Big bang 3d printer

"The Big Bang Theory" The Cooper/Kripke Inversion (TV Episode 2013)

The Big Bang TheoryS6.E14

All episodesAll

- Cast & crew

- User reviews

- Trivia

IMDbPro

- Episode aired Jan 31, 2013

- TV-14

- 20m

IMDb RATING

7.8/10

3.3K

YOUR RATING

Play clip0

:

48

Watch The Cooper Kripke Inversion

1 Video

8 Photos

ComedyRomance

Sheldon is forced to work with Kripke on a project and must concoct an elaborate lie when he can't hold up his end of the work. Howard and Raj get superhero figurines made of themselves.Sheldon is forced to work with Kripke on a project and must concoct an elaborate lie when he can't hold up his end of the work. Howard and Raj get superhero figurines made of themselves.Sheldon is forced to work with Kripke on a project and must concoct an elaborate lie when he can't hold up his end of the work. Howard and Raj get superhero figurines made of themselves.

- Mark Cendrowski

- Writers

- Chuck Lorre

- Bill Prady

- Steven Molaro

- Stars

- Johnny Galecki

- Jim Parsons

- Kaley Cuoco

IMDb RATING

7.8/10

3.3K

YOUR RATING

- Mark Cendrowski

- Writers

- Chuck Lorre

- Bill Prady

- Steven Molaro

- Stars

- Johnny Galecki

- Jim Parsons

- Kaley Cuoco

- 3User reviews

- 2Critic reviews

Videos1

Clip 0:48

Watch The Cooper Kripke Inversion

Photos8

Top cast

Johnny Galecki

- Leonard Hofstadter

Jim Parsons

- Sheldon Cooper

Kaley Cuoco

Simon Helberg

- Howard Wolowitz

Kunal Nayyar

- Raj Koothrappali

Mayim Bialik

- Amy Farrah Fowler

Melissa Rauch

- Bernadette Rostenkowski

John Ross Bowie

- Barry Kripke

- Mark Cendrowski

- Writers

- Chuck Lorre(story)

- Bill Prady

- Steven Molaro(teleplay)

- All cast & crew

- Production, box office & more at IMDbPro

Storyline

Did you know

- Quotes

[first lines]

Leonard Hofstadter: Sheldon, your food's getting cold.

Sheldon Cooper: I'll eat later. Right now I'm suckling at the informative bosom of Mother Physics.

Penny: Hot when Sheldon talks dirty.

- Crazy credits

CHUCK LORRE PRODUCTION, #406 According to futurist, inventor and all-around incredibly smart guy, Ray Kurswell, human beings actually reorganize their frontal cortex as they pursue mastery over different skills. For example, a musician redesigns his or her brain by means of constant study, practice and performance. The same thing applies to a mathematician, carpenter and pole dancer. The brain is physically changed over time by activity and learning. This means we have direct influence and control over how our minds operate. This means we actually mold our perception of the world by the way we mold our brains. This means that over the last twenty-five years, I have reshaped my frontal lobe to do one thing, and one thing only -- write sitcoms. I can't tell you what a relief this knowledge is to me.

To begin with, it single-handedly explains why I fail so consistently at other activities (golf, common courtesy and marriage come to mind). It also eases my fears about my disintegrating memory. Why would my brain waste precious neurons remembering where I put my glasses (on the top of my head), or the names of the camera crew (I think one guy is named John, or maybe Jamie or Nigel), when it's working overtime trying to structure a joke about a character masturbating like a moth-addled spider monkey? The answer is: It wouldn't. In other words, I have an advanced case of sitcom brain. On the plus side, I have been highly remunerated for my condition. The downside is that I am constitutionally incapable of ending any communication with a straight line. Just can't do it. Have to spin it somehow. Even if it's cheap or makes no sense. God forbid there's no laugh at the end. Vagina!

To begin with, it single-handedly explains why I fail so consistently at other activities (golf, common courtesy and marriage come to mind). It also eases my fears about my disintegrating memory. Why would my brain waste precious neurons remembering where I put my glasses (on the top of my head), or the names of the camera crew (I think one guy is named John, or maybe Jamie or Nigel), when it's working overtime trying to structure a joke about a character masturbating like a moth-addled spider monkey? The answer is: It wouldn't. In other words, I have an advanced case of sitcom brain. On the plus side, I have been highly remunerated for my condition. The downside is that I am constitutionally incapable of ending any communication with a straight line. Just can't do it. Have to spin it somehow. Even if it's cheap or makes no sense. God forbid there's no laugh at the end. Vagina!

User reviews3

ReviewFeatured review

8/

10

A Step Down

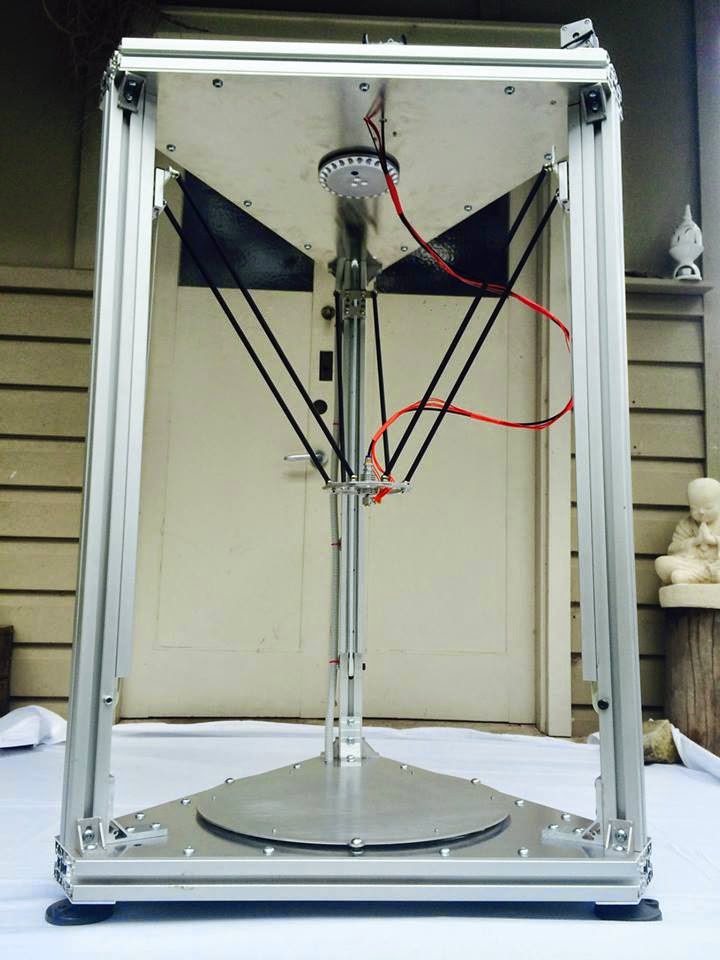

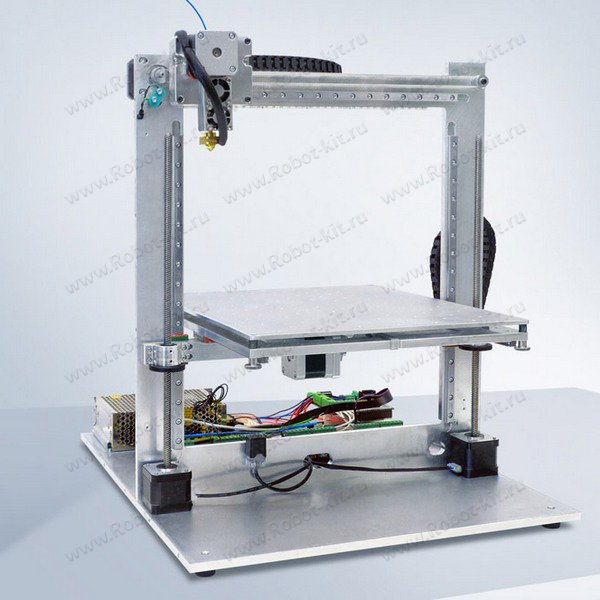

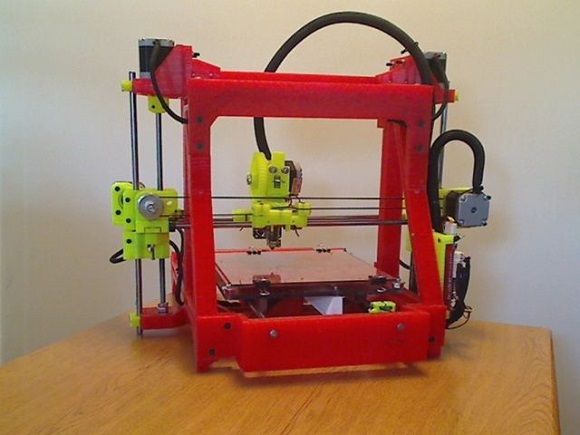

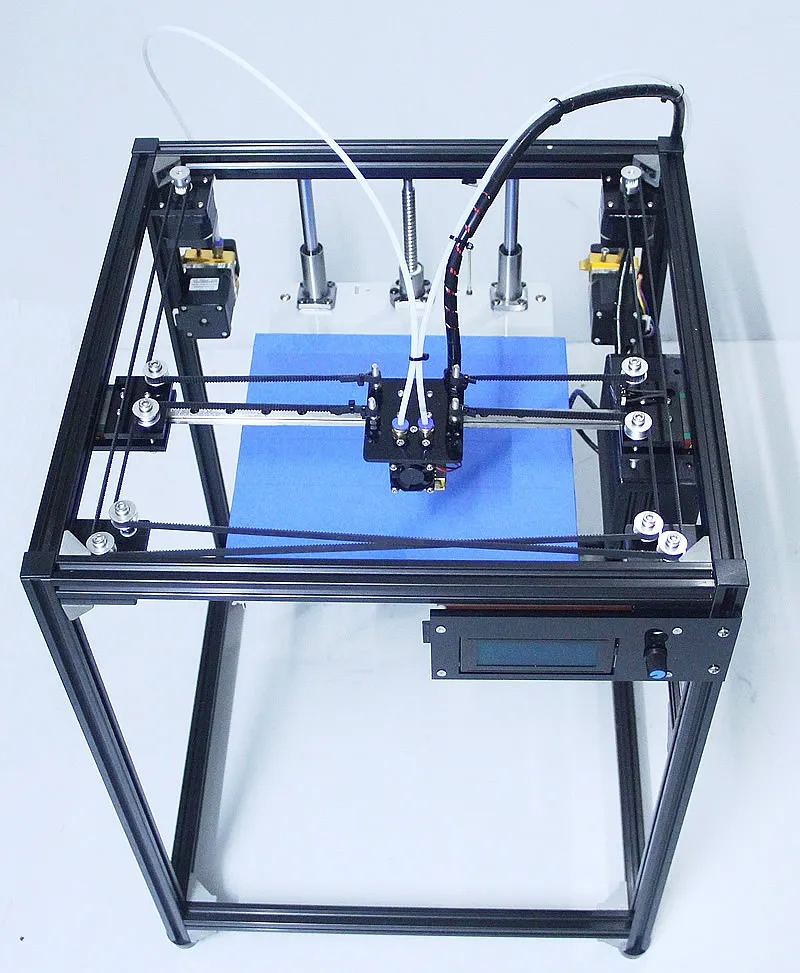

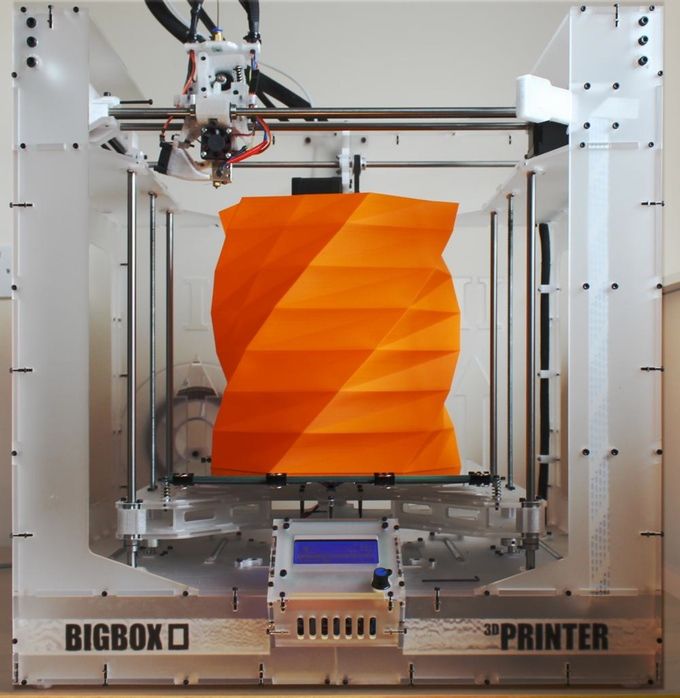

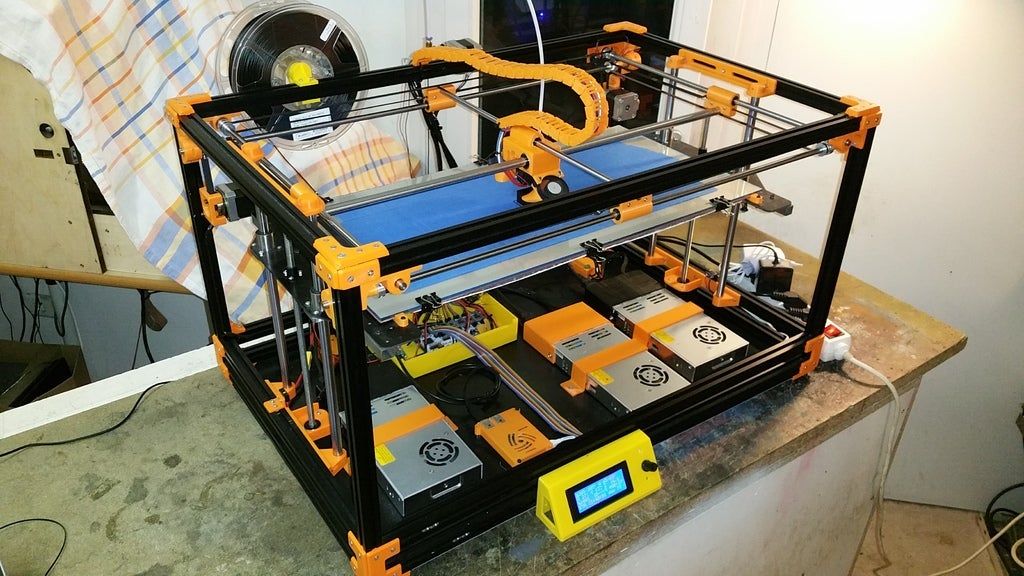

Sheldon dominates again as he realizes that on a joint project, Kripke is way ahead of him. This leads to Kripke's conclusion that Sheldon is getting too much sex. His comments are really outrageous and juvenile. Meanwhile, Howard and Raj shell out 5000 dollars to by a 3D printer.

This leads to Kripke's conclusion that Sheldon is getting too much sex. His comments are really outrageous and juvenile. Meanwhile, Howard and Raj shell out 5000 dollars to by a 3D printer.

helpful•1

2

- Hitchcoc

- Oct 23, 2021

Details

- Release date

- January 31, 2013 (United States)

- United States

- English

- Stage 25, Warner Brothers Burbank Studios - 4000 Warner Boulevard, Burbank, California, USA

- Production companies

- Chuck Lorre Productions

- Warner Bros.

Television

Television

- See more company credits at IMDbPro

Technical specs

20 minutes

- Dolby Digital

- 16:9 HD

Related news

Contribute to this page

Suggest an edit or add missing content

More to explore

Recently viewed

You have no recently viewed pages

3ders.org - In new episode of CBS "The Big Bang Theory" Howard and Raj get a 3D printer

Feb.3, 2013

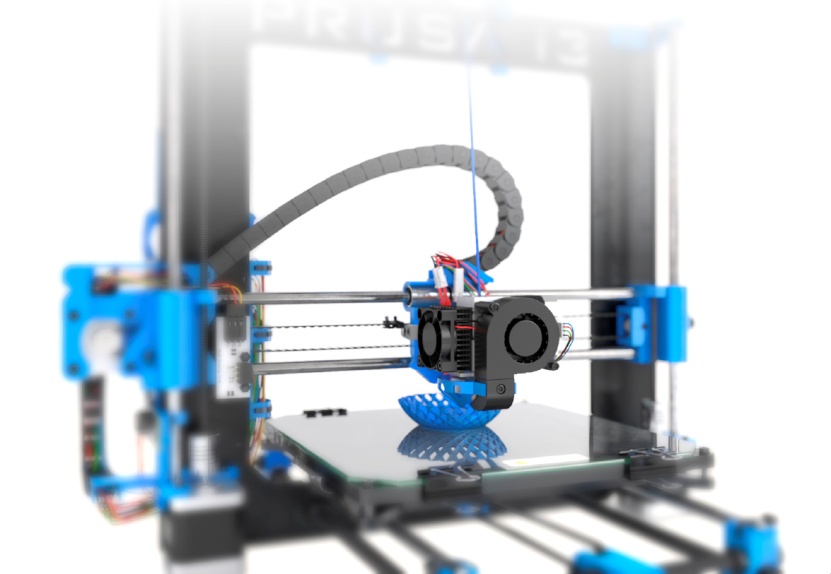

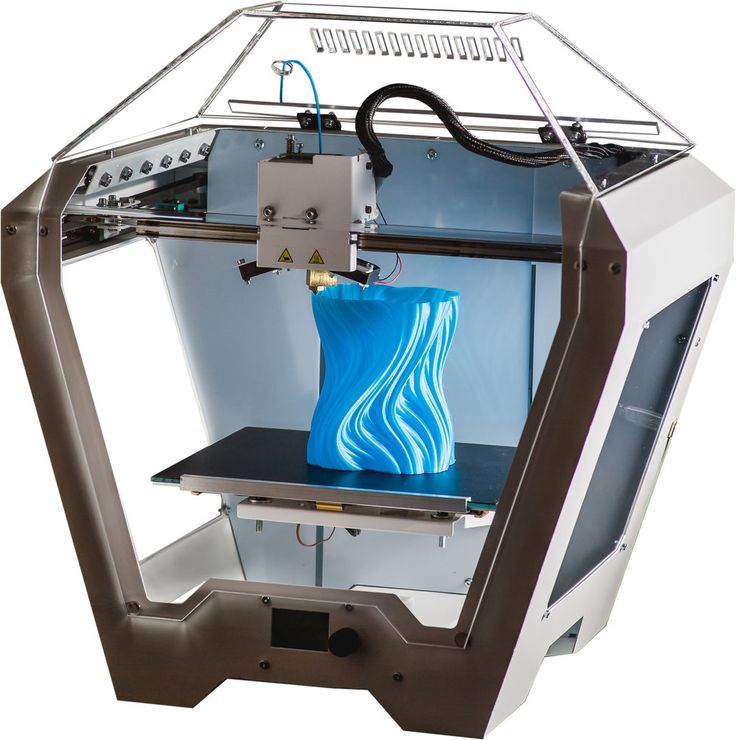

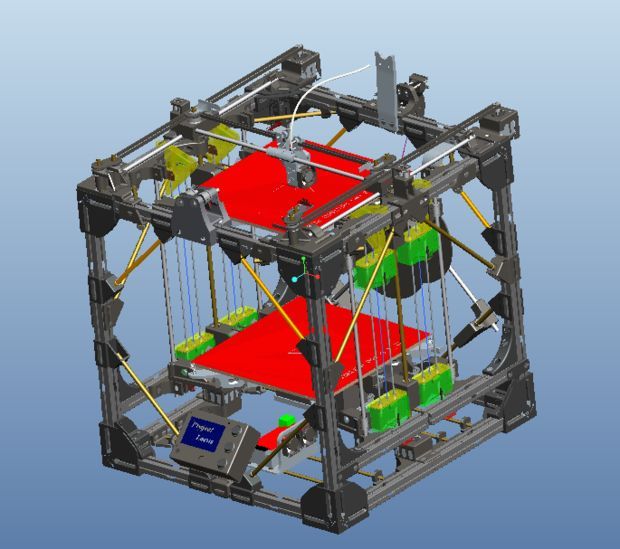

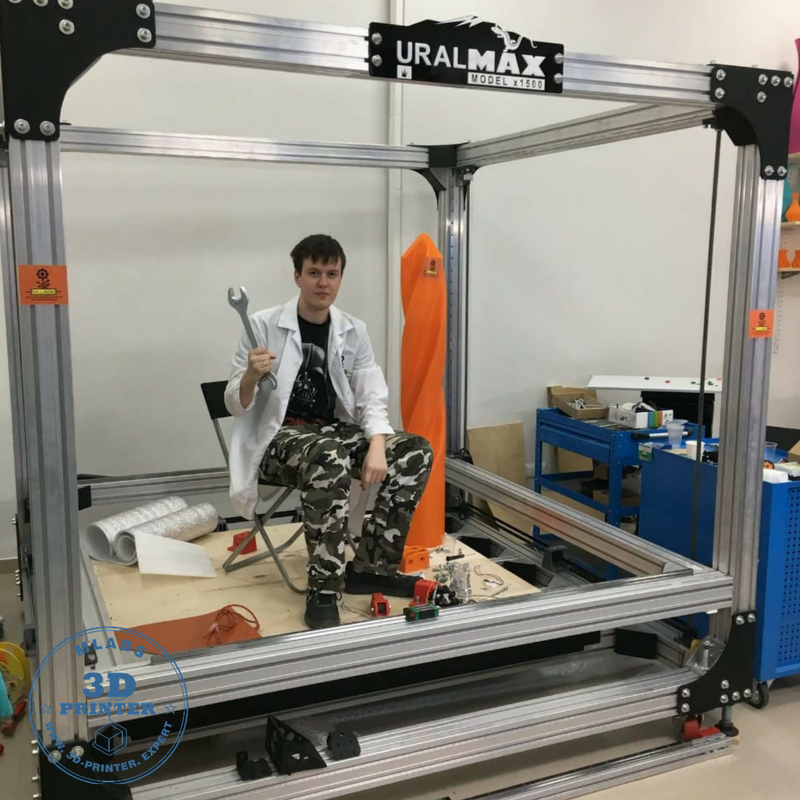

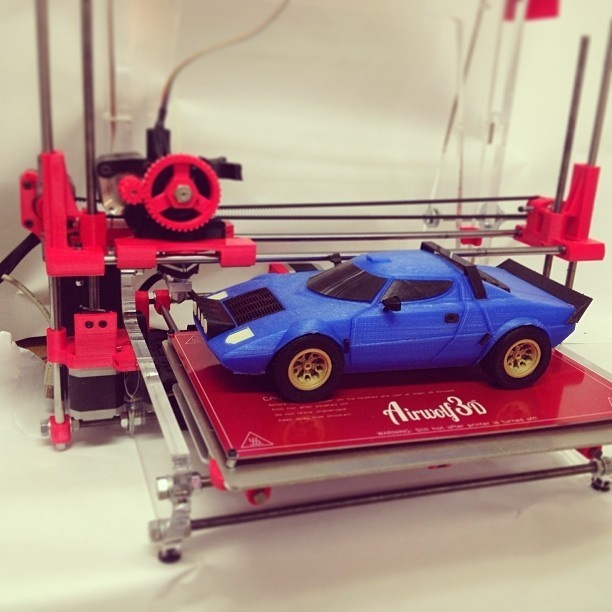

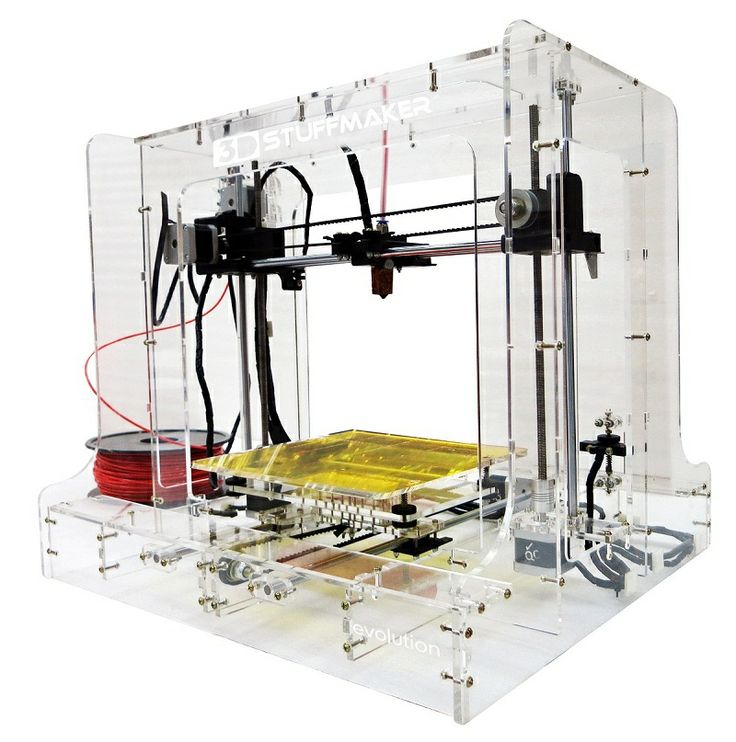

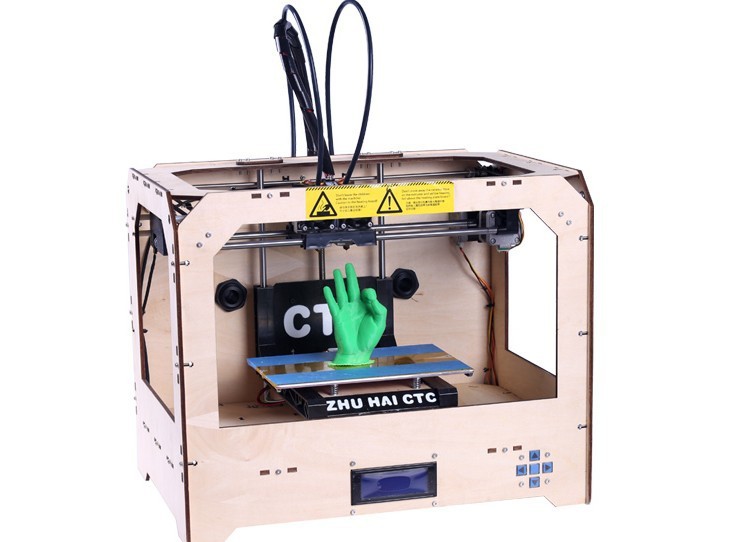

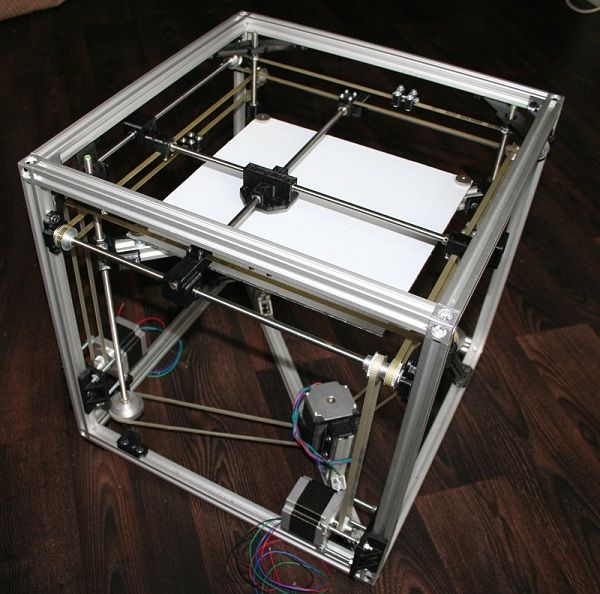

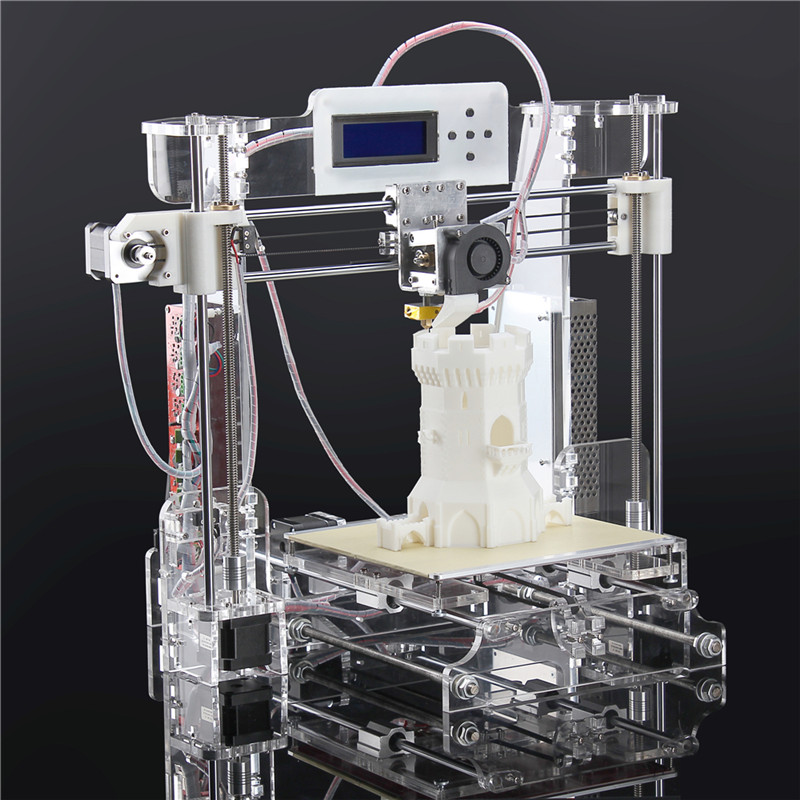

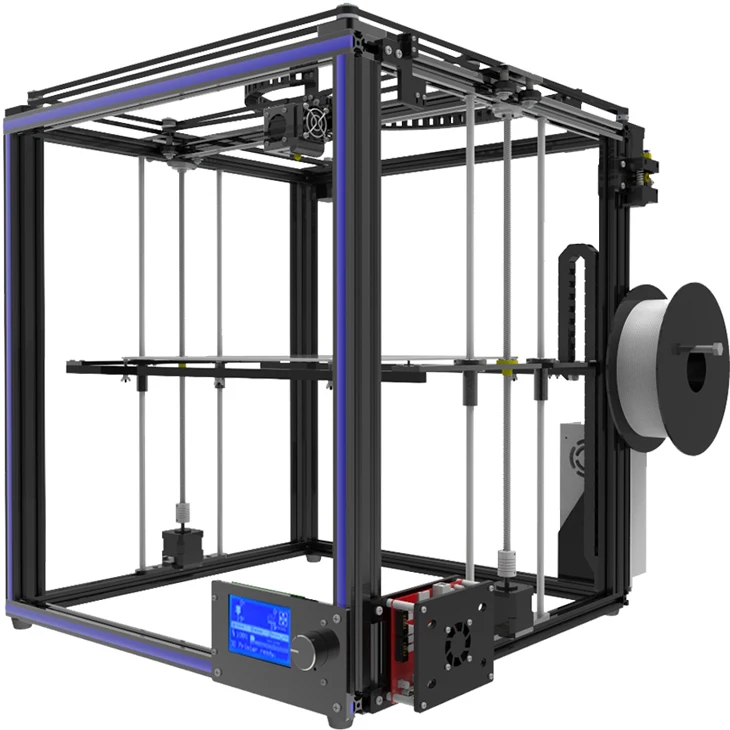

The latest episode of "The Big Bang Theory" showed last week on January 31, 2013 features some very interesting machines, one of them is a 3D printer.

In this episode Howard Wolowitz and Raj Koothrappali order customized action figures but soon they find out it was just waste of money. Raj suggests that they could get better quality action figures with "Three words": 3-D printer. That is also what Howard has always wanted because he could use it to make prototype parts out of plastic for his work.

The two decided to make their own figures by purchasing a 3D printer, even though the price is up to $5,000.

At around 11 minutes, this second-hand 3D printer, a new toy named as "1200 XT 3D modeler PRO" appears in the show.

Howard says that with 3D printing they are taking jobs away from China and returning manufacturing to the United States.

Then Raj looks at the 3D printer and says "I think this thing was made in China."

After three hours, they make their first object, a whistle worth twenty-five cents.

Then Howard has Raj make a superhero pose and scan him with a Microsoft Kinect. He tells Raj that it isn't necessary to suck in his stomach while making his superhero pose. Howard says he can just use a computer program to edit Raj's 3D model to have great abs.

Finally they print out action figures of themselves, even one for Howard's girlfriend Bernadette using the "1200 XT 3D modeler PRO" 3D printer. Howard says to her it didn't cost anything. ...

It is important that entertainment industry has paid attention to the power of 3D printing. As innovation pushes 3D technology forward, in the future 3D printers would just become part of the furniture in every home.

本站所有文章版权归3ders.org所有,未经许可不得翻译或转载。

Posted in 3D Printing Applications

Maybe you also like:

- 'People Wood' 3D printed infosculpture

- Inition develops iPad-based augmented 3D-printing

- 3D printed Atlas co-op bot got a fancy base

- Turning children's drawings into 3D printed figurines

- 3D printing helps develop the world's smallest hearing aid

- Using 3D scanning and 3D printing to recreate 19th-century face jugs

- Prowler: 3D printed remote controlled car

- China opens its first 3D printing photo booth

- Design and 3D print OP-1 synthesizer stand

- 3D printing experiment: 3D printed UAV identification kit

- Build a HEX air robot on a 3D printer

- Update: Ford investing in 3D printing with sand, goes digital to increase global efficiency

Steve Mullen wrote at 5/2/2015 4:39:36 PM:

Checkout mirrorimage3d. com to have yourself printed in 3d.

com to have yourself printed in 3d.

Mike G wrote at 2/4/2013 2:11:00 PM:

Since it was a used InVision XT, the price should have been about $15k.

KnightFire wrote at 2/3/2013 6:52:28 PM:

$5,000 USA Dollars! I'd pay $5,000 for that! I think they should have said $50,000.

Published 3D model of the cosmic background radiation for printing / Sudo Null IT News

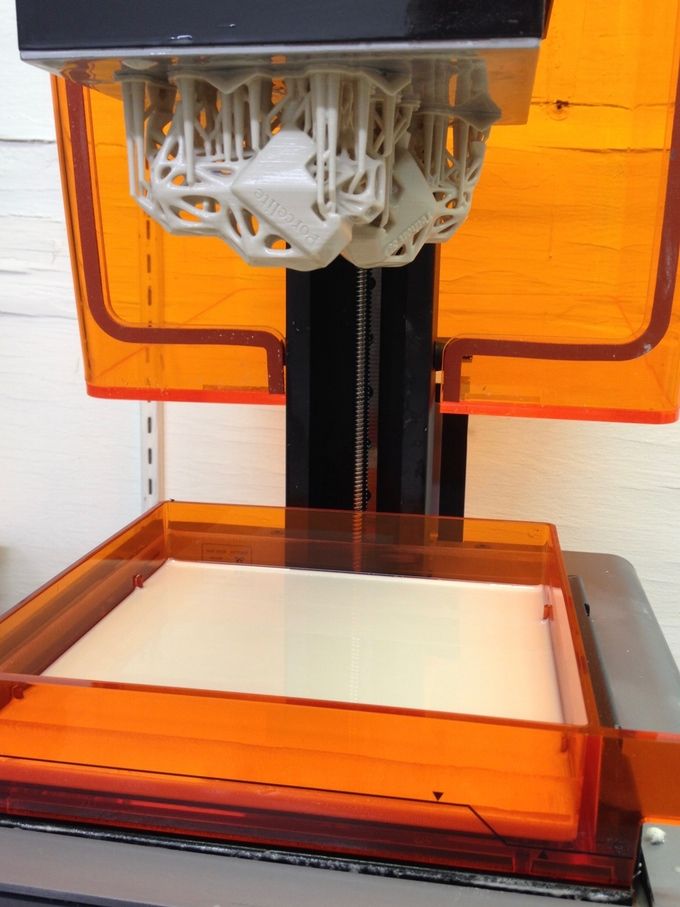

Don't know how to decorate your desktop? How do you like this option: a small copy of the early universe. Namely, the spheres of relic radiation - the microwave background radiation that fills the Universe, which arose in the era of the primary recombination of hydrogen.

This is not just a beautiful souvenir, but a scientifically verified model, compiled according to the data of the Planck space observatory. It can be used as a teaching aid. Along with the cosmological redshift, the CMB is regarded as one of the main confirmations of the Big Bang theory.

According to the Big Bang theory, the early universe was a hot plasma of electrons, protons, and photons. In this plasma, photons were constantly emitted, collided with other particles, and absorbed. As the Universe expanded, the cosmological redshift caused the plasma to cool, so that at a certain stage, the slowed down electrons began to combine with the slowed down protons, forming the first atoms in the Universe (this process is called the primary recombination of hydrogen). This happened about 380,000 years after the Big Bang, at a plasma temperature of about 3000°K.

In this plasma, photons were constantly emitted, collided with other particles, and absorbed. As the Universe expanded, the cosmological redshift caused the plasma to cool, so that at a certain stage, the slowed down electrons began to combine with the slowed down protons, forming the first atoms in the Universe (this process is called the primary recombination of hydrogen). This happened about 380,000 years after the Big Bang, at a plasma temperature of about 3000°K.

Since that time, some photons have been able to move freely in space, practically without interacting with matter. Relic radiation - those ancient photons that were emitted by the plasma of the early Universe after the Big Bang towards the future location of the Earth. After 13.8 billion years, photons are still coming towards us because the expansion of the Universe is still ongoing.

The radiation temperature is now around 2.7 °K. It comes from all sides almost evenly.

The observable Universe in refraction through relic radiation is called the last scattering surface. It is the most distant object we can observe.

It is the most distant object we can observe.

An interesting phenomenon of relic radiation is its anisotropy, that is, its inhomogeneity. In March 2013, the European Space Agency published the most detailed CMB map ever compiled by the Planck space observatory since 2009.

Two strange phenomena are clearly visible on this map. The first is the change in temperature amplitude in the two halves of the universe.

Changes in temperature amplitude in two halves of the Universe

The second phenomenon is an unusually large cold spot, clearly visible on the map. Previously, experts believed that this was a measurement error. But the Planck observatory provided more accurate information, confirming the effect.

Comparison of the resolution of astronomical satellites recording CMB

According to scientists, the unevenness of the CMB radiation - temperature fluctuations - is explained by plasma fluctuations in the tiny early Universe shortly after the Big Bang.

Traditionally, temperature fluctuations are displayed as areas of different colors. For example, the hottest areas are in red and the coldest areas are in blue. These areas are projected onto a flat map using a standard stereographic projection. There have been attempts to create 3D computer models of the CMB sphere that the user can rotate and view on a screen. But in this case, the anisotropy information was transmitted according to the same visual principle through the color scale.

Graduate students from the Department of Physics at Imperial College London have proposed a new way to visualize using 3D printing. On the sphere of relic radiation designed by them, regions of different temperatures are felt not only visually, but also tactilely. In their opinion, a portable sphere of cosmic microwave radiation, which can be taken in hand, has a number of advantages in educational and scientific work, and is especially useful for people with visual impairments.

3D printing has been used in the past to visualize mathematical functions and simulations of complex systems.

The Penrose Triangle is one of the impossible shapes that Knill and Slavkowski, authors of the paper “Illustrating Mathematics with 3D Printers” tried to 3D print. for scientific purposes. Young British scientists used MeshLab, Cura, Blender!, Netfabb and others to convert scientific data from the Planck space observatory into STL format.

Scientific paper published in European Journal of Physics (doi: 10.1088/0143-0807/38/1/015601).

Files for printing are posted separately on scientific hosting Zenodo.

128_scaled.stl - STL file for printing a monochrome version (the researchers used an Ultimaker printer).

cmbhollow.wrl - VRML file for coloring the product in ZPrinter.

A similar method is suitable for visualizing other scientific data, including astronomical observations. For example, for printing topographic maps of planets, surface models and the internal structure of stars, the distribution of stars in galaxies, the distribution of matter in a scale model of the Universe. In a sense, this work can be seen as the first blueprint for a large number of potential use cases.

In a sense, this work can be seen as the first blueprint for a large number of potential use cases.

The world's largest metal 3D printer launches rockets / News / Info | Elektrostroymarket

I will never forget the first time I saw a rocket materialize before my very eyes.

In October 2018, I stood in a small room and watched a massive robotic arm gracefully move around a large metal mold that rapidly grew in size as I looked at it. A hand accurately applied a jet of liquid aluminum to build the structure, layer by layer, while the other two hands waited with finishing tools at the ready. I stood at the headquarters of the new rocket company Relativity Space in Los Angeles and watched in awe as part of its first launch vehicle, the Terran 1 rocket, was born.

I just recently joined Relativity as the first engineer hired for its avionics department. Relativity was a game-changer from my previous job, even though other companies I worked for also made rockets. But they did it in vast, thousand-square-foot facilities, enough to house rows of bulky manufacturing tools such as metal rollers, dome spinning machines, and friction stir welders. However, in Relativity, most of the booster is built in the small room where I stood, which is only 9meters across.

But they did it in vast, thousand-square-foot facilities, enough to house rows of bulky manufacturing tools such as metal rollers, dome spinning machines, and friction stir welders. However, in Relativity, most of the booster is built in the small room where I stood, which is only 9meters across.

The room contained Stargate, the largest metal 3D printer in the world. Relativity invented the Stargate printer for the audacious goal of 3D printing an entire rocket designed to fly to low Earth orbit. We hope that our rockets will eventually fly even further. Perhaps one day we will send our 3D printers to Mars so that rockets can be built on the Red Planet. From there, who knows where they will go.

Does that sound crazy? Maybe insanely ambitious. But many people are serious about our idea. Four commercial customers have signed up for low-Earth orbit launches in early 2021. The US Air Force has approved our request to build a launch site at Cape Canaveral, the iconic site in Florida that has launched many of the historic human spaceflights. And NASA has leased us a building at the Stennis Space Center in St. Louis Bay, Mississippi, where Relativity will build a plant capable of producing 24 rockets a year. Such mass production will revolutionize rocket technology. We believe that with the help of additive manufacturing, that is, 3D printing, we can achieve this.

And NASA has leased us a building at the Stennis Space Center in St. Louis Bay, Mississippi, where Relativity will build a plant capable of producing 24 rockets a year. Such mass production will revolutionize rocket technology. We believe that with the help of additive manufacturing, that is, 3D printing, we can achieve this.

Video: Relativity Space

Launching a rocket into orbit is a binary proposition: either you succeed or you fail. During the roughly 10-minute flight from the launch pad to space, a staggering array of systems must work together perfectly - plumbing, avionics, software, pyrotechnics and pneumatics, to name but a few. If any component fails, the whole operation can literally collapse.

The cost of a rocket is not determined by its raw materials; it's pretty cheap. This is largely due to the human labor required to process these materials into usable components and test them for airworthiness. There are two ways to reduce these labor costs: you can reduce the total number of parts in a rocket so that less labor is required, or you can change manufacturing processes to reduce the need for human minds and hands.

Blue Origin, SpaceX and Virgin Orbit - leaders in the emerging commercial space sector - have tried a combination of the two to reduce labor costs. But these companies' use of traditional "subtractive" manufacturing techniques, in which chunks of raw materials are cut and shaped, limits their options. Companies have automated most of their supply chains, but they still have tens of thousands of parts to track through complex manufacturing systems. Automating the manufacturing process has reduced human labor but requires costly specialized tools to match the size of a particular rocket.

Side view [left] and bottom view [right] of the Aeon engine.

Photos: Relativity space

Simplify, simplify, simplify: The theory of relativity in space makes rocket science easy. Its Aeon engine, shown in side view [left] and bottom view [right], consists of three 3D printed parts. A classic rocket engine is assembled from thousands of parts.

Relativity solves the problem of labor by using additive manufacturing to print complex components using a single operation to turn raw materials into finished products. This approach greatly reduces the number of parts, since one of our components is often equivalent to dozens of small parts made in the traditional way. Our process also relies on our 3D printers rather than fixed tools, allowing us to be nimble and resourceful. We can make significant design changes at relatively little cost or loss of time.

This approach greatly reduces the number of parts, since one of our components is often equivalent to dozens of small parts made in the traditional way. Our process also relies on our 3D printers rather than fixed tools, allowing us to be nimble and resourceful. We can make significant design changes at relatively little cost or loss of time.

The rocket industry operates on a different scale than other manufacturing sectors. Consider that the Volkswagen plant in Wolfsburg, Germany produces about 3,500 vehicles per day. In contrast, any aerospace company that could build 100 rockets a year would be a huge success. What is considered large-scale in rocket technology is relatively small in other industries. This means additive manufacturing could have a big impact on the industry. Since only tens or hundreds of individual parts may be required per year, it makes no sense to invest in highly optimized tools to produce that part in mass quantities - the tools may not pay for themselves before the part is out of use. .

.

Making a new part on a 3D printer requires almost no upfront costs. For example, one of our Stargate printers can produce a 2m fuel tank followed by a 3m tank with minimal downtime. Instead of retooling the entire manufacturing facility to make the next piece of equipment in line, we only need to make a few changes to the software configuration.

Our co-founders Jordan Noane and Tim Ellis met in college at the USC Rocket Propulsion Laboratory in Los Angeles. No one worked for SpaceX and Ellis worked for Blue Origin before they teamed up again to create Relativity in 2015.

Both of their former companies use additive manufacturing to create some rocket components, but Noon and Ellis wanted to go further. They saw an opportunity to completely rethink how rockets are designed and built. They believed that by simplifying designs and manufacturing processes, they would also simplify the mental labor, the "cognitive overhead" associated with building a rocket.

Engineers are talking and looking at monitors.

Photo: ``Space of Relativity''

From start to finish: engineers oversee the printing process, which is fully automated.

Rockets usually consist of a huge number of individual parts: for example, the space shuttle system consists of 2.5 million moving parts. All parts must match exactly to each other and cannot unexpectedly form an assembly out of tolerance. Every part must be manufactured, tested, installed and tested again. If a part needs to be repaired, additional work will be required. And all these processes require engineers, technicians, tools and documents.

With additive manufacturing, you can design multi-part parts that would traditionally be separately manufactured and assembled. Less detail means fewer interfaces and less chance of things going wrong.

A prime example of this is our approach to designing and building our rocket engine. Inside a typical rocket engine, you'll find an injector that mixes the propellant with the oxidizer as they enter the combustion chamber, where the igniter starts the fire. During combustion, hot gas is formed, which moves through the nozzle, creating thrust. In principle, it sounds simple, but in fact everything is incredibly complicated. Note that Rocketdyne's F-1 engine, which was fired by a Saturn V rocket during NASA's Apollo program, contained a combustion chamber and nozzle assembly consisting of over 5,000 custom-made parts (and that's not including the injector).

During combustion, hot gas is formed, which moves through the nozzle, creating thrust. In principle, it sounds simple, but in fact everything is incredibly complicated. Note that Rocketdyne's F-1 engine, which was fired by a Saturn V rocket during NASA's Apollo program, contained a combustion chamber and nozzle assembly consisting of over 5,000 custom-made parts (and that's not including the injector).

The Relativity Engine, Aeon 1, is a different story. To create the engine, we use commercial 3D printers that use a process called direct metal laser sintering, in which a laser combines metal powder particles, creating layer by layer the desired structure. The simplest version of the engine, a pressurized version that uses pressurized gas to push the fuel and oxidizer from their tanks into the combustion chamber, is made by pressing the printer's power button three times (to print three parts). And we're moving on: we expect commercial printers to come out soon that will allow us to print the injector, igniter, combustion chamber, and nozzle as one unit.

Jordan Noone, co-founder of Relativity Space, stands in front of the company's latest 3D printer, which is building a fuel tank for the Terran 1 rocket. The company's 3D printer is building the fuel tank for the Terran 1 rocket. The additive manufacturing approach makes it easy for the Noone team to refine their designs.

We use this pressurized motor for development and testing; an engine that will eventually fly will use turbopumps instead of simple compressed gas to move fuel (liquid methane) and oxidizer (liquid oxygen). Better suited to rockets with large fuel tanks, these turbopumps will increase the number of parts, but the manufacturing process will still be much easier than ever.

Many rocket engines use a technique called regenerative cooling, in which liquid propellant is pumped through cooling channels around the combustion chamber to remove heat. In the traditional manufacturing and assembly process, a thick piece of copper is shaped by rotating it rapidly and applying pressure to form the internal contours of the combustion chamber. It is then milled to create intricate cooling channels on the outside. A strong outer shell is then soldered to the copper structure, and the fuel intake manifold is welded onto the outer shell. The entire engine assembly requires finishing to ensure tight tolerances when parts are joined. Each of these processes can lead to design or manufacturing errors. The Aeon engine also uses regenerative cooling, but its combustion chamber is one of a kind. Moreover,

It is then milled to create intricate cooling channels on the outside. A strong outer shell is then soldered to the copper structure, and the fuel intake manifold is welded onto the outer shell. The entire engine assembly requires finishing to ensure tight tolerances when parts are joined. Each of these processes can lead to design or manufacturing errors. The Aeon engine also uses regenerative cooling, but its combustion chamber is one of a kind. Moreover,

Men look at a rocket engine.

Photo: ``Space of Relativity''

Stage two: co-founders Tim Ellis (left) and Jordan Noane inspect the finished product: the second stage of the Terran 1 rocket, consisting of a fuel tank, engine and nozzle.

It is usually a daunting task to design, manufacture and put one engine on a test bench. This process takes 10 to 12 months using traditional methods. A major redesign takes almost the same amount of time. But we can iterate much faster. In our initial testing of the Aeon engine, we tested five versions over 14 months, running the engines more than 100 times.

As NASA astronaut Donald Pettit explained in his brilliant article "The Tyranny of the Rocket Equation" published on the NASA website, getting out of the Earth's gravity well is not an easy task. Missiles are basically empty ships waiting to be refueled. Pettit explains that 94 percent of the weight of a soda can is soda, and 6 percent is cans. The space shuttle's external fuel tank was 96 percent and 4 percent, which is an impressive improvement over soda can technology when you consider that the fuel tank contained cryogenic fluids that had to be pumped out at a rate of 1.5 metric tons of propellant per second. . .

The entire Terran 1 missile is designed for simplicity. The tanks that store the fuel and oxidizer are under "autogenous pressure", meaning that a small percentage of the vaporized fuel and oxidizer is pumped back into their respective tanks to replace the volume of liquid as it drains. Continuing with Pettit's analogy, imagine an unopened soda can that remains tough and strong despite the can's thin shell; However, once the jar has been opened, it can be easily crushed. Likewise, rockets use internal pressure to create a light but strong vehicle.

Likewise, rockets use internal pressure to create a light but strong vehicle.

These autogenous systems on the Terran 1 tanks eliminate the need for the special pressure vessel that many missiles use inside their fuel and oxidizer tanks. These pressure vessels contain inert gases such as helium at extremely high pressure until they are ready to be released into a tank to provide internal pressure. These ships are known to be complex systems in development and production, and have been involved in several rocket failures over the past decade, including the explosion of a SpaceX Falcon 9 rocket.in 2015 .

Commercial printers using metal laser sintering are suitable for our engines, but they are not suitable for tanks. These printers work by selectively melting desired portions of metal powder to create a solid material in each layer of the part. Since the layer of powder must be flat and even for each layer, the entire working space of the printer must be filled with powder, no matter how much material is actually cured. Most of this powder can be recycled, but some is lost in every print. Making a tank using a sintering laser printer would require an unrealistic amount of metal powder and would be a very slow process.

Most of this powder can be recycled, but some is lost in every print. Making a tank using a sintering laser printer would require an unrealistic amount of metal powder and would be a very slow process.

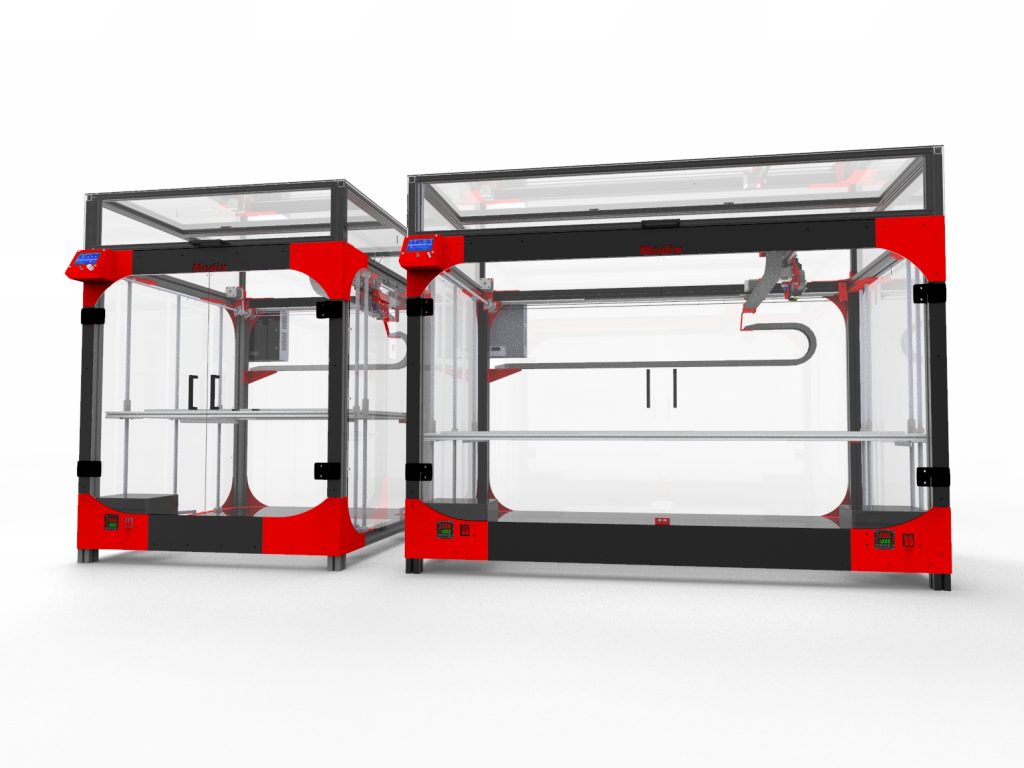

Photo of a Stargate 3D printer.

Photo: ``Space of Relativity''

Blazing The Trail: The Stargate printer is the world's first 3D printer that can produce massive metal objects such as a rocket's fuel tank.

That's why we designed and built Stargate, our huge 3D printer of a different kind. It uses an existing technique called directed energy overlay, but works on a scale never seen before. The printer feeds metal wire into the hardfacing zone and uses energy (usually a powerful laser) to melt the wire, creating printed parts layer by layer.

The Stargate places molten metal only where it is needed to build the structure, greatly reducing material consumption. It uses three massive robotic arms, one of which terminates in a printer head that ejects the wire; the other two contain working tools for finishing the printed component. We also wrote proprietary software to manage the "path planning" used to turn the design into detailed instructions for the robotic arm.

We also wrote proprietary software to manage the "path planning" used to turn the design into detailed instructions for the robotic arm.

The Stargate has several restrictions. Its robotic arms move their work tools in free space during printing, meaning that the geometry that can be printed is limited by the kinematics of the robotic arms - they can only reach a certain distance and must avoid colliding with the printed structure. As the wire melts, the size of the bead produced by the welding process determines the minimum print resolution. But these limitations are not serious when it comes to large pressure vessels and structural elements.

Our Stargate printer is new technology and we believe it breaks new ground in aerospace manufacturing. But the novelty of this printing process also means that we cannot rely on pre-existing material data or process parameters to produce high quality products. Relativity has in-house metallurgists who hone the process to ensure our components meet stringent aerospace quality standards.

Video: Space of Relativity

In traditional aerospace manufacturing, a design change can take nearly a year of retooling and adjustment. Since it takes a long time to replace equipment, the avionics department is usually the most dynamic division of an aerospace company. Avionics teams (which manage the electronics that govern missile guidance, navigation, communications, etc.) are used to making last-minute software changes to fix problems in other parts of the vehicle.

The situation is completely reversed in Relativity, where an equipment design team can make significant design changes and still produce a new tank or engine in a matter of days. They can revise their plans so quickly that they challenge the avionics team's ability to manufacture printed circuit boards (PCBs) and design the cable harness that connects all the electronics and wiring. Avionics must adapt to the constantly changing and improving missile.

That's why we designed the Terran 1's avionics to be as modular as possible. We assume that sensors and actuators will be changed, so we have designed the electronics in such a way as to limit the impact of such changes. To achieve this, we have developed several proprietary methods for connecting busbars, minimizing the number of connectors and pins. We are working hard to reduce the number of harnesses, which are one of the least reliable parts of avionics on a rocket - every connection of every wire is a potential point of failure. Whenever possible, we use standards such as the Controller Area Network bus protocol (for communication between microcontrollers and devices) and Ethernet, which allows the use of existing industry tools for testing and development. This approach means we don't waste time looking for bugs in user protocols and can instead focus on making sure our avionics work properly in their specific use cases.

We assume that sensors and actuators will be changed, so we have designed the electronics in such a way as to limit the impact of such changes. To achieve this, we have developed several proprietary methods for connecting busbars, minimizing the number of connectors and pins. We are working hard to reduce the number of harnesses, which are one of the least reliable parts of avionics on a rocket - every connection of every wire is a potential point of failure. Whenever possible, we use standards such as the Controller Area Network bus protocol (for communication between microcontrollers and devices) and Ethernet, which allows the use of existing industry tools for testing and development. This approach means we don't waste time looking for bugs in user protocols and can instead focus on making sure our avionics work properly in their specific use cases.

In every small avionics design we look at, we aim for global rather than local optimization. For example, we use standard electronics design automation tools such as Altium Designer to create spaceflight-friendly basic circuits that we can use in different ways throughout the rocket. We call these circuits "bread and butter" and use them in voltage converters, processors, sensor interfaces, and other components. When our engineers solve a new problem, they build on the work they've already done, rather than starting from scratch. While this may seem like a common sense approach, you'd be surprised to see how many rockets contain complex circuitry simply because different engineers solved the same problem in slightly different ways.

We call these circuits "bread and butter" and use them in voltage converters, processors, sensor interfaces, and other components. When our engineers solve a new problem, they build on the work they've already done, rather than starting from scratch. While this may seem like a common sense approach, you'd be surprised to see how many rockets contain complex circuitry simply because different engineers solved the same problem in slightly different ways.

The printer head lays down a metal wire and melts it into place, creating a tank. The lines of metal that make up the tank. Engine extension and 2nd stage injectors.

Photo: ``Space of Relativity''

Assembly: Printer head [top] lays down metal wire and melts it in place to build a reservoir, line by line [center]. The tank connects to the engine and nozzle attachment [below], forming the rocket's second stage.

Another example can be found in our firmware. For internal communications in our avionics units, we do not always use a PCB-optimized protocol, resulting in tiny performance and weight advantages. Instead, we sometimes use a protocol that we also use for external intercompany communications. This method greatly reduces the cost and time of firmware development. What's more, it gives us flexibility for our design decisions: we can make changes in the centralized unit, or we can add some sensor at the last minute to the tooling, but the software doesn't know the difference. This approach may not be optimal for avionics systems considered in isolation, but it gives us many advantages elsewhere in terms of missile design, manufacture, and flight.

Instead, we sometimes use a protocol that we also use for external intercompany communications. This method greatly reduces the cost and time of firmware development. What's more, it gives us flexibility for our design decisions: we can make changes in the centralized unit, or we can add some sensor at the last minute to the tooling, but the software doesn't know the difference. This approach may not be optimal for avionics systems considered in isolation, but it gives us many advantages elsewhere in terms of missile design, manufacture, and flight.

Ellis, CEO of Relativity, often reminds us that we need to focus as much on designing and building our corporate culture as we do on designing and building our rocket. Relativity aims to maintain flexibility, so experimentation is encouraged. This attitude is contrary to the culture of traditional aerospace companies, which are trying to block their developments as soon as possible. We have an aggressive goal of launching Terran 1 by early 2021.