Best 3d printer software 2023

Best 3D printing software in 2023

3D Learning Hub

See all categories

Contents:

- Introduction

- What is 3D printing software?

- Slicers and 3D printer host

- Tools to edit and repair STL files

- 3D modeling software

Introduction

What is 3D printing software?

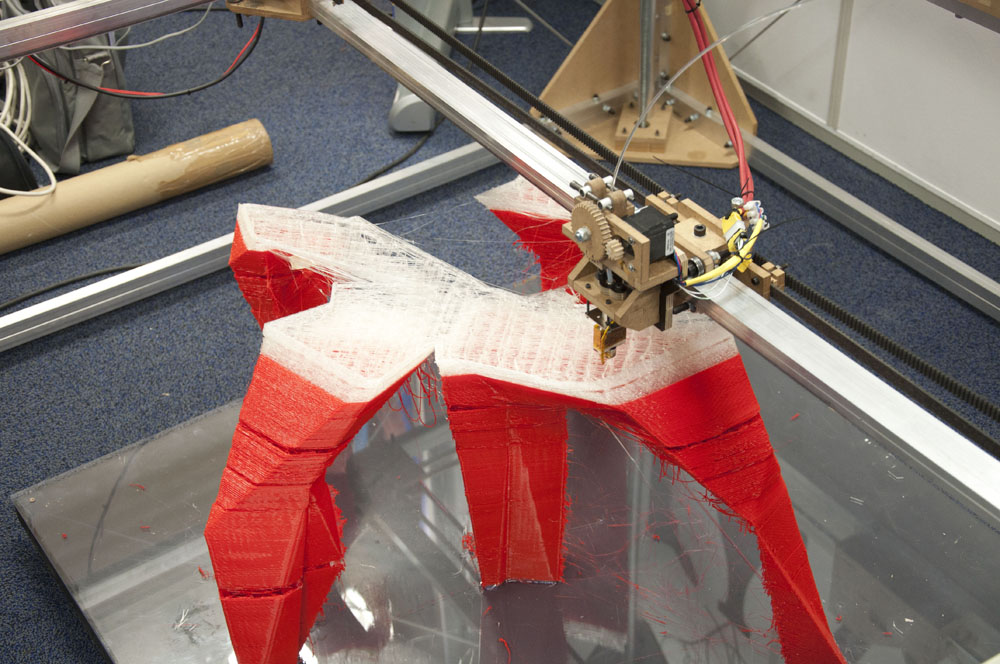

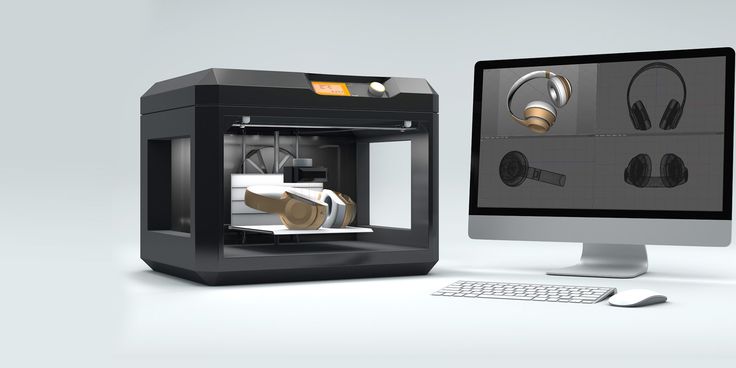

There is a lot of software applications to the 3D printing process. From designing your parts to slicing them into G-code and even controlling a desktop 3D printer while it fabricates your parts, you will inevitably have to choose some 3D programs along the way.

What is slicer software?

A 3D printing slicer is a program converting your 3D model into a language your 3D printer will understand to manufacture your object. The 3D slicer will digitally cut your 3D model into flat layers; these are the layers your 3D printer will then print one by one. This slicer software will define the model and instruct the 3D printer to print it. A 3D printing slicer usually prepares the model by generating G-code, the programming language the 3D printer will understand.

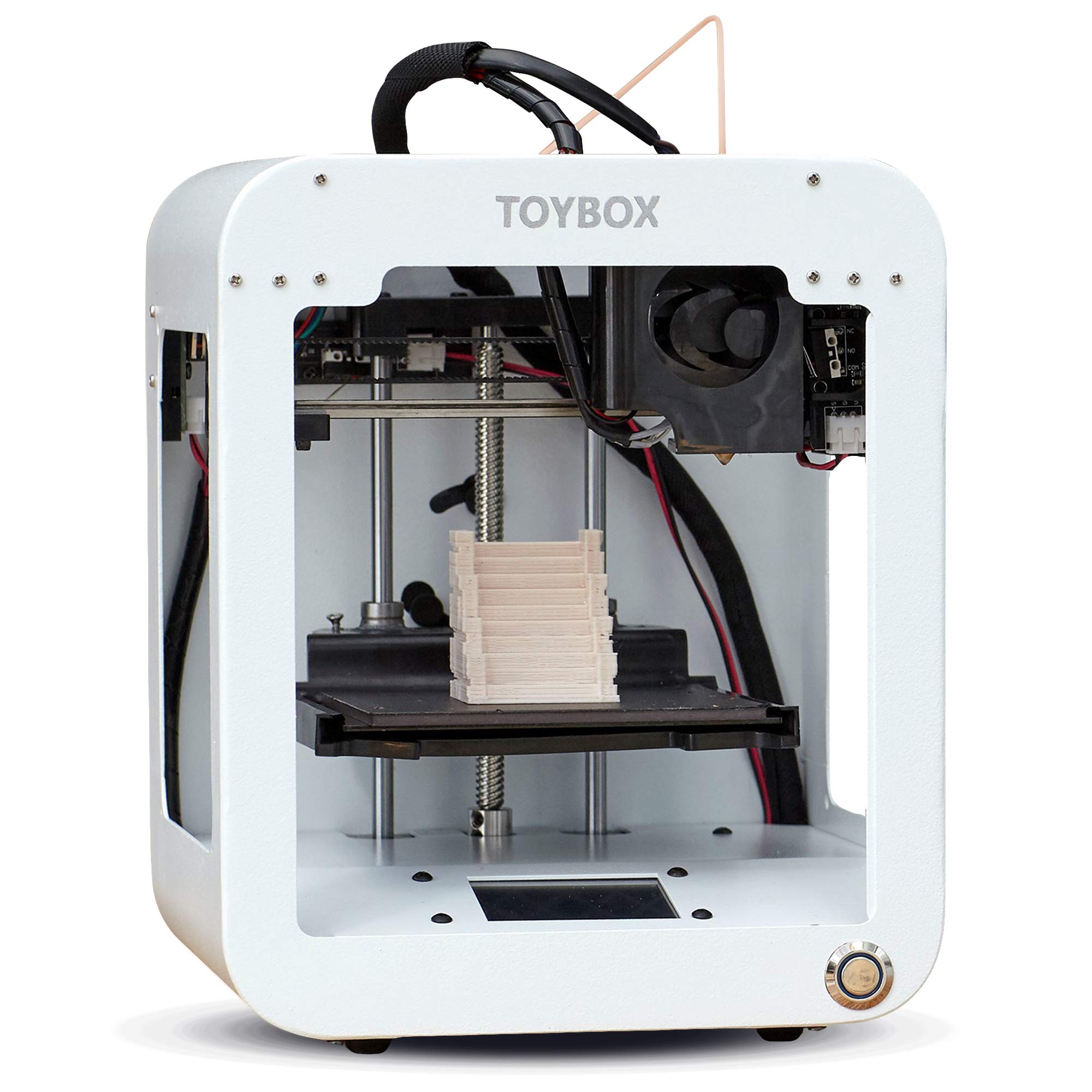

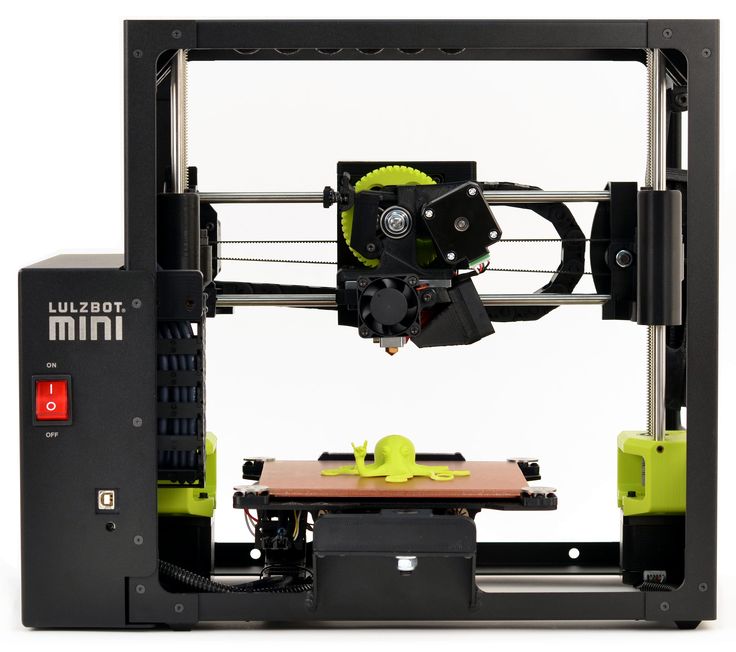

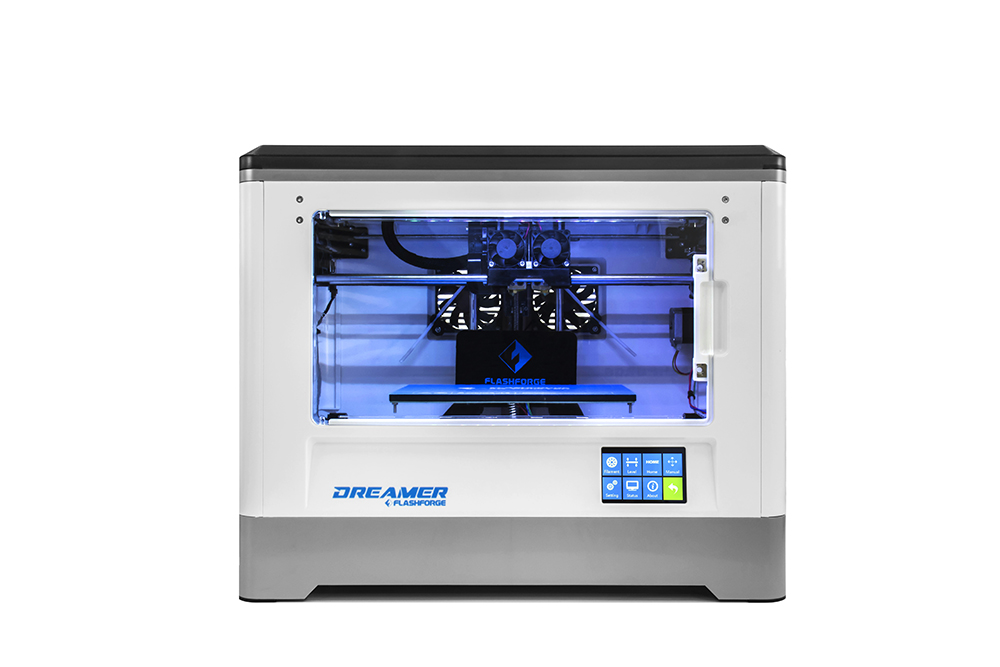

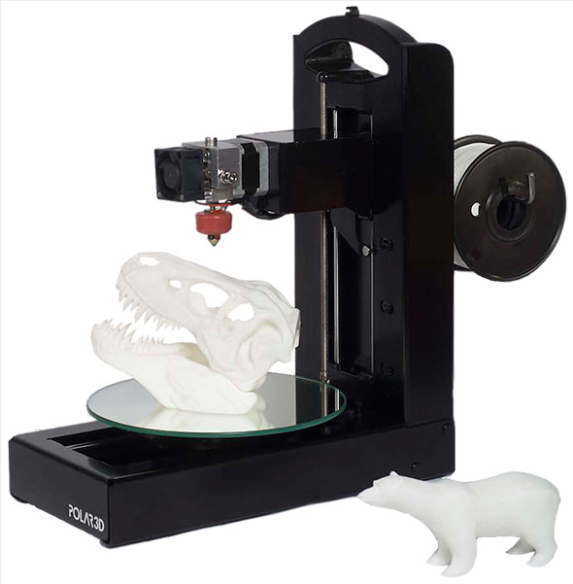

Slicer software is only helpful if you 3D print with your own FDM desktop 3D printer or resin 3D printer. When using a 3D printing service such as Sculpteo, no 3D printing slicer is needed!

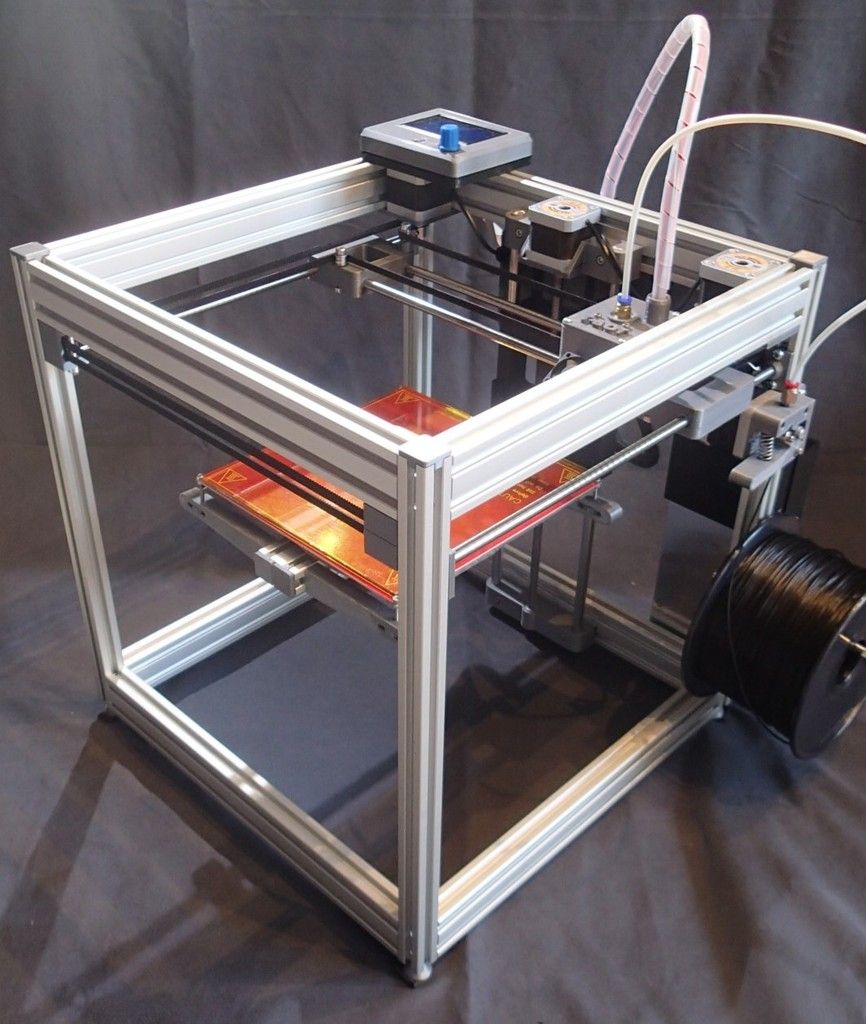

What are 3D printer hosts?

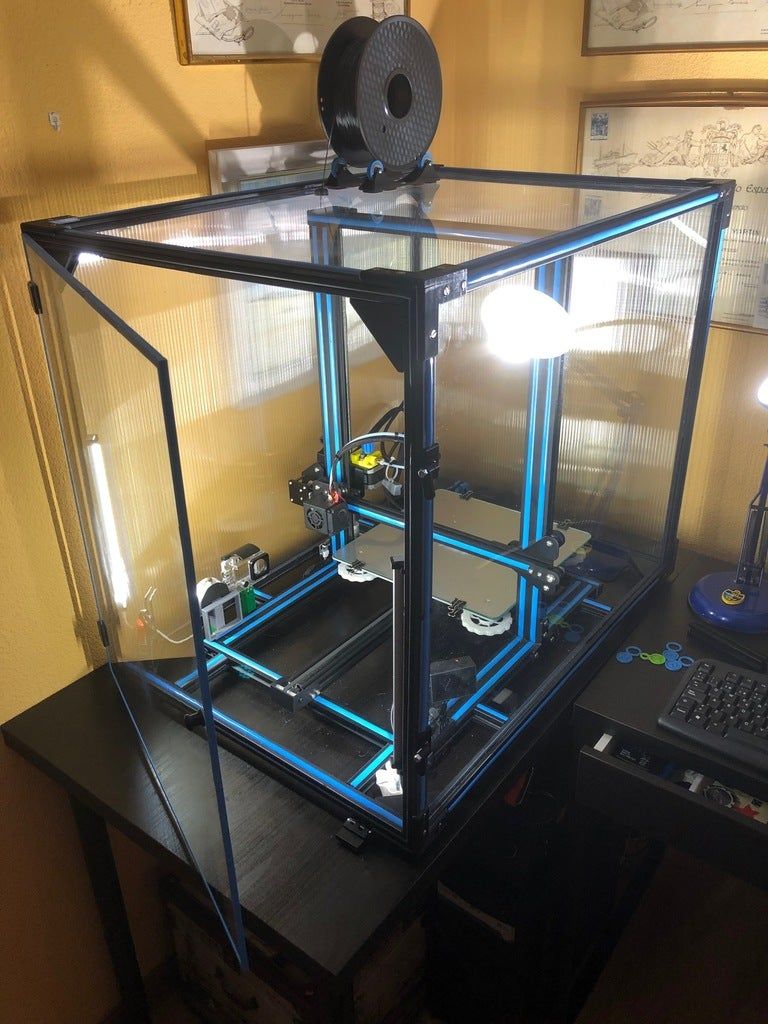

Some slicer software can also be 3D printer hosts, directly controlling your 3D printing machine. For this, you will need to connect your printer to your computer during the whole 3D printing process.

For this, you will need to connect your printer to your computer during the whole 3D printing process.

What are STL editors and repair tools?

If you want to use additive manufacturing, you need one essential thing: a 3D file and, more precisely, an STL file. You can either design one yourself or find one online. But the files you find might not always correspond precisely to your needs. It might lack some features, have too many elements in it that you don’t need, or even be damaged. Thus, you will need to use an STL editor to fit your needs perfectly.

You can use CAD software (Computer-Aided Design) or a mesh editing tool. They are made for modeling and objects represented by a 2D surface.

What is 3D modeling software?

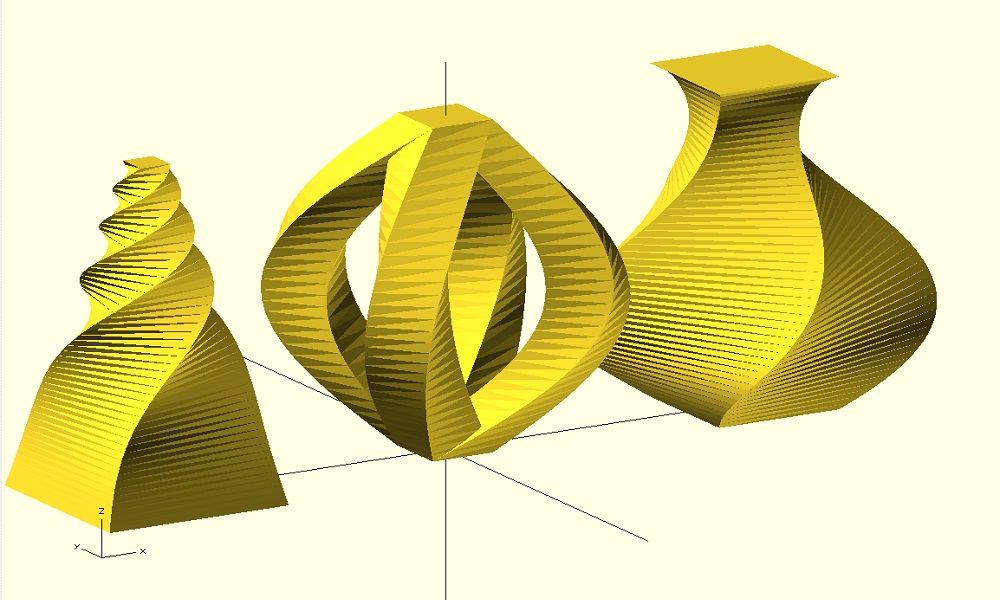

3D modeling software programs are designed to build 3D models of objects. Creating a 3D model is a mathematical representation of a three-dimensional object or shape. 3D models are used for various mediums, including video games, architecture, automotive, engineering, healthcare, etc.

If you want to 3D print an object, you need to design it on a 3D modeling software – or buy an already-made 3D model.

Slicers and 3D printer host

- Ultimaker Cura

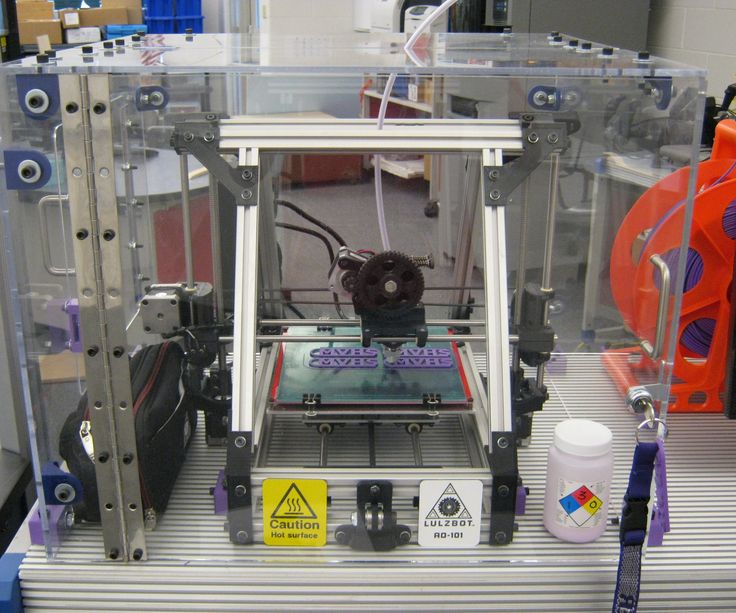

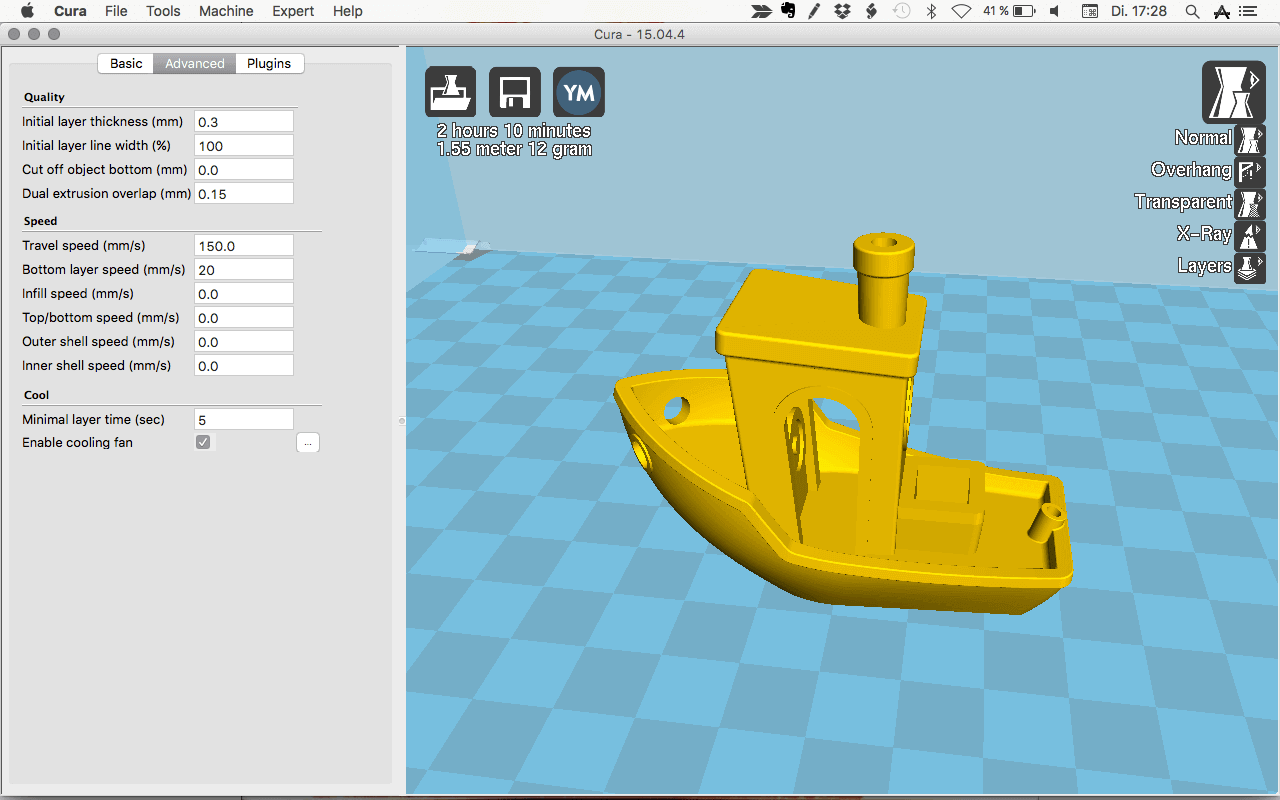

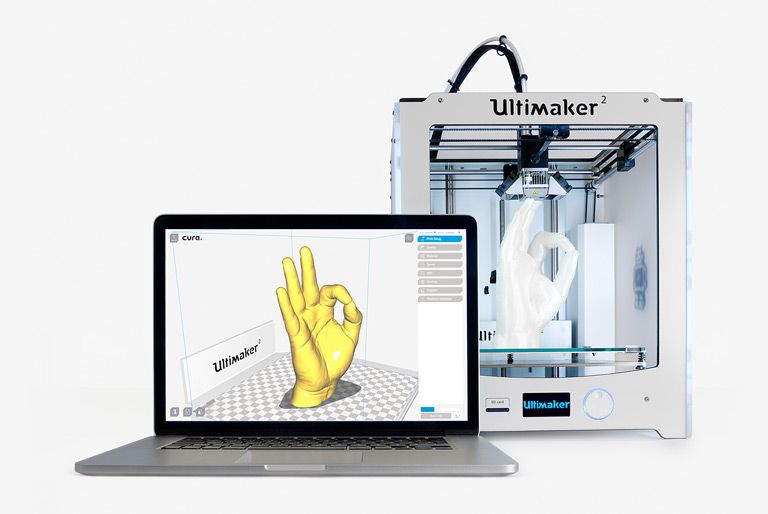

Cura is an open-source software tool developed by Ultimaker. A popular 3D printing slicer and new users can easily use the software with a quick learning curve. It is a fast and intuitive program, but advanced users can access another 200 settings when needing more precise control over print settings by switching from “Basic” mode to “Advanced” or “Expert.”

You can also use Cura as a 3D printer host software to control your machine, but the 3D printer needs to be connected to a PC during the whole 3D printing process. With Ultimaker Cura, users can monitor all the 3D printing jobs from a single user interface!

Price: Free

System: Windows, macOS, Linux

- Simplify3D

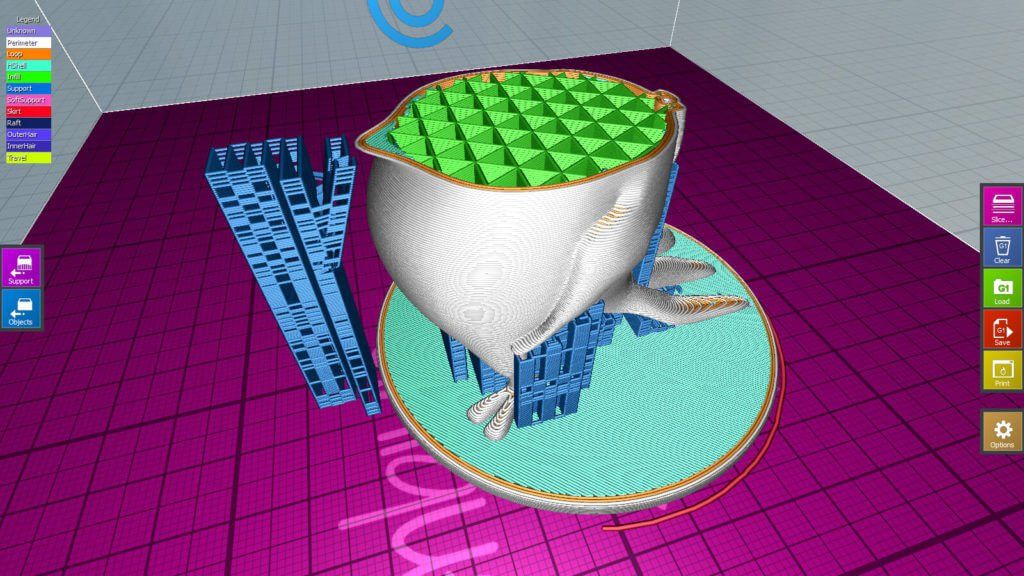

Simplify3D is a premium slicing tool. If you are looking for a slicer tool to improve the quality of your 3D prints, then this might be the right choice for you. Indeed, this tool is not only about slicing your model; it’s also correcting issues and allowing you to preview your 3D objects, preventing any other problems you might have.

If you are looking for a slicer tool to improve the quality of your 3D prints, then this might be the right choice for you. Indeed, this tool is not only about slicing your model; it’s also correcting issues and allowing you to preview your 3D objects, preventing any other problems you might have.

Simplify3D is compatible with most 3D printers and quickly switches between multiple machines.

Price: $149

System: Windows, macOS, Linux

- Slic3r

Slic3r is an open-source software allowing you to slice, preview, and more! Another widely used 3D printing tool. As a good slicing tool, Slic3r cuts your 3D design into horizontal layers, generates toolpaths to fill them, and calculates the amount of material needed to 3D print the object.

Slic3r is a non-profit community project which allows people to experiment with several advanced new features that have become quite common, such as multiple extruders, brim, micro layering, bridge detection, and so on!

Price: Free

System: Windows, macOS, Linux

- KISSlicer

KISSlicer is an easy-to-use and fast cross-platform app that efficiently slices STL files into printer-ready G-code files. The user interface is basic, but the software will deliver excellent results if you don’t need advanced setting options or customization.

The user interface is basic, but the software will deliver excellent results if you don’t need advanced setting options or customization.

The free version is only for single-head machines; if you want to use multi-head devices, you must choose the PRO version.

Price: Free for the basic version

System: Windows, Mac

- Repetier

This open-source slicer software will allow you to place, scale and rotate your object as well as slice it. You will also get the opportunity to preview your 3D model before 3D printing. Repetier supports three different slicing engines, Slic3r, CuraEngine, and Skeinforge, and handles 16 extruders. This 3D printing tool offers quite a lot of customization, ideal for more experienced users.

Price: Free, but you can donate to support the project

System: Windows, Linux, Mac

- PrusaSlicer

PrusaSlicer has been developed by the creators of the Original Prusa 3D printer, Prusa Research. They used the open-source program Slic3r to create their slicing tool.

They used the open-source program Slic3r to create their slicing tool.

This program includes many exciting features, such as customizable support structures, multi-material support, or even smooth variable layer height functions. PrusaSlicer 3D software can be used with both FDM and resin printers, and its various modes will allow you to adapt the settings to your skill level.

Price: Free

System: Windows, macOS, Linux

- OctoPrint

OctoPrint is a free, open-source software accessible from your web browser. It is a real web-based 3D printer host that allows for the control and monitoring of 3D printers. Moreover, OctoPrint is compatible with most 3D printers and offers the possibility to start, pause and stop the 3D printing process remotely.

This tool accepts G-code from any 3D slicer software but can also be used as a slicer for your 3D files, meaning OctoPrint can become your all-in-one print preparation package.

Price: Free

System: Web browser

- MatterControl 2.0

MatterControl 2.0 is developed by MatterHackers; this all-in-one program is a 3D printer host, slicer, and CAD software. This software will tackle your entire 3D printing process, from design to actual manufacturing.

This software package targets beginners and advanced users. Many tutorials are available on their website for new users, while experienced ones will have the pleasure to discover the possibilities of advanced settings for customized support generation.

Price: Free

System: Windows, macOS, Linux

- ISL

ISL is both a slicer and a 3D modeling tool. The developers’ goal was to make a powerful and accessible solution, particularly adapted to beginners. You can find a wide range of slicing settings and pre-configured options if you are not familiar with these programs.

Price: Free

System: Windows, Linux

Tools to edit and repair STL files

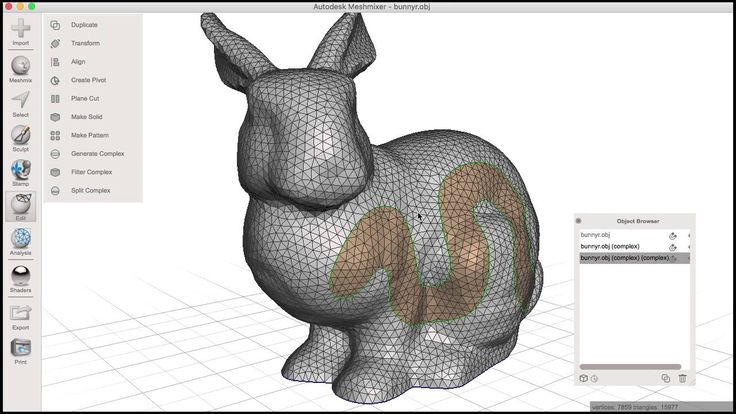

- Meshmixer

MeshMixer is a free mesh editing software. You can download it directly from Autodesk’s website. It’s straightforward to use if you want to edit STL files, especially if you wish to resize your 3D object or change some aspects. It considers all the different issues that you may face with your file. These software tools will allow you to get a repaired file ready for additive manufacturing.

You can download it directly from Autodesk’s website. It’s straightforward to use if you want to edit STL files, especially if you wish to resize your 3D object or change some aspects. It considers all the different issues that you may face with your file. These software tools will allow you to get a repaired file ready for additive manufacturing.

Moreover, it also has a built-in slicer tool. Thus, you can directly send your file from MeshMixer to a 3D printer.

Price: Free

System: Windows

- MeshLab

MeshLab is an entirely free and open-source program to edit your STL files. Professionals primarily use it since they appreciate its multiple mesh and point cloud processing functions. They also enjoy the possibilities it offers to manage massive files.

It has many processing tools like mesh analysis, cleaning of errors, remeshing, surface reconstruction, automatic smoothing, and visual inspection. Thus, it’s extremely powerful to edit your STL files. You can’t create an STL file from scratch, but you can create new models by merging some existing ones.

You can’t create an STL file from scratch, but you can create new models by merging some existing ones.

Price: Free

System: Windows, macOS, Linux

- FreeCAD

FreeCAD is a free and open-source CAD software. It uses parametric modeling and can be used by many different users, from beginners to professional 3D designers. Since it’s pretty easy to use, you don’t need to be an experienced CAD designer to use it. Architects and engineers mostly use it because its features were built for mechanical engineers.

Since it was designed for mechanical use and not for modeling, you can’t sculpt a model with it without difficulties. But it will be great to construct mechanical objects or fix your STL files.

Price: Free

System: Windows, macOS, Linux

3D modeling software

- Tinkercad

TinkerCAD is a browser-based program made by Autodesk, meaning you don’t have to download it; you can access it quite easily and start your 3D design and 3D modeling project. TinkerCAD is an excellent introduction to 3D software, perfect for beginners, and this program is adapted for educational purposes. This program will allow you to give life to your ideas without any previous 3D modeling experience.

TinkerCAD is an excellent introduction to 3D software, perfect for beginners, and this program is adapted for educational purposes. This program will allow you to give life to your ideas without any previous 3D modeling experience.

This app works by placing blocks one by one to create the object you want. It has a user-friendly interface making it easy to use the different 3D tools and create your 3D project. Keep in mind that you might need to switch to a more powerful 3D modeling tool for more complex and intricate designs.

Price: Free

System: Web browser

- 3D Builder

This 3D modeling application is integrated into Windows. Thanks to a simplified interface, 3D Builder can be used by anyone. A library is available, where you can choose among already made projects. This program is straightforward and doesn’t offer many options but still allows you to work on STL, OBJ, or 3MF files.

However, if you are looking for a program to initiate 3D modeling and 3D printing, you have to try it out.

Price: Free

System: Windows

- SketchUp Free

With many features and several advanced tools, Sketchup is a well-known professional-grade software. The software is beneficial for professionals who need to create 3D models easily to showcase them to their customers. This 3D software is primarily used for architecture, interior design, or engineering projects but can be used for 3D printing.

It offers an open-source library with an extensive collection of 3D models you can use and reuse for your projects. This 3D modeling program is free for personal use or students! Keep in mind that the accessible version of Sketchup is a web platform. This free version can already allow you to develop interesting 3D printing projects and is adapted to both beginners and advanced users.

Find out Sketchup alternatives.

Price: Free, pro version is $299/year

System: Web browser

- Fusion 360

Fusion 360 is cloud-based software developed by Autodesk, combining parametric, surface, freeform direct, and mesh modeling features.

This 3D software is gaining popularity among professionals and hobbyists. Fusion 360 by Autodesk combines Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Computer-Aided Engineering (CAE) software. It has a more modern take on design and will give you numerous design, simulation, and production tools. Fusion 360 will be excellent for 3D printing engineering projects, mechanical parts, and product design. It is also important to mention that Fusion 360 is cloud-based, making it much easier to work in teams.

Price: Yearly 495$

System: Windows, macOS, Linux

- Blender

Blender is a well-known computer-aided design software, and it is a powerful mesh-based direct modeling software and not a parametric one. Professionals even use Blender to develop video games or animation. It is pretty similar to software such as Mudbox or ZBrush, and it is not suitable for beginners.

This program is fantastic for artistic use, with excellent software tools such as sculpting, rendering, and fast modeling. But it is also a perfect software if you need to create 3D printable 3D models, as it also includes CAD features to repair your meshes. It can avoid bad surprises once parts come out of 3D printers.

But it is also a perfect software if you need to create 3D printable 3D models, as it also includes CAD features to repair your meshes. It can avoid bad surprises once parts come out of 3D printers.

Price: Free

System: Windows, macOS, Linux

Now that you have this selection of 3D printing software, you are ready for your 3D printing journey. If you don’t want to invest in your 3D printer and need professional quality, try out Sculpteo’s online 3D printing service! Upload your 3D file right now, and you will get an instant quote for your project.

Any questions about the 3D printing process of your parts? Contact us, our team of 3D printing experts, we’ll help you with your project.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

19 Best 3D Printer Software 2023 (For Every Stage!)

3D printing software programs are key for high quality printing, designing and monitoring — without software, 3D printers are just machines with no direction. 3D printer software take a variety of different forms: 3D software modeling tools to design 3D models, 3D slicers to slice STL files for printing, and specialist software for fixing errors in your models.

To make things easier for you, we have split each of these types of 3D printer software into sections. Within each section we have free 3D printing software options, as well as premium, paid options.

What makes good 3D printing software?

While we include a range of very different 3D printing software designed to address very different needs, there are some key aspects that make or break software for your 3D printer.

- Wide range of tools: we picked 3D printing software with a versatile toolset.

- Team-friendly: the best tools ideally let you collaborate with your friends, team and co-workers — especially in design software.

- Versatile: beyond the range of tools available, being able to work with a range of file types beyond just STL makes life much easier. For example, GCode, OBJ, DXF files and many other types that are commonly used.

- Save you money and time: a good example is simulation features in the most premium 3D printer design software that can simulate and analyze your model to identify areas likely to break or snap under strain, as well as any parts that are likely to warp or come out badly from printing unless supports are used.

Which is the best 3D printing software?

This is difficult to answer because there are simply so many different types of 3D printing software. These range from slicers, to 3D printer design software, to software for managing many 3D printers at once. Our ranking therefore covers:

- Part 1: 3D printer design software: including both CAD software for 3D printing, and 3D modeling software for 3D printing.

- Part 2: Sites to download 3D printer files: not technically software but still useful for those who do not want to design their own models.

- Part 3: 3D printer slicer software: for slicing models to print.

- Part 4: 3D printing software tools for fixing errors in your models and optimizing prints

- Part 5: 3D printing host software for remote monitoring and printing

Overall, we recommend almost 20 different 3D printing software options to maximize your 3D printing experience. We also include links to download each software, and a short description of the main advantages of each tool we recommend.

For any budding 3D designers, we recommend some 3D CAD design modeling tools for 3D printing below. We have sorted them from most beginner-friendly to most advanced, and included several free 3D printer design software.

1 – TinkerCAD — best free CAD software for 3D printing

- Price: Free — Available here

- Browser-based – no download

- Skill level: Beginner

Pros

Easy to use.

Browser based so no download is required.

Perfect for kids and beginners.

Cons

Not suitable for complex designs.

A free 3D printer software tool for creating printable models, TinkerCAD is suitable for both adults and beginners, and younger users will have no trouble understanding TinkerCAD’s beautifully simple interface and design tools.

This simplicity makes it accessible; all you need to do to get started is to drag and drop pre-designed objects, like cubes and pyramids, and adjust, rotate and resize them to create a cohesive model you want to print.

Some may want a more professional 3D software tool with more advanced creation and editing, but as a free 3D printer design software for beginners, TinkerCAD is a great introduction. More complex designs can be created by connecting many smaller shapes together, so it’s an underrated tool.

Younger kids are also getting experience with this 3D printing software tool in school, with increasing numbers of classes using TinkerCAD to teach basic design and engineering principles in STEM education.

Once designed, you can easily export your models as STL files for 3D printing, and view them in any previewer, as well as posting them to Facebook using their 3D viewing features. Perhaps after ascending TinkerCAD’s shallow learning curve you’ll want something more advanced, but as a tool to learn a 3D printing software modeling tool, TInkerCAD is a fantastic introduction.

2 – FreeCAD — great free 3D printer design software

- Price: Free — Download it here

- Type: Downloadable program

- Skill level: Intermediate

Pros

Easy to use.

Open-source.

Multiple options for exporting files.

Cons

Not beginner-friendly.

A free and open-source tool for creating 3D printing files, FreeCAD offers more depth and complexity than TinkerCAD, for those with some 3D design experience looking for a step up.

Heavily adopted in architecture, rapid prototyping for product design, and especially in mechanical engineering, FreeCAD has everything you need to create great prototypes, vehicle models and other fun projects.

You have far more control over the types of shapes and geometries with FreeCAD, such as in the advanced creation of curves and boundaries. Additionally, you can draw a 2D base for your eventual 3D model using their Sketcher Workbench tool, and use that blueprint to then build up your 3D design.

3 – Blender — most advanced 3D printer modeling software (and it’s free!)

- Price: Free — Available here

- Type: Downloadable program

- Skill level: Advanced

Pros

Huge active community.

Integrated game engine.

Comes with video editing capabilities.

Cons

Steep learning curve.

Like FreeCAD, Blender is a free and open source 3D printer modeling software tool, with a huge community committed to sharing their creations as well as coding new features that enhance Blender’s uses and offering.

Blender is a tool with huge depth; its features are not constrained to just 3D modeling, but include film and video game asset design and animation, video editing, and more. If you can traverse the steep learning curve, Blender is one of the most advanced and rewarding software tools you can ever learn.

If you can traverse the steep learning curve, Blender is one of the most advanced and rewarding software tools you can ever learn.

As a 3D printer software tool, Blender offers advanced sculpting, brushing and modeling tools, with ways to intricately change a design’s surface finish with a variety of different brushes, and UV unwrapping for advanced mesh editing options.

For advanced designers looking to create extremely precise models that fit their needs, especially in character design and 3D printed miniatures, Blender is one of the most sophisticated 3D printing software tools out there. If it cost $500 for the exact same feature list, most people wouldn’t bat an eyelid.

4 – Fusion 360 — best 3D printer modeling software (if you can afford it)

- Price: Free for students, or $495/year — Available on Autodesk here

- Skill level: Intermediate to Advanced

Pros

Great software for experts and educated beginners.

Cloud-based file sharing.

The modeling tools are really good and powerful.

Cons

No web-based version which is a drawback for cloud-based software.

One of the many sophisticated 3D modeling software for 3D printing offered by Autodesk, Fusion 360 is an expert program that’s still usable by an educated beginner. Fusion 360 is used extensively in designing products for rapid prototyping prior to manufacturing runs, electronics designs, mechanical engineering, and more.

One very useful aspect of Fusion 360 is the ability to collaboratively edit STL files in the cloud, so if you have a collaborator they can view and edit your designs prior to any 3D printing. If you’re both happy with your design, Fusion 360 can assess your models to locate any potential weak points that you can change and strengthen, saving you time and money from finding out any weak points later only after you’ve printing. Once finished, you can seamlessly export your finished 3D printer models as STL files and load them into a 3D slicer software program to print.

Though it comes at a cost, Autodesk have made Fusion 360 free for students on an educational license, as well as offering a free trial for all users. So, for any students looking to enhance their 3D design skills, Fusion 360 could be the ideal 3D printer modeling software for you.

5 – Rhino 6

- Price: $995 / $195 for students — Available here

- Skill level: Advanced

Pros

A more affordable option for professionals and students.

Built for intricate modeling and editing.

A wide variety of tutorials are available.

Cons

A better version of Rhino is now available.

Another premium software tool option, Rhino 6 is a more affordable tool for professionals and students, with a steep student discount to cost just $200. Built for intricate modeling and editing of even the smallest elements of parts, Rhino uses sophisticated curving, polygon meshing and surface editing tools to create perfect 3D designs.

Rhino can come in especially useful in the designing of strangely-shaped objects, using its free-form modeling features to create even the weirdest of shapes with ease. It’s very versatile, allowing for the creation of room-sized structures, as well as the smallest and most intricate jewelry designs or characters with minute and precise elements.

It’s very versatile, allowing for the creation of room-sized structures, as well as the smallest and most intricate jewelry designs or characters with minute and precise elements.

Some will also prefer Rhino’s payment method of a one-time, permanent license. This departs from the trend of monthly or yearly software subscriptions, making Rhino 6 a great 3D printer software option for those who want to pay once, and not pay again. The learning curve is not too steep, and Rhino themselves include a wide variety of tutorials to most of the complex tools available. Overall, it’s another good 3D printing software option for designing printable 3D models.

3D Printer Software Part 2: Sites to download STL files for 3D printing

This section features a few of the most well-known STL file download sites.

- We also have a full article for every STL file site, marketplace and repository, including niche STL file repositories for NASA spacecraft, medical models, and more.

Make sure to check our full article on STL file sites.

Make sure to check our full article on STL file sites.

6 – Thingiverse

- All files are free to download — Available here

Pros

Files are completely free to download and remix.

Easy-to-use search engine.

Cons

Has had repeated data breaches, making it not exactly safe.

The largest 3D printer model and STL file site on the web, Thingiverse is owned by Makerbot and was set up in 2008 to accommodate user-designed 3D files for Makerbot’s originally open source 3D printers.

Since then, the site has grown to host hundreds of thousands of 3D printer models; with so many quirky and fun designs available that you’ll never be left disappointed. All files are completely free to download and remix – make sure to post your edits! – and designs range from prints that will improve your productivity, hold your clothes, jewelry or stationery, and many movie, TV and video character designs hosted.

There are even designs that could potentially change your life, such as 3D printable prosthetic hand designs.

7 – Cults

- All files are free to download — Available here

Pros

A huge variety of downloadable files are available.

Encourage the use of gifs to better showcase how the 3D model will look.

Cons

Customer support is not great.

French site Cults was founded in 2014 and has grown to host over 120,000 3D printable files, receiving an incredible 17.5 million page views per month.

There are a huge variety of downloadable files available, ranging from a full-size 3D printed kayak, innovative wall storage, vases, light accessories, and even a to-scale 3D printable diplodocus skull!

An advantage of Cults is that they encourage the use of gifs and moving image to better showcase how a 3D model will look after printing, giving curious users more insight into how the model could function before committing to downloading and printing the model, saving valuable filament.Compressed by jpeg-recompress

8 – Pinshape

- Free and paid 3D models — Available here

Pros

Family-friendly.

Great for teaching children how 3D design works.

Huge variety of great files and projects available.

Cons

Only accepts two file types.

Pinshape is a family-friendly STL file hosting site with mainly free 3D models, but also features premium models you’ll need to pay to download.

The friendly UX makes Pinshape a great option for families looking for a fun 3D printing project, especially those who also want to teach their children how 3D design works and basic principles of engineering.

- If you’re looking to teach your kids about 3D printing, read our ranking of the best 3D printers for kids.

Nerds will love some user-uploaded attempts to replicate Batman’s grenade launcher, the 3D printable battle scene from the Avengers, or even a Buddha status with Yoda’s head – because why not? There’s a huge variety of great files and projects here, and you also have the option to pay a small fee (usually a few dollars) for premium 3D files.

9 – MyMiniFactory

- Free and paid 3D models — Available here

Pros

Great variety of models.

Designers can make money selling their premium 3D designs.

Cons

The user interface is poorly designed.

Mixing free and paid 3D models to load up into your 3D printing software, MyMiniFactory offers a great variety of models, including an extensive range of tabletop models – I particularly loved the Pokemon chess set with Ekans for a rook, and Mewtwo for a king.

Designers can also make money selling their premium 3D designs and have their own stores for fans and customers to visit, but the majority of models are still free for casual makers.

3D Printing Software Part 3: 3D Slicers

10 – Cura

- Price: Free — Available here

Pros

Powerful free and open-source slicing.

Huge active community.

One of the best free 3D slicers available.

Highly intuitive features and settings.

Cons

Unoptimized for low-end PCs.

Cura, made by 3D printing legends Ultimaker, is the most widely used 3D slicer. It’s free to download and use and open source, so you’re free to modify and improve the 3D printer software if you have the technical skills.

It’s free to download and use and open source, so you’re free to modify and improve the 3D printer software if you have the technical skills.

Though made by Ultimaker, Cura is compatible with almost any 3D printer you can ever think of, with custom pre-sets for hundreds of the most commonly used printers. Advanced users can tweak their settings according to their needs such as for supports and infills, whereas beginners can use the 3D printing software’s recommended settings for quick and easy printing.

Designed to be simple to use and integrate into your 3D printing workflow, Cura can seamlessly link with 3D CAD software tools, such as Autodesk Inventor and SolidWorks. Once you have a finished 3D model you want to print, simply choose your print settings and parameters in Cura’s Prepare stage, then preview the model in Cura’s Preview stage, which can alert you to any potential errors that would cause the print to fail, and correct them without wasting time and filament. Then once you’re ready to print, the Monitor stage allows you to remotely observe progress, including displaying estimated time remaining and the estimated amount of filament required.

Overall, it’s the most widely used, free 3D printing software for a reason, and millions of budding makers use Cura to realize their 3D dreams.

11 – Slic3r

- Price: Free — Available here

Pros

Non-profit initiative.

Open-source.

High levels of customizability and advanced features.

Cons

Less powerful engine than the likes of Cura.

Slic3r is another widely used free 3D printing software, more geared towards open source RepRap 3D printers than Cura. It’s a completely non-profit initiative, and is completely open source for other designers to adapt and improve the software – PrusaSlicer is a modified version of Slic3r.

High levels of customizability and advanced features come in this free 3D printer software package, including a wide variety of infill settings, extensive preview settings for ensuring you’re happy with your model prior to printing, and efficient dual extruder 3D printer settings for printing supports in a different material.

Known for its versatility, Slic3r can be easily integrated into OctoPrint, the 3D printing host program we discuss more later in this article. It even works with resin 3D printers as well as FDM printers, so you don’t need to use a resin 3D slicer if you have Slic3r.

12 – PrusaSlicer

- Price: Free — Available here

Pros

User-friendly interface.

Can handle a variety of printers and filaments.

Great for beginners and more advanced users.

Cons

No option to smart hide seams in models.

Prusa 3D printers are the leading 3D printer kits, known for their immense reliability, fantastic accuracy and workhorse-like resilience. You can now even turn your Prusa machine into a color 3D printer with the Multi Material Upgrade Prusa sell.

Prusa has adapted Slic3r for Prusa printers, with an updated, more user-friendly interface that can handle a variety of different printers, and a wide range of over sixty different filaments with custom settings. You can also print on resin 3D printers, such as the Prusa SL1, using PrusaSlicer.

You can also print on resin 3D printers, such as the Prusa SL1, using PrusaSlicer.

Beginners will appreciate the accurate automatic supports you can generate, with advanced users able to take control of more intricate support generation based on their needs. Overall, it’s a great 3D printing software and slicing tool for Prusa printers.

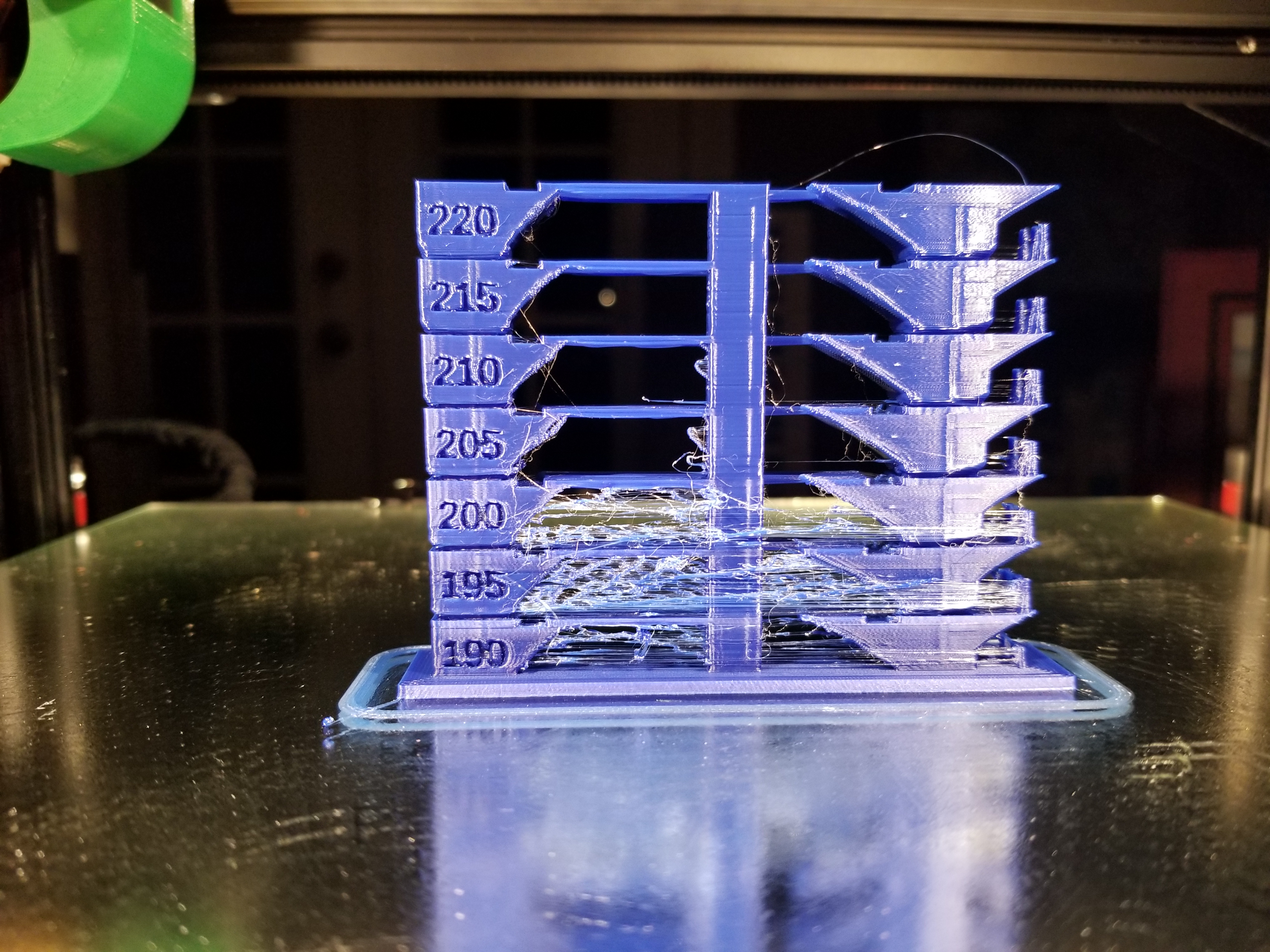

13 – Simplify3D

- Price: $149 — Available here

Pros

Offers some of the most advanced slicing and previewing features around.

Precise settings allow for customization of the thickness, layout, and material of your supports.

Cons

May be expensive for some people.

Though not a free 3D printing software tool, Simplify3D offers some of the most advanced slicing and previewing features around. It is claimed to be compatible with more printers than any other 3D printer software, and is used in STEM education, rapid prototyping, and many other hobbyist and industrial applications.

For the $150 purchase price you get to use Simplify3D on two separate computers. Your money buys you some of the most advanced support settings around, with precise settings allowing for the customization of the thickness, layout, and material of your supports, as you may be using a dual extruder 3D printer and want to print them in a soluble filament like PVA. Optimized support settings lead to better parts overall as parts keep their shape during printing, and have better surface finishes afterwards if supports can be removed more easily and without damaging the part.

You can precisely create rafts and brims, especially useful for tougher filaments like Nylon and ABS, and the previewing features can pick up things you might have missed that could cause the print to fail. Overall, if you’re spending several hundred dollars on a 3D printer, it is worth considering paying another $150 for an effective 3D printing software to ensure you print the best quality parts with optimized settings.

14 – Repetier-Host

- Price: Free — Available here

Pros

Can reshape, resize, and edit your imported STL files.

Open-source.

Good depth of features.

Cons

Might be too advanced for beginners.

Repetier-Host is one of a number of 3D printer software options that Repetier offer, and is a 3D slicer which lets you reshape, resize and edit your imported STL files before printing them.

Another open source 3D printing software tool, Repetier-Host is known for its effective multi-extruder support and its versatility and compatibility with such a wide range of 3D printers.

It’s not as user-friendly, and perhaps more for advanced users than beginners, but offers a number of key benefits including remote access (if you use their Repetier-Server software) to monitor printing on your smartphone or tablet on the move.

It has a good depth of features, and can handle any kind of slicing necessary for your 3D printing needs. Overall, Repetier-Host is a good 3D printing software for those with 3D printing experience, and who enjoy how well the full Repetier set of tools integrate together.

Overall, Repetier-Host is a good 3D printing software for those with 3D printing experience, and who enjoy how well the full Repetier set of tools integrate together.

Part 4: 3D printing software for fixing STL files and making edits

15 – Meshmixer — 3D printing program for fixing files

- Price: Free — Available here

Pros

Able to edit existing models with a variety of tools.

Topological optimization makes parts lighter, saving weight and costs.

Cons

Difficult to use when developing pieces from scratch.

Owned by Autodesk, Meshmixer is a great 3D printing program which not only cleans up user-designed models to print, but can also fix any 3D scans you have recently made on your 3D scanner.

Meshmixer has a huge list of features, including editing precise elements of meshes in your models, resculpting surfaces, aligning surfaces, filling any holes in your model, detecting and repairing errors, and smoothing existing meshes, and all for free.

Key advantages include re-orienting models, for example by laying a character model on its side to minimize the overhangs when printing, therefore reducing the number of supports needed. In addition, Meshmixer lets you trim the bottom or top of your design if you don’t need it, useful if you don’t have enough filament to print the whole thing.

For industrial, or just large prints, Meshmixer works well. You can split large models into separate slices, saving each individual slice as a separate STL file to print one at a time. This is especially useful if you have a small 3D printer.

16 – MeshLab

- Price: Free — Available here

Pros

Very useful for color 3D printing.

Can hollow out models to save costs.

Very sophisticated STL editing system.

Cons

May be too advanced for beginners.

An open source 3D printing tool for cleaning up 3D scans and enhancing models prior to 3D printing, MeshLab is a very sophisticated STL editing system.

MeshLabs supports the improvement of colors in prints based on contrast, saturation and sharpness of colors – very useful for color 3D printing – as well as aligning raw 3D scans to improve them.

Additionally, with 3D printing in mind, MeshLabs can also hollow out models for those who want to save on material costs and do not mind a lower strength part, close any small holes in the piece, and flatten the bottom of your models to improve layer adhesion to the print bed during printing.

Overall, it’s a sophisticated STL and 3D file fixing and editing system, and well worth using for advanced users who crave added customization.

17 – Autodesk Netfabb

- Price: $30/month or $240/year for Standard, $550/month or $4,415/year for Premium — Available on Autodesk here

Pros

Great for advanced and industrial 3D printing.

Includes topology optimization features.

Cons

Not for hobbyist projects.

An Autodesk product for extremely advanced and industrial 3D printing and rapid prototyping applications, hobbyists will have no need for this level of customization, but it can be key for high-added-value, industrial applications in sectors such as automotive, medical and aerospace.

NetFabb allows you to design and edit models especially with additive manufacturing in mind, and optimize them for printing multiple parts simultaneously by packing them into the build volume of your printer most efficiently. This is especially important for saving costs in SLS 3D printers, as well as maximizing efficiency in Multi Jet Fusion.

This 3D printing software includes advanced topology optimization features, the creation of internal lattice structures for lightweight yet strong parts, and a variety of other premium features. Overall, it’s the most advanced 3D printing software for additive manufacturing, and wholly for industrial applications, rather than hobbyist projects.NetFabb can generate extremely precise supports, shown above for this model, to ensure the part comes out perfectly.

Read more: the best STL editors

Part 5: 3D Printing Hosts & Remote Monitoring Software

18 – OctoPrint – best 3D printer management software

- Price: Free — Available here

Pros

Easy remote monitoring of prints on any device.

Hundreds of custom plugins are available.

Cons

Not a specialized 3D slicer.

Though OctoPrint also features 3D slicing tools, it functions as a full hosting 3D printing software system. Fully open source, and kept free by the kind donations of its supporters, OctoPrint allows for easy remote monitoring of prints on any device you can think of, from tablets to smartphones and more, and is commonly ran from a Raspberry Pi.

OctoPrint lets you see how far through your print is, the extruder temperature, estimated remaining time, and the GCODE visualizer shows you how much of your print has been completed, in real-time, without you needing to even be in the same country as your 3D printer.

If you see any clear errors are occurring, you can remotely stop the print, saving money on wasted filament. You can hook up your webcam to get actual footage of your print, and even move the print head across any axis as you need to.

You can also slice STL files for printing, but to just call OctoPrint a 3D slicer is underselling it. There are hundreds of custom plugins available to download that will enhance your experience within OctoPrint, with more technically-skilled makers able to benefit from OctoPrint’s data, remote viewing and increased control over prints.

There are hundreds of custom plugins available to download that will enhance your experience within OctoPrint, with more technically-skilled makers able to benefit from OctoPrint’s data, remote viewing and increased control over prints.

19 – 3DPrinterOS — great 3D printer software for schools and large businesses

Pros

Also an operating system.

Can send files to hundreds of 3D printers at once.

Ideal for designers wanting to sell their files online without the risk of exposing them to being copied.

Cons

Steep learning curve.

Not just a 3D slicer, 3DPrinterOS is an operating system you can run multiple slicers and other types of 3D printing-related software on — all in the cloud.

You can use it to send files to hundreds of 3D printers at once if you run a large prototyping service, or to all the 3D printers in your school or university for certain tasks, making it a great 3D printer management software option for schools and businesses.

Moreover, it’s even ideal for 3D designers who want to sell their files online but don’t want to risk exposing them to be copied. 3DPrinterOS’ API protects the source file as it is never exposed during the sale or print ordering process — so any 3D designers getting started will find this hugely useful.

The ability to manage several 3D printers simultaneously, with readily available data reports and control of files sent to each printer, makes it a huge asset as a 3D printing software for schools.

For businesses, companies like Kodak and Cisco organize their prototyping with 3DPrinterOS as it’s such a scalable 3D printer management program.

90,000 best 3D printers 2022-2023 for production and business: expert rating3D scanners

Analyst and business

The best on the topics

Experts recommend

3D-printers

Author: Semen Poladeyuk

Author: Semen Polaezhak

Summing up the results of the outgoing year, we tried to choose the most interesting solutions that appeared in 2022 on the global 3D printing and 3D scanning market. Of course, our top is far from covering even a small part of the novelties of the grandiose 3D industry. We have highlighted several developments that have attracted increased attention from users and professional industry experts.

Of course, our top is far from covering even a small part of the novelties of the grandiose 3D industry. We have highlighted several developments that have attracted increased attention from users and professional industry experts.

Note that the best 3D printers and 3D scanners of 2022 roundup does not include the home (consumer) segment. In accordance with the direction of the blog, we are considering professional and industrial equipment that will reduce time, material and labor costs for manufacturing enterprises, research, educational and medical organizations, as well as in the field of business projects. Thanks to such innovations, the locomotive of the industry is moving.

Blog materials will help you navigate the typology of equipment and choose the best solution:

-

Types of 3D printers: technologies, materials, applications

-

Choosing a 3D Printer: Find the Right Solution for You

-

How to choose a 3D scanner

If you have questions about the implementation of 3D technologies, please contact iQB Technologies experts

Top 8 3D printers

HBD E500

© HBD

HBD is one of the Chinese market leaders in metal 3D printing. The manufacturer's portfolio includes more than 15 models of printers with cameras from 150 to 1500 mm. In 2022, the line was replenished with perhaps the most versatile machine - the HBD E500. It's a true workhorse for trouble-free printing of complex custom or prototype designs up to 520mm.

The manufacturer's portfolio includes more than 15 models of printers with cameras from 150 to 1500 mm. In 2022, the line was replenished with perhaps the most versatile machine - the HBD E500. It's a true workhorse for trouble-free printing of complex custom or prototype designs up to 520mm.

The printer is equipped with two or three lasers, depending on customer requirements, equipped with a safe and reliable filtration system and provides a closed powder supply cycle. With its high print speeds of up to 10,000 mm/s, the E500 is well suited for continuous batch production in a variety of industries such as automotive, mechanical engineering, aviation, foundry, education and R&D.

SLM NXG XII 600E

© SLM Solutions

At Formnext 2022, SLM Solutions, market leader in metal 3D printing, announced its latest development, the largest additive manufacturing machine for selective laser melting technology. Based on the popular NXG XII 600 model, the new model has a larger build area of 1. 5 m in the Z-axis, which is reportedly 50% larger than the equipment of the nearest competitor.

5 m in the Z-axis, which is reportedly 50% larger than the equipment of the nearest competitor.

Metal-to-metal additive manufacturing customers are demanding ever larger parts – and as quickly as possible. Serial production of products of complex geometry can now be implemented in a few hours or days, rather than weeks and months. To meet these expectations, the NXG XII 600E provides an end-to-end manufacturing process to increase machine uptime.

The system platform features an open SLM architecture that allows flexible process parameters for maximum performance at a layer thickness of 90 micron or more (when working with popular materials such as IN718, AlSi10Mg, TiAl6V4 and copper alloys).

IEMAI FAST JET 1500

© IEMAI

-

Technology: FDM/FGF

-

Construction area: 1500 × 1500 × 1500 mm

-

Features: creation of large objects from granulated thermoplastics and remote control of the printing process

The use of polymers in the form of granules in 3D printing makes it possible to save even more on materials and speed up the process of printing large-sized objects compared to filaments. Another well-known Chinese manufacturer, IEMAI, introduced the FAST JET 1500 large-format FGF printer for printing products up to 1.5 meters in length, width and height.

Another well-known Chinese manufacturer, IEMAI, introduced the FAST JET 1500 large-format FGF printer for printing products up to 1.5 meters in length, width and height.

The 3D printer features an elevated extrusion temperature (500°C), a 3-stage extrusion temperature control system, and a closed isolation chamber to handle most thermoplastic pellets available on the market, including PLA, nylon, and high-performance materials such as PEEK and PEKK. .

The FAST JET 1500 also features a proprietary 6-axis control system and a 10″ full color touch screen with remote automatic loading. In addition, the printer is one of the first models to be sold with a built-in IEMAI cloud platform for remote control of material drying, G‑od file uploads, printing at regular intervals, and remote monitoring of the printing process.

F2 Gigantry

© F2 Innovations

The Perm company F2 innovations, which develops and manufactures industrial 3D systems, has introduced a novelty - a granule printer with the largest print area.

The F2 Gigantry is an open gantry with an extruder capable of creating parts up to 4 meters long, 2 meters wide and 1 meter high. The technology allows printing with polymer granules with a capacity of up to 10 kg/h, including recycled materials (recycled granulate).

FGF-printing technology is not new, but F2 Gigantry became the first domestic large-format 3D printer in this category. Today, the question of a quick and high-quality replacement of imported solutions, as well as the acceleration of production with an increase in the number of manufactured products, is acute. The novelty from F2 Innovations will help to solve these problems effectively.

ProtoFab PF‑S300 / PF‑S350

© ProtoFab

Professional Russian users are already familiar with SLA printers from the Chinese company ProtoFab, and this year the manufacturer introduced a series of high-precision industrial units based on selective laser sintering (SLS) technology.

The ProtoFab PF‑S300 and PF‑S350 are equipped with a new dynamic thermal control system that further optimizes temperature distribution monitoring, encapsulation and sensor performance. Nylon, carbon fiber composite nylon powder, glass fiber composite nylon powder and other plastics are used as consumables.

The speed of laser illumination is increased to 3 m/s, which significantly speeds up molding by increasing the speed of powder spraying. The printers are equipped with new, efficient powder removal accessories, which can reduce production costs and lead times. With a cylinder temperature of 220°C, the PF‑S300 and PF‑S350 are capable of sintering materials with a melting point of 225°C or lower.

Sinterit Lisa X

© Sinterit

The Polish company Sinterit sets another record: according to the manufacturer, the new SLS system is ten times faster than its predecessor, the Lisa PRO model. Lisa X is capable of sintering PA12 at speeds up to 14 mm/h and completing a full print session in just 30 hours. Relatively inexpensive and compact, a 3D printer can truly boast the performance of an industrial device and allow companies to speed up product development and time to market.

Relatively inexpensive and compact, a 3D printer can truly boast the performance of an industrial device and allow companies to speed up product development and time to market.

Open source software allows you to customize 32 print settings to suit your individual needs. Media changes can be done in 15 minutes, and printing and cooling can take up to 40% less time than any other compact SLS printer.

Lisa X also features a unique "airblade" system that automatically cleans the glass around the laser during production, meaning users don't have to do it manually in two out of every three sessions, speeding up print preparation.

Massivit 10000

©Massivit 3D

-

Technology: Cast-In-Motion

-

Construction area: 1200 × 1500 × 1650 mm

-

Features: production of molding equipment in the shortest possible time

Another interesting novelty for 2022 is a large-format additive machine from the reputable Israeli manufacturer Massivit 3D. The system uses a hybrid technology of photopolymer 3D printing and thermoplastic injection, called "Cast-In-Motion" (CIM). The printer is designed for the production of molding equipment for the subsequent manufacture of products from composite materials. Two printheads are used respectively to form the photopolymer gel formwork and to fill the internal cavities with thermoplastic. After heat treatment of the printed product, the photopolymer shell dissolves, and the resulting form undergoes finishing machining.

The system uses a hybrid technology of photopolymer 3D printing and thermoplastic injection, called "Cast-In-Motion" (CIM). The printer is designed for the production of molding equipment for the subsequent manufacture of products from composite materials. Two printheads are used respectively to form the photopolymer gel formwork and to fill the internal cavities with thermoplastic. After heat treatment of the printed product, the photopolymer shell dissolves, and the resulting form undergoes finishing machining.

This technology, according to the manufacturer, allows to reduce the number of stages of the production process and reduce the time for the manufacture of molding equipment by 80%.

BMF microArch S350

© Boston Micro Fabrication

-

Technology: projection microstereolithography (PµSL)

-

Construction area: 100 × 100 × 50mm

-

Features: high resolution microscale photopolymer printing

And here is one of the latest new products for 2022 - a photopolymer microprinting machine from Boston Micro Fabrication (BMF). The microArch S350 is the highest performing BMF printer for the final part industry, as it can print not only high-resolution micro-scale objects (up to 10 microns), but also many small objects that require high precision and detail. The 3D printer is suitable for prototyping and additive manufacturing in the amount of one thousand to 30 thousand products and will find its place in enterprises and research laboratories.

The microArch S350 is the highest performing BMF printer for the final part industry, as it can print not only high-resolution micro-scale objects (up to 10 microns), but also many small objects that require high precision and detail. The 3D printer is suitable for prototyping and additive manufacturing in the amount of one thousand to 30 thousand products and will find its place in enterprises and research laboratories.

The microArch S350 is based on BMF's projection microstereolithography (PµSL) technology, which is a form of masked stereolithography (MSLA) using ultraviolet light with microscale resolution.

Top 5 3D Scanners

FARO Focus Premium

© FARO

-

Type: ground laser 3D scanner

-

Distance measurement accuracy: ±1mm

-

Scanning speed: up to 2 million points per second

-

Features: Unsurpassed scanning quality in one minute

The super-hit FARO Focus series has been replenished with improved Premium models. The new line includes three instruments with a scanning range of 70, 150 and 350 meters and features higher speed, increased resolution, hardware noise reduction and the ability to remotely control the instrument from any mobile device.

The new line includes three instruments with a scanning range of 70, 150 and 350 meters and features higher speed, increased resolution, hardware noise reduction and the ability to remotely control the instrument from any mobile device.

Premium is 50% more productive than its predecessors: measurements take an average of one minute using the optional PanoCam, even when scanning in color. Remote control of the scanner and stitching of scans from a mobile device is performed using the Stream application with subsequent integration into the Sphere cloud platform.

New devices are perfect for projects in the field of manufacturing, architecture, civil and industrial construction. And a nice bonus: the official warranty period from the manufacturer has been extended to two years.

Also in 2022, FARO launched the Focus Core, a cost-effective terrestrial scanning solution with an optimal balance of speed and accuracy.

EPiC EasyScan T10

© EPiC

-

Type: terrestrial 3D laser scanner

-

Accuracy: 1cm at 10m, 2cm at 30m, 5cm at 100m

-

Scanning speed: 320 thousand points per second

-

Features: Easy-to-use entry-level device

The appearance of such devices marks a new milestone in the evolution of laser scanning technology, which optimally combines economy, quality and ease of use. The EasyScan T10 from China's EPiC (Wuhan Eleph‑Print Tech Co, Ltd.) will be in demand when processing time and measurement convenience are more important than obtaining high-precision data. The scanner is equipped with a 360 °C panoramic camera, and the signal emission system and sensors are securely and ergonomically integrated into the body.

The EasyScan T10 from China's EPiC (Wuhan Eleph‑Print Tech Co, Ltd.) will be in demand when processing time and measurement convenience are more important than obtaining high-precision data. The scanner is equipped with a 360 °C panoramic camera, and the signal emission system and sensors are securely and ergonomically integrated into the body.

The scanner is launched with one button. A dual scan mode is available, which allows you to combine the simultaneous operation of a panoramic camera and lidar. Data stitching is done on a mobile device. Weighing only 3.2 kilograms, the instrument is one of the lightest geodetic scanners on the market. The package includes everything you need for scanning, including a tripod, batteries and free software for data processing.

Artec Leo 2022

© Artec 3D

-

Type: Handheld Structured Illumination 3D Scanner

-

Accuracy: up to 0.1 mm

-

Scanning speed: up to 35 million points per second

-

Features: The legendary Leo - with double the power and even more accuracy

In the past year, Artec 3D introduced a new version of its popular Leo system, released in 2018. The Artec Leo 2022 Wireless Handheld 3D Scanner offers twice the processing power, improved capture of vibrant colors, an updated built-in touch screen, a multilingual interface, and guaranteed high accuracy. The new Auto Temperature Control feature allows the scanner to regulate its operation and maintain the optimal operating temperature of the components.

The Artec Leo 2022 Wireless Handheld 3D Scanner offers twice the processing power, improved capture of vibrant colors, an updated built-in touch screen, a multilingual interface, and guaranteed high accuracy. The new Auto Temperature Control feature allows the scanner to regulate its operation and maintain the optimal operating temperature of the components.

Powered by an updated NVIDIA Jetson TX2 processor, power consumption is reduced to less than 7.5W. The capture area is 160,000 cm 3 , which means the Leo 2022 can scan objects larger than 200 cm, from auto parts to people and rooms.

peel 3d peel 3

© Peel 3d

-

Type: Handheld Structured Illumination 3D Scanner

-

Accuracy: 0.250 mm/m, up to 0.1 mm

-

Scan speed: 80 sec/m 2

-

Features: A new generation of affordable scanners for reverse engineering

peel 3d, a subsidiary of Creaform, has released a completely redesigned peel 3 solution. This scanner boasts not only higher accuracy than the brand's previous models, but also improved usability thanks to its ergonomic design, tactile feedback and intuitive touch screen capabilities. All of these improvements aim to improve the scanning experience for both novice and advanced users. Applications of the 3D scanner cover product development, cultural preservation, AR/VR, healthcare, auto tuning, parts manufacturing, engineering, and more.

This scanner boasts not only higher accuracy than the brand's previous models, but also improved usability thanks to its ergonomic design, tactile feedback and intuitive touch screen capabilities. All of these improvements aim to improve the scanning experience for both novice and advanced users. Applications of the 3D scanner cover product development, cultural preservation, AR/VR, healthcare, auto tuning, parts manufacturing, engineering, and more.

The scanner is also offered with peel 3.CAD proprietary software, which has been specifically designed as a complete reverse engineering solution.

Scantech SIMSCAN

© Scantech

-

Type: Handheld 3D Laser Scanner

-

Accuracy: up to 0.2 mm

-

Scanning speed: up to 2.8M points per second

-

Features: compact and high performance device for professional use

Scantech (China) has released an updated version of the compact and portable SIMSCAN 3D scanner. It aims to set a new standard in metrology with palm-sized, high scanning performance, low power consumption and 0.020mm accuracy.

It aims to set a new standard in metrology with palm-sized, high scanning performance, low power consumption and 0.020mm accuracy.

Scantech engineers have been able to improve 3D scanning efficiency by 40% and reduce power consumption by 20% compared to the previous version. Thanks to its blue laser scanning technology, the device is ideal for digitizing narrow spaces. 42 laser lines further enhance scanning efficiency.

The device is designed for long-term and stable use. To ensure reliability, the 3D scanner calibration plate is made of aerospace grade carbon fiber, which is more resistant to shock and other loads. Finally, SIMSCAN is extremely portable, allowing you to carry it with you and take measurements anywhere.

Article published on 12/22/2022, updated on 03/13/2023

REC Wiki » Best 3D Printing Software in 2022

3D printing is a multi-step process, because you first need to design a 3D model, check it for errors, convert it to machine code, and only then the 3D printer goes into business . In this article, we will share examples of programs that can help at every stage of preparatory work and directly during 3D printing.

In this article, we will share examples of programs that can help at every stage of preparatory work and directly during 3D printing.

Contents:

2. Editing and repairing STL files:

- Meshmixer

- MeshLab

3. Slicers:

- Cura

- PrusaSlicer

- ideaMaker

- ChiTuBox Basic

- Lychee Slicer

- Kiri:Moto

- IceSL

4. Control programs:

- OctoPrint

- MatterControl 2.0

- AstroPrint

5. Programs for visualizing G-code

- UVTools

- WebPrinter

- Gcode Analyzer

- Design Software

1. 3D modeling software

If you are ready to create from scratch, you will have to learn special 3D modeling software. Many of them, especially professional computer-aided design systems, can be expensive investments, but on the other hand, there are plenty of quite capable and at the same time free offers on the market.

Many of them, especially professional computer-aided design systems, can be expensive investments, but on the other hand, there are plenty of quite capable and at the same time free offers on the market.

Tinkercad

Tinkercad is a browser-based application from Autodesk that is great for no-experience users, even kids, because of its simplicity. In this program, 3D models are built on the basis of basic blocks - simple geometric shapes that are joined together and then "filed" to the finished look. You can also convert 2D vector images into 3D models. Of course, you have to pay for simplicity - in the case of Tinkercad, rather primitive functionality that makes it difficult to create truly complex models. But such a task is not worth it: having gained basic skills on Tinkercad, you can always move on to more complex and more capable programs on our list.

Official website

ZBrushCoreMini

ZBrushCoreMini is primarily a 3D sculpting tool, especially popular among those who create human and animal figures, computer game characters and comics, and the like. This software is mainly aimed at beginners and users with moderate experience, but at the same time, it is full of impressive features that make the work easier. For example, dynamic tessellation algorithms constantly analyze the surface of the working model and automatically add polygons so that detail is not violated.

This software is mainly aimed at beginners and users with moderate experience, but at the same time, it is full of impressive features that make the work easier. For example, dynamic tessellation algorithms constantly analyze the surface of the working model and automatically add polygons so that detail is not violated.

ZbrushCoreMini is offered free of charge and is positioned as an entry-level program for learning and gradually moving to more capable and complex options - ZBrush and ZbrushCore.

Official website

3D Builder

This program was developed by Microsoft and was included with Windows 10 for some time, although now it must be downloaded and installed separately. 3D Builder allows you to edit models in STL, OBJ, and 3MF formats, as well as create models from scratch. In this regard, the program is quite primitive, but it is simple and understandable even for novice modelers.

One of the interesting features of 3D Builder is the ability to simplify meshes by reducing the number of polygons, file weight and processing time in the slicer - useful in cases where the original designer obviously went too far with polygons. Additionally, you can import models from the library and even use Kinect sensors to 3D scan and import models of physical objects.

Additionally, you can import models from the library and even use Kinect sensors to 3D scan and import models of physical objects.

Official website

SketchUp

SketchUp is a web application with a great combination of simplicity and functionality. The user-friendly interface is intuitive and greatly facilitates learning, and the set of tools is quite diverse even for advanced users - hence the wide popularity of this program.

The free version was formerly called SketchUp Make, but is now simply called SketchUp Free. It includes everything you need for 3D modeling for 3D printing, just don't forget to download the module for exporting STL files - it's also free. The kit comes with 10 GB of storage for projects in the cloud and access to the 3D Warehouse, a repository with open source user-generated content.

Official site

Fusion 360

Professional CAD developed by Autodesk and famous for its ease of use and advanced functionality. This includes parametric modeling and mesh analysis and load distribution tools, including through generative design with topological optimization. The program is great for those who are engaged in 3D printing of functional products, for example, for industrial applications.

This includes parametric modeling and mesh analysis and load distribution tools, including through generative design with topological optimization. The program is great for those who are engaged in 3D printing of functional products, for example, for industrial applications.

Some versions of Fusion 360, such as hobby and student versions, are even available free of charge. FreeCAD FreeCAD The program relies on a parametric approach: at any point in history, you can scroll back and make changes to the parameters. The program even includes finite element analysis and a robotic system simulator.

Official site

Blender

One of the most popular 3D modeling programs, but rather difficult to master. Not the best choice for a novice designer, but a great tool for those who have already gotten their hands on simpler editors. Fortunately, the popularity of Blender has led to a huge number of guides, tutorials, and visual examples published by experienced users for beginner colleagues.

Developers are trying to make the program more convenient without sacrificing functionality: the interface has recently been updated, rendering has been improved, and 3D design and animation capabilities have been expanded. And yes, it's open source and freeware, so you don't risk anything.

Official site

2. Editing and repairing STL files

If you find an interesting 3D model on the Internet, this does not mean that it can be immediately sent to a 3D printer. Many models are created for completely different needs, such as animations or video games, and in principle are not intended for 3D printing. But there is a solution: before processing such models into G-code, they must first be repaired so that the slicer can do its job well. The following programs on our list will help you cope with the repair.

Meshmixer

Meshmixer is an advanced and free program from Autodesk that allows you to view and check 3D models for errors in polygonal meshes that can ruin 3D printing. If such problems are detected, the program can automatically repair meshes. One example of an application is finishing 3D scans to a state suitable for 3D printing.

If such problems are detected, the program can automatically repair meshes. One example of an application is finishing 3D scans to a state suitable for 3D printing.

Additional functionality includes mesh blending, 3D sculpting, surface writing, cavity creation, support branching, mesh smoothing, and more.

Official site

MeshLab

MeshLab is another open source program for editing polygonal meshes. MeshLab has the necessary tools for editing, checking, cleaning and converting meshes with the ability to combine meshes into one model and patch holes that can lead to incorrect processing of models into G-code.

Official site

3. Slicers

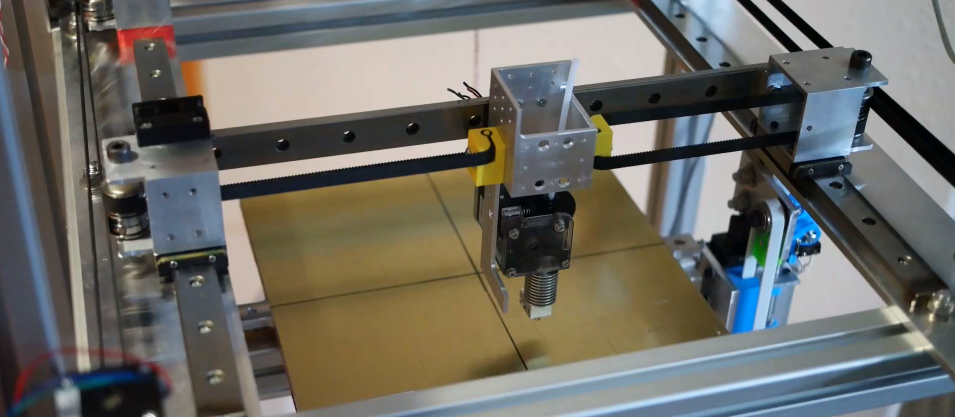

Having received a 3D model, it must be converted into machine code - a series of commands understandable to CNC machines, including 3D printers. Slicers are responsible for this task - programs that accept digital models (usually in the form of files with STL, OBJ or 3MF extensions), analyze their structure, and then compile lists of actions for 3D printers, called G-code (Gcode). Such lists contain all the information necessary for the equipment: to what temperature to warm up the extruders and tables, whether to use airflow, along what trajectory and at what pace to lay the plastic.

Such lists contain all the information necessary for the equipment: to what temperature to warm up the extruders and tables, whether to use airflow, along what trajectory and at what pace to lay the plastic.

Cura

Cura is a slicer from the Dutch company Ultimaker, designed primarily for proprietary 3D printers, but open source and compatible with most other FDM/FFF systems. The program is easily customizable with various plugins. Since this is a very popular program, the chances are that it already has a profile with optimal settings for your 3D printer. If not, then nothing prevents you from creating a profile manually or using profiles prepared by other users.

The program has several levels of difficulty depending on the level of training - basic, advanced, expert and complete. The higher the level, the more access to customizable options. At a basic level, the program takes the bulk of the work on itself, helping inexperienced users.

Cura is constantly being developed and improved through regular updates and is also offered free of charge, although a paid version of Cura Enterprise is available to professional users with licensed plug-ins from the Ultimaker Marketplace, technical support and additional security measures.

In addition to converting 3D models to G-code, Cura can also take on the role of a control program, but this will require a constant connection between the 3D printer and the computer throughout the 3D printing. Professionals appreciate another feature of Cura - seamless integration with professional computer-aided design systems such as SolidWorks and Siemens NX.

In general, Сura is suitable even for novice users, especially since a huge number of training videos and step-by-step guides are available for this program, both from developers and enthusiasts.

Official website

PrusaSlicer

3D printer manufacturer Prusa Research, under the leadership of the legendary Czech engineer Josef Prusa, whose designs are copied and refined around the world, has developed its own open source software based on the Slic3r slicer. PrusaSlicer quickly gained popularity as it not only retains the original program's extensive customizations, but also adds a number of useful features not found in Slic3r.

A redesigned interface, support for Original Prusa branded 3D printers, and profiles with settings to work with many common polymers are just some of the improvements. Additionally, algorithms for generating support structures have been improved, support for multimaterial 3D printing and the ability to dynamically adjust the layer thickness have been added.

PrusaSlicer can process models not only for FDM 3D printers, but also for stereolithographic systems printing with photopolymers. As with Cura, the user can select a difficulty level with appropriate access to fine-tuning.

Official website

ideaMaker

Raise3D's slicer is optimized for branded additive hardware in the same way that PrusaSlicer is optimized for Original Prusa 3D printers, and Cura is optimized for Ultimaker 3D printers, but this does not mean that it cannot be use with third party systems. The organization of workflows and the interface is somewhat more complicated than in Cura and PrusaSlicer, but on the other hand, ideaMaker allows you to set up individual layers and apply textures for product customization.

ideaMaker users can connect to the cloud platform and access hundreds of 3D printer profiles and materials created by other operators, or create their own library of settings.

Add the ability to customize support structures, split models for more efficient 3D printing of large parts, integrated mesh repair tools, and OctoPrint compatibility, and you have a flexible, versatile program to suit the needs of most 3D printers.

Official website

ChiTuBox Basic

This is a specialized slicer for those who use stereolithographic 3D printers that print with photopolymer resins. Most budget LCD masked stereolithography (MSLA) 3D printers rely on motherboards and firmware from ChiTu Systems, which also developed this software.

Users gain control over technology-specific parameters such as layer exposure time, as well as access to predefined profiles with settings for many popular 3D printers. The slicer takes into account such moments as the orientation of the model and the automatic construction of support structures with the possibility of manual optimization.

Official website

Lychee Slicer

A program from the independent French-Belgian team Mango 3D, not affiliated with 3D printer manufacturers, but with support for many popular stereolithographic 3D printers, including those from Elegoo, Anycubic, Phrozen and Creality.

One of the features of this program is the high level of automation. If you wish, you can simply click on the "magic" button (it's called Magic), and the slicer will do everything by itself: it will orient the model on the platform, generate supports, and so on. Although, here you are lucky: the results are not always optimal, but usually adequate for relatively simple models. Otherwise, everything can be configured manually.

The program is offered in free and paid versions. The functionality of the free version is slightly reduced, but it has everything you need.

Official site

Kiri:Moto

Browser solution for those who lack computing power. Kiri:Moto can prepare 3D models for both 3D printing and laser engraving or milling. The settings are somewhat more primitive than in locally installed slicers, but are sufficient for most users.

Official website

IceSL

IceSL is a combination software that combines slicing with 3D modeling. In the left window, you can edit 3D models using scripts in the Lua language, which makes it possible to perform parametric modeling. On the right side, the 3D printing settings are displayed. For beginners, pre-configured settings are available, while experienced users can take advantage of features such as specific adjustment of parameters for individual layers with automatic gradation of intermediate areas. For example, this allows you to gradually reduce or, conversely, increase the filling density of the product as it is built, or gradually change the thickness of the layers.

Official website

4. Control programs

Control programs are designed for exactly this - managing workflows during 3D printing. Although you can insert a G-code drive into almost any 3D printer and press the start button, this is not always convenient, especially when you have to work with several 3D printers at the same time, and even more so when you do it remotely. This is where control programs come to the rescue. In addition, some of them offer additional functionality, including slicing and even editing 3D models.

OctoPrint

A web-based appliance that requires connection to a 3D printer via a microcomputer such as a Raspberry Pi equipped with a Wi-Fi module. This system allows you to control 3D printers remotely. OctoPrint accepts G-code from almost any slicer and provides the ability to visualize - view files before and during 3D printing. Alternatively, STL files can be loaded and processed directly in OctoPrint.

OctoPrint not only provides all the necessary tools for remote management, but also allows you to track the work in progress using notifications via various instant messengers.

This is a completely free, open source program with many plug-ins created by enthusiasts and available on the official website.

Official website

MatterControl

MatterHackers offers its own control program, slicer and 3D editor in one package. MatterControl allows you to directly control and observe 3D printing, slice, export G-code to SD cards for offline printing, and even create 3D models from scratch. The 3D printer will need a Wi-Fi or USB connection to run MatterControl.