3D printed corals

A new dimension to marine restoration: 3D printing coral reefs

- Australian group Reef Design Labs submerged a 3D-printed artificial coral reef earlier this month in the Maldives, with the hope that this advanced engineering method will help coral regeneration efforts.

- Their product, called Modular Artificial Reef Structure or MARS, enables the user to build and install an adjustable structure by hand rather than barge or crane.

- 3D printing cannot fix ocean acidification, bleaching, and other dire threats reefs face, but it can facilitate desperately needed research on reef restoration and resilience.

The local fishermen looked on skeptically. From the deck of a small motorboat, scuba divers grabbed odd chunks of ceramic – which could be described as rocky brains stuck on stumpy stilts – and plunged into the aquamarine waters. The dive team assembled the pieces as a few triggerfish circled around to investigate the commotion. After just two air tanks (about an hour each), they had locked all of the items together into the final product: an artificial coral reef.

The 3D-printed reef, installed at Summer Island Maldives resort earlier this month, is the first of its kind on any of the 1,200 islands of the Maldives. Each of the artificial reef’s ceramic components was 3D printed with a custom design and then fitted with coral fragments that developers hope will grow across the entire structure.

Left: Reef Design Lab’s newest Modular Artificial Reef Structure (MARS) in the Maldives stands 2.5 meters (8.2 feet) tall with a 4-meter square (13-foot square) footprint. Right: 3D printing reefs allows researchers to experiment with restoration methods, such as how coral fragments are attached to reefs (here, using steel wire). Images by Alex Goad.3D printers have become faster, cheaper, and more accurate in the past decade, allowing enthusiasts to develop neat trinkets such as toothpaste squeezers and custom pasta makers. Australian entrepreneur Alex Goad had a more ambitious application: 3D printing coral reefs. He formed the not-for-profit Reef Design Labs (RDL) to apply the flexibility of 3D prints to coral restoration research.

Australian entrepreneur Alex Goad had a more ambitious application: 3D printing coral reefs. He formed the not-for-profit Reef Design Labs (RDL) to apply the flexibility of 3D prints to coral restoration research.

“I started Reef Design Labs to support marine research, that’s the main thing we do,” Goad told Mongabay. “I was interested in ceramic and how it could be used as an ideal material for coral nurseries. So we gave it a go.”

A customizable approach to reef restoration

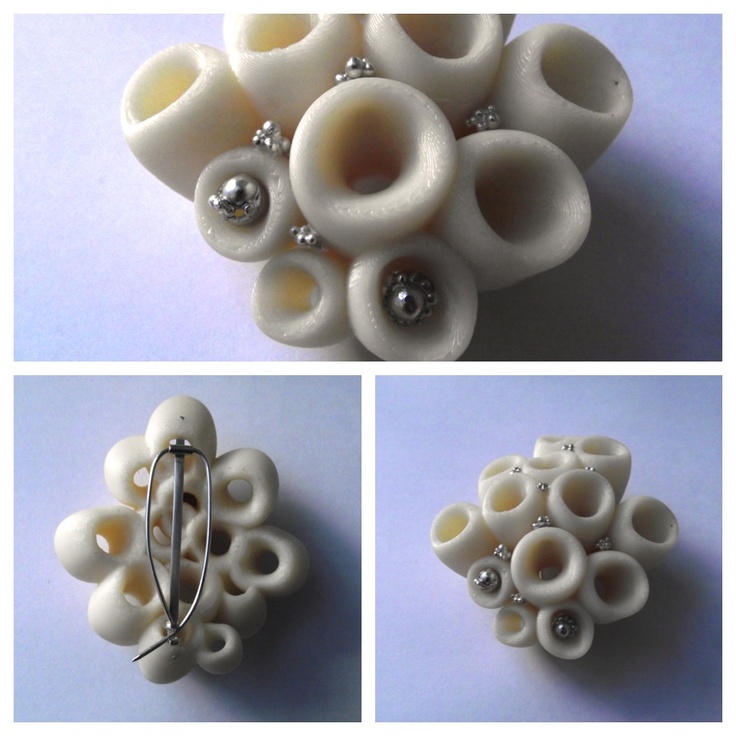

RDL calls its patented technique for 3D-printed coral formation Modular Artificial Reef Structure, or MARS. Instead of using steel or concrete, popular substrates for artificial reefs, RDL prints hollow blocks of ceramic, which can be molded into complex shapes, and fills them with concrete for stability. Divers bring these blocks underwater and fit them together like LEGOs to form a cohesive and resilient structure.

Divers bring these blocks underwater and fit them together like LEGOs to form a cohesive and resilient structure.

3D printing artificial reef structures may sound like a gimmick to draw attention, but Goad suggests several benefits of a custom-design reef mold. Coral begins its life cycle as drifting larvae that search for an unexposed place buffered from predators and water currents. 3D printing can replicate the intricate structure of existing reefs needed to foster new coral growth. Within minutes, the small alcoves and overhangs of the Maldivian MARS also began attracting curious fish; it may someday provide shelter to crustaceans, sponges and anemones to form a marine community.

A previous MARS installation, a few months after it was deployed, became the home for various marine species. Although 3D printing will not solve the global threats that reefs face, it can support targeted, small-scale restoration efforts. Image by Alex Goad.“[Reef Design Labs] actually designed the structure based on the corals that are most widely growing in the Maldives,” said Aminath Shauna, a native Maldivian and spokesperson for Summer Island Maldives. “[The 3D-printed reefs] have all these contours and shapes that mimic the natural reefs, so that corals can easily attach themselves…which we can’t do just building regular concrete structures.”

“[The 3D-printed reefs] have all these contours and shapes that mimic the natural reefs, so that corals can easily attach themselves…which we can’t do just building regular concrete structures.”

Goad was not the first to construct 3D-printed reefs; another Australian, James Gardiner, paired up with Sustainable Oceans International (SOI) to sink blocks of sandstone amongst sections of a damaged reef system in the Persian Gulf in 2012. The advantage provided by MARS is convenient installation. Rather than using barges to transport beefy chunks of concrete out to sea, divers can slot a customizable set of MARS pieces together by hand to form a sturdy skeleton in shapes inspired by the native coral community.

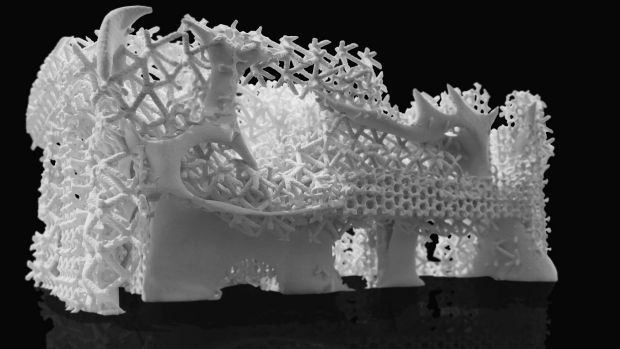

A Tasmanian blennie takes shelter in one of Reef Design Labs’ 3D printed habitat panels. Image by Alex Goad.Reef Design Labs has applied its technology to support other marine life as well. n June 2017, RDL supplied concrete reef units for Australia’s largest shellfish restoration, for which researchers sank more than 17,000 tonnes (18,740 US tons) of limestone near Yorke Peninsula and then released tiny oyster larvae to settle on the new structures. In April 2016, the lab teamed up with Riot Games to design marine sculptures, including a character from a popular online video game, as appealing hideouts for fish communities. The lab is now working with Volvo and Sydney Institute of Marine Science to create oyster habitat on seawalls. Each project’s design and implementation solicits input from marine biologists, who monitor the structures to assess which methods yield the most permanent habitats for corals and other reef organisms.

In April 2016, the lab teamed up with Riot Games to design marine sculptures, including a character from a popular online video game, as appealing hideouts for fish communities. The lab is now working with Volvo and Sydney Institute of Marine Science to create oyster habitat on seawalls. Each project’s design and implementation solicits input from marine biologists, who monitor the structures to assess which methods yield the most permanent habitats for corals and other reef organisms.

The materials and methods of installation for an artificial reef must be carefully chosen and prepared, or the structure may do more harm than good for the marine environment. 3D printing also requires specialized equipment and expertise, and there is a ceiling to how much custom reef design can be scaled up. Goad acknowledges there are limitations to the practice.

Goad acknowledges there are limitations to the practice.

“People assume that 3D printing is going to be some magic thing that is going to save the coral reefs – obviously not. This is to be used for small coral nurseries. I was interested in how MARS could help this cause: a permanent structure that had complexity and would allow other reef species [besides corals] to have a home.”

Healthy soft corals on a reef in the Maldives. Image by Tchami, Wikimedia Commons.MARS acts as a platform for targeted research on optimal coral farming methods. Prints can be tailored to specific experiments, for instance testing how different techniques of attaching coral fragments affect growth. Such research may help scientists better understand and adjust to the threats faced by coral reefs.

Coral bleaching threatens reefs worldwide

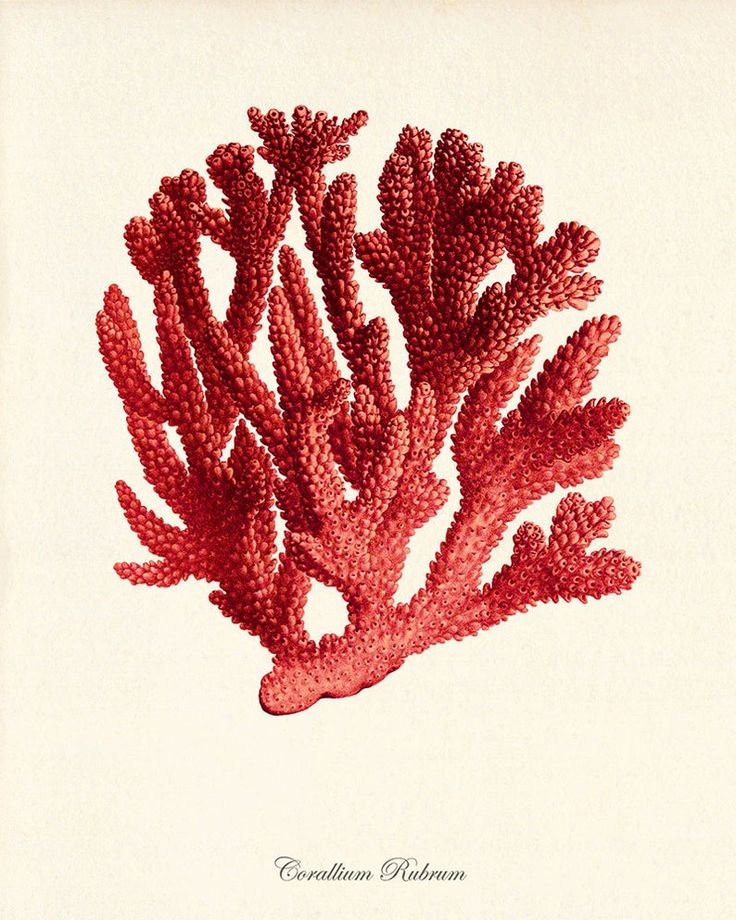

Corals face a number of threats globally, such as white band disease, coral skeletons dissolving from ocean acidification, and coral bleaching, the last of which has especially affected the Maldives. Warm ocean temperatures stress corals and cause them to eject the algal cells living inside them, which they rely on to produce energy. Prolonged separation kills both coral and algae, leaving nothing but a bone-white skeleton.

Warm ocean temperatures stress corals and cause them to eject the algal cells living inside them, which they rely on to produce energy. Prolonged separation kills both coral and algae, leaving nothing but a bone-white skeleton.

“[T]he ecological impacts of bleaching are near-instantaneous and can be severe,” reported Drs. Christopher Perry and Kyle Morgan, who quantified coral loss in the Maldives in 2016. “Such events thus have the capacity to also drive very rapid, and potentially severe, declines…in resultant reef growth potential.”

The Maldives is the largest atoll in the world, a geologic formation composed of thousands of years of coral growth. The nation also boasts the world’s 7th largest reef system — but this is quickly changing.

In 2016, a tremendous El Niño event, a shift in global wind and precipitation patterns that naturally occurs every two to seven years, caused the waters of the Indian and Pacific Oceans to dramatically heat up. This shock of warmth, combined with continually increasing global temperatures, disrupted one-third of the coral cover in Australia’s Great Barrier Reef, and killed an estimated 75 percent of the coral cover in the southern Maldives.

This shock of warmth, combined with continually increasing global temperatures, disrupted one-third of the coral cover in Australia’s Great Barrier Reef, and killed an estimated 75 percent of the coral cover in the southern Maldives.

Shauna recalled the summer of 2016 distinctly.

“There’s a reef that we would go for snorkeling near Male [the Maldivian capital],” she said. “It’s a beautiful reef, one of the most healthy reefs that I’ve seen near the capital city. And within a week, we saw it go completely white.”

Coral reefs support fisheries, attract tourists, and buffer waves that may flood coastal communities, but bleaching, ocean acidification, and disease are killing corals globally. Image by Aminath Shauna.Corals benefit coastal communities in the Maldives and beyond because they attract fish (and tourists), and they protect coastlines from storms and erosion. The Maldives is particularly vulnerable to sea level rise: the nation’s highest peak on Addu Atoll rises a whopping 2. 4 meters (8 feet) above sea level. Shelves created by coral growth act as a wall that buffers the impact of waves, reducing constant flooding as well as erosion of beaches, of which there are precious few left in the Maldives.

4 meters (8 feet) above sea level. Shelves created by coral growth act as a wall that buffers the impact of waves, reducing constant flooding as well as erosion of beaches, of which there are precious few left in the Maldives.

“I remember in 2016, when we were swimming it felt like we were in a bath,” Shauna added. “And it’s not just 2016…every year it is warmer, and with the El Niño, the coral don’t have time to recover.”

Optimism despite dire global conditions

Research and creative approaches to reef restoration are a glimmer of hope in the face of global threats that have already destroyed much of the world’s coral ecosystems. Ecologists have identified some corals that thrive in warm waters and others that partner with unique algae to resist high temperatures.

Arjan Sierink inspects the coral reef farm he initiated at Summer Island Maldives, on a budget of not more than $1,000. Image by Alex Goad.Goad maintains optimism in the toughest of times. “What really keeps me going is how much research is occurring. There is work on understanding heat-tolerant corals and identifying the genetic make-up that resists warming climates…there are also groups looking at how to start coral farms en masse.”

There is work on understanding heat-tolerant corals and identifying the genetic make-up that resists warming climates…there are also groups looking at how to start coral farms en masse.”

The charisma and flexibility of 3D printing will not do much to help reefs if ocean temperatures continue to rise to levels at which corals cannot survive. Yet technology like RDL’s can facilitate research to understand how we might adapt to climate change, so Goad is experimenting with approaches to address issues that coastal communities face.

“We’re starting to look into 3D modular design as a wave-breaking technology [to prevent storm damage and flooding]. That’s really interesting because there’s a real need for that in a place like the Maldives.”

The interlocked pieces of a MARS reef structure, upon installation and as marine life has begun to colonize it several months later. Image by Alex Goad.Goad said he hopes this work will engage researchers and local communities, demonstrating how easy coral restoration can be and inspiring others to follow. “Installing the structures underwater, it’s really fun. Everyone was just loving it.”

“Installing the structures underwater, it’s really fun. Everyone was just loving it.”

And those skeptical Maldivian fishermen scrutinizing the installation? “Now,” says Goad, “they’re starting their own coral nurseries.”

A healthy coral reef in the Maldives. Image by Aminath ShaunaCitations

Randall, C. J., & van Woesik, R. (2015). Contemporary white-band disease in Caribbean corals driven by climate change. Nature Climate Change 5, 375-379.

Perry, C. T., & Morgan, C. M. (2017). Bleaching drives collapse in reef carbonate budgets and reef growth potential on southern Maldives reefs. Nature Scientific Reports 7, 40581.

Hughes, T. P., Kerry, J. T., Baird, A. B., Connolly, S. R., Dietzel, A., Eakin, C. M., Heron, S. F., Hoey, A. S., Hoogenboom, M. O., Liu, G., McWilliam, M. J., Pears, R. J., Pratchett, M. S., Skirving, W. J., Stella, J. S., & Torda, G. (2018). Global warming transforms coral reef assemblages. Nature 556, 492-496.

Guannel, G., Arkema, K., Ruggiero, P., & Verutes, G. (2016) The power of three: coral reefs, seagrasses and mangroves protect coastal regions and increase their resilience. PLOS One 11(7), e0158094.

Baker, A. C., Starger, C. J., McClanahan, T. R., Glynn, P. W. (2004). Coral reefs: corals’ adaptive response to climate change. Nature 430, 741.

FEEDBACK: Use this form to send a message to the editor of this post. If you want to post a public comment, you can do that at the bottom of the page.

Climate Change, Climate Change And Coral Reefs, Conservation Solutions, Coral Bleaching, Coral Reefs, Ecosystem Restoration, Global Warming Mitigation, Oceans, Technology, Wildtech

PrintReforming coral reefs using 3D printing -- ScienceDaily

The world's coral reefs are becoming extinct due to many factors such as global warming and accelerated urbanization in coastal areas, which places tremendous stress on marine life. "The rapid decline of coral reefs has increased the need for exploring interdisciplinary methods for reef restoration," explains Natalie Levy, a Ph. D. student at Bar-Ilan University in Israel. "Examining how to conserve the biodiversity of coral reefs is a key issue, but there is also an urgent need to invest in technology that can improve the coral ecosystem and our understanding of the reef environment."

D. student at Bar-Ilan University in Israel. "Examining how to conserve the biodiversity of coral reefs is a key issue, but there is also an urgent need to invest in technology that can improve the coral ecosystem and our understanding of the reef environment."

In a paper recently published in the journal Science of the Total Environment, researchers from four of Israel's leading universities highlight a 3D printing method they developed to preserve coral reefs. Their innovation is based on the natural structure of coral reefs off the southern coastal Israeli city of Eilat, but their model is adaptable to other marine environments, and may help curb reef devastation plaguing coral ecosystems around the world.

The joint research was led by Prof. Oren Levy and Ph.D. student Natalie Levy, of the Mina and Everard Goodman Faculty of Life Sciences at Bar-Ilan University, Prof. Ezri Tarazi and Ph.D. student Ofer Berman, from the Technion's Architecture and Town Planning Faculty, Prof. Tali Treibitz and Ph.D. student Matan Yuval from the University of Haifa, and Prof. Yossi Loya of Tel Aviv University.

Tali Treibitz and Ph.D. student Matan Yuval from the University of Haifa, and Prof. Yossi Loya of Tel Aviv University.

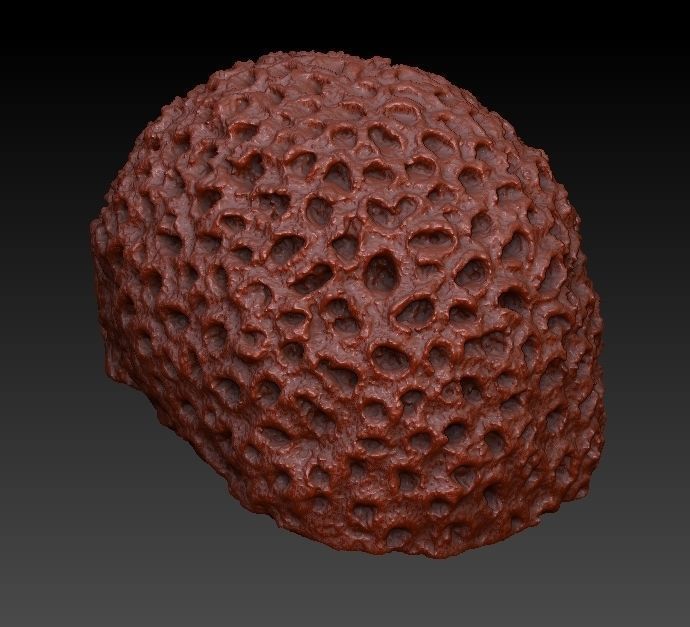

The 3D process begins by scanning underwater photographs of coral reefs. From this visual information, a three-dimensional model of the reef is assembled with maximum accuracy. Thousands of images are photographed and sent to the laboratory to calculate the complex form of the reef and how that form encourages the evolution of reef species diversity.

Next, the researchers use a molecular method of collecting environmental genetic information which provides accurate data on the reef's organisms. This data is incorporated with other parameters and is fed into a 3D technology algorithm, making it possible to build a parametric interactive model of the reef. The three-dimensional model can be designed to precisely fit the designated reef environment.

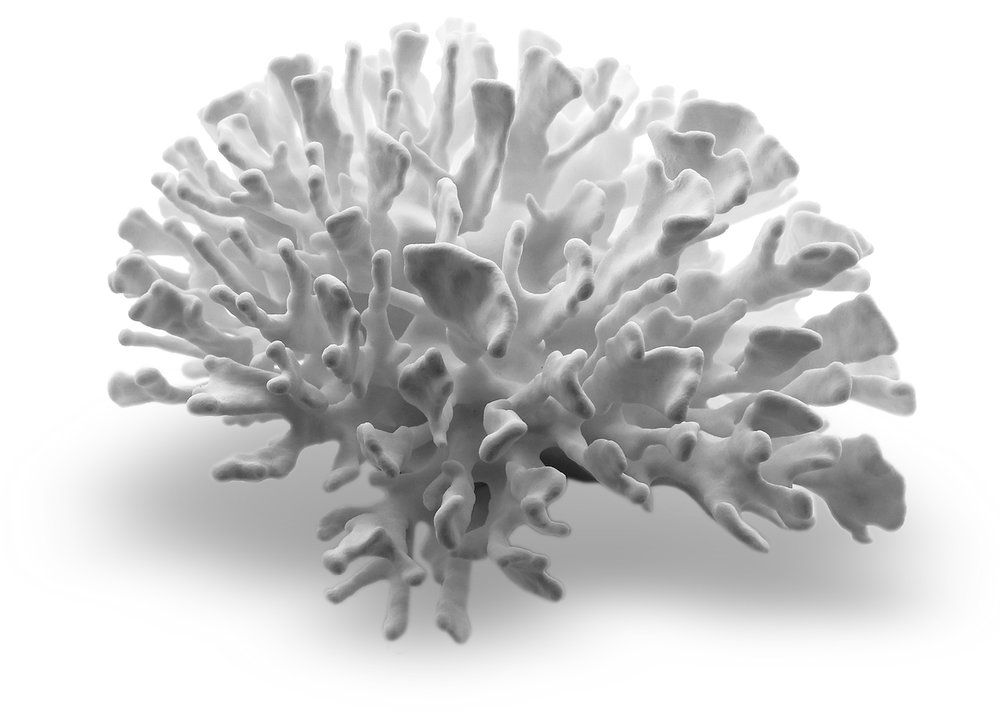

The final stage is the translation and production of a ceramic reef in 3D printing. The reefs are made of a unique ceramic that is naturally porous underwater and provides the most ideal construction and restoration needs to the affected area, or for the establishment of a new reef structure as a foundation for the continuation of life. "Three-dimensional printing with natural material facilitates the production of highly complex and diverse units that is not possible with the usual means of mold production," says Prof. Ezri. Tarazi.

"Three-dimensional printing with natural material facilitates the production of highly complex and diverse units that is not possible with the usual means of mold production," says Prof. Ezri. Tarazi.

The process combines 3D scanning algorithms, together with environmental DNA sampling, and a 3D printing algorithm that allows in-depth and accurate examination of the data from each reef as well as tailoring the printed model to a specific reef environment. In addition, data can be re-fed into the algorithm to check the level of effectiveness and efficiency of the design after it has been implemented, based on information collected in the process. "Existing artificial reefs have difficulty replicating the complexity of coral habitats and hosting reef species that mirror natural environments. We introduce a novel customizable 3D interface for producing scalable structures, utilizing real data collected from coral ecosystems," emphasizes Natalie Levy. Ofer Berman adds, "The use of three-dimensional printing allows extensive freedom of action in reality algorithm-based solutions, and the assimilation of sustainable production for the development of large-scale marine rehabilitation. "

"

This study meets two critical needs to save coral reefs, according to the researchers. The first is the need for innovative solutions that facilitate large-scale restoration that can be adapted to support coral reefs worldwide. The second is the recreation of the natural complexity of the coral reef -- both in size and design -- that will attract reef species such as corals, fish, and invertebrates that support the regrowth of natural coral reefs. The researchers are currently installing several 3D printed reefs in the Gulf of Eilat. They believe that the results they obtain will help them apply this innovation to other reef ecosystems around the world.

Story Source:

Materials provided by Bar-Ilan University. Note: Content may be edited for style and length.

90,000 Scientists came up with the idea to print the base for corals on a 3D printer. This will save their population Site searchScience November 1, 2021

Further

Elizabeth Console news editor

Elizabeth Console news editor

Charlotte Houser and her colleagues from the Saudi King Abdullah University of Science and Technology (KAUST) have unveiled 3D CoraPrint technology that will help restore coral reefs.

Read Hi-Tech in

New 3D printing technology to help speed up the initial stages of coral recovery.

Previously, scientists and activists began to leave special concrete and metal structures in the right areas where corals grow, which can serve as the basis for their new growth. But on such frameworks, limestone skeletons of coral polyps form slowly.

The authors of the new work proposed the use of structures that are closer to natural, produced using 3D printing. The researchers scanned the 3D shape of a real coral and printed it on a printer using a specially designed “ink” based on Calcium Carbonate Photo-initiated (CCP) limestone.

During the experiment, the authors tested this material in an aquarium, and it turned out to be non-toxic to living organisms.

After that, they placed microscopic fragments of living coral polyps on the printed structure and fixed them so that they actively began to grow. As a result, according to the authors, the basis for the future reef is more actively populated, and also develops more reliably.

As a result, according to the authors, the basis for the future reef is more actively populated, and also develops more reliably.

On our printed calcium carbonate surface, coral micro-fragments grow rapidly because they do not need to start building from a limestone structure.

Charlotte Houser, a scientist at the Saudi King Abdullah University of Science and Technology

Read more Scientists are looking for people who cannot contract COVID-19. Based on their data, a medicine will be made

Read more

Congratulations, you have subscribed to the Hitech digest! Check your email

Thank you, your message has been sent successfully.

Read article - Raise3D sculpture of a coral reef the size of a man.

Exploring the underwater world with 3D printing

Exploring the underwater world with 3D printing Jon Goebel, associate professor of art at the University of Hawaii at Hilo, is collaborating with the university's marine research team on coral ecology and has 3D printed coral visualizations so people can better understand them. The goal was to stimulate conversation about the impact of corals on the oceans, about the different types of corals and their sizes.

The benefits of the work can be seen in the e.Mandrinus coral. In this project, John Burns of the Marines team combined coral images from Waiape in Una, one of the best diving spots on the island, using photogrammetry. One of Waiape's corals is e.Mandrinus, a cauliflower-colored coral. Its size is about 1 cubic foot (0.028 m2 ), which is about the size of a milk carton. A major volcanic eruption occurred in 2018 and the Kapoho tidal basin where e.Mandrinus was mined is now completely filled.

This project began before the eruption and the team had samples from the now filled pool. John Burns has preserved the corals in a way that anyone can see them, whether in virtual reality or with a 3D viewer where they can be rotated and viewed.

Jon Goebel 3D Printing Project

Inspired by this project, Jon Goebel decided to go one step further and 3D print e.Mandrinus corals 80,000% larger than life size.

His goal is to print a large coral model that people can interact with as if they were fish. The ratio of the size of a person to coral is the same as natural coral and the fish that lived there. He wants his 3D printed coral to change the way people view corals in general, sparking curiosity and discussion about the role they play in the ecosystem.

Using a particular model as a prototype to reproduce a much larger version, Jon spent up to 6,000 hours printing. He has plans to one day take this project to a larger scale, including installing child-climbable corals in public areas.

Jon Goebel with 3D printed coral

Why was the e.

“It was one of the coolest corals,” Jon replied immediately. He went on to explain that this particular coral has the most interesting visual features. For example, it had the most branches, the distance between them, and the way the wavy petals added to its appeal. Its general structure also gave it the greatest potential for interactivity when magnified.

Lessons learned from 3D printing corals.

Jon took the model that John Burns made using photogrammetry, processed the model in a slicer program, cut it into layers for printing, and printed it on a 3D printer. However, he realized that when the model is scaled up by 80,000%, the end result of the 3D printing shows all the polygon faces, and it doesn't look good.

3D printed coral processing

Wanting to improve the result of 3D printing, Jon decided to change the size of the printed parts. He went back to Burns' photogrammetric model and cut it into quarters. He then increased the size of each piece by 80,000%.

Jon cut each enlarged quarter into 100-200 pieces and refinished the surface. He did anti-aliasing, retopology, anti-aliasing, about 10 of these iterations to bring the base polygon count up to 500,000, resulting in a beautiful, smooth model. Then he assembled the whole model in Meshmixer.

Improved 3D Printed Coral Design

Development of a new, more efficient design

The 3D printed pieces of the coral were heavy, weighing around 22.6kg each, which meant the magnets couldn't hold the different pieces together. Jon's engineering solution was to add hollow holes in the coral. This allowed him to get inside and add mechanisms to connect the parts.

To create these holes, Jon used a Meshmixer. Jon calculated how the cavities and thickness of the parts should be, so that the corals remain strong, but light. Jon also found that by printing parts vertically, he didn't have to use support structures or supports.

3D printed coral with access hole

Another advantage of the cavities was that Jon needed less plastic filament. Whereas previously he used half a spool for one large part, now he can print 4 or 5 parts with one spool.

PLA filament for coral 3D printing

One of the big reasons Jon chose PLA is because it is a bioplastic, which makes it sustainable. As the project aimed to change people's perceptions of coral ecology and marine life, it was important to have a sustainable 3D printing material. PLA is also a widely used, easy to print and affordable material.

3D printed coral

Raise3D Pro2 Plus wide format 3D printer used to print corals

The challenge was to print the coral, which, as mentioned, was larger than life. Raise3D's Pro2 Plus is a large format printer capable of reliably printing high quality, large models. The Pro2 Plus turned out to be the best large format 3D printer in the price range Jon could afford.

Installing coral in the presentation area

Jon has already printed 72 models and will print more. He then plans to paint each piece individually, fasten them with steel bolts, and touch up the already harvested coral. He also wants to add texture to make the coral look real. In nature, it is very colorful and beautiful.

3D Printed Coral Piece

Where will the coral model be placed?

"Library," Jon answered decisively. He explained this by saying that it was there that people would be able to interact with the model, see it in all its glory and receive information about the coral. “We put on quite a few exhibitions at the library, so we have a lot of viewers,” he explained.

Read more about 3D printing and its application in different areas in our blog.

Tsvetnoy Mir is a reliable supplier of 3D printers, 3D scanners and consumables, with many years of experience, supplying directly from manufacturers and guaranteeing their quality.