Big 3d printing

Large Industrial 3D Printers - Large Format AM

BigRep's large 3D printers are your partner for industrial additive manufacturing, whether for functional rapid prototyping, tooling, or end products.

The industrial 3D printers offer a number of state-of-the-art features that enable a wide range of professional applications. Benefit from expert advice on your 3D printer purchase and the wide selection of 3D printing filaments.

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

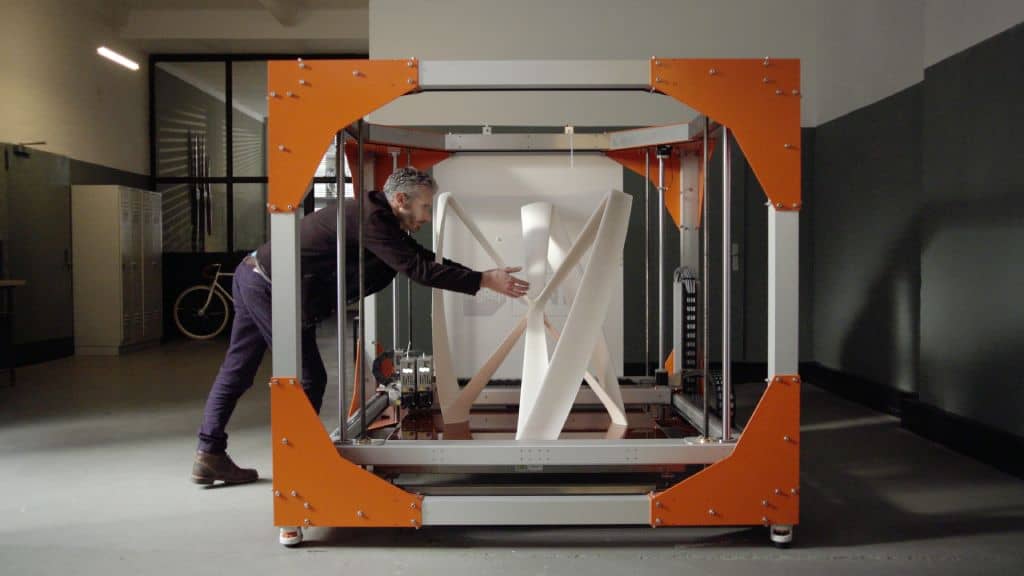

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

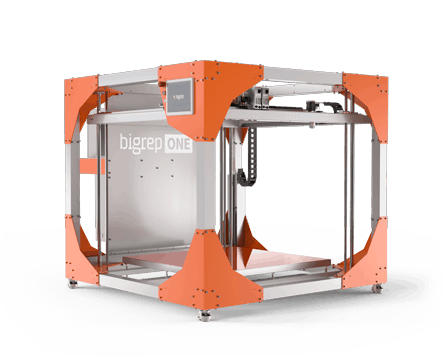

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

Request Pricing or Talk to a 3D Printing ExpertHelp Us Understand Your Needs

REQUEST PRICING

What is 3D Printing?

3D printing, also called additive manufacturing (AM), is a technology used to manufacture three-dimensional objects. 3D printers usually use plastic polymer materials (but also occasionally metal) and form objects by adhering layers to each other in succession.

3D printers usually use plastic polymer materials (but also occasionally metal) and form objects by adhering layers to each other in succession.

Like many other manufacturing technologies, a 3D printer’s production is mapped with computer-aided designs, or CAD models. Digital models are “sliced” by specialized 3D printing software (called slicers) into individual layers and accompanying support structures, then printed.

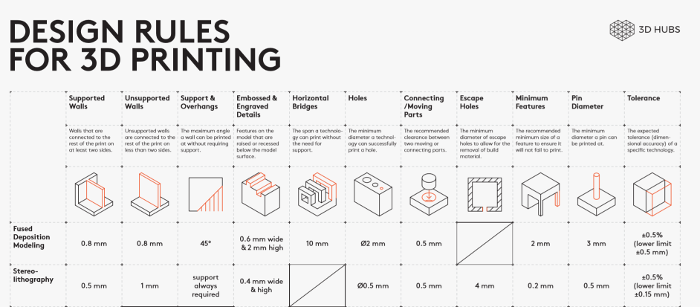

How does a 3D Printer work?How a 3D printer works depends on the specific technology it employs, the most common being FFF (FDM), SLA, and SLS in that order.

1

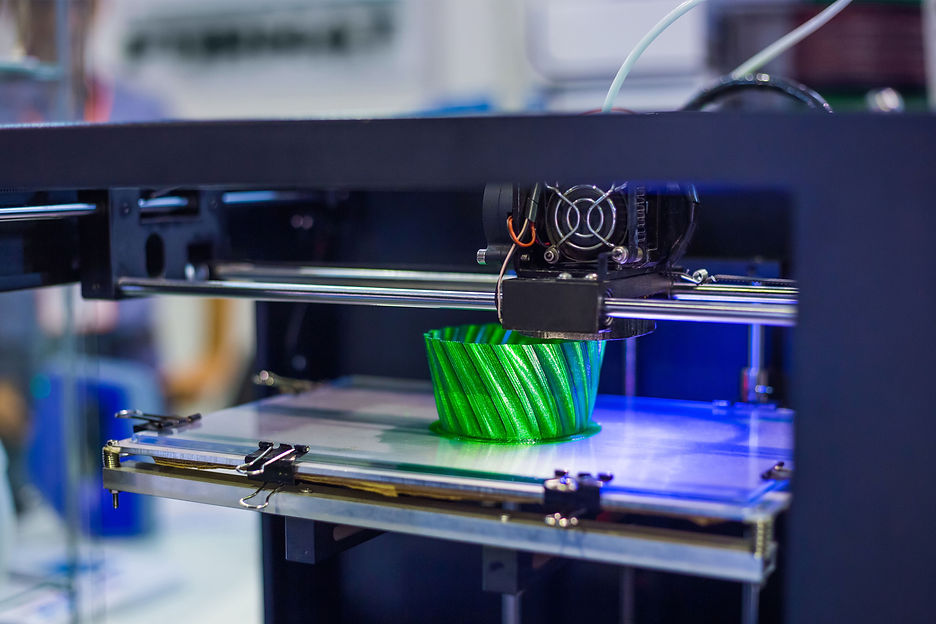

FFF - Fused Filament FabricationFused Filament Fabrication (FFF), also commonly known by its trademarked name; Fused Deposition Modeling (FDM), works by depositing molten filament on top of itself in individual layers until the desired object’s final geometry is formed. FFF is the most common – and usually most affordable – form of additive manufacturing technology available today.

In FFF 3D printing, polymer filament is pushed through an extruder that melts the material at a hot-end – similar to a hot-glue gun pushing solid glue sticks through its hot nozzle. The polymer material is then “printed” in layers as it is pushed through its nozzle, the diameter of which determines the layer size, and deposited onto a build platform (or “print bed”) or preceding layers.

There is usually minimal post-processing required for parts printed with FFF technology beyond support structure removal – if they were necessary at all.

What are some features of an FFF 3D printer?

- Usually fastest of common 3D printing technologies

- Lowest cost in both purchase price and consumables

- Extremely easy post-processing and minimal cleanup

2

SLA - StereolithographyStereolithography (SLA), the second most common additive manufacturing technology, works by curing liquid resin to itself in successive layers to form the desired object.

In SLA 3D printing, a build platform is lowered into a tray of liquid resin where it compresses the material against the bottom of a transparent tray before being cured by a mirrored UV laser. The process repeats, pushing each previous layer against the bottom of the tray until complete.

SLA is capable of incredibly detailed parts but is a material-intensive process. Significantly more of the resin material is normally required than the final object demands for the process to be effective. With excess material usually left in the tray, failed prints risk contamination. Dedicated trays are usually required for each liquid resin – which are themselves consumable as they are worn by light exposure from the UV laser.

What are some features of an SLA 3D printer?

- Capable of very small layer sizes for intricate model details

- Time-consuming process, increased exponentially with smaller layers

- Requires heavy clean up and post-processing with additional curing

3

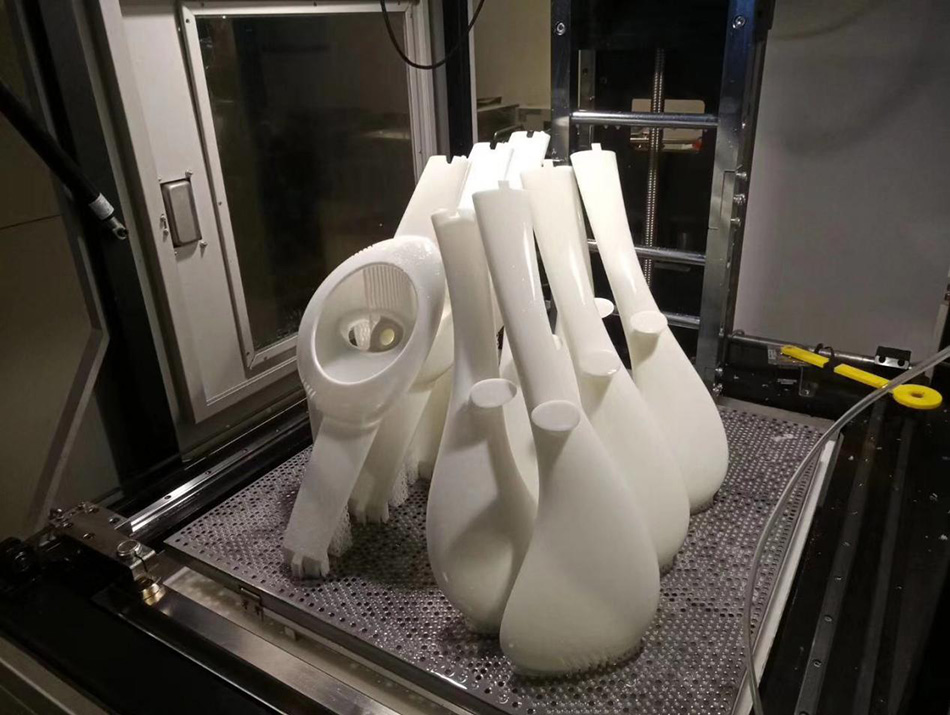

SLS - Selective Laser SinteringSelective Laser Sintering (SLS) works by curing powdered material in successive layers as it is repeatedly spread throughout a build volume until the final object is formed. It is significantly less common than the other plastic technologies listed here, but is commonly used in metal additive manufacturing.

It is significantly less common than the other plastic technologies listed here, but is commonly used in metal additive manufacturing.

Similarly to SLA technology, the SLS process requires an abundance more material than is used to form the final object. However, there is little chance of material contamination and the required excess material serves a secondary purpose as a natural support structure.

Because SLS uses its powder material as a support for printed objects, it requires virtually no post-processing after the print has completed. It is capable of intricate detail but is a relatively slow and expensive process.

What are some features of an SLS 3D printer?

- No post-processing required since excess material serves as supports

- Typically the most expensive of the common 3D printing technologies

- Time-consuming process, increased exponentially with smaller layers

DESIGN

3D printed objects are designed with computer-aided design software (CAD). Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. Increasingly, artificial intelligence and parametric design software is used to automate design processes.

Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. Increasingly, artificial intelligence and parametric design software is used to automate design processes.

3D PRINT

To be 3D printed CAD models must be broken down into individual layers and the printing process mapped with slicing software (or “slicers”). Slicers generate G-code, a computer-aided manufacturing control language, from CAD models that directs a 3D printer’s movements as it recreates the digital model as a physical object.

POST PROCESS

Depending on your design and 3D printing technology, you’ll likely want to improve your print with some post-processing. Post-processing is anything that is done to an object after the 3D printer has finished producing it. Additional curing, support removal, sanding, painting and other coatings are all examples of common post-processing used to achieve a perfect, final 3D printed object.

Advantages of 3D Printing

3D printing offers many advantages over traditional manufacturing technologies. As a uniquely disruptive technology, businesses who invest in additive manufacturing are rewarded with exceptional efficiencies in their production. As 3D printing methods improve and new polymer materials with increased capabilities are introduced to the ever-growing additive manufacturing market, the technology’s possible applications continue to increase exponentially.

3D printers work exceptionally fast to produce impressive, geometrically complex objects – often in a matter of hours, depending on the size.

Traditional manufacturing methods are notorious for long lead times that hold up dependent workflows, often for weeks at a time. As a highly reliable unattended process, 3D printing can produce even full scale objects overnight to be ready for use the next day.

FLEXIBILITY

Because 3D printing uses digital files (CAD models) instead of physical tooling like patterns and molds, it’s a highly flexible technology.

Small series or 100% personalized manufacturing and design processes with many iterations benefit greatly in both speed and cost when compared to traditional manufacturing processes that require manually machined tooling to operate.

Manufacturing costs can be determined by three metrics - material, operating and labor expenses. Unlike wasteful reductive manufacturing techniques, 3D printing is an “additive” process that uses just enough material to produce an object.

As a single unattended process, operating and labor expenses are eliminated by a consolidated process that frees staff for other tasks. Since 3D printers don’t require object-specific tooling, manufacturers also save whenever implementing product changes.

ENVIRONMENTALLY FRIENDLY

Though some forms of 3D printing are more ecological than others, the nature of additive manufacturing technologies – which use just enough material to produce an object – make them all significantly more environmentally friendly than reductive techniques.

In FFF 3D printing “closed-loop” material processes are becoming increasingly common, where polymer shredders are used to recycle filament in-house to be reused in the 3D printing process.

Advantages of Industrial 3D PrintersWith industrial 3D printers you can create functional, full-scale objects or industrial parts beyond the limitations of more standard build volumes.

In smaller build sizes large-format parts must be divided before slicing, printed separately and adhered together in an imperfect manual process. By manufacturing in full scale, you save time by not only avoiding multiple print jobs and post-processing, but also make parts exceptionally stronger. Objects printed with industrial 3D printers are often highly functional parts ranging from end-use products like furniture and recreational vehicles to high-strength industrial tooling.

What is a

large-format 3D Printer used for?3D printers are used for a wide variety of applications, with more becoming a reality every day. The three most common additive manufacturing applications are…

The three most common additive manufacturing applications are…

Increasingly, 3D printers are being used to create end-use parts and even consumer products. Because of the flexibility inherent in additive manufacturing, businesses offering highly personalized products have been using additive manufacturing to create small series or completely unique products for a long time. Today, even industrial manufacturers use 3D printing for serial production and to create affordable, industrial parts.

Tooling / FixturesThough 3D printers don’t require any tooling themselves, they’re fantastic at producing it. Manufacturers can use 3D printing technology to create molds, patterns, or even jigs and fixtures to aid other manufacturing processes.

Unlike traditional tooling production, which usually requires excessive lead times, creating tooling with 3D printing is a fast and simple process. Even larger tooling can be additively manufacturing in an unattended process and be quickly in use on the factory floor.

Because 3D printers can manufacture objects so quickly without specially designed tooling, it’s widely recognized as an ideal technology for product development. Products can be manufactured and redesigned at incredible speed allowing designers to create more iterations and perfect their product.

Later in the design process, the same technology and design files can be used to create functional prototypes, allowing a team to experience their product in the real world.

3D-Printer FAQ

What is considered a large 3D printer?

Large 3D printers are too big to fit on a desk and usually offer a build volume bigger than 500x500x500 mm.

Small or large 3D printers can be sorted into two categories:

- Desktop 3D printers

- Large-format 3D printers

BigRep 3D printers provide a build volume of up to 1000x1000x1000 mm.

Which 3D printer has the biggest bed size?

With serial production 3D printers the print bed size can be up to 1000x1000 mm like in the BigRep PRO.

However, there is no real limit to bed sizes as there are custom made 3D printers like the University of Maine's 100 feet (30,5 m) long printer.

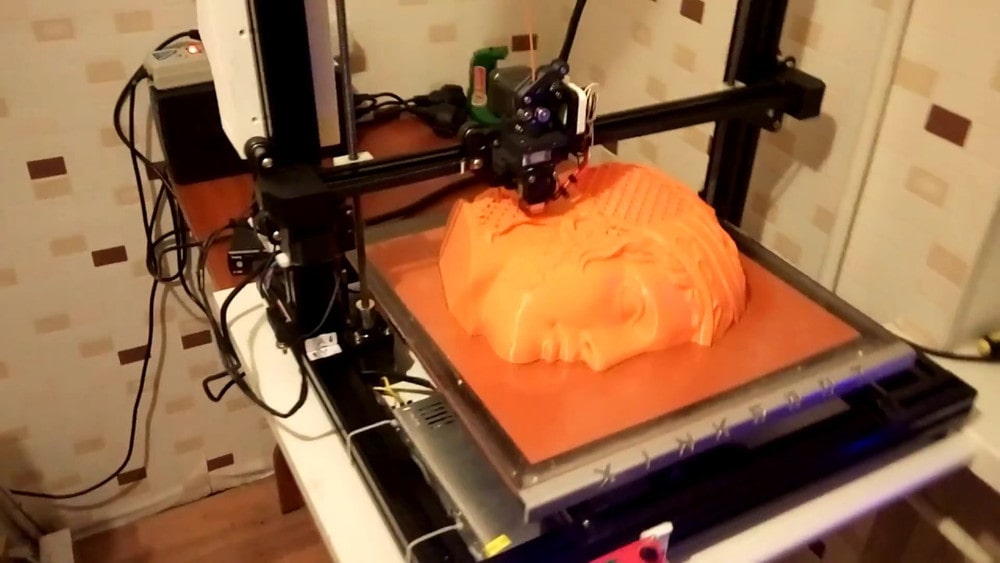

Can you 3D print large objects?

The size of a 3D printed object depends on the size of the 3D printer. With a BigRep ONE you can 3D print large objects up to 1000x1000x1000 mm or 35 cubic feet.

What does an industrial 3D printer do?

An industrial 3D printer saves time and money in product development, engineering and manufacturing.

What sets an industrial 3D printer apart from an entry level 3D printer is:

- High reliability

- Faster 3D printing

- High repeatability

- No assembly required

- Factory service

What is 3D printing? How does it work?

3D printing is a process for generating three dimensional objects by creating a cross sectional pattern of the object to be formed. 3D printing is a subset of broader term additive Manufacturing. In loose terms technology used here is slicing CAD model of part geometry in layers using software and producing one layer at a time. Each layer sticks to previous layer and thus building the whole solid part in layers.

In loose terms technology used here is slicing CAD model of part geometry in layers using software and producing one layer at a time. Each layer sticks to previous layer and thus building the whole solid part in layers.

What technology is used in 3D printing?

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses, but choosing between the various competing 3D printing solutions can be difficult.

Which technology is suitable for your application? What materials and equipment’s are available to get started? How about costs and return on investment?

There are three most established plastic 3D printing technologies for plastic: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

How many types of 3D printing are there?

There are 7 different types of 3D printing formulated by ASTM International officially in the ISO/ASTM 52900 standard:

- Material extrusion

- Material jetting

- Binder jetting

- Sheet lamination

- Vat photopolymerization

- Powder bed fusion

- Directed energy deposition

What materials can be used in 3d printing?

Plastics are the most widely adopted 3D printed material - and it comes in filament, resin, granule, and powder forms. Most thermoplastic 3D printing materials can be used in home 3D printing technology and professional applications as well. Below materials are also used widely:

Most thermoplastic 3D printing materials can be used in home 3D printing technology and professional applications as well. Below materials are also used widely:

- Acrylonitrile Butadiene Styrene (ABS)

- Polylactic Acid (PLA)

- Polyvinyl Alcohol (PVA)

- Nylon

- High-density polyethylene (HDPE)

What could an industrial 3D printer do for you?

Help Us Understand Your Needs

Get your quote now

Large Scale 3D Printers Big Enough to Print Furniture

Home / 3D Printers / Large Scale 3D Printers Big Enough to Print Furniture

Use Cases

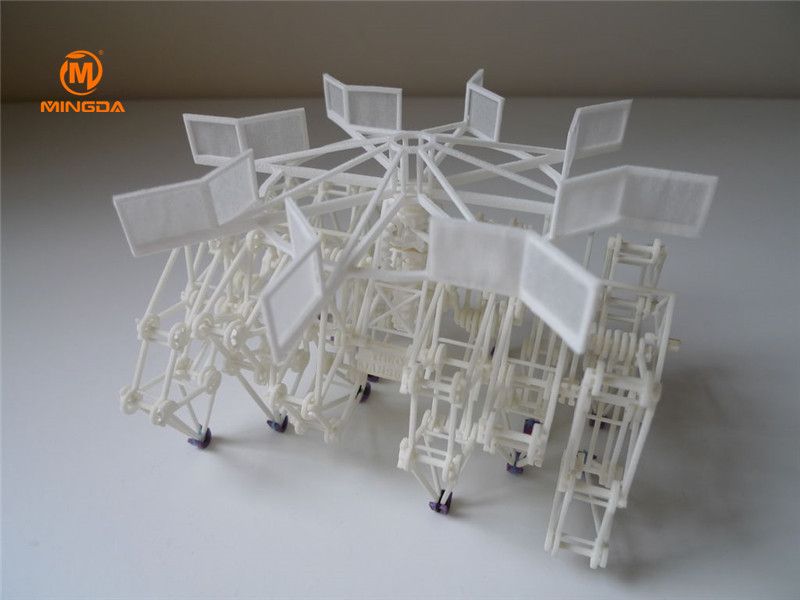

Just like all types of 3D printing, XL 3D printing has its own strengths and tradeoffs. Users are constantly finding more applications for these gigantic machines so the XL 3D printing space is getting bigger and bigger. Let’s have a closer look.

Quick jump to:

- Request XL 3D printer quote

- Request XL service quote

When To Consider Large Scale 3D Printing

It takes a large scale 3D printer to print furniture, vehicle parts and architectural components. Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

Obviously, size is the driving factor in choosing to use large-format printing but there’s more to it than that. Here’s a breakdown of some of the less-obvious considerations:

- Unibody Parts – Often, producers are already able to fabricate their large objects through traditional methods of assembly but those objects would perform better if they were produced as one solid piece, something only a large 3D printer can do efficiently.

- Weight Reduction – Large objects are usually made of wood, metal, or injection molded plastics. Printing the same objects in plastic will make them much lighter, especially when factoring that users can easily adjust the density infill of 3D printed objects. Consolidating large assemblies into single components also reduces weight by eliminating the need for fasteners like nuts and bolts.

- Faster Development – The larger an object, the longer it takes to create and setup the tooling to fabricate it through traditional means.

With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics.

With 3D printing, there are essentially no setup steps so large prototypes are significantly faster to print than to make them any other way. A large object may take a while to print, but by cutting out the time-consuming tooling step, it may also be faster to do production runs of large objects, depending upon the specifics. - Reduced Cost – 3D printed large parts can be cost competitive with conventionally-made parts almost entirely because of the tooling costs of the latter. Consolidated assemblies usually cost less as well because fewer materials have to be sourced from different places.

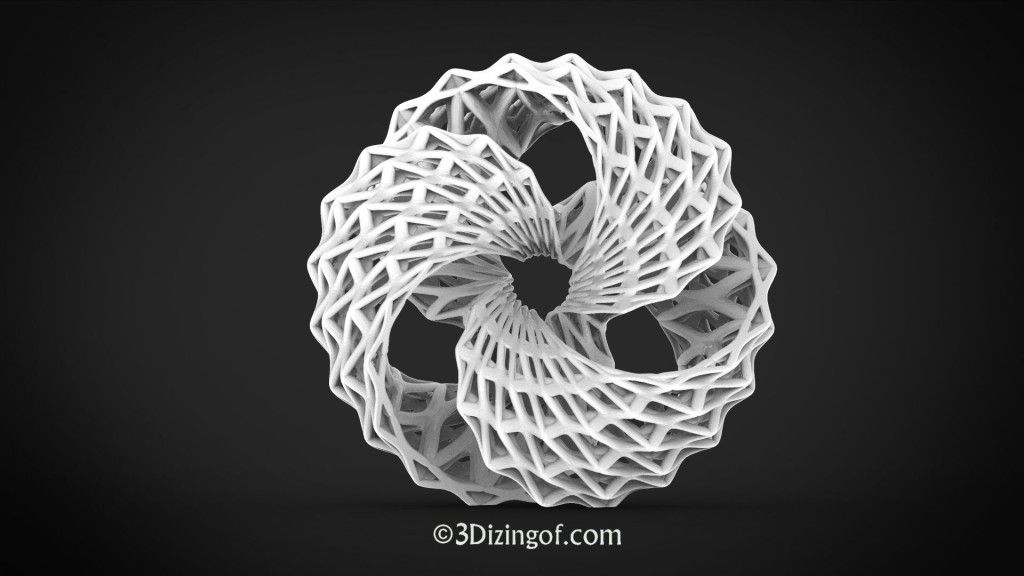

- Design Freedom – Using conventional manufacturing methods, many geometries are just not possible, such as internal channels and complex lattice structures. Many large objects, like furniture, benefit from such features and XL printers are the only way to realize those designs.

Large Scale 3D Printing Examples

- Restoration and replication – XL 3D printing has become rather popular among paleontologists as the technology allows them to both study and preserve the delicate fossils that they regularly handle.

- Furniture – Thanks to large-scale 3D printers it is now possible to create complex functional designs within a fully digitized process chain. From full-size prototyping to production of 3D printed furniture.

- Display advertising – XL 3D printers are perfect for making high-quality, modern signage and lettering for retail stores, businesses and exhibitions.

- Props – With the introduction of large scale 3D printers, designers can now produce enormous set pieces – overnight. 3D printing can help designers quickly manifest their wildest imaginations into the physical reality, and the Film & TV industry has taken notice.

Pellet Extrusion

One of the differences between desktop-sized machines and XL printers is the possibility to utilize pellet extrusion systems on the large printers. Pellet extrusion doesn’t use spooled filament as feedstock but instead uses the same virgin plastic pellets that are used for injection molding, which are much cheaper than spooled filament. This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

This makes it easy to mix different plastics to make custom polymer blends and colors. These systems can also take shredded plastics as feedstock, which enables users to directly recycle water bottles, milk jugs, and failed and unneeded prints into new objects. Such a degree of a circular ecosystem can not be achieved with any other form of manufacturing.

That’s all great but what compels most users to opt for pellet extrusion is its blazing speed as the technology enables output of several kilograms per hour. Printing times scale exponentially with part size so having a high extrusion rate is pretty important for large-format 3D printing. One drawback of pellet extrusion systems is that they struggle with retraction, a feature that filament extruders employ to improve surface finish by pulling back on the filament during non-extrusion travel moves; retraction reduces or eliminates blobs, dots, and stringing on prints. Some XL printers can operate with both filament and pellet extrusion systems, allowing users to choose the best toolhead for their specific application.

Get a Quote

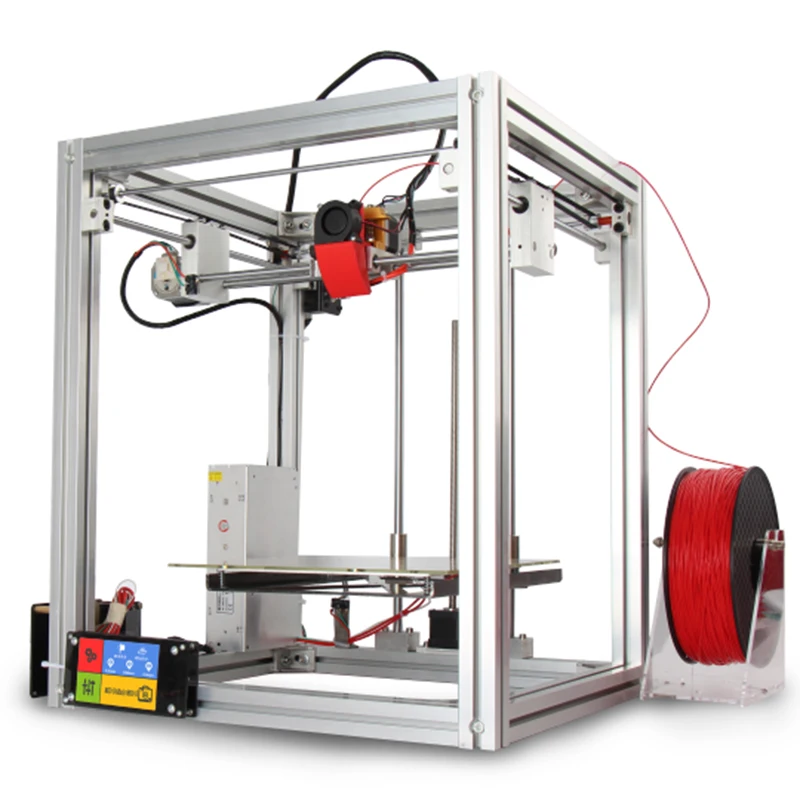

Large Scale 3D Printers

Looking to implement large scale 3D printers in your production process? Get a quote from Modix or Industry

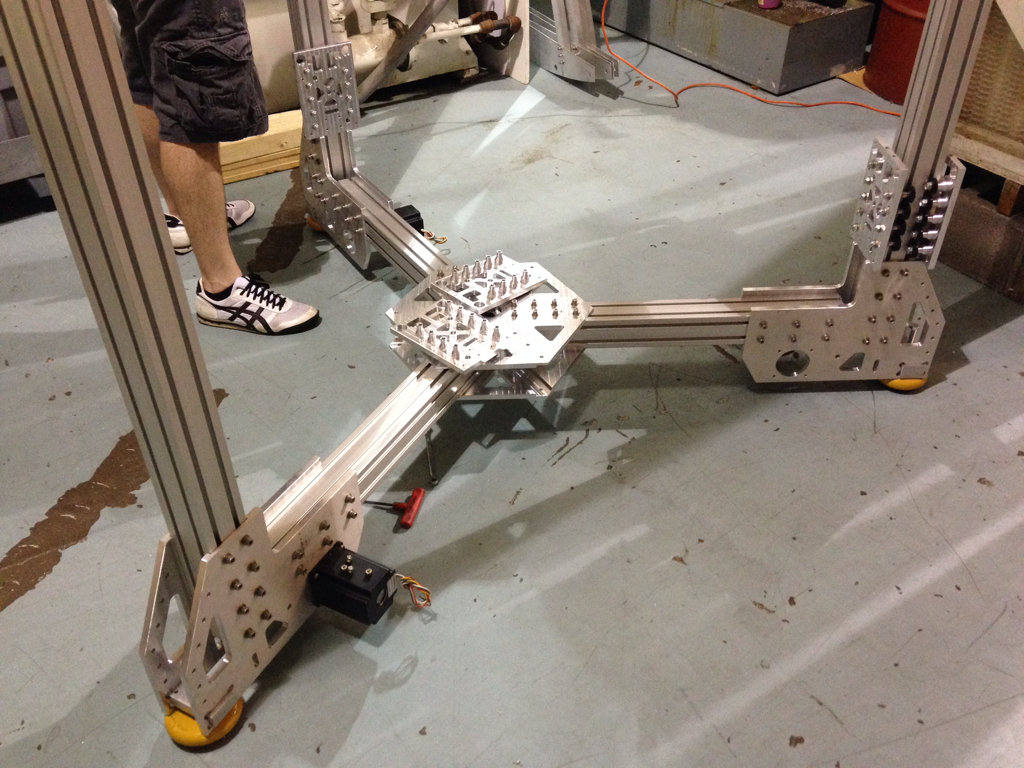

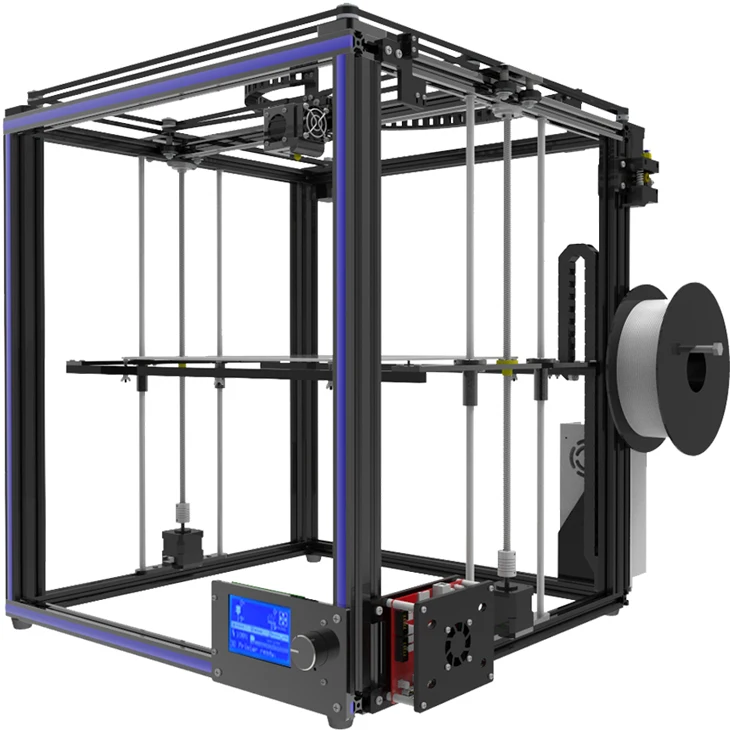

Modix BIG Meter

With the Modix BIG Meter, you are now able to manufacture objects as large as 1010 x 1010 x 1010 mm in one go!

$13,500Modix

Request a Quote

modix big meter

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1010 x 1010 x 1010 mm

- - Printer Dimensions: 1300 x 1470 x 1830 mm

- - Shipping Weight: 200kg

- - Included: Dual print head, E3D Aero & Volcano 1.75mm

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Automatic bed tilt calibration

- - Power Requirements: 32A, single phase, 208-240V

Mold Making, Prototyping, Research and Development, Restoration

Industry MAGNUM

Hailing from Sweden, Industry is a company that has made major waves in the world of 3D printing. The new MAGNUM large scale pellet 3D printer enables you to print parts measuring 1500 x 1200 x 1200 mm.

The new MAGNUM large scale pellet 3D printer enables you to print parts measuring 1500 x 1200 x 1200 mm.

A powerful E25 extruder manufactured to handle shredded material, granules or pellets. The MAGNUM handles nozzles between 2-8mm and has an average output between 1-8 kg / hour & a maximum output of 15 kg / hour.

MAGNUM offers powerful control features based on Bosch Rexroth MTX system control. It comes with a camera and mail/text module for external monitoring. A large touch screen display allows for easy setup and agile control.

€159,000Industry

Request a Quote

Industry MAGNUM

- Benefits

- Applications

- - Large scale pellet 3D printer

- - XL build size: 1500 x 1200 x 1200 mm

- - Granular extruder, which reduces material costs

- - Fast build rate: up to 15 kg per hour

- - Touch screen display

- - High quality linear motion modules from Bosch Rexroth MTX

Mold Making, Production, Prototyping, Research and Development, Restoration

Modix BIG-180X

The BIG-180X features a print volume of 1800 x 600 x 600 mm and comes at a competitive price of $12,000 USD. The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

The unique extra width of the build chamber is designed per request of customers working in the automotive industry.

$15,500Modix

Request a Quote

modix 180

- Benefits

- Applications

- - DIY self-assembly kit

- - Print Volume: 1800 x 600 x 600 mm

- - Printer Dimensions: 2170 x 1060 x 1430 mm

- - Shipping Weight: ~240kg

- - Included: Dual print head, E3D Aero & E3D Volcano 1.75mm

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - 4 X Z axis motors are controlled individually providing automatic bed tilt calibration.

- - Minimal Electricity requirements: 32A, single phase, 208-240V

Prototyping, Research and Development, Restoration

Modix BIG-120Z

The closed enclosure of the BIG-120Z is made of aluminum composite panels and polycarbonate doors. It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

It incorporates a premium motion system including HIWIN motion rails, Gates timing belts and IGUS signal cables. This is a smart 3D printer providing several key reliability features including power-off resume, filament runout sensor, 120 probing points based automatic bed leveling, stall detection and more. The manufacturer offers an active air filter device as an add-on.

$7,500Modix

Request a Quote

BIG-120Z

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 600 x 600 x 1200 mm

- - Z axis guides, HIWIN MGW Linear Rails

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - Dual print head

- - E3D Titan Aero extruder with E3D Volcano hotend

Displays, Fashion, Mold Making, Prototyping

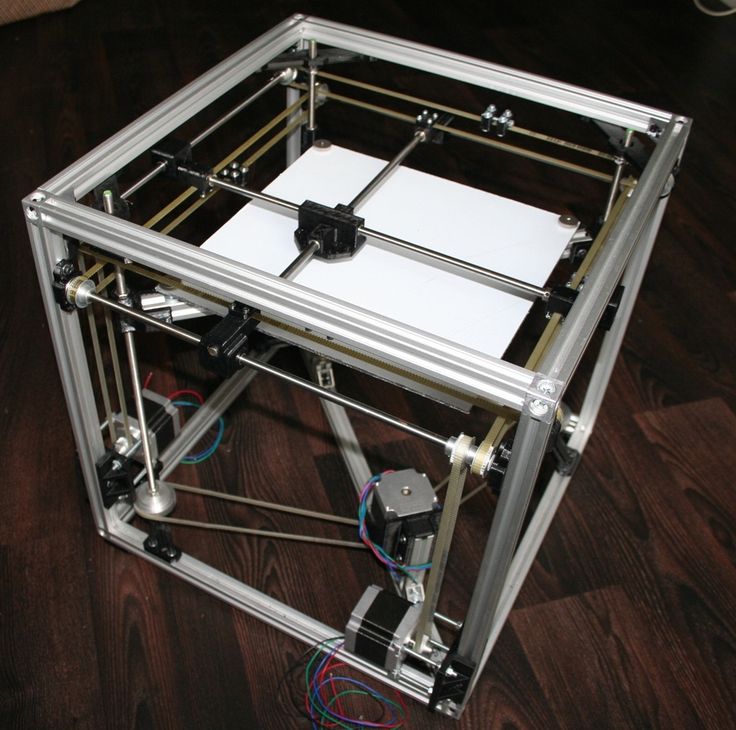

Modix BIG-120X

Modix BIG-120X Version 3 represents a major leap forward with regards to the printer reliability, print quality, ease of assembly and readiness to future advanced updates. Since Modix big60 and 120X share the same core design the new update is benefiting both models.

Since Modix big60 and 120X share the same core design the new update is benefiting both models.

$7,500Modix

Request a Quote

BIG-120X

- Benefits

- Applications

- - DIY self-assembly kit

- - XL print volume of 1200 x 600 x 660 mm

- - Duet 2 Wifi, 32Bit controller developed by Duet3D

- - Reprap Firmware developed and supported by Duet3D

- - 7 inch touchscreen made by Duet3D

- - E3D Titan Aero extruder with E3D Volcano hotend

- - Closed loop motion system (optional)

Mold Making, Prototyping, Research and Development, Restoration

Get a Quote

XL 3D Print Service

3D printing is a viable option for display advertising, large scale concept models, car parts, furniture, molds & tooling. We offer both cost effective solutions with thick layers and rough surfaces for rapid prototyping as well as highly detailed & post-processed end-use objects. Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

Please contact — [email protected] — for any questions or complete the form below and we’ll answer you as soon as possible.

- Technologies: FDM, SLA, GDP

- Materials: From PLA to CF composites & more

- Maximum print size: 1450 x 1100 x 1800 mm

- Post-processing: Spray paints, metal coatings, assembly & many more

How to create models that are larger than the print volume of a 3D printer

Don't have a large format 3D printer yet? When evaluating the capabilities of a compact desktop 3D printer, do not limit yourself to print volume. Many objects, like your smartphone or a bridge over a river, are made up of many individual components. Therefore, splitting the model into smaller parts that can be aligned after printing is a great solution for 3D printing large objects that do not fit on the platform. nine0003

Also, splitting the model can be a great way to get a high quality result, even if the whole model fits on the platform. This makes sense when multiple or opposing surfaces must be free from support structures, when the model has complex ledges, or contains cavities where liquid polymer can remain.

This makes sense when multiple or opposing surfaces must be free from support structures, when the model has complex ledges, or contains cavities where liquid polymer can remain.

3D printing of various parts opens up new possibilities, for example, the creation of prefabricated structures from various materials or the combination of rigid and flexible parts to simulate the overmolding method. nine0003

When choosing a gluing method, it is necessary first of all to take into account the required degree of strength of the glued joints, which depends on the purpose of the models:

-

chemical: use adhesive on artwork, scale models, and complex shapes that are not intended for functional use and should not be impacted;

-

Mechanical: Provide threaded holes or sockets for attaching parts that require a secure mechanical connection, or repeatedly detaching and attaching components as needed. nine0003

This tutorial focuses on building large, prefabricated 3D stereolithographic (SLA) printed models with chemically bonded components. Read on to learn all the steps in this process, from model separation to post-processing for a professional finish.

Read on to learn all the steps in this process, from model separation to post-processing for a professional finish.

Formlabs Form 3L is the first affordable, easy-to-use large format 3D printer optimized for reliable production of industrial-quality models. The Form 3L stereolithographic 3D printer features a huge print volume of 30 x 33.5 x 20 cm and unrivaled cost-effectiveness. nine0003

Meet the Form 3L

We recommend two ways to separate models: adding features to the design that will allow the parts to fit together, or separating the model with straight lines, which will require them to fit together properly during the bonding process.

Regardless of which method you choose, if you have a lot of parts, it's helpful to add a unique identifier (letters/numbers) for each one to make assembly easier. nine0035

Use CAD software to split a 3D model and add basic centering components such as slots, pins, slots, notches, and tabs, or more complex features such as dovetails and slots to match model folds.

Adding centering components to the design makes it easier to assemble parts.

Ideally, these components should make it easier to align and assemble parts, but can cause problems if they differ even slightly from your 3D models, preventing perfect centering. Therefore, it is best to use centering components only when the printer can print parts with accurate dimensions that are not subject to deformation. nine0003

Splitting a 3D model along straight lines requires less effort than adding components to center it. With this separation method, there are also fewer problems if the parts are slightly deformed or differ in size.

Adding IDs for each part makes the assembly process easier.

On the other hand, parts separated by straight lines can be time consuming to assemble, as each part must be manually centered and ensured that they all remain in the correct position until the adhesive is completely dry. nine0003

By default, when printing on a stereolithographic 3D printer, solid models without voids are obtained. Depending on the design, different requirements may apply to the manufacture of large items. In such cases, 3D printing the outer shell or converting the structure into a hollow is a great way to save a lot of material and time. When printing hollow models on a stereolithographic 3D printer, be sure to add ventilation holes to avoid creating cavities filled with air and pressurized resin. nine0003

Depending on the design, different requirements may apply to the manufacture of large items. In such cases, 3D printing the outer shell or converting the structure into a hollow is a great way to save a lot of material and time. When printing hollow models on a stereolithographic 3D printer, be sure to add ventilation holes to avoid creating cavities filled with air and pressurized resin. nine0003

SAMPLE PART

Experience Formlabs print quality first hand. We will send a free sample of the printed model directly to your office.

Request a free print sample

Converting a model design to a hollow saves a lot of time and material because the printer only needs to print the outer shell.

Learn more about how to save materials and time by hollowing out 3D models.

Depending on the size of the details and the purpose of the model, we recommend three mounting methods:

| Epoxy glue (5-30 min) | cyanoacrylate (CCA, Supercollah) | Resin | ||||

|---|---|---|---|---|---|---|

Square. | Large | Small/Medium | Small | |||

| Paintable | Yes | Yes | Yes | 9006 70072Medium | Low | Low |

For large parts and maximum adhesion, use 5-30 minute dry epoxy. It takes longer to dry than other adhesives, allowing you to fit large 3D printed parts but slows down the assembly process. Most 5-minute epoxy adhesives stop changing shape in as little as five minutes and cure by about 75% in less than an hour.

For large parts and maximum adhesion we recommend using epoxy adhesive. nine0003

The next option is cyanoacrylate (CA or superglue), which quickly forms a strong bond, ideal for small to medium sized parts. Thoroughly clean the part before applying CA to the surface, because contaminants adversely affect the quality of the connection. CA has a moderate impact strength, but is not recommended for models that require high strength.

For small models, you can simply use liquid resin from a stereolithographic 3D printer. Pour a small amount of resin into a tray from a bottle or cartridge, pick it up with a pipette or syringe, and place it on the surface to be bonded. Connect the parts and wipe off excess resin that may spill around the edges. Aim a 5mW (405µm wavelength) UV laser pointer at the contact area to cure the resin and bond the parts. nine0003

This method produces a chemical bond similar to 3D stereolithography printing, but is only suitable for bonding small surfaces as a low power light pointer cannot penetrate the model deep enough to create a strong bond.

Note. Protective equipment must be worn when working with polymers, including proper eye protection and gloves.

Download PDF

Don't have time to read the article now? Download it in PDF format.

Download as PDF

After assembling the model, it's time to move on to post-processing. This step includes geometric correction of the model to provide a smooth surface that matches the original 3D model, and aesthetic finishing to obtain a uniformly colored surface.

This step includes geometric correction of the model to provide a smooth surface that matches the original 3D model, and aesthetic finishing to obtain a uniformly colored surface.

Depending on the precision of the printer and the size of the printed parts, there will almost always be slight voids or mismatches at the contact points. Automotive sealant (e.g. Bondo 907) adheres well to polymers, therefore, to eliminate such inconsistencies, it is recommended to apply it in a thin layer on the surface. Lightly sand the surface after each coat has dried to bring the model to its final shape.

Sealing models with automotive sealant (red area in image) will help eliminate small gaps and inconsistencies between parts.

Sanding helps remove traces of support structures and remaining inconsistencies in the model. Gently start sanding the surface with 150-grit sandpaper to remove traces of support structures and smooth edges where parts meet. Once the surface is smooth, sand it wet using 320 grit sandpaper to remove any remaining layer lines. Sand the surface in random motions so as not to leave marks. In most cases, these two methods will produce a fairly smooth surface, but you can continue to increase the grit of the sandpaper up to 2 times and, after wetting it, sand the entire model until the surface is reasonably smooth. nine0003

Sand the surface in random motions so as not to leave marks. In most cases, these two methods will produce a fairly smooth surface, but you can continue to increase the grit of the sandpaper up to 2 times and, after wetting it, sand the entire model until the surface is reasonably smooth. nine0003

Power sanding is great for large flat surfaces, but can ruin fine details. Grinding of small models is recommended to be done by hand, and for large ones, a combination of manual and mechanical grinding is recommended.

Machining large parts with mechanical and manual grinding saves a lot of time. Power sanding is great for large, flat surfaces, but can ruin the fine details, sharp corners, and subtle contours that are typical of stereolithography. As a result of mechanical grinding, a lot of dust is also generated, so before starting processing, it is necessary to prepare the working area. nine0003

Note. The use of power tools requires full attention and the use of protective equipment.

The surface can be damaged very quickly without even realizing it, just by leaving the sander without moving.

When finished sanding the model, rinse it in soapy water to remove dust and debris and dry thoroughly before proceeding to the last step.

The primer helps the paint adhere to the surface and can indicate areas where additional sanding is needed or removal of traces of supports that you may have missed. The Universal Matte Gray Plastic Primer shows these spots exceptionally well. For best results, apply it to the surface in several thin coats. Sand critical areas and reapply a thin coat of primer. Repeat this process until the entire surface of the model is level. nine0003

Note. Use protective equipment during priming and painting, including a respirator to protect against paint fumes.

All-purpose matt gray primer for plastics is exceptionally good at showing fine details and helping to identify areas that need to be sanded down.

Find out more about sanding and priming in our detailed guide.

When painting with multiple colors, protect the model with a temporary coat. First, plan the order in which you will paint the model, depending on the color, transparency, and size of the area of a particular color. Start with small details so that fewer of them can be protected when painting with the main color. Apply painter's tape to the edges and corners. To quickly cover large areas, attach sheets of paper to them. Ribbon guides (laser cut) can also be useful for creating straight lines, circles and complex shapes. nine0003

When it comes to masking, figuring out the correct order is your first priority. In our case, the parts were first painted silver and the sections that would remain silver on the final part were then covered with painter's tape to hide them from the next l

painting. In our case, we first painted the parts silver and put masking tape on the areas that should remain silver in the finished model so that they do not get paint of a different color. nine0003

nine0003

As with primer, several thin coats of paint should be applied for optimal results rather than one thick coat. Most spray paints will achieve the best color in warm and slightly damp conditions in the absence of wind. In this case, you must always follow the manufacturer's recommendations, which can be given on the paint container or in the technical documentation.

Consider the time the paint needs to dry: Allow layers to settle before applying the same color and allow the paint to dry completely before applying a new color. nine0003

The area where we applied masking tape is still silver.

Become an expert in painting 3D models with our detailed guide

Already wondering what your finished model will look like?

"Sorry sir, that R2-D2 over there is in excellent condition and inexpensive."

Formlabs optics designer Adrien Tanner created this R2-D2 model from 105 parts printed on a Formlabs stereolithographic 3D printer. It even has working electronics borrowed from the Form 2 printer - a galvanometer drive for sound reproduction, a cartridge dispenser for lamps, and a Z-axis drive for dome rotation. nineThe 0003

nineThe 0003

Form 3L is the first large-format 30 x 33.5 x 20 cm 3D printer for producing massive, industrial-quality models.

Reduce order processing time when outsourcing or manual work when assembling large-scale 3D models. Now you can print large 3D models in their entirety on the Form 3L, the first affordable large format SLA printer.

Want to see how stereolithographic parts work? Explore our resources to learn more about stereolithographic resins, or request a free sample to evaluate print quality for yourself. nine0003

Request a free print sample

Precision metal 3D printing on order at Sprint 3D

Metal 3D printing – additive manufacturing of metal products, which is rightfully one of the most promising and rapidly developing areas in 3D printing as such. The technology itself originates from the conventional sintering of materials used in powder metallurgy. But now it has become more perfect, accurate and fast. And today SPRINT3D offers you metal printing on 3 D printer on really favorable terms. But first, a little information about the production process itself and its capabilities.

But first, a little information about the production process itself and its capabilities.

Selective Laser Fusion Technology

SLM or Selective Fusion Technology is a type of direct metal printing that achieves a density of 99.5%. The difference is especially noticeable when compared with models obtained by conventional casting. This indicator is achieved due to the introduction of the latest technologies in the hardware part:

- The use of special rollers for compacting powders and, as a result, the possibility of using powders with a particle size of 5 microns.

- Bulk density increase to help compact end products.

- Creates a rarefied atmosphere of inert gases, which ensures maximum purity of the material, no oxidation, and eliminates the risk of introducing third-party chemical compounds into the composition.

But most importantly, the modern 3 D metal printer makes it easy to customize the configuration for printing with a specific metal powder. Thus, even with inexpensive material, you can get a first-class result. But only if you use high-quality modern equipment. And here we are ready to surprise you too!

Thus, even with inexpensive material, you can get a first-class result. But only if you use high-quality modern equipment. And here we are ready to surprise you too!

Metal 3D printing B SPRINT 3D

3D printing with own 3D printers

The largest working area is 280x280x350 mm

layer thickness up to 15 microns

3D Various types of metals

CIS CIS

Installations for 3 D Semi metal, d d d d d d D which we use

Production quality is a key requirement that we set ourselves. Therefore, in our work we use only professional equipment with wide possibilities for metal printing. Let's take a closer look at each of the production units. nine0003

Production unit SLM 280HL

SLM 280HL is a development of the German company SLM Solutions GmbH, which uses the technology of layer-by-layer laser melting of powder metal materials. The installation is equipped with a large working chamber and allows you to create 3D objects with dimensions of 280x280x350 mm. Among the main advantages of printing with this installation are:

The installation is equipped with a large working chamber and allows you to create 3D objects with dimensions of 280x280x350 mm. Among the main advantages of printing with this installation are:

- Small minimum thickness of the applied layer - 20 microns.

- Filling the working chamber with an inert gas, which allows you to work with various reactive metals.

- Print speed up to 35 cm/hour.

- Building layer thickness – 30 and 50 µm.

- Power - 400 W.

A special highlight is the patented powder feed system, which delivers significantly faster print speeds than most production machines in the same price range. We use the following materials in production:

- Stainless steel (domestic 07X18H12M2 (Polema), 12X18H10T and imported 316L).

- Tool steel (imported 1.2709).

- Heat-resistant alloys 08KhN53BMTYu (similar to Inconel 718, produced by Polem) and EP 741 (produced by VILS).

- Cobalt Chrome (COCR)

The SLM 280HL 3D printer can be used to create all kinds of metal components, prototypes and final products. If necessary, we can provide small-scale production. nine0003

ProX 100 production unit

ProX 100 is a compact unit for 3 D metal printing, developed by the American company 3D Systems. It uses direct laser sintering technology, which ensures high speed and precision of production. Among the main characteristics it is worth highlighting:

- The size of the working chamber is 100x100x80 mm.

- Construction layer thickness – 20 and 30 µm. nine0016

- Power - 50 W.

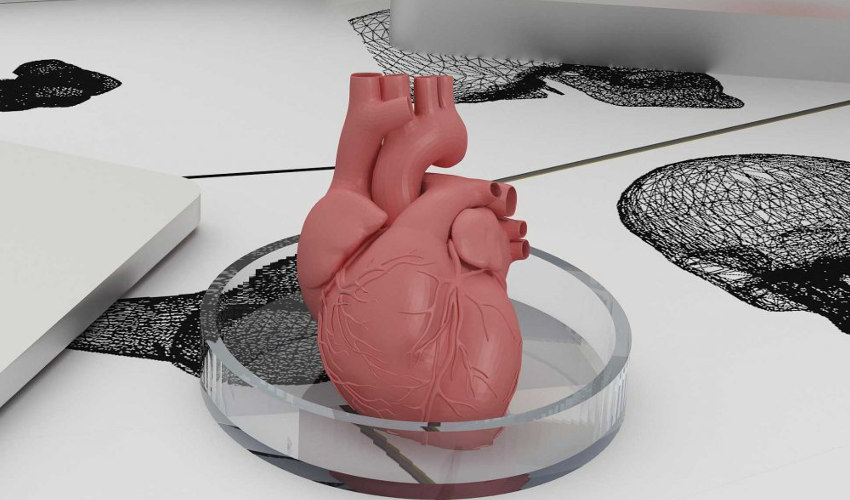

ProX 100 allows you to create prototypes that can not be developed by standard methods, provides short lead times, guarantees the absence of material porosity and high part density. In addition, we note the standardized quality of all products, regardless of their structure. At the moment, the model is actively used in dentistry when creating high-precision prostheses, but it has found wide application in other industries:

At the moment, the model is actively used in dentistry when creating high-precision prostheses, but it has found wide application in other industries:

- Manufacture of engines and their individual parts.

- Development of medical equipment.

- Printing jewelry and even contemporary art.

In printing, we use the cobalt-chromium alloy KX28M6 (manufactured by Polem), originally developed for additive technologies when creating endoprostheses.

Metal 3D printing - current application

Many experts argue that 3D printing as such has not yet fully revealed its potential. For example, Elon Musk plans to use technology in the colonization of Mars to build administrative and residential buildings, equipment and technology right on the spot. And this is quite real, because already now the technology of three-dimensional metal printing is actively used in various industries: The high precision of production and relatively affordable price have made 3D printing very relevant in this industry.