3D resin printer for jewelry

3D Printing Materials for Jewelry

3D Printing Materials for JewelrySkip to Main Content

3D PRINTING MATERIALS FOR JEWELRY

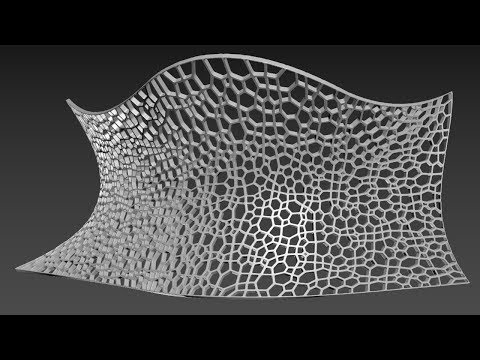

Reliably reproduce crisp settings, sharp prongs, smooth shanks, and fine surface detail with Formlabs Jewelry Resins and the world’s best-selling desktop stereolithography 3D printers. Whether you are 3D printing try on pieces for customers, ready to cast custom jewelry, or masters for reusable jewelry molds, Formlabs offers a material up to the task.

Request a Free Sample Part

Digital jewelry workflows with the Form 3 reduce the time and labor intensive process of traditional manual workflows. Custom designs are now within reach as digital designs can be preserved, modified or recreated as needed. With easy to cast materials like Castable Wax 40 Resin, the Form 3+ can efficiently create elegant cast pieces that are tailored to your customers.

Explore the Form 3+

See the future of digital jewelry firsthand and assess our materials for your application: we’ll mail you a free 3D printed sample part.

Request a Free Sample Part

Need more information or help transitioning to a digital workflow? Interested in ordering resin in bulk? We’re here to help!

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCastable Wax 40CeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempHigh Temp V2IBTModelModel V3Nylon 11Nylon 11 CFNylon 12Nylon 12 GFPU Rigid 1000PU Rigid 650Permanent CrownReboundRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 1500Tough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

5 Best 3D Printers For Jewelry 2022 (All Price Ranges!)

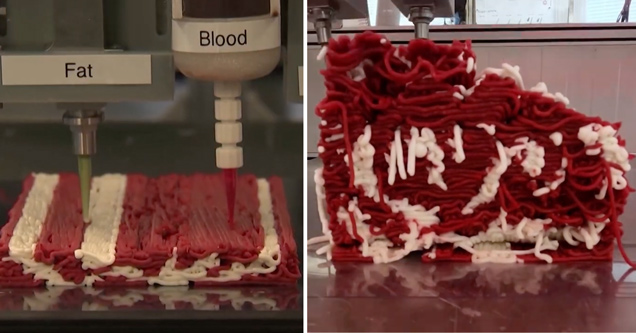

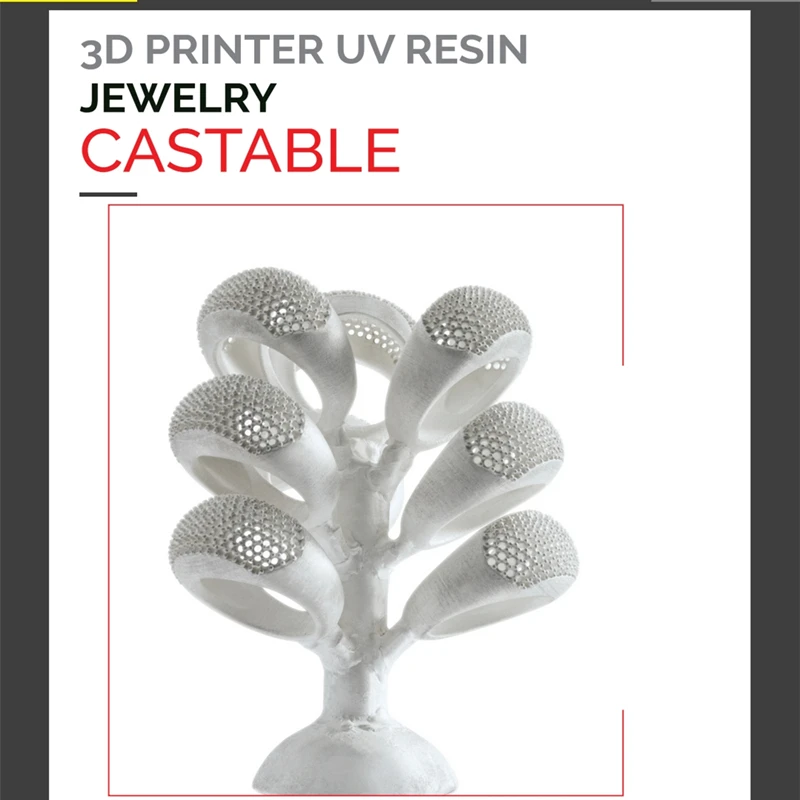

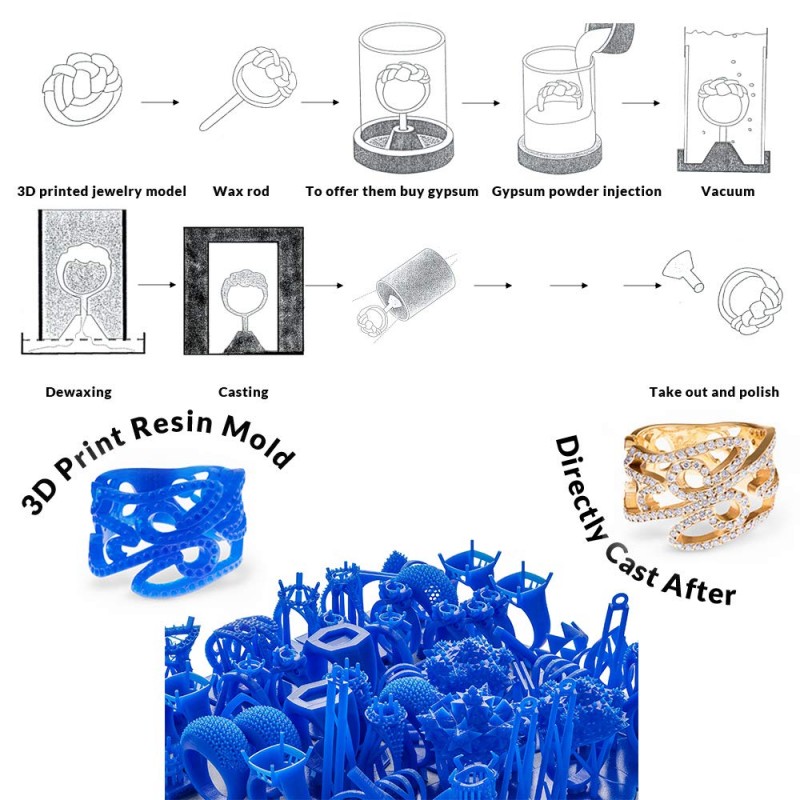

3D printing jewelry rarely means 3D printing actual wearable pieces made from filament or resin, but instead using a jewelry 3D printer to create high-resolution wax models of the eventual gold or platinum design, used to create a mold that is burned out and cast via investment casting or lost wax casting.

- We also have an article ranking some of the most beautiful 3D printed jewelry.

In fact, much jewelry is now created this way. There are entire factories of resin 3D printers set up to create castable wax resin models to be molded and then melted to create high-end jewelry.

However, owning your own jewelry 3D printer gives you more control over your production, and saves you money compared with paying someone to print your own molds. Castable resin molds can be produced for rings and other jewelry pieces for just the cost of the resin used, perhaps a dollar or two, whereas you could end up paying $25+ for someone to print it for you.

To insert the table into a page, post, or text widget, copy the Shortcode and paste it into the editor.

| Name | Build volume (mm) | Price | Where to buy |

|---|---|---|---|

| Elegoo Mars 2 Pro | 129 x 80 x 160 | $250 | Elegoo here |

| Peopoly Phenom | 276 x 155 x 400 | $1,999 | Matterhackers here |

| Formlabs Form 3 | 145 x 145 x 185 | $3,499 | Dynamism Store here |

| Solidscape S325 | 6″ x 6″ x 4″ | Quote | Get a Quote here |

| EnvisionTEC D4K Jewelry | 148 x 83 x 110 | Quote | Get a Quote here |

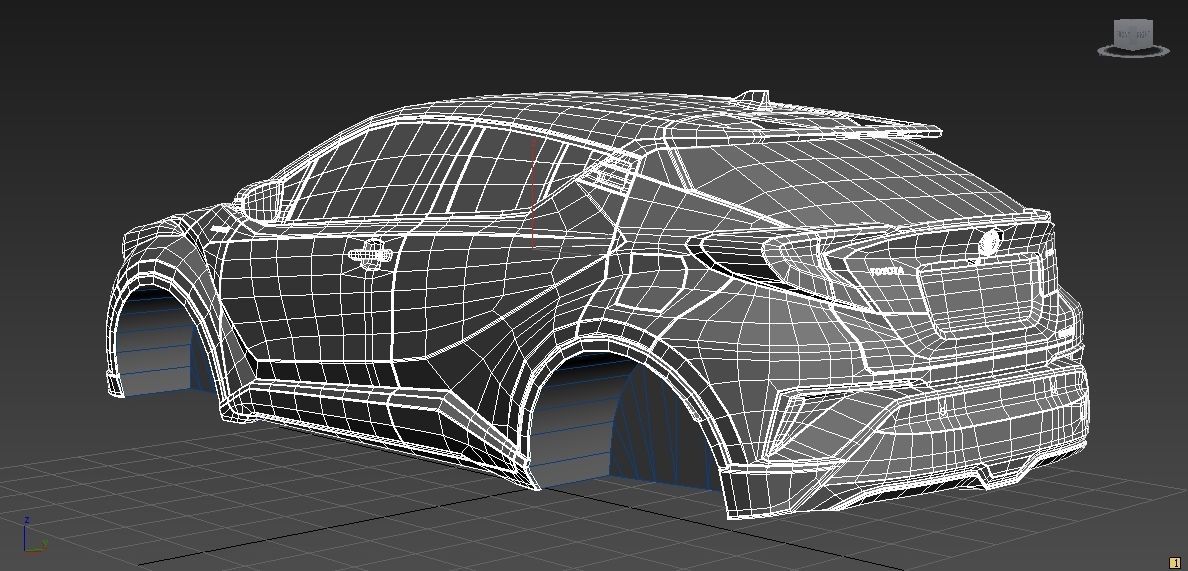

- CAD File: Either design your own jewelry piece on CAD software, pay someone to design your desired piece, or pay for an existing jewelry STL file online and download it.

- Slice & Prepare: If not already an STL or other compatible file, export it as one.

Then import it into your 3D slicer and slice it for printing.

Then import it into your 3D slicer and slice it for printing. - Print the model: Use a castable wax resin designed for jewelry model 3D printing.

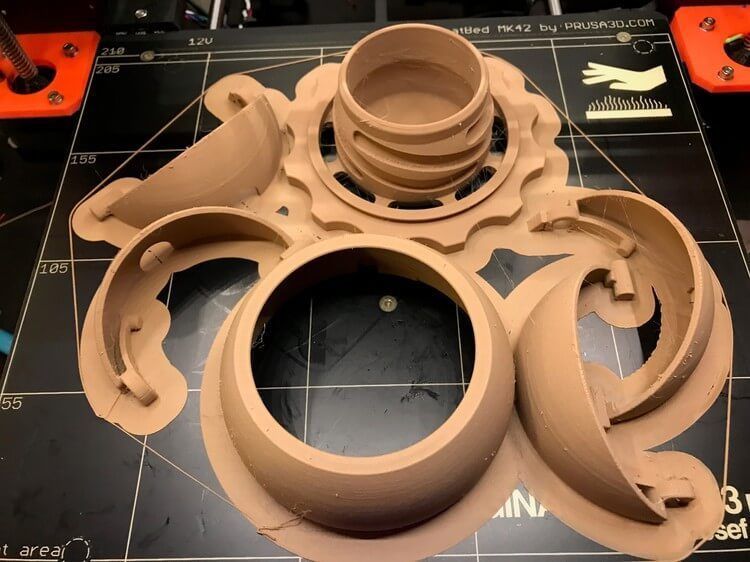

- Molding: Pour your molding material over your wax jewelry model, and leave it to harden.

- Melt the wax: Heat your new mold so that the original wax model melts and evaporates, leaving a hollow empty space inside with the exact dimensions of your planned jewelry piece.

- Casting: Pour melted liquid metal e.g. gold, silver or platinum into the mold to cast it.

Resin 3D printers are considered the best 3D printers for jewelry. They are used with specialized castable wax resins, which rather than going from solid to liquid when heated, transition directly into a gas from their solid state.

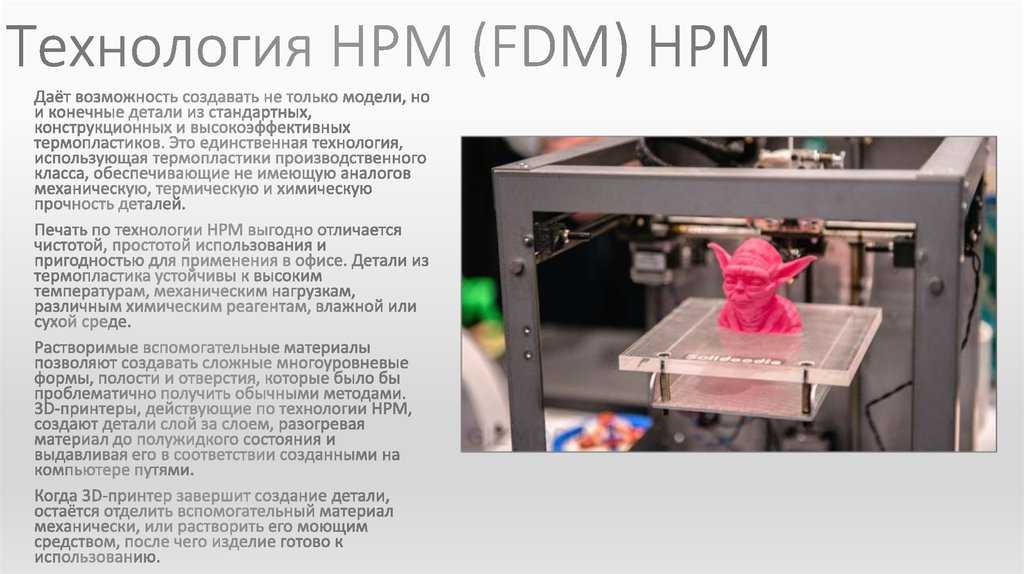

Though prevalent, FDM 3D printers are very rarely used as 3D printers for jewelry. They are not capable of the same resolutions, crisp surface finishes or accuracies required for intricate and delicate jewelry pieces. Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

Additionally, the better the jewelry 3D printer quality, the less finishing the resulting jewelry piece will need to perfect it.

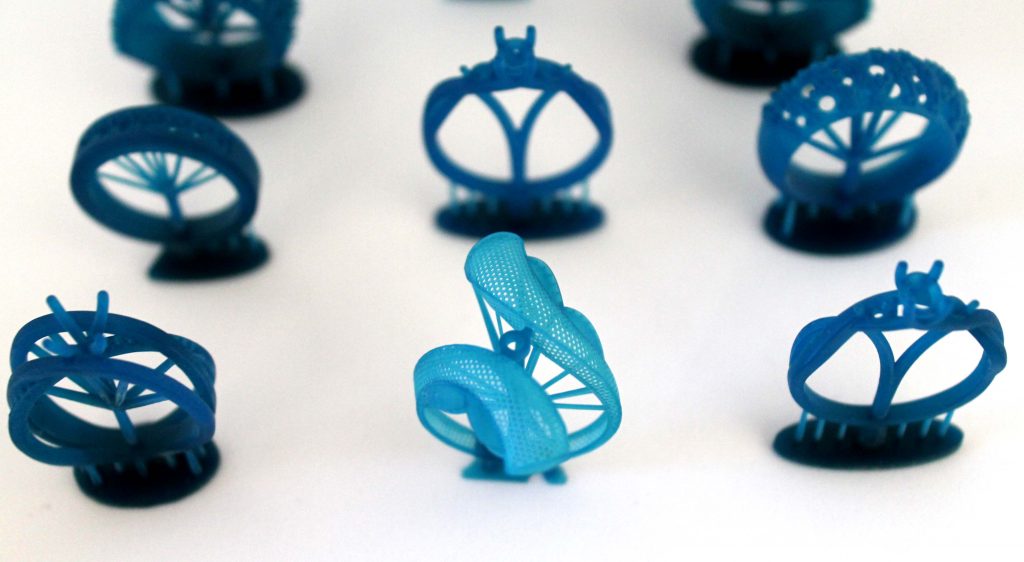

What do jewelry 3D printers make?Usually they 3D print wax jewelry molds, for example of ring designs before any stones are set, or individual chain links.

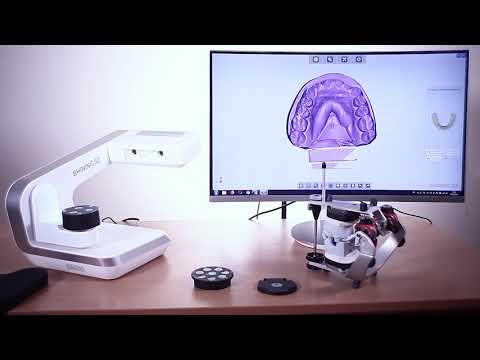

However, they can also be used to create like-for-like “fitting pieces” for testing the fit of an as-yet unmade ring for a client’s finger. Though making the final ring would be expensive and take time, an exact replica can be made on a jewelry 3D printer in just minutes to test the sizing.

This saves the trouble of creating a piece just to find it doesn’t fit properly. Whereas for jewelry molds specialized castable resins are required, for these fitting pieces standard resins can be used.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Learn more

The best 3D printers for jewelry

1 — Elegoo Mars 2 Pro

- Jewelry 3D printer price: $250 — Available at Elegoo store here / Available on Amazon here

- Build volume: 129 x 80 x 160 mm

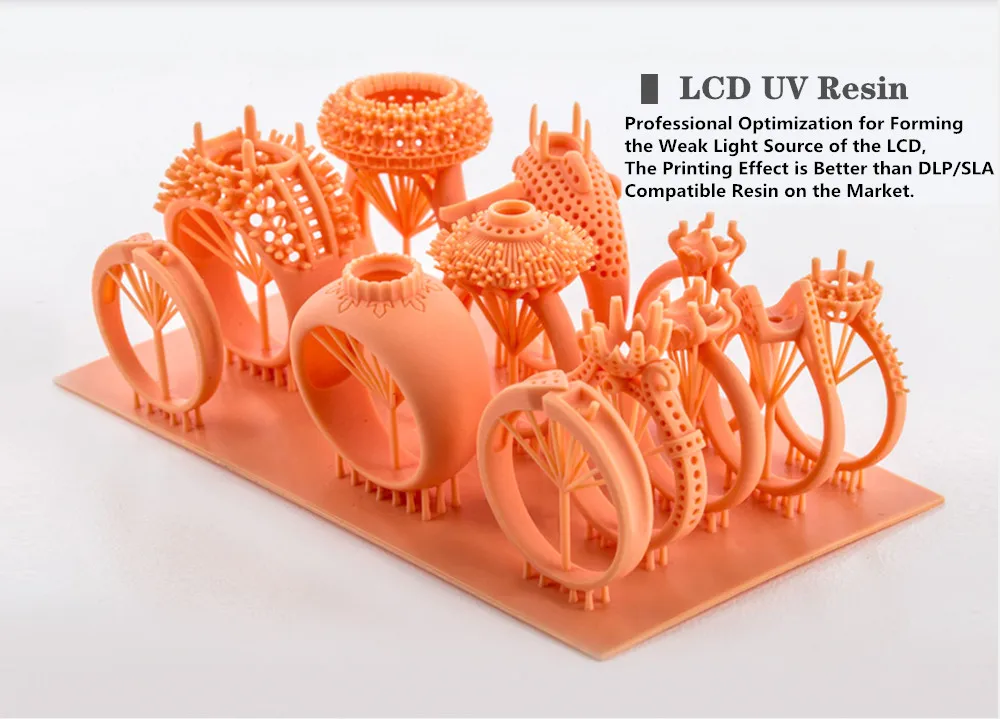

Featuring a 6-inch monochrome LCD screen offering HD 2K resolution, the Elegoo Mars 2 Pro offers precise jewelry printing for the price. Rather than DLP or SLA, the Mars 2 Pro uses LCD printing to cure entire resin layers at once, quickening print speeds and able to print at 30-50mm/h.This is the detail we achieved when using the Elegoo Mars 2 pro – enough for fine jewelry pieces.

Other 3D printers for jewelry on this list offer better quality, but for the price the Mars 2 Pro is a great option. It is sturdily built with its CNC-machined aluminum structure for better stability, and the mono LCD is upgraded for improved lifespan to save you money over the long term. It’s one of the best 3D printers for jewelry under $500.

The Elegoo Mars has Z-axis resolutions of up to 0. 00125mm, XY-resolutions of 0.05mm, and weighs 6.2kg. It also supports 12 different languages, so if you’re not a native English speaker you can choose your own language.

00125mm, XY-resolutions of 0.05mm, and weighs 6.2kg. It also supports 12 different languages, so if you’re not a native English speaker you can choose your own language.

The video below even shows, from start to finish, how accurately you can make wax models for gold jewelry using a standard Elegoo Mars. Even this standard version produces good quality wax models, and the Elegoo Mars 2 Pro comes with several upgrades on the original.Printing on our Elegoo Mars 2 Pro – read our full review here.

2 — Peopoly Phenom

- Jewelry 3D printer price: $1,999 — Available on Matterhackers here

- Build volume: 276 x 155 x 400 mm

The Peopoly Phenom offers truly enormous printing volumes, almost unheard of for a jewelry 3D printer. For jewelers looking to produce many rings or other pieces simultaneously, this larger volume provides space for dozens of wax jewelry models. If you’re in demand for jewelry and want to make as many as possible then this larger build volume is crucial.

With its 4K high resolution projection quality using MSLA technologies, the Phenom produces crisp, accurate and consistent jewelry molds. MSLA takes elements from both LED and LCD technologies, the result being fast, accurate and repeatable jewelry 3D printing.

- The even larger version, the Peopoly Phenom L, is available here.

- For faster print speeds, the premium Peopoly Noir is available here.

The Phenom uses Chitubox resin 3D slicer, useful if you’ve previously used it previously on another printer. Overall, it’s one of the best 3D printers for jewelry, and a great choice for people looking to make large numbers of castable wax jewelry models.

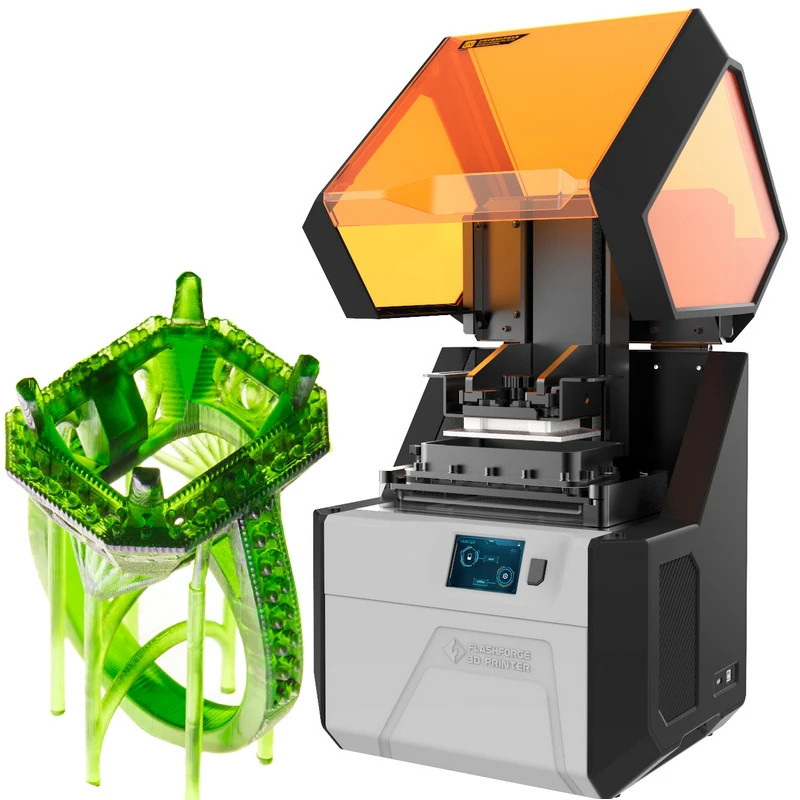

3 — Formlabs Form 3

- 3D for jewelry price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

Seen as the gold-standard in professional resin printing, the Form 3 is capable of fantastic precision, with its new custom Light Processing Unit (LPU) using lenses and mirrors to accurately print jewelry models.

For the price, the Form 3 offers 25-micron resolutions and very consistent and repeatable printing. For those looking for a 3D printer for jewelry able to produce the same design flawlessly again and again, or for producing custom intricate designs, the Form 3 can handle both without issue.

Formlabs make their own castable wax resins designed for jewelry with “crisp settings, sharp prongs and smooth shanks.” Within the Formlabs workflow therefore is a complete jewelry production process for wax models, though the Form 3 also excels as a dental 3D printer and in other industries, too.The Form 4, and several jewelry wax models it 3D printed.

4 — Solidscape S325

- Price: Requires a quote

- Build volume: 6” x 6” x 4”

Soliscape make specially designed jewelry 3D printers, so any Solidscape printer you buy is optimized for jewelry printing. Whereas other printers like the Form 3 are designed to excel in a number of industries, the Solidscape S325 is designed with jewelry wholly in mind.

The S325 is the cheapest of Solidscape’s jewelry 3D printer range. It offers great accuracy, material jetting wax models for the precise and effective investment casting of precious metals. Solidscape stress that all their models are castable in gold and platinum, and do not expand or shrink during the investment casting process.

The S325 is capable of 0.001-inch layer thicknesses, with accuracies of 0.005 inches. Overall, as a specialized 3D printer for jewelry, Solidscape have a rich history in jewelry 3D printing and can be trusted to deliver high-quality and precise ring wax models, time and time again.

Get a quote*

*One of our trusted partners will be in touch following a quote request.Compressed by jpeg-recompress

5 — EnvisionTEC D4K Pro Jewelry 3D printer

- Jewelry 3D printer price: Requires a quote

- Build volume: 148 x 83 x 110 mm

Described by EnvisionTEC are the highest resolution professional-grade desktop 3D printer, as well as claiming to have the fastest speed, the D4K is well suited to jewelry 3D printing. Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

EnvisionTEC are the originators of DLP 3D printing, having pioneered the process more than a decade ago. Now, their advanced D4K Pro can produce accuracies of up to 25 microns in the XY resolution, and 1 micron on the Z axis.

The jewelry 3D printer works well with EnvisionTEC’s WIC100 Series wax material, used to then burn out and investment cast precious jewelry. Though it’s an industrial 3D printer costing over $10,000, larger jewelers will find the D4K one of the best 3D jewelry mold printers.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

Advantages of owning a jewelry 3D printer

- Saves money long term: rather than paying a 3D printing service $20+ to print your mold for you, you can print your own wax jewelry molds for just a dollar each.

- Control your own jewelry production: with the ability to print jewelry in-house, you control your own workflow and apart from resin shortages, cannot be slowed down by supplier failures. Your order will always be top priority.

- Fast: going from CAD model to a piece ready to be investment cast is quick, especially when you can print and cast everything in one place.

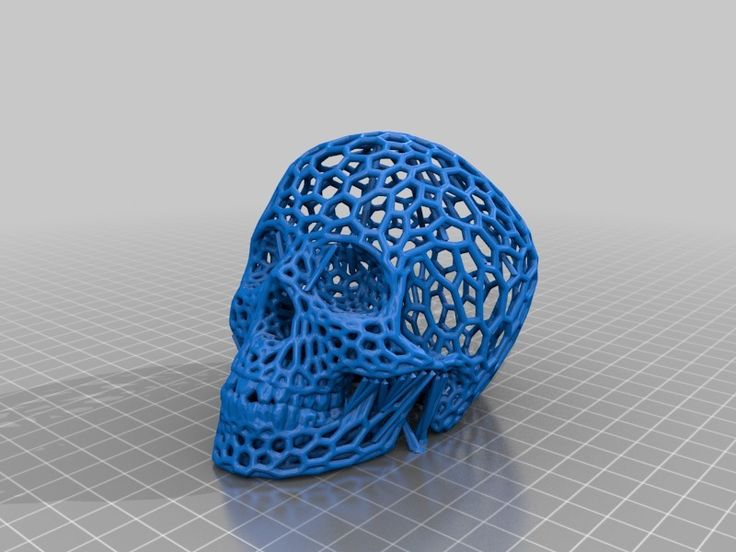

- Very accurate: precise, smooth and intricate jewelry is not an issue for jewelry 3D printers, some able to print with below 10-micron accuracy to capture your ring’s most delicate and beautiful features.

- Repeatable and scalable: 3D printers for jewelry can create potentially dozens of identical or customized ring molds at once, perfect for scalable jewelry production.

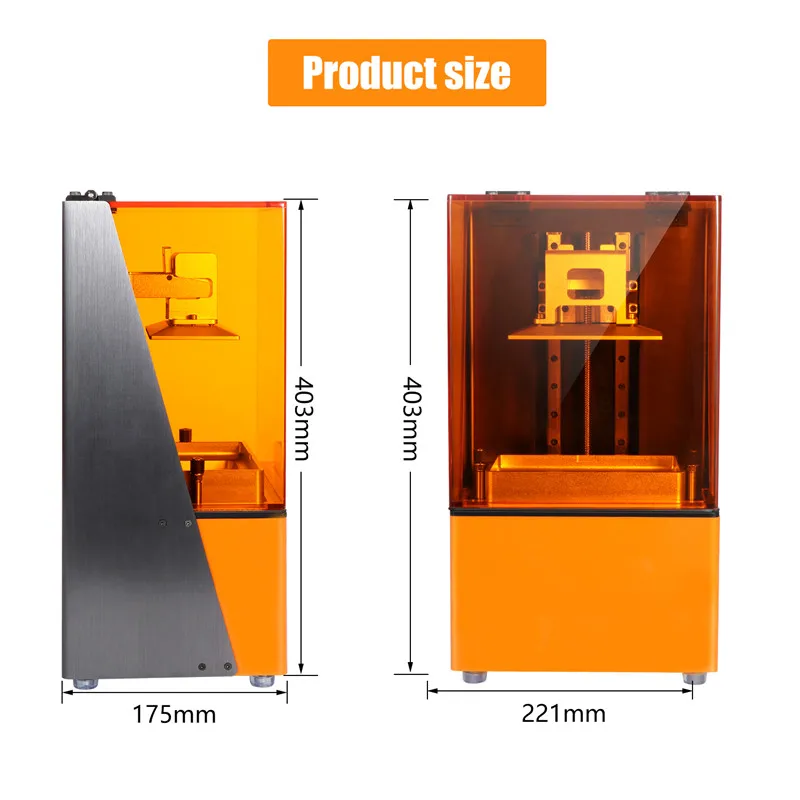

Which LCD 3D printer to choose for jewelry making

In this fast-paced world, even jewelry can now be created using 3D printing. Everything from rings to necklaces can be easily printed with the touch of a finger. Resin 3D printing allows the creation of high-quality jewelry with intricate detailing that would be extremely difficult to achieve with traditional manufacturing.

Resin 3D printing allows the creation of high-quality jewelry with intricate detailing that would be extremely difficult to achieve with traditional manufacturing.

In the traditional process, jewelers create intricate and fine patterns in wax or by hand. Although they put a lot of love and diligence into their work, this method remains very time consuming and the risk of human error is high. One mistake and you have to start the whole process from scratch. nine0004

Thanks to the advent of photopolymer 3D printing, a piece of jewelry can now be created digitally and then printed. If necessary, the design can be modified using a CAD program. Phrozen's Wax-Like Castable Violet imitates wax commonly used in jewelry. A sample of this resin is placed in a mould, filled with plaster, hardened and cast. It burns out, and the final product of gold or silver remains. nine0004

It burns out, and the final product of gold or silver remains. nine0004

What types of jewelry can 3D printers create?

Photopolymer 3D printing allows you to think outside the box and create all kinds of jewelry in the most unique shapes and designs. Also, LCD 3D printers allow you to make custom jewelry at a much more affordable price.

3D printers can be used for prototyping, rubber molding, and jewelry casting.

Let's see which Phrozen LCD 3D printer is suitable for creating jewelry: nine0004

Phrozen Sonic Mini 4K 3D printer - for highly detailed jewelry models

The 6.1" LCD resolution of the Phrozen Sonic Mini 4K is best suited for creating jewelry models. It prints delicate pieces in 4K resolution.

The Sonic Mini 4K is capable of printing a full platform of intricate details such as rings, brooches and pendants in a single print session. For example, it can be 10-20 rings on one platform. With fast printing capabilities, this 3D printer prints out a platform full of decorations in the minimum amount of time. nine0004

nine0004

With extremely precise printing, Sonic Mini 4K ensures that all the fine details on jewelry are executed without error.

The Sonic Mini 4K Desktop Resin 3D Printer can be easily stored at home, in the workplace or in a jewelry studio.

Specifications of the Phrozen Sonic Mini 4K 3D printer:

- LCD resolution 6.1" 4K Mono LCD

- Display 2.8" Touch Panel

- Construction area size 134x75x130 mm

- 35 µm XY resolution

- print speed 80 mm/hour

Sonic Mini 8K - for extremely detailed jewelry models

With a 7.1" LCD display resolution, the Phrozen Sonic Mini 8K is the best choice for those who want to create extremely intricate jewelry in 8K resolution.

The Sonic Mini 8K is able to print a full platform of the most intricate jewelry such as rings, brooches and pendants in a single print session. One plate may contain, for example, 10-20 rings. nine0004

Sonic Mini 8K comes with a matte laser cut platform while allowing your jewelry to attach to the build plate more firmly. This increases the likelihood of printing success.

This increases the likelihood of printing success.

With a matte pattern print platform on the surface, 3D models are firmly attached to it during printing, greatly increasing the success rate of 3D printing. Sonic Mini 8K is best suited for professional jewelers who want to increase their productivity and create the most detailed models. nine0004

Phrozen Sonic Mini 8K 3D Printer Specifications:

- LCD resolution 7.1" 8K Mono LCD

- Display 3.5" Touch Panel

- Construction area size 165x72x180 mm

- 22 µm XY resolution

- print speed 80 mm/hour

Why invest in 3D jewelry printers

Photopolymer 3D printing allows jewelers to create multiple samples and complex designs at once, saving both time and money. You can focus on the details and be as creative as possible. nine0004

Now, jewelry professionals have the time to craft exquisite jewelry with exceptional precision and attention to detail.

Formlabs Jewelry Resins material properties characteristics

Jewelry resins are specially developed by Formlabs for jewelry 3D printing. They create highly detailed prints for designing and making jewelry.

These resins are easy to work with. After all, they really accurately reproduce precise settings, sharp protrusions, smooth rods and fine surface details. By using Formlabs Jewelry Resins on the world-renowned Formlabs Form 3 Automated Desktop Stereolithography 3D Printer, you can be sure of the result of printing and casting. Resins are designed to mimic working with wax. They burn cleanly and residue-free with a controlled burn-out schedule and are suitable for traditional jewelry manufacturing methods. Thus, 3D printing with Formlabs jewelry resins fits into your traditional jewelry manufacturing workflow, accelerating and scaling it. nine0004

Printing precision and resin resin applications Formlabs

1| Compatible with printer | Bath compatible | Layer height, micron | Features and Applications | |

| Castable Wax | Form 2 Form 3 Form 3B | Form 2 Standard Form 2 LT Form 3 Tank V1 Form 3 Tank V2/V2.  1 1 | Form 2, Form 3/3B - 25, 50 µm | Accurate settings, sharp teeth, smooth shafts, fine surface details Photopolymer with 20% wax No post-curing required |

| Castable Wax 40 | Form 2 Form 3 | Form 2 LT Form 3 Tank V2.1 | Form 2, Form 3 - 25.50 µm | Photopolymer with 40% wax Heavy Statement Jewelry Pendants & Medallions Custom Wedding Jewelry |

1 Data as of March 2021

–

4

• Castable Wax V1 •

Accurate reproduction of even the smallest details and a clean casting every time. The photopolymer, which contains 20% wax, is specially formulated for reliable casting with 0% ash residue and clean burnout. Castable Wax Resin faithfully reproduces intricate details and offers the smooth surfaces that stereolithographic 3D printing is known for. nine0004

nine0004

Material Properties

Castable Wax by Formlabs| Green 1 | Method | |

| Tensile properties 2 | ||

| Tensile Strength | 11.6 MPa | ASTM D 638-10 |

| Tensile modulus | 220 MPa | ASTM D 638-10 |

| Elongation at break | 13.0% | ASTM D 638-10 |

| Burnout properties 2 | ||

| Temperature at 5% weight loss | 249 °C | ASTM E 1131 |

| Ash content (TGA) | 0.0-0.1% | ASTM E 1131 |

1 Material properties may vary depending on part geometry, print orientation, print settings and temperatures.

2 Data was obtained from parts printed on a Formlabs Form 2 3D printer, Castable 50 µm Fine Detail setting and washed without post curing.

Formlabs Standard Burnout Chart

Castable WaxBurnout Standard Chart is designed to give the highest possible investment strength and complete burnout of the finest details when using R&R Plasticast or similar investment materials. Use this schedule as a starting point and make adjustments as needed. nine0004

-

• Castable Wax 40 V1 •

Castable Wax 40 Resin contains a 40% mixture of solid and liquid waxes, which gives this polymer a low coefficient of expansion. The resin is available in a wide range of investment casting conditions and is compatible with leading plaster moulders. Parts printed with Castable Wax 40 have excellent detail and clean burnout across a wide range of workflows and casting conditions. Does not require additional polymerization. nine0004

Does not require additional polymerization. nine0004

Castable Wax 40 offers the easiest workflow on the market for 3D printing and casting tasks with a highly detailed design. With more flexible casting parameters and burnout, this resin ensures that casters of all skill levels can produce high quality resin jewelry. Formlabs Jewelry Resins

Formlabs Jewelry Resins. Material Properties

Castable Wax 40| Green 1 | Method | |

| Burnout properties 2 | ||

| Temperature at 5% weight loss | 249 °C | ASTM E 1131 |

| Ash content (TGA) | 0.0-0.1% | ASTM E 1131 |

1 Material properties may vary depending on part geometry, print orientation, print settings and temperatures. nine0171

nine0171

2 Data was obtained from “green” parts printed on a Form 3 3D printer, 50 micron, Castable Wax 40 Resin setting, no post-cure.

Formlabs Standard Burn-In Chart

Castable Wax 40The following burn-in chart is designed to reduce the thermal expansion of the resin in the mold, while ensuring complete burnout of thick jewelry pieces. Formlabs Recommends Certus Prestige Optima 9 Investment Powder0168 TM . Use this schedule as a starting point and make adjustments as needed.

| Phase | Time | °C graph | ||

| A | nine0104 After the setting period of the investment material (30-60 min), place the flasks in the stoving ovenHold | 180 min | 55 °C | |

| B | Thermal transition Wax sprue extends outwards, increasing air flow to the resin pattern.  The wax in the resin ends up in the investment. The wax in the resin ends up in the investment. Burn-in starts gently, destroying the structure without much expansion | Heating | 48 min | 2 °C/min |

| Hold | 180 min | 150 °C | ||

| Heating | 75 min | 2 °C/min | ||

| Hold | 180 min | 300 °C | ||

| C | Burnout Removes resin and ash residues in the package | Heating | 108 min | 4 °C/min |

| Hold | 180 min | 732 °C | ||

| D | Casting temperature Cool the flask to the casting temperature of the selected metal | Heating | 44 min | -5 °C/min |

| Casting window | Up to 2 hours | Desired casting temperature |

Wash Information:

Rinse Castable Wax 40 prints in isopropyl alcohol (IPA) for several minutes.