3D printed organs video

The race to 3D print living organs

Tech

3D Printing

With a staggering global shortage of organ donors, this technology offers a semblance of hope to millions.

Watch next

While drought continues to wreak havoc in Kenya, an age-old technology is providing relief for some 4:57

Will Ferrell resumes his title as Christmas King in 'Spirited' trailer

'Star Wars: Tales from the Galaxy's Edge' gets spruced up for PlayStation VR2

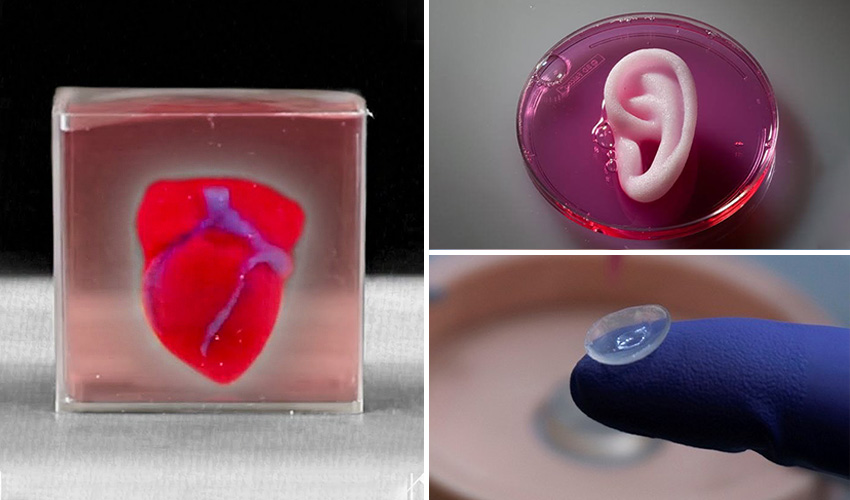

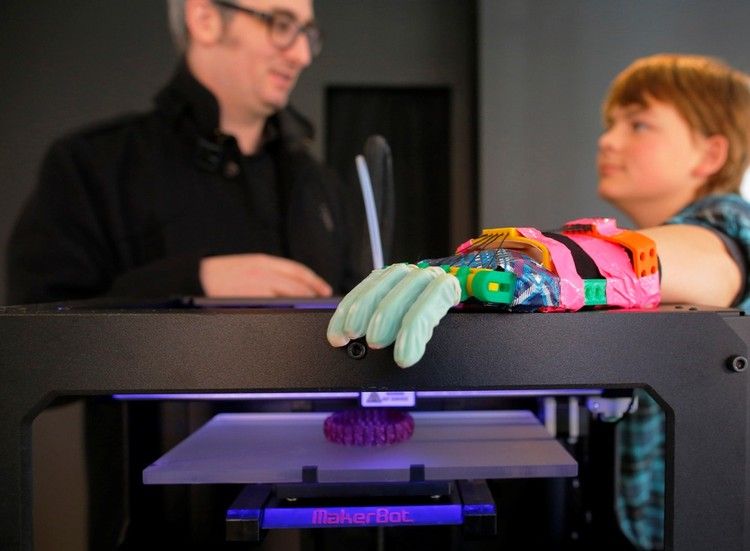

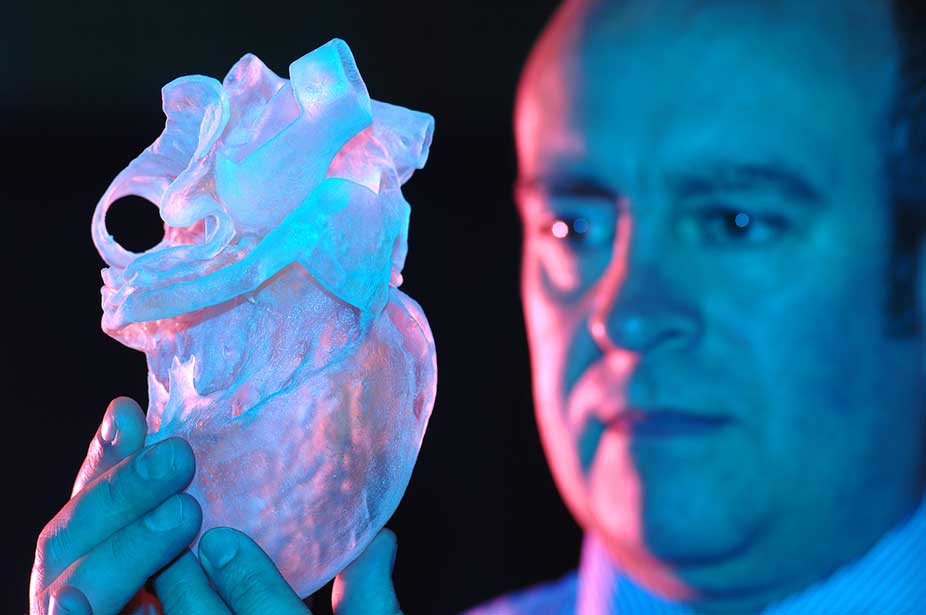

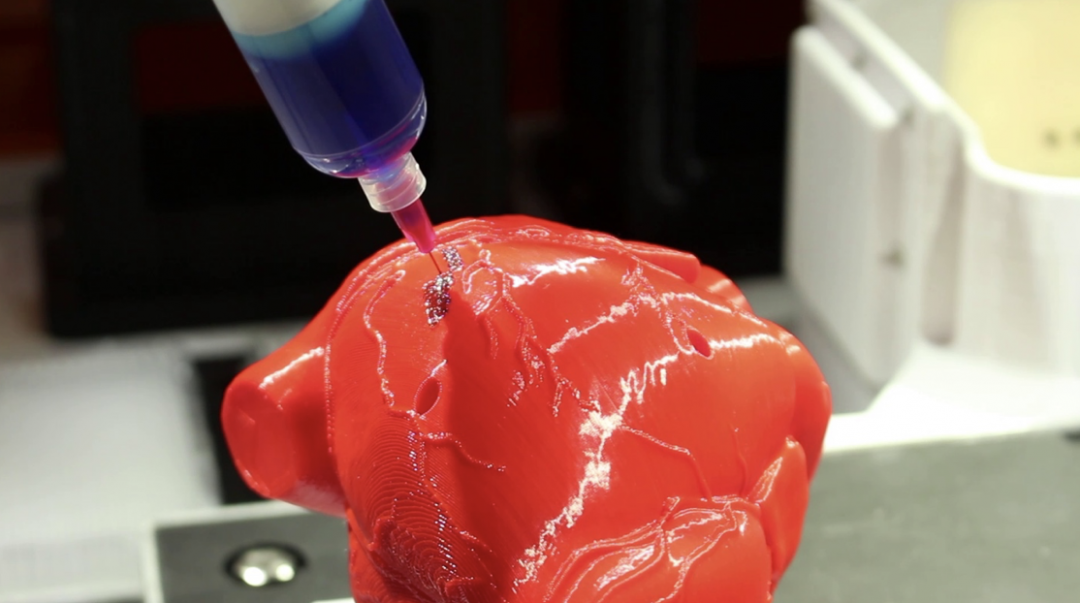

From a life-sized hand to a miniature liver with a functional vascular network, bioprinters edging closer to replicating living human organs and tissues. The ultimate goal of the technology is to make a dent in the global shortage for lifesaving transplants.

The company behind the project is eyeing the U.S. next.

By Emmett Smith

It also makes sharing measurements easier

By Jules Suzdaltsev

A spectacular show of both beauty and technological promise

By Emmett Smith

These two TVs only get smaller, but are fully functional and can stream content through USB-C

By Jules Suzdaltsev

It even comes with a refrigerator!

By Emmett Smith

It's about damn time.

By Meera Navlakha

He knows if you've been bad... 😬

By Sam Haysom

Yep, that happened.

By Sam Haysom

"I feel represented and it's not necessarily my culture."

By Mark Stetson

"A man has to look his best when it’s time to get married…or buried."

By Yasmeen Hamadeh

Travel back 1,200 years before Geralt, Yennefer, and Ciri.

By Shannon Connellan

The new John Lewis ad is here.

By Sam Haysom

Walmart can help you save on smart home tech — and on finding the perfect stocking stuffer.

By Mashable BrandX and Walmart

"Everyone shall love you and call your name, Pinocchio."

By Yasmeen Hamadeh

The American classic tells a story of time, history, and family.

By Meera Navlakha

By signing up to the Mashable newsletter you agree to receive electronic communications from Mashable that may sometimes include advertisements or sponsored content.

3D-printed organs: The future of transplantation

CNN —

What if doctors could just print a kidney, using cells from the patient, instead of having to find a donor match and hope the patient’s body doesn’t reject the transplanted kidney?

The soonest that could happen is in a decade, thanks to 3D organ bioprinting, said Jennifer Lewis, a professor at Harvard University’s Wyss Institute for Biologically Inspired Engineering. Organ bioprinting is the use of 3D-printing technologies to assemble multiple cell types, growth factors and biomaterials in a layer-by-layer fashion to produce bioartificial organs that ideally imitate their natural counterparts, according to a 2019 study.

This type of regenerative medicine is in the development stage, and the driving force behind this innovation is “real human need,” Lewis said.

In the United States, there are 106,075 men, women and children on the national organ transplant waiting list as of June 10, according to the Health Resources & Services Administration. However, living donors provide only around 6,000 organs per year on average, and there are about 8,000 deceased donors annually who each provide 3.5 organs on average.

47-year-old Steve Verze is to become the first man in the world to be fitted with a 3D printed eye, according to Moorfields Eye Hospital. He tried the eye for size earlier this month, as photographed here.

He tried the eye for size earlier this month, as photographed here.

British man given 3D printed eye in world first, hospital says

The cause of this discrepancy is “a combination of people who undergo catastrophic health events, but their organs aren’t high enough quality to donate, or they’re not on the organ donor list to begin with, and the fact that it’s actually very difficult to find a good match” so the patient’s body doesn’t reject the transplanted organ, Lewis said.

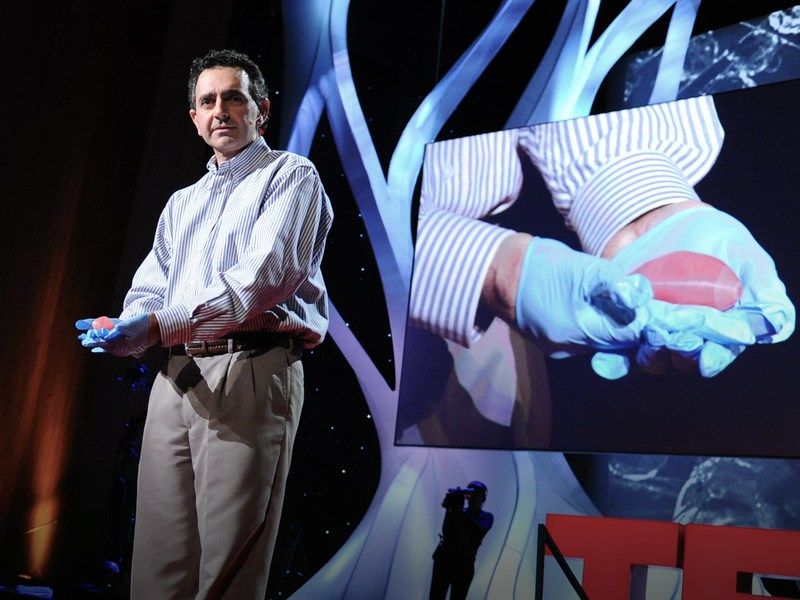

And even though living donors are an option, “to do surgery on someone who doesn’t need it” is a big risk, said Dr. Anthony Atala, director of the Wake Forest Institute for Regenerative Medicine. “So, living related donors are usually not the preferred way to go because then you’re taking an organ away from somebody else who may need it, especially now as we age longer.”

Anthony Atala, director of the Wake Forest Institute for Regenerative Medicine. “So, living related donors are usually not the preferred way to go because then you’re taking an organ away from somebody else who may need it, especially now as we age longer.”

Atala and his colleagues were responsible for growing human bladders in a lab by hand in 2006, and implanting a complicated internal organ into people for the first time – saving the lives of three children in whom they implanted the bladders.

A bladder scaffold is seeded with cells at the Wake Forest Institute for Regenerative Medicine.

Courtesy Wake Forest Institute for Regenerative Medicine Every day, 17 people die waiting for an organ transplant, according to the Health Resources & Services Administration. And every nine minutes, another person is added to the waitlist, the agency says. More than 90% of the people on the transplant list in 2021 needed a kidney.

And every nine minutes, another person is added to the waitlist, the agency says. More than 90% of the people on the transplant list in 2021 needed a kidney.

“About a million people worldwide are in need of a kidney. So they have end-stage renal failure, and they have to go on dialysis,” Lewis said. “Once you go on dialysis, you have essentially five years to live, and every year, your mortality rate increases by 15%. Dialysis is very hard on your body. So this is really motivating to take on this grand challenge of printing organs.”

“Anti-hypertensive pills are not scarce. Everybody who needs them can get them,” Martine Rothblatt, CEO and chairman of United Therapeutics, said at the Life Itself conference, a health and wellness event presented in partnership with CNN. United Therapeutics is one of the conference’s sponsors.

United Therapeutics is one of the conference’s sponsors.

“There is no practical reason why anybody who needs a kidney – or a lung, a heart, a liver – should not be able to get one,” she added. “We’re using technology to solve this problem.”

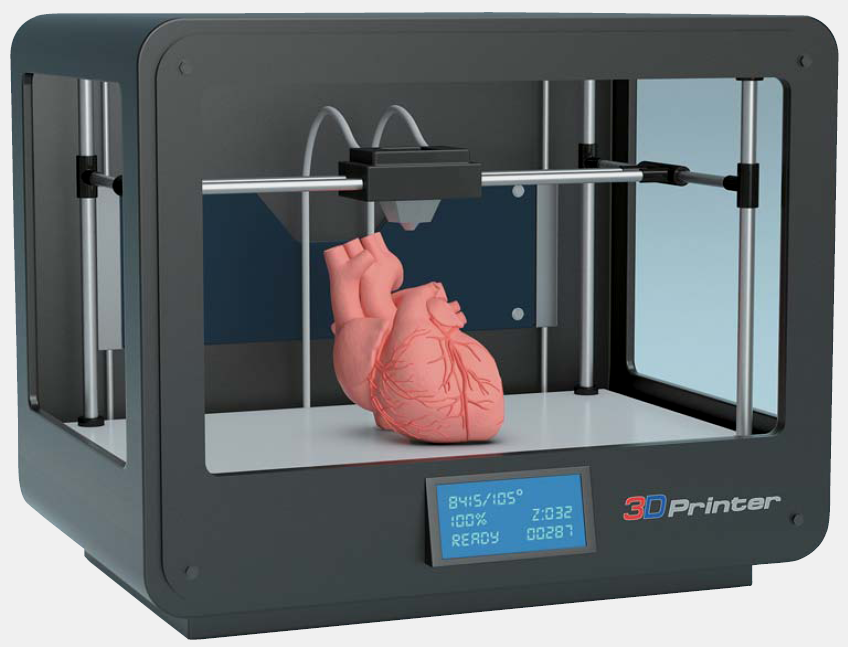

To begin the process of bioprinting an organ, doctors typically start with a patient’s own cells. They take a small needle biopsy of an organ or do a minimally invasive surgical procedure that removes a small piece of tissue, “less than half the size of a postage stamp,” Atala said. “By taking this small piece of tissue, we are able to tease cells apart (and) we grow and expand the cells outside the body. ”

”

This growth happens inside a sterile incubator or bioreactor, a pressurized stainless steel vessel that helps the cells stay fed with nutrients – called “media” – the doctors feed them every 24 hours, since cells have their own metabolism, Lewis said. Each cell type has a different media, and the incubator or bioreactor acts as an oven-like device mimicking the internal temperature and oxygenation of the human body, Atala said.

“Then we mix it with this gel, which is like a glue,” Atala said. “Every organ in your body has the cells and the glue that holds it together. Basically, that’s also called ‘extracellular matrix. ’ ”

’ ”

Richard Roth with Samira Jafari

Courtesy Samira JafariLiving organ donations save lives. This is how you become a donor

This glue is Atala’s nickname for bioink, a printable mixture of living cells, water-rich molecules called hydrogels, and the media and growth factors that help the cells continue to proliferate and differentiate, Lewis said. The hydrogels mimic the human body’s extracellular matrix, which contains substances including proteins, collagen and hyaluronic acid.

The non-cell sample portion of the glue can be made in a lab, and “is going to have the same properties of the tissue you’re trying to replace,” Atala said.

The biomaterials used typically have to be nontoxic, biodegradable and biocompatible to avoid a negative immune response, Lewis said. Collagen and gelatin are two of the most common biomaterials used for bioprinting tissues or organs.

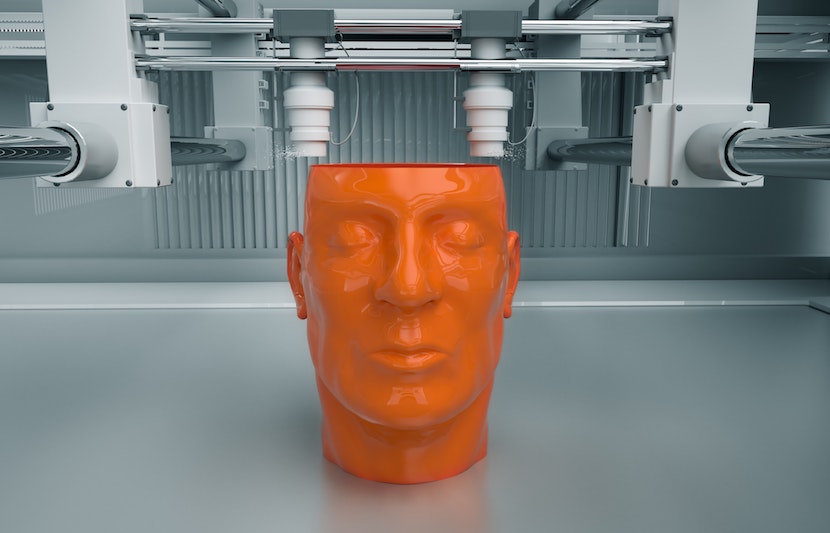

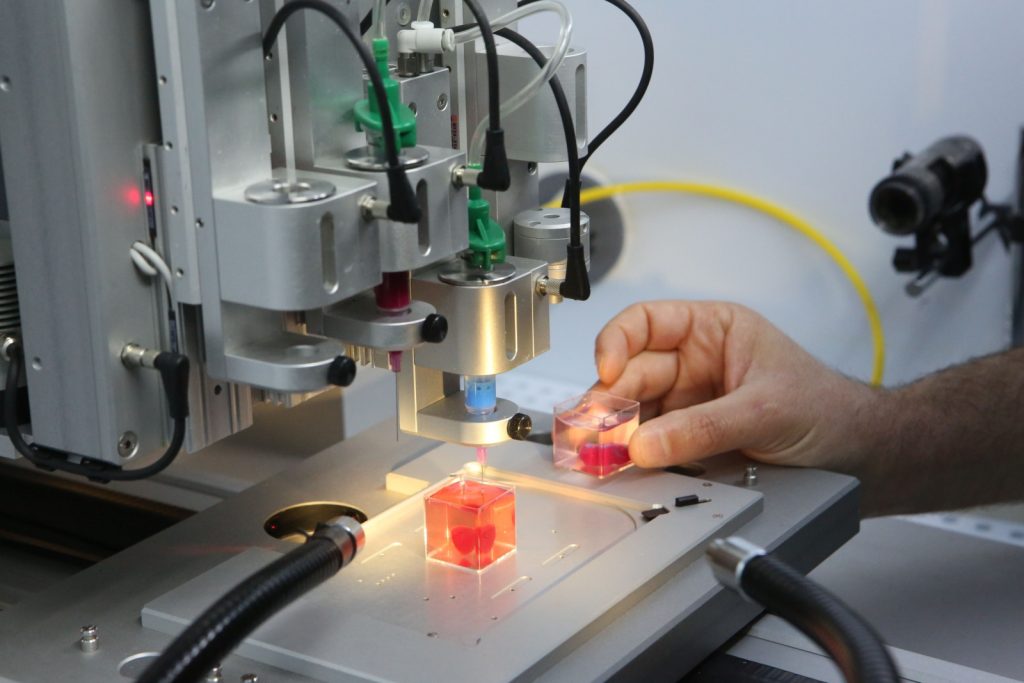

From there, doctors load each bioink – depending on how many cell types they’re wanting to print – into a printing chamber, “using a printhead and nozzle to extrude an ink and build the material up layer by layer,” Lewis said. Creating tissue with personalized properties is enabled by printers being programmed with a patient’s imaging data from X-rays or scans, Atala said.

“With a color printer you have several different cartridges, and each cartridge is printing a different color, and you come up with your (final) color,” Atala added. Bioprinting is the same; you’re just using cells instead of traditional inks.

How long the printing process takes depends on several factors, including the organ or tissue being printed, the fineness of the resolution and the number of printheads needed, Lewis said. But it typically lasts a few to several hours. The time from the biopsy to the implantation is about four to six weeks, Atala said.

A 3D printer seeds different types of cells onto a kidney scaffold at the Wake Forest Institute for Regenerative Medicine.

The ultimate challenge is “getting the organs to actually function as they should,” so accomplishing that “is the holy grail,” Lewis said.

“Just like if you were to harvest an organ from a donor, you have to immediately get that organ into a bioreactor and start perfusing it or the cells die,” she added. To perfuse an organ is to supply it with fluid, usually blood or a blood substitute, by circulating it through blood vessels or other channels.

Depending on the organ’s complexity, there is sometimes a need to mature the tissue further in a bioreactor or further drive connections, Lewis said._1400x0_16a.jpg) “There’s just a number of plumbing issues and challenges that have to be done in order to make that printed organ actually function like a human organ would in vivo (meaning in the body). And honestly, this has not been fully solved yet.”

“There’s just a number of plumbing issues and challenges that have to be done in order to make that printed organ actually function like a human organ would in vivo (meaning in the body). And honestly, this has not been fully solved yet.”

Once a bioprinted organ is implanted into a patient, it will naturally degrade over time – which is OK since that’s how it’s designed to work.

“You’re probably wondering, ‘Well, then what happens to the tissue? Will it fall apart?’ Actually, no,” Atala said. “These glues dissolve, and the cells sense that the bridge is giving way; they sense that they don’t have a firm footing anymore. So cells do what they do in your very own body, which is to create their own bridge and create their own glue.”

So cells do what they do in your very own body, which is to create their own bridge and create their own glue.”

Atala and Lewis are conservative in their estimates about the number of years remaining before fully functioning bioprinted organs can be implanted into humans.

“The field’s moving fast, but I mean, I think we’re talking about a decade plus, even with all of the tremendous progress that’s been made,” Lewis said.

“I learned so many years ago never to predict because you’ll always be wrong,” Atala said. “There’s so many factors in terms of manufacturing and the (US Food and Drug Administration regulation). At the end of the day, our interest, of course, is to make sure the technologies are safe for the patient above all.”

“There’s so many factors in terms of manufacturing and the (US Food and Drug Administration regulation). At the end of the day, our interest, of course, is to make sure the technologies are safe for the patient above all.”

Whenever bioprinting organs becomes an available option, affordability for patients and their caregivers shouldn’t be an issue.

They’ll be “accessible for sure,” Atala said. “The costs associated with organ failures are very high. Just to keep a patient on dialysis is over a quarter of a million dollars per year, just to keep one patient on dialysis. So, it’s a lot cheaper to create an organ that you can implant into the patient. ”

”

The average kidney transplant cost was $442,500 in 2020, according to research published by the American Society of Nephrology – while 3D printers retail for around a few thousand dollars to upward of $100,000, depending on their complexity. But even though low-cost printers are available, pricey parts of bioprinting can include maintaining cell banks for patients, culturing cells and safely handling biological materials, Lewis said.

Some of the major costs of current organ transplantation are “harvesting the organ from the donor, the transport costs and then, of course, the surgery that the recipient goes through, and then all the care and monitoring,” Lewis said. “Some of that cost would still be in play, even if it was bioprinted.”

“Some of that cost would still be in play, even if it was bioprinted.”

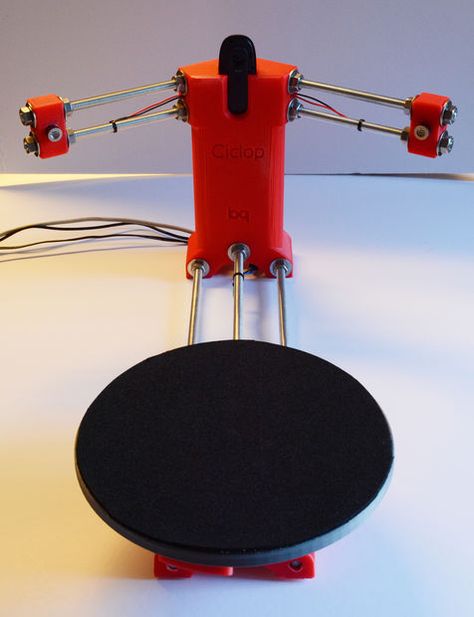

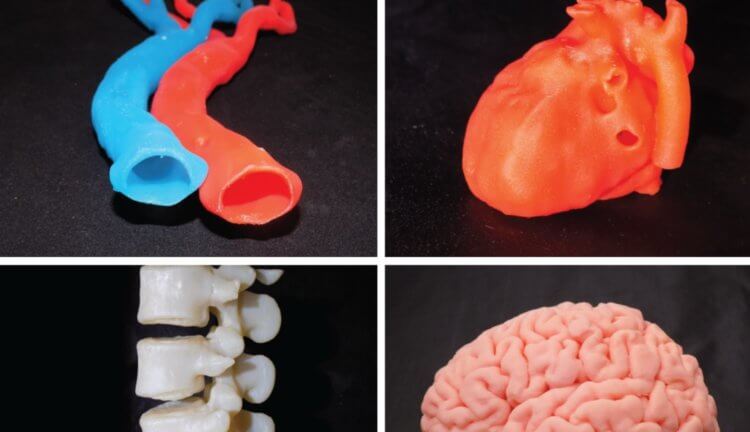

How bones, vessels and organs are printed using 3D printers / Habr

In the early days of rapid prototyping, it was widely believed that 3D printing would transform all manufacturing, spurring a consumer revolution that would bring a printer into every home. This has not yet happened, however, as has happened with many of the latest technologies, rapid prototyping has found its application in a completely different area - in medicine.

Article from the Gizmodo website.

The research and projects below are some of the most interesting examples of the use of bioprinting and the use of computer-controlled machines to assemble biological matter using organic inks and ultra-strong thermoplastics. The range of application of bioprinting is very wide - from the reconstruction of the main parts of the human skull to the printing of scaffolds - scaffolds on which stem cells can develop into new bones. Read the details below.

Read the details below.

Skulls

Osteofab is a product of the company

Oxford Performance Materials. Initially, OPM entered the market by selling in its raw form a high-performance polymer often used in the manufacture of medical implants - a thermoplastic called polyetherketone ketone (PEKK), but over the past few years the company has become the first to master the use of this material, primarily in additive manufacturing . So, in February 2013, an American patient

installedFDA approved 3D skull implant. The casting and printing was carefully crafted to match the unique geometry of the patient's skull, of which 75% is now an implant.

Leather

The main problem with creating new skin using printing is the difficulty of recreating a specific shade from the entire possible spectrum. Given that our skin is unique, thin and subject to change, it is quite difficult to create an exact copy of it. There is a huge amount of interesting research on this topic, the essence of which cannot be put into a short story.

Given that our skin is unique, thin and subject to change, it is quite difficult to create an exact copy of it. There is a huge amount of interesting research on this topic, the essence of which cannot be put into a short story.

However, here are two of the most interesting: Scientist James Yoo of Wyke Forest University, with a grant funded by the US Department of Defense, is working on a machine that can print skin directly on burn victims. Another study is being carried out by scientists at the University of Liverpool, who are using carefully calibrated 3D scanners to obtain skin samples containing all of its finest nuances, which will allow more realistic implants to be printed later.

The research is still ongoing and the team plans to create a "skin sample database" of scanned samples that can be accessed from remote hospitals that do not have the cameras needed to scan a particular patient's skin. [ Gizmodo ; PhysOrg ]

Noses and ears

The creation of prosthetic ears, noses and chins is often a painful, expensive and time-consuming process for both the patient and the doctor himself. British industrial designer Tom Fripp has worked with scientists at the University of Sheffield over the past 5 years to develop a cheaper and easier-to-make 3D printed facial prosthesis. The process of creating such a prosthesis includes 3D scanning the patient's face (which is much less painful than casting it), modeling the replacement part and printing it, which uses pigment, starch and medical silicone.

British industrial designer Tom Fripp has worked with scientists at the University of Sheffield over the past 5 years to develop a cheaper and easier-to-make 3D printed facial prosthesis. The process of creating such a prosthesis includes 3D scanning the patient's face (which is much less painful than casting it), modeling the replacement part and printing it, which uses pigment, starch and medical silicone.

These prostheses have the added bonus that when they wear out (which they eventually will), they can be reprinted at a very low financial cost. [

The Guardian]

Prosthetic eyes

Fripp and a team at the University of Sheffield published the results of testing a similar process for making prosthetic eyes. Prosthetic eyes are expensive and, because they are hand-painted, can take months to make. Fripp Designs printers can produce 150 prosthetic eyes in an hour, and details such as iris color, size and number of blood vessels can be easily changed to suit the needs of the patient. [

[

]

Functional implants

As electronic devices — from drones to medical implants — get smaller, scientists are struggling to create batteries for them that are small enough, but with those could provide the necessary charge. However, a team of engineers from Harvard University is already printing microbatteries the size of a grain of sand using a 3D printer. Here's what the press release says:

“…researchers created an anode ink using nanoparticles of one lithium oxide compound, as well as a cathode ink made from nanoparticles of another kind of this compound. The printer applied ink to the teeth of two gold combs, thus creating a tightly connected structure of anodes and cathodes. The scientists then placed the electrodes in a tiny container and filled it with an electrolyte solution to make a battery."

Over time, they will be able to charge medical implants, which are held back due to charging problems. [ Harvard ]

[ Harvard ]

Bones

3D printed implants such as the jaw have been around for several years. However, a small group of researchers is conducting an experiment whose goal is to print real bones. For example, scientist Kevin Scheiksheff of the University of Nottingham invented a bioprinter that creates matrices from polylactic acid and gelatin alginate, which are then coated with stem cells.

The implanted matrices will gradually dissolve and be replaced by new growing bone: it will take approximately three months for the bone to completely transform. [ Forbes ]

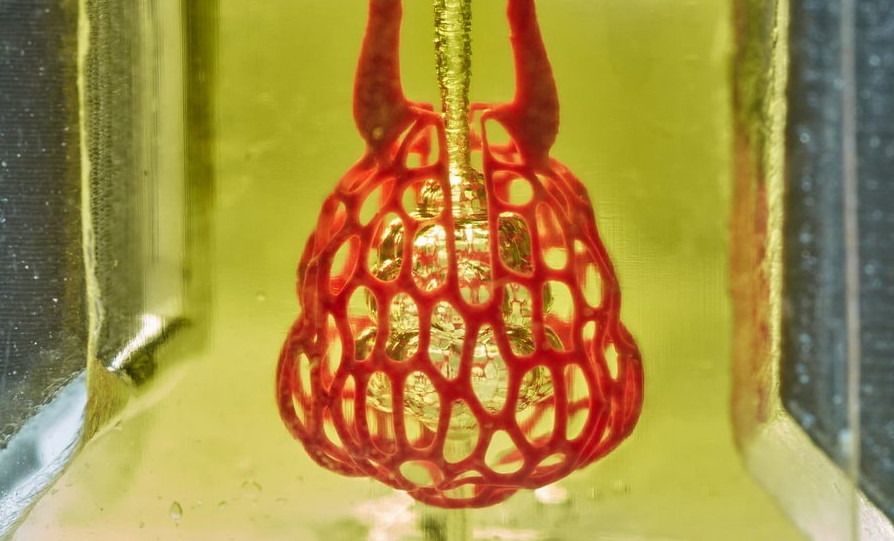

Blood vessels and cells

We can already print

organs, but there is a serious problem in creating a functioning circulatory system.

German scientist Günther Tovar, head of the Fraunhofer Institute for Interfacial Engineering and Biotechnology, is working on a project called BioRap. His task is to use a 3D printer to print blood vessels, which uses a mixture of synthetic polymers and biomolecules. The printed circulatory systems are being tested on animals - they are not yet ready for introduction into the human body. However, they will eventually make organ transplants possible. [ Fraunhofer Institute ]

His task is to use a 3D printer to print blood vessels, which uses a mixture of synthetic polymers and biomolecules. The printed circulatory systems are being tested on animals - they are not yet ready for introduction into the human body. However, they will eventually make organ transplants possible. [ Fraunhofer Institute ]

How do you see the future of 3D printing with living and substitute artificial materials for use in the human body? Will we soon be able to grow and replace full-fledged organs, such as the liver? Share your opinion in the comments.

Video 3D Printing - Shazoo

Cohen

12The craftsman created a stunning sliding box with a mysterious sphere on a 3D printer

3D printers can be used for a variety of purposes. With the help of industrial ones, you can print parts, engines, prostheses and much more. There are printers that can print entire houses. And amateur ones allow you to print everything at home, on ...

There are printers that can print entire houses. And amateur ones allow you to print everything at home, on ...

scavenz

eight3D printed rocket engine tested in India

Indian startup Agnikul Cosmos has successfully completed the world's first test of a 3D printed rocket engine. It can be used to deliver satellites and any other cargo weighing up to 100 kilograms into space. It took 4...

to printCohen

0There is a guide for creating a working tracker from The Mandalorian

The target tracking gadgets used by the bounty hunters in The Mandalorian make it easy to find targets, making the profession less confusing. How this tracker works is not that important,...

How this tracker works is not that important,...

cyber_samovar

eightJetpack Gravity Industries equipped with a shoulder rifle

A couple of years ago, Gravity Indutstries introduced the jetpack, teasing people that they could just fly errands instead of stuck in traffic. Apparently, just the company's jetpack is not enough, so they invited an engineer...

Sun4oyZ

12The Martian crew will be able to print their own bones and skin in case of injury

The journey to Mars will take several years, and people will not be able to turn back if the astronaut suddenly gets burned or broken bones. Therefore, scientists from the University Hospital at the Dresden University of Technology create the first bioprinted skin samples and...

Therefore, scientists from the University Hospital at the Dresden University of Technology create the first bioprinted skin samples and...

Cohen

29Bioengineers 3D-print complex vascular networks

Bioengineers are one step closer to 3D printing of complete organs and tissues. A team from the University of Washington and Rice University has developed a tool to 3D print complex and intricate networks of vessels. They are able to mimic natural air vessels,...

scavenz

22NASA will start using 3D-printed chips

NASA will start using 3D-printed chips in its planetary rovers. To do this, the space agency has invested two million dollars in the team of the Goddard Space Flight center. A research team has developed a special 3D printing technique that...

To do this, the space agency has invested two million dollars in the team of the Goddard Space Flight center. A research team has developed a special 3D printing technique that...

scavenz

25Finalists of the NASA competition showed models of residential buildings for a colony on Mars

Before sending people to colonize Mars, NASA needs to think through as many little things and details as possible. For example, housing in which the astronauts will be. For this, the space agency launched the 3D-Printed Habitat Challenge in 2015,...

Cohen

19Lockheed Martin has created the largest part of the spacecraft on a 3D printer

Lockheed Martin has completed its final series of quality tests on a titanium hemisphere that will serve as a cap for the satellite's fuel tank. However, this is not an ordinary titanium part - in terms of diameter, it has become the largest space ...

However, this is not an ordinary titanium part - in terms of diameter, it has become the largest space ...

Cohen

51Cheap "printed" houses for a billion homeless people

Food, water and a roof over your head are basic human needs, but according to the latest data, about 1.2 billion people on Earth do not have a home. During SXSW, a startup from Austin presented a low-cost solution for developing countries -...

Cohen

23The world's first augmentation with which you can double the number of your hands

Federico Chicariz and his company Youbionic have imagined a near future where we will see the world through the prism of augmented reality, and the capabilities of the body can be expanded with the help of physical augmentations. One of these is already available...

One of these is already available...

Cohen

9Hearthstone cards turned into 3D smartphone cases

Hearthstone fans can now use their favorite cards or their backs as a stylish 3D printed embossed case. Fabzat has partnered with Blizzard to offer a variety of cards and card back designs as...

Editorial

tenThe real BFG gun is just huge

Doom is known as one of the first shooters that paved the way for the genre of multiplayer shootouts, where teams of friends could destroy each other to pixels. However, most gamers know Doom rather for one of the most famous weapons in. ..

..

Kamiastel

tenHomemade NES can do what the officially re-released console does not

When a couple of weeks ago, Nintendo announced the re-release of a smaller and improved version of its legendary NES console, many were extremely excited about this event. However, there were those who, despite the joy, realized that with ...

Editorial

5A gamer printed a turret from The Division on a 3D printer

Alas, at the moment it is nothing more than a pile of plastic with the most minimal functionality - the ability to stand on three legs. However, given the ability of many craftsmen, in the future there may be those who equip this turret with. ..

..

Editorial

ten3D-printed semi-automatic weapons

What do you do to keep your head busy? Someone is playing chess. Other Sudoku. When a Youtube user named Derwood stretches his brain, he gets a semi-automatic weapon, which is 95% made on a 3D printer. His...

Editorial

fourNew 3D printing method allows complex ceramics to be created

Ceramics has amazing abilities. Ceramic materials have strength, lightness and excellent thermal properties. Now researchers have learned how to use 3D printing to create complex and previously impossible ceramic structures that can withstand temperatures up to 1,300 degrees Celsius.