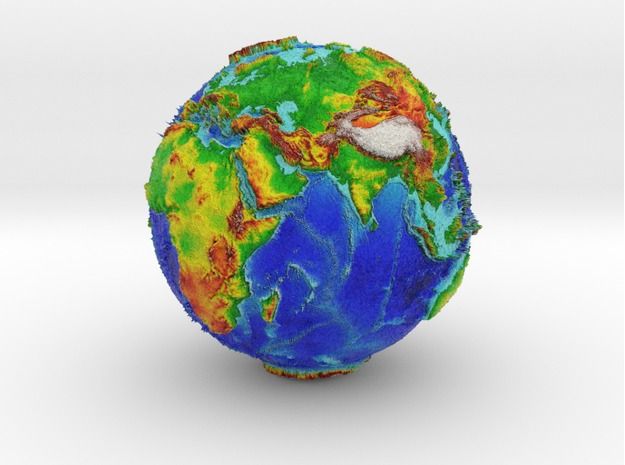

Globe 3d print

Globe 3D Printing Models | CGTrader

Here you can find Globe 3D models ready for 3D printing. Purchase and download 3D models, stream and print with your own 3D printer, or buy 3D-printed product - we will 3D print and ship it to your home....Show more

Premium

stl, ige, igs, iges, sldprt and more

Premium

stl

Premium

$15.00

stl, obj, mtl, ige, igs and more

Premium

$15.00

stl

Premium

$10.00

Premium

$19.00

stl, obj, fbx, dae, mtl

Premium

stl, obj, skp, dae, 3ds and more

Premium

stl, obj, skp, 3ds, dae and more

Premium

$14.99

obj, dae, mtl, fbx

Premium

stl, obj, mtl, 3ds

Premium

$15.00

stl, obj, mtl, fbx

Premium

stl, obj, skp, dae, fbx and more

Premium

stl

Premium

stl, obj, mtl, dxf, dae and more

Premium

$170. 00

stl

Premium

$10.00

stl, 3dm

Premium

$10.00

stl

Premium

$10.00

stl, obj, fbx, bip, ksp and more

Premium

stl

Premium

$50.00

stl

Premium

stl

Premium

stl

Premium

$25.00

stl, obj, 3dm, bip, ksp and more

Premium

$25.00

stl, obj, mtl, bip, ksp and more

Premium

$15.00

stl, obj, bip, ksp, fbx and more

Premium

$25.00

stl, c4d

Premium

stl

Premium

$10.00

Premium

obj, mtl

Premium

stl, obj, mtl

Premium

stl

Premium

stl

Premium

stl, obj, mtl

Premium

stl, obj, mtl

Premium

stl

Premium

stl, 3dm

Premium

stl

Premium

$15. 00

00

stl

Premium

$19.00

stl, obj, fbx, dae, mtl

Premium

stl, obj, mtl

Premium

stl

Premium

stl, obj, mtl

Premium

stl

Premium

stl

Premium

stl, obj, mtl

Premium

$12.00

stl, obj, 3ds, fbx, mtl and more

Premium

stl, obj, mtl

Premium

stl

Premium

stl, obj, mtl, f3d

Premium

$14.99

obj, dae, mtl, fbx

Premium

stl, obj, mtl, dxf, dae and more

Premium

stl

Premium

obj, mtl

Premium

stl, obj, mtl, 3ds

Premium

stl

Premium

stl, ige, igs, iges, sldprt and more

Premium

stl

Premium

$29.00

obj, mtl

Premium

$27.00

stl, obj, mtl, amf, 3mf

Couldn't find what you're looking for?

Request a custom 3D model

3d Printed Earth - Etsy.

de

deEtsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

3d printed globe.

3D printing

Subscribe author

Subscribe

Don't want

16

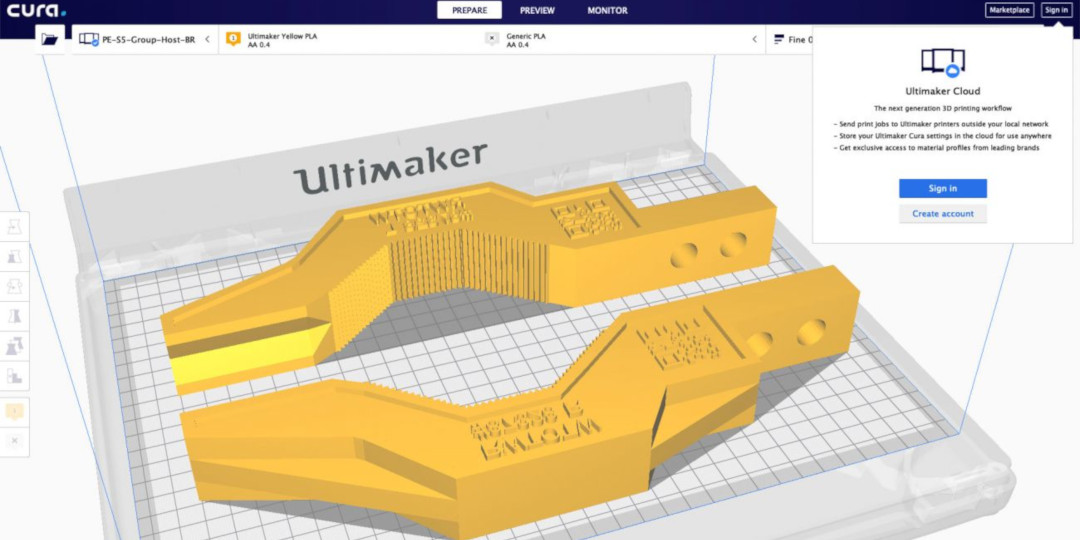

Friends, today I would like to tell you how important it is to double-check the model before printing, despite the fact that at first glance there are no errors in it.

First post so to speak)

The goal is to print a globe according to the model. The model is available, everything seems to be fine.

However, if you select cut in netfabb, you can see that the model consists of several objects.

After loading the model into Z-Suite and a detailed view, it turned out that there is a void at the junction of two objects and, if you notice it in time, you can save 40 hours of printing and a huge skein of thread.

After separating the objects, carrying out the Boolean addition operation, the model became solid

and sent to print.

The printer is protected from drafts and equipped with plastic SEM milky (original so to speak)))).

41 hours at maximum quality setting, 20% coverage, 19 layer thickness0 microns, the thickness of the Earth's crust is 5-6 mm.

While printing, risking the model took pictures:

20% of the time has passed somewhere.

40%. In the center, support is formed for the upper layers.

Due to the black color of the body of the Zortrax M200, they glued the head of the Dark Lord on the tower))) Now it began to print better))))

When they arrived in the morning the model was almost printed)))) Some 1-2 hours more.

And finally, the result:

20 minutes to clean the substrate from the table - ingrained insanely strong)

And finally, after a long cleaning of the model, you can enjoy the result.

The model was not subjected to acetonation because it looked amazing anyway)))))

Loading

11/08/2022

1276

9

Follow author

Subscribe

Don't want

We continue to uncover the incredible opportunities of enterprises from China, to...

Read more

0

Subscribe to the author

Subscribe

Don't want

Ones Technology is a research and development center under the Ministry of Industry of Turkey. According to G...

Read more

Leoluch

Loading

09/07/2015

356946

346

Subscribe to the author

Subscribe

Don't want

Good afternoon, dear visitors of the portal.

Today I decided not to leave in art...

Read more

Printer for the materialization of ideas

Alexander Osinev

Printing deep and wide!

General in boxes and globes

How it works

3D printer - a universal tool

Even for our parents, computer technology was inextricably linked with grinding numbers and solving mathematical problems formulated by specialists from various exact sciences. But obsession with mathematics is a thing of the past. The phrase "computer creativity" does not surprise anyone. If we talk about traditional creativity, it seems that writers were the first to move from typewriters to computer terminals, who appreciated the text editor as an alternative to marginal entries and manual reprinting of pages due to minor editing. Further more. The computer is now often almost the main tool for musicians, designers, architects and even filmmakers. It is especially important that the quality of films and books still depends not on the computer, but on the person. Computers, in fact, are still crunching numbers, saving us time (and most often money), leaving more opportunities for creativity itself.

Computers, in fact, are still crunching numbers, saving us time (and most often money), leaving more opportunities for creativity itself.

Print deep and wide!

The development of computer peripherals - scanners, printers and other equipment - also did not stand still. New types of human activity, subdued by the general computer boom, often require special output and input devices. Computers have long been able to translate text, images and sounds into their native form and back, even the first developments in the field of analysis and reproduction of smells have appeared. In the 90s, a lot was done to make computer technology perceive and make digital models of real objects, which was solved by several 3D scanning technologies. Finally, the way back was paved: the computer was taught to create, on the basis of a digital three-dimensional model of an object, its completely material prototype. This was done thanks to 3D printing, which we will discuss in more detail in this article.

3D printing is not so new as to claim any cutting-edge scientific developments: the roots of this technology go back to the early 90s. However, many of us may consider 3D printing a curiosity. 3D printers have not become widespread up to entry into every home, it is too early to even say that these devices are in every company where the creation of a three-dimensional prototype is one of the mandatory steps. You can print literally anything - from a one-to-one scale model of a bolt to a miniature copy of a satellite or a future stadium, but the development of technology has long been held back (and partly still held back) by important factors. A 3D printer is an expensive piece of equipment, and although prices have steadily declined over the years, not every organization can afford it. In addition, a fairly high qualification is required when creating a computer three-dimensional model, and in this sense it is gratifying that in recent years designing on paper with a pencil and a ruler has become an anachronism.

General information in boxes and globes

There is a company in Noginsk near Moscow that has been mainly engaged in the production of packaging with full-color printing for many years. Here, quite a long time ago, they appreciated the convenience of working with computer three-dimensional models when creating a construct and design, and therefore they also mastered the corresponding software products. “When, over time, we learned how to operate with computer images well,” says Alexander Dobrolyubov, head of the Public Market company, “the idea arose to show customers not yet existing boxes in three-dimensional form. We found and mastered complex software products like Autodesk Maya, and then realized that you can not limit yourself to packaging alone.”

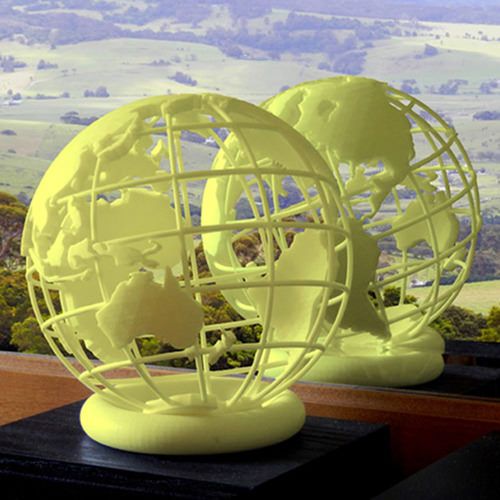

The company began to look for the right technology and discovered 3D printing. In 2007, a ZPrinter 510 3D machine was purchased. “Through trial and error,” says Alexander Dobrolyubov, “we came to the conclusion that some products at the prototyping stage can be done quickly and well by 3D printing. We began to take orders for the creation of prototypes of all kinds of products from outside. In order to be less dependent on external orders for 3D printing, the Public Market made sure that the company also had its own project for a 3D printer. This project was the creation of a large relief globe. By itself, the globe may not be 100% used for its intended purpose, but as an original piece of furniture it will decorate the office of any leader and will be a great gift. The choice was based not so much on opportunistic considerations as on the personal sympathies of employees for such a project. Nevertheless, the project needed to be brought to the stage where a globe of one size or another could be placed on the floor or on a table, and not stop only at the contemplation of the model on the computer screen. And the ZPrinter 510 helped with that.

We began to take orders for the creation of prototypes of all kinds of products from outside. In order to be less dependent on external orders for 3D printing, the Public Market made sure that the company also had its own project for a 3D printer. This project was the creation of a large relief globe. By itself, the globe may not be 100% used for its intended purpose, but as an original piece of furniture it will decorate the office of any leader and will be a great gift. The choice was based not so much on opportunistic considerations as on the personal sympathies of employees for such a project. Nevertheless, the project needed to be brought to the stage where a globe of one size or another could be placed on the floor or on a table, and not stop only at the contemplation of the model on the computer screen. And the ZPrinter 510 helped with that.

How it works

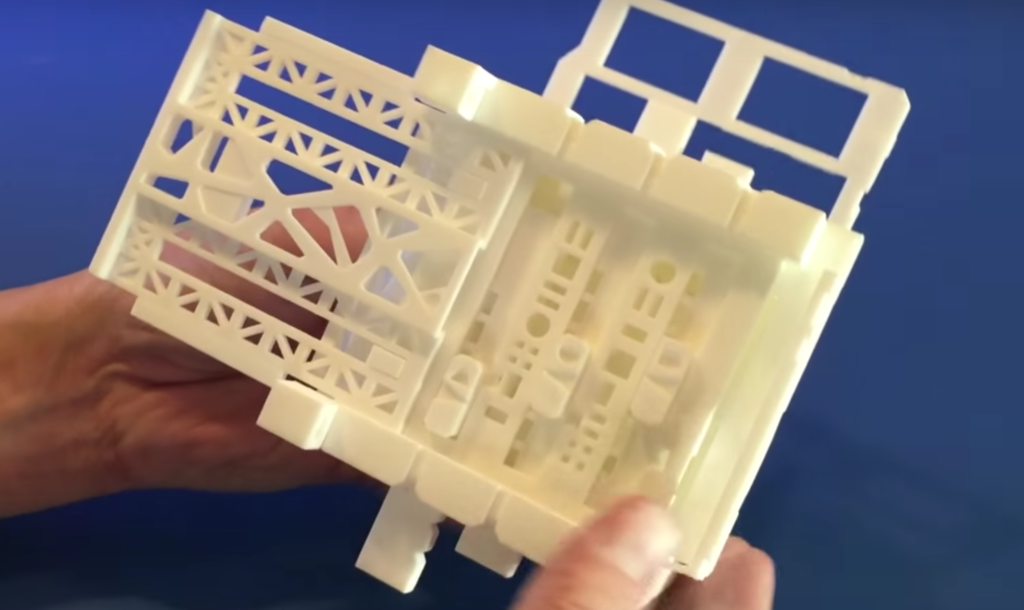

The technology used by Z Corporation printers (namely, this company produces devices under the ZPrinter brand) basically involves layer-by-layer growth of a model from gypsum powder in a special chamber. In various models of Z-printers, the build chambers have different volumes, which determine the maximum size of the object being grown.

In various models of Z-printers, the build chambers have different volumes, which determine the maximum size of the object being grown.

The model to be printed must be as realistic as possible, without infinitely thin walls and open surfaces. If it’s quite simple, it should fully correspond to the future subject, and not be its simplified likeness. For example, it is not enough if the computer models of the fragments of the globe are only some parts of the surface of the sphere. These fragments must have a certain thickness, calculated on the basis of the expected loads on the final product. The printer software is able to point out a number of errors in the simulation, but the operator, based on his own experience, must also see the weaknesses himself.

If everything is in order with the computer model, the printer driver programmatically breaks it into layers of 0.1 mm, which are then applied one after another. In the course of printing, the gypsum particles are held together with a special binder, and the surface of the future model is simultaneously painted in accordance with the developed design.

Printing is from top to bottom, while the movable bottom of the chamber drops slightly after applying the next layer. The chamber is gradually filled with gypsum over the entire area to the current level of the height of the model, but the binder unites only those particles that should become part of the final prototype. It turns out that at every moment the model being built is surrounded on all sides by powder - it performs the function of supporting the model and its individual parts. This is necessary because the printer allows you to print objects with fairly small details, and before special processing after printing, gypsum remains a very fragile material that breaks even with a slight impact. An additional plus of this approach is that Z Corporation printers allow you to grow several models at once, which can be located throughout the volume of the chamber. So, for example, it happens when growing fragments for three-dimensional globes in the Public Market.

After printing is completed, the grown models are dried. Then the chamber is freed from excess powder, which will be reused. Almost finished and still very fragile models are carefully moved into a special blowing chamber, where powder residues are removed from them and treated with an impregnating composition that makes the model durable. Which one depends on the specified strength criteria. Finally, in order for the model to dry after impregnation and be ready for use, you need to wait a few more minutes. Depending on the model, ZCorp printers allow you to perform certain auxiliary actions automatically.

Then the chamber is freed from excess powder, which will be reused. Almost finished and still very fragile models are carefully moved into a special blowing chamber, where powder residues are removed from them and treated with an impregnating composition that makes the model durable. Which one depends on the specified strength criteria. Finally, in order for the model to dry after impregnation and be ready for use, you need to wait a few more minutes. Depending on the model, ZCorp printers allow you to perform certain auxiliary actions automatically.

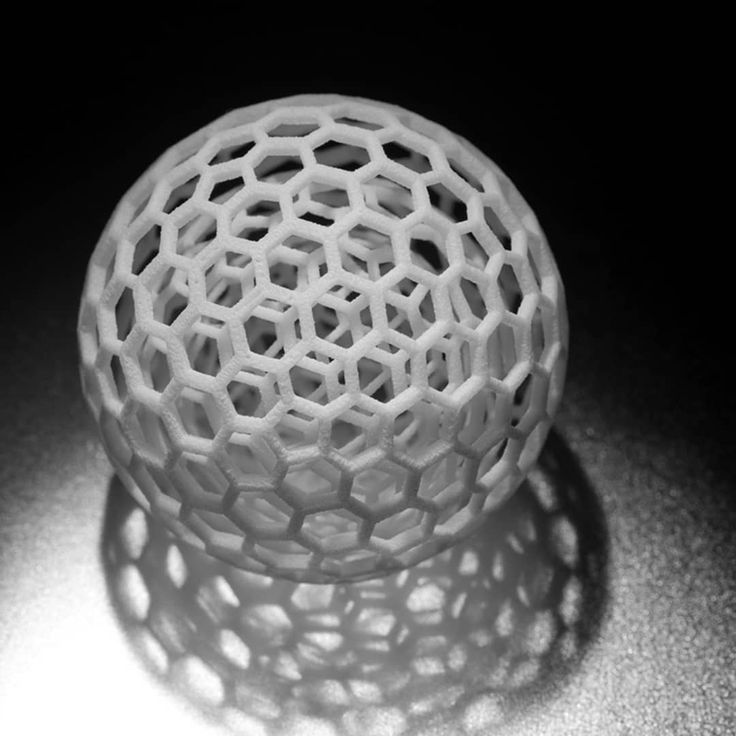

3D printer - universal tool

The above technology, of course, limits the designer's imagination to some rules, but for the most part they are tied to the elementary laws of physics. Otherwise, you can print the most complex models, which makes the scope of the printer very wide. According to Alexander Dobrolyubov, the possibilities of 3D printing technology awaken creativity, which he sees in the example of Public Market employees. “Our ZPrinter 510 is especially interesting and often indispensable for creating prototypes of products that have a great artistic component. These are shoes, architectural objects, and clothes,” says Alexander. “Healthcare institutions are asking us questions about preparing ideal training models.” In this regard, he spoke about a recent call from doctors who needed help preparing for a complex operation - a full-size model of a human head that accurately takes into account the internal structure of a particular patient and was created on the basis of tomography results. “And I don’t know how it would be possible to solve such a problem without a 3D printer,” Alexander concludes.

“Our ZPrinter 510 is especially interesting and often indispensable for creating prototypes of products that have a great artistic component. These are shoes, architectural objects, and clothes,” says Alexander. “Healthcare institutions are asking us questions about preparing ideal training models.” In this regard, he spoke about a recent call from doctors who needed help preparing for a complex operation - a full-size model of a human head that accurately takes into account the internal structure of a particular patient and was created on the basis of tomography results. “And I don’t know how it would be possible to solve such a problem without a 3D printer,” Alexander concludes.

At the same time, it must be admitted that 3D printing is still expensive due to the low prevalence of the technology and the lack of awareness among end users. The price of components, consumables and, as a result, the cost of printing is very high. Buying a printer for occasional use may not justify itself. Alexander has no doubt that without his own project, his company would certainly not have profited from the printer. “It so happened,” he explains, “that the embossed globe is a unique product, and we can really make money on it. The uniqueness of the project is that we can make the globe the way the customer wants to see it: we vary the sizes, textures, colors. In addition to being unique, it is also convenient for both us and our clients.” Public Market has already produced a considerable number of various products, including globes, and on the day when Alexander answered questions for this article, another globe was in the works, the diameter of which, at the request of the customer, will be 1 m 20 cm.

Alexander has no doubt that without his own project, his company would certainly not have profited from the printer. “It so happened,” he explains, “that the embossed globe is a unique product, and we can really make money on it. The uniqueness of the project is that we can make the globe the way the customer wants to see it: we vary the sizes, textures, colors. In addition to being unique, it is also convenient for both us and our clients.” Public Market has already produced a considerable number of various products, including globes, and on the day when Alexander answered questions for this article, another globe was in the works, the diameter of which, at the request of the customer, will be 1 m 20 cm.

The secret of Public Market's success is that they have not forgotten the main thing here: a printer, even if it performs three-dimensional printing, is just a tool. To make money with such a device, you need ideas and the ability to bring them to mind. “The production of globes is not only printing,” says the head of the Public Market. - Print - twenty percent of the whole case. Bringing the product to such a form that it can be used for a long time is not easy. Fragments must match in color and size, and meet strict strength criteria. To solve some problems, it was necessary to develop their own techniques. But it is the 3D printer that suits us more than any other technology.”

- Print - twenty percent of the whole case. Bringing the product to such a form that it can be used for a long time is not easy. Fragments must match in color and size, and meet strict strength criteria. To solve some problems, it was necessary to develop their own techniques. But it is the 3D printer that suits us more than any other technology.”

Our interlocutor admits that the ZPrinter 510 is not only expensive, but also difficult to use. At the same time, he is convinced that any thinking person understands that complex, unique equipment requires additional efforts from the user, including intellectual ones. “Developers from Z Corporation do not stand still, they offer new options for both software and equipment,” notes Alexander. “I think that with proper service support, reasonable prices for spare parts and consumables, 3D printing technology will definitely have a worthy future.”

Public Market decided not to reduce its own three-dimensional projects to globes alone.