Belt printer 3d

The 5 Best Belt 3D Printers for Infinite Printing (2022) – Clever Creations

3D printer designs have evolved a lot since their inception in the 1980s. Cartesian, CoreXY, and Delta 3D printers are the standard norm in the hobby 3D printing space. Recently, we have seen the introduction of conveyor belt 3D printers.

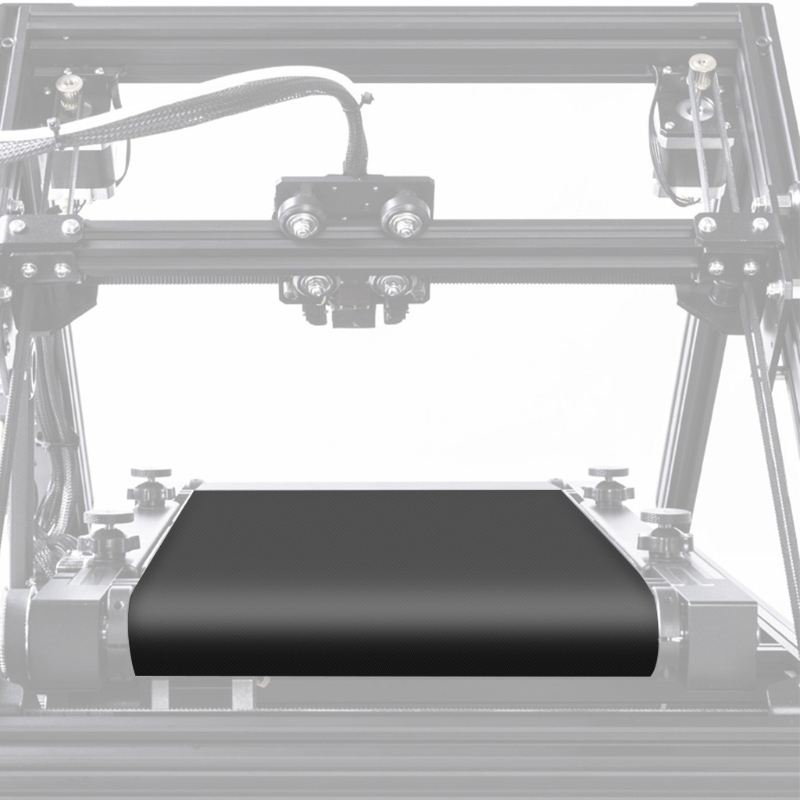

These 3D printers have the belt embedded into the build platform, essentially creating a printer with an infinite Z-axis. This is an interesting design and raises the question: is a belt 3D printer viable for your 3D printing needs?

Read on to learn more about continuous printing and see the best belt 3D printers that are currently available on the market.

| Belt 3D Printer | Build Volume | Inclination | Price (~) | Best Offer |

|---|---|---|---|---|

| Creality CR-30 3DPrintMill | 200 x 170 x ∞ mm | 45° | $1049 | Creality |

| Blackbelt 3D Printer | 340 x 340 x ∞ mm | 15°/25°/35°/45° | $10450 | Blackbelt 3D |

| IdeaFormer IR3 | 250 x 250 x ∞ mm | 45° | $499 | Amazon |

| SainSmart INFI-20 | 200 x 180 x ∞ mm | 45° | $849 | SainSmart |

| White Knight Belt Printer | 400 x 430 x ∞ mm | 45° | $2000 | GitHub |

What is a Belt 3D printer?

Originally invented by the Dutch company Blackbelt in 2017, rolling conveyor belt 3D printers are a radical take on the existing 3D printer designs. Belt 3D printers consist of a moving belt that lets you print long objects in the Z-axis without any limits (infinite Z printing).

You can use a belt 3D printer to carry out bulk printing and print continuously without the need to stop the 3D printing process.

The original Blackbelt 3D printer had a price tag of over $9000, limiting its user base to professional users. Subsequently, Creality’s CR-30 3DPrintMill brought continuous printing technology to the masses. Several other conveyor belt printers have appeared on the market after that.

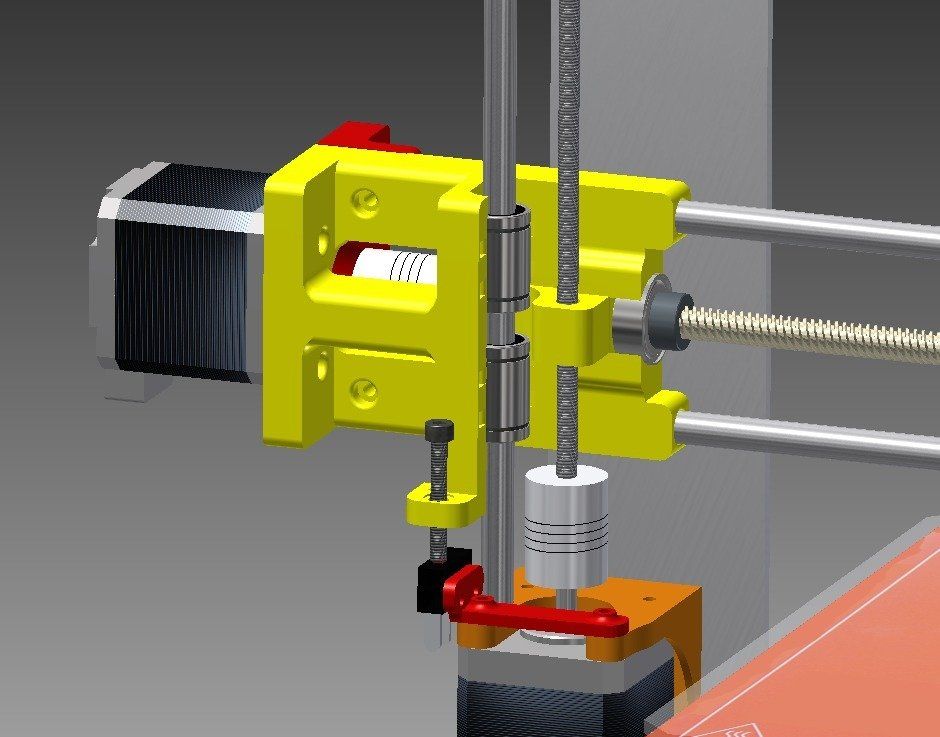

How do belt 3D printers work?

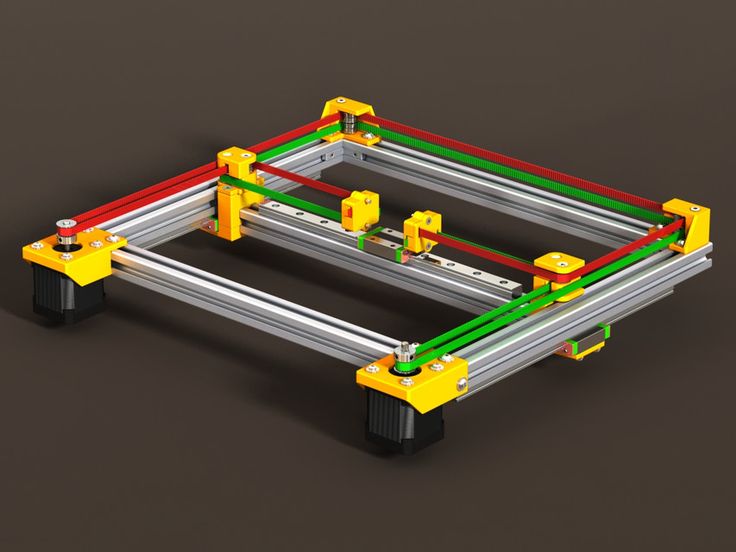

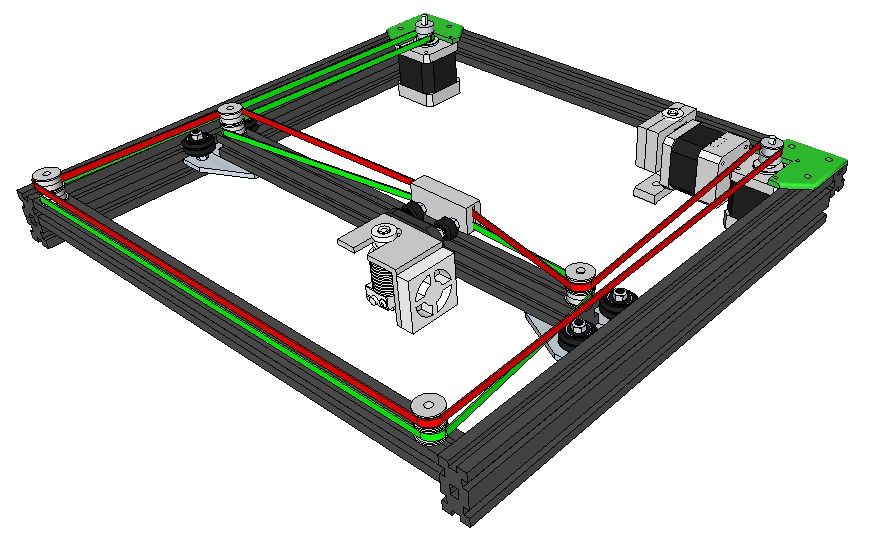

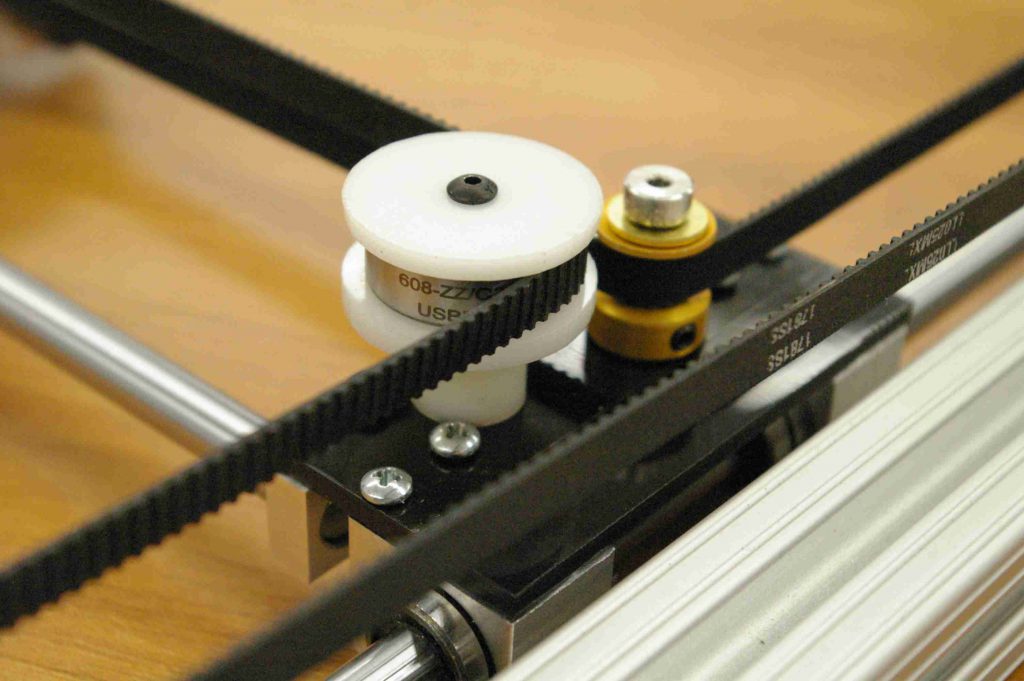

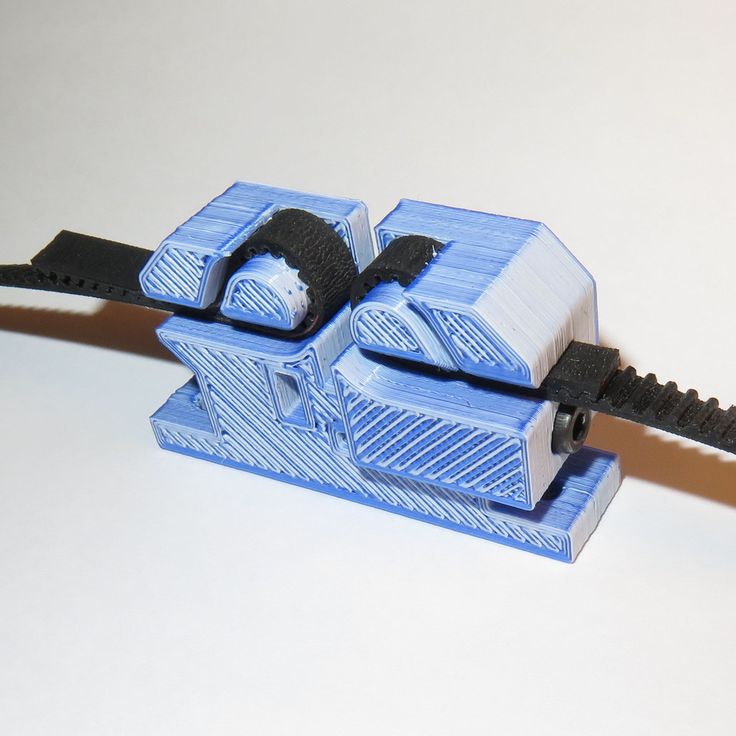

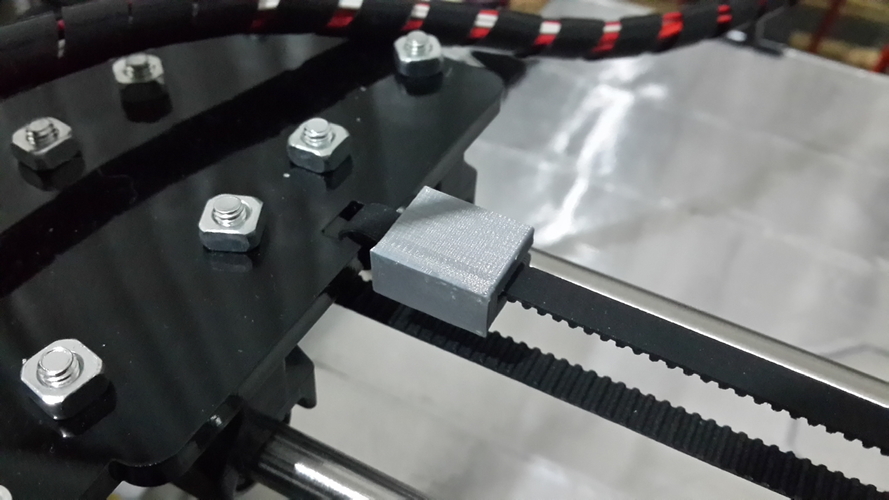

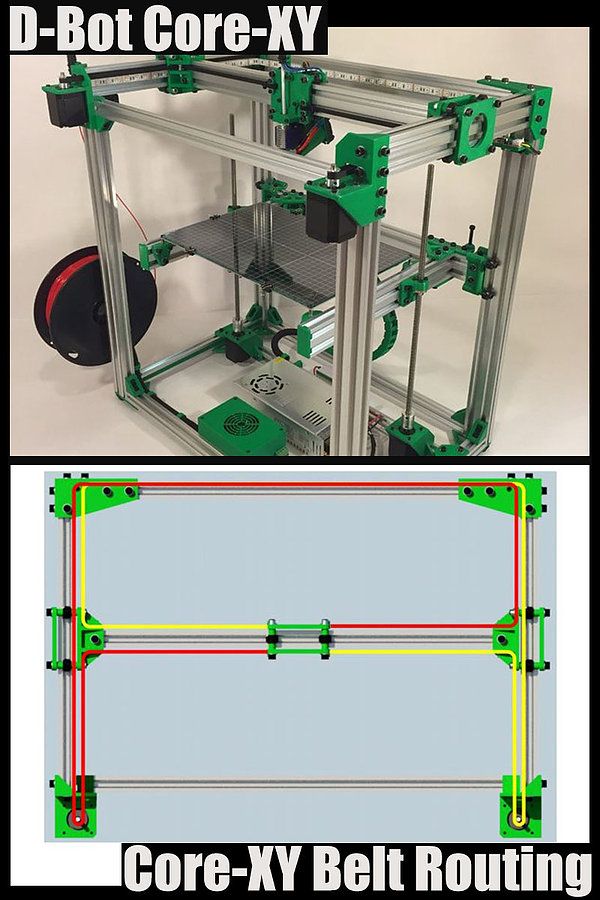

A conveyor belt 3D printer is a drastic modification over your typical Cartesian or CoreXY 3D printer. Its stand-out feature is a continuously moving belt instead of a fixed print bed.

On a belt 3D printer, a Core XY motion gantry is positioned inclined to the belt, usually at a 45° angle. The belt is used as the Z-axis for your 3D prints, whereas the inclined print head constitutes the X and Y axes.

The print head prints the objects in an inclined plane. While doing so, the belt moves ahead or backward, depending on your object’s design. The printing process is pretty much like that of a standard CoreXY 3D printer, albeit on an inclined plane.

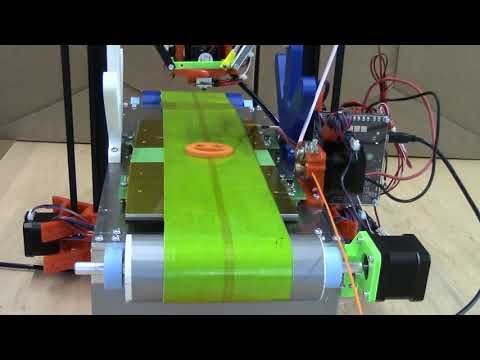

3D prints fall off the belt’s far end once they’re done printing. Because of this, you can use belt 3D printers to print large production runs of your designs without any intervention.

Technically, there’s no restriction on the object’s height that you can print on belt 3D printers. Here is an example of a CR-30 3D printer printing a 6-meter extended model on the conveyor belt.

Why use a belt 3D printer?

One of the biggest advantages of a conveyor belt 3D printer is that it lets you 3D print long objects. As the 3D printer has no actual limit in the Z direction, you can 3D print swords, large model buildings, and other prints that would not fit the print volume of traditional FDM printers.

As long as you can support your parts beyond the belt’s length, you can print models as long as you want. For that reason, some belt 3D printers come with a removable extension bracket accessory.

For that reason, some belt 3D printers come with a removable extension bracket accessory.

Alternatively, you can use belt 3D printers to automate your printing process. If your work consists of 3D printing numerous parts, you might not want to go through the effort of removing them from the print bed, cleaning the bed, and starting a new 3D print each time.

Advantages:

- Infinite z-axis offers infinite length 3D prints

- Cost-efficient bulk 3D printing

Disadvantages:

- No belt 3D printers with enclosure

- Rougher surface finish than glass print beds

- Limited slicer options

- Requires additional support structures

The Best Conveyor Belt 3D Printers in 2022

Creality CR-30 3DPrintMill

Best overall

Check price at

AmazonCrealityCreality3DOfficial

Creality’s CR-30 3DPrintMill is probably the best-known conveyor belt 3D printer at the moment of writing. It carries a similar design to the Blackbelt 3D printer, but comes at a considerably more attractive price. At a price tag of $1049, it provides a great set of features and easy accessibility to spare parts.

It carries a similar design to the Blackbelt 3D printer, but comes at a considerably more attractive price. At a price tag of $1049, it provides a great set of features and easy accessibility to spare parts.

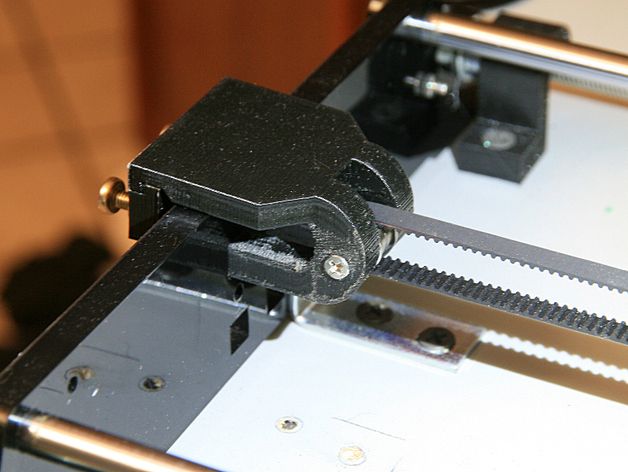

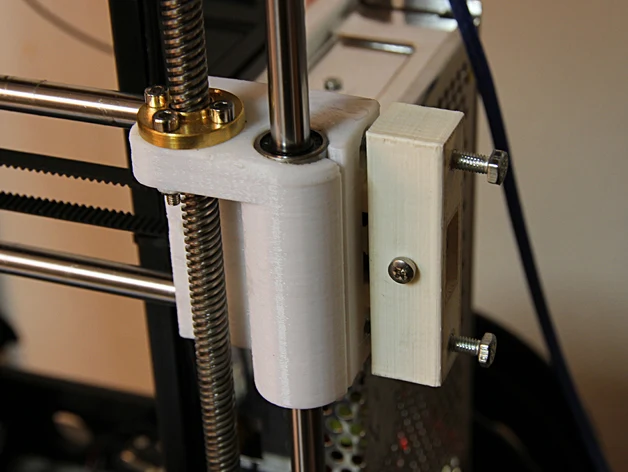

The CR-30 comes with a CoreXY gantry inclined at 45°. This lets the 3D printer have a rigid triangular frame that aids in print quality. The design is similar to other Creality 3D printers with V-slot extrusions, a dual gear Bowden extruder, and a spring adjustable bed platform.

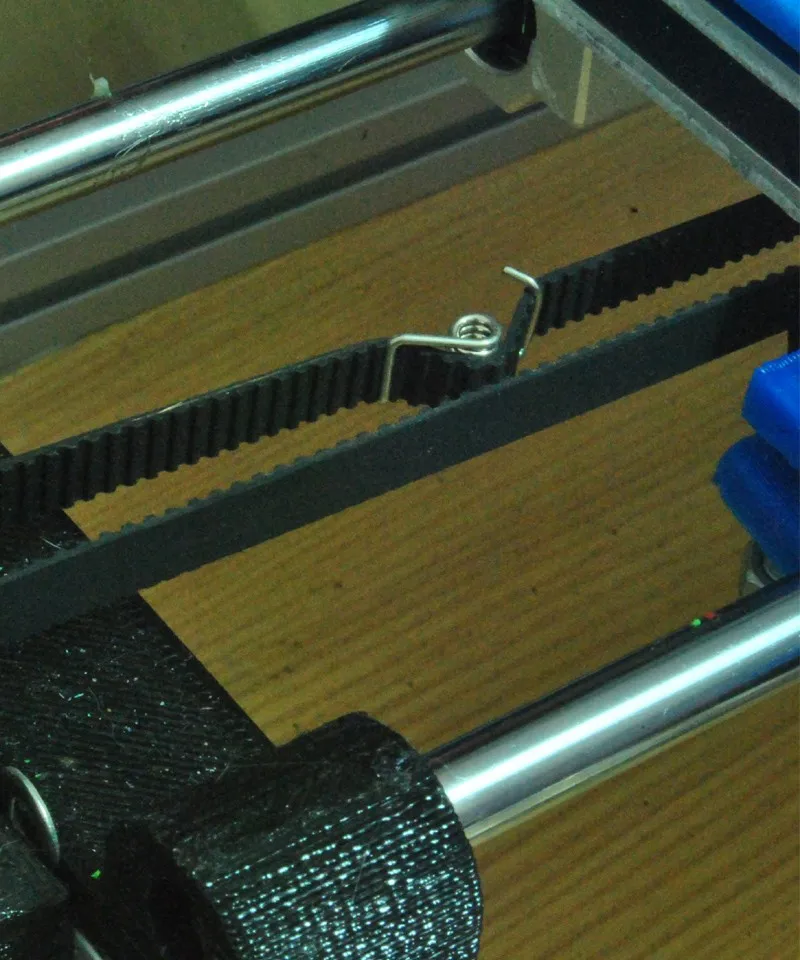

The wear-resistant nylon belt surface and partially heated print area both promote print adhesion. The printer’s belt can be easily removed for cleaning or replacement.

Keep in mind that you will need to spend time fine-tuning it to get the best quality results. Nonetheless, the CR-30 Print mill opens up many avenues for cosplay 3D printing and is one of the best belt 3D printers for hobbyists looking for an endless printing solution.

Standout Features

- Nylon conveyor belt

- Dual metal gear extruder

- Silent stepper drivers

Technical Details | |

|---|---|

| Build volume | 200 x 170 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 240°C |

| Overall dimensions | 535 x 656 x 410 mm |

| Weight | 16. 5 kg 5 kg |

What We Like

- Easy to assemble

- Add-on rollers and replacement belts available

- Great community support

Could Be Better

- Sub-par print quality out of the box

- Poor quality control

Find Creality CR-30 3DPrintMill at

AmazonCrealityCreality3DOfficial

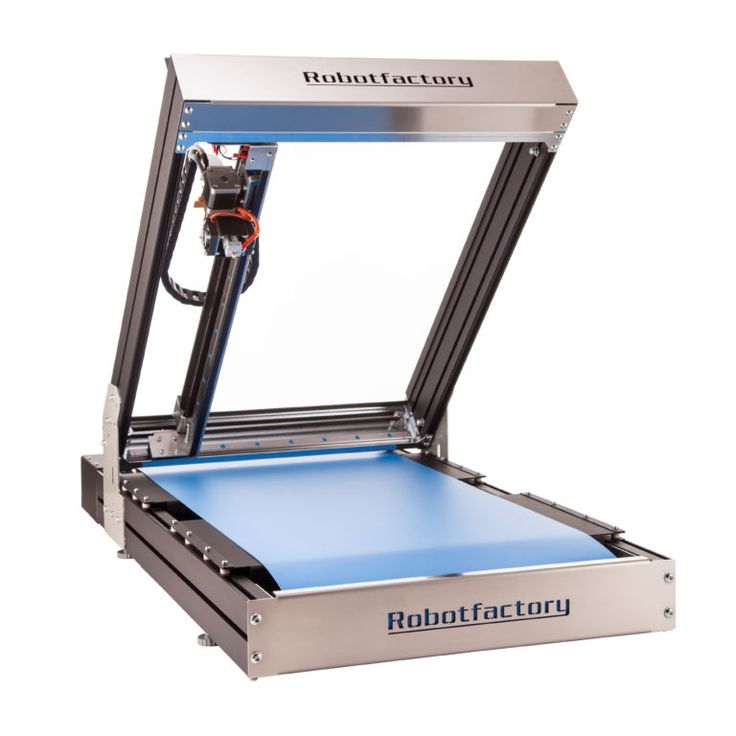

Blackbelt 3D Printer

Best high-end

Check price at

Blackbelt 3D

The Blackbelt 3D printer was the first commercial solution to realize infinite Z-axis 3D printing. Its revolutionary design and high-end components brought belt 3D printing to industrial applications.

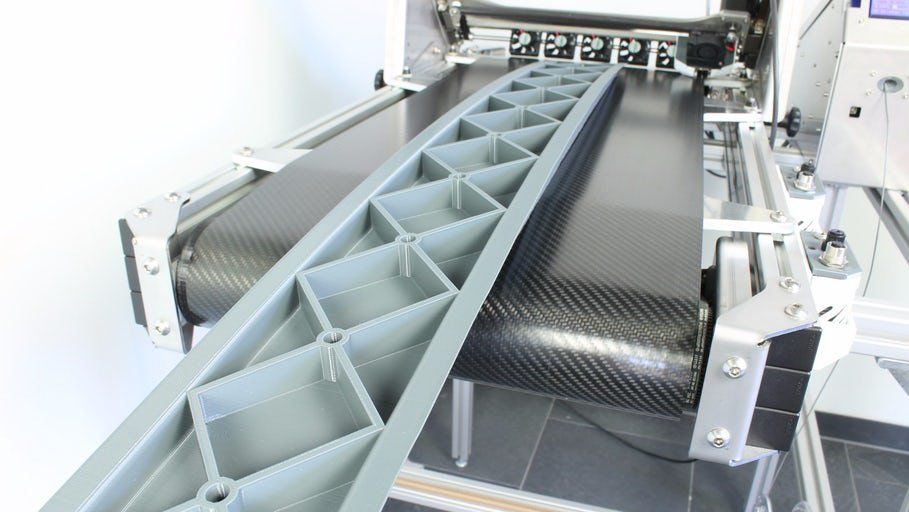

The belt is made up of a durable carbon fiber composite material and holds your prints firmly in place. It features a modular design letting you quickly change the printhead assembly to print flexible filaments. Additionally, the Blackbelt team can customize the printer to fully suit your 3D printing workflow.

The industrial linear guides on the printer facilitate a smooth motion, and you get the option to adjust the inclination angle of the printer frame as well. It certainly has a premium design and a rugged build quality and is developed with industrial applications in mind.

It certainly has a premium design and a rugged build quality and is developed with industrial applications in mind.

If you have the budget for a >$10,000 conveyor belt 3D printer, the Blackbelt will be the best choice for you.

Standout Features

- Modular design

- Carbon-fiber composite belt

- Adjustable print angles

Technical Details | |

|---|---|

| Build volume | 340 x 340 x ∞ mm |

| Inclination angle | 15°/25°/35°/45° |

| Max hot end temperature | N/A |

| Overall dimensions | N/A |

| Weight | N/A |

What We Like

- Industrial build quality

- Customizable to your needs

- Large build volume

Could Be Better

- Expensive

- Outdated user interface

Find Blackbelt 3D Printer at

Blackbelt 3D

IdeaFormer IR3

Best on a budget

Check price at

AmazonAliExpress

The IdeaFormer IR3 is a desktop-sized conveyor belt 3D printer catered to budget 3D printer users. It has a simple design and comes with typical features of a budget 3D printer but in a belt printer package.

It has a simple design and comes with typical features of a budget 3D printer but in a belt printer package.

The printer features a CoreXY structure with a PU polyester belt as the print surface. You get linear guides on the XY axes for smooth and precise movement. The hot end on the printer is exclusive to it and has the addition of a dual gear extruder and a filament breakage detector. These key features are designed to provide reliable 3D printing over long periods of time.

As the printer is focused on novice users, it is easy to assemble, You will be able to put it together within half an hour.

The lack of a heated bed makes it most suitable for 3D printing low-temperature filaments like PLA. Similarly, its non-triangular frame is less rigid than the one you can find on the CR 30.

If you can handle its limitations and want to experience printing with a budget belt 3D printer, the IdeaFormer I3 is an excellent option.

Standout Features

- Easy to assemble

- Linear rail guides on X and Y axes

- Exclusively designed hot end

Technical Details | |

|---|---|

| Build volume | 250 x 250 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 250 °C |

| Overall dimensions | 575 x 436 x 506 mm |

| Weight | 16. 8 kg 8 kg |

What We Like

- Beginner-friendly design

- Low-cost

- Good printing volume

Could Be Better

- Separate control unit takes up extra space

- Limited community support

Find IdeaFormer IR3 at

AmazonAliExpress

SainSmart INFI-20

Most rigid

Check price at

AmazonSainSmart

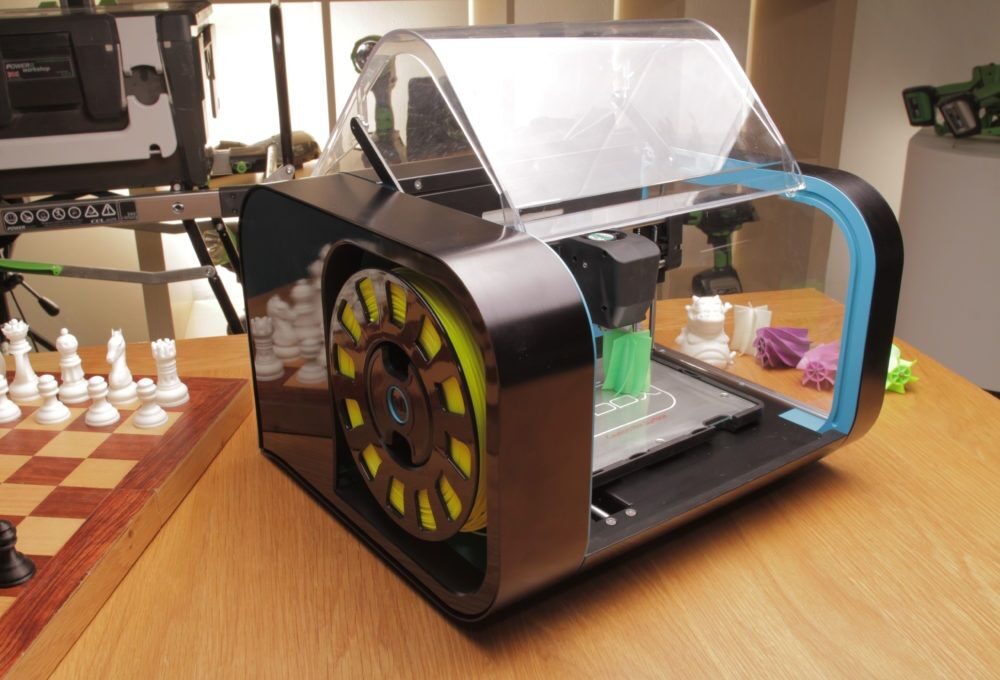

The Sainsmart INFI-20 is one of the most compact and modern-looking conveyor belt 3D printers. Its spec sheet is comparable with that of the CR-30. At a slightly lower cost, the Sainsmart still delivers a decent printing experience and is an excellent alternative to the CR-30.

The INFI-20 comes with TMC 2208 stepper drivers for silent 3D printing. You also get a textured nylon belt surface designed for durability and good print adhesion. To help with setup, the included layer test model lets you quickly level your print bed.

The sleek brush metal finish display with a rotary knob on the control panel adds a touch of modernity to the printer. And with the inbuilt Wi-Fi capabilities, you can print wirelessly through the Octoprint app.

And with the inbuilt Wi-Fi capabilities, you can print wirelessly through the Octoprint app.

Reviews of the INFI-20 aren’t as positive as those of the CR-30. While it comes packed with nice features in a small form factor, you can expect to do a lot of tinkering before you get good results.

That said, if you get it dialed in correctly, the SainSmart INFI-20 conveyor belt 3D printer can be a decent belt printer for beginners, and hobbyists to print multiple models at once.

Standout Features

- Compact form factor

- Modern user interface

- Wi-Fi printing

Technical Details | |

|---|---|

| Build volume | 200 x 180 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 240 °C |

| Overall dimensions | 630 x 530 x 290 mm |

| Weight | 18. 5 kg 5 kg |

What We Like

- Easy to set up

- Silent 3D printing experience

- Integrated Octoprint support

Could Be Better

- Requires considerable fine-tuning

- Inconsistent Z-axis homing

Find SainSmart INFI-20 at

AmazonSainSmart

White Knight Belt Printer

Best DIY Conveyor Belt 3D Printer

GitHubThingiverse

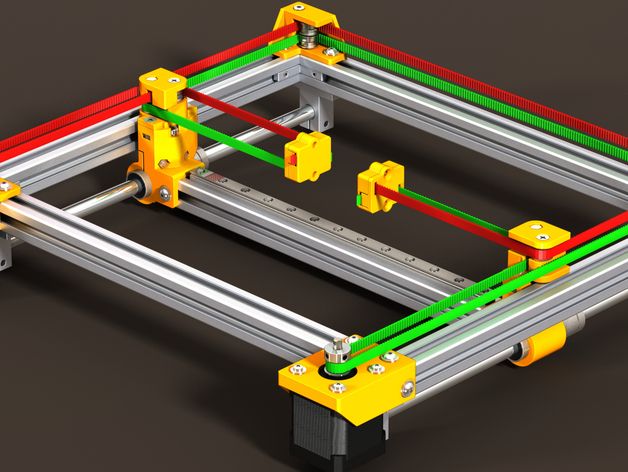

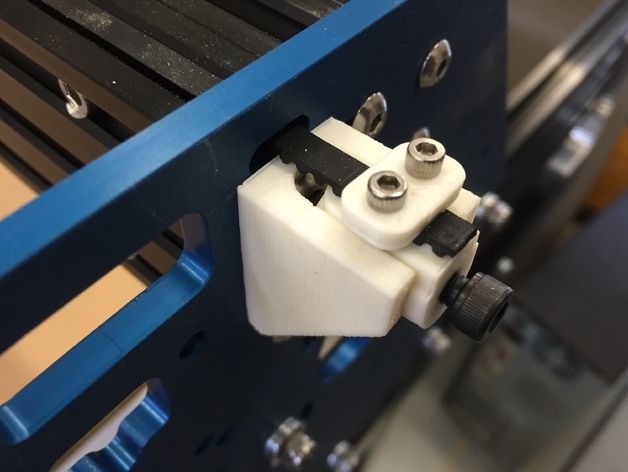

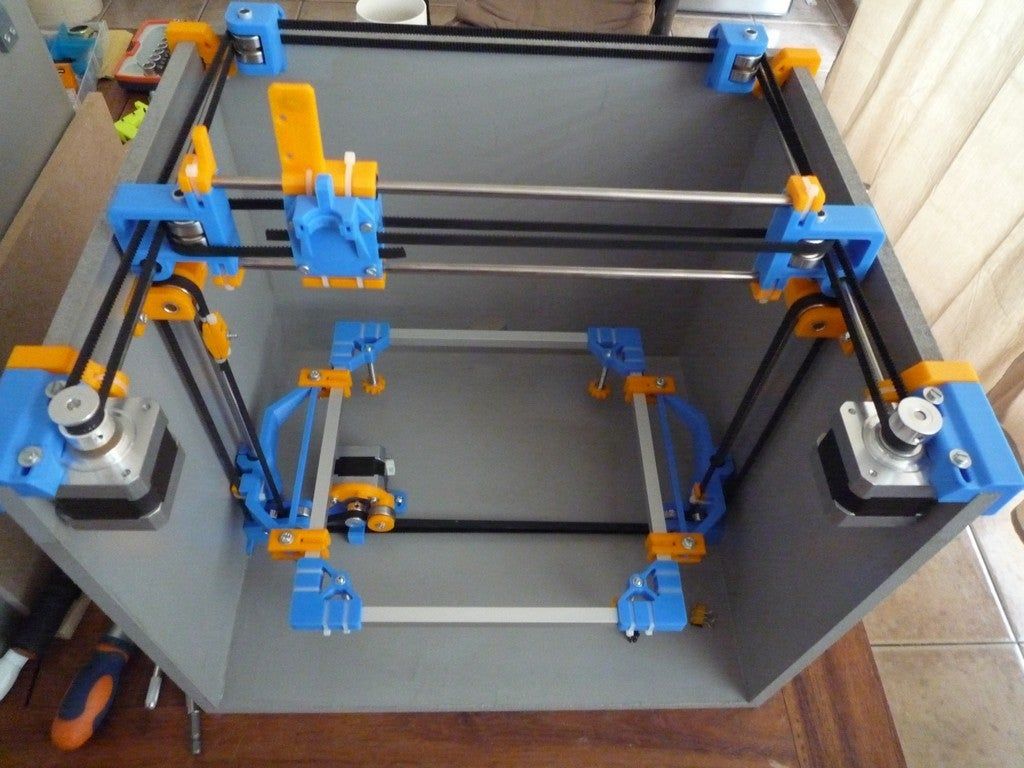

If you’re looking for a DIY belt 3D printer, the White Knight Belt 3D Printer is certainly worth looking at. Built by NAK 3D Designs, it is an entirely open-source conveyor belt 3D printer. It uses premium components but costs considerably less than its ready-to-buy counterparts.

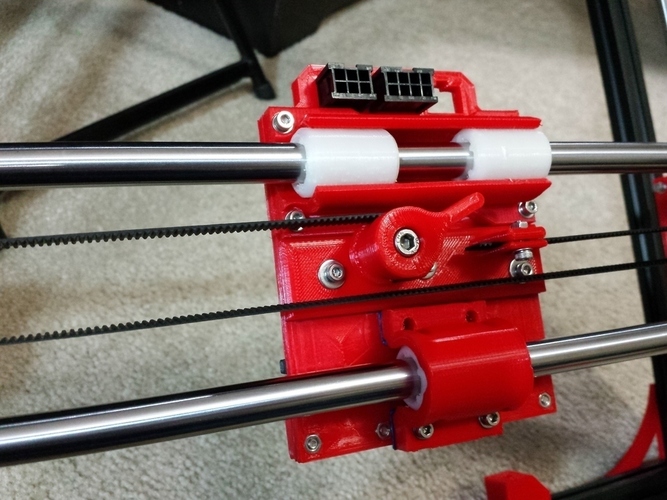

The White Knight has a 400 mm x 430 mm print area with its CoreXY structure. It is designed to use a Duet WiFi 3D printer controller board along with an all-metal hot end. The Bondtech Extruder and the BuildTak printing surface are additional aids in delivering excellent 3D printing quality.

You can find all the files and instructions to build the 3D printer on its GitHub page. It is definitely not for beginners, and it will be helpful to have prior knowledge about assembling a 3D printer. Yet, the White Knight is a testament to the open-source and 3D printing community and is a great addition to your 3D printing setup if you’re up for building it.

Standout Features

- Large build area

- Duet WiFi motherboard

- BuildTak print surface

Technical Details | |

|---|---|

| Build volume | 400 x 430 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 450 °C |

| Overall dimensions | N/A |

| Weight | N/A |

What We Like

- Excellent features

- Open-source design

- Customizable to your specifications

Could Be Better

- Long Bowden tube may lead to issues

- Needs considerable 3D printing expertise

Key Factors When Buying a Belt 3D Printer

Slicer support

Conveyor belt 3D printers have a unique design. Their inclined printing angle makes traditional slicer software setups unusable for slicing models. As these printers are relatively new, slicing support for belt 3D printers is very limited in popular slicers.

Their inclined printing angle makes traditional slicer software setups unusable for slicing models. As these printers are relatively new, slicing support for belt 3D printers is very limited in popular slicers.

When choosing a conveyor belt 3D printer, you need to consider its slicer compatibility. It is a crucial aspect of all the belt printers and will dictate your software experience with the printer. You need to ensure that you have alternative slicer options available if one of them doesn’t work out for you.

The Blackbelt 3D printer comes with its Blackbelt slicer based on an older version of Cura. The Creality CR-30 works on the Creality Belt slicer, another old version of the Cura Slicer. But it has extensive support and profiles available with the Ideamaker Slicer software.

Build quality

Build quality is often neglected in budget 3D printers. However, in the case of belt 3D printers, solid build quality is absolutely essential. A stable structure will help provide good support to the prints and is helpful in long-duration 3D prints.

Belt 3D printers have an inclined printing angle, and even a slightly wobbly structure can lead to disastrous results. In the best-case scenario, only print quality is affected. In the worst-case scenario, a large print can come loose and ruin hours of work.

A sturdy frame will help avoid these issues. A triangular frame typically creates the best support structure for the 3D printer.

The Creality CR-30 and the BlackBelt 3D printer come out on top in terms of build quality. The White Knight belt 3D printer, too, has some high-end components and an all-metal frame to keep up with the extended demands of long 3D printing objects.

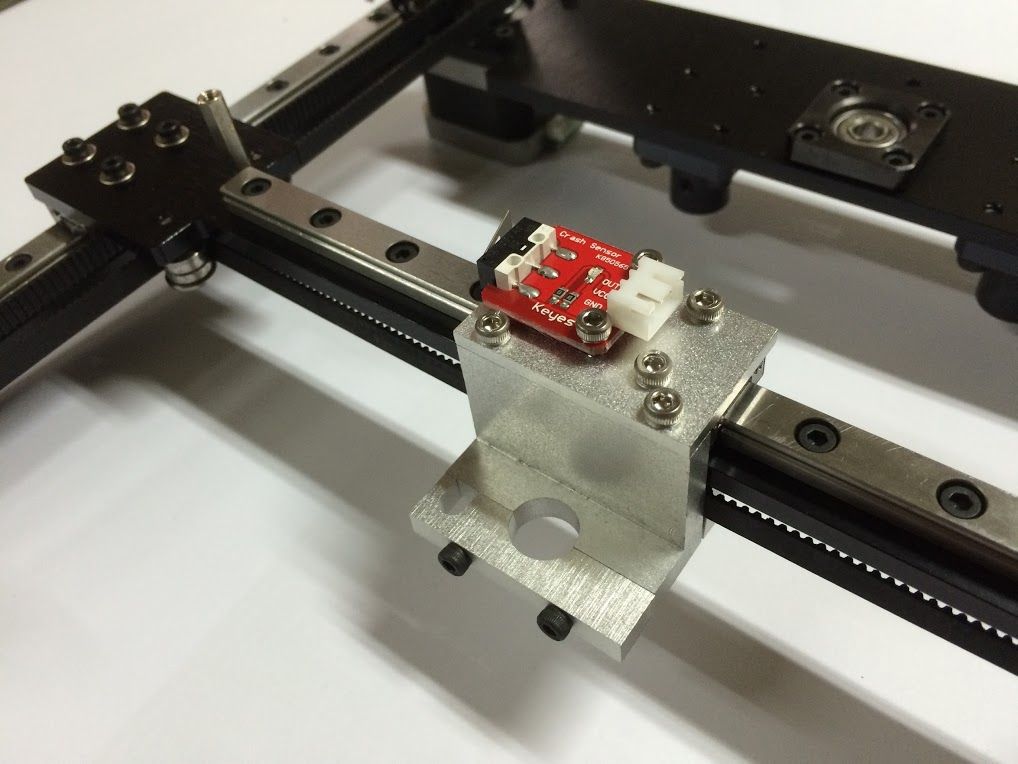

Filament sensor

The filament sensor is an integral part of any belt 3D printer. Its function is to inform you about your filament feed to the printer. If your filament spool empties or the filament breaks in the middle of a 3D print, the sensor will notify the printer and stop the printing process.

This can save your current model from failing due to a lack of filament. You can quickly load up a new filament spool and resume printing your model. Considering a belt printer’s objective of printing long-duration prints, a filament sensor becomes almost a necessity to avoid any print failures.

You can quickly load up a new filament spool and resume printing your model. Considering a belt printer’s objective of printing long-duration prints, a filament sensor becomes almost a necessity to avoid any print failures.

Almost all the 3D printers mentioned in the list have a smart sensor for filament embedded in their hardware. Even if the conveyor belt 3D printer you are looking at does not have a filament sensor, it is typically fairly easy to add one.

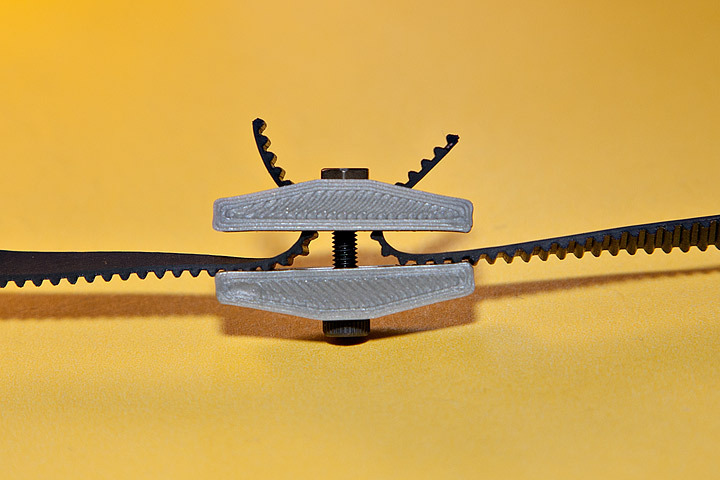

Belt surface

Unlike typical FDM printers, which can use a glass bed, PEI-coated spring steel, BuildTak surfaces, and more, belt 3D printers come with limited build platform options. There simply aren’t many options available to swap out the belt with. This is why choosing a belt 3D printer with a high-quality belt surface is vital.

You’ll find the Creality CR-30 and the SainSmart INFI-20 have Nylon as their belt surface material. The Nylon belt material is used for long-term durability and offers excellent print adhesion. It also helps to keep the overall cost of the 3D printer down.

It also helps to keep the overall cost of the 3D printer down.

The top-end BlackBelt 3D printer comes with a special infinite Z belt made up of carbon fiber composite. It has a low coefficient of friction and high stiffness. This reduces expansion during the heating process and ensures maximum print adhesion. Additionally, the material adds to the aesthetic of the 3D printer and gives it a premium feel.

While carbon fiber will give you the best printing performance, you need to consider the cost aspect of the belt too. In that aspect, a Nylon surface delivers the best balance between cost and bed adhesion.

Filament Support

It is important that the belt 3D printer you buy can print with all filament materials you need it to. The type of 3D printer extruder you need and the belt surface you choose will heavily depend on the kind of filaments you want to use.

The most popular 3D printing filament is PLA. It is easy to print with and does not require a heated bed. As a result, it is ideal for belt 3D printers that don’t have a heated belt.

As a result, it is ideal for belt 3D printers that don’t have a heated belt.

You can use other materials like ABS, PETG, and TPU as well. However, you will need a belt material and an extruder that can handle the higher temperatures required to print with these filaments.

The ability to print with different materials gives you a lot of freedom when it comes to choosing the right belt 3D printer for your needs. It is always better to have more options rather than be limited by the printer you choose.

Repairability

The belt 3D printer you choose should be easy to repair and maintain. This is important because, with extended use, things are bound to break down. When they do, you want to be able to quickly fix them. If you want to make money with your 3D printer, reducing downtime is key.

Frequently Asked Questions

Can 3D printing be automated?

Yes, 3D printing can be automated with a conveyor belt 3D printer. These can print objects continuously without the need for the user to manually remove 3D prints. This type of printer is perfect for mass production because it can print large quantities of objects quickly and efficiently.

This type of printer is perfect for mass production because it can print large quantities of objects quickly and efficiently.

Can you run a 3D printer continuously?

Yes, you can run a 3D printer continuously, but it will depend on the type of printer you have. If you have a belt 3D printer, then you should be able to run it continuously without any issues.

However, if you have a traditional 3D printer, then you will need to remove finished prints by hand.

Regardless of the type of 3D printer, it is important that it is properly designed and components don’t get too hot when used for longer periods of time. This helps prevent any potential issues with overheating or jamming.

Conclusion

Belt 3D printers are still relatively new to the 3D printing world. While they don’t provide the most extraordinary printing experience, their unique design opens up a new approach to printing long objects. Infinite length printing is an excellent solution for printing long swords, knives, and cosplay items.

Printing many smaller objects non-stop is also a great way of using belt 3D printers. Combined with large spools of filament, belt 3D printers can run for days unattended.

Within the limited available options, we found that the Creality CR-30 is the overall best belt 3D printer that you can buy right now. It has a rugged build quality and a compact form factor with a slightly modern design. Once you configure it correctly, you should have no issues printing the swords in your wishlist in a single piece.

The White Knight belt 3D printer is an excellent alternative. While you need to source the components and assemble them yourself, this belt 3D printer DIY project offers a lot of potential. If you are an experienced user, then the challenge of building and configuring this machine might be an excellent option for you.

What are your thoughts on the belt 3D printers? What would be the first object you’d 3D print if you were to use one? Let us know your thoughts in the comments below.

Conveyor Belt 3D Printer: Complete Buyer's Guide 2022

3D printing technology has come a long way in recent years and is still constantly evolving. One of the most recent innovations is the creation of the conveyor belt 3D printer.

Conveyor belt 3D printers, or just belt 3D printers, are a fairly new innovation designed to make 3D printing easier and more efficient, but aren’t very widely known yet. So what exactly are conveyor belt 3D printers, how do they work and what are they used for?

We answer those questions and more in this guide to conveyor belt 3D printing. Once we’ve explained what conveyor belt 3D printers are and how they’re beneficial, we’ll then review the top models on the market in case you’d like to buy one for yourself.

What is a Conveyor Belt 3D Printer?

As the name suggests, a conveyor belt 3D printer uses a belt as a bed so that you can print continuously. This means you can easily mass-produce small models and print large parts that wouldn’t be possible, or would at least be a lot more difficult, with a regular 3D printer.

Conveyor belt 3D printing is still a relatively new technology that came about in 2017 when the Dutch company Blackbelt 3D released its first model. Several other companies have since followed suit in exploring conveyor belt 3D printing, although these types of printers are still currently restricted to just a few manufacturers.

Although these printers are more expensive than regular ones, they have intrigued many 3D printing enthusiasts, both hobbyists and professionals. So, how exactly do they work and in what kind of situations would a 3D printer belt suit you? Let’s find out.

How Does 3D Printer Belt Technology Work?

Conveyor belt 3D printers use fused deposition modeling (FDM) technology. This is where materials are fused together by melting them just past their glass transition temperatures and then layering them on top of each other to create an object.

However, they are different from other FDM printers, such as Cartesian, polar, Scara, and delta models, as they use tilted nozzles. Whereas a standard Cartesian frame has its top tilted sideways, 3D belt printers have a CoreXY gantry in which one side is tilted down. The angle is typically 45 degrees, although it can be smaller.

Whereas a standard Cartesian frame has its top tilted sideways, 3D belt printers have a CoreXY gantry in which one side is tilted down. The angle is typically 45 degrees, although it can be smaller.

If you’re unsure what these mean, read: the main types of FDM 3D printer

In a 3D belt printer, the machine the X and Y axes are rotated at an angle rather than being parallel to the build plate. The Z-axis build plate itself is placed with a conveyor belt, meaning there is infinite build potential along the Z-axis.

During printing, the belt pulls prints away from the nozzle. The hot end is suspended in the CoreXY gantry and travels within a titled XY plane, whereas the belt travels along the Z-axis, meaning it can in theory print objects of infinite length.

Of course, prints would eventually fall off the belt, but this can be avoided simply by having a support structure in place. If you have this, which could be anything from a beam at the printer’s height or a set of rollers in front of the bed, then you can print objects with no length restrictions.

Conveyor Belt 3D Printers Uses & Applications

The fact that a conveyor belt 3D printer can be used for continuous printing offers two main benefits – the ability to mass-produce small models and the ability to print extremely large models. This means they’re particularly well suited for semi-automated or fully automated production.

A 3D printer belt means the machine can automatically remove objects so that it can start the next job as soon as one part is done, massively increasing productivity. In terms of model size, this type of printer can print infinitely long objects in the Z direction, so you’re not limited by the size of the build platform like you are with regular printers.

These aren’t the only advantages, though. With a conveyor belt 3D printer, there’s no loss in average print speed, print removal is automatic and hassle-free, and it’s also possible to have a partially heated printing bed.

In most cases, conveyor belt 3D printers are best suited to professionals working in business and industry. This is due to the types of projects they’re best suited for, their size and their expense. That’s not to say that they’re not useful for serious hobbyists, but that they’re outside the scope of beginners and casual 3D printing hobbyists.

This is due to the types of projects they’re best suited for, their size and their expense. That’s not to say that they’re not useful for serious hobbyists, but that they’re outside the scope of beginners and casual 3D printing hobbyists.

If you’re considering purchasing a conveyor belt 3D printer, it’s important to consider the limitations as well as the benefits. For example, in addition to the high prices and requirement of additional support structures, these types of printers print at relatively slow speeds, can’t print in ABS and some other materials, and you can’t have glass print beds.

The Best Conveyor Belt 3D Printers to Buy

If you’ve read our guide and fancy buying a conveyor belt 3D printer for yourself, here are our recommended printers that you can purchase today.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Creality CR30 – Overall Best Conveyor Belt 3D Printer

- Price: $1,049 — Available at Creality Store here / Available at Amazon here

The Creality CR30 is currently the best and most popular conveyor belt 3D printer on the market. This model has set the benchmark for this type of 3D printer.

This model has set the benchmark for this type of 3D printer.

For starters, it has an extremely stable CoreXY precision structure with isosceles right triangle support. This means the printer is very sturdy and robust, offering an overall very smooth experience.

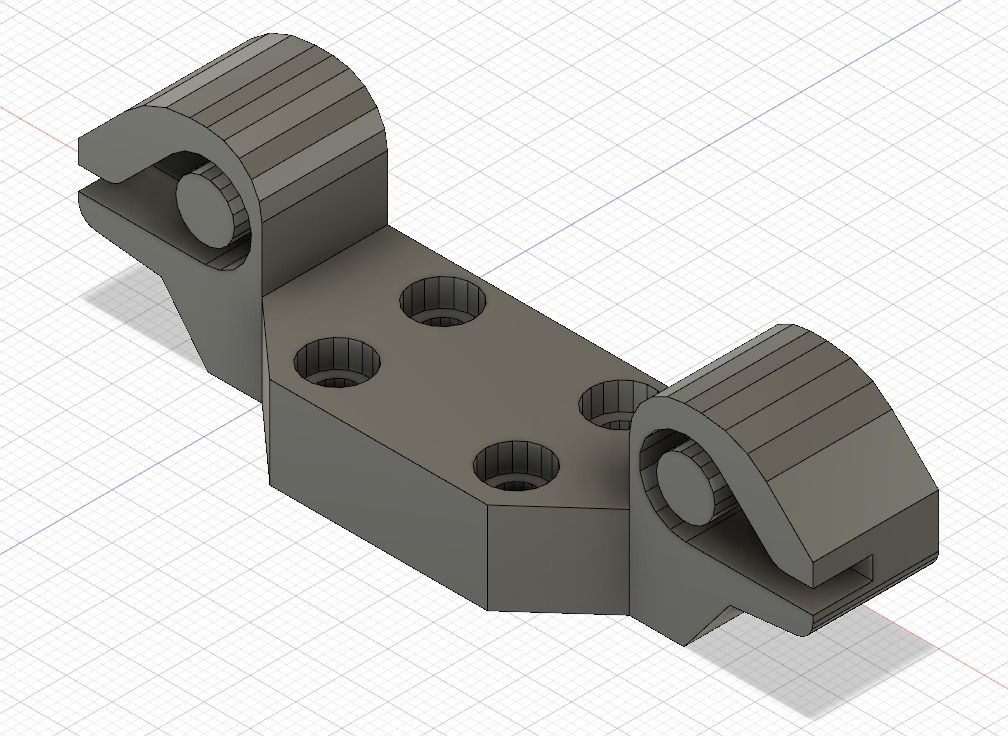

The conveyor belt itself is made of wear-resistant nylon for durability, extending the working life and enabling the printer to work to a high level over long periods of time. It has strong adhesion, well-balanced conveyance, and offers simple removal of products, as it has a removable extension bracket to prevent models from falling during printing.

This belt 3D printer has an all-metal frame that’s designed to minimize vibrations from the Core-XY motion gantry for smoother, more stable printing. The nozzle can reach temperatures of 240°C, so it’s capable of printing a wide range of materials including TPU and PETG.

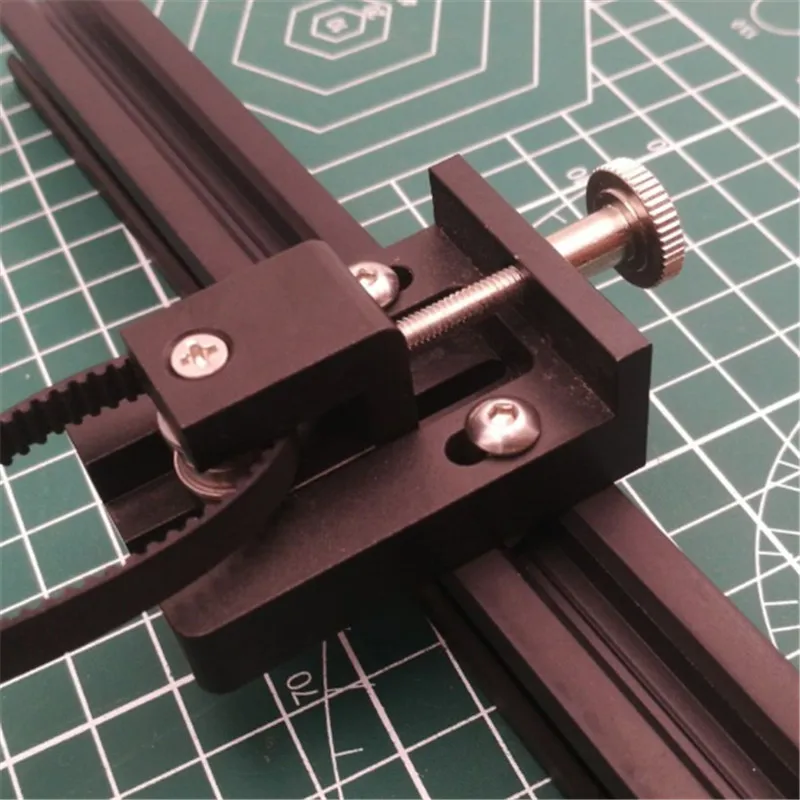

Thanks to the high-quality dual gear metal extrusion mechanism, as well as the 45 degrees slanting nozzle, this printer is capable of printing for over 200 hours at a time. The printing bed itself has a max temperature of 100°C, so it provides plenty of adhesion for printing polymer parts. You can easily level the bed using the knobs on the edges of the conveyor belt.

The printing bed itself has a max temperature of 100°C, so it provides plenty of adhesion for printing polymer parts. You can easily level the bed using the knobs on the edges of the conveyor belt.

Another really useful feature is the filament breakage detector. It has a smart sensor that suspends printing whenever the filament runs out or there is a breakage, and then printing resumes automatically after you have fed in the new filament.

This printer comes in four separate parts – the base, front, rear, and control panel – but it’s simple to set up and should only take half an hour or so to get started.

Finally, this 3D belt printer comes with the CrealityBelt slicer software included. With the software, you can slice a model of any length as well as multiple models in a line, and the package includes ready-made slicing profiles developed by Tom Jackson, a well-known slicer expert.

Blackbelt 3D – Excellent 3D Printer Belt for Industrial Settings

- Price: Upon enquiry

Blackbelt was the trailblazer of 3D belt printing with the release of its own model back in 2017, and it’s still one of the best on the market.

There are actually two purchasing options for the Blackjack 3D conveyor belt printer. You can choose the standalone version which consists of the printing platform with the controller and support construction, or you can go for the roller table version which has an extended support table capable of supporting prints of two meters.

You also have the option of adding a VarioDrive setup extension to your printer. It comes with a Bowden set up as standard, which works well with rigid materials. If you go for the VarioDrive setup, you’ll be able to print with a wide range of flexible materials, as well as nylon and carbon-filled filaments.

There is a choice of angles from 15 to 45 degrees, so you can adjust it based on your production needs. The belt is made from carbon fiber, so it’s lightweight yet incredibly durable.

While this is an exceptionally high-quality machine, it doesn’t come cheap. You have to request a quote from the company before you can get a firm price, but the average cost is around $10,000. The higher price means that this machine is best suited to business and industry, whereas the Creality machine is more open to hobbyists.

The higher price means that this machine is best suited to business and industry, whereas the Creality machine is more open to hobbyists.

Other Conveyor 3D Printer Belt Machines

While the Creality and Blackbelt machines are the best 3D belt printers on the market for both hobbyists and professionals, they’re not the only choices you have. Here are some other machines worth checking out if you’re looking to purchase a 3D belt printer.

Powerbelt3D Zero

- Price: around $500

This is another low price conveyor belt 3D printer that’s designed to make the technology more accessible to hobbyists. It’s certainly not as visually appealing as the Creality or Blackbelt machines, but it does have some benefits. For example, it has a semi-heated bet, an all-metal hot end, and it can print flexible filaments such as TPU.

You’ll need to request a quote if you want to buy the Powerbelt3D Zero.

iFactory One

- Price: $999

The iFactory One 3D printer belt was released around the same time as the Creality machine and has some nice features. The belt was made in conjunction with one of the world’s biggest belt manufacturers for optimum durability, the nozzle and other parts are custom made, and the drone also has Raspberry Pi, a webcam and the OctoPrint software built in.

The belt was made in conjunction with one of the world’s biggest belt manufacturers for optimum durability, the nozzle and other parts are custom made, and the drone also has Raspberry Pi, a webcam and the OctoPrint software built in.

This conveyor belt 3D printer will set you back $999.

The White Knight

- Cost: around $2,000

Whereas the printers we’ve profiled so far are complete models you can purchase as one, the White Knight is an open source DIY project in which you build the printer yourself. The total cost comes to around $2,000, and you don’t get the quality you get with the Creality or Blackbelt 3D printer belt machines. However, it’s certainly a fun and challenging project for 3D printing DIY enthusiasts and comes with a lot of community support.

What products can be 3D printed?

4153 views Posted on: 04.05.2019

Author: 3D4U.COM.UA

Thanks to the technology of three-dimensional plastic printing at home, today you can get almost any product within the volume of the working area of the available 3D printer model. First of all, such products are of interest to those who are engaged in the manufacture of models for architectural and design projects. Instead of the complicated gluing of the desired structure from cardboard and foam, you can simply use a 3D printer and get the desired element with almost no effort. The only thing you need is the ability to create three-dimensional objects on a computer using special programs.

First of all, such products are of interest to those who are engaged in the manufacture of models for architectural and design projects. Instead of the complicated gluing of the desired structure from cardboard and foam, you can simply use a 3D printer and get the desired element with almost no effort. The only thing you need is the ability to create three-dimensional objects on a computer using special programs.

Many people today are engaged in providing services to the population, making to order useful products: gears that cannot be bought, handles for kitchen utensils to replace broken ones. You can also make exclusive handles for furniture and interior doors according to an individually designed sketch, clothing accessories. Moreover, with the help of three-dimensional printing, it is quite easy to get almost full-fledged shoes, cases for electronic devices, belt pouches, cosmetic bags and cases for business cards.

In addition to useful things, 3D printing allows you to implement any unusual ideas, create souvenirs: caskets, vases, toys. The latter can be produced in especially large quantities, since today many are fond of modeling or collecting miniatures. For children, you can make armies of soldiers that will also interest adults who are fond of creating dioramas. For fashionistas, it is easy to cast any jewelry.

The latter can be produced in especially large quantities, since today many are fond of modeling or collecting miniatures. For children, you can make armies of soldiers that will also interest adults who are fond of creating dioramas. For fashionistas, it is easy to cast any jewelry.

3D printer allows you to get a copy of any object, if you additionally connect a three-dimensional scanner to work. If you do not have the skills to work with graphic editors, the Myriwell 100B 3D pen will be a good alternative. With this device, you can draw like a regular marker, and not only on some basis, but also by drawing a line from the plane vertically upwards. Thus, you can draw a cube by hand, and then completely “paint over” its faces, getting a hollow figure. More complex objects are also available, including miniatures of houses, cartoon characters, as well as individual images and entire compositions suggested by the imagination.

Related Products

-

3D Printing Varnish (3DLAC) 400 ml

Old price: 400 ₴ Price: 360 ₴ Discount: 10% Save up: -40 ₴

3D LAC is an excellent spray for fixing a part to a 3D surface.

..

.. -

Flashforge Guider II 3D Printer

Price: ₴59,000

FlashForge Guider II is an improved version of the popular Guider 3D printer with...

-

CR-10S PRO 3D printer Creality

Price: 21,000 ₴

Creality CR-10S PRO is a 3D printer with a large printable area (300x300x400),...

Related articles

- Top 20 interesting toys for children on a 3D printer.

Category: 3D printing

02/15/2022

7200 views

What kind of toys can be created with a 3d printer? What are the advantages of 3d printing toys at home? In this article you will find...

Read more - 12 common 3D printing mistakes to avoid.

3437 views

As an industry, 3D printing is evolving every day, so it's important to know all aspects of this technology today. In this...

Read more - 9 romantic 3D printed gifts for Valentine's Day.

Category: 3D printing

02/09/2022

1682 views

3D printing can help you create unique and personalized gifts for your significant other. Compilation 9...

Read more - What can be printed on a 3D printer?

Category: 3D printing

03.02.2022

1992 views

When hearing about a 3D printer for the first time, most people are interested in the question of what can be printed on a 3D printer. In this article...

Read more - Why Succeeding With a 3D Printer Is Easier Than You Think.

Category: 3D printing business ideas

02/01/2022

1673 views

Arguments in favor of a business with a 3D printer. Why the first steps in such a business are much easier to take than in any other.

Read more

Naomi Wu Interview on Creality 3DPrintMill 3D Printer

Supermaker Naomi Wu answers our questions about the upcoming Creality 3D Printer -thirty.

Shenzhen-based Naomi is well known in the 3D printing community for her efforts to promote the achievements of manufacturers as well as creating some interesting designs. One of them, the T-beam impact-resistant TTGO case, was our project of the week a few months ago.

The project she is currently working on is the upcoming Creality CR-30 or 3DPrintMill 3D Printer. This unusual 3D printer prints at an angle on a moving conveyor belt to enable continuous 3D printing or the production of objects larger than the size of the 3D printer itself. In this video, Naomi introduces the device:

We asked a few questions to find out more about the project and what we can expect when it's released.

Fabbaloo : Can you tell us how this project started and how you got involved? What is your relationship with Creality and White Knight/NAK 3D?

Naomi Wu : “I learned about Infinite-Z printers around 2016 when Bill Steele showed off his designs. I immediately saw the potential, but at that moment both the creation and the purchase were beyond my means. In 2018, I arranged for Bill to meet the founders of Creality here in Shenzhen to develop a custom infinite Z-axis 3D printer for them. It was a friendly and productive meeting, but the Creality bosses had not yet seen the market for tape printers. Bill, fortunately, was very kind and we kept in touch. In the end, the founders of Creality agreed to dedicate some internal resources and development time to a project under my control. In 2019Carl Braun aka Nax3D made his White Knight and I talked to him but since he was selling kits I decided as a matter of courtesy not to use his open source design and instead continue to develop an independent design, though of course based on his ideas. We kept in touch and when I finally had something pretty close to going to market, Carl agreed to act as a paid consultant and really took it to the next level.

I immediately saw the potential, but at that moment both the creation and the purchase were beyond my means. In 2018, I arranged for Bill to meet the founders of Creality here in Shenzhen to develop a custom infinite Z-axis 3D printer for them. It was a friendly and productive meeting, but the Creality bosses had not yet seen the market for tape printers. Bill, fortunately, was very kind and we kept in touch. In the end, the founders of Creality agreed to dedicate some internal resources and development time to a project under my control. In 2019Carl Braun aka Nax3D made his White Knight and I talked to him but since he was selling kits I decided as a matter of courtesy not to use his open source design and instead continue to develop an independent design, though of course based on his ideas. We kept in touch and when I finally had something pretty close to going to market, Carl agreed to act as a paid consultant and really took it to the next level.

For those of us who have been here for a while, the way previous open source 3D printer projects were brought to market in China. .. among other things, it was just disrespectful to the people who created these projects: by companies that took credit for "reinventing" the standard Prusa and Replicator clones. Yes, you can copy, but there is a correct way to do it. It was bad and I never liked it and you have to bite your tongue when the community complains about it because they are right. I waited for years to prove that it was unwise and not good to do so, that it was short-sighted. So far with 3DPrintMill that has been true and I owe a lot to Carl and Bill for letting me show some people here that if you do it right, play by the rules, the community will support you.”

.. among other things, it was just disrespectful to the people who created these projects: by companies that took credit for "reinventing" the standard Prusa and Replicator clones. Yes, you can copy, but there is a correct way to do it. It was bad and I never liked it and you have to bite your tongue when the community complains about it because they are right. I waited for years to prove that it was unwise and not good to do so, that it was short-sighted. So far with 3DPrintMill that has been true and I owe a lot to Carl and Bill for letting me show some people here that if you do it right, play by the rules, the community will support you.”

Fabbaloo : Is this a CR-30 or a 3DPrintMill? Or are they different things?

Naomi Wu : “Creality model number is CR-30, product name is 3DPrintMill. It's really meant for small-scale production, so I needed a name that would resemble it: sawmill, rolling mill, etc. But at the same time, it's a treadmill game because of the belt."

But at the same time, it's a treadmill game because of the belt."

Fabbaloo : I first used a belt driven 3D printer in 2010 with MakerBot's "Automated Build Platform". Although the device was a little unstable, the ability to 3D print a continuous stream of objects seemed very powerful. Today, I still see skepticism about the tape concept from many people. Why do you think there was no interest in this concept? What do people not understand?

Naomi Wu : “Lack of interest is news to me, my inbox is full of requests for pre-samples. From most of my discussions, I've always been worried about the ABP patent, which is now owned by Stratasys. Infinite-Z doesn't break that, but people are still worried about objections from such a big player and don't want to take the risk.

The interest has been huge, and frankly, a bit of skepticism is great. I'm not trying to sell it to people who don't need it and convince them they need it. There won't be a single bearded hipster video on Kickstarter with a MacBook and ukulele music in the background. That's not who it's aimed at. People who need 3DPrintMill know exactly why they need it as soon as they see how it works. It's like a Bridgeport milling machine or a high-end gaming computer. People who look at them and ask "What is this for?" probably shouldn't buy them.

There won't be a single bearded hipster video on Kickstarter with a MacBook and ukulele music in the background. That's not who it's aimed at. People who need 3DPrintMill know exactly why they need it as soon as they see how it works. It's like a Bridgeport milling machine or a high-end gaming computer. People who look at them and ask "What is this for?" probably shouldn't buy them.

This is not for small figurines, not the best first printer for kids. I was really targeting people or companies that print long objects such as cosplay and prop makers, sign makers, molding restorers and other long decorative items, but mostly those who need to make 10-1000 items - small scale production, Etsy and eBay stores, local machine shops as a cheaper alternative to CNC to offer to customers, people printing PPE and daily necessities, all that sort of thing.

It has the potential to be fantastic for education when we can line up the prints, which means little hands can get their part after they fall into the bin without touching the hot parts to tear them off heated base. But 3DPrintMill is not intended to replace traditional FDM 3D printers, and a little reality check is a good thing. If you're a pocket-saving teenager, for God's sake, buy an Ender-3 as your first $200 printer, not this thing."

But 3DPrintMill is not intended to replace traditional FDM 3D printers, and a little reality check is a good thing. If you're a pocket-saving teenager, for God's sake, buy an Ender-3 as your first $200 printer, not this thing."

Fabbaloo : The main problem with the MakerBot ABP was the tape itself, which after repeated heating could deform, becoming an uneven surface for subsequent prints. How has belt technology changed? How durable can a belt be over the long term? Will it be consumable?

Naomi Wu : “I think the first impression was that special belts were needed. I think the reality is that it took a larger belt ecosystem to find the right belt. When Charles Pax created ABP, he had at best what McMaster-Carr had to work with. And whatever relatively small assortment of conveyor belts they had, nothing worked, not in paper, Kapton, or other materials he tried to make his own out of. The straps they tried warped from the print or fell apart, so it was decided that more exotic straps were needed.

The fact is that problems such as twisting, stretching, heat resistance are actually not all that unusual in a production environment. Here in Shenzhen, we have had no problem ordering dozens of different belts from local suppliers, designed in different materials to solve exactly these problems. So while I'd like to tell you that the belt is Creality's "secret sauce" or some ridiculous startup crap, it really isn't. There are well-established, proven materials that do exactly what we need really well and do it industrially for thousands of hours in much more severe conditions. Exactly how many hours remains to be seen, but far more than either Carl or I managed to put in even if we were typing 24/7 for weeks at a time.”

Fabbaloo : Obviously modified versions of the current cutting software must be used to prepare a 3D print job for 3D tape printers, and this has been known to work. But how do you think tape printer slicing software will evolve? For example, do we want to randomize the location of a repeating print on the tape to avoid wear, or do we want to automatically generate serial numbers to keep track of the prints that go into the collection container? What other slicing features on a tape printer do you see in the future?

Naomi Wu : “Well, BlackBelt3D has been a huge contributor to the development of BlackBelt Cura and deserves a lot of credit for that. Bill Steele has a post processor to convert the standard GCODE to infinite Z, but it's nowhere near as perfect. Bringing software and firmware up to an acceptable standard in China is difficult, but now I have the opportunity to hire foreign consultants in Creality, such as Carl Brown and Scott Lachtein - now the lead developer of Marlin. It worked well for them, so I think they will expand it. Therefore, I am confident that software improvements will be done properly, even if we cannot do it ourselves. What features will be added - it will be community feedback."

Bill Steele has a post processor to convert the standard GCODE to infinite Z, but it's nowhere near as perfect. Bringing software and firmware up to an acceptable standard in China is difficult, but now I have the opportunity to hire foreign consultants in Creality, such as Carl Brown and Scott Lachtein - now the lead developer of Marlin. It worked well for them, so I think they will expand it. Therefore, I am confident that software improvements will be done properly, even if we cannot do it ourselves. What features will be added - it will be community feedback."

Fabbaloo : What was the most difficult technical challenge when creating 3DPrintMill? What advice would you give to others intending to develop a belt 3D printer?

Naomi Wu : “I think Carl, Nak3D, really solved the biggest problem when he proved that there is not a single insurmountable problem that stands in the way of inexpensive infinite Z printers. Of course, belts are the source of the problem but his steel belt works great. 3DPrintMill is not a revolution, it's just an iterative thing. I did not try to invent something completely new - we are not very good at it. I did what they knew in the Chinese factory, and a big team of engineers could do really well: make it cheaper, more reliable, and start mass production. The plan is for 3DPrintMill to be open source, if you want to make a belt printer these design files are a great place to start and I'm really looking forward to seeing what people come up with."

Of course, belts are the source of the problem but his steel belt works great. 3DPrintMill is not a revolution, it's just an iterative thing. I did not try to invent something completely new - we are not very good at it. I did what they knew in the Chinese factory, and a big team of engineers could do really well: make it cheaper, more reliable, and start mass production. The plan is for 3DPrintMill to be open source, if you want to make a belt printer these design files are a great place to start and I'm really looking forward to seeing what people come up with."

Fabbaloo : Complex 3D printing is much easier if you can use a soluble support material, but it requires the ability to use multiple materials. Do you think it is possible to implement multi-material capabilities on the 3DPrintMill or future versions of the 3D printer? What is the best way to do this?

Naomi Wu : “Multiple printheads is definitely the next step. It won't be a big deal, but definitely something for the 'professional' version of the printer once this one is released and we get more feedback from users."

It won't be a big deal, but definitely something for the 'professional' version of the printer once this one is released and we get more feedback from users."

Fabbaloo : While I'm sure 3DPrintMill will be of interest to hobbyists, what features will 3DPrintMill and its software bring to the attention of small manufacturers? What will make the device attractive for business?

Naomi Wu : “Automatic printing. The old knock off base trick is cute, but it's time consuming in the real world to set up because each shape of the piece fits the base slightly differently, so it's not a standard practice written into firmware or software slicing. Tray robots work, but they cost as much as the annual salary of two employees. Tape printers - you just put a basket in front of it and the parts pile up. The real key feature we need to implement there is the ability to have one GCODE file of an object on the map and choose in the machine interface how many copies you want.

.jpg)