely:

- Acrylonitrile Butadiene Styrene (ABS)

- Polylactic Acid (PLA)

- Polyvinyl Alcohol (PVA)

- Nylon

- High-density polyethylene (HDPE)

What could an industrial 3D printer do for you?

Help Us Understand Your Needs

Get your quote now

Industrial Large-Format 3D Printer for Professionals

MEET THE NEW

ITERATE FAST. PRODUCE FASTER.

GET TO MARKET FASTEST.

Play Video

Video embed code not specified.

ITERATE FAST. PRODUCE FASTER.

GET TO MARKET FASTEST.

REQUEST PRICING

WATCH DEMO NOW

With a 1 cubic meter build volume, the BigRep PRO is a fully enclosed industrial 3D printer for producing fullscale, large parts including functional prototypes, factory tooling, patterns and molds, and end-use parts. Built for productivity throughout all stages of manufacturing, the PRO provides designers, engineers, and manufacturers with an easy-to-use, agile solution to produce faster and cheaper.

Built for productivity throughout all stages of manufacturing, the PRO provides designers, engineers, and manufacturers with an easy-to-use, agile solution to produce faster and cheaper.

Supported by its Precision Motions Portal, a durable, custom-built gantry, along with Bosch Rexroth CNC components, the PRO consistently delivers on speed, precision, and quality. Now thanks to JUMPSTART, a new BigRep hybrid software-hardware solution that lets you skip the hassle and just start printing, the PRO is easier than ever to use.

Industrial Applications with the BigRep PROPROTOTYPES- Produce full-scale, functional parts from the alpha phase to zero series

- Learn faster and iterate designs in hours and days, not weeks and months

- Avoid expensive, outsourced, and traditional slow production

- Customize tools for perfect fit, reduced weight, and ergonomic design

- Slash lead times with on-demand production and avoid outsourcing logistics

- Reduce production and material costs of optimized tooling

- Replace high-cost patterns and molds made from expensive materials

- Speed up design iteration, product testing, and production

- Minimize outsourcing, external logistics, and supply chain dependence

- From small-series production to unique parts without added costs

- Produce on-demand to reduce inventory and warehousing

- Reduce lead times and get to market fast to stay ahead of the competition

JUST PRINT.

JUST PRINT.Using the latest PRO 3D printer is easier than ever thanks to BigRep JUMPSTART, a hybrid software-hardware solution that lets you skip the hassle and just start printing. It includes the SWITCHPLATE®, a removable and flexible print bed surface, the LOCKSTAGE for easy and secure extruder mounting, and the MXT® Control System that bypasses manual calibration ensuring crucial first print layers are optimal every time.

SWITCHPLATE®

The SWITCHPLATE® is a removable and flexible print bed surface available in different coatings, each optimized for various materials ensuring proper bed adhesion. It is magnetic and easily snaps into place. Heat increases the adhesiveness of the surface so your print stays fixed during printing, but is easy to remove once cooled.

MXT® CONTROL SYSTEMThe MXT® Control System employs proprietary algorithms that improve your gcode print file. The result is better quality, higher accuracy, and all-around consistent results. MXT® is the brain powering JUMPSTART, which simplifies the user experience, bypassing the need for manual calibration for the print bed, extruder, and dual extrusion.

MXT® is the brain powering JUMPSTART, which simplifies the user experience, bypassing the need for manual calibration for the print bed, extruder, and dual extrusion.

The LOCKSTAGE allows simple and secure extruder mounting without the need for manual position calibration. Extruders easily snap into place and provide consistent precision throughout your entire print.

3D PRINTER MATERIALS FOR YOUR APPLICATIONThe BigRep PRO is designed to print engineering-grade and carbon fiber-reinforced materials as well as bio-polymers and water soluble support. BigRep develops and certifies filaments specifically for the BigRep PRO and also is third party compatible meaning you can print with BigRep materials as well as other brands.

NOW COMPATIBLE WITH

PA12-CF3D PRINTER MATERIALS FOR YOUR APPLICATIONThe BigRep PRO is designed to print engineering-grade and carbon fiber-reinforced materials as well as bio-polymers and water soluble support. BigRep develops and certifies filaments specifically for the BigRep PRO and also is third party compatible meaning you can print with BigRep materials as well as other brands.

BigRep develops and certifies filaments specifically for the BigRep PRO and also is third party compatible meaning you can print with BigRep materials as well as other brands.

BigRep ASA is an engineering-grade UV-resistant filament for high-strength and environmentally exposed applications.

Learn More

BigRep PETG is ideal for 3D printing projects requiring strength, toughness and thermal resistance in a filament.

Learn More

BigRep's HI-TEMP CF is a high-strength and heat-resistant engineering-grade filament.

Learn More

BigRep’s BVOH support material is an ecologically friendly advanced water-soluble filament that eliminates post-processing for 3D printed parts.

Learn More

BigRep's Pro HT is a general-use bio performance material for open-environment 3D printing.

Learn More

BigRep PLA is an easy-to-use filament optimized for producing prototypes and pattern making, for end-use parts to the wide range of tooling applications.

Learn More

BigRep's PA6/66 is a highly durable 3D printing filament for industrial applications.

Learn More

BigRep PRO is now compatible with PA12-CF, carbon fiber reinforced PA12 filament.

Get to know the

BigRep PRO 3D PrinterLARGE-SCALE & GERMAN ENGINEERED

High Accuracy at High SpeedsThe Precision Motions Portal

The PRO's massive 1m3 build volume is supported by a durable, custom-built gantry engineered for high speed, fast acceleration, and accuracy. The robust frame eliminates vibrations during 3D printing assuring fast, yet precise movement gliding the extruders along a reinforced carriage system. Powered by Bosch servo motors with integrated encoders, the PRO calculates the real-time location of the print head to self-monitor for position accuracy.

Fast, Precise & Fiber-ReadyThe Advanced Capability Extruder

BigRep’s Advanced Capability Extruder (ACE) expands the material capabilities of the PRO while still reliably delivering quality 3D prints with speed and precision. ACE is a direct drive extruder, perfectly equipped for fiber-reinforced materials such as BigRep’s HI-TEMP CF. With ACE you can print large-format, strong parts 50% faster than other large-scale printers.

ACE is a direct drive extruder, perfectly equipped for fiber-reinforced materials such as BigRep’s HI-TEMP CF. With ACE you can print large-format, strong parts 50% faster than other large-scale printers.

The Dry Material Storage

The PRO’s environmentally sealed filament chamber with a two-spool capacity ensures that all materials, including engineering-grade and water-soluble, remain dry in a consistently temperature and humidity-controlled environment. Even when powered off, the PRO’s airtight material storage ensures best-in-class quality and reliability.

“The first prints that we ran lasted 17 days. Since then, we have been

running the PRO non-stop to print parts and components using its large capacity, high resolution and accuracy throughout the entire process. ”- Riley Gillman, Technical Operations Manager of Nikola Corporation

Technical Specifications| Version | BigRep PRO. 2 2 |

| Build Volume | Up to x 1020, y 970, z 985 mm (x 40, y 38, z 38.5 in) |

| Materials | PLA, HI-TEMP CF, PRO HT, PETG, ASA, PA6/66, PA12-CF Water Soluble BVOH Other filaments upon request |

| Slicing Software | BigRep BLADE |

| Extruders | Fiber-Ready PRO ACE Extruder |

| Layer Heights | 0.3 mm, 0.6 mm (Other layer heights supported through slicer software) |

| Nozzle Diameters | 0.6 mm, 1.0 mm |

| Speed | Acceleration (XY) | Max. 600 mm/s | Max. 5000 mm/s² |

| Achievable Part Accuracy | ±0.2mm or ±0.002mm/mm (whichever is greater)* |

| Material Storage | 2x sealed keep dry filament chambers supporting up to 8 kg spools each |

| Machine Size | x 1950 y 2500 z 2105 mm / x 77 y 98 z 83 inches (with tower) |

| Machine Weight | Approx. 1550 kg (3417 lb) 1550 kg (3417 lb) |

| Power | 3 Phase 400V AC, PE, 16 A, 50 / 60 Hz |

| Safety Certifications | UL, CE, EC Machinery Directive 2006/42/EC Compliant |

* accuracy depends on part geometry and material used

Request Pricing or Talk to a 3D Printing ExpertFind out what the BigRep PRO can do for you.

REQUEST PRICING NOW

BigRep PRO DemonstrationLarge-Format 3D Printing Now Easier Than Ever

WATCH DEMO NOW

INTRODUCING

UNLOCK

DATA. DISCOVER CONVENIENCE.BigRep CONNECT is a one-stop platform connecting you with your BigRep printers to boost productivity with remote monitoring and data analytics. Best of all: it's free.

LEARN MORE

Industrial metal 3D printers

Technology | Benefits | Usage examples | Equipment selection

Metal 3D printing is rightfully considered one of the most promising technologies that can replace traditional production methods in the near future. metal 3D printers are already appearing today in industrial plants, construction sites, design offices and other industries. nine0003

metal 3D printers are already appearing today in industrial plants, construction sites, design offices and other industries. nine0003

Industrial Metal 3D Printers are the product of the most technologically sophisticated Additive Manufacturing business . Attempts to 3D print metal were made in the early stages of 3D printing, and over the past decade have made a tremendous leap in this direction.

Technologies

With the advent of metal 3D printers , the hegemony of traditional technologies was somewhat shaken, but a decade ago, few believed in the possibility of printing, and few imagined that the question of a comprehensive replacement of technologies and means of creating products in metallurgical production would arise . nine0003

Today the situation has changed radically. The technology used in the best 3D metal printers has already proven its effectiveness.

Selective Laser Melting (SLM)

This technology allows you to create objects of any geometric shape from metal powder. The principle is based on the ability to create metal models by layer-by-layer melting of powders of various metals and alloys. Such materials include titanium, stainless and tool steels, chromium and alloys, as well as other raw materials. nine0003

Machines using SLM technology, such as SLM 280HL and Realizer SLM 250, allow you to create high-precision metal parts of any complexity and geometry directly from a digital model. This technology is excellent for manufacturing high-precision parts and assemblies of various designs. At the same time, 3D printers based on SLM technology provide a huge performance and cost advantage compared to traditional metal fabrication technologies. nine0003

Benefits of

Talking about the prospects of 3D printing with metal can take a long time, but initially it is worth considering in more detail what a modern metal 3D printer is like. Until two decades ago, mold casting was seen as the only cost-effective way to make 3D products. Years passed before the metal 3D printer appeared, capable of competing with, and in the future, replacing traditional methods of metal production. nine0003

Until two decades ago, mold casting was seen as the only cost-effective way to make 3D products. Years passed before the metal 3D printer appeared, capable of competing with, and in the future, replacing traditional methods of metal production. nine0003

So, what are the advantages of 3D printing with metal compared to standard production methods?

1. More complex shapes and designs.

Additive technologies give you more design freedom. 3D printing is able to produce much more complex products than the longer standard process can offer. metal 3D printers can create components with pits, cavities, thin walls and closed objects. nine0003

2. Low cost.

3D Printer metal printing process does not require any additional tools. Therefore, it is easy to replace the complex and expensive processes of stamping, mold casting. This will not only reduce costs, but also free up funds for the further development of the enterprise.

industrial metal 3D printers create products using less kW of energy and generating much less waste. It also reduces costs and eliminates the need to install environmentally friendly equipment. nine0003

3. Any combination of materials.

Metal printing technologies allow the use of any combination of powder materials for the needs of the automotive and aircraft industries, the space industry, as well as other types of production. Mixing of various materials based on titanium, nickel and aluminum, as well as various alloys, makes it possible to obtain new components and assemblies in terms of their thermal conductivity, electrical conductivity and other characteristics.

Application examples

Enhancement 9The 0007 industrial metal 3D printer has enabled these machines to replace entire sectors of traditional manufacturing.

For example, thanks to the SLM 500 HL 3D printer, NASA specialists successfully tested titanium nozzles for rocket engines, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, presented the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

What if a tragedy happened to a person and some tissues cannot be restored? 3D printing can carry out prosthetic surgery. For example, the Swedish company Acam, using a Realizer SLM 250 metal 3D printer, creates monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products, and their number has already exceeded thirty thousand copies. nine0003

In addition, 3D printed limbs can compete with high-tech designs, but cost ten times less.

Selection of equipment

Globatek.3D is the official dealer in Russia of the best manufacturers of 3D equipment. The company represents world famous brands: 3DSystems, SLM Solutions, Realizer, Artec, Creaform, Solutionix. The equipment of these manufacturers reliably serves in various areas of human activity: from medical laboratories to industrial production. nine0003

Globatek.3D provides delivery, setup and efficient operation of equipment. If you need advice on choosing a 3D printer, call +7 (495) 646-15-33 and our experts will answer all your questions.

If you need advice on choosing a 3D printer, call +7 (495) 646-15-33 and our experts will answer all your questions.

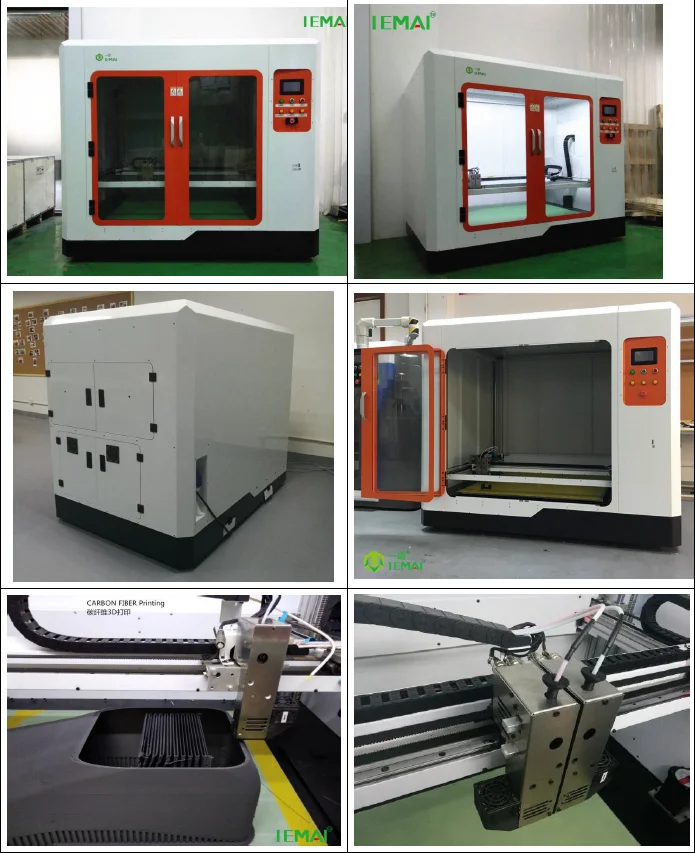

Total Z industrial 3D printers

FDM and SLS 3D printers, drying and post-processing equipment

About company

FDM 3D printers nine0021

Industrial 3D printers Total Z PRO series

450-PRO 950-PRO

Total Z High Performance LPRO Series 3D Printers

1000-PRO-LL

Total Z G3 Series Desktop 3D Printers

250-G3 250-G3 (2X) XL250-G3(2X) nine0003

Total Z G5 Series Desktop 3D Printers

G5

SLS 3D printers Total Z

SLS-250

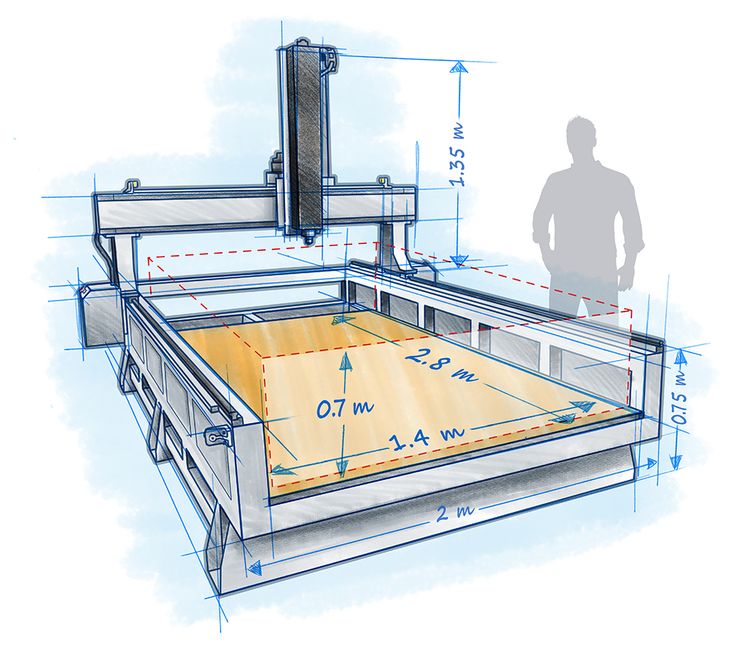

Portal systems for 3D printing with granules

Total Z AnyForm FGF

Total Z machines for drying and post-processing nine0021 Total Z D5

Vacuum drying chambers

Help prepare plastic for printing. Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

View →

Total Z MPC-310Acetone baths nine0105

Equipment for chemical post-processing of finished objects. Helps to achieve a glossy and smooth product surface.

View →

Total Z UB-450; 500; 650; 950; 1200;Ultrasonic baths

Machines for physical and chemical post-processing of models. Remove the supporting plastic from the surface of finished products. They clean the material in places inaccessible for manual processing. nine0003

See 5 models →

Our capabilities

The equipment complies with Russian and international standards

Consumables for printers and equipment are always in stock

We participate in R&D, cooperate with research institutes

We work with defense enterprises and government customers nine0003

Operational warranty service

Departure and training on the territory of the customer

Implemented projects by industry

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM. nine0003

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group. nine0003

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time. nine0003

nine0003

Education

Production of a desktop 3D printer for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain. nine0003

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM. nine0003

nine0003

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group. nine0003

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time. nine0003

nine0003

Education

Production of desktop 3D printers for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain. nine0003

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Services

3D printing

Casting

Reverse engineering

prototyping nine0259

Upcoming Events

New models of Total Z industrial 3D printing systems in Moscow at the Interplastica exhibition

Interplastica is a key event for the plastics and rubber market, which annually brings together experts from all over the world at one business platform.