3D printing rock hill sc

Careers at 3D Systems | 3D Systems

Why 3D Systems?

Meaningful work, passionate and bright people, and a company that supports your life from day one. There’s a lot to explore at 3D Systems, we hope you’ll join us.

Be part of a team with brainpower, heart, and grit.

We have a diverse team with some of the world’s most dynamic and forward-thinking talent. Not only do we have the brainpower, we have people with heart, grit and a ton of curiosity. And the cornerstone of our work is to lead, explore, and innovate with the utmost integrity.

Be you, at your best.

We care about treating people right and we know that life is more than work. This is why we approach rewards and benefits at a personal level so that you have the resources you need to take care of yourself and be you, at your best. See a few of the rewards and benefits we offer.

Write your own story.

-

E-Verify

3D Systems participates in E-Verify ENGLISH/SPANISH (PDF)

Right to Work (English)

Right to Work (Spanish)

Equal Employment Opportunity

3D Systems is an Equal Opportunity Employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, or status as a protected veteran.

EEO is the Law

3D Systems Employment Opportunity, Anti-Discrimination, & Anti-Harassment Policy

Pay Transparency Nondiscrimination Provision

-

Accessibility and Accommodations

In compliance with the ADA Amendments Act, if you have a disability and would like to request an accommodation in order to apply for a position with 3D Systems, please call 803-326-3933.

Federal Employment Laws

Applicants have rights under Federal Employment Laws:

Family and Medical Leave Act (FMLA)

Employee Polygraph Protection Act (EPPA)

3D Systems commitment to gender equality in the workplace 2021 – Phenix Systems, Riom-France

Equality in the workplace means ensuring the absence of any discrimination within a company.

The challenge for any company is to achieve true equality between men and women at work, in particular through action against day-to-day sexism at work, equal pay, gender parity at management level, and a gender-balanced workforce.

The challenge for any company is to achieve true equality between men and women at work, in particular through action against day-to-day sexism at work, equal pay, gender parity at management level, and a gender-balanced workforce. Under the law on freedom of choice in professional careers, the index uses five indicators for companies to monitor their commitment to workplace gender equality. These are:

- Equal Pay

- Pay Increase between the genders

- Promotions of each gender

- Pay increase when returning from maternity leave

- Number of woman amongst the 10 most highly paid employees in the company ( in France)

For 2021, 3D Systems has achieved 60/100.

Link to the gender equality website: https://www.gouvernement.fr/index-de-l-egalite-femmes-hommes-comment-ca-marche

3D Printing Service Rock Hill, SC | Instant Quotes Online

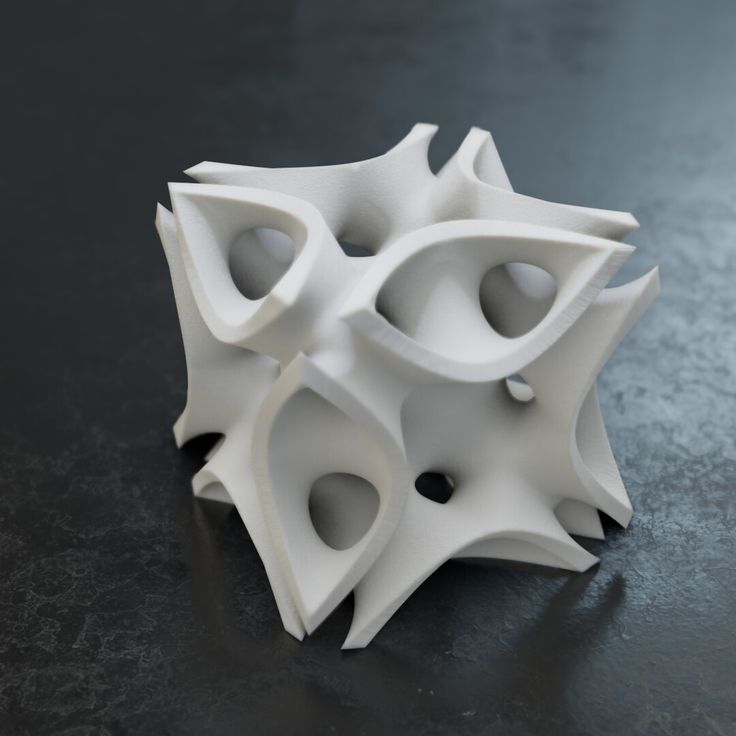

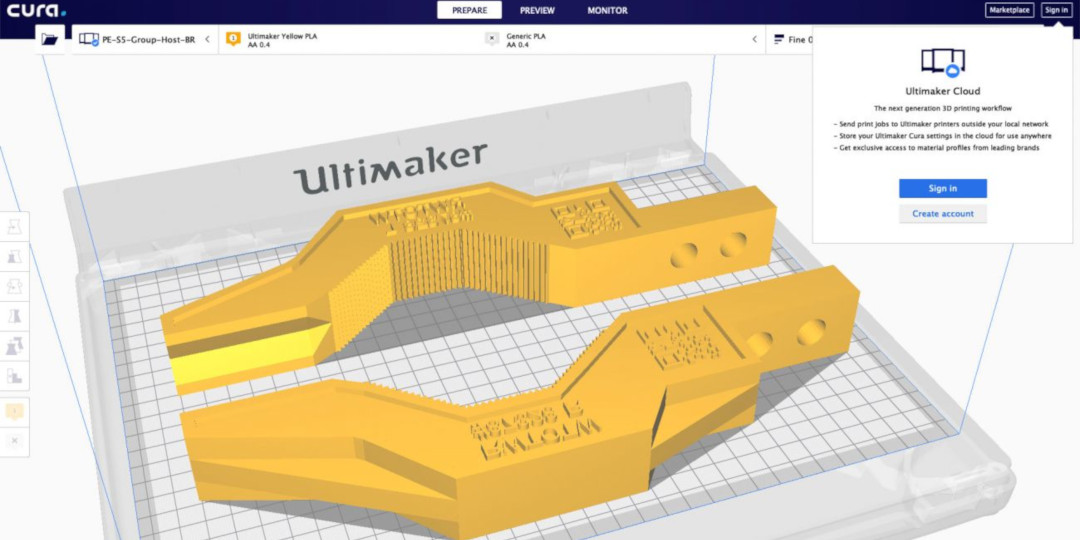

Our 3D printing capabilities

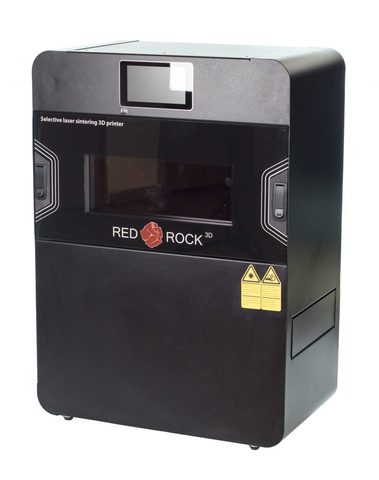

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

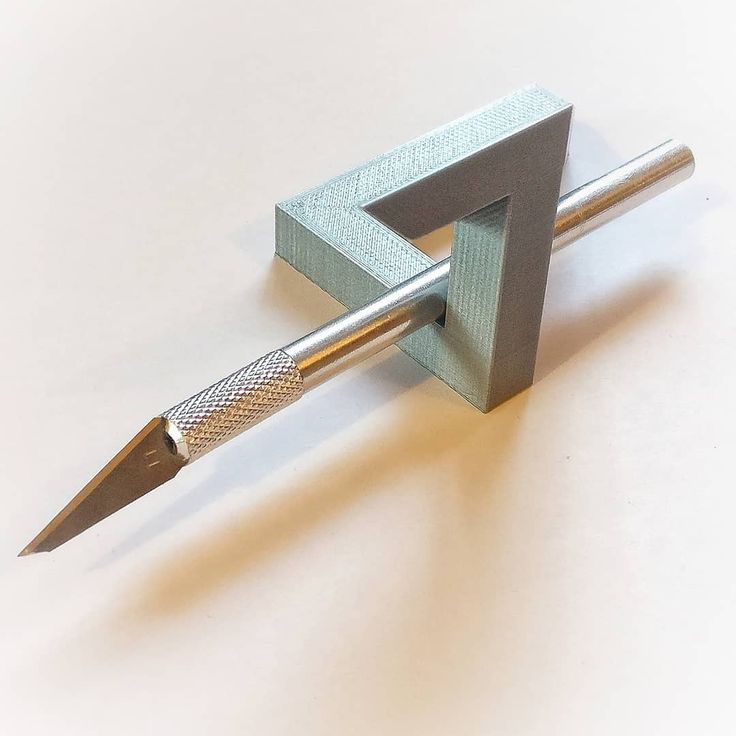

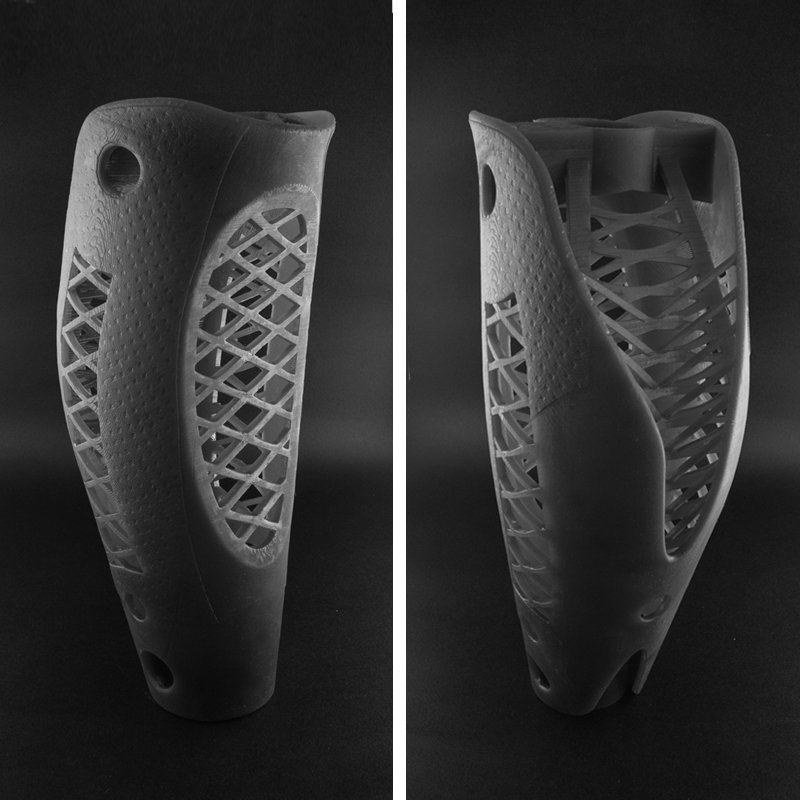

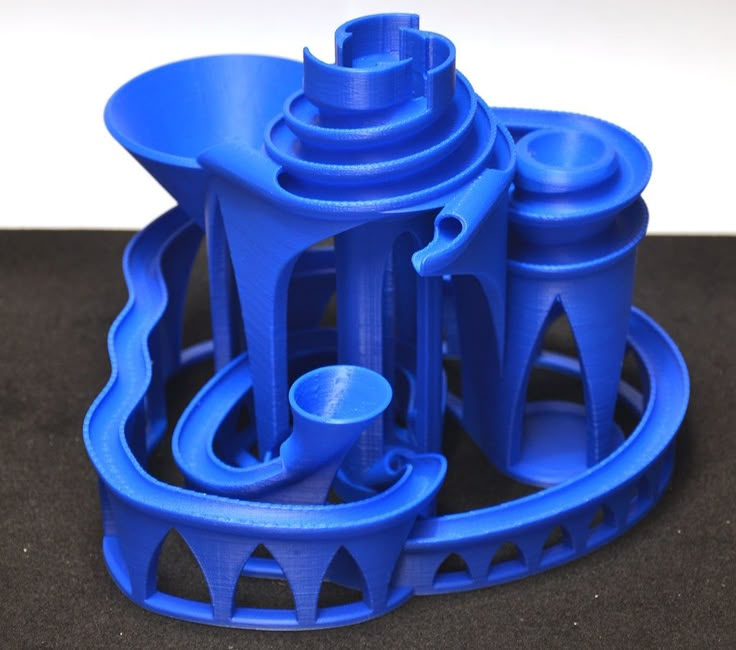

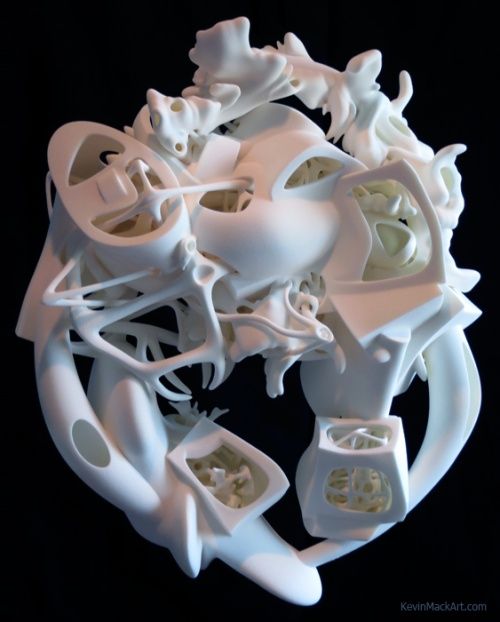

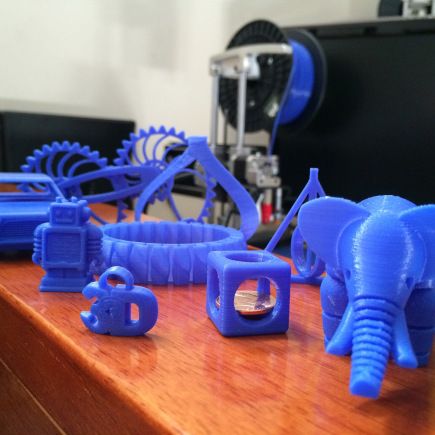

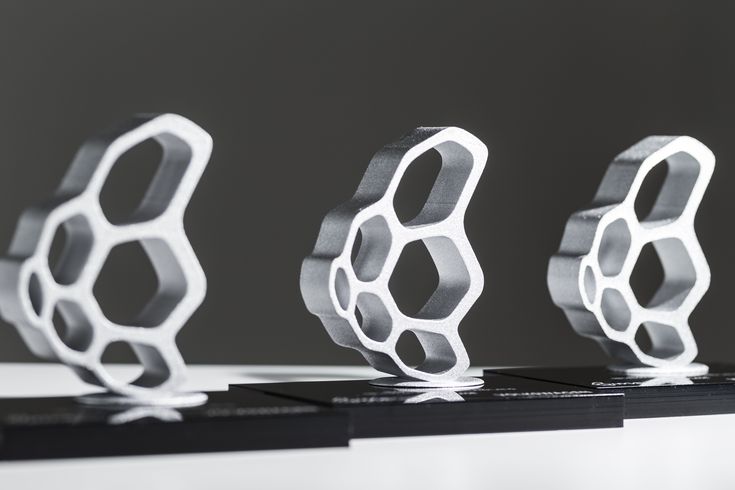

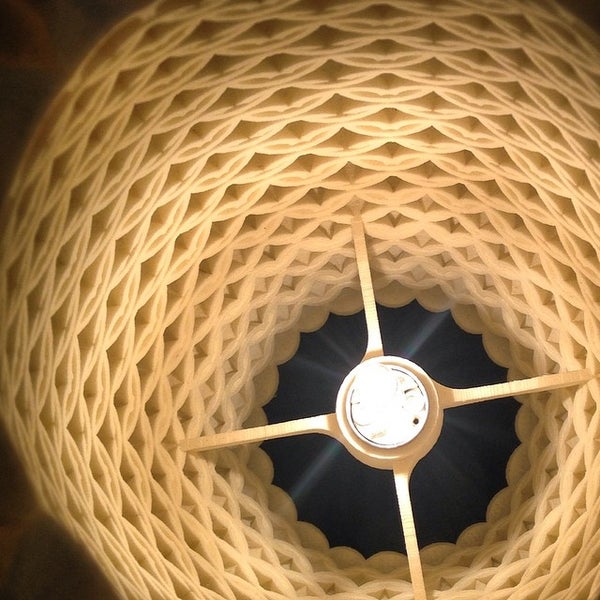

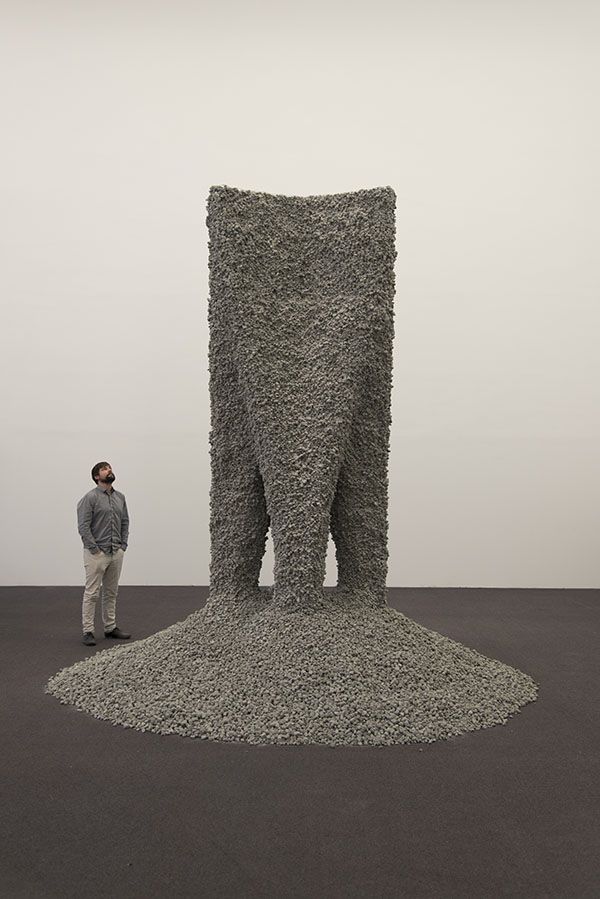

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

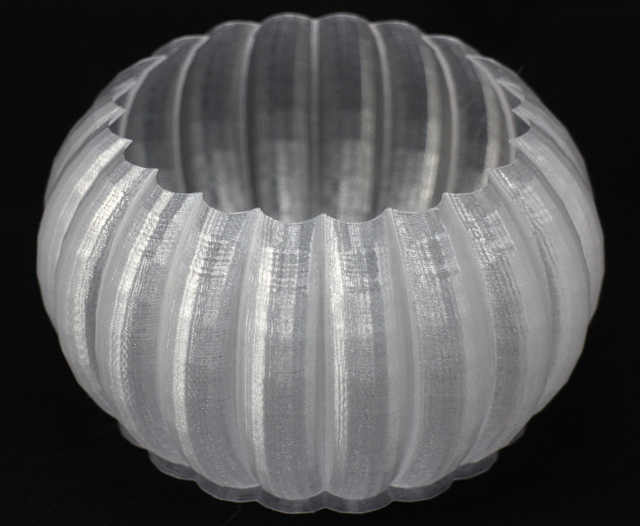

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

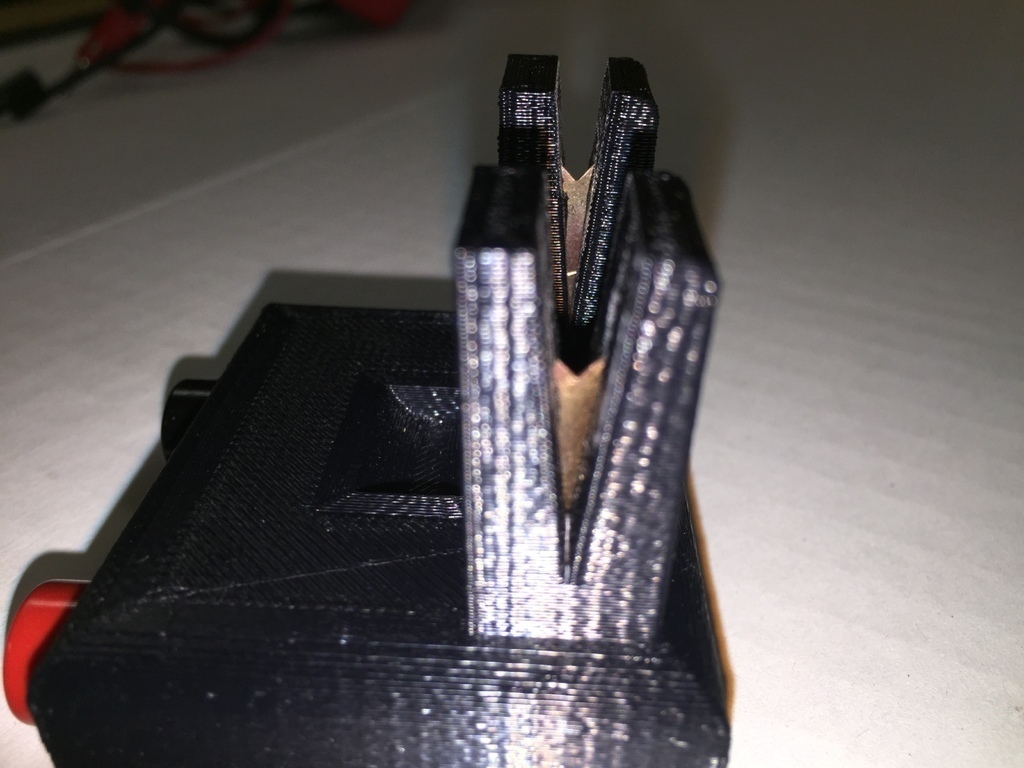

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 293 customers are satisfied with our 3D printing service.

“Super quick response time, very helpful and knowledgable. Received my parts very quickly and exactly as ordered, no complaints at all!”

“another great work from David - thank you”

“Great part, price, and communication was superb! Our company's go to for polyjet prints.”

“Part was made quickly and quality was excellent ”

“Looks Great !! Thanks for the timely response and high quality.”

“Good communication, quick service, good print. Thanks!”

“Super great job! and I'm so sorry about being late confirming the order delivered. I've been super busy. ”

“Great job, with fast professional responses.”

“Very pleased with the results. Thanks for a great transaction.”

“Prints are in excellent quality and were printed and shipped same day.”

“Parts arrived perfect and ahead of schedule!”

“The parts look great - thanks for completing this for me!”

“Fast turnaround, and parts turned out great.”

“Very happy with the print quality and service. ”

”

“The parts look great. Thanks for the extra effort in shipping to meet my schedule. I appreciate it!”

“I greatly appreciate your promptness and quality of your print. This design is being used as a cell phone holder installed into the console of my Nissan 370Z, whereas otherwise, this car has no other practical place to hold a cell phone. The new install looks like an OEM feature of the console and adequately provides for the intended purpose. Thank you sincerely for your professional service.”

“Great job! Definitely recommend you for anyone needing printing done!”

“Super happy with the quality and speed of service. I will definitely be using your company for all of my 3D print needs in the near future. ”

“Excellent work! Printing parts this thin is not easy. Highly recommended. Thanks!”

“Great hub, quick service and helpful information.”

“Everything went well. Great service for my first try on your site.

I will be taking a look a the 3D Printing Handbook next. Very quick turn around time.

thank you again, Jeff”

Very quick turn around time.

thank you again, Jeff”

“Great service and way faster than expected!”

“Good quality prints, would be willing to use again”

“Order was completed early and as expected!”

“Quick turn-around for a prototype! Very affordable! Will use again!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

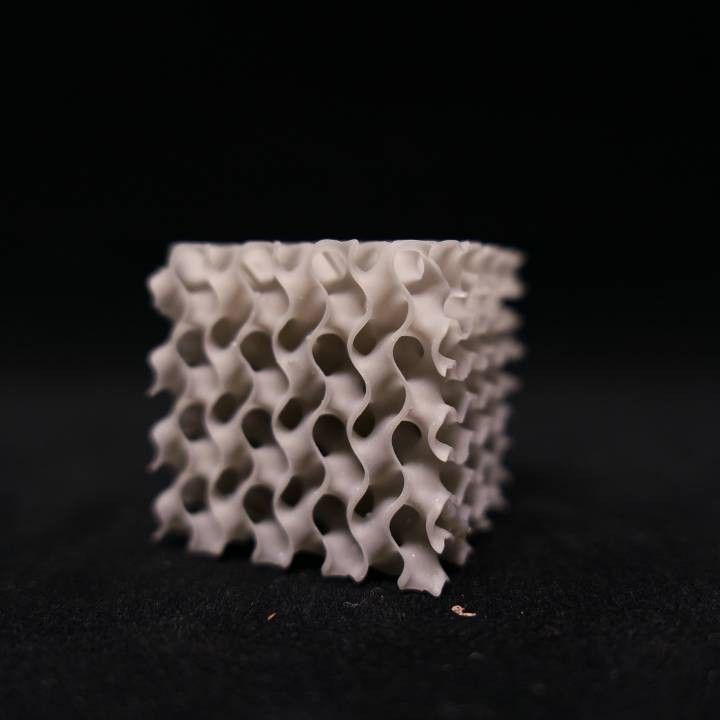

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Rock Hill, SC

Rock Hill, SC Charlotte, NC Gastonia, NC

Huntersville, NC Concord, NC Hickory, NC

Spartanburg, SC Columbia, SC Sumter, SC

Mauldin, SC

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Largest listed companies in the 3D printing sector

3D printing dates back to the late 1980s. At the end of 2018, the size of the 3D printing market, according to various estimates, reached from $9 trillion to $10 trillion. Calculations were made based on the cost of producing printers, components and 3D printing.

At the end of 2018, the size of the 3D printing market, according to various estimates, reached from $9 trillion to $10 trillion. Calculations were made based on the cost of producing printers, components and 3D printing.

In the coming years, expert agencies (IMARC, Inkwood Reasearch, Marketwatch, etc.) predict a steady growth of at least 20% per year. In this scenario, by the end of 2025, the scale of the entire 3D printing segment will reach at least $ 32 trillion - 3.5 times higher than the current values.

The outlook for the sector makes it attractive to investors. Consider the largest and most stable companies in this segment, whose shares can be considered for purchase and take their rightful place in your portfolio.

1. HP Inc Capitalization: $29.3 billion

HP manufactures computers, printers, tablets and a number of other devices. The release of 3D printers is not the main specialization of the company, but HP occupies one of the leading positions in the 3D printing segment. In 2014, the company developed the Multi Jet Fusion technology, which allowed to increase productivity and reduce the cost of professional (industrial) 3D printers. The technology has been successfully applied in mass production of printers since 2016.

In 2014, the company developed the Multi Jet Fusion technology, which allowed to increase productivity and reduce the cost of professional (industrial) 3D printers. The technology has been successfully applied in mass production of printers since 2016.

In 2017, HP opens the world's first 3D lab, equipped with printers in various build states and essential tools for device experimentation. The company has opened up the first opportunities to test new materials in 3D printers to increase efficiency.

In 2018, HP will open a joint manufacturing center with China's Guangdong in Guangdong, China, which is the largest such 3D printing project in Asia Pacific and Japan. The facility is equipped with ten high-tech next-generation HP Metal Jet printers to produce parts and prototypes for industrial customers.

2. Proto L abs (NYSE: PRLB). Capitalization: $2.56 billion

The company was founded in 1999 and has more than 10 production sites in seven countries. The head office is located in Minnesota. The company specializes in the production of parts for other manufacturing companies. The corporation positions itself as the fastest in the world in the production of custom prototypes and finished parts for industrial customers. In 2014, Proto Labs launched 3D printed parts.

The head office is located in Minnesota. The company specializes in the production of parts for other manufacturing companies. The corporation positions itself as the fastest in the world in the production of custom prototypes and finished parts for industrial customers. In 2014, Proto Labs launched 3D printed parts.

In addition to 3D printing, the company produces CNC (Computer Numerical Control) parts, injection molding and sheet metal parts. In 2015, Proto Labs bought Alphaform (specializing in innovative 3D printing) with divisions in Germany, Finland and the UK. This allowed the company to expand its 3D printing business in Europe. To diversify its business and introduce sheet metal manufacturing, the company acquired Rapid Manufacturing in 2017 for $120 million. 9 Systems ( NYSE: DDD). Capitalization: $1.01 billion

3D Systems was founded by inventor Chuck Hull in 1986 as the world's first 3D printing company. It produces 3D printers and components, including software, and also designs them. The company provides services at various stages of design, development and production of products for many large industries, including aerospace, automotive, medical, entertainment and other areas. It should be noted that the corporation also works with retail consumers. Business diversification within the 3D segment makes the company financially stable.

It produces 3D printers and components, including software, and also designs them. The company provides services at various stages of design, development and production of products for many large industries, including aerospace, automotive, medical, entertainment and other areas. It should be noted that the corporation also works with retail consumers. Business diversification within the 3D segment makes the company financially stable.

3D Systems is headquartered in Rock Hill, South Carolina, USA. The number of employees of the company exceeds 2600 (as of the end of 2018), which is twice as high as five years ago.

4. Stratasys ( NASDAQ: SSYS). Capitalization: $0.98 billion

The company was founded in 1989 by Scott Crump. The technology was based on the idea of creating the shape of a figure by layering after Scott decided in 1988 to make a toy for his daughter using a gun filled with glue. At 1992 Stratasys released its first 3D Modeler product.

Today, Stratasys manufactures industrial and desktop 3D printers and related accessories. The range of services includes installation, maintenance and training in working with printers. The company serves various industries by developing technologies for the production of prototypes and parts. The first public offering of Stratasys shares took place in 1994 at $5 per share and a total volume of $5.7 million. The head office is located in Minnesota.

5. Materialize Capitalization: $0.88 billion

Incorporated in 1990 in Leuven, Belgium, Materialise specializes in 3D printing services and 3D printer software. Like other leaders in this sector, Materialize works with various major manufacturers around the world (Adidas, HP), but a significant share of the business is in cooperation with medical centers and institutions. The company's portfolio includes more than 150 medical patents. Materialize offices are located in 18 countries, including one office located in the CIS in Ukraine.

Issuer Comparison

The most valuable company among the leaders is HP, which is due to the scale and diversification of the company's business in the entire technology segment. 3D Systems, Stratasys and Materialize specialize exclusively in the 3D printing segment, while their capitalization is on the same level. Proto Labs has three businesses besides 3D printing and is in the middle of our list in terms of capitalization.

The most undervalued company in terms of EV/EBITDA is HP, but it is not correct to compare it with other issuers by this multiplier due to the differentiation of the company's products and services. 3D Systems has the highest EV/EBITDA, and from this point of view, the paper is not so attractive to buy. Moreover, over the past four years, 3D Systems shares have been in a stable sideways trend without technical prerequisites for growth.

The remaining three companies, in our opinion, may be of interest. At the same time, if your long-term goal is to get the maximum increase from the growth of the 3D printing sector, then investing in HP shares is less preferable compared to other securities. After all, the reaction of the shares of companies with a direct specialization is more sensitive to changes in the sector. Below are the consensus forecasts of investment houses according to Reuters, according to which Stratasys (14.9%) and Materialize (13.6%) shares have the greatest potential now.

After all, the reaction of the shares of companies with a direct specialization is more sensitive to changes in the sector. Below are the consensus forecasts of investment houses according to Reuters, according to which Stratasys (14.9%) and Materialize (13.6%) shares have the greatest potential now.

HP Inc (NYSE: HPQ): $20.5 (+3.4%)

Proto Labs (NYSE: PRLB): $98.7 (+3.0%)

3D Systems (NYSE: DDD): $8 .6 (+0.6%)

Stratasys (NASDAQ: SSYS): $20.8 (+14.9%)

Materialize (NASDAQ: MLTS): $19.2 (+13.6%)

OPEN ACCOUNT

BCS Broker

Overview of 3D printer manufacturers

3D printing appeared in the late 1980s, but 2020 became a breakthrough year for the technology. The pandemic disrupted supply chains, and it was 3D printing that made it possible to quickly obtain the necessary items and spare parts, ranging from consumables for hospitals and clinics to parts for medical, industrial and other equipment.

The prospects and pace of development of the sector in recent years have significantly increased its investment attractiveness, however, there are certain risks that should not be discounted.

Vadim Kizimov

private investor

Author profile

Buy

Buy

Buy

Buy

Service in partnership with Investment. Quotes are updated every 15 minutes

Technology Brief

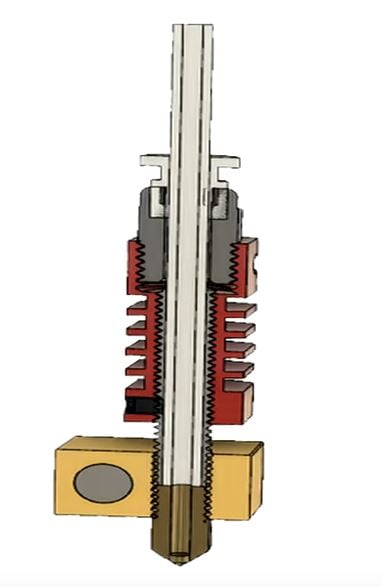

3D printing is the process of converting a model developed on a computer into a real three-dimensional object. Printing occurs due to the successive layering of thin layers of material. These are mainly thermoplastics of various types, but ceramic, biocompatible and other composite mixtures can also be used. That is why this technology is called additive.

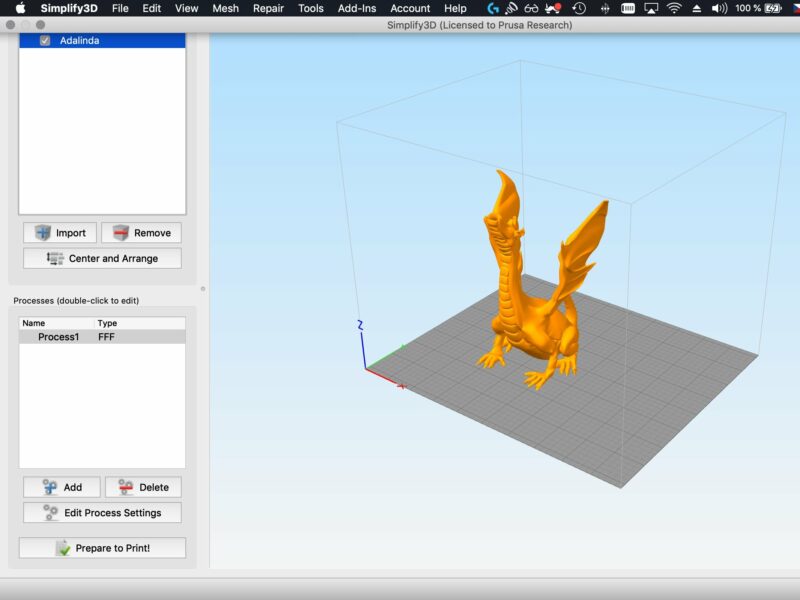

3D printing technologies differ depending on the materials and equipment used, but the general scheme of the process is always the same:

- A virtual layout of the object is created on the computer, and in order to make a model, you do not need to have 3D modeling skills.

A special scanner photographs a real object from different angles, creating a digital copy of it.

A special scanner photographs a real object from different angles, creating a digital copy of it. - The program makes slicing - splits the model into many thin horizontal layers.

- The template is loaded onto the 3D printer, the device reads the diagram and prints it layer by layer in volumetric form.

Application

Using a 3D printer, you can copy any object or create your own. The possibilities for additive printing are almost limitless. Now the technology has already found application in various industries:

- health care: the creation of orthopedic orthoses, dentistry, transplantology, the manufacture of prostheses;

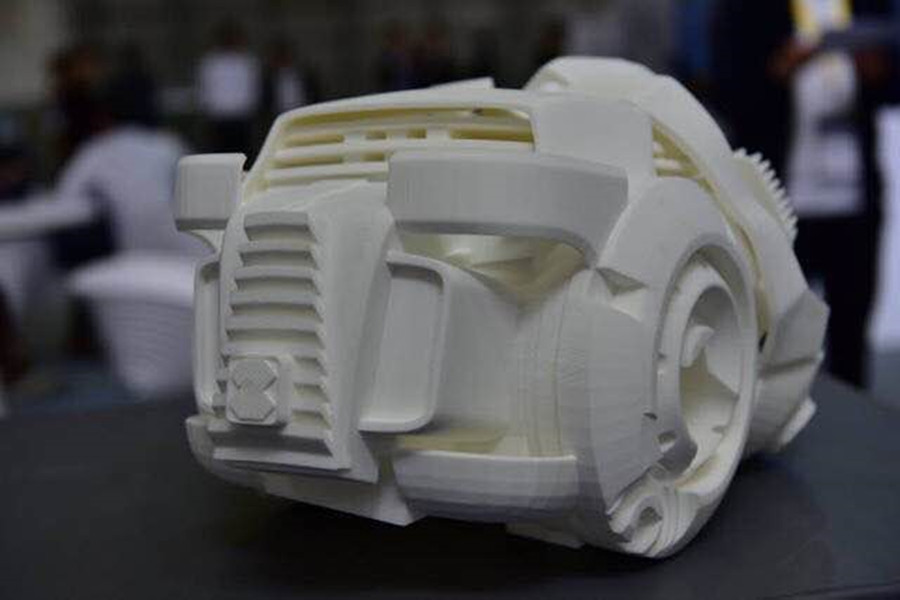

- industrial production: parts of machine tools and equipment;

- space, aviation and automotive industries;

- robotics;

- construction: models of buildings or individual structural elements;

- food production: figured chocolate, jellies and other desserts;

- household items: from smartphone cases and collectible figurines to shoes and interior items;

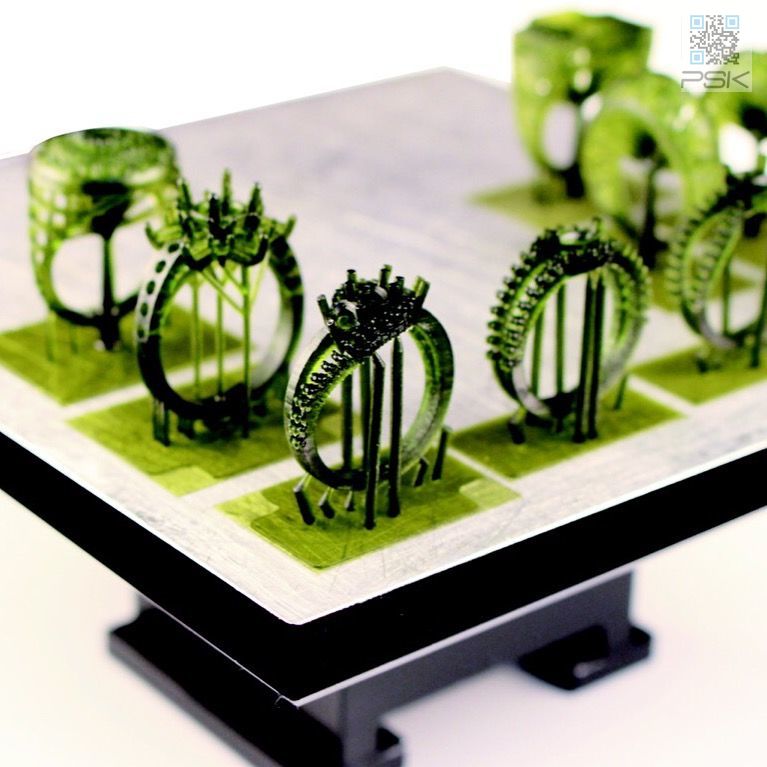

- jewelry.

At the moment, additive technologies are most in demand in medicine — 3D printing makes it possible to create consumables, prostheses, orthoses, mouth guards, and even absolutely accurate models of human organs — and in industrial production when creating parts and equipment elements.

But the scope of 3D printing is constantly expanding, opening up new opportunities for both large companies and small start-ups.

Industry Prospects

While 3D printing is not yet able to achieve fast and large-scale results, the technology has proven itself in areas that require precision and uniqueness.

The increased availability of equipment and the absence of the need for long training of personnel to work with 3D printers also played a role. Over the past six years, the number of global and specific industries that use 3D printing technology has increased, and this market is truly limitless:

- large companies or organizations may refuse to purchase the necessary consumables or parts, producing them on their own in the volumes they need;

- the role of additive printing in medicine has already been mentioned above, and there are also broad development prospects here;

- 3D solutions lower the barrier to entry for new players.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity.

Now, to launch your own production, there is no need to rent a room and purchase sophisticated equipment. For example, niches for creating custom car tuning parts, collectible figurines for computer game fans or unique gifts have just begun to open and have already begun to gain popularity.

At the end of 2021, the value of the additive printing market was $15 billion, calculations were based on the cost of 3D printing and the production of printers and components. In the coming years, the expert agency Business Insights predicts an annual growth of the segment by more than 24%. At this pace, by the beginning of 2029, the size of the 3D printing market will grow at least five and a half times.

Technology deficiencies and risks of companies

Despite the prospects for the development of 3D technologies, 3D printing cannot yet be unequivocally called a profitable industry. There are a number of difficulties that do not allow you to fully rely on additive technologies.

Still high cost of equipment. Cheap 3D printers can print small objects. To create parts of large dimensions, it is necessary to purchase expensive equipment, which may turn out to be unprofitable.

Poor performance. This disadvantage should be considered in conjunction with the previous one: now the speed and cost of 3D printers do not allow them to be used in mass production, making a tangible profit.

Insufficient strength of manufactured parts. The layered structure is more brittle in the direction of the layers than the monolith and cannot withstand heavy loads.

Lack of stability. The use of additive technologies on an industrial scale requires equipment and materials that can provide higher production reliability. At the moment, 3D printing is most often used for prototyping, quality control, or for the production of single parts.

The need for post-processing , which increases the cost and time of production of each unit.

Unpredictability. Additive manufacturing is constantly evolving, new materials and printer models are emerging, and there is always a risk that equipment that has been heavily invested in will suddenly become obsolete.

3D printing companies on the St. Petersburg Stock Exchange

There are quite a few companies associated with 3D printing on the St. Petersburg Stock Exchange, and it is not their main activity. This industry is so young that at the moment it does not even have a benchmark significant index.

But the global trend of increasing demand for additive technologies in various areas of life can open up new prospects for industry pioneers.

Proto Labs (NYSE: PRLB). Capitalization - 2.56 billion Proto Labs was founded in 1999 in Minnesota, and by 2022 it already has more than ten branches in seven countries of the world. The company specializes in the creation of prototypes and finished parts for individual orders. In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity.

In this niche, Proto Labs is one of the largest and fastest manufacturers: it takes only a few days to create a part of any complexity.

Since 2014, Proto Labs has been using additive technology for manufacturing parts. In total, the company operates in four areas:

- Injection molding, revenue growth +4% year-on-year.

- CNC machining, +41%.

- 3D printing, +17%.

- Sheet metal production, +24%.

While 3D printing still only accounted for 14.8% of the company's revenue as of the end of 2021, the technology's growth trends may bring more tangible profits in the future.

Source: Tinkoff Investments Source: Tinkoff Investments3D Systems Corp (NYSE: DDD). Capitalization - 1.88 billion. The company was founded in 1986, headquarters - in Rock Hill, South Carolina.

3D Systems manufactures and sells equipment, software and materials for additive manufacturing. Most often, the company's products are used in the aerospace, automotive, semiconductor and healthcare industries.

In 2021, 3D Systems announced two separate acquisitions. The company has agreed to acquire Titan Additive LLC, a developer and manufacturer of large-format industrial 3D printers, and Kumovis, a German provider of additive manufacturing solutions for personalized medical applications.

After the announcement of the results for the fourth quarter of 2021, the company's quotes increased by 15%. This positive reaction was driven by double-digit revenue growth of 13.1% yoy, excluding sales of part of the business. In addition, 3D Systems reduced its net loss by almost three times, and the revenue forecast for 2022 was increased by 10%.

Source: Tinkoff Investments Source: Tinkoff Investments Align Technology (NYSE: ALGN). Capitalization - 32.4 billion American company Align Technology is a manufacturer of medical equipment for dentistry and orthodontics. The patented Invisalign bite treatment system is based on the use of transparent removable orthodontic caps, which are printed on a 3D printer individually for each client.

The company is headquartered in Silicon Valley and has a rapidly growing branch network covering Russia, Mexico, Costa Rica, the Netherlands, Australia and Japan.

Digital orthodontics is rapidly evolving, and Align Technology is not going to give up just yet. The percentage structure of revenue for 2021 is distributed as follows: 80% - sales of Invisalign products, 20% - sales of intraoral scanners and other dental equipment.

Source: Tinkoff Investments Source: Tinkoff InvestmentsHP Inc. (NYSE: HPQ). Capitalization - 39.7 billion. The company does not specialize in the production of 3D printers, but is still one of the leaders in the additive printing market.

In 2014, HP developed Multi Jet Fusion 3D powder printing technology to lower the price and speed of industrial 3D printers, and two years later, the first HP Multi Jet Fusion models went on sale.

In 2017, Hewlett Packard introduced the world's first 3D lab for testing various types of additive printing raw materials. And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products.

And in 2018, it announced Metal Jet technology for 3D printing of industrial quality metal products.

HP Metal Jet Printer delivers 50 times the performance and significantly lower cost of finished parts than other technologies.

On April 7, 2022, investors were shocked by the news that Warren Buffett had bought $4.2 billion worth of shares in the company. Immediately after the announcement of the deal, HP shares grew by 14.75%.

Compare companies by multiples, growth rates, and R&D spending.

Source: Tinkoff Investments Source: Tinkoff InvestmentsCompany multiples

| Capitalization, billion dollars | P/E | Forecast P/E | P/S | Debt to equity | |

|---|---|---|---|---|---|

| PRLB | 2.56 | 38.00 | 28.00 | 2.81 | 0.01 |

| ALGN | 32.40 | 41.00 | 32.00 | 8.18 | 0.04 |

| DDD | 1. 88 88 | 5.30 | 5.00 | 2.88 | 0.60 |

| HPQ | 39.70 | 6.80 | 8.70 | 0.69 | −3.58 |

Capitalization, billion dollars

PRLB

2.56

ALGN

32.4 DDD 9008

39,7,000

Algn

32

HPQ

8.7

PRLB

2.81

Algn

8,18

DDD

2.88

HPQ

0.69 9000 9000 DEBT TO equity

PRLB

0.01

Algn

0.04

DDD

0.6

HPQ

−3.58

REPARY PRODUCTIONS, million dollars

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | 458 (+2.69%) | 434 (−5.24%) | 488 (+12.44%) |

| ALGN | 2406 (+22%) | 2471 (+3%) | 3952 (+60%) |

| DDD | 636 (−8%) | 557 (−12%) | 615 (+10. 4%) 4%) |

| HPQ | 58,760 (+1.3%) | 56,630 (−3.62%) | 63,000 (+11.25%) |

2019

458 (+2.69%)

2020

434 (−5.24%)

2021

488 (+12.44%)

2019

2406 (+2222 %)

2020

2471 (+3%)

2021

3952 (+60%)

2019

636 (−8%)

2020

557 (−12%)

2021

615 (+10.4%)

2019

58 760 (+1.3%)

2020

56 630 (−3.62%)

2021

63 000 (+11.25%)

Help growth, million dollars

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | 63 | 50 | 35 |

| ALGN | 442 | 1775 | 772 |

| DDD | −69 | −149 | 322 |

| HPQ | 3152 | 2884 | 6503 |

2019

63

2020

50

2021

35

2019

442

2020

1775

2021

772

2019

−69

2020

−149

2021

322

2019

3152

2020

2884

2021

6503

R&D costs, as a percentage of revenue

| 2019 | 2020 | 2021 | |

|---|---|---|---|

| PRLB | 7. 2% 2% | 8.5% | 9.0% |

| ALGN | 6.5% | 7.1% | 6.3% |

| DDD | 13.1% | 13.3% | 11.2% |

| HPQ | 2.6% | 2.6% | 3.0% |

2019

7.2

2020

8.5

2019

6.5

20200003

7.1

2021

6.3

2019

13.1

2020

13.3

2021

11,2,2

2019

9000

2020 9,0003

2.6

Summarizing the data, several conclusions can be drawn:

- All companies are profitable, with the exception of DDD, which received a one-time profit in 2021 through the sale of non-core assets.

- ALGN and PRLB have the lowest leverage.

- All companies are growing.

- DDD has the highest R&D spending, while the company has the lowest revenue growth rate. Investors should pay attention to this.

Bottom line

Modern 3D printers can significantly reduce the time and cost of solving geometry control and reverse engineering problems in the automotive, aviation, mechanical engineering, shipbuilding, jewelry and medicine industries.