3D printer bed too hot

build plate - How to tell if PLA temp is too hot/cold

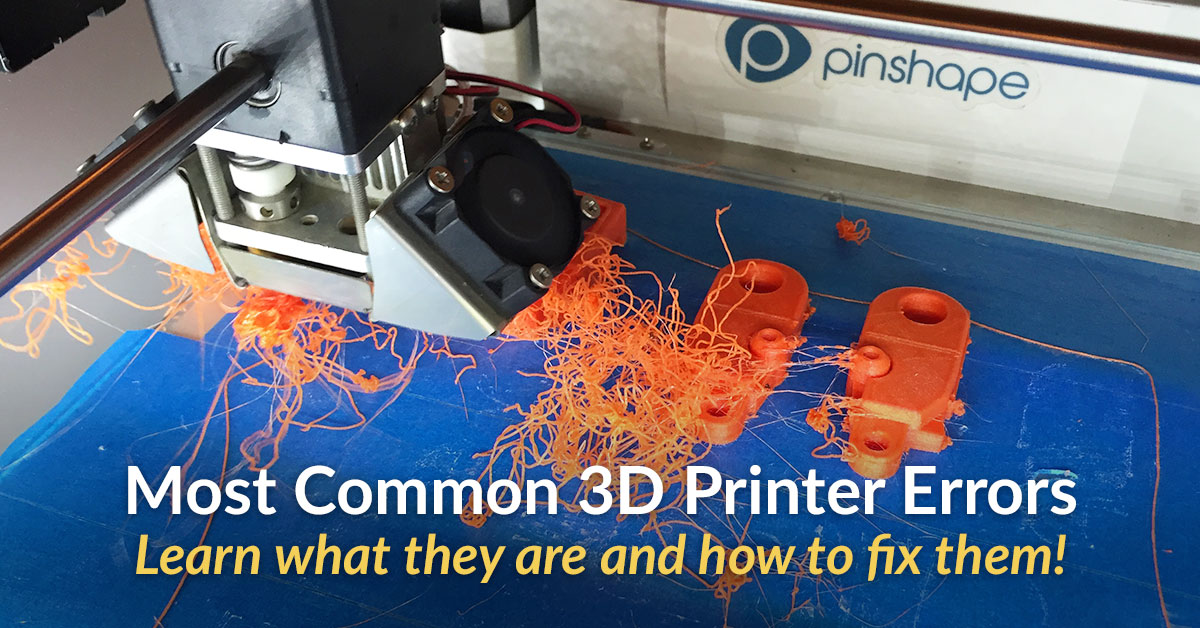

If you're printing too hot (with any filament, not just PLA) you're going to see stringing and blobs/oozing because the material is getting runny and exiting the nozzle in an uncontrolled manner. Because it's uncontrolled, you will also likely see artifacts showing up in your prints.

You might also see your filament burning. Instead of coming out of the nozzle as whatever color it should be, it will look brown or discolored because it was overcooked.

If your bed is too hot, you might start to see "elephant's feet" where the lowest layer(s) are being heated to the point of becoming soft and the weight of layers on top of them are pushing down, causing that layer to "pooch out."

You might also have problems removing the print from the print bed's surface because the plastic has seeped into the details of the print surface and hardened, essentially welding the part to the surface.

If you're printing filament that is too cold, you're going to run into an issue where the material being pushed into the hot end is not getting melted sufficiently. This means that pressure will build up in the hot end that can't be released through extruding material through the nozzle. If you've ever tried to pipe frosting using a bag/tip and the frosting was too thick, you'll know what I'm talking about.

When material is being fed into the hot end but not being allowed to flow out of it, something has to give. That thing is your extruder. It has a wheel with little teeth on it to grip the filament and feed it into the hot end (or bowden tube which leads to the hot end). It can exert a certain amount of force on that filament. When the hot end's back pressure builds to the point that it becomes greater than the extruder's force, it will start skipping.

Imagine trying to push a large, heavy object. Your feet will begin to slip as your the force of your exertion overcomes the friction between your feet and the ground. That's what will happen to your extruder. It will make clicking/clunking noises as the extruder unsuccessfully tries to push the filament through and the friction between the teeth of the gear and the filament is overcome. This is called grinding.

This is called grinding.

If your bed is too cold, you simply just end up with problems getting the print to adhere to the surface.

In your particular case, you're describing warping. Remember from physics 101 that cold things contract and warm things expand. Your print bed is warm, and so, too, are the first layers that are near it because the bed's heat is transferring up into them and keeping them warm.

Obviously, your active (topmost) layer will also be a bit warmer as it as just come out of the hot end. However, in general as you move higher up away from the printed bed, the printed layers get colder. Because they are getting colder, they are undergoing thermal contraction.

This creates a thermal gradient where layers go from greater thermal expansion to greater thermal contraction. The combination means that the bottom of the print will start to curl up (away from the expansion and towards the contraction).

This is not an issue with your printing temperature. It's a problem with your ambient temperature.

It's a problem with your ambient temperature.

The easiest way to fix this issue is to put your printer in an enclosure. This isolates the air immediately around the printer from the rest of the air in the room. Because your heater's bed and nozzle are throwing out a lot of heat, they will heat up the print chamber quite a bit (mine typically runs over 30 degrees celsius, even in the dead of winter).

Because the ambient temperature in the print chamber is so much warmer than the outside air, that temperature gradient is much, much smaller. As a result, warping will stop becoming a problem.

heated bed - PLA and bed heating?

Asked

Modified 3 years, 8 months ago

Viewed 70k times

$\begingroup$

I've read different things about PLA and heat-bed. Some say it is not needed, others recommend 60-70°C, but not for the first layers.

Some say it is not needed, others recommend 60-70°C, but not for the first layers.

For larger objects I often have the problem that the object does not stick to the blue-painters-tape-covered aluminium print plate. Instead the print "curls" up on one or more corners. To reduce this effect, I'm using a brim between 5 and 10mm. Depending on the size of the object the brim works quite well. Will heating the bed also improve the print quality by reducing the amount of heat warping / curling?

- pla

- heated-bed

- warping

$\endgroup$

3

$\begingroup$

I actually find it's not needed for PLA. I generally have it heated to 40 °C and use blue painters tape along with some hairspray (I prefer Tresemme as it smells gorgeous).

I've experimented with a glass bed, and Buildtak but I find blue painters tape is the key. I overlap the blue tape ends to the bed so it sticks, then spray the hairspray onto the tape. Also bed leveling is super important as are your print settings. What you want for the first layer is to have it essentially "pushing" into the bed. That way it gets good contact and wont curl up during the print, though it can be a challenge to get off later.

I overlap the blue tape ends to the bed so it sticks, then spray the hairspray onto the tape. Also bed leveling is super important as are your print settings. What you want for the first layer is to have it essentially "pushing" into the bed. That way it gets good contact and wont curl up during the print, though it can be a challenge to get off later.

TL;DR for PLA you dont need a heated bed, its more about the surface and 1st layer height.

$\endgroup$

1

$\begingroup$

Heating the bed helps me, even with PLA. I print with a 60 °C bed. The bed is 3/8" 6061 alloy aluminum, sanded with 600 grit sandpaper, coated with Elmer's purple glue stick, and dried.

The brim will help. You might make the brim thicker than one layer (like 2-3 layers).

If you look at the bottom of your print, are there large gaps where the PLA doesn't touch the bed? If so, you could zero the head closer to the bed, or increase the flow for the first layer.

I haven't set up a cooling fan, although many praise the results. It is an experiment for a future day.

$\endgroup$

3

$\begingroup$

Heated beds can help, but you have to be careful using too much heat. If you go above the glass transition temperature (about 60 °C for PLA), the stresses of the upper layers cooling will warp the bottom, because above the glass transition temperature, the PLA can deform.

For example, I was making very tall and skinny parts, a recipe for warping. At 65 °C, I had a bit of the bottom corners curling, but the part finished. I turned the heat up to 80 °C, and the parts warped so much they came off the build plate. I ran the exact same parts at 58 °C, and they came out beautifully every time.

A higher bed temperature can aid adhesion, (see Effect of the printing bed temperature on the adhesion of parts produced by fused filament fabrication), but if the temperature is above the glass transition, the parts can and will deform much more easily.

$\endgroup$

1

$\begingroup$

This is fundamentally a heat transfer problem. As a large print is being made, it is very thin. Thin things cool off quickly, especially when no new hot material is being placed on top in the meantime. A heated bed will only help for a time, depending on the print size, before it starts to actually contribute to warping due to rapidly cooling upper layers and still- heated lower layers.

A hack can be found by improving bed adhesion, but this leaves the underlying problem of thermal stresses intact. Only through better 3D printing thermal properties design or through better object design will the warping problem be solved rather than mitigated.

$\endgroup$

$\begingroup$

It really depends on your formulation. 70 °C would be on the higher end. I think I do between 70 °C - 75 °C. Not any higher.

70 °C would be on the higher end. I think I do between 70 °C - 75 °C. Not any higher.

Add a glue from a glue stick to help with keeping it on the bed.

Use a raft to reduce the issue as well.

A fan is the number one thing you can do.

The last solution is to build a heat enclosure. They are not on every 3D printer because of patents blocking them. You can easily make your own.

Technically it is not 100 % needed, i.e. the MakerBot does not use it, but the guys at MakerBot have PLA down to a science.

Also I thought Kapton is not for PLA usually... see these MatterHackers articles:

- How to succeed when printing with ABS;

- How to succeed when printing with PLA.

From RepRap Wiki - Glossary:

Raft

A technique used to prevent warping. Parts are built on top of a 'raft' of disposable material instead of directly on the build surface. The raft is larger than the part and so has more adhesion.

Rarely used with heated build surfaces. For the small area models, it is very useful to prevent warping via adding a raft for the model before slicing it. It can also help with with precision parts by removing the slight first few layer distortion caused by the heated bed.

$\endgroup$

2

$\begingroup$

For printing PLA you can manage to succeed without a heated bed. You can use blue painting tape on any platform. It will help a lot. But sometimes the tape itself curls up and you end up with a bad print. Heated bed helps here for better adhesion of the blue tape to the bed. You can also use hair sprey to ensure that the blue tape sticks to the bed.

Hair sprey is pretty effective on ABS. If you use a heated bed + glass + hair sprey ( Akat Gardi is the best brand) you will never have any problem with your prints.

$\endgroup$

$\begingroup$

I can only go with my own experiences; a Printrbot simple metal originally with no heated bed and blue tape was fine for small parts if printed with a reasonable brim and rafts when needed (Slic3r does that) but larger prints tended to warp and curl. I upgraded to a heated bed, which I run at 55 - 60 °C for every print. Additionally, I now use Kapton tape on the bed and glue stick. I have recently reprinted a part for my printer, an LCD housing, to replace the badly warped original, which is my benchmark print. I have no warping/curling problems to the point that I have reduced the standard brim from 5 mm to 2 mm to save some material. Some additional detail - only PLA at present from a 0.4 mm extruder at 205 °C in 0.2 or 0.3 mm layer height for the finer detail. Takes longer but the results are worth it.

$\endgroup$

$\begingroup$

The answer depends a bit on the type of PLA (supplier of specific filament), type of machine, type of build platform, size of model and ambient temperature.

PLA has less issues with warping compared to ABS or Nylon, but can still warp depending on everything mentioned. My usual first try to minimize warping is to heat the bed. 60 - 70 °C works well but I'll also go up to 100 depending on a variety of factors. If still not having any luck, generally on larger parts I try adding a raft. If I STILL have issues after that I'll add 'helper disks' (small quarter dollar sized disks) around the part to increase the surface area of the raft. The disks will add more material but I have about a 99 % success rate using these.

If a part is going to take more than about 3 hours and I can't have any warping at all, I always use a heated build plate and place the discs all the way around the part. Generally will add about a hour or more, but well worth the extra time.

$\endgroup$

2

$\begingroup$

A lot depends on exactly which PLA you use and the build surface. I'm using one of those new-fangled high-temperature PLA's (MakerGeek's Raptor PLA, black) and a BuildTac surface on a MonoPrice Select Mini v2. From my experiments, I believe that the biggest influence in preventing warping is the BuildTac.

I'm using one of those new-fangled high-temperature PLA's (MakerGeek's Raptor PLA, black) and a BuildTac surface on a MonoPrice Select Mini v2. From my experiments, I believe that the biggest influence in preventing warping is the BuildTac.

My slicer is Simplify3d, so the settings may be in a different format than yours. I use a hot-end temperature of 240 °C, a bed temperature of 40 °C, layer height of 0.0875 mm, a first-layer modifier of 1.5, an extrusion modifier of 0.95, and a retraction distance of 3 mm.

I've never had a problem with warping, but these settings prevent stringing and allow me to more easily remove parts after printing. And yes, I wait until the bed gets to room temperature before removing the part.

$\endgroup$

$\begingroup$

Heated bed definitely helps with PLA adhesion, it also helps depending the surface, for example PEI offers better adhesion than glass. Another option is to try to overextrude the first layer (125 %) and make sure it is squeezed out, so basically you get a wavy effect on the first layer. This should help a bit even in the curly corners. Another thing I have noticed from experience is the PLA itself, not all PLAs are the same so you could try another manufacturer or try your PLA in a friend's printer to see if you get the same effect. Generally on PLA we do not expect any warping, but the reality is that some do have.

Another option is to try to overextrude the first layer (125 %) and make sure it is squeezed out, so basically you get a wavy effect on the first layer. This should help a bit even in the curly corners. Another thing I have noticed from experience is the PLA itself, not all PLAs are the same so you could try another manufacturer or try your PLA in a friend's printer to see if you get the same effect. Generally on PLA we do not expect any warping, but the reality is that some do have.

$\endgroup$

$\begingroup$

Heating the bed helps with adhesion to the bed, but can seriously interfere with cooling of the layers just above the bed that are in contact with large amounts of material touching the bed. I've found that, if I have a model with a flat region touching the bed and walls leaning outward from it (overhangs) as they go up, any corners will curl upwards before they can cool if the bed is 60 °C or above - it's effectively a heat bath at the glass transition temperature that's going to be hard for a fan to overcome.

At 50 °C the effect is almost gone, and at 40 °C and below it seems entirely gone, but the exact temperature that's safe is going to depend on ambient room temperature, cooling fan power, and effectiveness of the fan duct. I've just found this as a solution to my curling-corner problems, so I might end up tweaking things more, but I think I'm going to try printing PLA without heating the bed at all unless I have trouble with adhesion.

An example showing slightly warped vertex/edge from curling corners at 50 °C vs good ones at lower temperatures:

$\endgroup$

REC Wiki » FDM 3D Printer Basics

Thinking about buying a 3D printer and don't know where to start? Then you are welcome under the cat: in this article we will try to explain as clearly as possible what FDM 3D printing is and how to work with FDM 3D printers.

To begin with, let's immediately deal with possible confusion in terms. In industry literature, FDM (Fused Deposition Modeling) and FFF (Fused Filament Fabrication) 3D printing technology is abbreviated. What is the difference between them? Absolutely none, it's all about patent law. Initially, the technology was called FDM, and the patent belonged to the American corporation Stratasys. Competitors had to come up with an alternative name - FFF. Patent expired in 2009year, so nowadays these designations are completely interchangeable - a matter of taste.

What is the difference between them? Absolutely none, it's all about patent law. Initially, the technology was called FDM, and the patent belonged to the American corporation Stratasys. Competitors had to come up with an alternative name - FFF. Patent expired in 2009year, so nowadays these designations are completely interchangeable - a matter of taste.

The technology itself involves the layer-by-layer application of a polymer melt with thin threads - layer by layer, until the entire model is grown. It is the most affordable and at the same time highly versatile 3D printing technology thanks to a huge range of compatible materials. This includes conventional polymers, and refractory structural thermoplastics, and even composites with various reinforcing and cosmetic fillers - fiberglass, carbon fiber, metal, ceramic, wood, and so on.

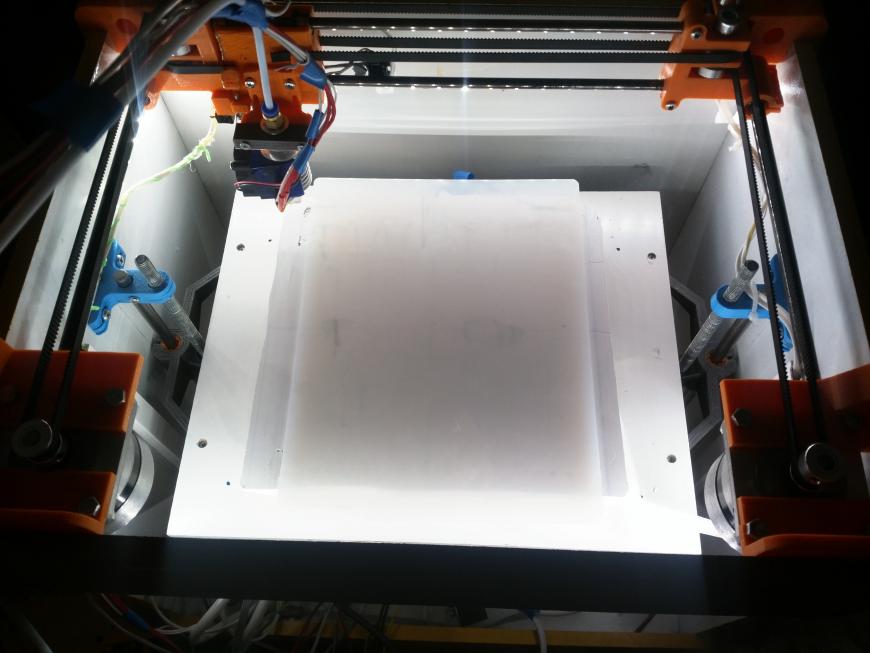

To understand how FDM 3D printing works, you first need to understand how FDM 3D printers work. Most of them are three-axis systems, relying on a conventional, rectangular coordinate system (aka Cartesian, aka Cartesian): left-right on the X-axis, front-to-back on the Y-axis, and up-down on the Z-axis.

How FDM works 3D printer

Main components:

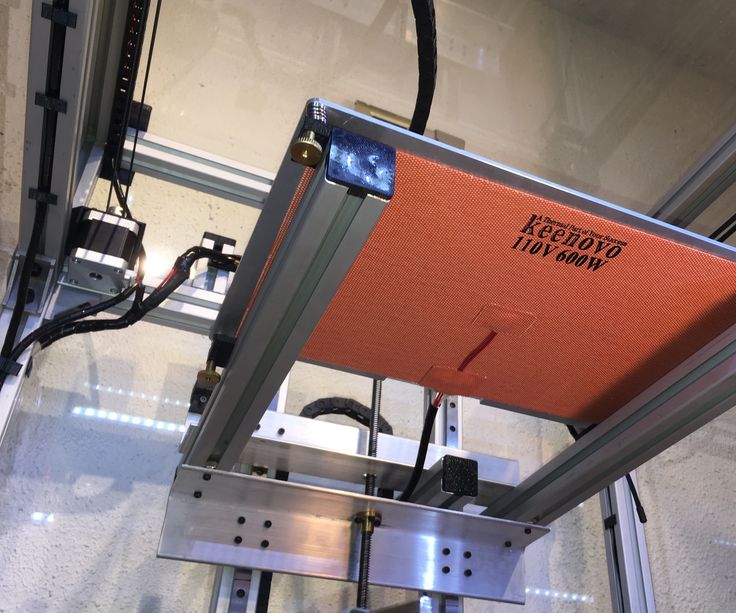

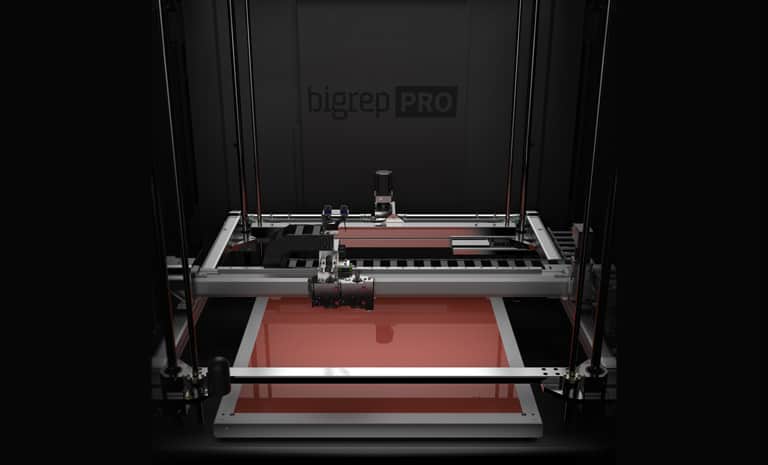

Stage . This is the work surface on which products are built. Tables can be made of different materials (glass, aluminum and others) and are mounted on the platform. The platform can be cold or heated: heating often helps with adhesion (i.e. sticking) and shrinkage. More on this below.

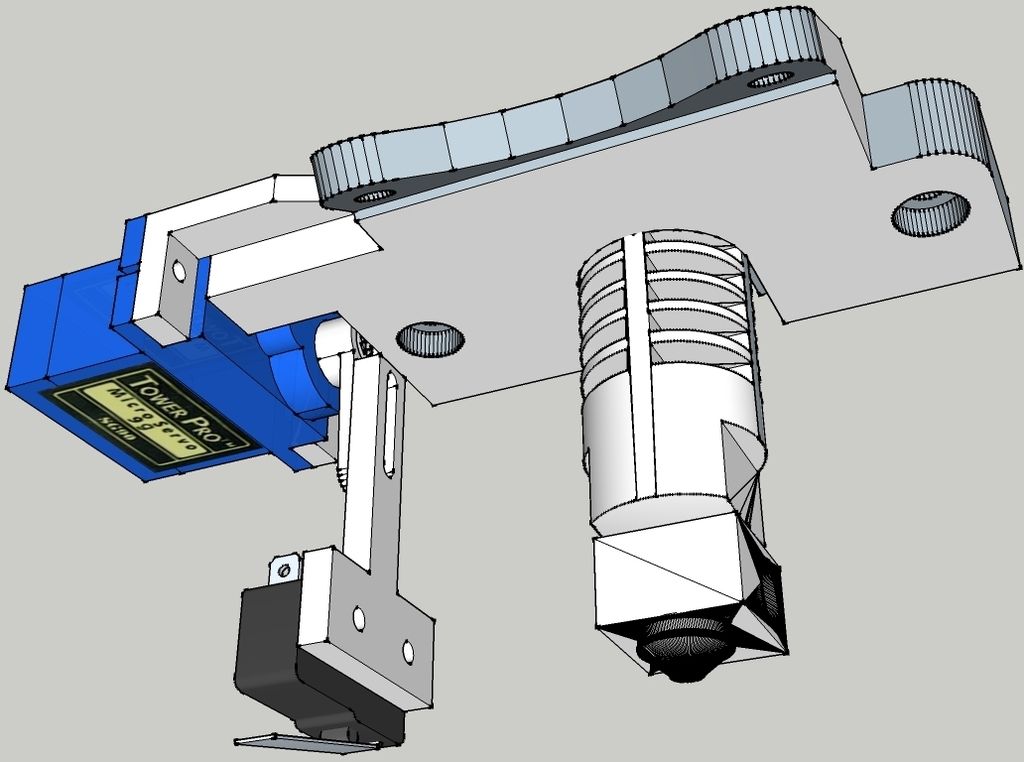

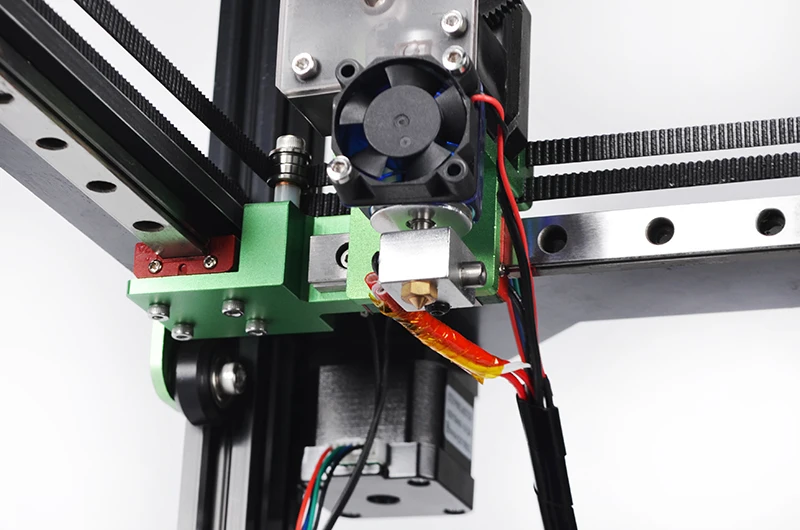

Extruder . Mechanism responsible for feeding the filament, heating the material and applying the melt. Extruders, in turn, consist of two parts:

- cold part, including a filament feeder with a motor and gears;

- hot end, including a hot end (a metal tube in which plastic is melted), a heating block, a nozzle, a heat sink and fans to cool the thermal barrier and the material to be laid.

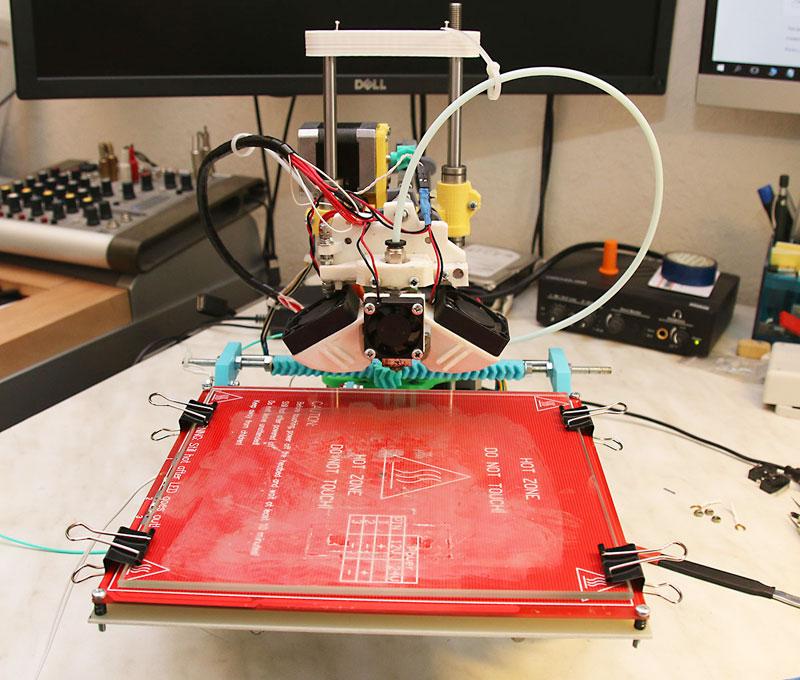

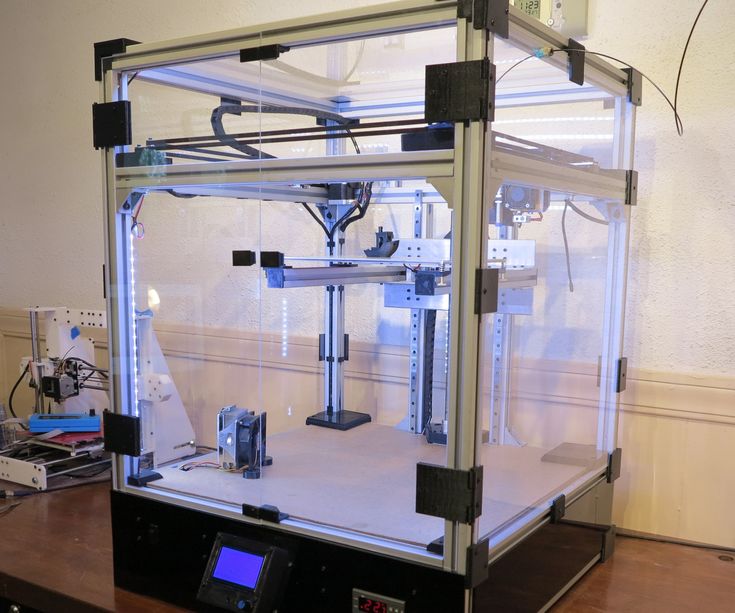

3D printer with Bowden extruder

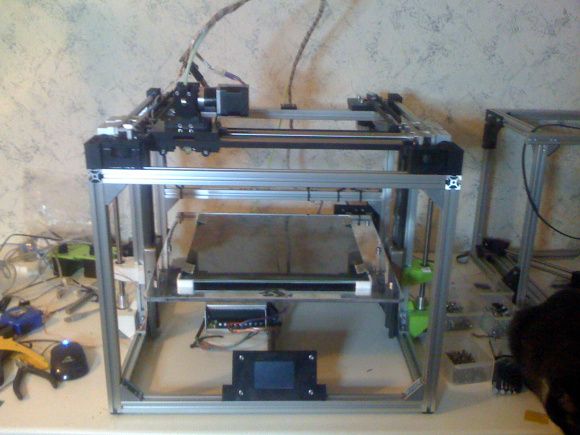

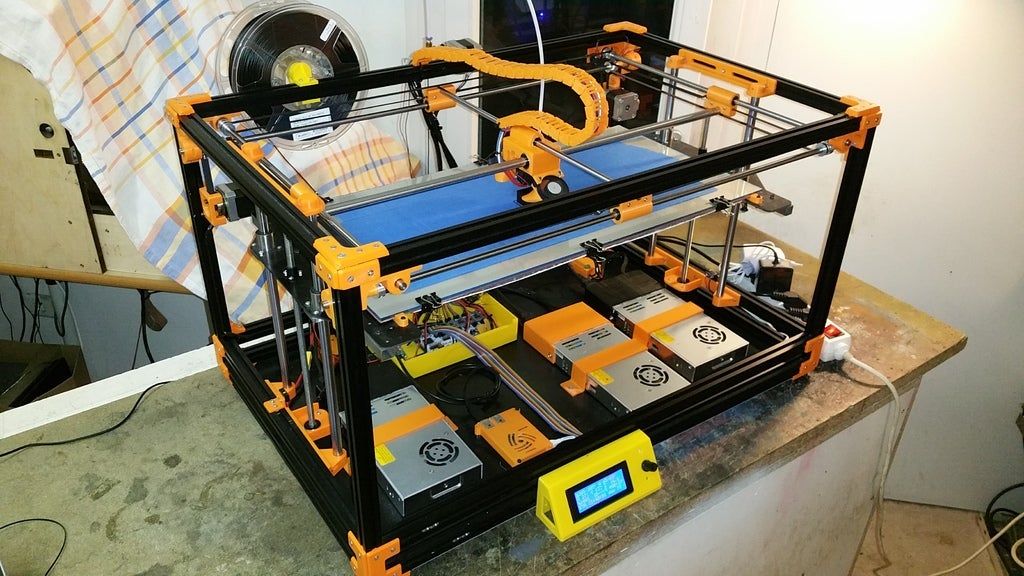

Extruders can also be divided into two types - Bowden extruders and direct extruders - according to the material feeding method. If only the hot part is installed on the carriage, and the cold part is attached to the frame of the 3D printer, such a scheme is called Bowden - in honor of the Bowden tube connecting the two parts and conducting the filament from the feeder to the hot end ( in the illustration above ). If the cold and hot parts are installed on the carriage together as a single unit, such a scheme is called a direct feed or direct extruder ( in the illustration below ).

If only the hot part is installed on the carriage, and the cold part is attached to the frame of the 3D printer, such a scheme is called Bowden - in honor of the Bowden tube connecting the two parts and conducting the filament from the feeder to the hot end ( in the illustration above ). If the cold and hot parts are installed on the carriage together as a single unit, such a scheme is called a direct feed or direct extruder ( in the illustration below ).

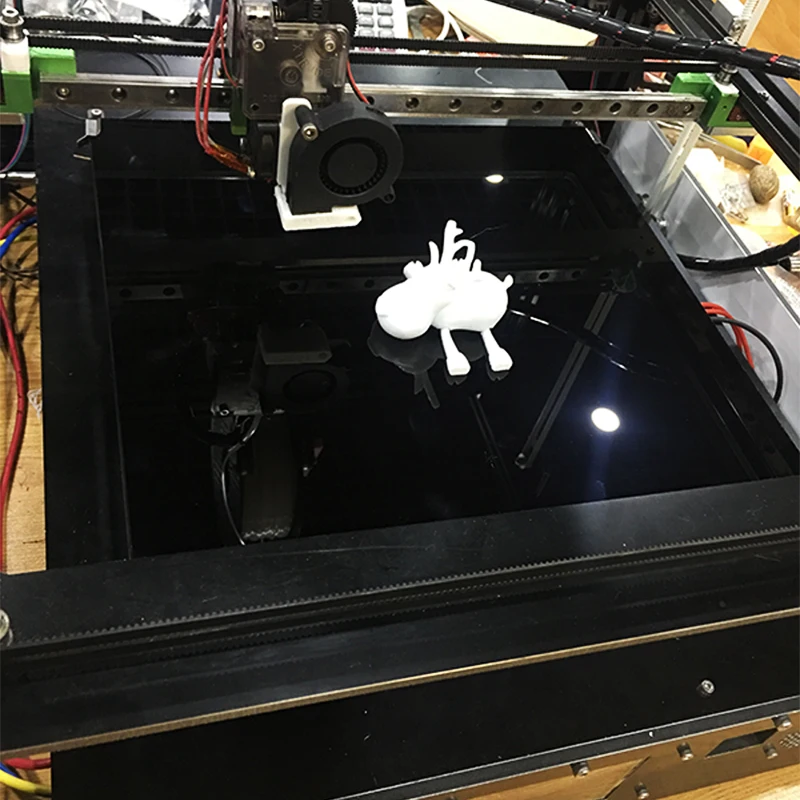

3D printer with direct extruder

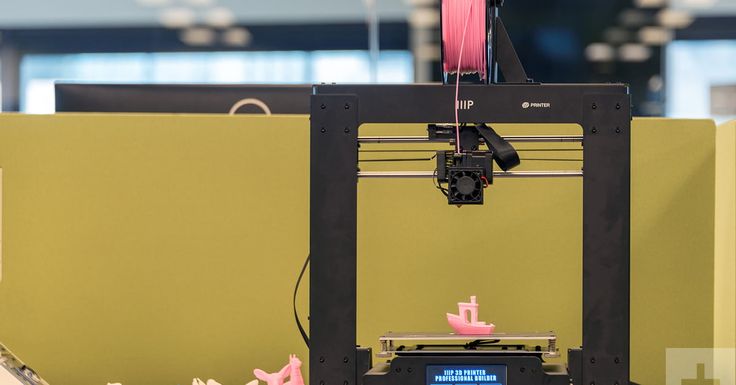

There can be several extruders on a 3D printer to work with different materials at the same time, but most systems, especially budget ones, are equipped with only one.

Control system . The operation of the electrical and mechanical components of the 3D printer is controlled by a board with a connected interface. These can be either simple LCD screens with an encoder, a USB port and a card reader, or more advanced options with touch screens, built-in memory, wireless communication modules, and so on. It all depends on the manufacturer and the cost of the equipment.

It all depends on the manufacturer and the cost of the equipment.

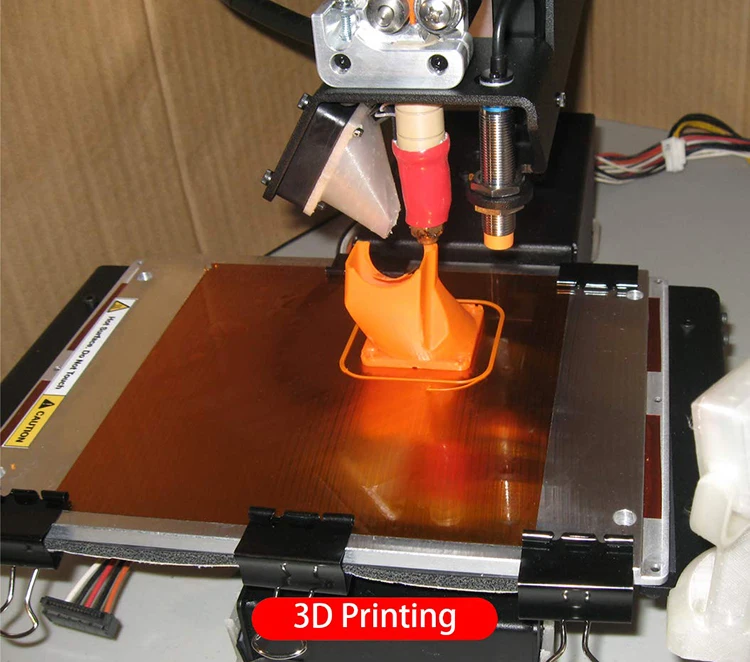

How an FDM 3D printer works

The process begins with transferring a file with a digital 3D model converted into machine code (G-code, Gcode) to a 3D printer. Such files contain a complete set of step-by-step commands that tell the 3D printer to what temperatures the hotend and platform need to be heated, at what speed to feed the material, along which trajectory to move the head.

After receiving the start command, the 3D printer heats up the hot end and the stage to the set temperatures, depending on the plastic used. When the hot end is ready, the filament feed begins. At this point, the 3D printer is ready to print. Further, the head is lowered (or the table is raised towards the head, depending on how the equipment is arranged), and the melt begins to be applied to the table through the nozzle. Depending on the material being used and the print speed, one of the fans on the head can blow over the plastic being laid to allow it to harden before applying the next layers. After applying the layer, the head rises slightly (or the table lowers), and then the laying of the next layer begins - and so on over and over again until the whole model “grows”.

After applying the layer, the head rises slightly (or the table lowers), and then the laying of the next layer begins - and so on over and over again until the whole model “grows”.

How to make or find a digital 3D model

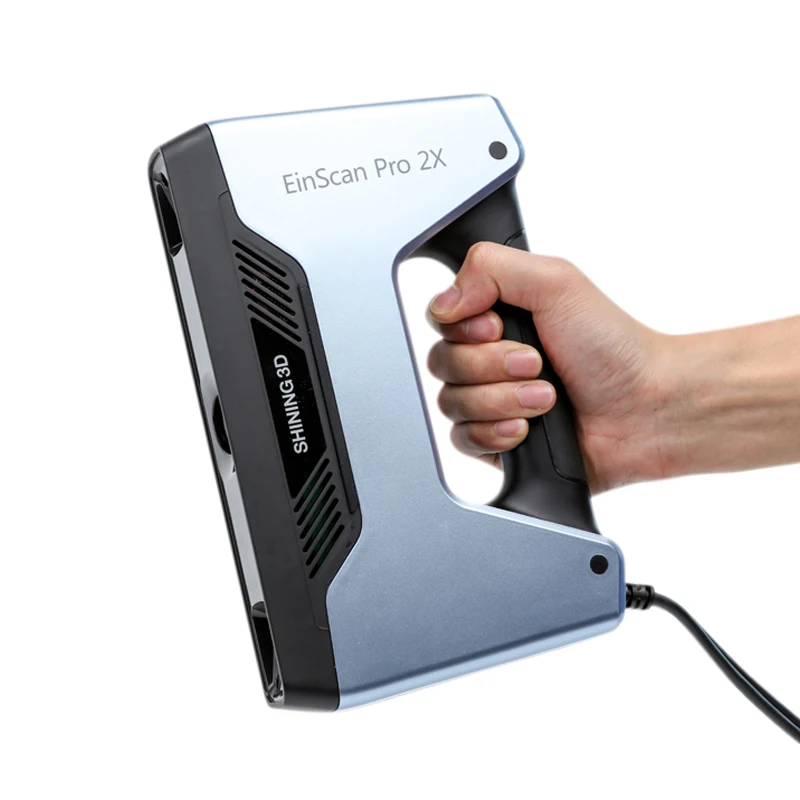

To print products, you need to have a digital copy on hand. There are two options here: you can model it yourself or to order, or you can find a ready-made 3D model on the Internet.

3D modeling requires special editing programs or computer-aided design systems such as Fusion 360, SolidWorks, Blender, Compass-3D and others. Some are offered for free, while others require payment. If you are ready to try your hand at 3D modeling, we have prepared a special article with links to the most popular programs, including free ones.

If you do not have the time or desire to model yourself and are not ready to pay professional modelers, there is also a way out: many sites, such as Thingiverse, 3Dtoday or MyMiniFactory, offer libraries with again paid and free 3D models designed specifically for 3D printing. A list of the most popular sites can be found in the article at this link.

A list of the most popular sites can be found in the article at this link.

Preparing digital 3D models for 3D printing

As we have already mentioned, 3D printers accept files with machine code, so having a digital model on hand is not enough - it must be processed into G-code using a special program called a slicer .

Slicers allow you to manually set 3D printing parameters such as temperature and speed, wall and layer thicknesses, infill density, and more. The program then “slices” the 3D model into horizontal layers (hence the name: to slice means “cut”), converts each layer into a series of machine instructions (G-code) understandable by 3D printers, and saves the code in a separate file, ready to 3D printing.

Support structures (supports)

One of the key functions of slicers is the generation of support structures, also called supports. FDM 3D printers cannot print by air - the nozzle must apply the material either to the table or to the already laid material. Accordingly, at strong angles of inclination or when building long "bridges" between different segments of the part, overhanging sections need some kind of support. The supports are just temporary structures, also printed by a 3D printer with the sole purpose of supporting the hinged sections of the model itself. Once the 3D printing is complete, such supports are removed - either by hand or with a solvent or even water if a special water-soluble filament such as REC PVA is used to print the supports. The option with soluble supports is relevant in cases where the 3D printer is equipped with at least two extruders - one prints the base material, and the other the support one.

Accordingly, at strong angles of inclination or when building long "bridges" between different segments of the part, overhanging sections need some kind of support. The supports are just temporary structures, also printed by a 3D printer with the sole purpose of supporting the hinged sections of the model itself. Once the 3D printing is complete, such supports are removed - either by hand or with a solvent or even water if a special water-soluble filament such as REC PVA is used to print the supports. The option with soluble supports is relevant in cases where the 3D printer is equipped with at least two extruders - one prints the base material, and the other the support one.

Results of 3D printing of models with soluble support structures before and after removal of supports plastic will turn into garbage at the end of the work. There are other nuances: for example, supports should not touch vertical walls, otherwise it will be difficult to remove them later, and at the same time the risk of damage to the product will increase.

Fortunately, all popular slicers can analyze 3D models and place supports automatically. A detailed list and descriptions of the most popular slicers are available in the article at this link.

Preparing the FDM 3D Printer

Loading Filament . Consumables for FDM 3D printers are round bars of plastic called filaments. The filaments are wound on spools or supplied in coils. Coils are cheaper, but they need to be rewound onto spools by hand or the plastic can get tangled up during 3D printing.

The filament must be fed into the extruder before printing can begin. To do this, the hotend must be heated to a temperature that depends on the selected plastic. This information can be found on the packaging.

The filament is then inserted into the feeder, which feeds the filament into the heated hot end. If the automatic loading function is not provided, the filament can be threaded manually: to do this, press the drive gears of the feeder and gradually push the bar into the hot end until molten plastic flows from the nozzle.

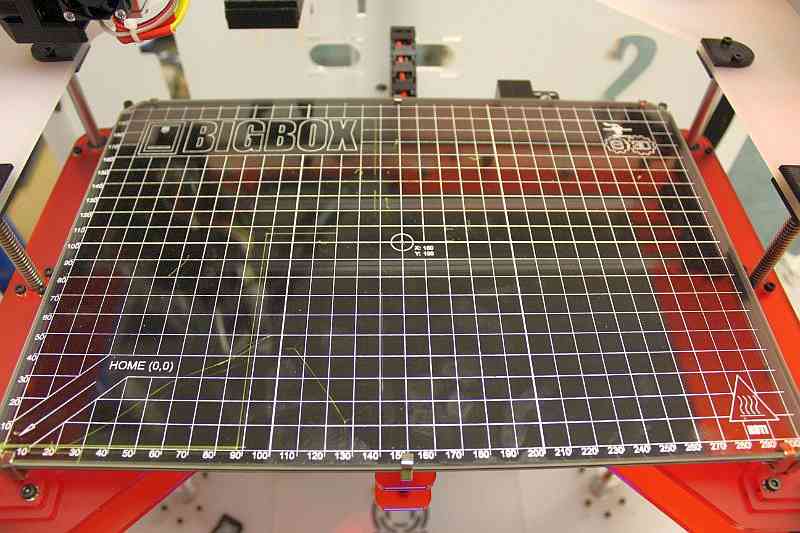

Platform adjustment . Calibration of the 3D printer is very important, as the successful laying of the first layer depends on it. Before starting 3D printing, you need to make sure that the platform sits level. Many modern 3D printers are able to perform calibration automatically using built-in sensors, such as BL Touch. Otherwise, the platform must be manually leveled: for this, special adjustment screws must be provided under the platform.

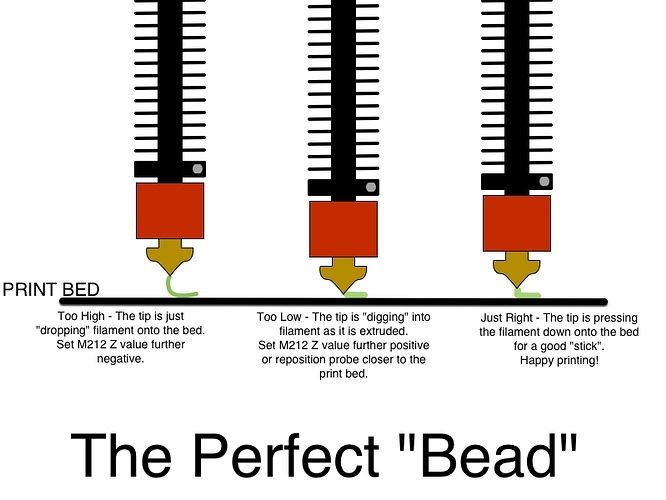

The correct zero on the Z axis is the key to a successful start of printing

At the same time, do not forget to correctly set the zero on the Z axis, that is, the distance between the nozzle and the platform at the very beginning of 3D printing. If the distance is too low, then there will be problems with the supply of the melt, and if it is too high, then the plastic will not set to the surface of the stage.

Consumables

As we have already mentioned, FDM 3D printers are loaded with spools of filaments. The most common bar diameter is 1.75 mm, but there are also printers that work with filaments with a diameter of 2.85 mm. This point must be taken into account when buying plastic for 3D printing. The mass of the coils can be different - from 500 g to 3 kg and even higher. Pay attention to the recommendations of the manufacturer of your 3D printer and the design of the system itself: in some 3D printers, the spool mounts are located inside the working chambers or special compartments, so a spool that is too large may not fit.

The most common bar diameter is 1.75 mm, but there are also printers that work with filaments with a diameter of 2.85 mm. This point must be taken into account when buying plastic for 3D printing. The mass of the coils can be different - from 500 g to 3 kg and even higher. Pay attention to the recommendations of the manufacturer of your 3D printer and the design of the system itself: in some 3D printers, the spool mounts are located inside the working chambers or special compartments, so a spool that is too large may not fit.

Compatibility of 3D printers with different materials depends on the maximum extrusion temperature, nozzle material, the need for a heated stage and the use of a heat chamber. For example, to work with polysulfone, you will need an extruder with a hot end temperature of 350-380 ° C, and if you are going to work with abrasive materials, such as composites of the X-Line, Clotho and Technika lines, the brass nozzle should be replaced with a more wear-resistant one, such as steel. Key parameters are always indicated on the packaging and in product descriptions.

Key parameters are always indicated on the packaging and in product descriptions.

Some examples of 3D printing plastics:

Polylactide (PLA, PLA), acrylonitrile butadiene styrene (ABS, ABS) and polyethylene terephthalate glycol (PETG, Relax) are the most common and inexpensive polymers with different properties, well suited for most applications .

Thermoplastic polyurethane (TPU, Easy Flex), styreneethylenebutylene styrene (SEBS, Rubber), and thermoplastic polyester elastomer (TPEE, Flex) are flexible, elastic polymers that replace rubber and silicone. They require special working conditions, a detailed guide is available at this link.

FormaX, GF Max, UltraX, Clotho and rPETG GF are carbon and glass reinforced composites with increased strength and wear resistance.

Polyetheretherketone (PEEK) and polysulfone (PSU) are refractory engineering thermoplastics that can replace metals in some applications.

A complete list of consumables is available in our catalog.

Post-processing

Post-processing is the last production step. Depending on the geometry of the product, the material used and the task at hand, this may include:

Remove supports . Support structures are often essential and need to be removed once the 3D printing is complete. This should be done carefully so as not to damage the product itself. If you have a 3D printer with at least two extruders on hand, the supports can be printed with soluble materials, such as water-soluble polyvinyl alcohol (PVA). This is somewhat more expensive, but greatly simplifies the procedure and improves the final quality.

Sanding . The visibility of the layers depends on the diameter of the nozzle, but ribbing in general cannot be avoided - this is the specificity of the layer-by-layer 3D printing technology. When working with hard plastics, the surfaces can be sanded to the desired smoothness.

Painting . Items can be printed in different colors using multiple extruders or manually changing the filament, but this approach is limited. Fortunately, most polymers lend themselves well to being primed and then painted.

Items can be printed in different colors using multiple extruders or manually changing the filament, but this approach is limited. Fortunately, most polymers lend themselves well to being primed and then painted.

Polishing and smoothing . Perfectly smooth, glossy surfaces can be achieved in two ways: either by polishing after sanding, or by chemical treatment. In the latter case, a suitable solvent will be required for surface treatment. Which one depends on the polymer. For example, acetone is good for ABS, but not effective for PLA.

Bonding and welding . Connections are necessary in cases where the products simply do not fit into the working area of the 3D printer. Many polymers can be bonded, but in some cases welding may be required, such as with a hot air gun.

Read more about post-processing in the article at this link.

Common problems

Web (left) and twist (right)

Curl . This usually occurs when the material to be laid cools, contracts and simultaneously pulls previously laid layers towards itself, causing them to break away from the table at the corners and edges.

This usually occurs when the material to be laid cools, contracts and simultaneously pulls previously laid layers towards itself, causing them to break away from the table at the corners and edges.

Web . Thin threads of plastic between different parts of the model, appearing when the head is idle, may be the result of incorrect temperature, speed and retract settings. Some materials, such as PETG, are particularly prone to web formation due to their high fluidity.

Clogged nozzle . One of the most annoying faults that has ruined many models in the history of FDM 3D printing. Signs of a clogged nozzle are feed mechanism clicks and no melt flow from the nozzle. The reasons may be different: defective filament, incorrect temperature settings, inefficient cooling of the thermal barrier, and others.

Layer offset . Ripples or the so-called "ringing" on the walls of products most often indicates play or curvature of the shafts along the Z axis.

Under extrusion . Efficient material feeding problems can cause gaps in layers.

Overextrusion . The opposite is true here: Applying the melt too quickly leads to sagging.

A guide to troubleshooting the most common problems is available at this link, at the same time we suggest that you familiarize yourself with separate articles on cleaning nozzles and combating deformations.

Maintenance of the 3D printer

To keep the 3D printer in good condition, the following operations should be carried out regularly:

Cleaning the stage Before starting 3D printing, it never hurts to clean the stage with a cloth soaked in isopropyl alcohol and apply a fresh coat of glue, varnish or other adhesive if necessary. Read more about adhesion here.

Nozzle cleaning . Corks and carbon deposits are easier to prevent than to remove, so be sure to wipe the nozzle clean immediately after or at least before starting 3D printing.

Waste collection . During hot end warming up, 3D printers often "snot" - they squeeze out a small amount of melt before starting to build a model. Such "snot" should be promptly removed so that they do not interfere on the table and inadvertently do not fall into the moving mechanisms.

Consumable storage

Proper storage of filaments is a separate and very important aspect. First, many plastics age when exposed to ultraviolet light, so it is advisable to store the filaments in a dark place or opaque containers. Secondly, dust deposited on the bar can contribute to the formation of plugs in the nozzles. Thirdly, some plastics are very hygroscopic, that is, they easily absorb moisture, and this can lead to the formation of all kinds of defects.

The best option is to always store unused filaments away from sunlight in airtight bags or containers with silica gel sachets inside. The storage and drying of filaments are described in more detail in separate articles - here and here.

Unpacking and setting up the Wanhao Duplicator i3 3D printer

The Wanhao Duplicator i3 3D printer is by far the most popular 3D printer in Russia and Europe. Due to the simplicity of design, low price and high print quality, the Duplicator i3 will impress any user. The Duplicator i3 3D printer is already widely used in various fields and solves many 3D printing tasks, from simple home to complex engineering.

In this article, we will show you how to properly unpack, assemble and set up the Duplicator i3 3D printer for the first test print.

Unpacking and assembly. |

Instructions for setting up, calibrating and test printing. |

1 . Safety information

1. 1 Attention: The Duplicator i3 generates high temperatures and includes moving parts that can cause injury. Do not touch the printer platform and print head (extruder) of the Duplicator i3 while it is in use. Stop printing and allow the platform and extruder to cool down.

1 Attention: The Duplicator i3 generates high temperatures and includes moving parts that can cause injury. Do not touch the printer platform and print head (extruder) of the Duplicator i3 while it is in use. Stop printing and allow the platform and extruder to cool down.

The Duplicator i3 is sensitive to ESD. Make sure you are free of static electricity by touching a grounded object before using the Duplicator i3 or attempting to make any changes. When opening the Duplicator i3 for service, make sure the power is off and the cord is unplugged.

2. Setting up

The spools of thread are mounted on the spool holders. Now you can connect the power supply.

When you're done, turn on the power button on the back of the Duplicator i3. If the discharged air flow is too strong, you should contact technical support at [email protected]

When you turn on the Duplicator i3, you should see the Wanhao logo on the LCD screen and the initial temperature settings. As a rule, at the first start, the ambient temperature is displayed on the screen.

As a rule, at the first start, the ambient temperature is displayed on the screen.

There is a control joystick near the LCD screen. Rotate and press it to navigate and select.

The next step in this manual is to help you level the bed, load the filament, and perform a test print.

Follow the instructions below to set up your Duplicator i3 for the first time! And remember, if anything goes wrong, or if anything happens differently than what's in this manual, unplug the printer and contact us.

Attention! Before proceeding with the next step, remove all shipping labels from the platform and from the level sensors.

3. Platform Leveling

3.1 Pay special attention: a properly leveled platform affects print quality! First of all, go to menu function "Quick Setup" - "Home All". The extruder should move to the bottom left of the printer.

The extruder should move to the bottom left of the printer.

Attention! When setting up for the first time, be sure to watch the extruder move, if the extruder nozzle presses on the platform, be sure to turn off the printer, check if the transport stickers on the extruder height level sensor are removed, then lower the edge of the platform according to the note described below.

Go to function "quick setting" --- "disable step. Now there is no power on each engine. Thus, you can move the extruder freely in the X-axis. The print bed can also move freely in the Y-axis. Manually move the extruder to different positions above the print platform while adjusting the distance between the extruder nozzle and platform with adjustment screws and a sheet of paper placed between the platform and nozzle.

Note:

To level the build platform, you need to install the four adjustment screws that are under the print platform. Loosen these four adjustment screws and raise the work platform.

Loosen these four adjustment screws and raise the work platform.

• Tightening the adjusting screws [turning them to the right] moves the build platform away from the extruder nozzle.

• Loosening the adjusting screws [by turning them to the left] moves the build platform towards the extruder nozzle.

• The distance between the extruder nozzle and the work platform must be suitable for the thickness of the A4 paper. For successful operation, this thickness should be about 0.12 mm.

The following is a diagram of how to correctly calculate the distance between the nozzle and the platform.

Duplicator i3 nozzle height is now normal.

If your platform is set too low, the print may not stick to the surface, if it is too high, it will damage the platform coating and nozzle. These cases are out of warranty If you have problems, or if you just need to re-level your platform, you can always return to the chapter on assembling the working platform.

4. Loading the filament

4.1 The first step in loading the filament is to trim the end of the filament so that it is as sharp as possible. Then go to function "Quick setting" - "Filament preheat" depending on your material type PLA or ABS. The printer will start heating the extruder to the set temperature.

4.3 At this time, insert the filament into the hole all the way to the end of the extruder. Then release the lever and you can feel the filament being tightly gripped by the extruder.

Turn the control joystick clockwise to load the filament.

Make sure the filament is loaded from the top of the spool so you don't get any jams while printing. After you have skipped the thread, release the Control Joystick. The machine will stop extrusion.

After you have skipped the thread, release the Control Joystick. The machine will stop extrusion.

IMPORTANT NOTE

Wait a few minutes after heating starts. Be careful not to touch the bottom of the Stepped Extruder while it is heating up - it heats up to 220°C, which is too hot and could cause burns!

After the nozzle has reached the correct temperature, you can load the filament. You will need to apply some force, but as long as you only hold the thread, you will not damage the Duplicator i3.

Maintain tension on the thread, release the spring lever and after a few moments you should feel the motor tighten the thread. You will see a small amount of plastic begin to come out of the nozzle. After that, release the control joystick. Don't be surprised if you don't see the color you expect - there may be some plastic left inside the extruder from the testing process.

After the Duplicator i3 has finished extrusion, wait a few seconds for the extruded plastic to cool before pulling it out.