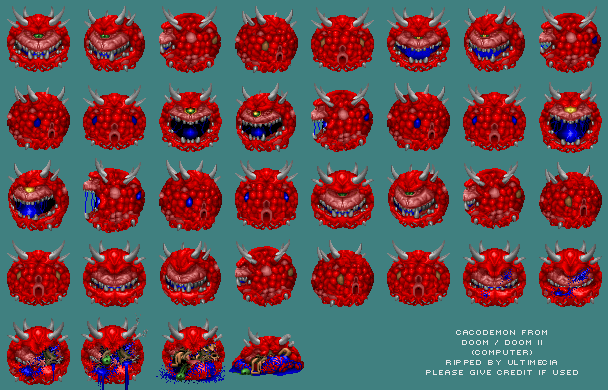

Cacodemon 3d print

Free 3D file Doom - Cacodemon・3D printing model to download・Cults

Doom - Pinky

Free

The Seven Deadly Sins - Hawk

Free

Doom - Baron of Hell

Free

Doom - Mancubus

Free

Revnant

Free

Dick Hanger

Free

Custom phone case part 2: weighted charging phone dock with audio ports

Free

Flat wall VESA mount 200mm M8

Free

Best 3D printer files of the Art category

He-Man MOTU Action Figure MOTU Style

€4.50

Love Robot

Free

Lioness head

€6

FLEXI PRINT-IN-PLACE CHRISTMAS DRAGONS

€3. 79

Low Poly Fawn

Free

Pottermore Wand 2 - Harry Potter

€2.99

SLAVE 1 CHIBI VERSION

€1.25

Best sellers of the category Art

CUTE FLEXI PRINT-IN-PLACE CROCODILE

€2.80

Winter Dragon

€3.80

Cute Flexi Print-in-Place Fox

€2.38

ZOU GHOST - GHOST WITH LEGS

€2.72

Flexi Print-in-Place Imperial Dragon

€3.75

Adorable Articulated Axolotl, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3.31

Flexi Print-in-Place Astronaut

€2. 80

80

Cute Flexi Print-in-Place Frog

€1.85

Biting Archaeopteryx

€3

Cute Flexi Print-in-Place Sloth

€2.80

Cute Flexi Print-in-Place T-Rex Dinosaur

€2.80

The Annoying Gift Box

€2.85

Cute Flexi Print-in-Place Skeleton

€2.80

Thing

€7 -50% €3.50

FLEXI PRINT-IN-PLACE STANDING YETI

€2.80

Flexi Print-in-Place kangaroo and Joey

€2.80

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

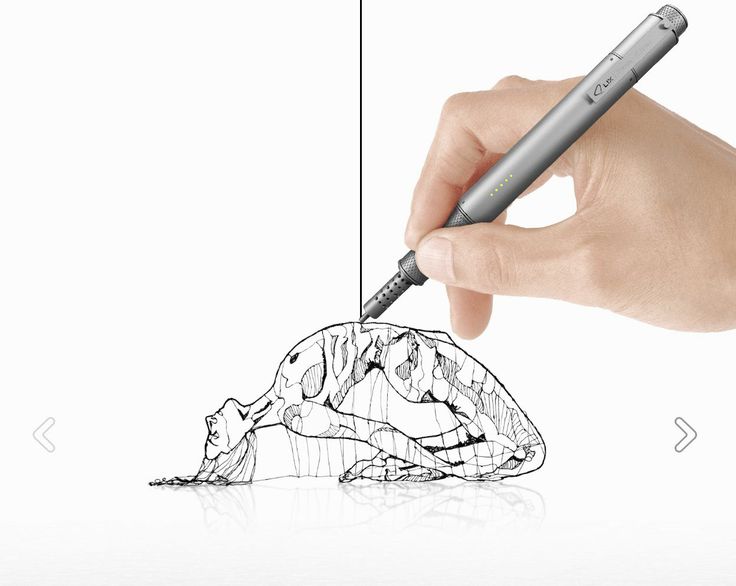

▷ cacodemon 3d models 【 STLFinder 】

Cacodemon

thingiverse

Doom cacodemon

Cacodemon 3D print model

cgtrader

. 3

3

Cacodemon

sketchfab

Cacodemon from DooM

Cacodemon Free 3D model

cgtrader

This 3D model was originally created with Sketchup 13 and then converted to all other 3D formats. Native format is .skp 3dsmax scene is 3ds Max 2016 version, rendered with Vray 3.00 It's one of the monsters from the well known Doom. If you are not...

Cacodemon

thingiverse

Scanned with the MakerBot Digitizer Desktop 3D Scanner

Cacodemon STL for 3D Printing

prusaprinters

This is a Doom inspired Cacodemon STL file for 3D printing! It will probably print best on a resin printer, but I'm sure someone could pull it off with FDM. If you would like to help support what we do you can join patreon.com/chaoscoretech

If you would like to help support what we do you can join patreon.com/chaoscoretech

Doom Cacodemon Free 3D model

cgtrader

Cacodemon, monster from DOOM. If you print it please share a photo with me. ...

CacoDemon 3D Print model 3D print model

cults3d

Modern interpretation based on classic Doom's Cacodemon sprite. This model is prepared for 3D Printing. It's split into 12 pieces and has been scaled to a total height of 17,5 cm / 7 inch. But can be scaled up to your own preference. All parts are in...

DOOM - CACODEMON

thingiverse

DOOM - CACODEMON - 22 years of terror The original 3d model are found on github, but remodeled and customized by me for 3d printing. With support version. Infill : 20% minimum. use caution when you remove the support in the mouth!! ...and post your...

With support version. Infill : 20% minimum. use caution when you remove the support in the mouth!! ...and post your...

Cacodemon Statue

thingiverse

A sculpt of a Cacodemon I made a while back and reconfigured into a statue

Cacodemon Doom

thingiverse

I was looking for a model of cacodemon for a long time and decided to create it myself

Cacodemon Keycap

thingiverse

Custom Keycap for CherryMX switches. ... Cacodemon model by TankerRU, fixed to my cherry_mx design template, using Meshmixer. ...

Feel free to paint it!

...

Feel free to paint it!

DOOM Cacodemon

thingiverse

Additionally, the Cacodemon has a psychoactive narcotic bile which it spews at range. On contact, this bile inhibits the perception of the target and compromises movement. The effects wear off after a few moments, which is often enough time for the...

Cacodemon Figure

sketchfab

3D modeled using Maya, sculpted in ZBrush, and textured in SP. ...Took about 4 days.

Cacodemon (Doom 4)

thingiverse

Game : Doom 4 Figur : Cacodemon High : 34 cm Source : Exported from the game and polished

Cacodemon Fan Art

cults3d

My take on the classic Cacodemon from Doom '93. ... Model is split and keyed.

... Model is split and keyed.

Cacodemon - Doom Classic

thingiverse

... The original can be found here: https://sketchfab.com/3d-models/cacodemon-c8e36476d01742f69bd213a62a028024 Please check out the designer's page, linked here!: https://sketchfab.com/z4g0 Be careful, when printed in resin the horns are super sharp!

Doom Cacodemon Keychain

cults3d

Model Images The Model is detailed and scalable so you can edit the size to your preference for your 3D Printer. The Cacodemon is a character from the video game "Doom Eternal". Subscribe so i can bring more content from movies & games! :) FOLLOW. ..

..

Doom Eternal - Cacodemon

thingiverse

Doom Eternal Cacodemon. Checked with Meshmixer: No errors. You can cut him in Meshmixer however you like. Enjoy! ... <a href="https://www.patreon.com/bePatron?u=9698080" data-patreon-widget-type="become-patron-button"><img...

Matt Bey, Cacodemon

sketchfab

Currently learning ZBrush. ...I decide to create the Cacodemon in honor of the new Doom. “They float in the air, belch ball-lightning, and boast one Hell of a big mouth. ...You’re toast if you get too close to these monstrosities.”

Cacodemon - Split with arms

thingiverse

Something in Blender messed them, so I will remedy that over the weekend** I hate gluing tiny fiddly parts to things so I put the arms of the split cacodemon model and attached them to the body. So the model can still be printed flat to the plate,...

So the model can still be printed flat to the plate,...

LowPoly Monster head CACODEMON Low-poly 3D model

cgtrader

LowPoly model for texturing, Normal Map and AO Map are included (Maya file). ...The possibility of buying a ZBrush model can be discussed, write in the comments.

Doom - Cacodemon

thingiverse

Made with Reality Capture, Meshmixer, Meshlab, and Instant Meshes

3D Models

grabcad

3D

3D MODELS

grabcad

3D WORK

3D models

grabcad

3D models

3d models

grabcad

designed in 3d

3D MODELS

grabcad

MADE VARIOUS 3D MODELS OF COMPONENTS USING CREO

cacodemon waiting - Tinkercad Christmas

myminifactory

This object was made in Tinkercad. ...https://www.tinkercad.com/things/89WfEkUSk4J

Tinkercad Christmas

...https://www.tinkercad.com/things/89WfEkUSk4J

Tinkercad Christmas

Cacodemon cookie cutter

thingiverse

Cacocookie! ... Includes 3 versions: a single piece(v2), 2 piece set(v3), and my original more detailed design that may not be suitable for small cookies I have only tested v2, which works fine when the dough doesn't get stuck, hence why i made the...

Bestreview. Summing up the results of the past days and awarding the winner

Greetings, friends.

As the end of the week approaches, it's time to take stock of your work in the challenging yet exciting field of 3d printing.

Once again, we had to make sure that there is no limit to human imagination and the possibilities of FDM printing.

In order not to be unfounded, we offer you a selection of the following works.

I wonder if Alexander Kormich was inspired by everyone's favorite cartoon “Just you wait”? nine0005 Agree, there is some similarity.

The guitar from the animated series “Adventure Time” was made a reality by the efforts of Ivan Volobuev and a 3d printer.

In our opinion, it turned out very cool. With such a guitar, it is not scary to conquer the rock Olympus.

Spirit of Evil, Terrible Cacodemon performed by colleagues from Novosibirsk.

Red symbolizes strength and determination. Probably for this reason Maxim Burmistrov's Hulk is made in this color. nine0003

There are countless areas of application for 3d printing, here everything will most likely depend on the rampage of your imagination and the capabilities of a 3d printer.

Watching a movie or a children's book can inspire you to print.

3D printing in Abakan; Raccoon Workshop; 3D printing workshop Khabarovsk; UNI 3D printer; 3DAXE; Alexander Tiguntsev; 3D Magic

Tirex performed by Alexander from Veliky Novgorod.

Through the efforts of colleagues from Kursk and a 3d printer, the cutest dinosaur was created.

Puzzle from Maxim Burmistrov.

More examples of interesting work from our fellow 3d printers.

3D Magic; UNI3D; Alexander Tiguntsev; Maxim Burmistrov; MetvKube, BoberPrint

Alexander from Veliky Novgorod took part in the implementation of the image for cosplay. It's great that with the help of a 3D printer you can achieve amazing detail accuracy.

The sword of the goddess of death Hela performed by colleagues from Novosibirsk.

Superhero helmet from 3DPlab.

We never tire of being surprised and delighted with the work of our clients, and as you remember, we promised to give gifts to the authors of the most interesting, useful or unusual projects.

This time the prize goes to our Moscow colleagues for the Khinkal Modeling Machine project. We at BestFilament believe that such a device should be in every home, because, as you know, delicious food unites! nine0003

We at BestFilament believe that such a device should be in every home, because, as you know, delicious food unites! nine0003

An excellent option for storing various small things from Maxim Burmistrov. Now drills will not be lost.

The advent of the 3D printer has made life much easier - various breakdowns and loss of the necessary parts can be easily restored using printing.

3D printing in Abakan; ZAKAT; 3Dpoint; Eternity print; UNI 3D printer; 3D Magic gear0009 “Labeler control box” DDD. 3D Miass

“Details of an anamorphic attachment for a digital camera” LEON3D

As a matter of routine, at the end of each issue, we reward the author of the best work. Only now the decision to whom the prize will go is made by the winner of the previous Best Review. This time the role of the honorary jury went to our colleagues from Krasnoyarsk.

The best work of this issue was "Ferris Wheel" by Sergei Svetlitsky! nine0010

Sergey, please accept our congratulations.![]() The plastic coil of your choice will come to you with the next order!

The plastic coil of your choice will come to you with the next order!

Running out of plastic? Order it here.

Send us your works and we will be happy to tell you about them!

And we also award the author of the best work!

You can see the winners of the previous weeks here »»»

write to our mail [email protected],

call 8-800-234-47-78,

and, of course, remember that there is Vkontakte and Telegram!

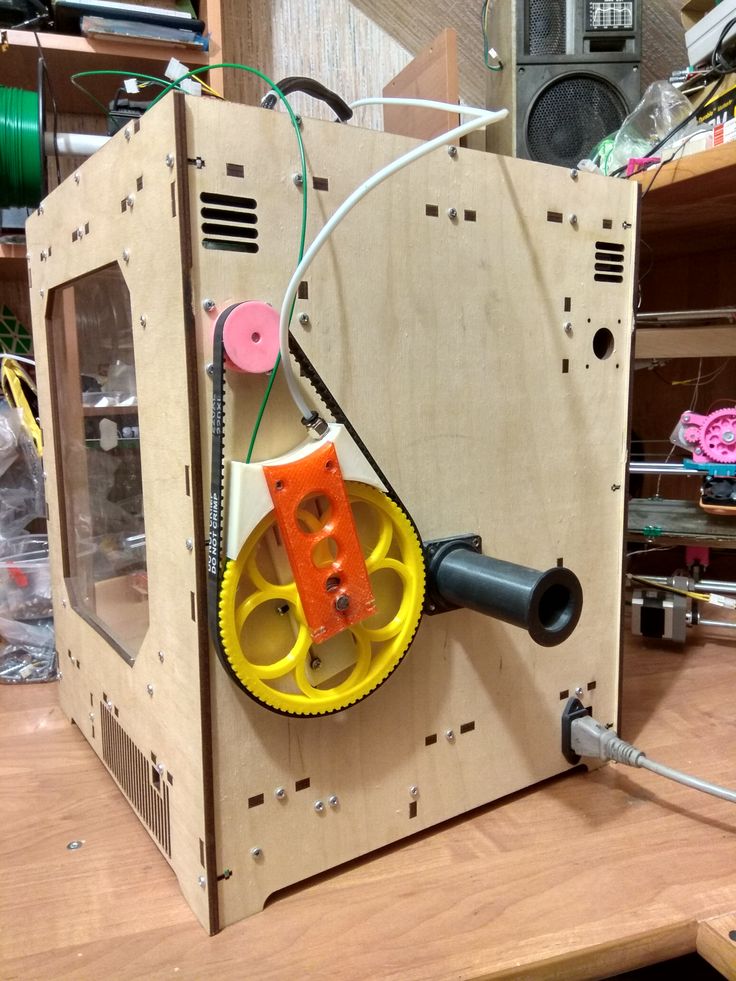

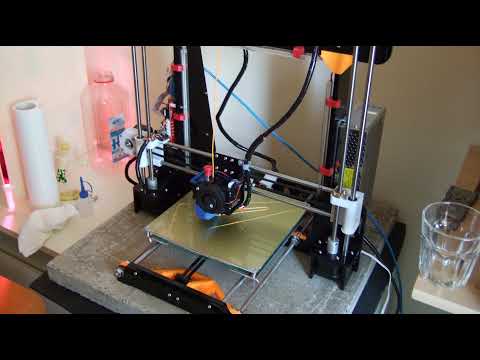

Review and setup of 3D printer Anet A3

Review and testing of a new Chinese 3D printer Anet A3 with GearBest from a well-established manufacturer. Initial setup, refinement, calibration and of course 3D printing! Welcome to the 3D era!

Good day, dear readers!

My long-awaited Anet A3 3D printer has finally arrived! It is worth saying that this is my first 3D printer, but before buying, I studied this topic for a very long time: features of different types of plastic (filament), types of 3D printers, main components, differences, fragile moments, ways to improve the quality of 3D printing and much more. Shenzhen Anet Technology's first 3D printers, such as Anet A8 and Anet A6, have won a lot of popularity for printers from China. A large number of add-ons have been released for the A8 printer, created by the community on thiniverse and in the official facebook group, which, at the time of writing, has about 11.5 thousand members. nine0003

Shenzhen Anet Technology's first 3D printers, such as Anet A8 and Anet A6, have won a lot of popularity for printers from China. A large number of add-ons have been released for the A8 printer, created by the community on thiniverse and in the official facebook group, which, at the time of writing, has about 11.5 thousand members. nine0003

The last thing I want to say before we directly proceed to the review of the Anet A3 3D printer itself is that a 3D printer is still not for everyone. Although every year 3D printers are getting cheaper and closer to our home, they still continue to be quite niche devices, since even the most expensive home FDM 3D printer in the world requires the same care, supervision and control as the most cheap printer models, and also have a number of common problems. nine0003

As one person said somewhere on the Internet - "A 3D printer can be perfect for someone who, when his equipment breaks down, does not run to a repair shop, but successfully repairs it himself. "

"

Delivery, packaging and assembly

I ordered a printer from the GearBest online store at a price of $309. Recently, I began to order more often in this store, because there I have never had problems with delivery, and the delivery itself is an order of magnitude faster than in Ali. Together with the printer, I ordered a kilogram of plastic from Anet, an additional cooler for cooling the plastic at the outlet of the nozzle, as well as belts and additional nozzles in reserve. The delivery of this whole thing cost me about $40 and how surprised I was when, after the parcel passed the border, they called me from the SDEK delivery service (how happy I was that it wasn’t Russian post!) And they said that they would deliver the goods, moreover right in to the door! To say that I was pleasantly surprised is to say nothing, since the total weight of all the contents was around 14kg! nine0003

Delivery due to the New Year holidays went to rest for eight days, because the total delivery time of the parcel took 26 days.

The printer itself came in a double, thick corrugated cardboard box and was additionally wrapped with soft wrapping so that nothing was damaged. The printer arrived safe and sound, but not without flaws - more on them later.

Separate movable elements were also tightly fixed, so I had no questions about the safety of delivery. nine0003

Included with the printer, the Chinese put a power cable, a horseradish for attaching a coil with plastic to the back of the printer, a blower for cooling plastic and nozzles at the same time, as well as a “rich” set of tools and other small things straight from the heavenly fixed price and, well, very “generous” 10 meters PLA plastic that you will spend on the first day, I guarantee you :D

Printer view

I specifically chose a small 3D printer with an acrylic body to give it a slightly more domestic feel. The maximum size of a 3D object for printing on this printer is only 150mm150mm150mm, but nobody bothers to print a large object piece by piece, right? nine0003

Some mechanical parts of 3D printer

Interaction with the 3D printer is carried out using a simple screen, a knob and a reset button.

You can see the full specifications of the 3D printer on the product page in the GearBest store, or on the manufacturer's website.

Anet A3 disassembly and fixes of the Chinese "fuk-huyak and in production"

When I took the printer out of the box, I noticed the sound of something rattling inside the bottom of the 3D printer case. Having unscrewed the bolts and removed the acrylic bottom, I found that the main brains of the printer (Anet 2.0 mainboard) were not screwed at all, but simply lay in a pile of wires, and 4 bolts with racks were completely neatly lying in the corner of the case.

While I was screwing the board into place, I discovered that the “+” power contact of the heated table was not clamped in the terminal (apparently it was loosely tightened). After returning it to its place and carefully tightening it, I turned on the whole thing until the case was completely closed to see if everything was working. The printer started up without any problems - everything worked as it should. nine0003

And yes - cable management is clearly not about the Chinese. On the other hand, when you buy cheap Chinese 3D printers of about the same quality you expect, but there is no problem with that. All FDM 3D printers are arranged in approximately the same way and any parts can be easily obtained for it, everything can be repaired / replaced even if it fails.

So before the first print, I still recommend getting inside the case and checking if all the wires are connected. Then run a couple of tests - after turning it on using the printer control menu, try to move the extruder, heat it and the platform, etc. In my case, everything went fine, so I immediately proceeded to the next step - setting up the 3D printer and calibrating it. nine0003

Just in case, I'll attach an image of the Anet 2.0 board with signatures where and what to connect.

Installation and setup of 3D printer Anet A3

The main profiles for preparing 3D models for printing using the popular "slicer" programs are on the microSD card that comes with the kit. There are also instructions for using the Anet 3D printer, initial installation instructions, slicer programs for windows and several test 3D models in STL format and ready-made models cut into layers directly for printing with the .gcode extension. So you should not have any problems with the first launch and installation. nine0003

There are also instructions for using the Anet 3D printer, initial installation instructions, slicer programs for windows and several test 3D models in STL format and ready-made models cut into layers directly for printing with the .gcode extension. So you should not have any problems with the first launch and installation. nine0003

I recommend that you immediately save these files to your cloud, because during the time I used the complete memory card, I knocked down the format several times, so I had to format it every time.

Before proceeding, it is necessary to ensure the best adhesion for the first layer. If you print with organic (PLA) plastic, then for this I advise you to carefully stick Kapton tape over the table, or put a piece of durable glass. I do not recommend printing on masking tape. From my humble experience, I can say that an acceptable level of adhesion cannot be achieved with it. nine0003

Next, you need to insert the plastic blower that comes with the kit into the cooler hole 50x15 near the extruder. The “blower” itself is hastily printed on a 3D printer, so before inserting it, it may be necessary to process it with a file.

The “blower” itself is hastily printed on a 3D printer, so before inserting it, it may be necessary to process it with a file.

Then you need to pull the plastic thread into the extruder. To do this, we screw the holder for the spool with plastic into the prepared place on the back side of the case and install the spool / skein with plastic on it. The plastic thread must be pulled through the plastic tube straight up to the extruder. To securely clamp the plastic thread in it, you must first warm up the extruder - for this you need to perform a number of certain actions. And so, how to fill plastic in a 3D printer? nine0003

- Go to the menu and select Preheat

- We choose the heating option for PLA (it will be enough for us). Be careful - the extruder will be heated up to 200 degrees, and the platform up to 50.

- We are waiting for it to heat up (the status is displayed on the main screen)

- Press on the hex screw to press the metal plate.

This must be done carefully, holding the entire mechanism so as not to accidentally warp the axis.

This must be done carefully, holding the entire mechanism so as not to accidentally warp the axis. - Pressing the screw, we drag the plastic 3-4 centimeters inside and release the screw

Answering the supposed question "How to replace the plastic filament in an Anet 3D printer"?

- Repeat the previous 5 steps. (yes, it is also necessary to push the plastic through)

- Lightly begin to remove the plastic. Ready!

- Insert the plastic as in the previous 5 steps

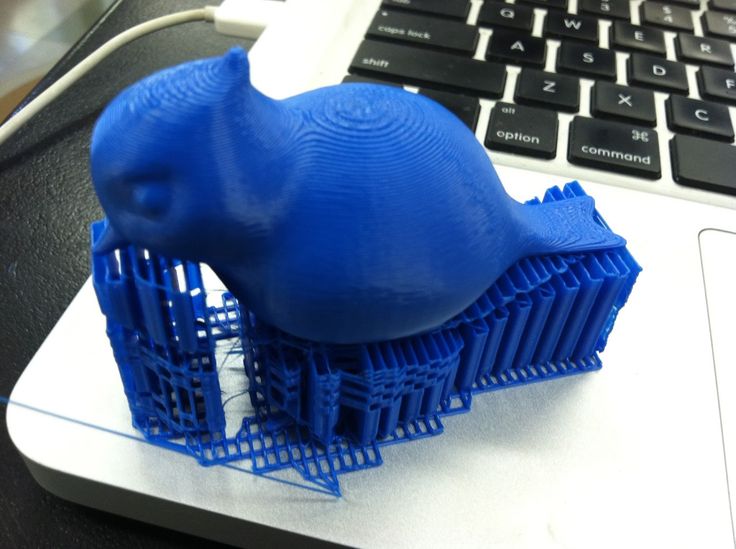

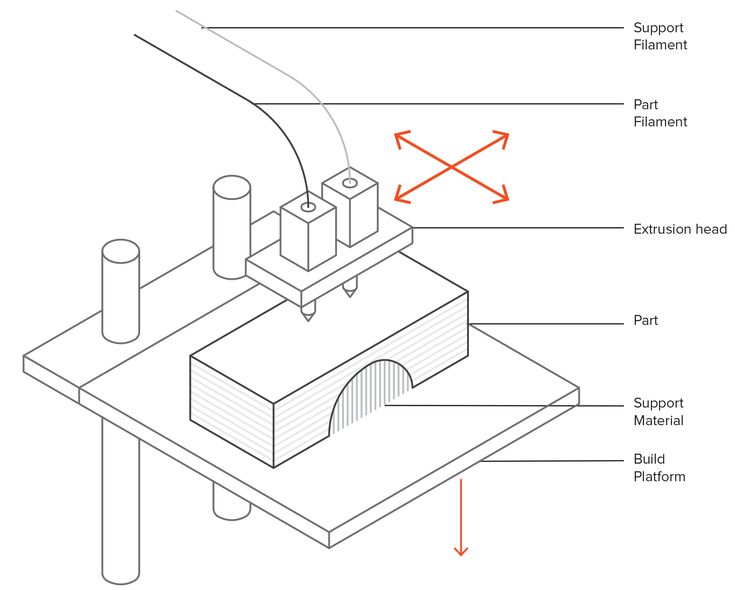

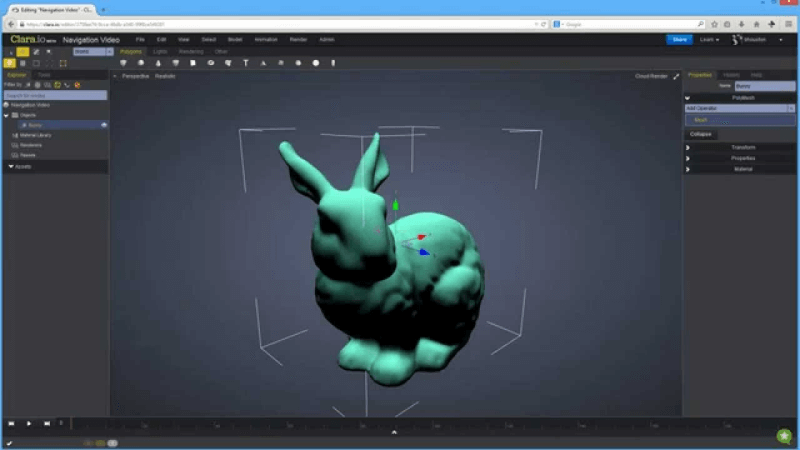

Preparing a 3D model for printing

You can download free 3D models in STL format from thiniverse and a number of others. The STL format is necessary for slicer programs that will cut our model into soybeans and think over the paths and other necessary information (in principle, you can work with the obj format). nine0003

In order to prepare a 3D model for a 3D printer, you need to load it into the slicer program, which is already configured and prepared to work with our printer. For this purpose, I will use the Cura program for which there is already a ready-made profile with presets from the manufacturer (available on microSD).

For this purpose, I will use the Cura program for which there is already a ready-made profile with presets from the manufacturer (available on microSD).

To be honest, the standard set of parameters did not suit me at all, so I began to select my settings to create a suitable profile for medium and high print quality in Cura - I will tell you about this in the next article. nine0003

After the program finishes cutting, you can safely save the resulting gcode file to a microsd card and insert it into the printer!

3D Printer Calibration

Printer calibration is extremely simple, but very annoying! It is recommended to calibrate before each print.

To calibrate the 3D printer, turn it on, select Position, and then Auto home to set the extruder and bed to home position. Then go to the Control section and select Disable steppers to have the printer release the stepper motors and let you freely move the extruder manually. nine0003

Move the extruder so that the nozzle is in the left corner about 1 cm from the edge of the platform. stretch a sheet of plain paper under the nozzle - it should pass freely, only slightly touching the nozzle. If the nozzle is slightly higher, or the sheet does not pass at all, tighten the bolt in this corner. Repeat this operation for all corners of the platform.

stretch a sheet of plain paper under the nozzle - it should pass freely, only slightly touching the nozzle. If the nozzle is slightly higher, or the sheet does not pass at all, tighten the bolt in this corner. Repeat this operation for all corners of the platform.

Even the smallest oversight in the calibration can significantly ruin your object during printing, so take this process as seriously as possible! nine0003

First attempts at 3D printing

The first thing I printed for the test is a simple cube with 20% infill and size 20x20mm, layer height 0.2mm. It took about 15 minutes to create the cube - all this time I stared at how it appeared.

Unfortunately, I did not experience such success with cylindrical parts - the plastic lay down too quickly, often not having time to really stick to the printed surface. Two main things influenced this one: I printed the cube on masking tape, and also the default Print Speed and Travel Speed parameters were somewhat stupidly set, so the next time I had to select them manually.