What data does 3d printing use

Does a 3d Printer Use Data? – 3dprintscape.com

I’ve been using a 3d printer for quite a while, and a question I had when I was first getting into it is whether a 3d printer uses data. So, I thought I’d summarize whether a 3d printer does or does not use data, and what for.

As a general rule, a 3d printer does not use data. A 3d printer executes instructions written in a special type of file – similar to a Microsoft Word document. However, these files are loaded from a computer onto a 3d printer using a USB cable or an SD card.

There are a few special types of software that you can use to create a 3d print, and there are also options to download files that other people have created.

But, it’s good to know how a 3d printer works, and why a 3d printer doesn’t need an internet connection so below I will explain that as well as everything you need to know about whether a 3d printer uses data.

Does 3D Printing Use Data?

So a 3d printer itself doesn’t use data, but you may be wondering whether a 3d printer uses data as it’s printing…

Printing a 3d print does not use data. As a 3d print is being printed it is following the step-by-step instructions outlined in the 3d print file. The print file is copied onto the hard drive of the 3d printer. The 3d printer then uses only filament and electricity to print the 3d print design.

You have the option to print a 3d print design you create, but there are online libraries of 3d prints that others have made that you can download for free. And there are also some paid designs.

All of this is done on a separate computer though. The computer you use will need to have an internet connection to download 3d print files. And certain 3D printing software is used in a web browser like Safari or Google Chrome. Therefore, they won’t work without an internet connection.

How Does a 3D Printer Work?

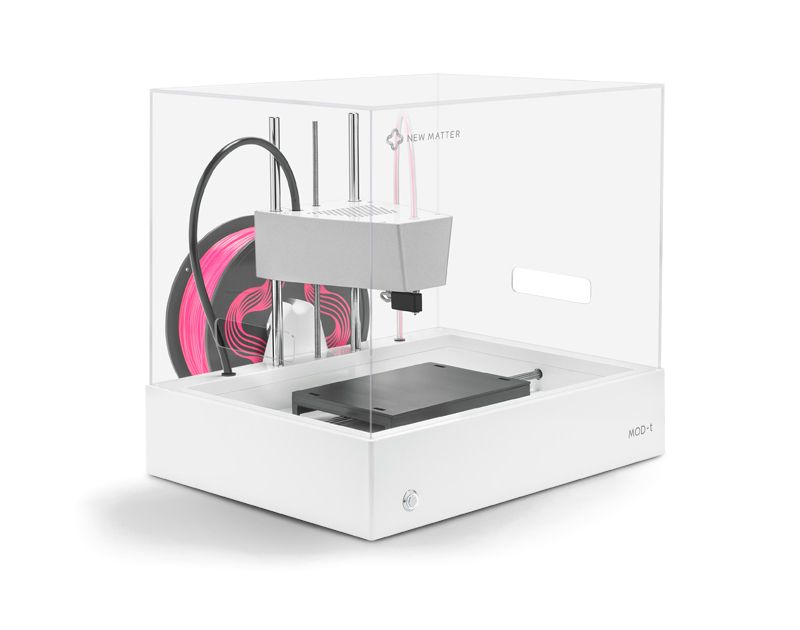

A 3d printer is a fairly new technology and unlike computers and smartphones, they aren’t that widespread. Therefore, most folks don’t know how a 3d printer works at a big picture level. Here’s how a 3d printer works.

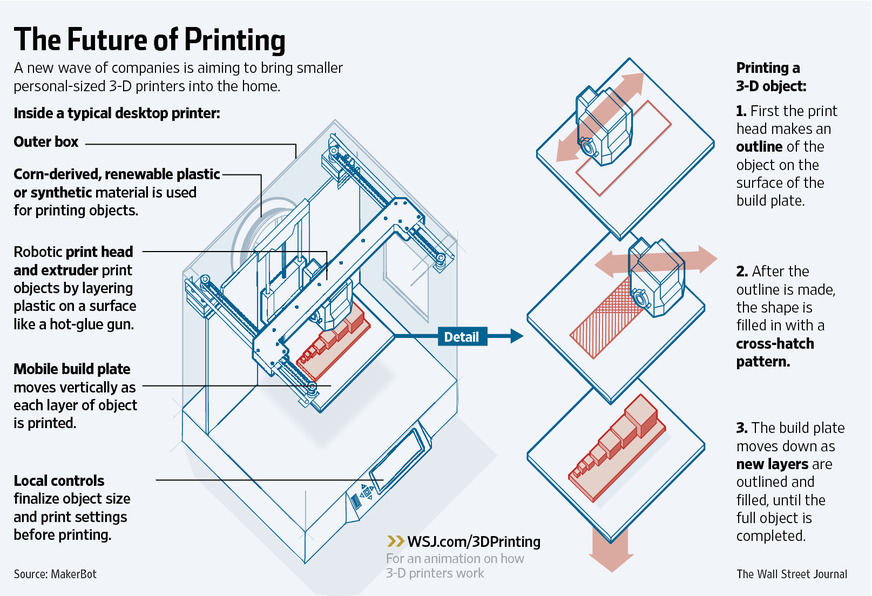

A 3d printer prints one layer of plastic at a time. Each layer has a 2d design and all of the layers in a 3d print are the same thickness. A 3d printer prints each layer from a file that contains what each layer looks like.

A 3d printer uses computer code to give instructions to the 3d printer. These instructions and X and Y coordinates. The top left corner is the location 0, 0. If it goes a little bit to the right but not up or down it will be at a location of around (¼ inch, 0).

However, computer pixels are used for measurement on 3d print software. And as you may know on programs like Photoshop. So, the coordinates would be (4px, 0px) for example. Where px stands for pixels.

The 3d print file has instructions for the 3d printer to go to different locations around the 3d printer plate. And as it’s doing that it heats up the filament, and extrudes it at the right time so that it prints each layer until it is finished. Then, it moves on to the next layer.

For example, if you are printing a square cube, it will print the same shape over and over one layer after another until it makes a cube. But, a pyramid starts with a square but then prints a slightly smaller square each time until the final layer is only a tiny dot or filament. Which is the very top of the pyramid.

The filament is hard at room temperature and it’s heated until it melts. It’s then fed through what’s called the extruder where it draws each layer onto the 3d printing bed. After that, it will go hard and be a solid object.

3d printer compared to an ink printer

Both a 3d printer and an ink printer have the word printer in them. And they are remarkably similar. The major difference is that a 3d printer will print only one layer, whereas a 3d printer will print many many layers one on top of the other.

But apart from the fact that 3d printers print plastic whereas ink printers print with ink they are virtually identical and work in a very similar way.

The print file is sent to the printer. The printer then reads the file and moves a mechanical arm according to X and Y coordinates, and prints either ink or plastic. Depending on what kind of printer it is.

How Does 3D Printing Software Work?

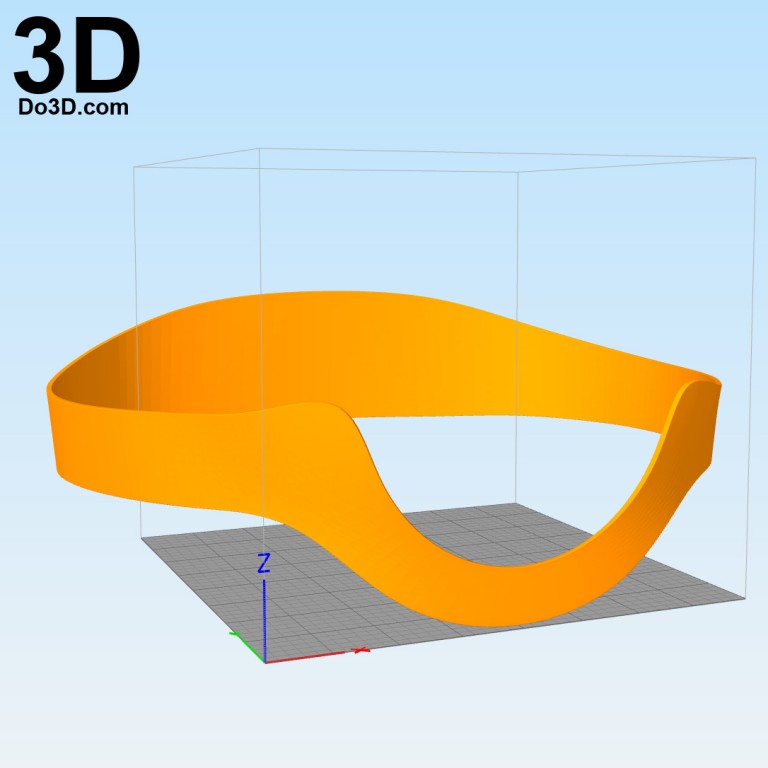

3D printing software is used to create 3d print designs that a 3d printer can read. And then subsequently print a complete object from the 3d print design. But, how exactly does 3d printing software work?

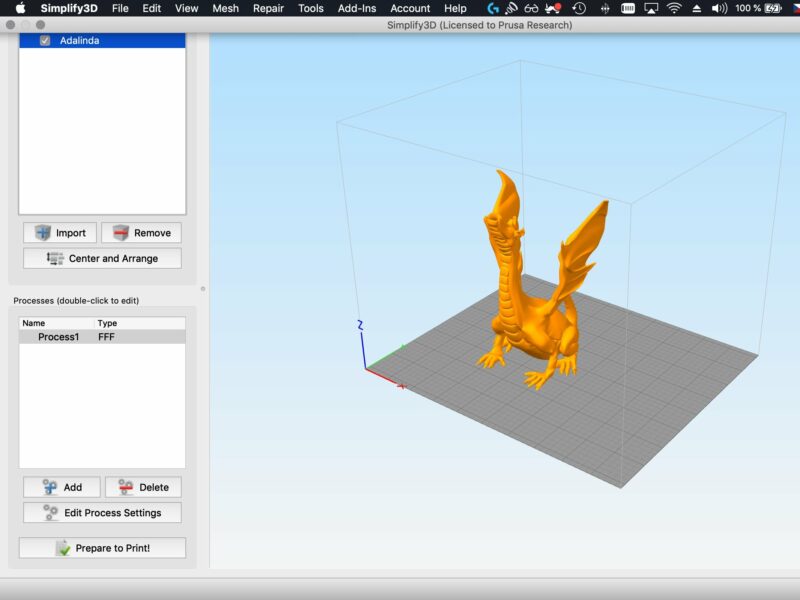

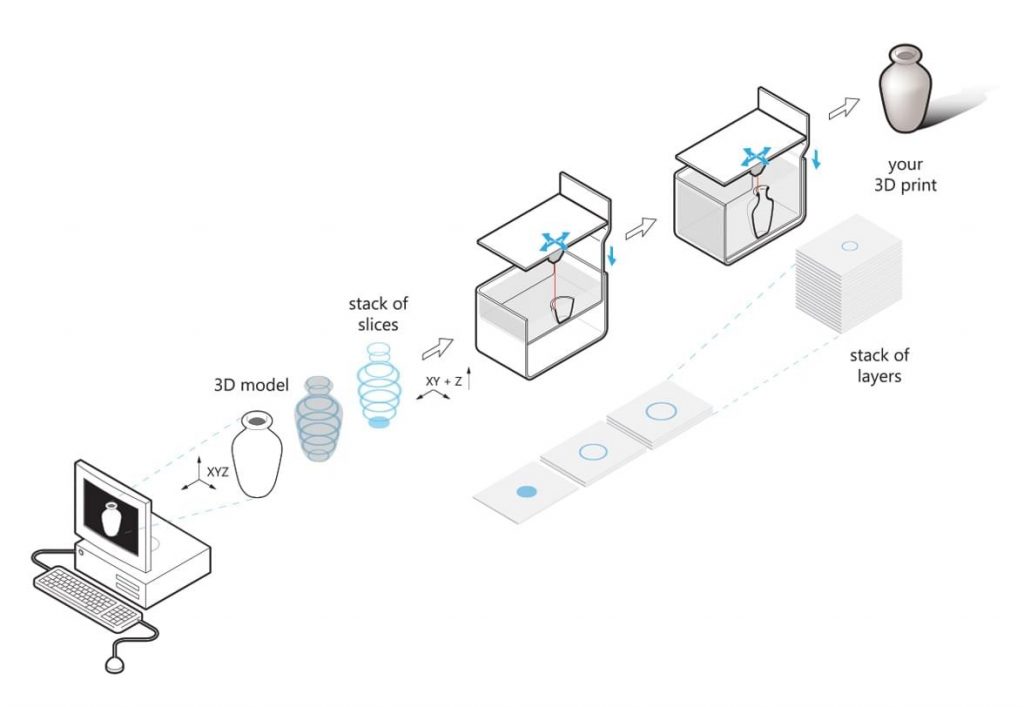

3d printing software creates a 3d model. The 3d model is then sliced into layers. Each layer of a design is printed one by one in the 2d space. Each layer builds on the previous layer and creates a 3d object.

There are 2 different kinds of 3d printing software – one can be used to create the design – and the other is used to slice the design. The software used to slice the design is conveniently called slicing software.

A 3d print design needs to be sliced so that the 3d printer has the information it needs. And can then print each layer on top of each other until it has printed the entire design.

And can then print each layer on top of each other until it has printed the entire design.

One of the most popular 3d printer designing software is TinkerCad. It is designed to be used by both school-aged children and adults. It has a tonne of lessons that explain how to create 3d print designs and best of all it’s completely free.

After you have a design you can slice it with Cura and is one of the most popular 3d printing slicing software. It’s also 100% free. Once the file has been sliced using Cura, then you send it to your 3d printer.

Some designs are very complex and the 3d printer nozzle needs to make a lot of back and forth movements. Whereas, in more simple designs the nozzle can print in long lines back and forward without stopping to reposition.

Because of that more complex designs tend to take longer to print, whereas simpler designs print a lot quicker. However, on a hobbyist type of 3d printer that most people would use at home, most prints don’t take longer than 12 hours.

Related Articles

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

- Can You Mix 3D Filament Colors?

- This Is How Much 3d Printer Filament You Really Need!

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.

4 common types of 3D printer file formats and when to use it

File formats are like the blueprints for printing three-dimensional objects. A 3D printer file is known to be the carrier of information from CAD model to 3D printer. It can encode a 3D model’s appearance, geometry, scene and animations. However, not all 3D printer file formats can carry all kinds of data.

There are several 3D file formats that are used today. These are FBX, 3DS, COLLADA, IGES, STEP and many more. This blog post will introduce 4 3D printer file formats that are commonly used by engineers and designers and when to use it. These file formats are considered as “go-to” formats for 3D printing.

These are FBX, 3DS, COLLADA, IGES, STEP and many more. This blog post will introduce 4 3D printer file formats that are commonly used by engineers and designers and when to use it. These file formats are considered as “go-to” formats for 3D printing.

- STL

Nowadays, STL is known to be the most common file format in 3D printing. Ever since its invention in 1987, it has remained to be the de facto standard in the 3D printing industry.

STL (Standard Triangle Language/Standard Tessellation Language) is the first file format developed for 3D printing. Its corresponding file extension is .stl.

STL files save 3D models as surface of geometrical shapes and turn it into a triangular mesh. But, it cannot display information about the model’s colour or texture.

When to use STL?STL file format is used by some designers because of its flexibility and popularity. Almost any piece of software and hardware supports this file format. This means that you can use your favourite CAD programs, repair tools and slicers without any problems.

This means that you can use your favourite CAD programs, repair tools and slicers without any problems.

STL file format is also used when the 3D model requires a single type of colour. If you want to be able to download plenty of ready-to-use 3D models, then use STL file format.

- OBJ

OBJ (Wavefront OBJect) is a 3D printer file format that was originally used by graphics designers as a neutral interchange format for 3D graphics. It was first developed by Wavefront Technologies for its animation package. This file format has the extension .obj.

Unlike STL, OBJ can encode colour and texture information, it also supports both approximate and precise encoding of surface geometry. This means that it doesn’t restrict its surface mesh to triangular facets. The designer can also use polygons such as quadrilaterals. However, OBJ doesn’t support any kind of animation.

When to use OBJ?OBJ is often used when the 3D object requires more than one colour. It is also the choice of some developers because it offers a lot of flexibility on how it encodes the 3D model’s geometry.

It is also the choice of some developers because it offers a lot of flexibility on how it encodes the 3D model’s geometry.

Aside from that, with OBJ, the designer can use more advanced schemes such as free-form curves and free-form surfaces. These schemes can be used to encode curved geometry without losing any data.

This file format is also widely used in industries such as aerospace and automotive which are demanding when it comes to precision.

- AMF

AMF was introduced in 2011 as a replacement for STL file format and then was called “STL 2.0”. AMF was developed to address the shortcomings of STL format. Some issues that STL has includes bloated, error-prone, incapable of storing colour, material and texture information.

AMF is an XML-based format that has native support for geometry, lattices, scales, duplicates and orientation. Thus, it is a superior format for STL file.

Unfortunately, the 3D printing industry has been slightly slow to adopt this format in spite of its technical advantage.

AFM 3D file format is used if a 3D model requires precision, multiple materials and multi-colours all at once. This format will ensure that the file will be easy to read, write and process.

Furthermore, aside from planar straight triangles, AMF allows curved triangles. In this way, you can easily describe a curved surface without the use of many facets.

- 3MF

As 3D printing industry advances, developers are trying to look for solutions to some of the notable problems with STL. Thus, Microsoft, along with other big companies such as Autodesk, 3D Systems, EOS, Stratasys, Ultimaker, etc. developed 3MF 3D printer file. It has the goal of creating a seamless and high-quality 3D printing experience for consumers and manufacturers.

3MF features a geometry representation similar to STL but more compact than AMF 3D printer file format. However, 3MF is relatively new to the manufacturing industry. It still lacks more industry recognition.

However, 3MF is relatively new to the manufacturing industry. It still lacks more industry recognition.

3MF is often used by designers who want to avoid frustrations related to print failures, bad geometry, etc. 3MF file format can also handle 3D models that use different colours and materials. Thus, it can be used for complicated 3D printing projects.

3MF file format is trying to resolve all issues from other 3D printer file format and bring it together in a single file. Hence, it is considered as an ideal format for the future of 3D printing.

ConclusionThere are a lot of 3D file formats that are used by 3D printing designers today. But STL, OBJ, AMF, and 3MF are the most important among all of them. They have their own strengths and varies in their levels of compatibility with software and hardware.

It is vital to understand and know the key differences between these 3D printer file formats. Your choice of 3d file format can greatly affect the production efficiency, 3D printing toolchain and the quality of 3D prints.

If you have more questions or want to learn more about 3D printing-related topics, cooperate with a 3D printing service provider in Sydney. Aside from that, they can offer services such as 3D design modelling, industrial 3D printing and many more.

What is 3D printing in 2021

3D printing technology has changed the manufacturing process of everything that surrounds us. From children's toys and clothes to prostheses, implants, etc.

The 3D printing process is also known as additive manufacturing. In simple terms, a computer program tells the printer where to lay thin layers of material that gradually turn into a solid object.

Types and processes of 3D printing technologies

The first mention of 3D printing technology appeared in the late 1980s. They were called rapid prototyping technologies. The name refers to a process that was conceived as a faster and more cost-effective method of prototyping in product development. The very first patent application for this technology was filed by Dr. Hideo Kodama in May 1980. But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object.

The very first patent application for this technology was filed by Dr. Hideo Kodama in May 1980. But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object.

Years later, the American Scott Crumb developed the most common type of 3D printing today - FDM (Fused deposition modeling). This technology stands for deposition modeling. This type is characterized by the fact that the thermoplastic material is heated to a liquid state and extruded through the nozzle layer by layer.

Charles Hull, co-founder of 3D Systems, was one of the inventors of the 3D printing technology known as stereolithography. The technology is based on photochemical processes.

But Kodama, Crump, and Hull weren't the only ones to develop 3D printing techniques.

WINBO 3D printer at Art-Up Design Studio

Here are some other types of 3D printing in use today:

- FDM (Fused Deposition Modeling) is by far the most common method for producing thermoplastic parts and prototypes today.

Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms.

Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms. - SLA (Stereo Lithography Apparatus) is based on the layer-by-layer curing of a liquid photopolymer material under the influence of UV study. Can print objects in multiple colors and materials with different physical properties, including rubber-like parts. The high printing accuracy of this method makes it more expensive and not optimal for simple plastic structures.

- DLP (Digital Light Processing) cures polymers using a light projector rather than an ultraviolet laser. This allows you to create a whole layer in one exposure, thus increasing the speed of production.

Metals too have their own 3D printing techniques. The type of technology is selected depending on the features of the object.

The type of technology is selected depending on the features of the object.

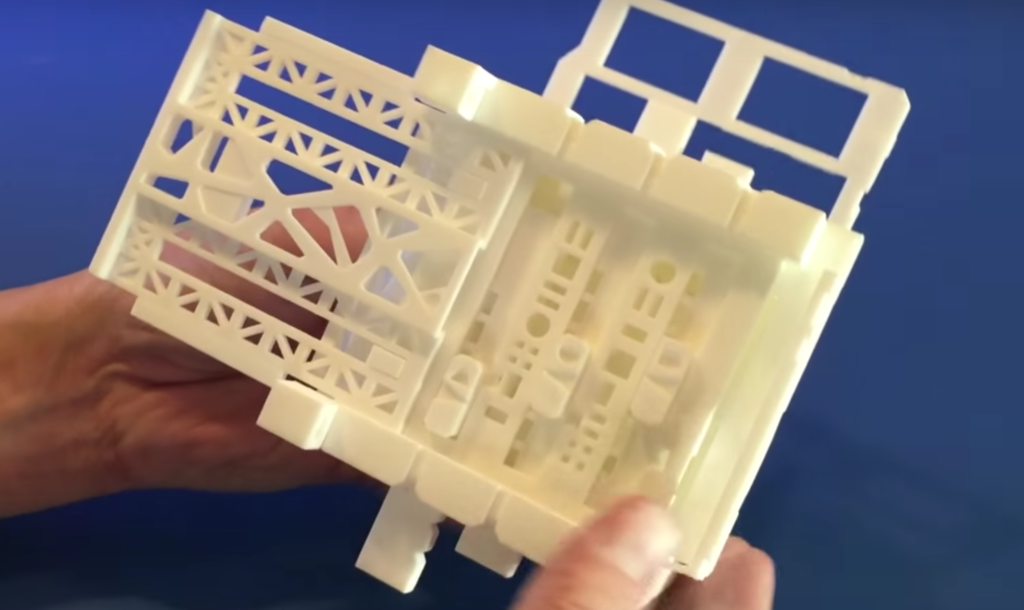

- SLS (Selective Laser Sintering) is based on layer-by-layer sintering of polymer powder particles using laser radiation. The nylon powder melts into a strong, hard plastic. Due to the peculiarity of the technology, the surface of the part is not ideal, but very functional for use in prototypes with hinges and latches.

- SLM (Selective Laser Melting) is based on layer-by-layer sintering of metal powder under the action of a laser beam. Used in the manufacture of decorative items. Therefore, it is useful for applications in medicine and lightweight structures. Often this method is used in conjunction with traditional metal casting technology to create prototypes or final products.

- EBM (Electron Beam Melting) is based on layer-by-layer melting using an electron beam. The printing uses electromagnetic coils to superheat the metal powder in a vacuum.

How 3D printing works

3D printing is the process of layering one on top of another. Every 3D printed object starts life as a 3D model in a computer program.

Every 3D printed object starts life as a 3D model in a computer program.

You can create your own design in programs such as Maya, Blender, ZBrush, CATIA, Solidworks. In addition, ready-made 3D models of parts can be downloaded from sites such as Thingiverse or CGTrader.

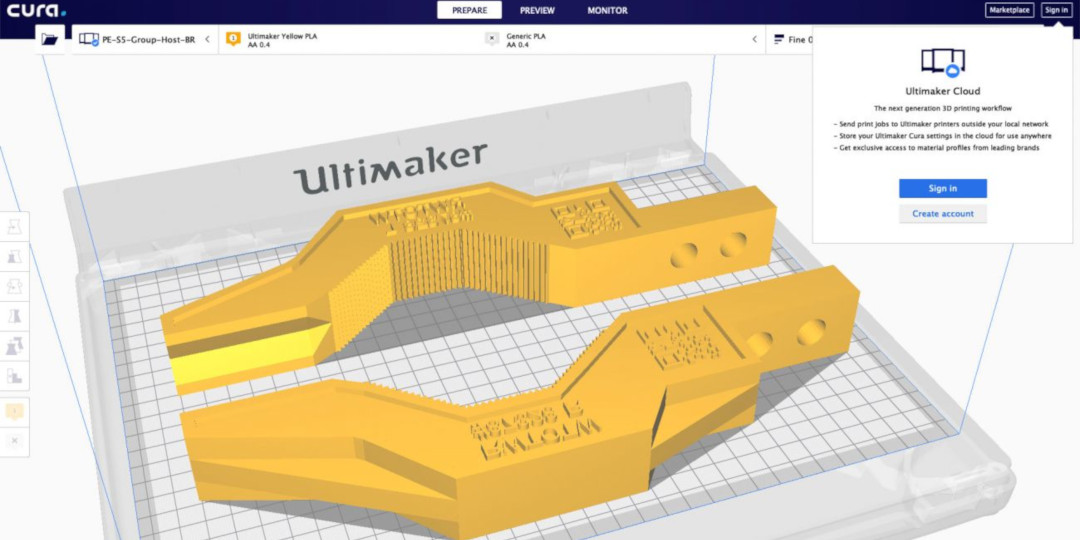

When you have a 3D model obtained in one way or another, you “run” it through the “slicer” program (from the English word “to slice”), which converts the original 3D model in STL format into print layers. The information received is eventually converted into a special data format called G-code for further printing on a 3D printer.

Such programs usually come with the 3D printer, or they can be freely downloaded, such as the Cura program. What these softwares have in common is that they create thousands of lines of code for layers. This code tells the printer how to print.

Next, you need to set up your 3D printer, select the print quality and the correct material settings. To start printing, you load your "sliced" part into the printer via a USB stick, SD card, or send directly from your computer. And the printer starts a slow additive layering process.

And the printer starts a slow additive layering process.

Photograph of Christian Rail from Pixabay

Materials used in 3D printing

The materials available for 3D printing have come a long way. Currently, there is a wide range of materials that differ both in properties, types, and in the states supplied (powder, threads, granules, resins, etc.).

Some materials are developed for specific applications to perform special tasks. For example, the medical sector, where special photopolymer resins (SLA 3D printing technology) are used, the properties of which make it possible to print implants, casts, and so on.

Some of the most commonly used materials:

- Plastics. Sintering (SLS) typically uses polyamides or nylon supplied in powder form. It is a strong, flexible and durable material. It is white in color, so it needs to be tinted before or after printing. The most common 3D printing technology today is FDM, which uses ABS or PLA plastic filaments.

These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS.

These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS. - Metals. More and more metals and metal composites are finding their way into industrial 3D printing. The most common of them are derivatives of aluminum and cobalt. Due to its strength characteristics, stainless steel is often used in powder form in 3D printing technologies such as sintering, melting, EBM. In the last couple of years, silver and gold have been added to the list of metals suitable for printing. This made it possible to significantly expand the possibilities of jewelry production.

- Ceramics. A relatively new group of materials used in 3D printing. The peculiarity of printing with these materials is that the printed ceramic parts must go through the same processes as ceramic products made by traditional methods - firing and glazing.

- Biomaterials. Currently, a large number of studies are being conducted aimed at exploring the possibility of 3D printing from biomaterials for the needs of medicine.

This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues.

This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues. - Food. Over the past few years, there has been an increase in experimentation with food 3D printing extruders. Chocolate printing is the most widely used. There are 3D printers that use sugar, pasta, meat, dough.

Photo of mebner1 from Pixabay

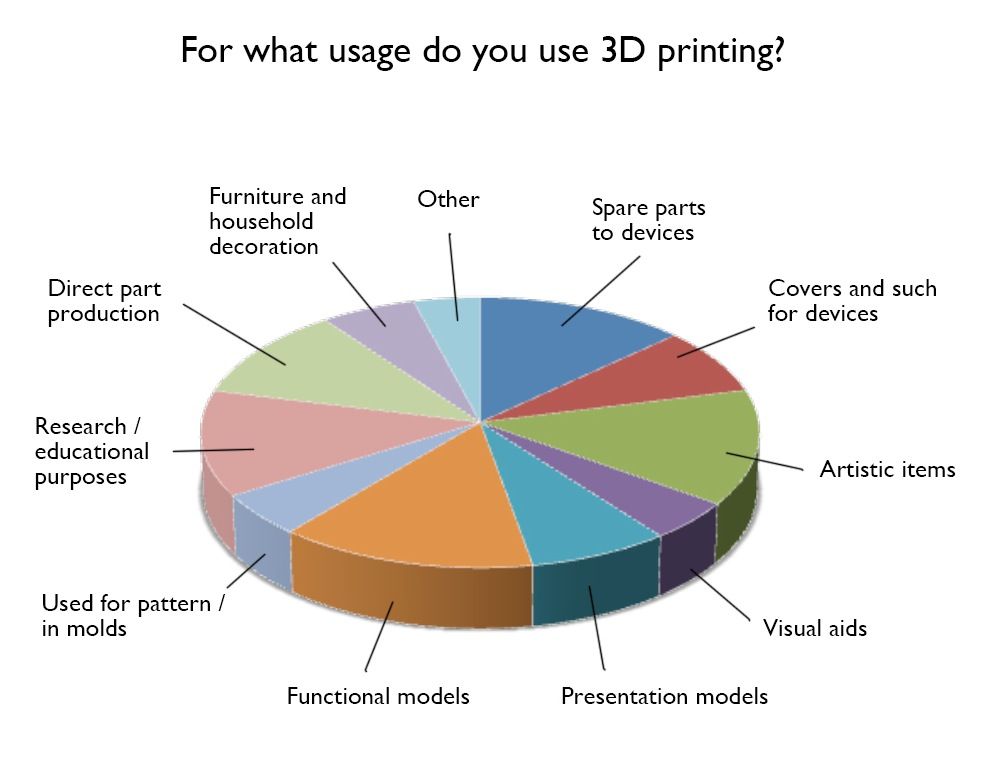

What 3D printing is used for

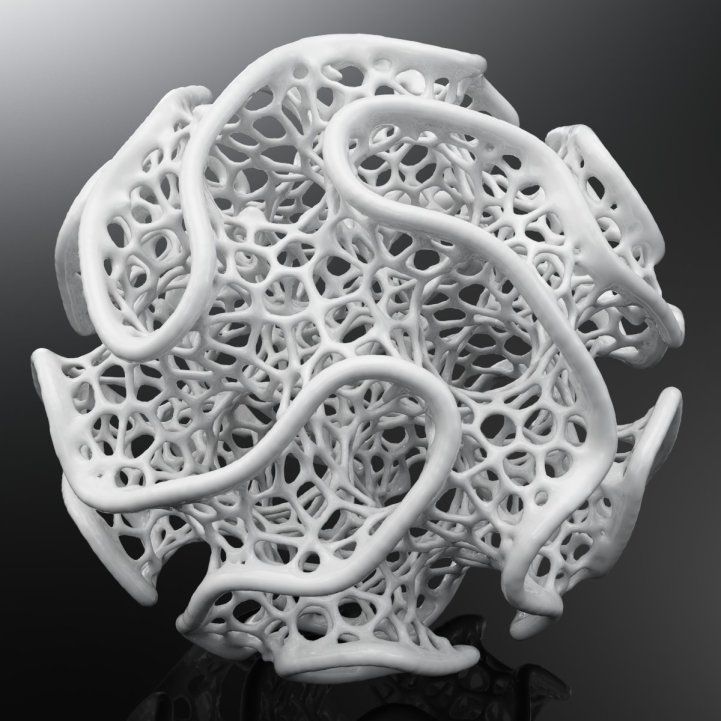

If you can think of an item, then most likely you can print it. Children's toys, jewelry, phone cases and much more are already being printed by enthusiasts on 3D printers. Some use 3D printing for fun. Fun projects already exist: a printed guitar, a loom, and an intricate sculpture created from a combination of laser-fused glass and nylon. 3D printing has already moved beyond its origins in plastic printing and has moved into the use of metal, rubber, wood, synthetic fabrics, and ceramic resins. Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future.

Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future.

Because additive manufacturing of complex objects is faster and cheaper than traditional molding and casting methods, it has found its way into industry and the arts. The possibilities of this technology are almost limitless, but 3D printers are not perfect machines. In addition to all the advantages, there are also reasons for concern.

Ethical issues in 3D printers

3D printers consume a lot of energy and emit ultra-light plastic particles into the air, which are then inhaled by humans. These harmful emissions can be compared to a cigarette lit indoors.

While humanity is trying to reduce the use and consumption of plastic, 3D printers are another technology heavily dependent on it. This presents a problem for all ecosystems, in particular for the already suffering oceans with their floating islands of plastic.

A few years ago, the news of the first 3D printed firearm caused a media frenzy. The creation of untraceable weapons by a private individual remains a modern security problem.

From a legal point of view, there is no clear answer to the question of who is liable in the event of harm to health caused by a printed object. Indeed, in most cases, the developer of a 3D model, the manufacturer of a 3D printer, and the one who printed it are different people or organizations. Determining liability for potential injury and death is a new challenge.

At the same time, the use of 3D printing technology in the medical field to print tissue raises a number of ethical and moral questions. These issues are similar to the talk of stem cell research and gene editing that has been going on for decades.

On the other hand, we have a powerful tool in our hands that is changing the way we create and produce things. We still don't fully understand what this means for our future.

Potential effect on the global economy

If 3D printing continues to develop at the same pace as it is now, then its use could potentially affect the global economy. The transition of production and distribution from the current model to localized custom manufacturing can reduce the imbalance between exporting and importing countries.

3D printing is creating new industries and new professions. Professions related to the production of 3D printers or, for example, a vacancy for a rapid prototyping technician at the Cartier jewelry house. New professional services are emerging, such as supply of materials, printer operator, legal services in dispute resolution and intellectual property issues. With the development of 3D printing technology, the issue of "piracy" becomes an urgent problem.

The impact of 3D printing on developing countries is a double-edged sword. The positive effect for such countries is the reduction in the cost of production through the use of recycled and other local materials. But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance.

But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance.

Where can I use a 3D printer

Owning a 3D printer with the necessary software and materials can still be expensive for individual needs, so public 3D printers are becoming more common.

There are places like labs and 3D printing shops. You can send your design and pick up the finished part in a couple of days. Some companies, such as ART AP Design Studio, also do 3D printing.

If you are a student or student, 3D printing services may be available at your school.

Printed products in Art-Up Design Studio

Where can I learn how to use a 3D printer

For those who already have the specialty of an engineer, there are advanced training programs (Additional education) from the Russian Academy of Crafts, designed for 36 or 72 academic hours.

The training course in an accessible lecture form reveals the theoretical and practical foundations of design, three-dimensional modeling, design of plastic products. It provides for the performance of work and tests within the framework of the design tasks of the course and the final exam.

As a result of mastering the program, the trainee receives a certificate "Specialist in Additive Technologies". Profession Code 15.02.09

If you are just starting out, you can find vocational training programs with 144 academic hours.

It is important to understand that the basic knowledge is obtained in practical exercises on real equipment. For example, you can get up-to-date skills using modern equipment at the SKOLKOVO Technopark at the production base of the CUC OOO Design Studio ART AP, which is the anchor partner of this educational program.

As a result of training, the student of the course "Specialist in additive technologies" independently solves the following professional tasks:

- modeling and design of plastic parts,

- fundamentals of aesthetics in the design of industrial products,

- features and types of 3D printing equipment,

- preparation of the model for 3D printing,

- setting up and launching a 3D printer,

- features of printing from various materials,

- post-processing of 3D printing results,

- Product assembly.

Investing in yourself is the most profitable and rewarding investment.

Nikita Pelevin, Alexey Kutyaev for the Russian Academy of Crafts

On the cover of the article ZMorph4D photo from Pixabay

What technologies underlie 3D printing?

The plethora of 3D printing methods currently on the market does not preclude continued ongoing research to develop more innovative technologies. Although the material differs depending on the printing method used, each technology has its own advantages. They are mainly related to the specific applications for which these printers are intended.

Overview of 3D printing technologies in use

The 3D printing technologies available today are grouped into three main families. These include printing by wire deposition or extrusion (FFF, FDM), the use of liquid photosensitive resin (SLA, DLP), and finally the use of powder or sintering (SLS, SLM, DMLS).

Fusion or extrusion printing allows you to create an object layer by layer. It involves the use of plastic thread. Placed on the printhead, the latter melts and deposits superimposed layers on the print bed.

As for the liquid photosensitive resin, it is cured by projector or laser. This operation, also known as polymerization, causes the object to be created to form inside the tray containing the resin. Stereolithography (SLA) is one of the technologies that regularly uses this printing process. ₽

An energy source - for example, a laser - melts the metal powder previously placed in the tank of a 3D printer. The term used for this type of printing is powder sintering or laser sintering. This is a technology with several options: SLS (Selective Laser Sintering) or SLM (Selective Laser Melting).

Molten filament printing

Two expressions are used to characterize this technology. The first, FDM, comes from English (Fused Deposition Modeling).

As for the second one, FFF, it stands for Fused Filament Fabrication. The term extrusion is another name for this 3D printing process. The consumables are plastic filament (PLA or AB).

A 3D printer has a print head, also called a nozzle. It is on this nozzle that the previously heated fiber is melted. The nozzle moves along two axes, x and y, parallel to the print platform, which moves in the vertical direction. Only after the first layer is completed, the print platform lowers along its axis.

Molten thread is applied layer by layer to create a 3D object. The fusion of the various layers is due to the rapid solidification of the molten plastic. As soon as the layers of plastic are stacked on top of each other, we get a designed object, the model of which is visible on the computer screen. Extrusion can also be carried out using an energy source such as a laser and by direct application of energy. This 3D printing mode, better known by its acronym DED (Directed Energy Deposition), can be found on some industrial printers. The material pushed out by the energy source then melts before being fused into an object.

The material pushed out by the energy source then melts before being fused into an object.

3D printing by polymerization of photosensitive resin

The use of SLA or DLP technology is typical for 3D printers using resin as a printing material. The process of their printing is polymerization. It refers to the curing of the photosensitive resin under the influence of a light source such as a laser or a light projector. The liquid resin in the printer tray hardens as a result of the reaction created by the light beams.

The print tray is located at the bottom of the tray that holds the liquid resin. A DLP projector or SLA laser emits light that hardens the resin from layer to layer. Finishing the layer allows the tray to sink further into the tray and so on until the object is made.

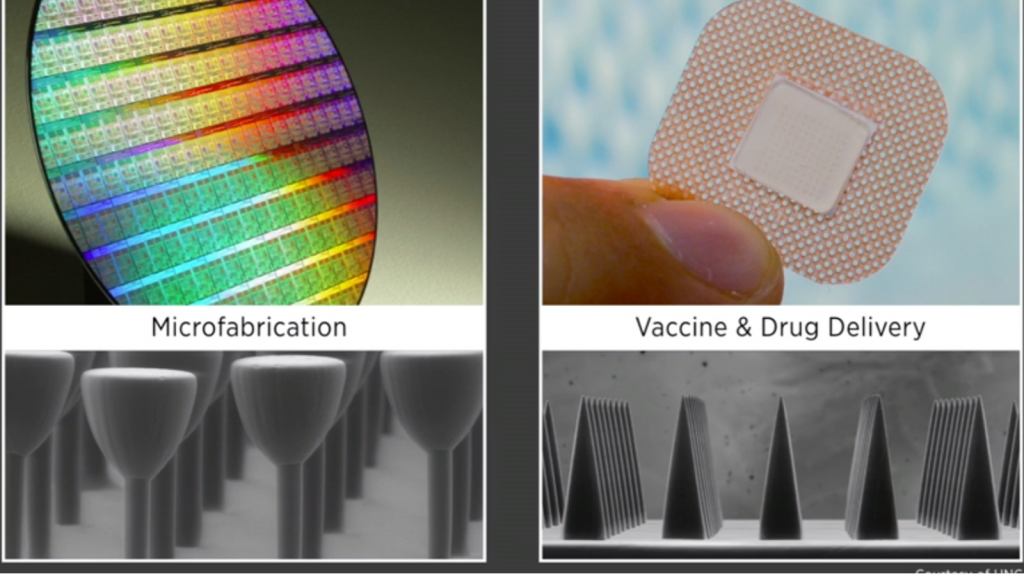

Having parts that require a high level of detail and resolution on the smooth side is a reason to use a 3D printer such as an SLA or DLP printer. Areas such as jewelry and medicine are the most common areas where this printing process is used. The production of molds intended for the manufacture of jewelry or dentures requires both precision and finesse.

Areas such as jewelry and medicine are the most common areas where this printing process is used. The production of molds intended for the manufacture of jewelry or dentures requires both precision and finesse.

Only resin polymerization makes it possible to distinguish between the two categories of SLA and DLP printers. On a DLP printer, the resin hardens layer by layer. In an SLA printer, on the other hand, it solidifies point by point. In addition, a DLP printer uses a projector, while an SLA printer uses a laser to print.

3D powder melt printing

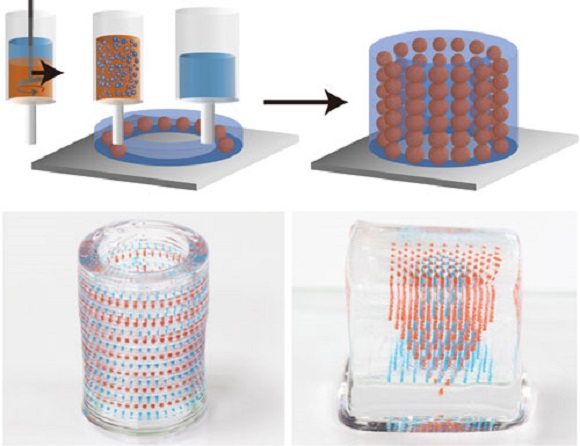

Four technologies use this 3D printing process. These are powder sintering and melting, material grinding, paper lamination and, finally, 3D bioprinting.

The use of metal powder as printing material is common in the industrial sector. Selective laser sintering or selective laser melting are two 3D printing technologies that use powder. In the field of aviation, for example, this technology allows the production of highly complex parts intended for use in aircraft.

Spraying or inkjet printing of material is a printing process in which molten material is deposited on a printing platform. The object is formed by the layer-by-layer solidification of the previously melted material. Multi-Jet Modeling (MJM) is another name for this printing method.

3D printing technology known as lamination uses paper or aluminum foil as the material. Objects produced using this technique are distinguished by the perspective of details and colors. The decoration and toy manufacturing sector are those who regularly use this technology.

The creation of living cells or organic tissues is the field of bioprinting experiments. This scientific process represents a real revolution in the field of medicine. Ultimately, bioprinting aims to produce functional organs or living tissues. While this technology is at the experimental stage. 3D bioprinters with this printing ability are not yet a reality. However, if they existed, such machines would make it possible to create organs and treat many pathologies.