Brands of 3d printers

Best 3D Printers Of 2023

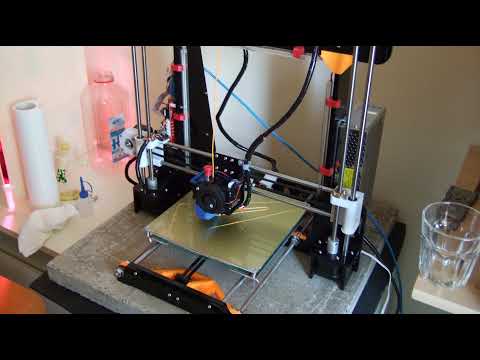

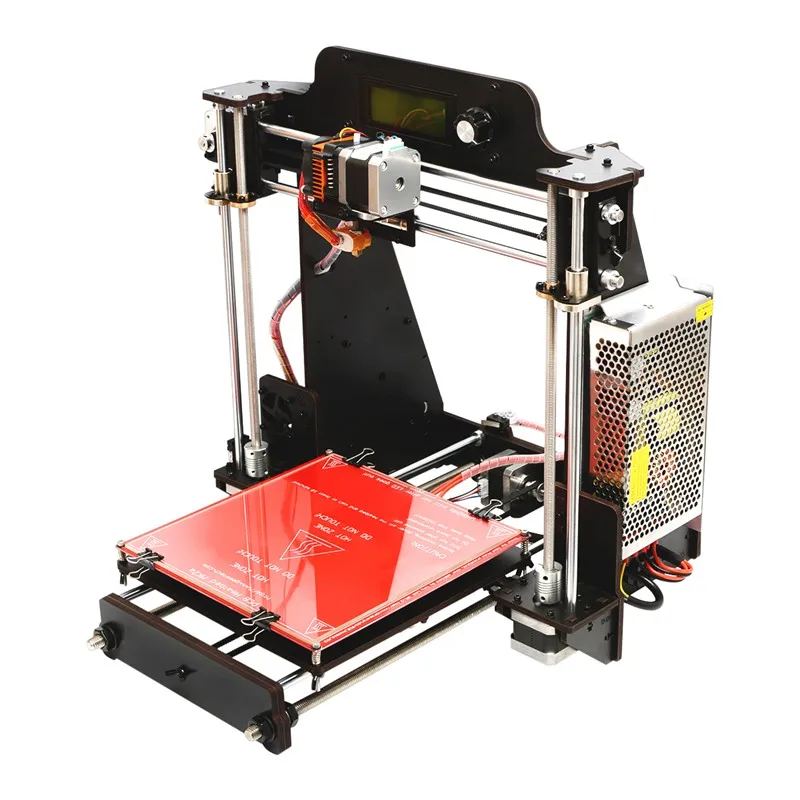

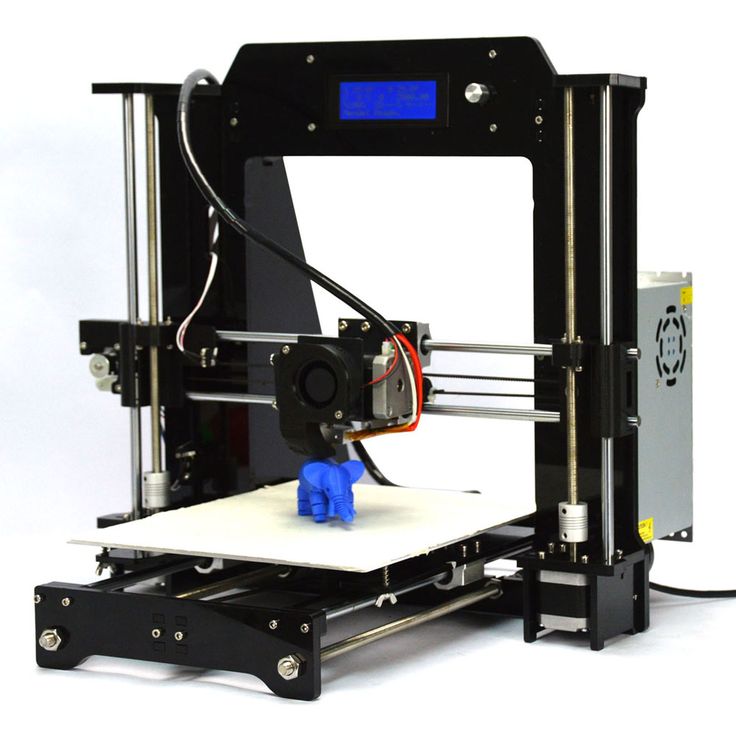

Our list of the best 3D printers contains clear and concise information on all kinds of 3D printers. (Image credit: Future)The best 3D printers have become more affordable, and the 3D printer market is growing at an explosive rate, with new brands and styles of printing making an appearance each year. Where many 3D printers used to be huge, expensive machines, developments in technology and production now mean that many of the best options you can buy are increasingly affordable and can sit on a desk in your home without needing workshop space.

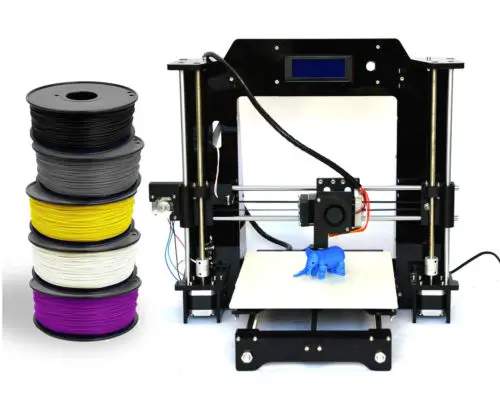

Naturally, this means there's now a massive choice of 3D printers that cater to all sorts of user needs and budgets. While this choice is excellent, picking the best 3D printer for your specific needs can be difficult. However, this guide can help, as we pick some brilliant 3D printers for all uses and budgets, with clear buying advice to help you determine which one you should buy.

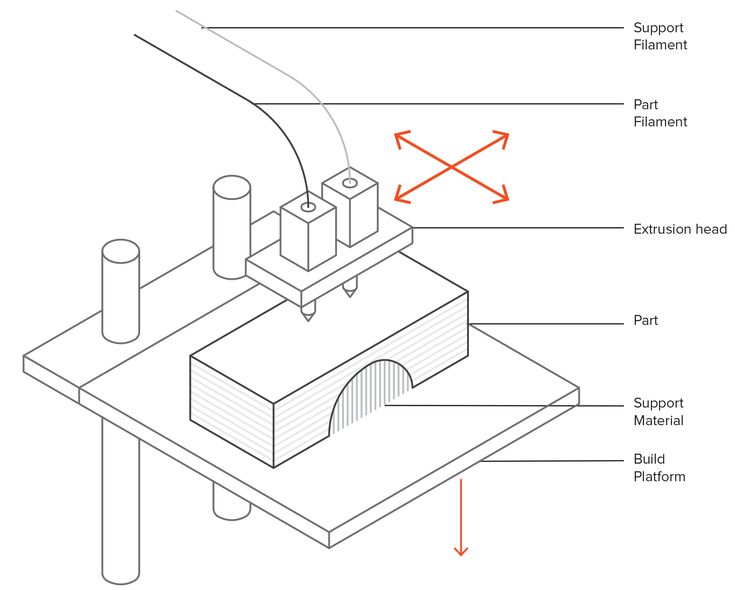

Printing hardware has taken off in recent years, so while a handful of filament printers (otherwise known as FDM printers) were all that was once available, there's now a wide variety of different styles to suit your needs across a range of budgets.

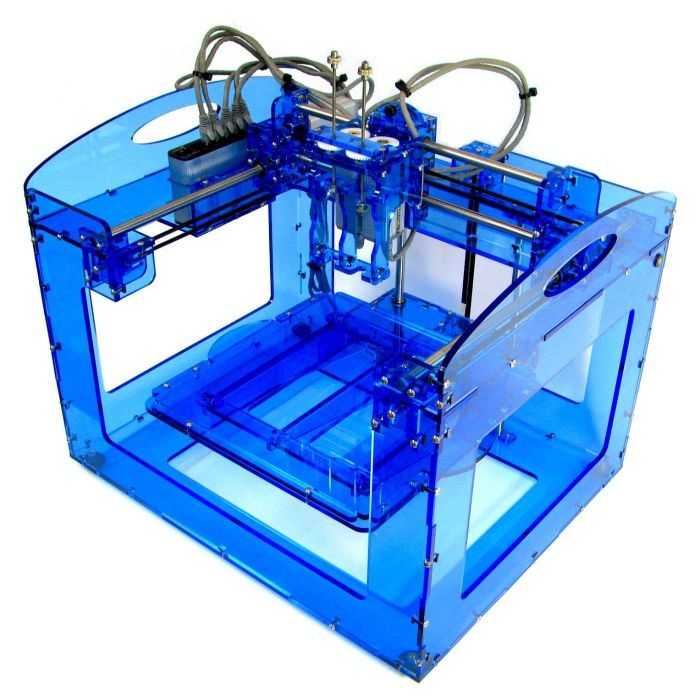

Unlike office-style printers that just print ink onto paper, 3D printers turn digital models into real-world objects made from plastic, metal, and wood. FDM printers now come in all shapes and sizes and are well-suited to prototyping and crafting larger objects. At the same time, resin-based (SLA, MSLA, and DLP) allow for much greater detail, typically at a smaller scale, making them a fantastic buy for anyone looking to design jewelry or create tabletop miniatures.

You can use 3D printers to build complete products, make spare parts, or simply create things you’ll find helpful for your home, office, and workshop. And, since 3D printing technology is within the grasp of just about anyone, you don’t have to utilize one to your advantage.

Whether you’re just getting your feet wet or are an expert, here are the best 3D printers ranges to consider. We've compared these printers across size, functionality, and use case, so there should be something for you, whatever it is you’re looking for. We also looked at their print resolution, build platform, filament type, and pricing.

We also looked at their print resolution, build platform, filament type, and pricing.

Remember that the more expensive choices are better suited for professionals, while the best cheap 3D printers are ideal for those just starting.

The best 3D printers of 2023 in full:

Why you can trust TechRadar Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

The best 3D printers

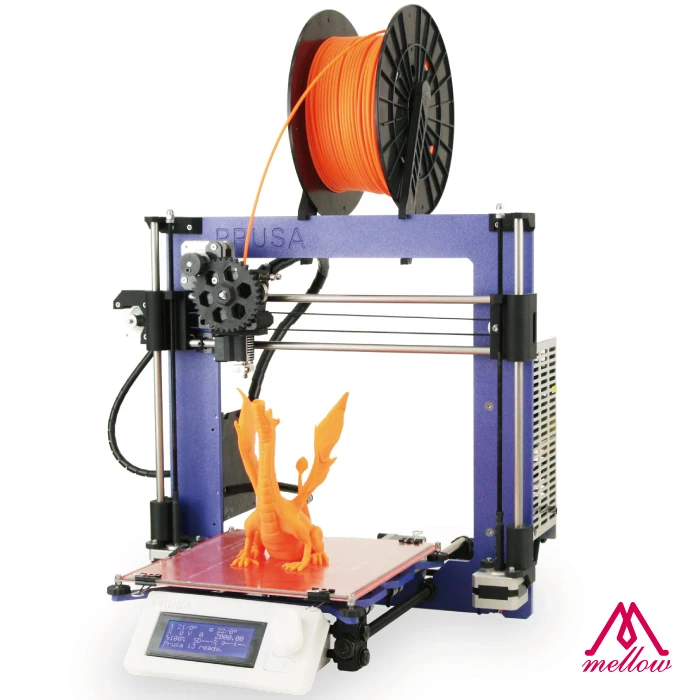

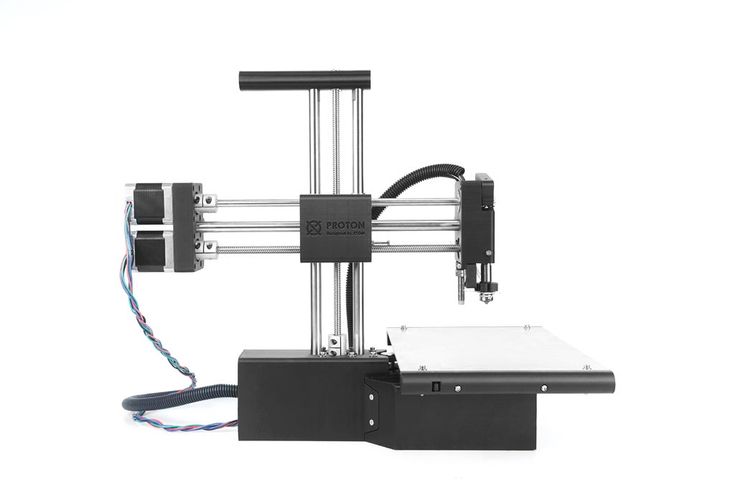

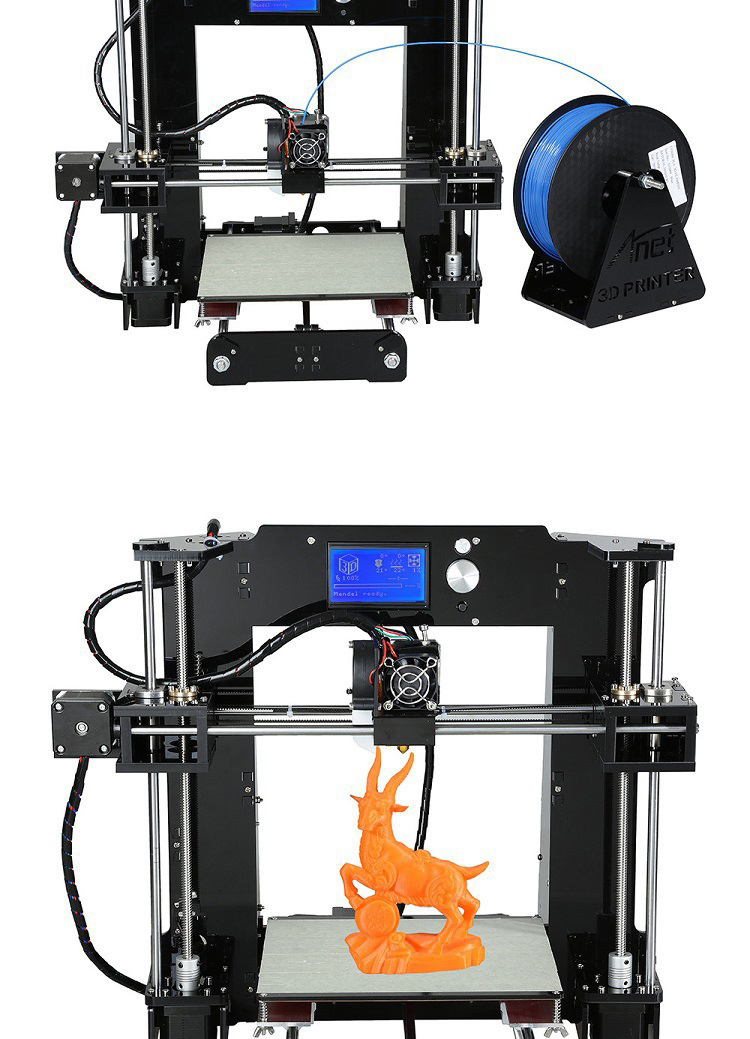

Original Prusa MINI (Image credit: Prusa)1. Original Prusa MINI+

Small, affordable, and remarkable 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build Area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 33 x 33 x 38cm

Weight: 4.5kg

Today's Best Deals

Reasons to buy

+

Great value for an FDM printer

+

Easy to use

+

Supports a variety of filament types

Reasons to avoid

-

Reel sits separately

-

Imperfect print quality

-

Calibration can be tricky

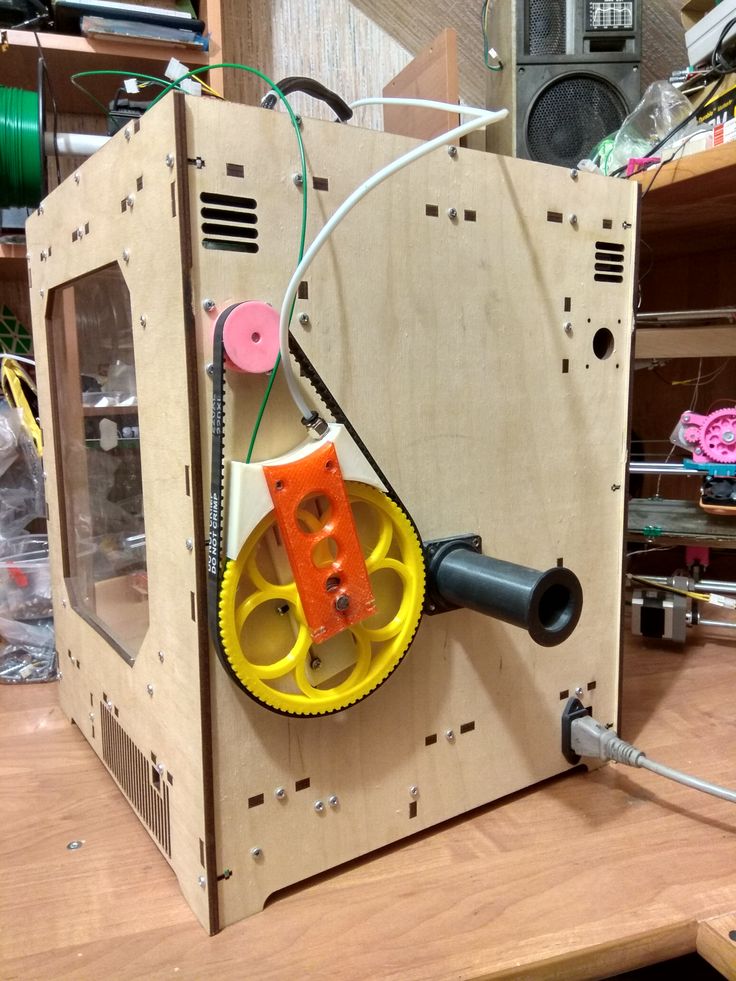

This affordable open-frame 3D printer is small enough to sit on your desk and easy enough to assemble yourself without expertise. It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into accurate printed products.

It comes in kit form and uses FDM (Fused Deposition Modeling) to turn popular modeling materials such as PLA, PETG, ASA, ABS, and Flex into accurate printed products.

There’s a Network LAN and USB port for simple connectivity and a user-friendly interface. The 2.8-inch 65k colour screen makes navigating the options and settings easy, and on first starting the machine, it takes you step by step through the set-up process. This entry-level printer should be the first choice for crafters, modelers, and engineering enthusiasts.

The Original Prusa MINI+ is a replacement for the Original Prusa MINI (minus the plus), the key advantage being that it now comes with a superPINDA sensor, which is not temperature dependent allowing the first layer calibration to be faster and more reliable.

Read the full review: Original Prusa MINI.

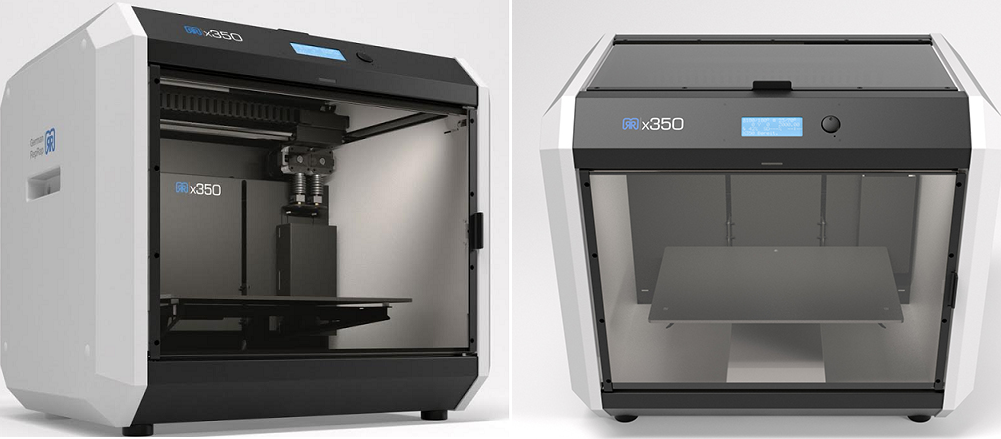

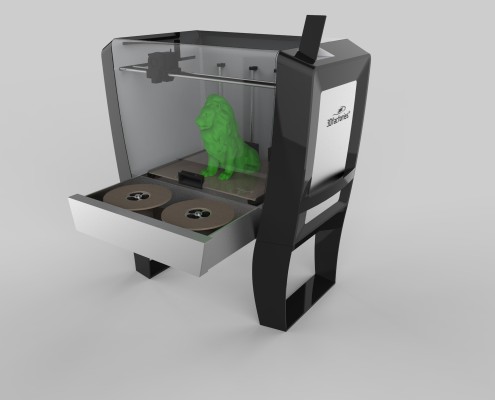

CEL-UK RoboxPro (Image credit: CEL-UK)2. CEL-UK RoboxPro

Best 3D printer for commercial printing

Specifications

Print technology: Fused Deposition Modeling

Build Area: 210 x 300 x 400mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 500 microns

Dimensions: 513 x 508 x 605mm

Weight: 26kg

Today's Best Deals

Reasons to buy

+

Swappable print heads

+

Dual Extruder and auto bed leveling

+

Network ready, no wired needed

Reasons to avoid

-

Large scale printer, not ideal for home use

-

Can be difficult to load filament

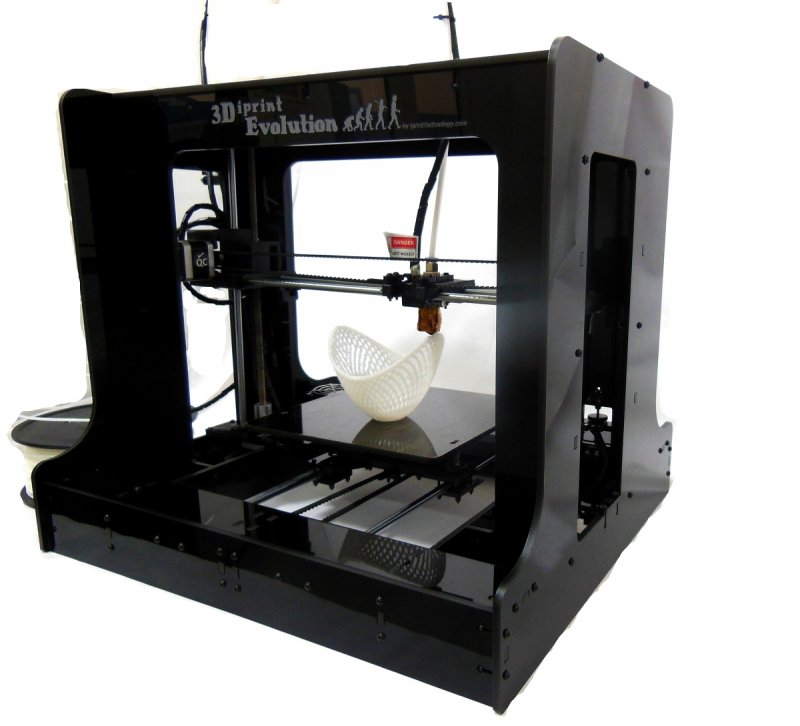

CEL-UK is a leader in 3D Printer innovation, with the original Robox printers introducing many new features to the world of FDM 3D printers. The RoboxPro is Robox on a large scale with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing, and swappable tool heads.

The RoboxPro is Robox on a large scale with a feature set that reads like a 3D print wish list; auto filament loading, auto bed leveling, Wi-Fi, network printing, and swappable tool heads.

The main focus of the machine is quality and reliability, designed for anyone wanting a printer that can realize product ideas and get them to market. The enclosed design makes it an ideal choice for commercial and educational use.

There's a sizable touchscreen panel built into the front of the machine. It displays the current materials and can be used to navigate settings and print directly from USB or other external drives.

Read the full CEL-UK RoboxPro review.

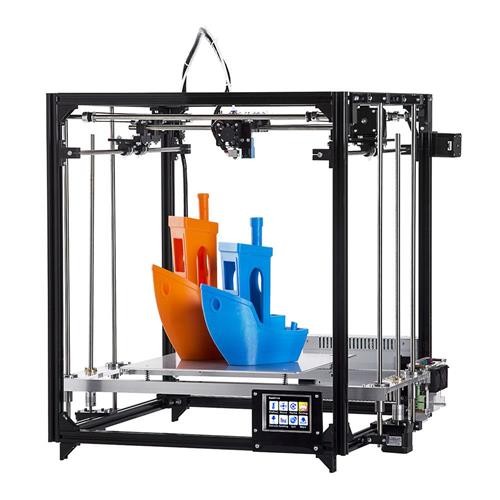

(Image credit: Creality)3. Creality Ender-5 S1

An ideal 3D printer for any 3D print enthusiast or small business on a budget

Specifications

Print Technology: Fused Deposition Modeling

Build Area: 220 x 220 x 280mm

Minimum Layer Resolution: 0. 05mm

05mm

Maximum Layer Resolution: 0.35mm

Dimensions: 425 x 460 x 570mm

Weight: 12.1kg

Today's Best Deals

Reasons to buy

+

Incredible value

+

Robust design

+

High-quality tool head

Reasons to avoid

-

Not a true CORE XY printer

-

Large footprint

-

No enclosure for enhanced materials (Optional extra)

Having a predecessor with a decent reputation instantly puts pressure on the new model to perform. From the small amount of initial construction needed to build the printer to the outstanding bed leveling technology, the Ender-5 S1 proves to be a decent upgrade and on a completely different level of quality to the original Ender-5.

The cubed design might not be a true CORE XY printer, but the robust frame and tool head design's and precision enables a print quality that pits this printer against models that are at least twice the price.

The design is refined, the tool head completely overhauled, and with upgrade options such as an enclosure and laser head, there is plenty of scopes to expand your creativity. This is a printer designed for both enthusiasts and small business users.

Read our full Creality-5 S1 review.

(Image credit: TRILAB)4. TRILAB DeltiQ 2

Distinctive delta design for professional 3D printing

Specifications

Print technology: Fused Deposition Modeling (FMD)

Build area: 25 x 25 x 30cm

Minimum layer resolution: 50 microns

Maximum layer resolution: Variable

Dimensions: 41 x 50 x 81cm

Weight: 10kg

Today's Best Deals

Reasons to buy

+

Elegant design

+

Easy expansion

Reasons to avoid

-

Not suitable for all materials

-

Fully open design

This elegant delta design should get your attention if you’re looking for a professional 3D printer for fairly large and complex projects. It uses FDM technology to build 3D models from rolls of filament. Still, instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axes. It gives this model a fairly small footprint, while its high tower design ensures it can print some quite large pieces.

It uses FDM technology to build 3D models from rolls of filament. Still, instead of the more common cartesian printers, the TRILAB DeltiQ 2 has a fixed round build plate with the extruder suspended between three arms that move the print head along three axes. It gives this model a fairly small footprint, while its high tower design ensures it can print some quite large pieces.

And unlike most 3D printers, it has two extruder options, one for standard PLA and PETG and the other for flexibles. It just requires a little retooling to swap between them. The TRILAB DeltiQ 2 uses some of the best components available in its construction, and the interface is a smartphone running a dedicated app. This handsome, high-end workshop printer would sit well in any laboratory, studio or classroom.

Read our full TRILAB DeltiQ 2 review.

Original PRUSA SL1 (Image credit: PRUSA)5. Original PRUSA SL1S SPEED

The best MSLA printer just got better

Specifications

Print technology: Stereolithography

Build area: 320 x 450 x 500mm

Minimum layer resolution: 25 microns

Maximum layer resolution: 100 microns

Dimensions: 400 x 237 x 225 mm

Weight: 4. 5kg

5kg

Today's Best Deals

Reasons to buy

+

Rapid printing

+

Great build quality

Reasons to avoid

-

High maintenance

-

Limited build volume

Prusa Research revolutionized the FDM 3D printer market, and this model looks set to do the same for SLA printers. While this printer uses stereolithography technology, it's a slight variant known as MSLA.

This uses a monochrome LCD and UV LED to expose the resin, which is cheaper than precision lasers but just as accurate. The SL1S SPEED replaces the outgoing SL1, and as you might have guessed from that model name, it’s faster – around ten times faster and with a vastly improved print quality.

The SL1S's design hasn't physically changed a great deal over the SL1. It features the same touchscreen LCD on the front, which is again good and responsive.

The speedy new model looks set to lead the SLA market with support from the excellent PrusaSlicer software and a huge open-source community.

Read our full Original Prusa SL1S 3D printer review.

Anycubic Vyper (Image credit: Anycubic)6. AnyCubic Vyper

The best beginner friendly FDM 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 245 x 245 x 260mm

Dimensions: 508 × 457 × 516mm

Weight: 10kg

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

Built-in accessories drawer

+

Reliable automatic bed-leveling

+

Great value for the features you get

Reasons to avoid

-

Excessive initial stringing

-

Questionable build quality in places

-

Cura profile needs fine-tuning

If the world of 3D printing ever seemed too intimidating for you, look no further than the AnyCubic Vyper. While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

While perfect for beginners with its auto-leveling feature and minimal assembly, seasoned printing hobbyists will also appreciate what it can offer, albeit with a few adjustments.

As the 'automatic leveling' might imply, the AnyCubic Vyper removes the need to align your build plate manually should you want to move the machine to a different location. It's fast and accurate, saving time when setting up your first print, which makes setting up and getting started a breeze.

The touchscreen control panel is satisfyingly fast and easy to use, but we found that the estimated print completion time was consistently incorrect. Once the printer is properly optimized, you'll enjoy impressive print quality.

Read our full AnyCubic Vyper review.

Raise3D E2 (Image credit: Raise3D)7. Raise3D E2

The best workhorse 3D printer

Specifications

Print technology: Fused Deposition Modeling

Build area: 330 x 240 x 240mm

Minimum layer resolution: 20 microns

Maximum layer resolution: 250 microns

Dimensions: 607 x 596 x 465mm

Weight: 35kg

Colour

Black

Condition

New

Today's Best Deals

Reasons to buy

+

High-resolution print capability

+

Innovative ouch screen interface

+

Dual Extruder system can work independently

Reasons to avoid

-

Huge and heavy, not ideal for home use

-

Careful placement of bed required

-

Needs manual assistance for filament loading

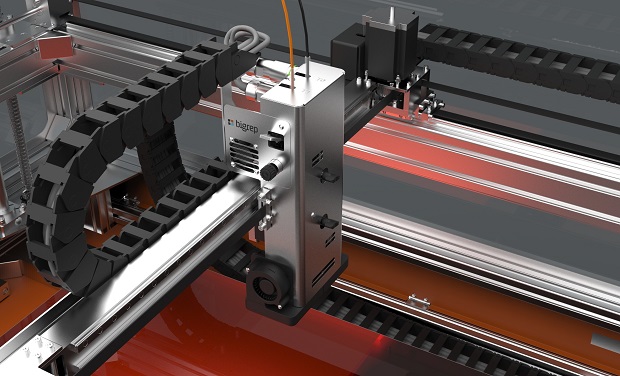

3D printing has come of age, and machines like the Raise3D E2 bring high-end FFF printing to the home, education, and business. This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration.

This dual extrusion printer goes head-to-head with the RoboxPro and will fulfill most companies' design and development needs with slick business and network integration.

The printer display is vast and detailed, and you can swiftly access all the printer settings through the fast and responsive touchscreen interface. You can print directly from a USB key, wired connection, network, or Wi-Fi, making it ideal if several people are utilizing the printer. You will also find many step-by-step videos for many of the printer's features.

Home and educational users will benefit from a simple interface and near-faultless reliability. The only drawback of this machine is its size and weight.

Read the full Raise3D E review.

(Image credit: Anycubic)8. Anycubic Photon M3

Detailed 3D modelling for beginners

Specifications

Print technology: Stereolithography (SLA)

Build area: 18 x 18 x 18cm

Minimum layer resolution: 50 microns

Maximum layer resolution: 200 microns

Dimensions: 18 x 16. 4 x 10cm

4 x 10cm

Weight: 7kg

Colour

Yellow

Condition

New

Today's Best Deals

Reasons to buy

+

Good value

+

Detailed models

Reasons to avoid

-

Print size is small

-

Poorly placed USB port

The Anycubic Photon M3 is the ideal entry-level resin printer to introduce you to 3D printing. It’s relatively easy to set up and operate, and the box includes everything you need to get started except for the UV resin. This compact model will fit easily on your desk in a well-ventilated room, though the build volume is somewhat limited at 180 x 163.9 x 102.4mm or 7 x 6.5 x 4-inches.

This modest machine can turn out surprisingly detailed models for printing small plastic parts or artistic pieces. The interface is a 7.6-inch panel, and the software will help you print your project and slice it. If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but this is a great place to start for $299 (about £275 / AU$480).

If you want to make larger models, you should consider one of Anycubic’s larger 3D printers, but this is a great place to start for $299 (about £275 / AU$480).

Read our full Anycubic Photon M3 review.

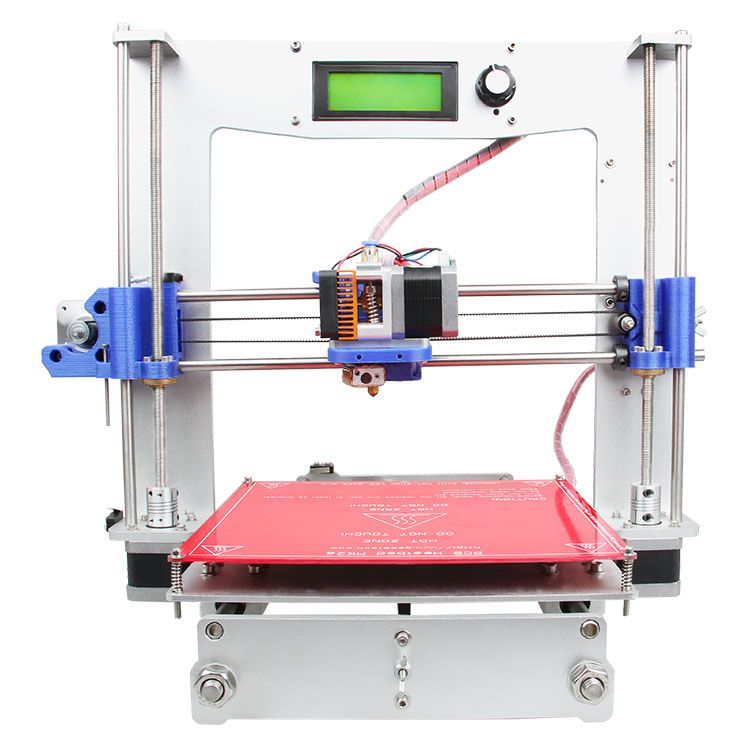

Snapmaker 2.0 A350 (Image credit: Snapmaker)9. Snapmaker 2.0 A350

Best 3-in-1 3D printer

Specifications

Print technology: Fused Filament Fabrication, CNC, Laser

Build area: 350 x 350 x 350mm

Minimum layer resolution: 50 microns

Maximum layer resolution: 300 microns

Dimensions: 645 x 480 x 580mm

Weight: 29kg

Today's Best Deals

Reasons to buy

+

3D printer, CNC, and Laser cutter in one

+

Solid design and build quality

+

Easy to understand software

Reasons to avoid

-

Switching between uses takes time

-

Enclosure purchased separately

-

Very noisy when printing

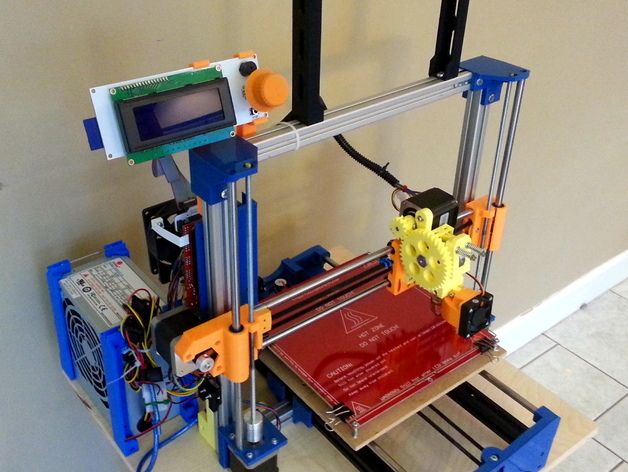

A true 3-in-1 machine makes sense because 3D printers, CNC, and Laser cutters all use the same basic mechanics and technology. The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features.

The original Snapmaker has a dedicated following, so it is no surprise that Snapmaker 2.0 builds on its predecessor's reputation and features.

The SnapMaker boasts excellent build quality and comes with clear assembly instructions. The assembly takes around 20 minutes. There's a 5-inch (720x1280px) touchscreen on the machine that can be used to select options, preview models, calibrate and open stored files. The touch screen is a powerful addition to the usability of the machine — it runs on Android OS and features a Quad-Core A7 CPU @1.1GHz.

The A350 is the largest of three models and proves proficient in all disciplines. Swapping between the three heads and beds does take time to reconfigure and calibrate, but for the price and features, it's worth it.

Read the full Snapmaker 2.0 A350 review.

- We've also featured the best printers and the best laptops for graphic design.

What is a 3D printer?

A 3D printer is a machine that creates three-dimensional objects using computer-created designs (like a digital 3D or CAD model).

These machines rely on an additive manufacturing process to build objects layer by layer.

How to choose the best 3D printers for you?

To select the best 3D printer, you'll need to consider what you're going to do with it. If you're going to be printing small objects, then a small-size printer is apt, but a large printer is naturally the best option for bigger creations.

For printing high-quality objects with fine details, you'll need a high resolution printer, but these prints will cost more and take more time to get ready.

Look out for the printer's interface and the overall ease of use, along with other aspects like the kind of software it uses, the type of filament, build platform, and pricing.

The best 3D printers: How we test

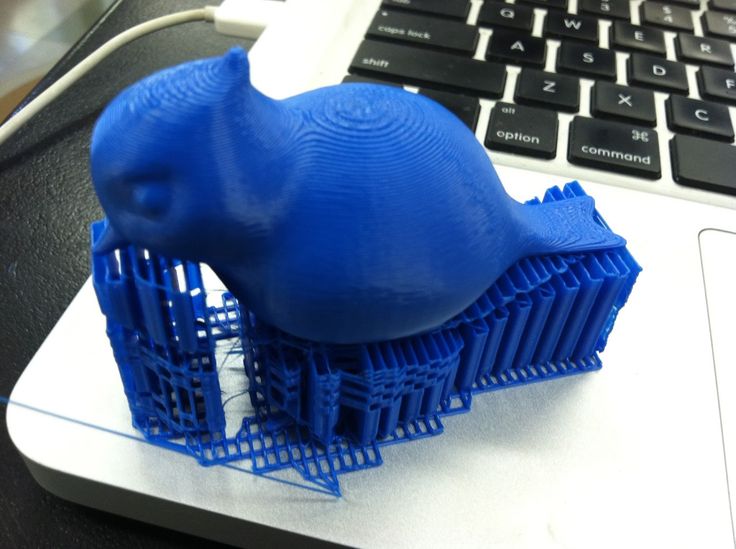

3D printers are tested using a collection of bespoke benchmarks that help show the strengths and weaknesses of each model that, after time, can be compared against other products. These will differ depending on printer type, but a filament printer will be tested for stringing, bridging, and speed, as well as additional commentary on detail, achieved, and noise levels.

This will be done fairly, with dues given to different materials and printer types, with resin printers being subject to smaller, more detailed models to replace the stringing test. Design, price, and performance will also be explored as sections within the reviews.

All our tests are conducted from the perspective of the printers target market where possible, so expect to see a lot of tabletop miniatures and figurines alongside the usual 'benches' (test models that are also dubbed as 'torture tests' to see where a printer needs to be better optimized for future prints).

Round up of today's best deals

Creality Ender-5 S1

$89.99

View

See all prices

Reduced Price

Anycubic Vyper

$499

$339. 99

99

View

See all prices

Deal ends Mon, Jan 9

Raise3D E2

$3,499

View

See all prices

Anycubic Photon M3

$319.99

View

See all prices

powered by

Sign up to theTechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

Contact me with news and offers from other Future brandsReceive email from us on behalf of our trusted partners or sponsorsCollin is the B2B Hardware Editor for TechRadar Pro. He has been in journalism for years with experience in both small and large markets including Gearadical, DailyBeast, FutureNet and more.

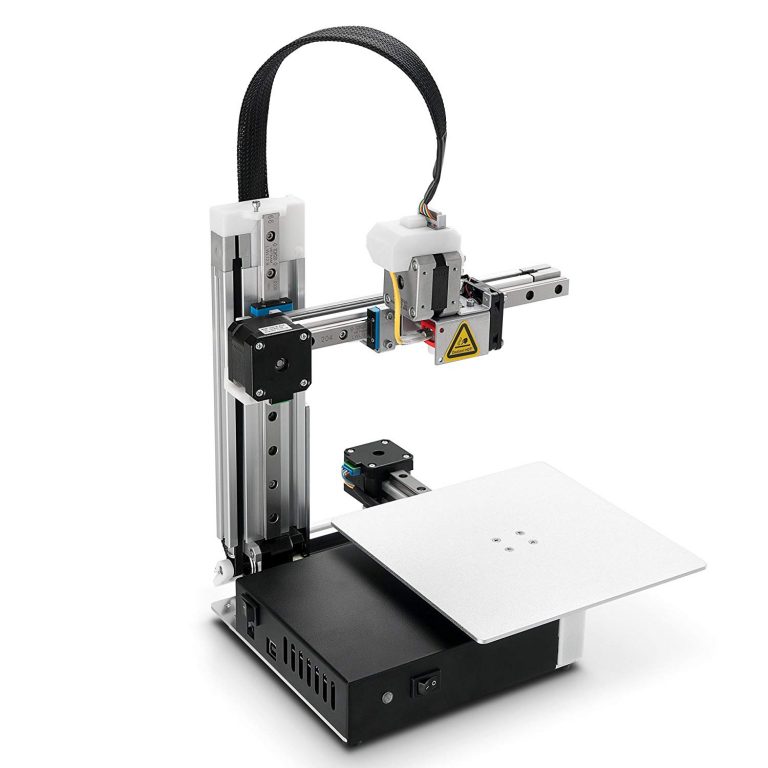

Creality Ender-5 S1 3D Printer Review

Skip to main contentWhen you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

An ideal choice for any keen 3D print enthusiast or small business that needs a professional-level printer on a budget

(Image: © Future)

TechRadar Verdict

We've seen Creality release suped-up versions of their existing 3D printers before, and each time we've seen a big performance upgrade. The Ender-5 S1 is true to form, and while the basic set-up might look much the same as the Ender-5, there's been a complete overhaul of the control board and hotend. The result is an impressive step up in speed and print quality. The price still pits this at the mid-range; however, the quality of the prints is comparable with printers many times more expensive.

TODAY'S BEST DEALS

Pros

- +

Solid performance

- +

High-quality components

- +

Accurate print dimensions

Why you can trust TechRadar Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Find out more about how we test.

Intro

Creatlity's S1 machines are the suped-up versions of their standard 3D printers. While the frame and design remain much the same, styled along the Cartesian make-up, the parts that matter, such as the main board and tool head, have all been upgraded. As you check over the machine, you realize that multiple other tweaks have also been made, resulting in this being a very different machine from the standard version. That difference is also reflected in the price tag, with the S1 costing nearly double that of the standard.

(Image credit: Future)Specs

Print Technology: Fused Deposition Modeling

Build Area: 220x220x280mm

Minimum Layer Resolution: 0.05mm

Maximum Layer Resolution: 0.35mm

Dimensions: 425x460x570mm

Weight: 12.1kg

Once assembled, which is a smooth and easy-to-follow process, you realize that the enhancements that have been made upgrade the Ender-5 from an entry-level machine into something with real potential.

- Creality Ender-5 S1 at GeekBuying for $89.99

The upgraded machine is excellent, but what peaks interest is the ability to upgrade the machine further with the inclusion of an optional enclosure and compatibility with the Creality Sonic Pad (available soon).

Sonic Pad is essentially a 3D print tablet that upgrades a machine's firmware and operates a visual interface for the machine. The sonic Pad not only upgrades the user experience but also improves performance.

At first, the Creality Ender-5 S1 might look like a tuned Ender-5, but it's a completely different beast.

Design

Firmly placed as a Cartesian machine, the Creality Ender-5 S1 differs from many standard 3D printers by having a print head that moves along the X and Y axis and a print bed that raises on the Z axis.

The design of these printers is a little more complex and does, of course, mean that with the square box design, the machines look far larger than standard Cartesian printers.

However, when it comes to size, the footprint is smaller than some printers with this size of build platform due to all the moving parts being contained within the size of the printer rather than having a build plate that slides back and forth.

(Image credit: Future)Read More

When the Creality Ender-5 S1 arrives, it does require a little assembly, but with a clear set of instructions, the whole machine can be built in around 10-20 minutes. There's nothing intricate to assemble, and the main bulk of the construction has already been done for you; you need to bolt in the uprights, install the tool head and then wire everything in. At each step, the instructions are clear, and for the most part, it's impossible to plug any of the wires into the wrong place. Even with no prior experience, there should be nothing here to challenge a complete novice.

As you go through the construction process, the real differences between this and the standard Ender-5 become apparent. The base is all-inclusive, with the main board and LCD touch screen nicely contained, and the tool head that incorporates both the hot and extruder is in another league, being direct drive rather than Bowden.

The base is all-inclusive, with the main board and LCD touch screen nicely contained, and the tool head that incorporates both the hot and extruder is in another league, being direct drive rather than Bowden.

Once the machine is constructed, the filament reel can be popped on the side and fed through the system. A filament run-out sensor is included as standard, which is nice to see, and this is where the filament journey starts as it is fed through the system. From the filament run-out sensor to the top of the direct drive hot end is a connected Teflon tube that guides the filament through the system. While the new tool head is far more advanced, there's still no automatic feed for the filament through the system, so there's a little manual feeding of filament to get it started.

(Image credit: Future)This part of the printing process is slightly primitive compared with everything else about the printer. Unlike other printers of this quality, there's usually a load filament feature that automatically pulls the filament through. Here, you need to preheat the filament, PLA or ABS, then activate the extruder motor to feed the filament through the hotend until it drips out.

Here, you need to preheat the filament, PLA or ABS, then activate the extruder motor to feed the filament through the hotend until it drips out.

With the filament loaded, you can then follow the bed leveling process. The bed leveling utilizes the same process as the Ender-3 S1 Pro. This takes you through the leveling process of z-axis offset, then manual leveling, and finally, auto leveling. As I've seen with other Creality printers, the auto bed leveling is about the best I've come across.

Features

The cubed design of the Ender-5 S1 creates an incredibly solid printer that creates an ideal environment for the accurate printing of models. The print area of the S1 is slightly smaller than the standard model, not that you would notice, with 20mm less on the height to accommodate the new all-in-one hotend and extruder design. This gives a modeling dimension of 220x220x280mm, which is pretty decent for most projects.

Once again, the heated bed features a magnetic spring steel sheet that's slightly textured. What's nice about the design of the sheet is that two alignment cuts outs ensure the sheet sits snuggly on the bed.

What's nice about the design of the sheet is that two alignment cuts outs ensure the sheet sits snuggly on the bed.

All functions and features are set through the LCD touchscreen interface, including the bed leveling. The process is extremely smooth, with the manual height adjustment made possible by four large wheels under each corner.

Before each print, the auto leveling double-checks the platform height with the CR Touch sensor fitted to the tool head's side.

(Image credit: Future)Creality has stuck with the standard 0.4mm nozzle, which can be swapped out for other nozzle sizes and replacements if needed. What's impressive is the new control board and motors enable a typical print speed of 120mm/s with the standard nozzle fitted. Checking through the settings, this can be pushed to 250mm/s.

One feature that appeals is the use of the direct drive extruder and tool head; this has the advantage of enabling compatibility with a huge variety of filaments from PLA to flex. To maximize the material compatibility, the nozzle temperature can reach up to 300ºC and the heated bed 110ºC.

To maximize the material compatibility, the nozzle temperature can reach up to 300ºC and the heated bed 110ºC.

There's also the option to add an enclosure if you frequently print with more advanced materials such as ABS and Nylon. Creality has also confirmed that it will be compatible with the Creality Sonic Pad.

Performance

On the first run watching the first layer being printed, a small amount of fine-tuning was needed on the Z-axis. This was easily controlled through the touch screen LCD. Once the first layer height is correct, the printer is set to go, and then it's over to the touch sensor to ensure the height is correct.

(Image credit: Future)Starting with the usual test prints, 3DBenchy, and other test models, they all rattled off the build plate at speed. The printer's solid build minimizes shake and vibration, which is apparent in the quality of the prints. The model's overall appearance at all default settings is excellent and shows a fine filament extrusion. At the finer layer heights, the layers are visible but show how good this printer is.

At the finer layer heights, the layers are visible but show how good this printer is.

Printing at the typical 120mm/s and the print quality was superb, and as the layer height increases, this can be pushed to quickly fire out prints at a rate, although the quality does suffer, although the filament flow remains good.

Print quality

Dimensional accuracy - score of 5

Target 25 = 25.02mm / 0.02mm Error | Y: 25.02mm / 0.02mm Error

Target 20 = 20.06mm / 0.06mm Error | Y: 20.05mm / 0.05mm Error

Target 15 = 15.08mm / 0.08mm Error | Y: 15.02mm / 0.02mm Error

Target 10 = 10.07mm / 0.07mm Error | Y: 10.01mm / 0.01mm Error

Target 5 = 5.06mm / 0.06mm Error | Y: 5.00mm / 0mm Error

X Error Average = 0.058

Y Error Average = 0. 02

02

X&Y Error Average = 0.049

Fine Flow Control - score of 2.5

Fine Negative Features - score of 4

Overhangs - score of 4

Bridging - score of 5

XY resonance - score of 2.5

Z-axis alignment - score of 2.5

Adding up the totals gives a final score of 25.5 out of 30.

Verdict

There's no doubt the Creality Ender-5 S1 is a big step up from the Ender-5. This is a completely overhauled machine with so many additions that help dramatically boost the printer's performance.

From the outset, the machine is impressive, and while the initial build takes a little longer than the single vertical upright design seen on the Ender-3, the four columns help create a rock-steady base for the printer. What I also like about the design is that everything is contained, from the electronics to the print platform staying within the perimeter of the printer. It also features two handy carry handles, making it incredibly easy to move around the workshop when needed.

It also features two handy carry handles, making it incredibly easy to move around the workshop when needed.

Ultimately the new control board and tool head leap this printer forward; add in the potential of the addition of the Sonic Pad in the near future and wrap it in a case, and you have a printer that is hard to beat.

For keen enthusiasts, modelers, product designers, and anyone who what's top-of-the-range quality from a mid-range priced machine, the Ender-5 S1 won't fail to impress.

- Looking for a great workspace for your 3D Printer? Check out our best standing desks

Creality Ender-5 S1: Price Comparison

$89.99

View

$119.99

View

$119. 99

99

View

No price information

Check Amazon

powered by

TechRadar is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

3D Printer Manufacturers: Quality 3D Printers

3D Printer Manufacturers

If you are interested in 3D printing and want to buy your own 3D printer, you might be wondering which 3D printer manufacturers are out there. In this article, we will try to answer this question in as much detail as possible and list the existing manufacturers.

Of course, it makes no sense to talk about all the developers, because there are a lot of them. Manufacturers of 3D printers today are divided not only by the type of technology used by their devices, but also by the class of devices. nine0005

nine0005

In general, all 3D printer manufacturers can be divided into three groups:

- Professionals. They produce the highest quality equipment, including industrial ones. The cost of their goods, respectively, is significantly higher than the average market prices, but the buyer pays not only for the brand, but also for reliability;

- Middle segment. The vast majority of 3D printer manufacturers fall into this category. These are companies that have already established themselves in the market, but have not yet reached a certain point. It produces good quality products at an affordable price; nine0012

- Start-up producers. Basically, these are young enthusiastic developers who are eager to bring their product into circulation. It is possible that their products can be quite good, but often such 3D printers are very raw and unfinished.

Other questions and answers about 3D printers and 3D printing:

Quality 3D printer

Of course, if you want to buy your own device for 3D printing, you want to buy the highest quality 3D printer. But what if all the manufacturers of 3D printers are touting their products? How to decide? Let's figure it out. nine0005

But what if all the manufacturers of 3D printers are touting their products? How to decide? Let's figure it out. nine0005

First of all, you should trust only proven equipment developers. See which 3D printer manufacturers have been on the market for a long time and what they offer.

Secondly, analyze the proposed options. Compare prices and features of 3D printers, see reviews. It is also a good option to get professional advice from distributors. For example, in 3DDevice you will always be helped to make a choice.

Popular 3D printers

In order to bring some clarity and help you make your choice, it is worth mentioning the most popular 3D printers. Well-known 3D printer manufacturers such as Stratasys, 3D Systems, MakerBot, Formlabs, CreatBot, Ultimaker offer good options and the market is flooded with their products. The advantage of choosing a popular 3D printer is its ease of use. After all, there is probably a training video or a review on the desired model on the network. nine0005

nine0005

Of course, when choosing a 3D printer, you should not focus solely on the manufacturer. There are many selection criteria to consider. However, 3D printer manufacturers are not the last factor to consider.

If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

We would like to remind you that in our store you will find a large number of equipment for 3D printing - desktop and professional 3D printers. We also have 3D scanners, 3D plastic and photopolymer resins, as well as spare parts and accessories at the best prices on the market with delivery throughout Ukraine. In addition, we provide 3D modeling, 3D printing and 3D scanning services. For all questions, please contact us in any of the ways convenient for you using these contacts. We look forward to collaborating! nine0005

Back to main page

AM-COR. Distributor and integrator of additive technologies.

3D printers SLS, Gypsum, DLP, FDM.

3D printers SLS, Gypsum, DLP, FDM.

3D printers made in China, Thailand.

Without sanctions

Our brands

AMcore is the exclusive supplier of the world's leading manufacturers of 3D printers in the territory of the Customs Union. In the product catalog of 3D printers you will find products of recognized leaders in the production of devices for three-dimensional printing and scanning and consumables for them. Here you will find professional and desktop 3D printing solutions. We will help you choose the device that will perfectly fulfill your tasks! nine0005

To go to the catalog of the brand you are interested in, please click on the corresponding manufacturer's logo below.

01.XYZprinting PRO

For professionals

XYZprinting, one of the world's largest manufacturers of 3D printers. The professional line of 3D printers is based on the following technologies:

SLS (Selective Laser Sintering) 3D printers

Selective Laser Sintering (SLS) technology has long been the platform of choice for producing 3D printed parts with strong mechanical properties. MfgPro230 xS allows you to organize small-scale production and production of functional prototypes, at an affordable price. DETAILS...

MfgPro230 xS allows you to organize small-scale production and production of functional prototypes, at an affordable price. DETAILS...

3D printers BINDER JET (gypsum)

3D printerPARTPRO 350 XS is a high-speed 3D printer for printing full-color plaster products at an affordable price. MORE...

DLP and SLA 3D printers

The line of photopolymer 3D printers is represented by three models, including the ultra-fast PARTPRO120 XP DLP 3D printer, which allows you to print at speeds up to 30 cm/hour! MORE...

FDM and Color fdm 3D printers

In addition to the traditional two-head FDM 3D printer, XYZprinting offers a unique PARTPRO200 XTCS full color FDM 3D printer with a large print area. DETAILS...

02.XYZprinting DeSKTOP

for Education & Prototyping

XYZprinting, a leading manufacturer of 3D printing technology, has been growing rapidly since its founding in 2013, with offices in Taiwan (Head Quarter), China, Japan, South Korea, USA and Europe. With proven industry expertise and an innovative spirit, it is becoming a leading global brand in desktop 3D printing products and services. XYZprinting is backed by the world's leading electronics manufacturing conglomerate New Kinpo Group, which generates over 36 billion euros in revenue annually and has over 8,500 R&D engineers across four continents. Kinpo Group has over 17 years of experience designing and manufacturing printers for personal and commercial use. nine0005

With proven industry expertise and an innovative spirit, it is becoming a leading global brand in desktop 3D printing products and services. XYZprinting is backed by the world's leading electronics manufacturing conglomerate New Kinpo Group, which generates over 36 billion euros in revenue annually and has over 8,500 R&D engineers across four continents. Kinpo Group has over 17 years of experience designing and manufacturing printers for personal and commercial use. nine0005

Educational 3D printers

Bring the future into the classroom and into your home! Inspire the next generation by standing on the shoulders of giants. Teach the skills and professions of the future with XYZprinting 3D printers, LEARN MORE...

3D printers for design and prototyping

New frontiers in 3D printing. Take 3D printing to the next level with the da Vinci Color series. DETAILS...

03. WEBER granular 3D printers

for large items

“Direct extrusion” involves creating components layer by layer from plasticized granules. The fact that filament is not used has a number of advantages:

The fact that filament is not used has a number of advantages:

WEBER SINGLE SCREW EXTRUDER

Can be used to process highly filled, fiber reinforced or even soft materials. MORE...

HIGH PRODUCTIVITY UP TO 20 KG/H

High output extruder provides faster printing (up to 20 kg/hour), which is very important for large volume products. DETAILS...

PELLETS 10 TIMES CHEAPER!

Pellets are much more economical than using a plastic thread (filament). DETAILS...

04. Makerbot (Stratasys)

for FUNCTIONAL prototyping

Makerbot is a division of the world leader Stratasys - manufacturer of professional 3D printers.

3D printer FOR PROFESSIONALS

Modernize manufacturing and accelerate product development with the powerful METHOD Additive Platform. DETAILS...

Professional Education 3D Printers

Bring ideas to life with Makerbot 3D printing solutions designed for students and educators. DETAILS...

DETAILS...

TECHNOLOGIES

Additive Manufacturing (AM) is a term to describe a set of technologies that create 3D objects by adding material layer by layer. Materials may vary from technology to technology. But there are some common features for all additive manufacturing, such as the use of a computer along with special 3D modeling software. The first thing to do to start this process is to create a CAD sketch. The AM device then reads the data from the CAD file and creates the structure layer by layer from the printed material, which can be plastic, liquid, flux-cored filaments, or even a sheet of paper. nine0089

XYZprinting SLA printer

SLA technology produces smooth surfaces and fine details.

Package body

Functional product.

Jewelery

SLA 3D printers are widely used by jewelers to make burnout models.

Functional prototypes

Prefabricated products - this is the calling of SLA technology in prototyping.

Stereolithography is a 3D printing technique that can be used for your 3D printing projects. Although this method is the oldest in the history of 3D printing, it is still in use today. The idea and application of this method is amazing. Whether you're a mechanical engineer who needs to check if a part fits your design, or a creative person who wants to create a plastic prototype for a new future project, stereolithography can help you turn your models into a real 3D printed object. nine0089

Brands: XYZprinting

DLP 3D printers, like SLA, work with photopolymers. But what makes SLA and DLP processes different is the different type of light source. For fans of DLP 3D, more traditional light sources such as arc lamps are commonly used. Another important part of the process is the liquid crystal display panel, which illuminates the entire printable area at once. Therefore, DLP 3D printers print faster than SLA 3D printers. The material used for printing is liquid plastic resin, which is placed in a transparent resin container. The resin hardens quickly when exposed to light. The print speed is pretty impressive. A layer of cured material can be created with such a printer in seconds. When a layer is finished, it moves up and work begins on the next layer. nine0089

The resin hardens quickly when exposed to light. The print speed is pretty impressive. A layer of cured material can be created with such a printer in seconds. When a layer is finished, it moves up and work begins on the next layer. nine0089

Brands: XYZprinting

Casting

Casting of medium and large parts with metals and polymers

Cylinder head block

DLP technology is ideal for medium and large parts.

Aligners

Making master models for vacuum crimping - making aligners

Marketing group

Nunc ullamcorper, justo a iaculis elementum, enim orci viverra eros, fringilla porttitor.

nine0043 ImpellerComplex geometry and engineering, high temperature plastics are the main advantages of FDM technology.

Drone body

Carbon-filled plastics are ideal for making strong, lightweight structures.

Upper of sneakers

Printing of shoe elements from elastic materials.

Medical devices

Bio-inert and engineering plastics - widely used in the manufacture of individual medical devices. nine0005

With FDM, you can print not only functional prototypes, but also concept models and functional products. What's great about this technology is that all FDM printed parts can be made from high performance engineering grade thermoplastics, which is very beneficial for mechanical engineers and manufacturers. FDM is the only 3D printing technology that allows parts to be produced from production quality thermoplastics, so the printed products have excellent mechanical, thermal and chemical properties. nine0089

Brands: Weber, MakerBot, Dremel, XYZprinting PRO, XYZprinting Desktop

SELECTIVE LASER SINTERING (SLS) uses a 3D printing process called Power Bed Fusion.

Common applications for SLS are functional parts, complex ductwork requiring hollow structures, and light production.

His strength lies in the creation of functional parts, parts with good mechanical properties and complex geometries. nine0005

nine0005

Brands: XYZprinting PRO

Chain mail

SLS technology allows printing non-separable structures without supports

Case

Cased, thin-walled products with complex geometry - an ideal application for SLS printing technology.

Cylinder head

Functional products

Three-dimensional picture

Full-color full-fledged three-dimensional picture printed on a plaster 3D printer.

Antique vase

Antique vase - an exact full-color copy of the museum exhibit.

Gypsum plaster

Your imagination is not limited

Souvenirs

Binder Jetting technology — layer-by-layer bonding of a composite powder with a binder (usually based on gypsum or quartz sand).

Plaster 3D printers are used in architecture, model making, archaology, design and art.

Sand-based 3D printers find their way into foundries and are used to make molds and cores. nine0005

Brands: XYZprinting PRO

Industries

Additive technologies are already widely used in various industries, education and workshops.

AVIATION

The aerospace engine, air duct, low volume interior and cockpit industries require components that are stronger, lighter and more durable. Modern additive manufacturing technologies open up new possibilities for solving these problems.

AUTOMOTIVE

Additive manufacturing is a revolutionary and rapidly evolving technology that allows designers to create rapid or rapid prototypes as well as complex designs that would otherwise be impossible with legacy manufacturing processes. The new technology provides the automotive industry with innovative design, the freedom to innovate and professionalism in the supply chain. This technology is also being used to test, manufacture and assemble automotive parts and components with higher efficiency, optimization and cost effectiveness. nine0089

INSTRUMENT-MAKING

Small-scale production of housings, connectors, tooling allows you to reduce time and cost of production. rapid prototyping using additive technologies significantly reduces the time to bring products to market.

JEWELERY

Additive manufacturing is the perfect fit for the jewelry industry due to its ability to produce complex shapes and be COST EFFECTIVE in small to medium batch production. nine0005

DENTISTRY

Dental labs can now digitally design and process large volumes of customized products. This technology is easily integrated into the dental laboratory workflow without any disruption to the current flow or standard protocols. With no costly upfront costs or set up and minimal training time, this is turnkey technology.

MEDICINE

manufacture of custom implants and scaffolds for rehabilitation, models for preoperative surgical planning, anatomical models for mechanical testing and examination of human bones or new medical technologies, manufacture of drug delivery devices, and the development of new manufacturing methods specifically designed for medical applications. nine0089

ARCHITECTURE

and DESIGN

Additive technologies in design and architecture are the endless possibilities of geometry. Modern technologies make it possible to create unique shapes and structures, light and durable details, unique and functional interior items and models of future buildings.

Modern technologies make it possible to create unique shapes and structures, light and durable details, unique and functional interior items and models of future buildings.

EDUCATION

training of future personnel for additive manufacturing and technologies of the near future - this is the main task of education and we have something to offer. nine0005

COMPANY ABOUT

AMcore specializes in distribution of equipment and sale of industrial solutions for 3D printing, 3D scanning and consumables. In our product portfolio you will find manufacturers that are world leaders in their segments. On the territory of the Russian Federation and the countries of the customs union, we are the official exclusive supplier (distributor): XYZprinting, MakerBot, AFS, Weber, Shining3D, eSUN.

In the product catalog of 3D printers you will find products of recognized leaders in the production of devices for three-dimensional printing and consumables for them. DETAILS.