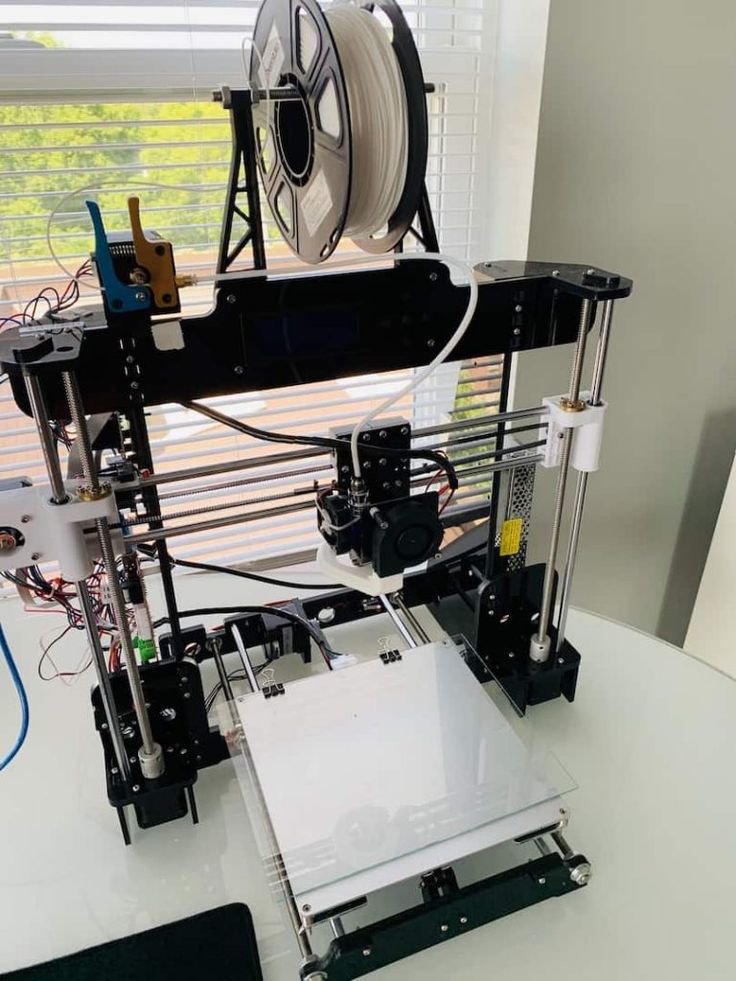

Bead blasting 3d prints

Additive post-processing: Bead blasting, vapor smoothing, and sanding

Additive manufacturing involves more than just sending your design off to the printer. Because 3D-printed parts often have visible layer lines or rough surfaces, post-processing can be used to ensure your parts look and feel finished — especially if you’re creating an end-use product.

In addition to cleaning, fixing, curing, and coloring, smoothing and sanding are two popular additive post-processing options. Both can result in pieces that look and feel smoother, but they aren’t interchangeable. Each process is different and better suited for different situations.

Benefits and drawbacks of post-processing smoothing

Post-processing smoothing is ideal for cases where aesthetic appearance is a top priority, but it can also improve your part’s mechanical performance when creating a watertight part.

After cleaning off your part to remove any excess resin, you may need to smooth it to achieve your desired surface finish. There are several different smoothing processes that can be used, depending on the process and material you selected, as well as your desired surface finish. Two of the most common smoothing options that achieve the best results are bead blasting and vapor smoothing.

Bead blasting

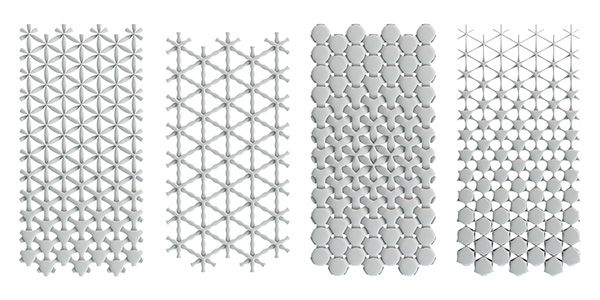

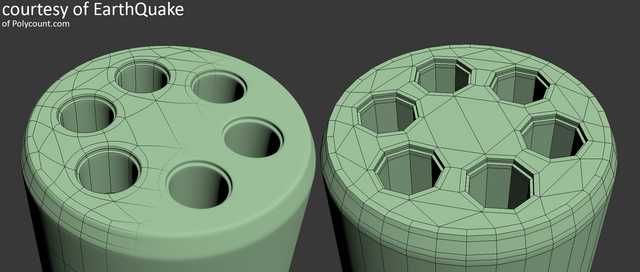

Bead blasting involves blasting glass or quartz beads at the surface of a part at high pressure. Propelling the beads at a surface cleans and polishes the surface to the desired finish. Fine glass beads leave a “dull” or “satin” smooth finish that’s a cross between a matte and high-gloss finish. Coarse glass beads yield uniform roughness and mask any imperfections.

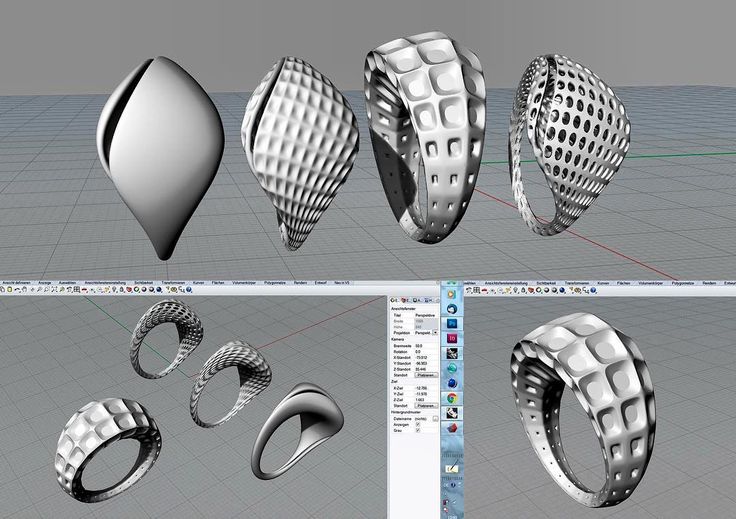

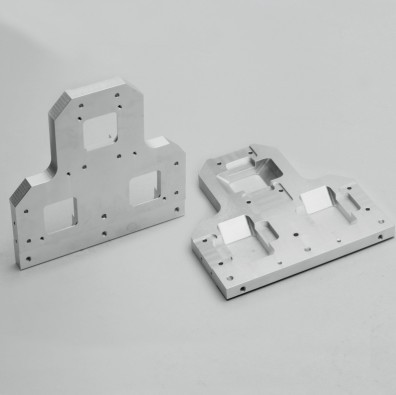

The left side of this jig shows how bead blasting can even out a part’s surface. The right side of the part has not undergone post-processing. Manufacturing process: Carbon® Digital Light Synthesis™The left side of this part has been sanded with 120 grit sandpaper. The right side shows how bead blasting smooths a part’s surface after sanding. Manufacturing process: Carbon® Digital Light Synthesis™

Manufacturing process: Carbon® Digital Light Synthesis™Vapor smoothing

Vapor smoothing, also known as chemical smoothing or chemical vapor smoothing, involves exposing your part to a vaporized solvent that reacts with the part’s outer layer. The vapor will liquefy and redistribute material on your part’s surface, melting away layer lines and sealing small cavities to create a smooth and glossy surface.

Left: An unprocessed sample of PA 12 Right: A vapor-smoothed sample of PA 12 Manufacturing process: HP Multi Jet FusionUnfortunately, it’s impossible to control post-processing smoothing completely. It’s all too easy to melt or blast away small features when smoothing your part or to accidentally remove material unevenly, impacting your part’s dimensional accuracy. This means smoothing processes require close observation to achieve an optimal finish while reducing the risk of damage to small features.

Benefits and drawbacks of post-processing sanding

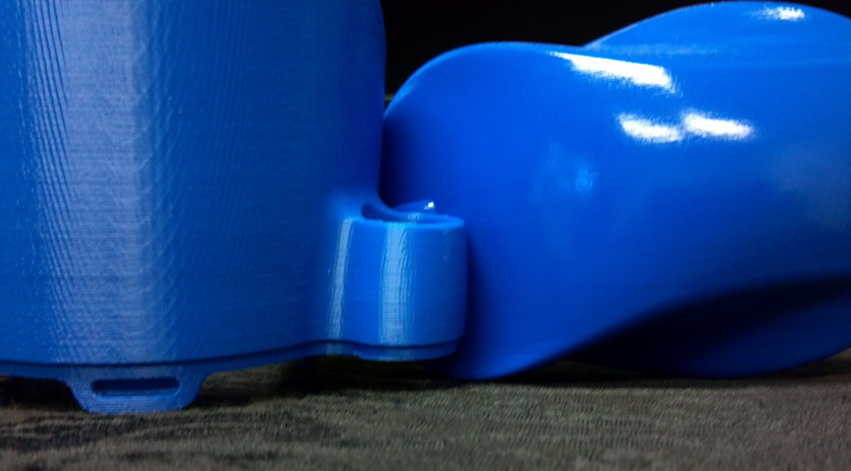

Sanding is a post-processing option that removes more material than smoothing. Rough surface finishes are normal in areas where supports are used during the 3D printing process, and prominent layer lines are also relatively common when using fused deposition modeling (FDM). If you have nubs left behind from support structures and need a part that looks and feels smooth, sanding may be the right option to achieve your desired finish.

Rough surface finishes are normal in areas where supports are used during the 3D printing process, and prominent layer lines are also relatively common when using fused deposition modeling (FDM). If you have nubs left behind from support structures and need a part that looks and feels smooth, sanding may be the right option to achieve your desired finish.

Much like smoothing, there’s a tradeoff between achieving a smoother surface and an accurate part, and sanding can sometimes remove material unevenly. This can impact your part’s dimensional accuracy.

Manual post-process sanding is also a labor-intensive and time-consuming process. Parts need to first be sanded with low-grit sandpaper, such as 120 grit, before re-sanding with higher grit sandpaper, such as 240 grit, 800 grit, and even 2,000 grit to achieve a desirable finish. Leaving this step to the professionals may cost more money than attempting to sand parts yourself, but experts with the right tools and skillsets will reduce the risks of damage to your parts and will save you time, as well.

Why choose post-processing in additive manufacturing?

Both smoothing and sanding take time, effort, and expertise to achieve quality results and can also be a costly endeavor, especially when done by hand.

While unfinished parts may be acceptable for prototyping and are cheaper and faster to produce, they aren’t usually suitable for end-use products. By engaging in smoothing, sanding, cleaning, curing, fixing, and coloring, you can refine your 3D printed parts, making them stronger (in the case of vapor smoothing FDM parts), smoother, more aesthetically pleasing, and even more functional.

Post-processing parts with Fast Radius

Post-processing smoothing and sanding can significantly improve the look and feel of your part. However, each process has its drawbacks and the potential to create inconsistencies. To ensure your final part or product is as intended, consider partnering with an experienced manufacturer.

To ensure your final part or product is as intended, consider partnering with an experienced manufacturer.

If you work with Fast Radius, our team will partner with you to refine your design, print your product, and post-process it when necessary. You can also upload your part files to access design insights, view cost analyses, and get a quote instantly. Create an account today to get started and to begin leveraging the benefits of cloud manufacturing.

Want to learn more about additive manufacturing? Check out our resource center to learn about layer height, support structures, and more.

Ready to make your parts with Fast Radius?

Start your quote

Be the first to know

Sign up for our monthly newsletter for white papers, case studies and more.

Bead Blasting in Additive Manufacturing

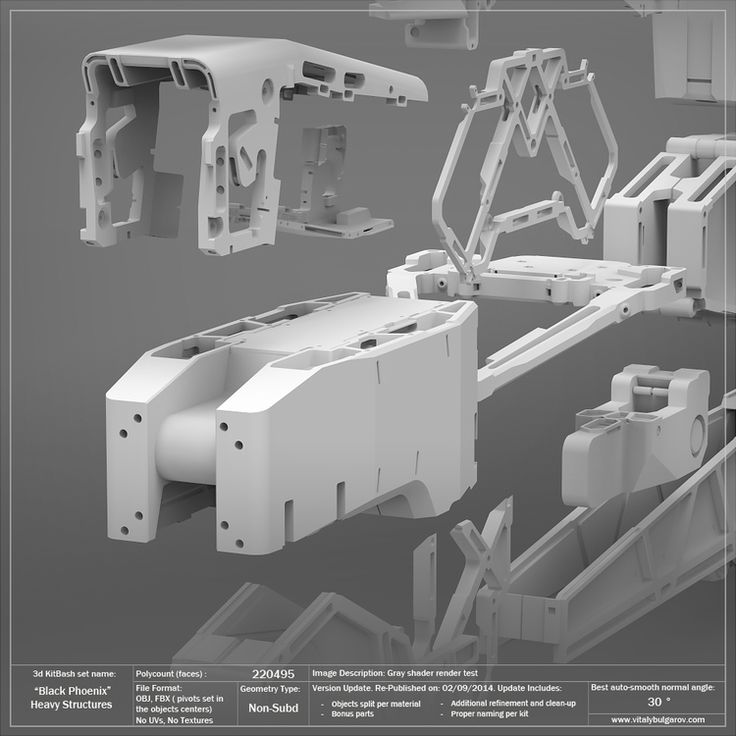

Just like other building processes, 3D-printing usually involves a finishing step. This could be sanding, polishing, or one of many other types of finishing. 3D-printed parts need finishing because the process of additive manufacturing usually leaves traces of the building process. The traces could be “lines” where the layers of the build come together, or could be tiny marks where manufacturing supports were removed.

This could be sanding, polishing, or one of many other types of finishing. 3D-printed parts need finishing because the process of additive manufacturing usually leaves traces of the building process. The traces could be “lines” where the layers of the build come together, or could be tiny marks where manufacturing supports were removed.

Have you considered which type of finishing you need for your 3D-printed parts? Bead blasting offers a functional matte finish that might be ideal for your application. Here’s a quick introduction to bead blasting—what it is, and why you might want to choose it.

What is bead blasting?Bead blasting is a finishing technique for 3D-printed parts. It’s an abrasive blasting method, which means that it is similar to sandblasting and water blasting (pressure washing). In bead blasting, fine beads of plastic, glass, or another substance are forcibly sprayed over the surface of a part. The type of beads are chosen depending on the part’s material in order to smooth the finish of the part without damaging it.

Bead blasting creates a uniform matte finish over the surface of the part. Most customers consider this the standard finish—build markings are smoothed out, but additional high quality finishing has not been applied. It’s ideal for assessing a prototype, or for finishing a piece that doesn’t need a “show ready” finish. Bead blasting also makes it easier to photograph parts because it reduces the light reflections from the part’s surface. For pieces that will be used for sales meetings and trade shows, most customers prefer a higher quality finish.

How bead blasting compares to sandingSandingSanding is the traditional method of finishing additive manufactured parts. Sanding is performed by hand and is a reliable choice for all but the smallest or most detailed parts. Sanding can reduce the tolerance of a part, because it is hard to control exactly how much material is removed by sanding.

Bead BlastingBead blasting is performed with a hand-held blaster gun within an enclosed chamber. It is a good technique for finely detailed and small pieces that would be difficult to sand. It can offer more precision than sanding due to the bead gun’s uniform output per second. Bead blasting is limited to parts that can fit inside the blasting chamber, so this technique might not work for larger parts. Bead blasting generally takes less time than sanding.

It is a good technique for finely detailed and small pieces that would be difficult to sand. It can offer more precision than sanding due to the bead gun’s uniform output per second. Bead blasting is limited to parts that can fit inside the blasting chamber, so this technique might not work for larger parts. Bead blasting generally takes less time than sanding.

See our finishing guide for a table comparing additive manufacturing finishing techniques, along with descriptions. ProtoCAM offers all of these techniques, and we’re always innovating new ones.

Contact Us for Top-Quality Finished PartsIf you’re not sure which finishing technique is best for your product, we’re happy to help you decide. Send us a message here, or request a quote. No matter the destination of your finished part, we’ll help you choose the best finishing technique for your goals and your budget.

STL File 3D Printing of Beaded Crown Stud Earring Model・Template for Download and 3D Printing・Cults

Bronchial tree 3d printing model

18. 79 €

79 €

Simple box clasp 3D print model

6.11 €

3d model-replica of a human eye anatomy

14.09 €

Turbine blade 3d print model

2.35 €

Mini Metric V Pulley Set 3D print model

2.82 €

Miniature model making steel beams

1.40 €

Hammered texture panel relief 3D print and cnc model

7.51 €

Mini set of shipyard bollards 3D print model

5.64 €

Best 3D Printer Files in Jewelry Category

d e b o s s

5.54 €

Ring - Hexagons

Free

Alien Tentacle Bracelet

2 €

Golden Ring

14. 09€

09€

Key Fob Containers

Free

Superman Ring (sizes US 6 - 12)

0.62 €

Geometric Jewelry

Free

Stitch ring

1.25 €

Bestsellers in Jewelry category

Case for Disney MagicBand+ watch

0.93 €

Mini Polaroid souvenir camera

1.88 €

5 One Piece Keychain 1

2 €

llaveros / key ring / key ring , BANDAS DE MUSICA / band

€3.30 -thirty% 2.31€

key rings / key ring , POKEMON , EEVVE EVOLUTIONS

1,88 €

DISNEY LOCK - BOX FOR RINGS

2,50 €

POLYMER CLAY STAMP IN 3D silhouettes of plants and leaves 🌿🌾-LORREN3D

1,78 €

Chain set 1 Commercial license

€9. -40% 5.64 €  39

39

Hello Kitty pendant

1 €

STARBUCKS ORNAMENT MINI TUMBLER STUDDED KEYCHAIN V2 REMOVABLE SCREW

5 €

Crown of Viserys Targaryen - Series 9 trinket0004

9.38 €

Keychain Helmet / Keychain Helmet

0.61 €

5 Keychain Disney Stitch

2 €

SHEET ROLLER PIN STL FILE

1,87 €

Jewelry organizer "Cactus"

2,82 €

Stanley 9 Tumbler Replica0004

0.93 €

💖 Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via Ko-Fi here 💜.

-

INVITE FRIENDS: Invite your friends, discover the platform and the great 3D files shared by the community!

Company profile - HARZ Labs

Your imagination

HARZ Labs was founded in Moscow in 2017 after 5 years of research in the field of polymer chemistry. In 2018, our company opened its first representative office and warehouse in Europe (Latvia)

HARZ Labs offers a wide range of products for DLP/LCD, SLA and other 3D printing technologies. Our own research and production complex in Russia allows us to produce polymers for various applications and develop innovative materials. We cooperate with leading institutes, dentistry and dental laboratories worldwide.

We cooperate with leading institutes, dentistry and dental laboratories worldwide.

HARZ Labs is a customer focused company. We do our best to meet customer needs and make 3D printing easy for everyone. We never stop researching, constantly improving our materials. The fact that our photopolymers are used in more than 75 countries around the world shows that we are moving in the right direction!

Our materials

We are a team of like-minded people united by the idea of creating innovative Russian products and promoting them to foreign markets. The main direction of the company's work is the creation of products for digital dentistry.

The main priorities in our work are high quality products and focus on customer satisfaction. HARZ Labs provides great opportunities for professional and career development of employees, including young professionals with university graduates who do not yet have work experience. We pay special attention to the formation of a positive and friendly atmosphere in the team, we encourage new ideas and proposals, a creative approach to solving scientific and technological problems.

We pay special attention to the formation of a positive and friendly atmosphere in the team, we encourage new ideas and proposals, a creative approach to solving scientific and technological problems.

2017

- Recognized as the best startup of the year at the 3D Print Expo. Harz Labs was founded in Moscow in 2017 by graduates of Moscow State University. The company is one of the largest Russian developers and manufacturers of materials for 3D printing. The production building is located in Mytishchi.

2018

- In 2018, an international representative office and a warehouse were opened in Europe, Latvia. The company is a regular participant of Russian and foreign exhibitions in the field of 3D printing technologies.

- Participant of the world's largest annual 3D printing exhibition FORMNEXT in Frankfurt am Main.

2019

- Since 2019, a resident of the Skolkovo Innovation Center, the scientific program includes the creation of innovative materials within the framework of the Nuclear Technologies cluster.

- Launch of a new production building and its own research laboratory.

- Participant of the world's largest annual 3D printing exhibition FORMNEXT in Frankfurt am Main.

2020

- Winner of the "Exporter of the Year" award in the Moscow region at the end of 2020.

- Certification of dental photopolymers in Russia. Obtaining a registration certificate for a medical device No. RZN 12007.

- Development and launch of production of photopolymers for industrial 3D printers.

- Participant of the world's largest annual 3D printing exhibition FORMNEXT in Frankfurt am Main.

2021

- The network of reseller companies includes 40 companies, products are sold in 70 countries around the world.

- Participant of the world's largest annual 3D printing exhibition FORMNEXT in Frankfurt am Main.

- Participant of the world's largest dental exhibition IDS in Cologne.

Registration in accordance with

of the Labor Code of the Russian Federation

Democratic friendly atmosphere

Personal and career

growth

Comfortable

modern

office

Employee benefit programs

Account manager

Read more

Chemical Process Assistant

Read more

Development Chemist / R&D Chemist

Read more

Warehouse picker

Read more

There is no suitable vacancy?

upload your CV and we will contact you

Upload your CV in PDF

Certificates

Registration certificate for a medical device

Certificate of Conformity

Trademark Certificate

Exporter of the Year

Patent for invention

US Trademark

Trademark in the EU

Quality Policy

Quality management system documentation

download

2 Mar 2023

Meeting with the head of the city district of Mytishchi

Yesterday, the grand opening of the new production complex HARZ Labs took place. The head of the urban district of Myti took part in the launch ceremony...

The head of the urban district of Myti took part in the launch ceremony...

27 Feb 2023

Meeting with partners from China

Recently, our R&D department held a meeting with our partners from China. We walked around the office and discussed issues of further cooperation.

2 Feb 2023

Meeting with representatives of the STC "Aerospace Innovation Valley"

The other day we hosted representatives from the Science and Technology Center “Aerospace Innovation Valley”. Decree on the Establishment of a Subscription Center...

6 Jan 2023

In 2022 we delivered our resins to 79 countries

79- this is the number of countries we covered in the past 2022 (including Russia).

3 Mar 2023

Opening of a new production site at HARZLabs

Feb 15, 2023

HarzLabs: from a startup to a leader in its field

22 Dec 2022

Interview with Business Development Director Konstantin Churkin to Business Law

22 Nov 2022

Top 10 Moscow enterprises that develop new materials

All media mentions

Mytishchi

Production + Warehouse

141006, Russia, Mosk. region, Mytishchi, st. Silikatnaya, 51A, building 6

self-delivery of orders is carried out at this address

10:30 to 17:30

Mytishchi

Office

141002, Russia, Mosk. region, Mytishchi, st. Kolpakova, 2, building 13, office 265

region, Mytishchi, st. Kolpakova, 2, building 13, office 265

From 10:00 to 19:00

Moscow

Innovation Development Center

121205, Russia, Moscow, the territory of the innovation center "Skolkovo", st. Lugovaya, d. 4, k. 5, room. 6

From 10:00 to 19:00

Riga

European office + International warehouse

LV-1073, Slavu street 7, Riga, Latvia

From 10:00 to 19:00 (Moscow time)

Company card

Full name

Limited company "HARC Labs"

Abbreviated name

LLC "HARC Labs"

Legal address

90G.TER.VN. MUNICIPAL DISTRICT KHOROSHEVO-MNEVNIKI, STR. 3rd KHOROSHEVSKAYA, D.13, K.1, ROOM. 4.4Actual address

141001, Mytishchi, st. Silikatnaya, 51A, building 5

Postal address (correspondence address)

141013, Moscow region, Mytishchi district, Mytishchi, st. Silikatnaya, d.37, a/I No. 466

TIN/KPP

7751087784/773401001

OGRN

517774603728 Awarded: 05.