Big data 3d printing

How 3D Printing and Big Data are Working Together

Reading Time: 5 minutes

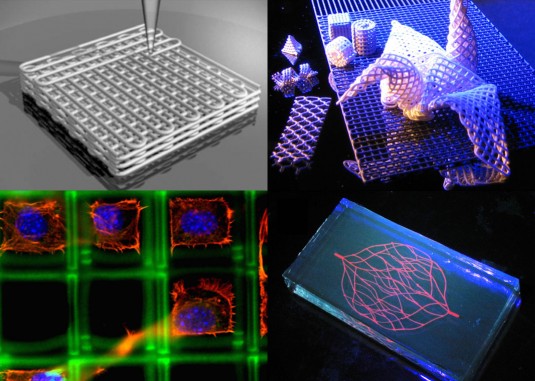

3D printing has become a hot topic in recent years, and is being used in a variety of industries such as healthcare, engineering, architecture, and more. However, there is one key tool that 3D printing relies on that could make or break its future: big data.

Without the existence of this advanced data, some of the functions used in 3D printing would not be possible. But how do big data and 3D printing work together? Let’s examine.

What is 3D printing?

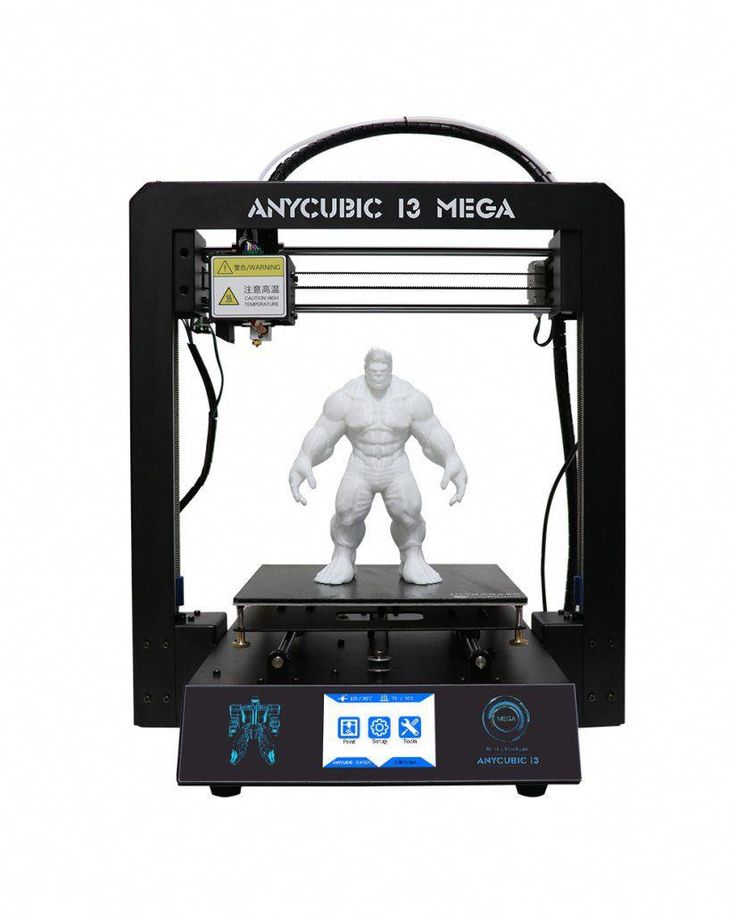

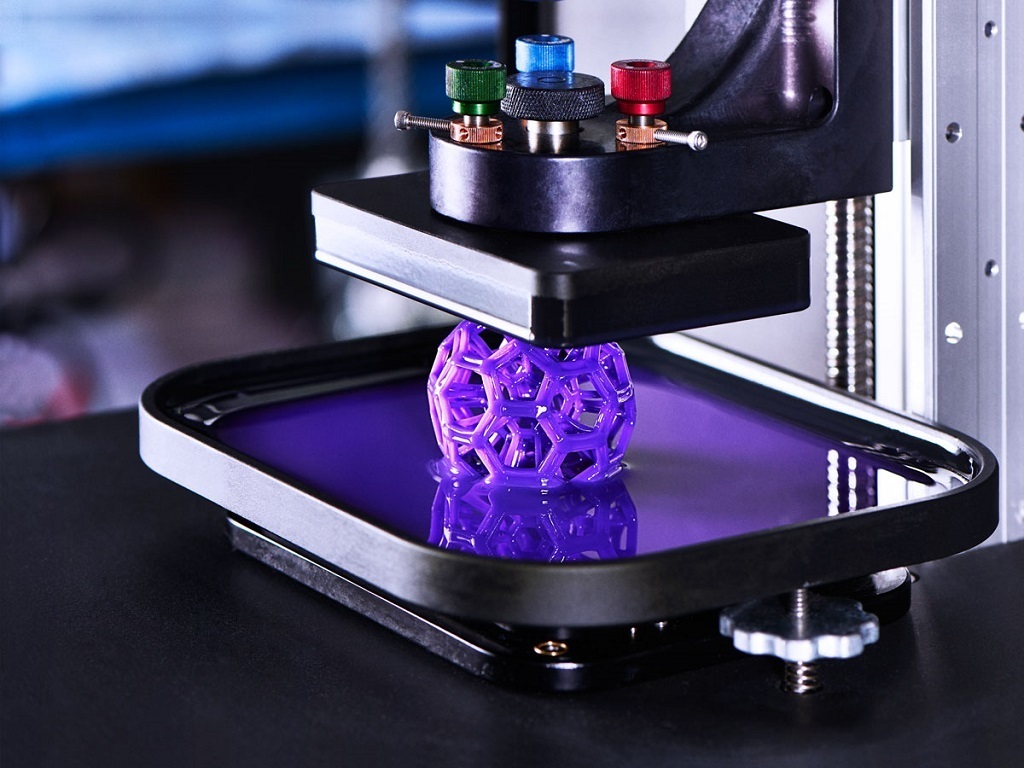

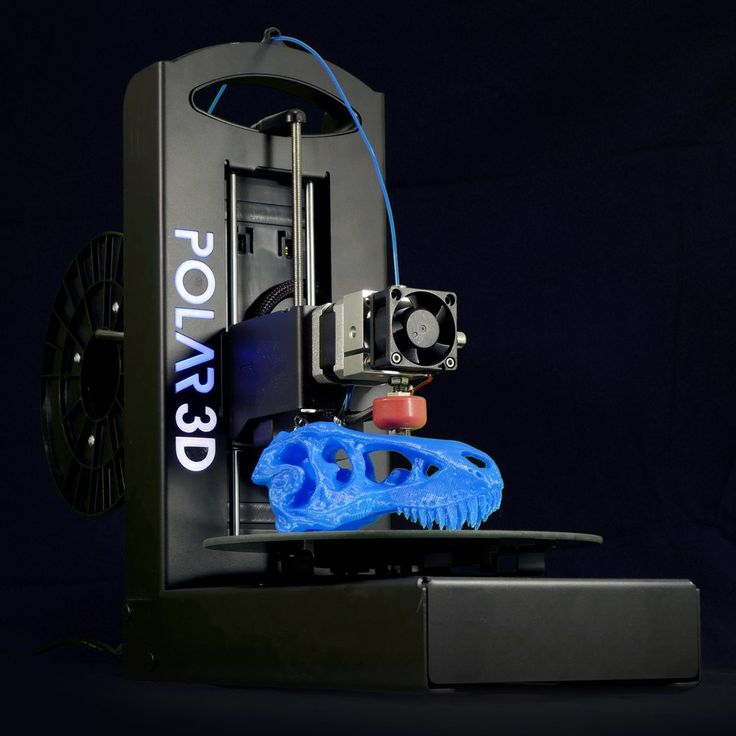

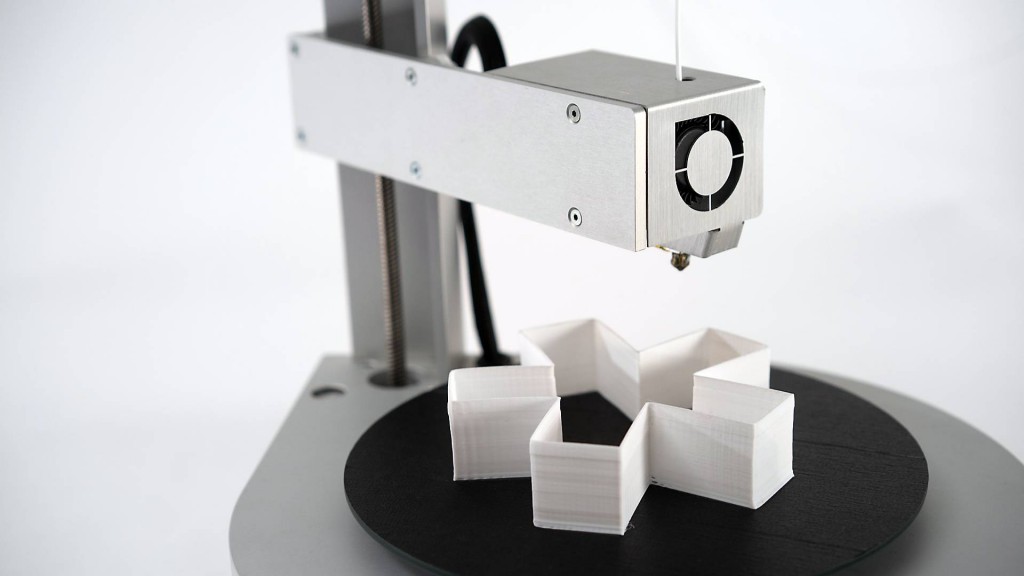

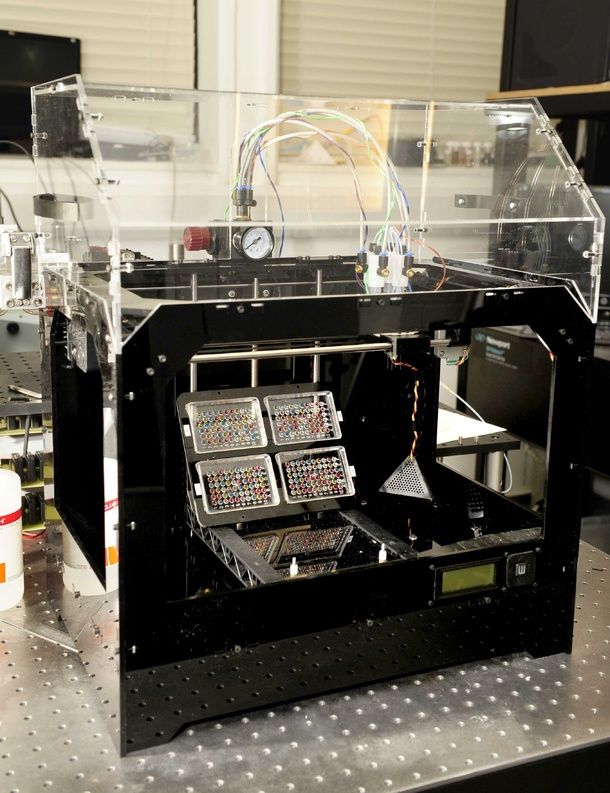

3D printing is the process of making a three-dimensional solid object from a digital file. Just like a regular printer prints text or photos created on the computer, a similar process can be done with 3D printing. An individual can design or download an object and then print the object in a full three-dimensional form.

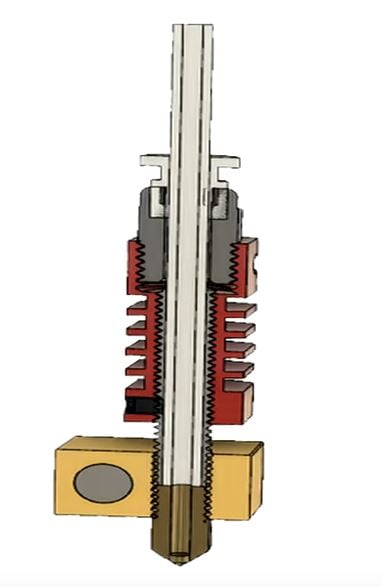

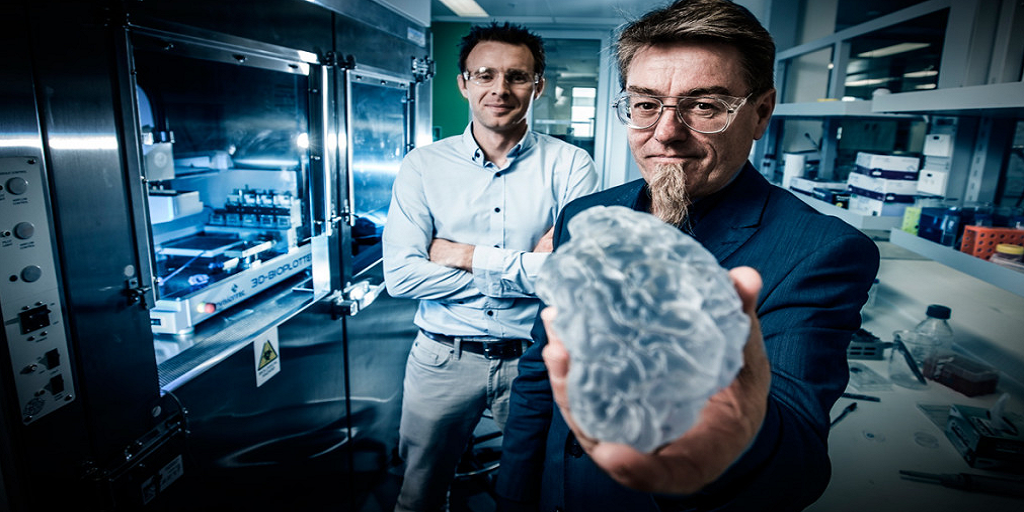

Unlike regular printers, 3D printers work like plotters, moving a point along the X and Y axes. The printed material is typically drawn with plastic rather than ink. Once the object is drawn, the base moves up and down in an ongoing cycle, creating a layered effect until the product is completed in three-dimensional form. Products can be as simple as toys to as complex as medical tools used hospitals. For example, surgeons can replicate patient-specific organs with the help of 3D printers, and they’re even able to produce realistic skin for burn victims or prosthetic limbs for amputees.

What is big data?

While there is an ongoing debate as to what constitutes “big data,” it is essentially a compilation of information that comes from multiple sources. These sources could include satellites, microphones, cameras, computers, and more. The information can be gathered by opt-ins or lead forms, tracking softwares, or cookies. For example, a fitness app may track how many steps an individual takes per day. The sources that allow it to track those steps are all a part of big data.

The sources that allow it to track those steps are all a part of big data.

How do they work together?

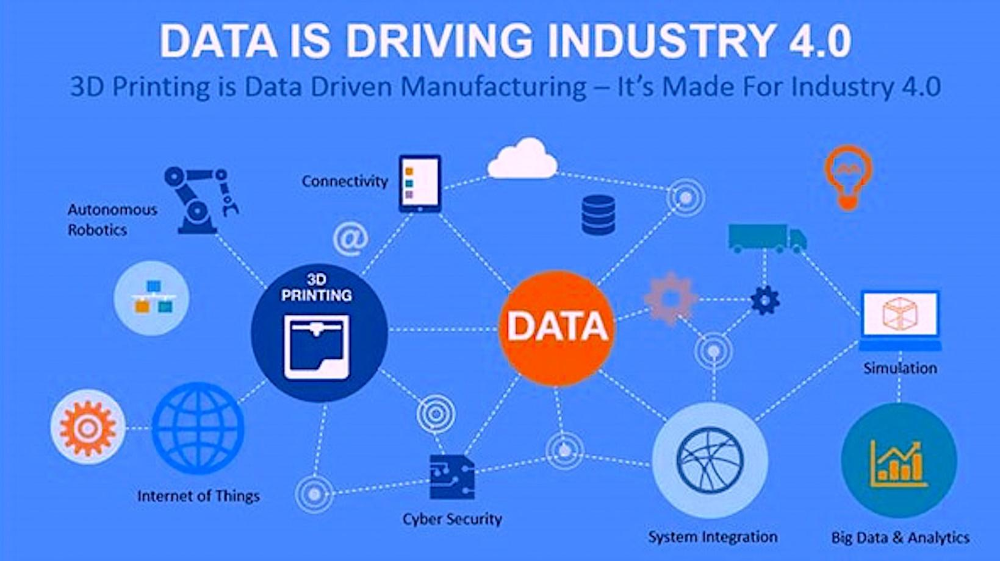

3D printing is a data-heavy technology, which means it is essential for both big data and 3D technology to keep up with each other through technological advancements every year. That being said, there are a number of ways in which big data and 3D printing are already proving to be the perfect fit for each other. Two main ways in which they work together are with data visualization and manufacturing.

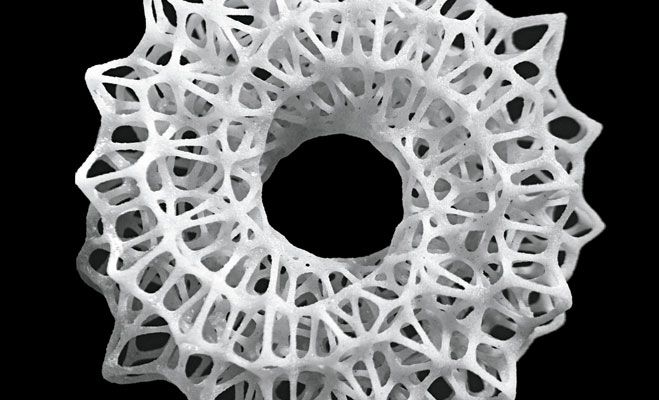

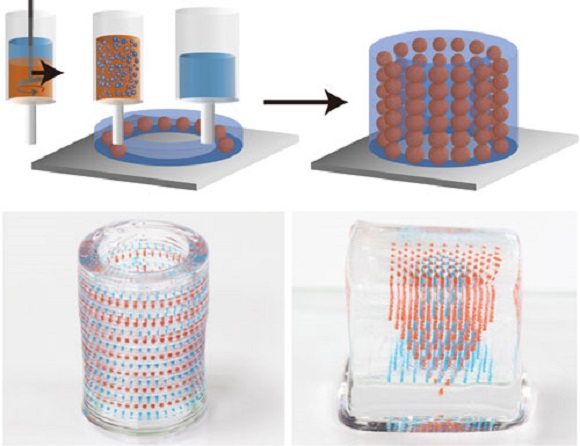

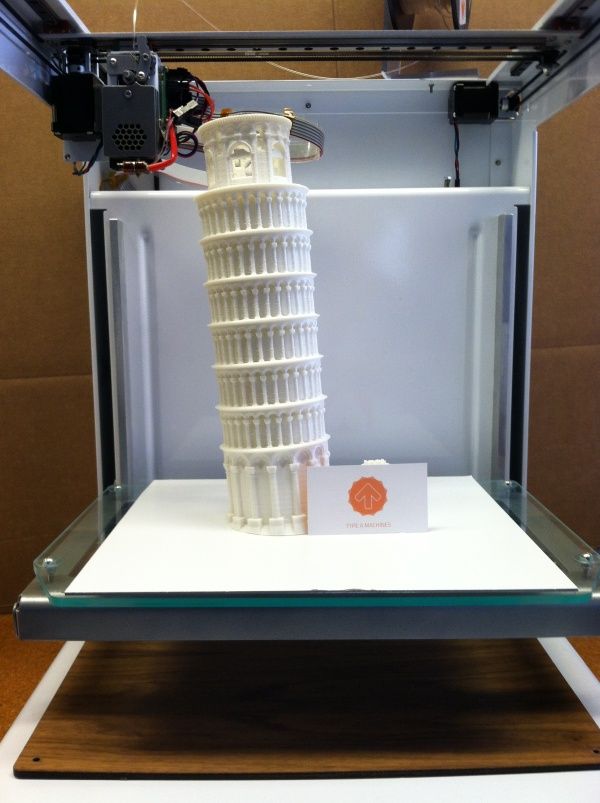

Data visualization

Visualization tools such as datasets, graphs, charts, or blueprints are used in almost every field in order to better understand aspects like products and company growth. While these tools are extremely useful, with the help of 3D printing, companies can bring their charts or drawings to life. The type of in-depth analysis that 3D printing can create allows for better pattern recognition, deeper information absorption, higher realistic representation of products, and additional product viewpoints. One example of using 3D printing for better data visualization comes from a 2014 case study, where two researchers at MIT, Zachary Weber and Vijay Gadepally, created a 3D printed model of their university campus and added Twitter data which was streamed onto the product based on geographical location. This allowed them to see “twitter volume as a function of time and space to provide insight into campus patterns or life.” Charts and info-graphs can easily show individuals the “numbers” side of a projection, but 3D printing is an even bigger game-changer in the industry as it can offer physical models of such visualizations, which makes the information that much easier to both analyze and understand.

One example of using 3D printing for better data visualization comes from a 2014 case study, where two researchers at MIT, Zachary Weber and Vijay Gadepally, created a 3D printed model of their university campus and added Twitter data which was streamed onto the product based on geographical location. This allowed them to see “twitter volume as a function of time and space to provide insight into campus patterns or life.” Charts and info-graphs can easily show individuals the “numbers” side of a projection, but 3D printing is an even bigger game-changer in the industry as it can offer physical models of such visualizations, which makes the information that much easier to both analyze and understand.

Manufacturing

One key aspect that 3D printing is known for is revolutionizing the modern manufacturing industry, and big data plays a large role in doing so. One way that big data is helping maximize 3D printing’s capabilities is with quality control.

For example, “simple” objects such as children’s blocks may not carry high risk, but when it comes to objects such as car engines or essential parts used in surgeries, the risk factor increases significantly due to safety hazards. In any type of manufacturing, even the smallest of errors can result in fatal accidents or health issues. However, big data can analyze each printing action and internally inspect every element, detecting and correcting any possible imperfection to each product, therefore preventing product risks.

Another example of big data working with 3D printing in the manufacturing aspect is in the case of General Electric’s (GE) 3D printed jet engine fuel nozzle. The nozzle was built as a single piece made up of super alloy dust and then finished with lasers, and is 25% lighter and up to five times more durable than the current nozzle made from 20 different parts. However, since 3D printing is still fairly new to engineers, they have to figure out better quality control methods before they take their products to mass production facilities. With big data, they can do just that. GE Aviation is developing inspection technology that can analyze manufacturing data and identify any issue (such as temperature anomalies) during production using a certain algorithm. Overall, with the use of big data, GE estimates that its inspection technology used for the production of aviation parts could increase production speeds by a quarter and reduce the time allotted for inspection after the product has been made.

With big data, they can do just that. GE Aviation is developing inspection technology that can analyze manufacturing data and identify any issue (such as temperature anomalies) during production using a certain algorithm. Overall, with the use of big data, GE estimates that its inspection technology used for the production of aviation parts could increase production speeds by a quarter and reduce the time allotted for inspection after the product has been made.

Conclusion

The growth of 3D printing is moving fast and could ultimately provide realistic solutions to many different setbacks industry-wide. 3D printing is cost-effective, eco-friendly, and customizable, but when it works together with big data, the combined solution becomes even better as it sparks a new kind of technological revolution.

Related reading:

- 5 Data Analytics Trends for 2020

- How Analytics Helps During an Economic Recession

- Image Recognition: The New Frontier for Targeted Ads

- Author

- Recent Posts

Lindsey Berke

Lindsey is a public relations and social media specialist at Dimensional Insight. She is a recent graduate from Merrimack College with a major in Applied Communication and double-minor in Political Science/Law and Psychology. Her favorite seasons are fall and spring, and in her free time you can find her listening to/practicing music, taking photos, and spending time with her family, friends, and puppy.

She is a recent graduate from Merrimack College with a major in Applied Communication and double-minor in Political Science/Law and Psychology. Her favorite seasons are fall and spring, and in her free time you can find her listening to/practicing music, taking photos, and spending time with her family, friends, and puppy.

Latest posts by Lindsey Berke (see all)

You may also like

by John Sucich | Nov 10, 2022 | General BI

I think there must be something wrong with me….Christmas is coming, but I’m not happy. I don’t feel the way I’m supposed to feel. Those words belong...

read more

by John Sucich | Oct 27, 2022 | General BI

Data can help a business predict trends or it can provide a road map for how an organization can react to a possible disruption five years from now....

read more

3 Ways 3D Printing and Big Data Can Work Together

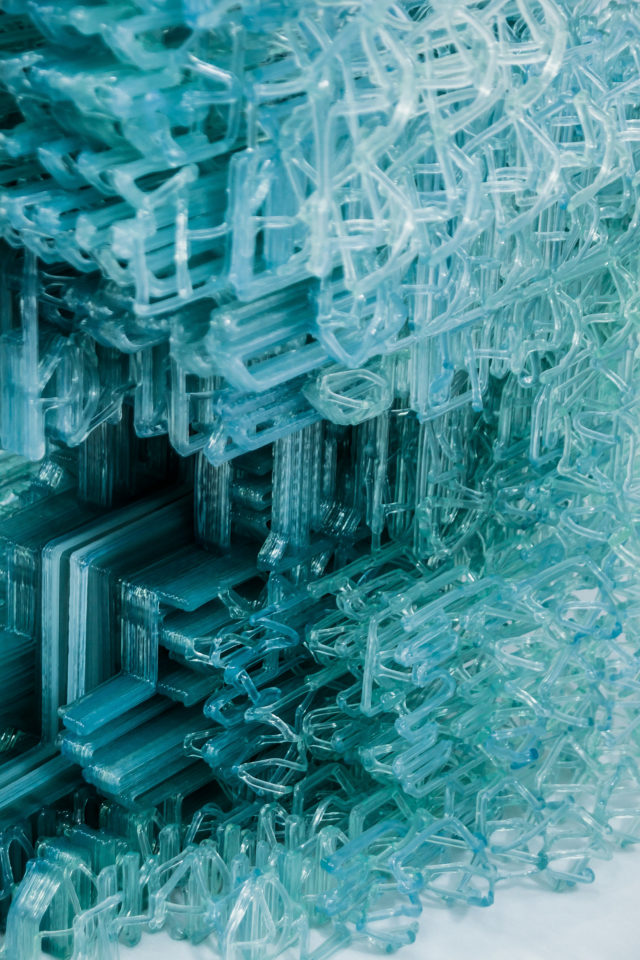

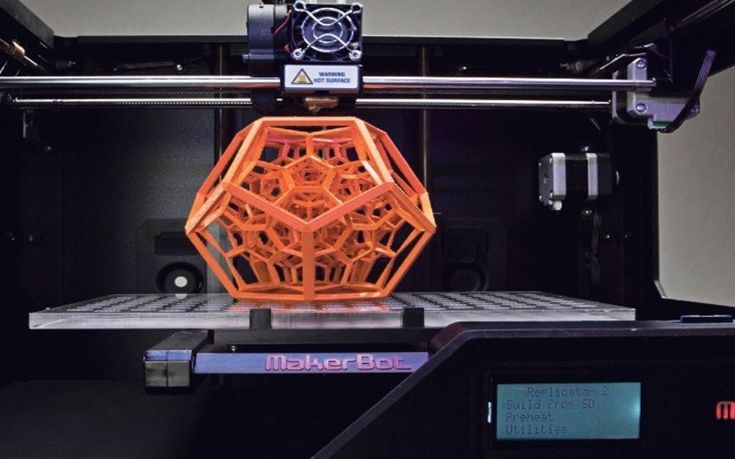

Printing in 3D has become a practical reality that has changed the way people think about production and manufacturing. Now that the technology has matured, almost everything from smartphone cases to human organs can be 3D printed. Customized products and parts made by 3D printers have empowered entrepreneurs and sped repairs in many settings.

Now that the technology has matured, almost everything from smartphone cases to human organs can be 3D printed. Customized products and parts made by 3D printers have empowered entrepreneurs and sped repairs in many settings.

Extra capabilities resulting from the development of the Internet of Things and 3D Data Exchange & Translation promise to make 3D printing useful in new ways. Remote printing and the creation of objects from scans have combined with print sharing to make 3D printing an integral part of the business world. The advent of big data means that even more uses for 3D printing will soon emerge.

3D Printing and big data

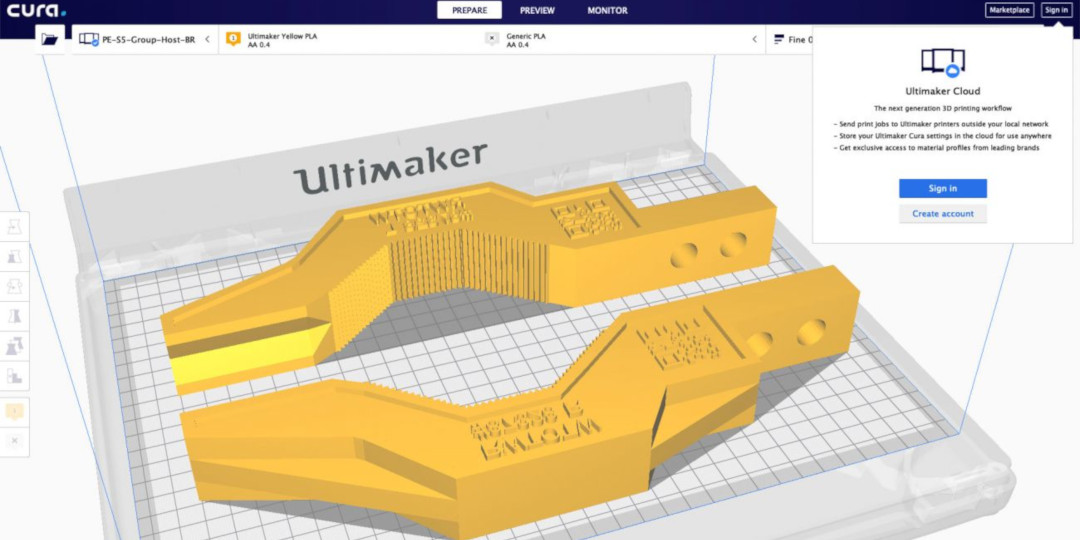

Analytics technologies make big data useful to a growing number of markets that make new uses for affordable 3D printing. Both technologies accelerate the large-scale product customizations needed to serve targeted markets discovered through the use of big data.

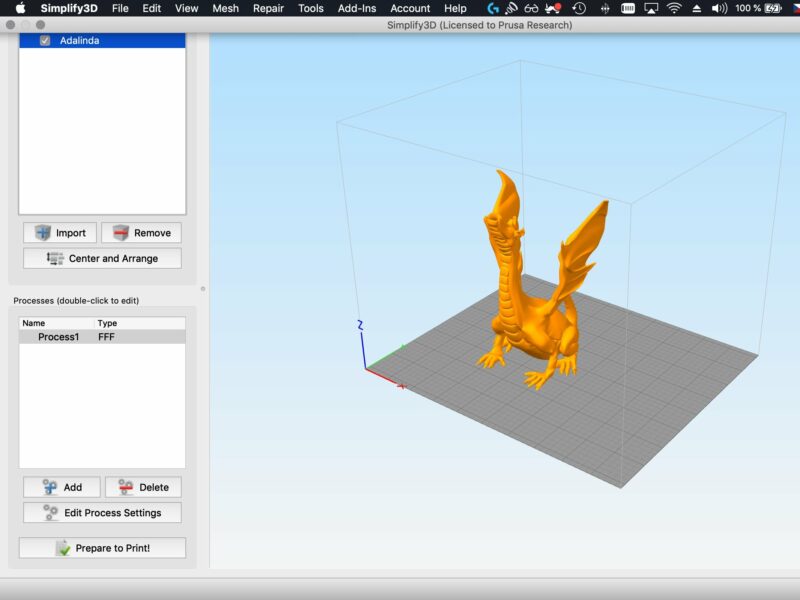

Fields that have shown the potential to benefit from the integration of big data with 3D printing include computer-aided design (CAD) and engineering (CAE) as well as computer-aided manufacturing (CAM). In each market segment, the two technologies have a mutually beneficial relationship. The following three examples will help you understand how big data and 3D printing can interact.

In each market segment, the two technologies have a mutually beneficial relationship. The following three examples will help you understand how big data and 3D printing can interact.

Data Visualization

Corporations increasingly turn to 3D printing to help them conceptualize the data they collect. The same holds true for small businesses and private individuals. Two MIT researchers designed a model of their campus and printed it using 3D printers. Streaming data on the mockup demonstrated how it can become a rigid framework that displays variable data.

Geospatial models that interact with big data can help city planners who study traffic patterns and other dynamic data. In the past, such professionals only had access to flat data, often printed on paper. Now, with 3D modeling, they can see multiple perspectives from a single experience. People can hold such models and share them together with alternate models to make better real-world decisions.

Data Storage

Driven substantially by big data, the world now generates about 2. 5 quintillion bytes of data every day, creating an enormous demand for storage. Companies of every size contribute to the storage challenge by hoarding the data they collect. From almost any perspective, big data will increasingly disrupt the world as businesses and governments use it to create predictions and make decisions.

5 quintillion bytes of data every day, creating an enormous demand for storage. Companies of every size contribute to the storage challenge by hoarding the data they collect. From almost any perspective, big data will increasingly disrupt the world as businesses and governments use it to create predictions and make decisions.

The expense of data storage continues to grow along with data stores. Luckily, as the amount of big data grows, so does the speed at which 3D printing develops. The 3D printing market continues to grow and it is expected to reach $21 billion by 2020.

Technology that provides for the 3D printing of electronics has become necessary because of the applications such electronics have for creating electronic storage. Forthcoming technologies include Functionalize F-Electric, an electrically conductive filament that 3D printers can integrate into electronic circuit boards. Another promising development, Carbomorph, uses 3D printing technology to create custom electronic designs for portable devices. Such developing technologies suggest that electronic circuits will become ubiquitous enough to meet the global demand for data storage.

Such developing technologies suggest that electronic circuits will become ubiquitous enough to meet the global demand for data storage.

Monitoring Manufacturing

The printing of 3D objects has revolutionized the manufacturing world. Companies use 3D printers to create prototypes and other models as well as the products they sell to business customers and consumers, disrupting traditional business practices. Now that companies can print large numbers of customized products, they can expand the appeal of their brand to niche markets.

Companies also use 3D printing for on-demand manufacturing, eliminating the need for large and diverse inventories. The technology also reduces the time required to develop products from concepts to marketable goods. In cases where a company intends to mass-market products, 3D printing gives them an easy way to validate the existence of demand before committing to high-cost production runs.

However, with 3D printing still being a relatively new technology, engineers need to create adequate quality control methods. This is where big data can help. A company called GE Aviation has connected big data to 3D printing in order to collect and analyze manufacturing data to detect production problems in real time using strategically placed sensors. The technology identifies factors such as temperature and structural integrity, alignment, deflection, etc. The data that is gathered helps improve the quality of outputs from many manufacturing products.

This is where big data can help. A company called GE Aviation has connected big data to 3D printing in order to collect and analyze manufacturing data to detect production problems in real time using strategically placed sensors. The technology identifies factors such as temperature and structural integrity, alignment, deflection, etc. The data that is gathered helps improve the quality of outputs from many manufacturing products.

Conclusion

Big data has changed the way businesses operate. Collecting information from multiple virtual and physical channels has provided unprecedented decision-making capabilities to firms of every size. Companies understand markets and customers better and use that information to use 3D printing technologies to deliver customized products to an almost unlimited number of clients.

Meanwhile, 3D printing provides the ability to create visual depictions of available data to help organizations communicate their ideas and compare solutions. Ironically, 3D printing feeds the growth of big data. Ultimately, the relationship of 3D printing and big data becomes cyclic as 3D promises to increase the availability of storage available for use by big data applications.

Ironically, 3D printing feeds the growth of big data. Ultimately, the relationship of 3D printing and big data becomes cyclic as 3D promises to increase the availability of storage available for use by big data applications.

Large Area 3D Printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer additive machines produce objects from high-strength thermoplastics and are designed for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts automotive, shipbuilding and oil and gas industries

Creation of objects of exterior and interior design and design products for construction, production of facing materials

Production of functional prototypes for R&D and design bureaus in mechanical engineering, shipbuilding and aircraft construction

Production of large-sized wax or burnt master models for metal casting and metallurgy or trolleys)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D printers

3D printer DISCOVERY 3D Printer 2021

Compact solution for 3D printing of large-sized products

Read more

3D printer Super Discovery Compact

Combination of compactness and high performance of the performance

Learn more

Super Discovery 3D Printer Hybrid

Advantages of granule and filament printing in one machine

More details

Super Discovery 3D Printer 3D Printer

Large build chamber and print speed up to 6 kg/h

More details

Super Discovery 3D Printer Workstation 3D Printer

3D large format printer combination: unique 2 in 1 combination and milling systems

More details

Your unique 3D printer

Do you need to print a product larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare specifications by model

Compare 3D Printer

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is elastic, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Advantages of Discovery 3D Printer Solutions

ISO 9001 certified products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling a part after printing

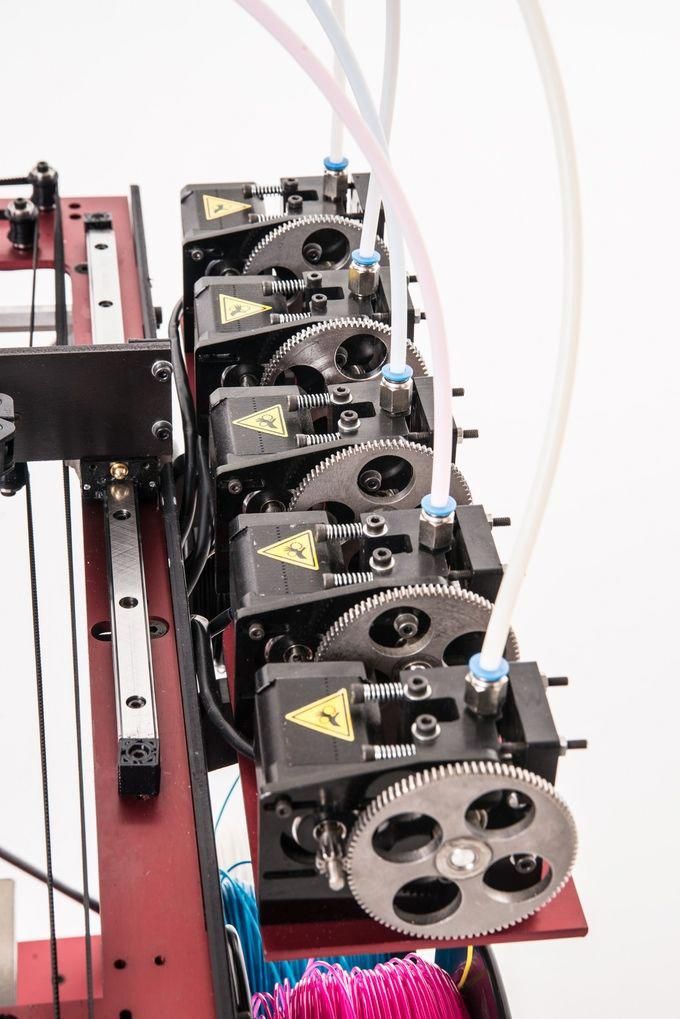

Accelerate the creation of new products thanks to the dual extrusion system

Repair and replacement of products faster and more economically than contractors

Ability to use a large number of third-party materials

Self-leveling platform function for automatic compensation of irregularities

Case Studies

FDM Airbus Spare Parts 3D Printing

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low thermal expansion coefficient.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

The solid statue is printed and is 1. 87 m high and 45 kg in weight.

87 m high and 45 kg in weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles 3D printed for exclusive display at Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed at 29 x 19 x 4.5 cm and weighing 146 g.

A prototype of a modular toilet has been printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Ventilation grill printed 59 x 89 x 4. 5 cm and weight 3500 g.

5 cm and weight 3500 g.

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g.

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlayer adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help you optimize production?

- Features FDM-technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

The best prices for this class of equipment

Training on how to use 3D printers

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology to choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process. If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

This is often not necessary as the product is not visible.

full name *

Company *

E-mail *

Telephone *

Message

3D printed branded merchandise

- 3D printed

What we offer:

- Delivery of finished products to all cities of Russia and CIS countries

- We work with single items and large lots

- We print with wax and photopolymer

- The price is calculated individually.

How the price is formed, you can find here

How the price is formed, you can find here - Ability to print color models

- Fast printing in a few days depending on the volume

- Accuracy of final sample about 0.1 mm

- Own 3D printers

- You can write to us at [email protected], call +7(495)223-01-21 or leave an online application

What we do:

There are many companies in the modern market that are in constant competition. For proper positioning, organizations use logos in an exclusive corporate style and place it on branded souvenirs. 3D printing has no restrictions on the complexity of the design and can be performed using completely different materials, depending on the technical task of the customer. Corporate business souvenirs can increase brand awareness in the service market and increase consumer loyalty.

Why?

The ease and speed of 3D printing and its final result cannot be compared with traditional means. Also, a 3D printer will be useful in the production of single and small batches of exclusive corporate souvenirs for your business, which can set you apart from your competitors in the market.

Most recently completed projects

3D photopolymer souvenir More 3D printing of a human figure More 3D printing of a master model of a game character More Creating a character figurine from a game on a 3D printer More Obtaining a 3D model of a souvenir More Creation of jewelry products More Creating a 3D model of the award More Creating a chandelier with many elements More

see all projects

The price of creating exclusive souvenirs is calculated individually

For an accurate price calculation, send a request to our specialists with the necessary information

Stages of work

Obtaining initial data from the customer, drawing up technical specifications. assignments (TOR)

Estimating the price and terms of work, agreeing on working conditions

Signing the contract and invoicing

Making an advance payment

Carrying out work on agreed dates

Providing the customer with the finished result of work in the required format

Signing the certificate of completion

Do you have any questions about 3D printing?

Write to us, and our managers will answer all your questions and solve your specific problem!

Ask a question

Call me back

Hardware and software park

- Protofab SLA 600

- Geomagic Design X

- Geomagic Wrap

- 3D Studio Max

- 3D Systems ProJet 2500W

Protofab SLA 600

Technology: Stereolithography (SLA) is a technology for layer-by-layer curing of a liquid material under the action of a laser beam. Suitable for creating mock-ups, tooling and burn-out models for casting.

Suitable for creating mock-ups, tooling and burn-out models for casting.

Material: photopolymer

Max. model dimensions: 600 × 600 × 400 mm

Layer thickness: 0.05 - 0.25 mm

Order

Geomagic Design X

Geomagic Design X is software for converting 3D scans into high quality geometrically parameterized CAD models. Easily integrates with 3D scanning equipment. Convenient for processing billions of scan points.

It is applied for:

- control and modification

- receiving digital layouts

- engineering analysis and simulation

- repair and production of components

- visualization and graphic animation

Order

Geomagic Wrap

A fast and accurate tool for modeling, correcting and optimizing 3D data. Provides the shortest and most accurate path from point cloud to 3D surface creation and 3D model processing.