J850 3d printer cost

Stratasys launches the PolyJet J850 Pro 3D printer - technical specifications and pricing

0Shares

3D printer OEM Stratasys has launched its new multi-material PolyJet 3D printer, the J850 Pro.

Designed for engineering-grade prototyping applications, the latest addition to the industrial J8 Series is primarily aimed at engineers and designers seeking monochrome functional prototypes at an affordable price. The company has tailored the J850 Pro’s 3D printing capabilities to suit concept verification and performance testing purposes in a wide variety of sectors such as automotive, medical, and consumer products.

Shamir Shoham, Design Vice President at Stratasys, states, “We’ve seen the value to customers of our PolyJet 3D printers – in throughput, accuracy, reliability, and multi-material capabilities – and are excited to have the J850 Pro now bring that value to our engineering customers, at an attractive price.”

The J850 Pro. Photo via Stratasys.PolyJet production with Stratasys

Stratasys is an industry leader in material jet 3D printing, and offers its own take on the technology with its extensive PolyJet range. The flagship J8 Series is led by the J850 Prime 3D printer, a full-color variant of the newly released J850 Pro. The smaller and more accessible machine in the series is the J826, with a maximum model size of 255 x 252 x 200mm. However, what it lacks in build volume it makes up for in material flexibility, as it is compatible with rigid, transparent, and tear-resistant materials capable of withstanding extreme torsion.

The company also manufactures several niche-specific 3D printers, namely for the dental industry. The J700 Dental is intended for clear aligner production; the J720 Dental allows for full-color orthodontic parts; and the J750 Digital Anatomy is capable of mimicking bone and tissue for life-like medical models.

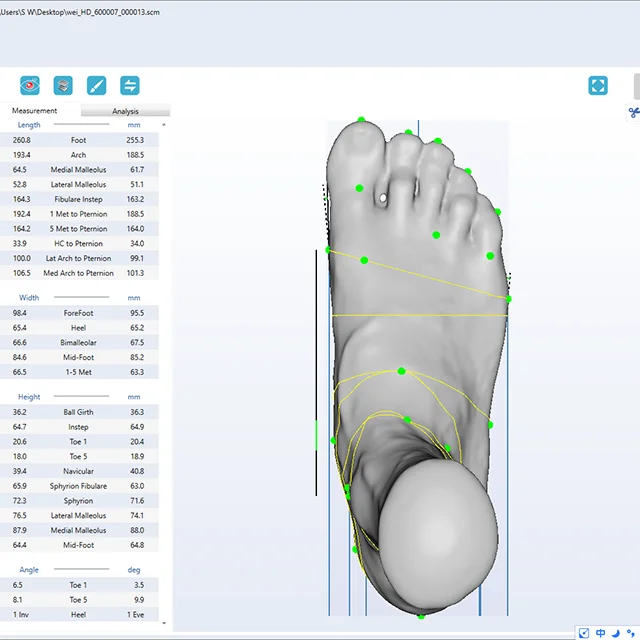

Shoe sole prototypes 3D printed on a J850. Photo via Stratasys.The J850 Pro

Stratasys has designed every aspect of the J850 Pro to enable users to work faster with greater productivity. The company has boldly claimed that the machine can achieve prototyping cost reductions of 80% and throughput improvements of 500% when compared to traditional manufacturing.

The system is able to jet seven different 3D printing materials at the same time, granting engineers huge scope for multi-material combinations. The machine is compatible with the company’s full suite of grayscale (and transparent) resins, including the rigid Vero family, the flexible Agilus30 family, and the Digital ABS range. By loading their most used resins into the slots, users can significantly reduce the downtime associated with material changeovers.

With a large-format build volume measuring 490 x 390 x 200mm, the machine lends itself quite well to both high-throughput and large part production. Models can also reportedly be printed at twice the speed of the company’s own legacy systems when using the new Super High Speed mode, allowing for more rapid design iterations than ever. Typical applications here would be texture simulation, product labeling, shock absorbers, living hinges, and even transparent elements for optics products.

Ofer Libo, Product Manager for the J850 Pro, concludes, “The ability to easily create prototypes delivers great value to engineering teams in different stages of the development cycle. In addition, the J850 Pro’s multi-material capabilities and large throughput enables them to test different designs, textures, and material properties to accelerate time to market and precisely deliver on user needs.”

In addition, the J850 Pro’s multi-material capabilities and large throughput enables them to test different designs, textures, and material properties to accelerate time to market and precisely deliver on user needs.”

Technical specifications and pricing

Below are the technical specifications for the Stratasys J850 Pro. The system is available to order now and readers interested in purchasing the machine should visit the Stratasys store page for a quote. For those seeking full-color printing capabilities, the J850 Pro is also software-upgradeable to the Prime version.

| Build volume | 490 x 390 x 200mm |

| Layer thickness | Down to 14 microns |

| Connectivity | LAN – TCP/IP |

| System size | 1400 x 1260 x 1100mm |

| Weight | 430kg (excluding material cabinet) |

| Software | GrabCAD Print |

| Resin slots | 7 |

| Material compatibility | Vero, Agilus30, Digital ABS, grayscale and clear |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the J850 Pro. Photo via Stratasys.

Tags J850 Pro Ofer Libo Shamir Shoham Stratasys

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

3D Printers & Additive Solutions | Stratasys & EOS Reseller

AdvancedTek champions cutting-edge technology to provide innovative business solutions to our clients.

Latest News

August 1, 2022 News

Why It's so Easy to Choose the Wrong 3D Printer

The purpose of this article isn’t to convince you to buy from us. Instead, the goal is to help you avoid choosing the wrong 3D printer. Of course, we’d love to be your partner, but we understand our technology won’t be the perfect fit for everyone, and that’s okay. That’s why we approach every new […]

Instead, the goal is to help you avoid choosing the wrong 3D printer. Of course, we’d love to be your partner, but we understand our technology won’t be the perfect fit for everyone, and that’s okay. That’s why we approach every new […]

Continue Reading +

June 24, 2022 News

Customer Spotlight: A Marriage of Tradition and Future

How one company found the path of least resistance – combining traditional and additive manufacturing to become an automated powerhouse. For over 65 years, Iowa’s United Equipment Accessories (UEA) has been engineering and manufacturing custom slip rings, rotary unions, cable reels, and shift controls for various industries throughout the US and worldwide. The company’s core […]

Continue Reading +

Upcoming Events

January 4, 2023 Events

January 26, 2023 | How It Works: Automated PolyJet Post-Processing Webinar

Sign up today for a PostProcess webinar and demo of automated 3D post-processing focused on PolyJet support removal. Conducted by one of PostProcess Technologies’ experts broadcasting from their lab, you will get a close-up view of how software, hardware, and chemistry work together for transformative end part results. See the solutions running on the […]

Conducted by one of PostProcess Technologies’ experts broadcasting from their lab, you will get a close-up view of how software, hardware, and chemistry work together for transformative end part results. See the solutions running on the […]

Continue Reading +

October 28, 2022 Events

November 2-3, 2022 | Advanced Manufacturing Minneapolis

We’re excited to be exhibiting at Advanced Manufacturing Minneapolis, November 2 – 3! Come see us at Booth #2533. We will have the latest industrial 3D printers, materials, and post-processing solutions on site for you to explore and chat with our 3D printing experts. Advanced Manufacturing Minneapolis is an immersive live expo and conference […]

Continue Reading +

September 12, 2022 Events

October 26, 2022: 3D Printing Happy Hour - Green Bay, WI

Whether you’re new to 3D printing or interested in exploring additional 3D printing technologies, materials, or post-processing solutions, attend our 3D printing happy hour at Ahnapee Brewery in Green Bay on Wednesday, October 26th from 4:00 pm – 6:00 pm. Get hands on with a variety of 3D printed parts and materials Discover automated […]

Get hands on with a variety of 3D printed parts and materials Discover automated […]

Continue Reading +

September 9, 2022 Events

October 20, 2022 | Stratasys Webinar: Why Victrex AM200 is a Great Fit for Aerospace Applications

Title: Why Victrex AM200 is a Great Fit for Aerospace Applications Date: Thursday, October 20, 2022, 11:00 AM CDT SPEAKERS Robert McKay has led New Business Development for Additive Manufacturing at Victrex for the past six years. Rachael Wratkowski is an Industrial Materials Applications Engineer on the products team at Stratasys. Victrex AM200 […]

Continue Reading +

September 27, 2022 Events

October 13, 2022 | AdvancedTek Webinar: DyeMansion Print-to-Product Workflow

Webinar Title: DyeMansion Print-to-Workflow Date: Thursday, October 13, 2022, 11:00 AM – 12:00 PM CDT Speakers: Lester Hitch Application Consultant, DyeMansion David Kadlec Senior Applications Engineer, AdvancedTek Overview: Join us on October 13 as DyeMansion Application Consultant Lester Hitch provides insight into DyeMansion’s Print-to-Product Workflow by way of the industry’s most advanced post-processing technologies. […]

[…]

Continue Reading +

3D printer Stratasys J850 digital anatomy at the manufacturer's price with delivery – TopStanok

- Description

- Characteristics Har-ki

Description

Stratasys J850 Digital Anatomy, a printer specifically designed for printing realistic organs and body parts. nine0009

The printer has the ability to print with three specially selected materials that allow you to make the most realistic model of the organ, to prepare for the operation and to better understand the possible methods of influence. At the same time, the structure of the product also completely repeats real materials, which allows for a preliminary trial operation.

The J850 Digital Anatomy also allows medical students to perform surgery and improve their skills for the next real job. nine0009

nine0009

Full-color printing makes it possible to obtain a product that exactly repeats the anatomical features of the human body, including the smallest veins and vessels. As a result, the cost of training compared to other methods is reduced by more than 70%.

J850 Digital Anatomy is a combination of chemistry and technology that creates human bones and tissues at an unprecedented level of realism.

Video

General characteristics

| Specification | strat-j750 |

|---|---|

| General characteristics 3D printing | nine0041|

| Print technology | PolyJet |

| Media | Photopolymer |

| Features (filter) | nine0039 Multimaterial, Colored|

| Country of origin | US |

3D ABS Printer - J850 Prime - Stratasys

Add to Favorites

Add to Compare

More information on the Stratasys website

Characteristics

- Printed materials

- ABS, several materials

- Technology

- Polyjet

- for automotive industry, Medical

- Other characteristics with high speeds, colorful.

feet

feet - Stroke X

-

490 mm (19 in)

- Stroke Y

-

390 mm (15 in)

- Travel Z

-

200 mm (8 in)

- layer thickness

-

14 µm, 55 µm

-

430 KG (948 LB)

Description full color 3D models in 20% of the time required to produce traditional models. This enables faster design decisions and faster time to market by reducing design iterations and development costs. The J850 Prime can create over 600,000 PANTONE® proven color combinations, print with seven resins simultaneously, and provide multi-material capability to bring the most fantastic ideas to life. For design With over 500,000 unique colors, realistic texture modeling, flexible and transparent materials, and a click-to-print workflow, the J826 and J850 Prime 3D printers are the most versatile full color printers on the market. For engineering From effective concept models to functional testing and single color multi-material prototypes, the J850 Pro is the perfect engineering solution to help you speed up form and fit verification.