Beginner 3d printer reddit

gettingstarted - 3dprinting

- Getting Started

- Why 3D Printing?

- Getting started with 3D Printing

- Where to get a model printed

- What printer to get

- Where to find models

- Material Choices

- Slicers

- Printing and Troubleshooting

- Post Processing

- How to make models

- Further Info

| If you're new around here, welcome! We thought we'd put a few links together to springboard your foray into the fabulous (and sometimes frustrating!) world of 3D printing. :) |

|---|

| If you are contributing to this wiki please keep this page incredibly concise and extremely high level, keep further detail for the Detailed Info pages. |

Why 3D Printing?

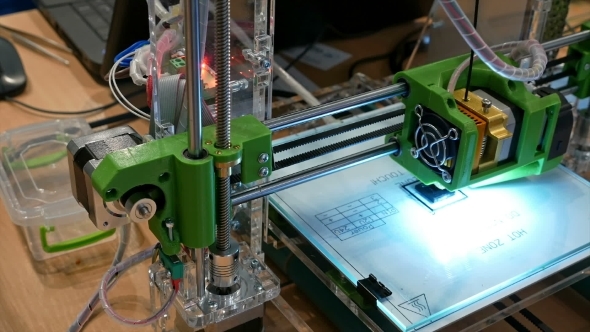

3D printing (a.k.a Additive Manufacturing) is now pretty well established in industry as a prototyping tool, and is becoming more common as a process for creating finished custom or low-run parts.

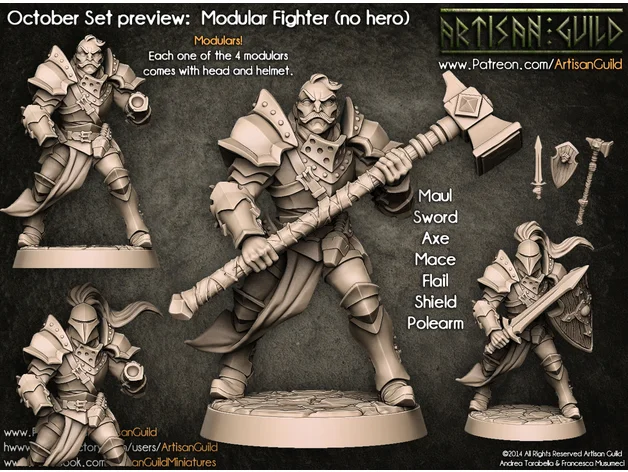

In the home, printers can be a marvelous tool for solving practical household problems for example by repairing items, or creating new items that are fully customised for their position or use case. They also can be used for fun, and are popular for making tabletop gaming minis, and toys.

For inspiration browse the top posts of this subreddit.

Getting started with 3D Printing

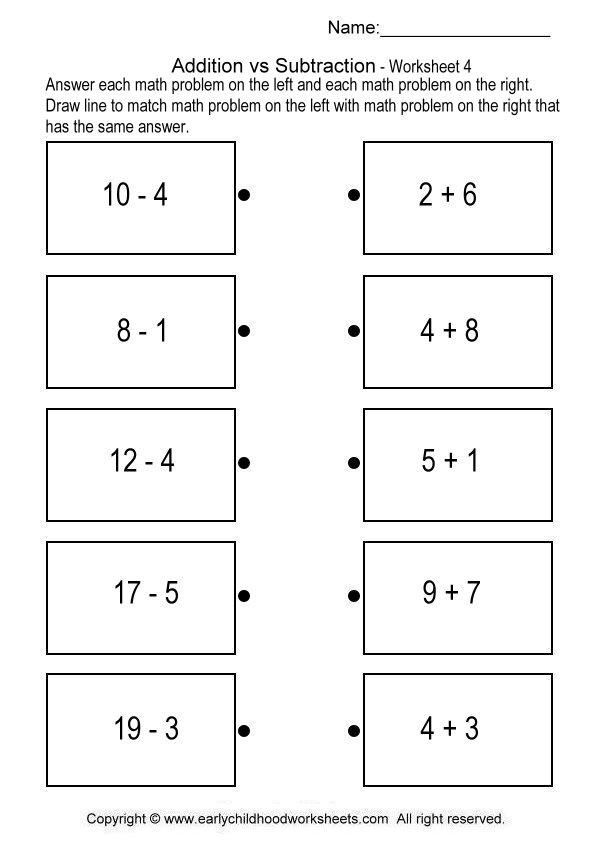

The various types of 3D printing technologies all create real-world three-dimensional objects from digital models via the addition of material. These processes are able to produce novel structures that other manufacturing techniques cannot. Usually the 3D printing process looks like this:

Get a digital 3D model (by downloading or making one)

Slice it (use a program to generate instructions for the printer)

Print it (and troubleshoot it)

Post-process it (remove support material, clean up areas, paint etc)

Where to get a model printed

If you don't want to buy a printer (and you just want to have something printed), you can engage the help of a 3D printing service. Some popular choices include:

Some popular choices include:

For a full list of service-providers (including design and model hosting services), please see the Services page.

What printer to get

If you're totally new to printing, the best place to ask for help when deciding what printer is right for you is our stickied monthly Purchase Advice Megathread.

Generally personal printers come in two main categories;

FDM (FFM) printers are best suited to larger objects and functional parts and work a bit like a like a hot glue gun that moves around, extruding plastic filament and building up an object layer by layer.

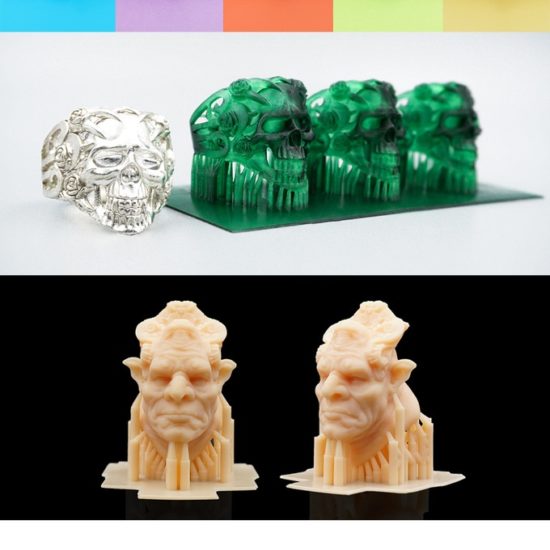

DLP (Layer Masking) printers are best suited to extremely detailed prints, and use light to cure resin in layers, masking it with an LCD screen.

There are, however, many other types of 3D printing technologies, which are explained here.

Where to find models

If you don't want to make your own models to print, there are many sites that host models for download. The more popular ones are:

The more popular ones are:

Printables: upcoming and community-focused, feature-rich

Thingiverse: biggest model host, often buggy

Thangs: free models, which can be searched by geometry

My Mini Factory: free and paid models, guaranteed to print

GrabCad: functional/ technical models

YouMagine: Open source models

pinshape: free and paid models

yeggi: 3D model aggregator/search

CGTrader: free and paid models, not all of them made to be printed

A community-curated list of model host services can also be found on the services page.

The RepRap foundation also keeps a list of printable model-host services here.

When selecting a model you need to ensure they are manifold, here's an explanation of what that means and guide on fixing them. You can also try these free, automated services; Netfab, and Microsoft's tool

Material Choices

When you are just starting out with FDM 3D printing PLA is the recommended choice. It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

If you are starting on a resin printer, check out our Resin Info page.

Slicers

Slicing software takes a 3d model and turns it into instructions for the 3D printer. The instructions are generally exported in GCode which essentially is a list of locations to move to, amount of filament to extrude, etc.

The popular choices for slicing software are:

Ultimaker Cura: free, open source, highly customisable. Getting Started, Full Manual

Prusa Slicer (Based on Slic3r), Beginning with Prusa Edition (old version)

There are, however, many other options, most of which are discussed here

Be sure to check the layer preview to see if it makes sense in your slicer before printing (no unsupported overhangs, no parts missing, etc). More info on the Slicers Page

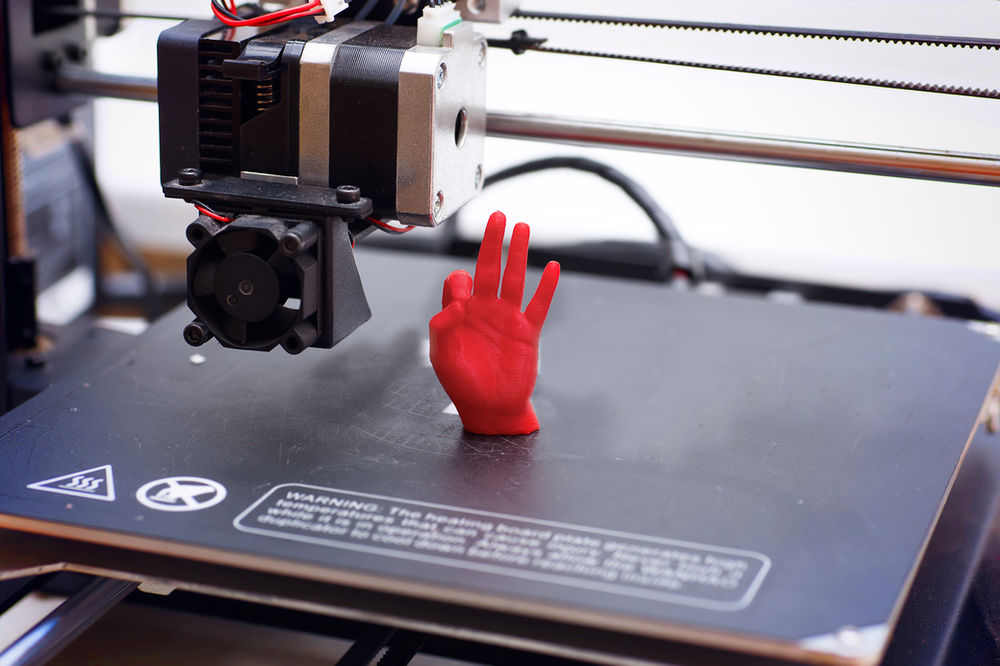

Printing and Troubleshooting

Follow your manufacturer's instructions in setting up your printer and starting your first print. It's a good idea to print a test print first (usually printers come with one).

It's a good idea to print a test print first (usually printers come with one).

If it succeeds congrats on your first print! You can now start slicing and printing your own models or some calibration prints

If your print fails you can begin troubleshooting.

This video helps you get to know the parts of your machine, so you know what we're talking about! :)

By far the most common reason for prints failing is an issue with levelling/tramming:

Full-resolution printable copy can be found here.

This visual reference, and this video may also help.

Once you have your prints sticking and printing, these guides can help you identify and solve any other issues you're experiencing:

Our Troubleshooting and Calibration wiki page

A Printa Pro PrintaGuide

rigid.ink poster and visual guide

Matterhackers Troubleshooting Guide

Simplify 3D Visual Troubleshooting Guide

Ultimaker Visual Troubleshooting Guide

RepRap Wiki Pictorial Troubleshooting Guide and Descriptive Troubleshooting Guide, these are a bit more technical/ advanced

It's also worthwhile seeking information from the manufacturer of your machine.

You can try searching for similar issues that other folk have experienced in the following communities: /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord

If the above suggestions don't solve your issue then it's time to seek help from the community:

This video is a great overview on how to seek help with prints.

The best places to ask for help are here on /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord. When asking for help be sure to provide the following:

- A highly descriptive title (even if you don't know exactly what everything is officially called, please do your best to describe the issue in plain English. This not only helps you get the help you want, but also helps the rest of the community by keeping the sub searchable, so others can benefit from the help you receive.)

- Photos of the issue, screengrabs of the layer view in your slicer, screengrabs of the model itself.

- A description of what the machine was doing as it produced this issue.

- Your basic settings such as: nozzle and bed temperature, speed, nozzle/line width and later height, the printer you're using and the material you're printing in. Or better yet, a screengrab or an export of your settings (you can upload files free without an account here)

- Any other information you think could be relevant such as modifications or hypotheses.

Post Processing

Most prints need some work after they come off the printer to turn them into a finished part. Supports need to be removed, and surfaced may need to be smoothed. Here are some tutorials:

- How to finish 3D Prints guide

More info on the Post Processing page

How to make models

Can't find what you want online? Why not design and make it? Model-making software is split into 4 main categories, depending on your goal:

Full-resolution, printable copy here

These are just the top picks, model making is discussed in more depth on the Making Models page

More communities:

/u/Devtholt keeps a Multireddit of all 3d printing subreddits including some specifically for help, or tailored to certain printers or printer manufacturers.

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC3D Printers Discord great platform for troubleshooting and socialising.

RepRap Forums

Purchase Advice Megathread - November 2022 : 3Dprinting

Welcome back to another purchase megathread!

This thread is meant to conglomerate purchase advice for both newcomers and people looking for additional machines. Keeping this discussion to one thread means less searching should anyone have questions that may already have been answered here, as well as more visibility to inquiries in general, as comments made here will be visible for the entire month stuck to the top of the sub, and then added to the Purchase Advice Collection (Reddit Collections are still broken on mobile view, enable "view in desktop mode").

If you are new to 3D printing, and are unsure of what to ask, try to include the following in your posts as a minimum:

Your budget, set at a numeric amount.

Saying "cheap," or "money is not a problem" is not an answer people can do much with. 3D printers can cost $100, they can cost $10,000,000, and anywhere in between. A rough idea of what you're looking for is essential to figuring out anything else.

Saying "cheap," or "money is not a problem" is not an answer people can do much with. 3D printers can cost $100, they can cost $10,000,000, and anywhere in between. A rough idea of what you're looking for is essential to figuring out anything else.Your country of residence.

If you are willing to build the printer from a kit, and what your level of experience is with electronic maintenance and construction if so.

What you wish to do with the printer.

Any extenuating circumstances that would restrict you from using machines that would otherwise fit your needs (limited space for the printer, enclosure requirement, must be purchased through educational intermediary, etc).

While this is by no means an exhaustive list of what can be included in your posts, these questions should help paint enough of a picture to get started. Don't be afraid to ask more questions, and never worry about asking too many. The people posting in this thread are here because they want to give advice, and any questions you have answered may be useful to others later on, when they read through this thread looking for answers of their own. Everyone here was new once, so chances are whoever is replying to you has a good idea of how you feel currently.

Everyone here was new once, so chances are whoever is replying to you has a good idea of how you feel currently.

Reddit User and Regular u/richie225 is also constantly maintaining his extensive personal recommendations list which is worth a read: Generic FDM Printer recommendations.

Additionally, a quick word on print quality: Most FDM/FFF (that is, filament based) printers are capable of approximately the same tolerances and print appearance, as the biggest limiting factor is in the nature of extruded plastic. Asking if a machine has "good prints," or saying "I don't expect the best quality for $xxx" isn't actually relevant for the most part with regards to these machines. Should you need additional detail and higher tolerances, you may want to explore SLA, DLP, and other photoresin options, as those do offer an increase in overall quality. If you are interested in resin machines, make sure you are aware of how to use them safely. For these safety reasons we don't usually recommend a resin printer as someone's first printer.

For these safety reasons we don't usually recommend a resin printer as someone's first printer.

As always, if you're a newcomer to this community, welcome. If you're a regular, welcome back.

A small guide for choosing a 3D printer for beginners / Sudo Null IT News

The reason for writing this article was the article “ I wanted to buy an inexpensive 3D printer, but I looked at YouTube and got sick of ”, at the end of which the author asks to answer a few questions. I will try to answer from the point of view of my seven years of experience as a 3D modeler and 3D printer. First, a few caveats.

This article will not contain advice: “Buy a printer from manufacturer X - it is good, but do not take manufacturer Y in any case”, only general recommendations. nine0005

Informal classification of printers, adopted in the domestic segment of printers.

Everything written is based on the personal experience of the author and is his personal opinion.

If these warnings do not scare you - welcome under cat.

First, let me introduce myself: my name is Maxim and I bought the first printer back in 2013. It was a Chinese clone of Makerbot 2 with the hilarious name "Migce Cuble".

Photo from the personal archive There was almost no information on 3D printing on RuNet, only one topic on the “Roboforum” and several scattered articles about what a cool thing it is - 3D printing, so to master it, I had to google a lot in English, come up with their crutches and delve deeply into the physics and technology of the printer. We must pay tribute, in the English-speaking segment, then there was an active development of this technology and interesting articles such as “Selection of the type of notches of the extruder feed gear for a specific type of plastic” or “Determination of the optimal printing temperature using a strain gauge installed on the extruder” came across. Since then, 7 years have passed. I managed to master modeling, assemble a printer from scratch, be a moderator of “3D Today” for a while, work as a freelancer in the field of modeling and printing, organize a prototyping circle for children and bring it to the Russian level. Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Recent achievements: volunteered as a coordinator for the supply of plastic in the project “ Anti covid makers ”. A lot has changed during this time, including printers in my home zoo. One thing has remained unchanged - the question: "What should I buy as my first printer?".

Currently, two types of printers are mainly used at home: printing using FDM (FFF) technology - layer-by-layer plastic fusion, which is fed in the form of a rod and SLA (LCD) - printing with a photocuring polymer. FDM technology is more common, due to the lower cost of equipment and consumables, but in recent years, the prices of LCD printers and printing resins have decreased significantly and photopolymer printing has almost caught up with FDM printing in terms of cost and entry level. nine0005 SLA and FDM

To be honest, I almost never did SLA printing and there is still no LCD printer in my home zoo (but it may appear soon), so we will mainly talk about FDM printers. They can be divided into 3 main categories according to the type of mechanics:

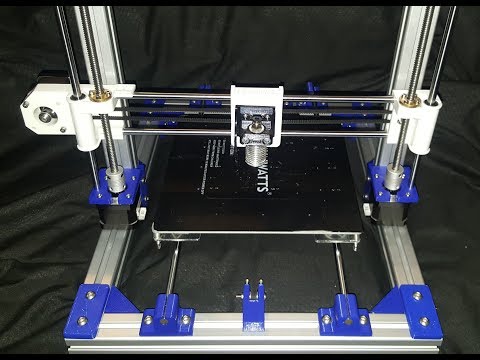

Dried tables - printers with a table that moves horizontally. Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU. nine0005 Typical drygosts

Perhaps the most common printer model. It is distinguished by low cost of components, ease of assembly and adjustment, for which it is loved by the Chinese and printers. The disadvantages include the difficulty of creating a closed body and printing thin, tall parts that begin to wobble as the height increases, especially if the part is printed from flexible plastic such as TPU. nine0005 Typical drygosts

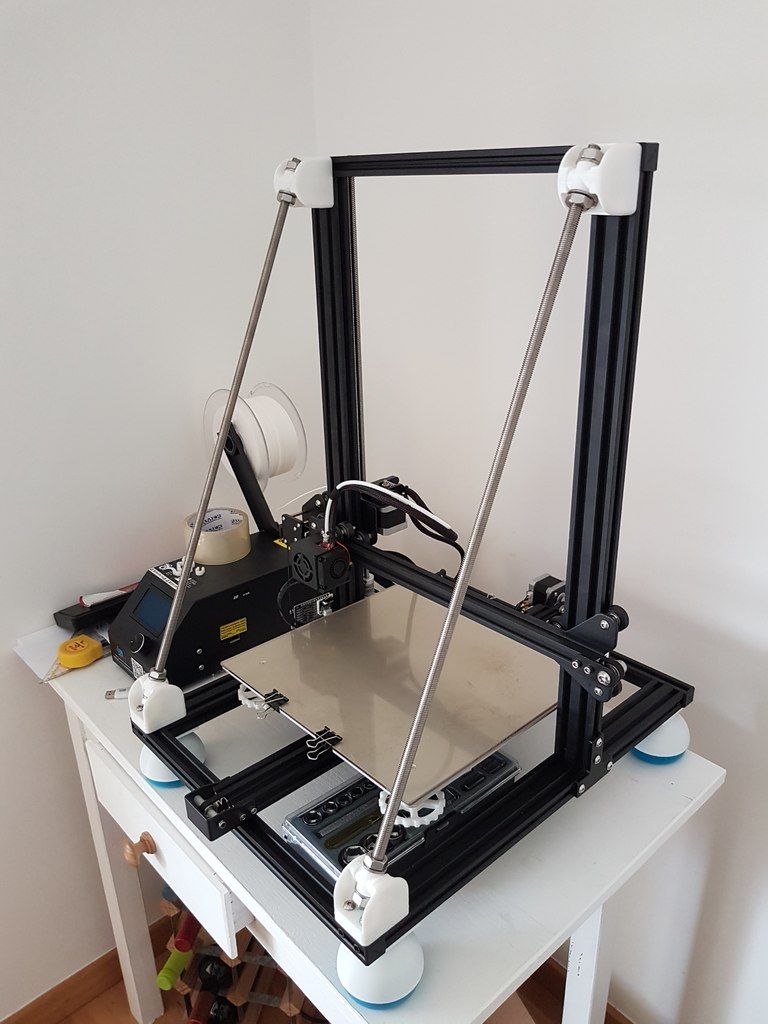

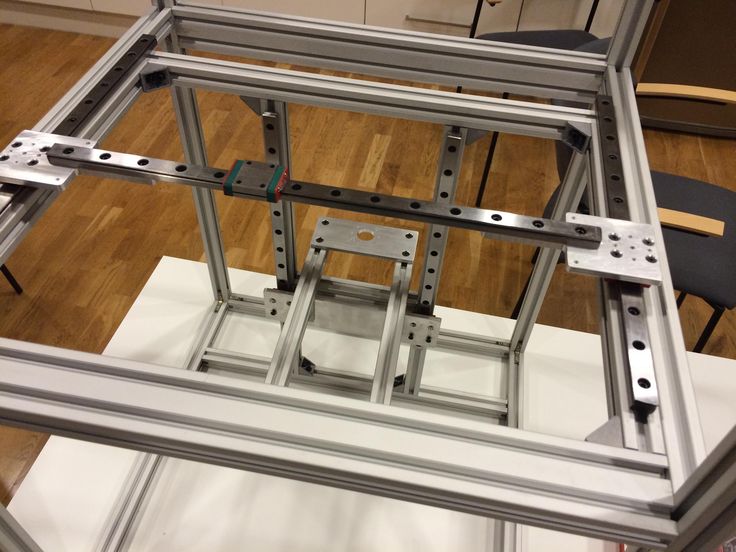

Cubes - printers in which the table travels vertically. The cost of such printers is higher, as are the requirements for straightness of hands during assembly and setup. But a properly designed die delivers faster print speeds while maintaining print quality. At the same time, the design of the printer is very easy to make closed, which allows printing with engineering plastics such as ABS and Nylon. This type of design is often used in semi-industrial and industrial grade printers. Some manufacturers manage to shove the drygost into the body of the cube, but this does not bring any special advantages for printers. nine0005 Typical cubes

nine0005 Typical cubes

Delta - printers with the so-called delta kinematics, when the print head is attached to the carriages moving along vertical guides using a system of rods. The cost of the mechanics of such printers is comparable to the cost of dry-tables. Can print at very high speeds. But they are very demanding on the correctness of keeping the dimensions, the straightness of the hands during assembly and adjustment, and the speed of the “brains” due to the complex mathematical calculations of the trajectory of the head movement. nine0005

Strongly not recommended as a first printer, although the widespread use of the table level sensor somewhat reduces the requirements for straight hands during setup and operation.

Typical deltasBy availability on the market, 3 main categories can also be distinguished:

Chinese (cheap Chinese printers) are almost always designers, even if they come assembled.

-

The advantages include low cost, wide distribution and uniformity, which allows you to buy failed parts in the nearest radio shop or on well-known Chinese sites.

Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely print right out of the box, but will require improvements during more or less long-term operation. nine0005

Popular models gather around a relatively large number of users who actively share their experience in the field of self-repair and improvement of this type of printer. The most popular models will most likely print right out of the box, but will require improvements during more or less long-term operation. nine0005 -

The disadvantages include the quality of components / assembly and the need to refine these printers to obtain acceptable quality / print speed. It is recommended to take models that have already formed a large community around them. This means that most of the shortcomings have already been identified and there are standard inexpensive methods to solve them.

Kits (assembly kits, mainly domestic production) - google for the words “ ZAV ”, “ UlTi ”, “ UlTi ”, etc. Usually they are a set for assembling a plywood cube. Recently, options with metal cases have appeared. Supplied in different versions - from a kit for building a case with printed parts, ending with completely finished assembled products.

-

The pluses include a fairly good engineering study, the ability to choose the components for the mechanical and electronic parts and make the printer completely to your requirements. With good components, they provide fast, stable and high-quality printing. The price is somewhat more expensive than Chinese printers, but cheaper than semi-professional printers of domestic or European / American manufacturers. nine0005

-

The disadvantages include a decent amount of time spent on assembly and waiting for components if you decide to save money and order these components yourself from different sellers and assemble a printer from them. When assembling, direct hands are required.

Factory Printers (Semi-professional printers from domestic or American/European manufacturers). There are a lot of models, the designs are very different.

-

The advantage of this class of printers is printing with acceptable quality out of the box.

In addition, you get operational reliability and warranty support from the manufacturer. nine0005

In addition, you get operational reliability and warranty support from the manufacturer. nine0005 -

The main disadvantage is the price. It is often not clear what factors it depends on. You can buy a high-quality printer relatively inexpensively, or you can take something incomprehensible for a high price. The second disadvantage is the presence of specific solutions that are incompatible with popular solutions on the market: these can be nozzles with their own thread pitch, special fans, electronics, belts, and even slicers. Some are demanding on the quality of plastic, there are models that work only on chipped coils. nine0005

Now that we have decided on the classification of printers, we can proceed to the procedure for choosing a printer for yourself, your loved one. If you are on fire with the purchase of a 3D printer, first decide what you are going to take it for, the type and configuration of the printer depends on it. Let's analyze several typical situations:

I want to do something for myself and my family - if you don't plan to print products from engineering plastics that can withstand decent loads and temperatures, a Chinese drygostol or a cube will suffice. If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics. nine0005

If you have a budget and want to figure out how the printer works before starting, and not during printing, you can look in the direction of domestic assembly kits - with them you can get the best quality and painlessly switch to engineering plastics. nine0005

I can't do anything with my hands, but I have to. Therefore, I want a printer that will do everything for me - in this case it is better to look at semi-professional printers. If the budget is not enough, you can look at used ones or order an assembly of a domestic set - usually manufacturers offer this service through intermediaries. When ordering an assembly - look for experience and positive reviews, there are nuances.

I want to print for sale - a farm of the same type of printers, depending on the budget. If there is no budget, but there are resources for regular tuning / repair - you can even from Chinese drygosts. Additionally - a printer with a large print area, a printer with a closed case and a heated table for printing engineering plastics, an SLA / LCD printer for printing products with a high degree of detail. nine0005

nine0005

Whether at work or at home, the need arises to design and print enclosures and parts. If only small prototypes are planned - an LCD printer, if functional products - a closed cube with the ability to print with engineering plastics.

Kids are growing up and this is the technology of the future, I want you to master - see what printers are used in prototyping competitions in your area. Take the same one. May be used. nine0005

I want to make figurines for desktops, beautiful little things for home - LCD printer.

I want to figure out what kind of technology and how it works in general - a kit for assembling a domestic manufacturer. By the time you collect it, you will understand.

There is no money at all, but I want to print, I will collect it myself from scratch - it will turn out better and cheaper than the Chinese. Strange as it may seem, no. The cost of components with Ali will be more expensive than a printer with Ali. Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

Of course, if there is a machine park, the ability to use it, a set of iron, shafts and electronics lying around in the corner of the workshop, it can burn out. There are options for building printers from boards and furniture rails, but their print quality is, to put it mildly, lame. For example, the construction of the printer shown below cost its author 80-9, according to him.0 dollars.

If you want to completely build your printer from scratch, then it's better to treat this as a separate hobby and accept that it will not turn out very cheap. Well, or look in the direction of used printers.

I don’t know why I need a printer, but I want to try - a Chinese or a domestic assembly kit. Can be used. If it doesn't work, you can always resell.

Decided on the type of printer - what to look for first of all when buying ?

-

First of all - on the rigidity of the structure - the accuracy and speed of printing depend on it.

It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better.

It is in the direction of strengthening the rigidity that your first modifications of the Chinese printer will be directed, since the material “steel plasticine 3 (c)” is considered an unaffordable luxury for the Chinese. In the case of the purchase of domestic kits, the situation is slightly better. -

Secondly - if the printer will be in the apartment - "silent" drivers for stepper motors. 3D printing is not a fast process, and having a constant loud enough buzzer under your ear is annoying. nine0005

-

Third - the presence of a heated table and ease of modification to a closed case. Over time, the desire (need) to print ABS will come, and it is problematic to do this on an open drygost.

-

Fourthly, the presence of a good plastic blowing system is also important.

-

Fifthly, when choosing printers with CoreXY, H-Bot or Delta mechanics, it is highly desirable to have a 32-bit control board, or you will encounter fading (freezes) at high print speeds.

nine0005

nine0005 -

In the sixth, seventh, etc. - there are many nuances in the design of printers. If something is unclear, feel free to ask the community.

In any case, if you are going to buy or have already bought a 3D printer, start learning some 3D editor. The easiest, in my opinion - https://www.tinkercad.com . You can simulate a washer in it or the well-known plate changer without much effort.

Over time, its capabilities will no longer be enough - then you can switch to more serious CAD systems. In my opinion, a printer should own two types of editors - a solid state for modeling technical products (CAD) and a polygonal (Blender, etc.) - for modeling art, but many printers consider this redundant and master only one. nine0005

On this, perhaps, I will round off - the article has already turned out to be quite voluminous, if you have questions, I will be happy to answer them in the comments or in a separate article. I’ll say right away - I won’t answer questions like: “ which is better: flying bear 5 or ender 3 ” - a lot of copies have already been broken on this topic on specialized resources, I don’t see the point in repeating.

Best regards, Maxim.

how not to miss the choice of a specific model for a beginner 3D printer / 3D printers, machines and accessories / iXBT Live

A 3D printer is a modern gadget that allows you to create unique models from polymer materials using FDM or SLA technologies. Such printers allow you not only to print the model you have designed according to individual drawings, but also to replicate it, repeating it over and over again. 3D printers have found their application in modeling, construction and design, industry and medicine. But users often make mistakes, obeying wow impulses and making spontaneous purchases. Knowing what you need a printer for will help you narrow down your search and choose the right model. nine0005

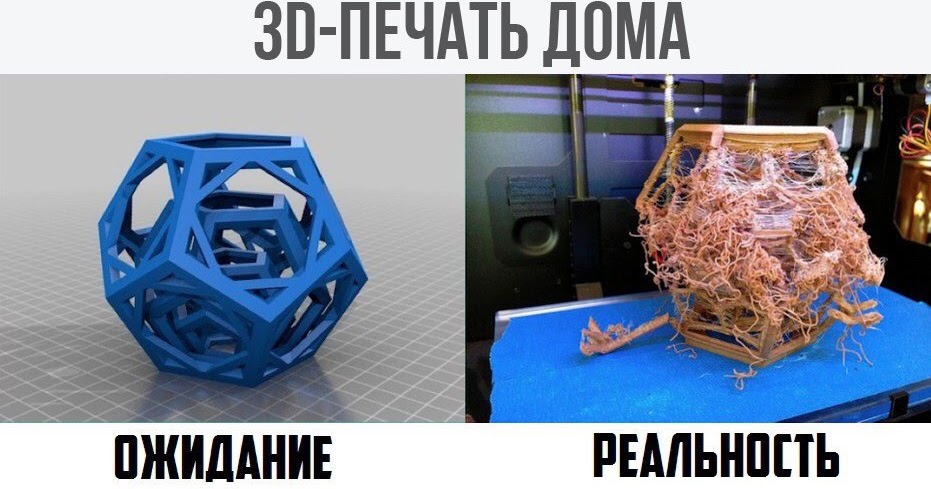

Beginners often fall for a number of common mistakes and make the wrong choice. Most often, this leads to a situation where a person “cools down” to 3D printing, and the purchased printer remains gathering dust in the corner. Sometimes this is caused by technical problems and a lack of the required level of knowledge and experience, sometimes by an incorrect choice of printer model.

The first mistake is the lack of a purposeful choice

First, try to decide on the purpose - what do you need a 3D printer for. Honestly imagine what models or details you will print on it and what scale. This is necessary in order not to waste money and time, and not to get an unclaimed device in a dusty corner. A compact 3D printer will be appropriate in the office or at home, it will be helpful in studies, hobbies or in your own business. The printer allows you to print models that you yourself have drawn in CAD, create components for a training project, shapes and parts for hobby and modeling, use open projects. Determine the media you plan to print with. FDM filaments such as PLA/ABS/PETG are available, as well as exotic (WOOD/Carbon/Nylon), elastic (TPU/Flex), etc., as well as photopolymer resins (SLA Resin). And if PLA / ABS are available for almost all FDM models, then compatible printers should be selected for the rest. For example, Nylon is extremely demanding on adhesion, TPU / Flex - on the plastic feed mechanism, etc. nine0005

nine0005

For example, for modeling in scales 1:72, 1:350, etc. It will be convenient to use an SLA printer that allows you to create products with high detail of photopolymer resin. That is, first we set a goal for ourselves - what the printer is for, and then we select the appropriate model. For example, quite high-quality and popular ANYCUBIC Photon models with high printing accuracy. And for an introduction to 3D printing, a simple and reliable printer like the Artillery Hornet or the Creality3D Ender-3 will do.

Second mistake - buying 3D printers with a large margin

One of the most common user mistakes when choosing a 3D printer is buying a “bigger” and “oversized” model. I encounter this type of error quite often. First, the user "invests" in a large printer, and then realizes that there is nothing to print on this option, and for small parts, a smaller printer could be chosen. First of all, large printers are more expensive, larger in size and more demanding on the rigidity of the frame as a whole. On a large area of the table, the effects of shrinkage of plastic, distortion of the dimensions of the printed model, delamination of the applied plastic, as well as peeling off of the corners from the working surface of the table, are more pronounced. This can be dealt with, but the listed points can become a serious problem for a novice user. And the printing time for large-volume models can be measured in tens of hours. nine0005

On a large area of the table, the effects of shrinkage of plastic, distortion of the dimensions of the printed model, delamination of the applied plastic, as well as peeling off of the corners from the working surface of the table, are more pronounced. This can be dealt with, but the listed points can become a serious problem for a novice user. And the printing time for large-volume models can be measured in tens of hours. nine0005

Purchasing large margin 3D printers can be justified in cases where you really plan to print large models without splitting, as a whole. A good example of a 3D printer with a large workspace would be Anycubic's Chiron (table size 400 x 400 mm with a maximum print height of 450 mm), the LONGER LK5 Pro (300 x 300 x 400 mm with additional frame reinforcement), or the Artillery Sidewinder X1 (also 300 x 300 x 400 mm).

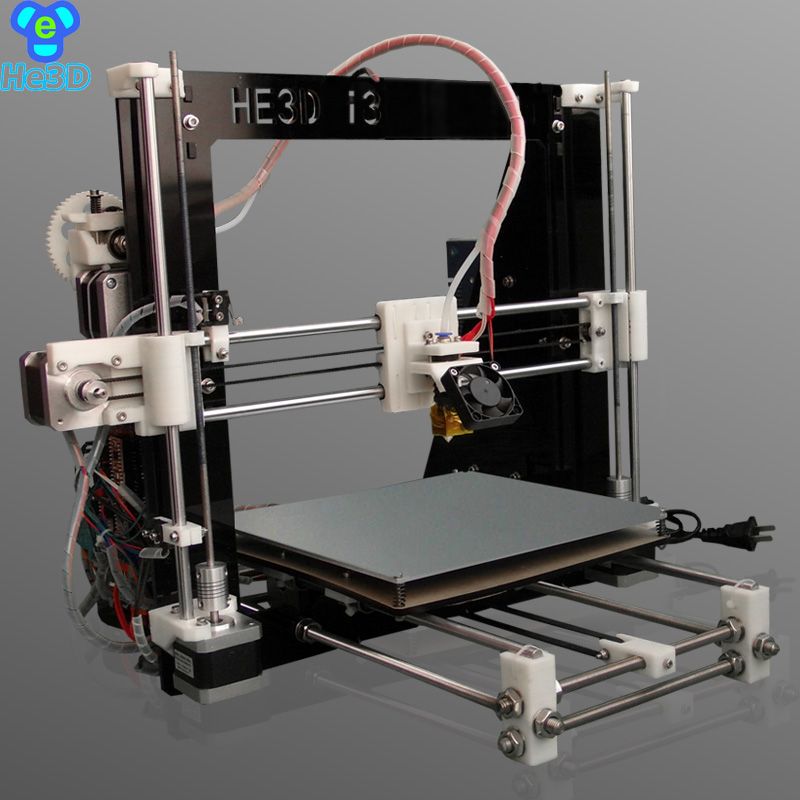

Third mistake - buying 3D printers with complicated calibration

Another common mistake users make is buying 3D printers with complicated calibration. These can be Delta printers, Scara models and the like. At first glance, they may seem interesting and simple, but from experience I will say that fine-tuning such printers can be a significant problem for the owner, requiring a deep understanding of the mechanics of the printer and the principles of 3D printing, as well as quite complex calibration of the movement of the print head along all axes of the device. Up to the fact that the resulting printing problems can completely discourage further desire to print and study 3D modeling. nine0005

These can be Delta printers, Scara models and the like. At first glance, they may seem interesting and simple, but from experience I will say that fine-tuning such printers can be a significant problem for the owner, requiring a deep understanding of the mechanics of the printer and the principles of 3D printing, as well as quite complex calibration of the movement of the print head along all axes of the device. Up to the fact that the resulting printing problems can completely discourage further desire to print and study 3D modeling. nine0005

Therefore, we check the characteristics and description of the selected models in advance. Examples of similar printers from Aliexpress are Flsun Delta Kossel, Anycubic Kossel, HE3D Kossel and the like. An acceptable option is when modern 3D printers are equipped with automatic sensors for calibration and table calibration assistants in the regular display menu.

Mistake Four - Color 3D Printers

Buying complex printers that can print with multiple colors or multiple plastics can cause additional problems. Yes, the result of multi-color printing of models or colored figures without the need for coloring can be interesting. But in real printing, you will face the complex preparation of the model in the slicer, the need for a deep understanding of the process and the nuances of printing with several types of plastics. nine0005

Yes, the result of multi-color printing of models or colored figures without the need for coloring can be interesting. But in real printing, you will face the complex preparation of the model in the slicer, the need for a deep understanding of the process and the nuances of printing with several types of plastics. nine0005

There are several options for printing with two filaments, ranging from Y-extruders to multiple independent printheads. When printing alternately one of the two heads, heated plastic can seep out of the unused one - you need to take into account retracts, “cleaning” before changing plastics (an additional separate “service” model is built nearby), calibration and alignment of the heads along the same coordinates. Color models must be loaded into the slicer separately, assigning a different model to each extruder. And if you still need color printing for work or your own project, then it makes sense to choose one of the proven models. For example, the JGMAKER Artist D 3D printer, which has two movable and independent print heads at once, each of which can be filled with a separate spool of plastic. This makes it possible not only to print color models, but also to create two separate models on the table at the same time, and it will also be convenient for printing soluble supports. nine0005

This makes it possible not only to print color models, but also to create two separate models on the table at the same time, and it will also be convenient for printing soluble supports. nine0005

Fifth mistake - choosing simplified "children's" models

There are entry-level models in the range of 3D printer manufacturers. Sometimes a manufacturer saves by releasing models at the bottom of the market. These are budget options for novice users; in fact, these are “children's” printers. A good example is the Wanhao Duplicator i3, a simplified L-layout printer. The reduced rigidity of the carrier frame does not allow for high print quality. I note that the choice of models without blowing the thermal barrier can also be a potential problem. When printing for a long time, the thermal transition in the print head overheats and plugs can occur, leading to damage to models. This also includes 3D printers without a heated desktop, designed to print only with PLA plastic. nine0005

However, children's models are also important and needed. They are designed to provide basic skills and an introduction to the world of 3D printing on a limited budget. A vivid example of such a model is the Funtastique EVO and LONGER Cube2 3D printers, which can be an interesting gift for a schoolchild.

They are designed to provide basic skills and an introduction to the world of 3D printing on a limited budget. A vivid example of such a model is the Funtastique EVO and LONGER Cube2 3D printers, which can be an interesting gift for a schoolchild.

What to choose from the range of available 3D printers?

Thus, imagining the use of a 3D printer specifically for your purposes, you can choose the right model. If you do not have serious skills, then it is better to purchase a simple and reliable printer that has proven itself. Long-sold models from Anycubic, Wanhao, Longer and others will be a good choice. nine0005

But after gaining experience in 3D printing, you can move on to other options. Don't forget to get some 3D printing plastic too! If you are interested in other models of 3D printers, I recommend that you look at the following articles:

Choosing a 3D printer for home and hobby: a selection of current models for plastic printing using FDM technology.