Autodesk 3d print software

What is 3D Printing? | 3D Printing Software

What is 3D printing?

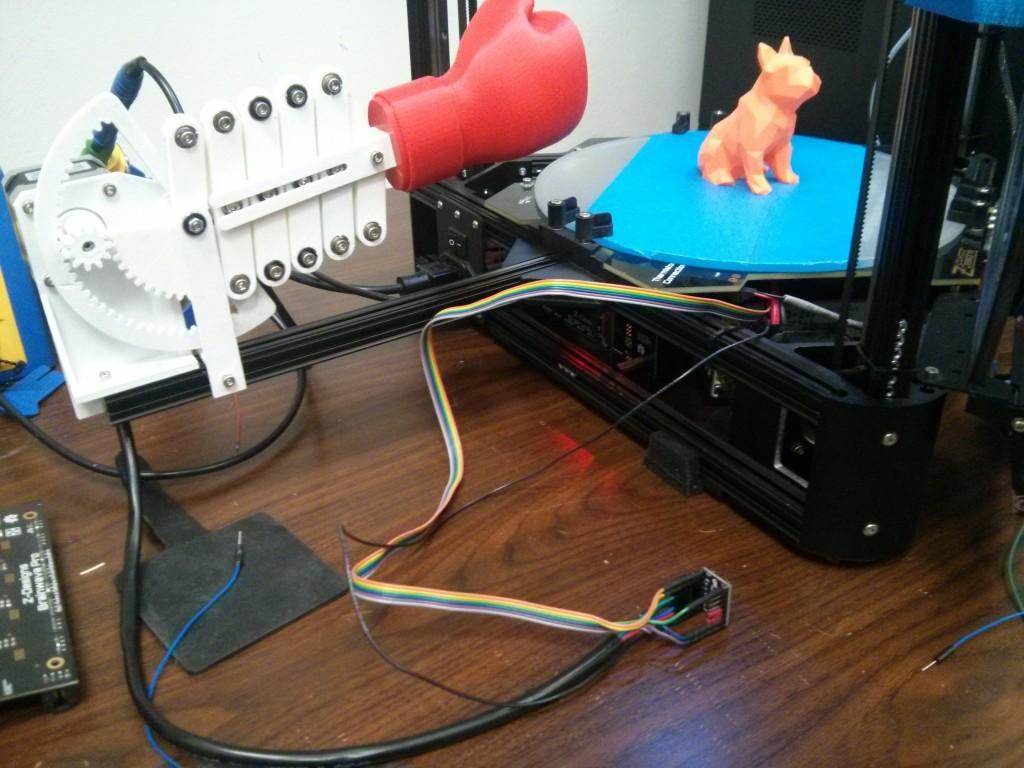

3D printing, also called additive manufacturing, is a family of processes that produces objects by adding material in layers that correspond to successive cross-sections of a 3D model. Plastics and metal alloys are the most commonly used materials for 3D printing, but it can work on nearly anything—from concrete to living tissue.

Featured 3D printing software

What is 3D printing used for?

Efficiently make one-off parts and create highly complex geometries that are only possible with 3D printing.

-

Prototyping

3D printing has long been used to quickly create prototypes for visual aids, assembly mockups, and presentation models.

Learn more

-

Lightweight parts

Fuel efficiency and emissions reductions are driving the need for lightweight parts via 3D printing in aerospace and automotive applications.

Learn more

-

Functionally enhanced products

3D printing removes many of the constraints imposed by traditional manufacturing processes that prevent engineers from truly designing for optimal performance.

Learn more

-

Custom medical implants

To achieve osseointegration, manufacturers are using 3D printing to precisely control surface porosity to better mimic real bone structure.

Learn more

-

Toolings, jigs, and features

3D printed composite tooling and machining fixtures are often cheaper and faster to produce, and conformally cooled inserts for injection molds can dramatically reduce cycle times.

Learn more

-

Metal casting patterns

Combining 3D printing with metal casting bridges the gap between generatively designed parts and proven manufacturing approaches for large metal objects.

3D printing processes & materials

Understanding the different additive manufacturing processes

Explore different additive manufacturing processes and technologies to help you find the right one for your workflow.

Learn more

What materials can be 3D printed?

Using the right material for your 3D printed project can make or break a product. This article will cover what materials can be 3D printed.

Learn more

How is 3D printing software used?

-

Granta

Mexico City start-up disrupts medical-implant manufacturing

Mexico City start-up Granta is changing medical implant design and fabrication for patients who suffer head trauma.

Read story

Image courtesy of Granta

-

Airbus

Airbus bionic partition

Airbus uses generative design and 3D printing to create a strong yet light cabin partition for the A320—and takes the first step toward the plane of the future.

Read story

Image courtesy of Airbus

-

Stanley Black & Decker

A computer designed Stanley Black & Decker’s new tool

Using generative design and 3D printing, Stanley Black & Decker’s Infrastructure Innovation Center is exploring new approaches to creating high-performance industrial tools.

Read story

Image courtesy of Stanley Black & Decker

Future of 3D printing

-

What does the future of 3D printing look like?

3D printing has come a long way from the early days of desktop figurines. As technology continues to evolve, the future is brighter than ever.

Learn more -

How 3D printing is revolutionizing the medical industry

Amidst a global healthcare crisis, 3D printing has become a flexible solution to modern medical challenges.

Learn more -

The future of additive manufacturing in aerospace

Learn about how aerospace companies are buying into additive manufacturing and what it means for the industry’s ongoing success.

Learn more

3D printing tutorials

-

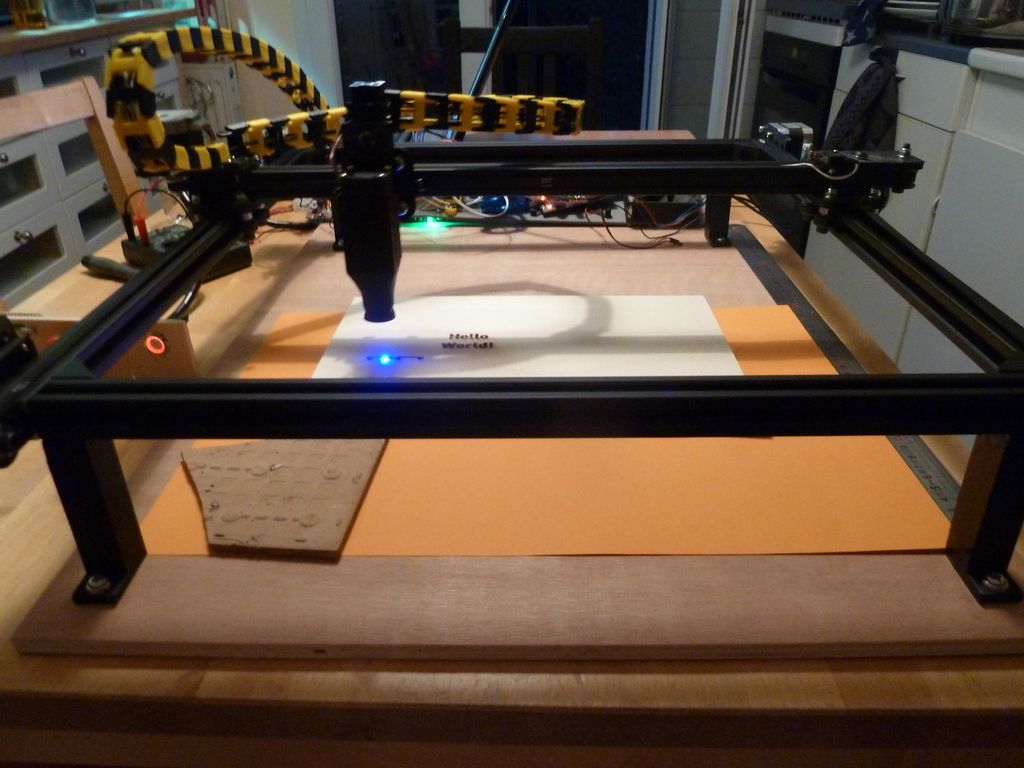

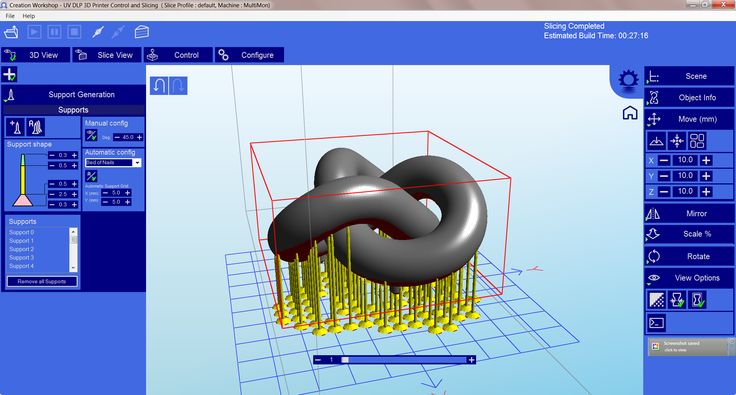

How to SLICE 3D Prints with Fusion 360

Fusion 360 can slice models for 3D printing, without the need to save the file as an STL. In this tutorial, we'll take a design model into the Manufacture workspace. From there, we'll slice it, simulate the 3D print, and save the Gcode.

Watch video

-

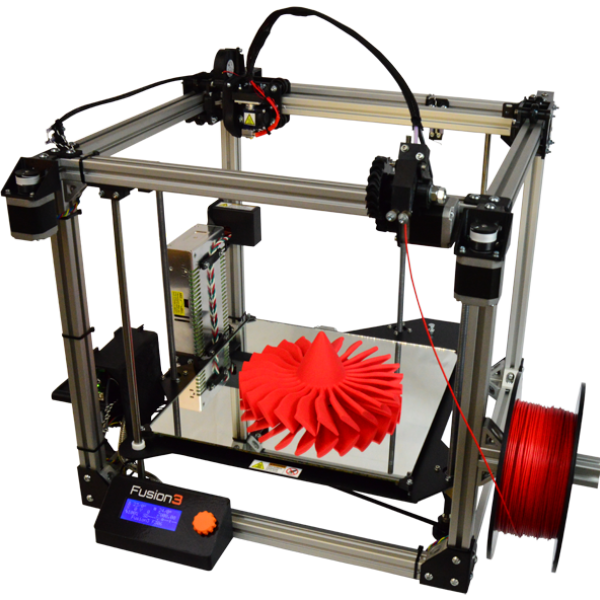

Fusion 360 Additive for your Ultimaker 3D printer

This video details the FFF workflow along with tips and tricks to utilize Fusion 360 Additive FFF for a Ultimaker 3d printer.

Watch video

-

Fusion 360 for 3D printing FDM technology workflow

Learn more about the design process using fused deposition modeling (FDM) 3D printing technology through the power of a very flexible modeling workflow in Fusion 360 software.

Watch video

3D printing & sustainability

How sustainability and Fusion 360 can help you save money and the planet

Find out how you can use Fusion 360 software to drive efficiencies and innovation in your processes that will benefit your bottom line and the planet.

Learn more

Three environmental considerations for the FFF 3D printing process

Every manufacturing process, including FFF 3D printing, has an environmental impact. Learn how to reduce your parts' environmental footprint.

Learn more

Do your actions match your ambitions for success?

Get the right tools to achieve your new possible. Extensions amplify the functionality of Fusion 360 by unlocking advanced capabilities for machining, additive manufacturing, generative design, nesting, and fabrication. Discover Fusion 360 extensions.

Try Extensions

How long has 3D printing technology been around?

3D printing is much older than you might think! The first patents for an additive manufacturing process are dated all the way back to the 1970s. The first true additive manufacturing patent that led to a product is dated to 1984. The first real-world applications of additive manufacturing are in the dental industry, printing out masks of teeth as a replacement for plaster casting from molds.

What are the benefits of 3D printing?

3D printing is a rapid prototyping process, mass customizable manufacturing process, and a technology that enables the creation of complex geometries previously not possible through other manufacturing processes. It’s also a digital manufacturing technology that requires no tooling changes for revised parts, which means there’s no downtime between product revisions or manufacturing entirely new products.

How much does it cost to 3D print something?

3D printing a part is a combination of the material you wish to use, and the volume. Because 3D printing can output using a plethora of plastics and metals, the cost of a part can vary dramatically depending on what you are using, but it can be more affordable per part than other processes.

What 3D printing services does Autodesk offer?

Autodesk offers Netfabb as a dedicated additive manufacturing prep, analysis, and simulation tool, as well as Fusion 360, which has a dedicated additive manufacturing space, marrying design, engineering, simulation and manufacturing all together.

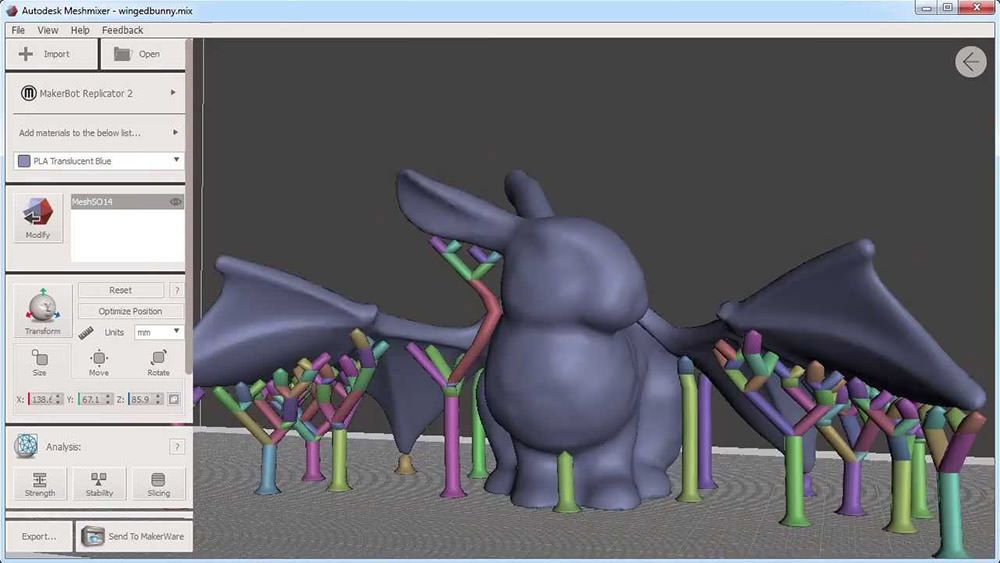

Fusion 360 is an excellent choice for creating CAD models for 3D printing. It allows you to create not only “prismatic” models such as gears or brackets, but it also allows you create more “organic” models using T-Splines, including characters, plants, and vehicles. You can use Fusion 360 to create and then edit your objects for 3D printing. Bring in models from other software and make modifications, such as de-featuring them by removing small features or blends. Fusion 360 can export as an OBJ or STL file format that is read by most 3D printing software. It also has the ability to print directly to your 3D printer. In addition, Fusion 360 even allows you to edit mesh or STL data that is brought in from a laser-scan or other source. Before printing, you can reduce or increase the surface count, edit out features, fill holes, etc.

CAD 3D printing software allows you to conceptualize, design, and optimize your models for fitting production technologies

Free resources for 3D printing

-

Additive manufacturing resource center

Access a variety of resources designed to help you identify how you can add value to your products with additive manufacturing.

-

Learn how to use Tinkercad to model, align and group parts, cut holes, add custom text, and specify dimensions. Tinkercad allows you to export and download designs for laser cutting and 3D printing to send designs to Autodesk® Fusion 360.

-

Learn how to take your ideas to reality through the use of design in Fusion 360 software, and how to utilize 3D printing to manufacture your idea.

-

Get product updates and enhancements, useful Fusion 360 tips and tutorials, roadmap updates and community stories.

-

Stay current with the latest in 3D printing trends and Netfabb software updates.

-

Learn how to print a PPE face shield in under four minutes and large-scale additive manufacturing.

Choose the best Autodesk software for your project in 2022

3D Learning Hub

See all categories

Contents:

- Introduction

- Different types of software

- Top 10 of Autodesk software

- Which software do you choose?

Introduction

Autodesk is a leader in CAD and 3D modeling software. With over 90 Autodesk products to choose from, you might feel a little lost. That is why we prepared for you a list of Top 10 most popular 3D Autodesk software. Which one fits your needs best? Let’s find out!

With over 90 Autodesk products to choose from, you might feel a little lost. That is why we prepared for you a list of Top 10 most popular 3D Autodesk software. Which one fits your needs best? Let’s find out!

Different types of software

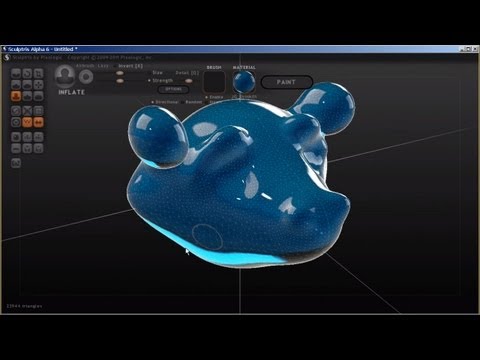

As we already mentioned Autodesk is very well known for its 3D modeling and CAD software. What is the difference? We dedicated a whole blog post to this topic, but as a summary, CAD software is always based on precise technical drawings for engineering purposes whereas 3D modeling is more free, like sculpting, aimed more for video game creators. Do you want to improve your rapid prototyping process? Are you working on a construction project, or on 3D design engineering?

Autodesk didn’t stop just there. In their wide range of products, you can also find software dedicated especially for the creation of good renders, which can be highly beneficial for those who work on presentational models, for example of product concepts or architecture engineering.

Top 10 of Autodesk software

We will take a closer look at different products from Autodesk. Autodesk has software for everyone, no matter if you have no idea about 3D modeling or you’re a professional searching improvement for your workflow. We organized this list by the level of skills required to operate the software, so make sure you stick with us till the end of our list and you will see a wide path for our future 3D modeling skills!

TinkerCAD

We recently wrote about TinkerCAD as it also made our list of the easiest 3D software to use. TinkerCAD is a free, web-based app that allows you to build models starting with simple shapes. It is known to be intuitive and easy to learn.

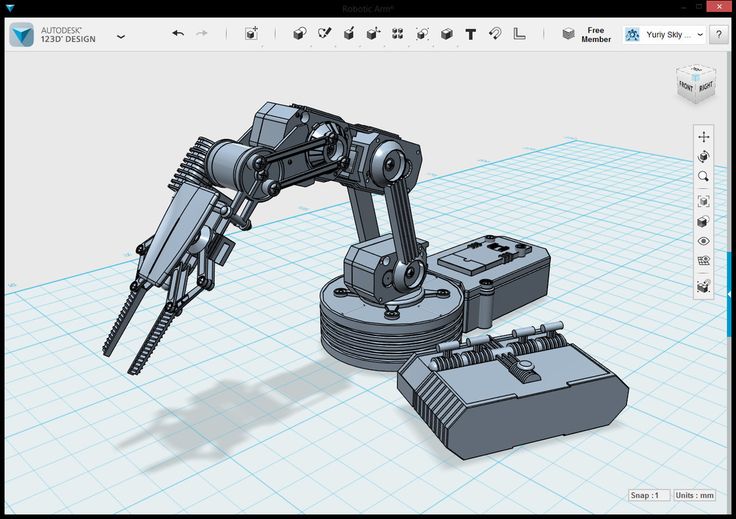

AutoCAD

As its name suggests, it is a CAD software. It is widely used by professionals in many industries. 3D models are based on 2D geometries, all with assigned dimensions. Autodesk AutoCAD is a very powerful software with a wide set of tools and plugins dedicated to specific industries, such as architecture, or mechanical. It is fairly easy to learn with online tutorials, however, keep in mind that is it very technical.

Autodesk AutoCAD is a very powerful software with a wide set of tools and plugins dedicated to specific industries, such as architecture, or mechanical. It is fairly easy to learn with online tutorials, however, keep in mind that is it very technical.

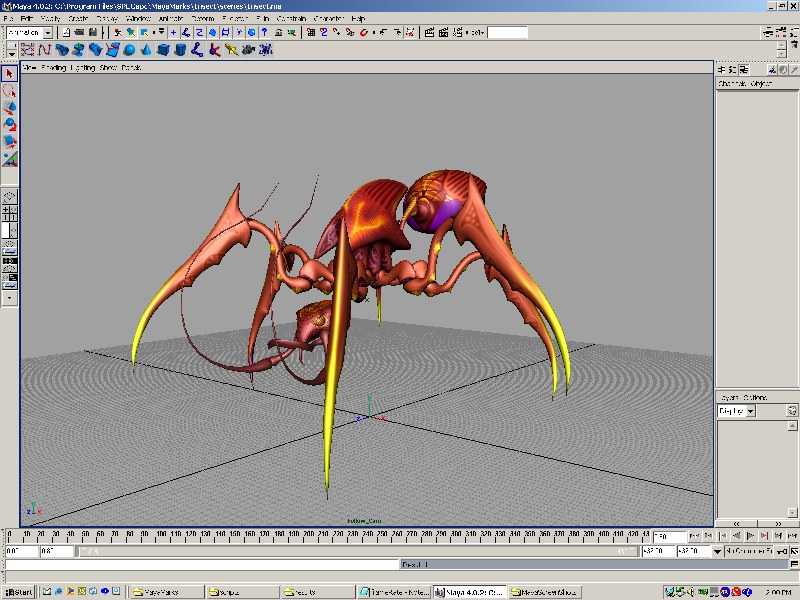

Maya

Maya can be considered the opposite software of AutoCAD. It provides artists, modelers, and animators with pretty impressive tools for 3D modeling, simulation, 3D animation with rigging, texturing and rendering. It allows for the creation of HD visual effects, photorealistic environments, design visualization, and characters. It is also capable of handling heavy and complex projects thanks to dedicated tools and support workflows.

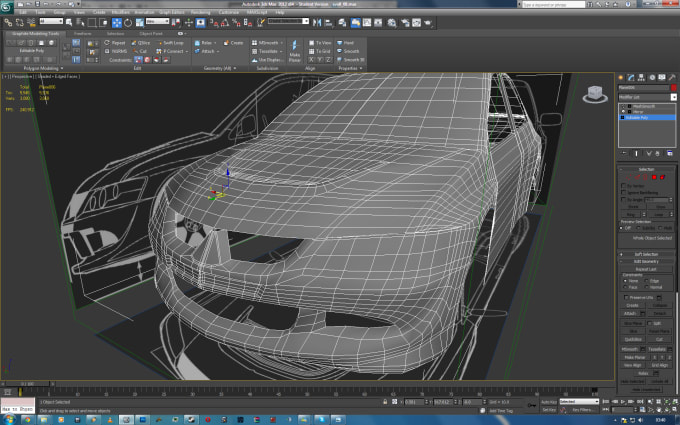

3Ds Max

3Ds Max, from our experience, seems to be a mix between Maya and AutoCAD. It is capable of creating product designs for 3D printing, however, they might not be as precise as designed in Autodesk AutoCAD. But if you’re not an engineer, 3Ds Max might be easier to adapt to than AutoCAD.

It is capable of creating product designs for 3D printing, however, they might not be as precise as designed in Autodesk AutoCAD. But if you’re not an engineer, 3Ds Max might be easier to adapt to than AutoCAD.

This 3D modeling software is also capable of high quality renders, content creation for games, environments, and effects for movies, 3D animations or simulating fluid behavior.

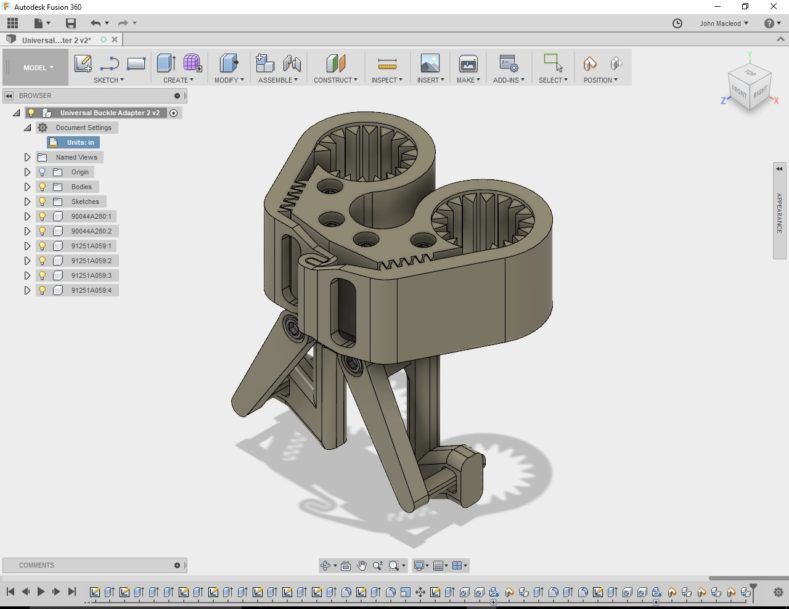

Fusion 360

This CAD software is also a mix of different tools. It brings together industrial and mechanical design, simulation, collaboration and machining in one place. The creation of your 3D model starts with a technical drawing, however, Fusion 360 also gives you a choice of different modes, therefore also giving you powerful tools for different design variations.

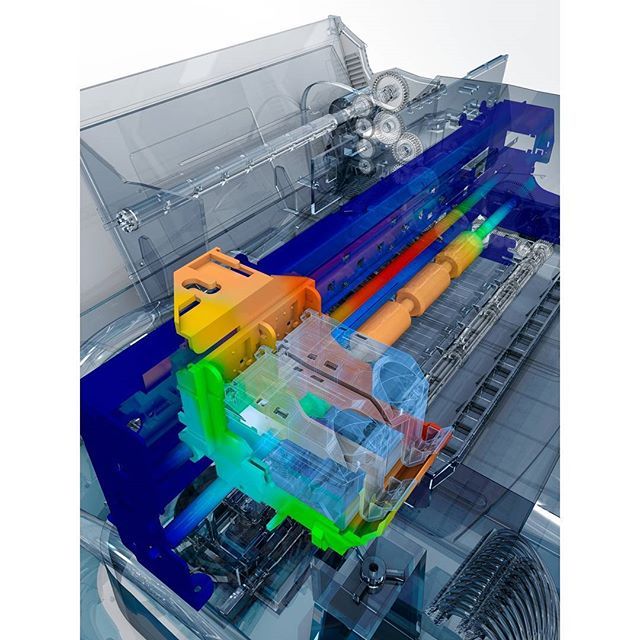

In Autodesk Fusion 360 you can simulate different types of stress on the parts, digital prototyping, test fit, and motion, but also photorealistic renders and 3D animation if needed. Additionally, it has a set of tools dedicated to 3D printing your models.

Additionally, it has a set of tools dedicated to 3D printing your models.

We have used Fusion 360 on several occasions, for example in our 3D printed thread tutorial and pipe fitting tutorial, and you can see that Autodesk Fusion 360 is pretty straight forward. This software is getting more and more popular not only thanks to a wide range of tools, but also because of its user-friendly UI.

Mudbox

Mudbox is a 3D modeling software clearly designed for game designers, animators, filmmakers. This software allows for creating 3D characters and environments, highly detailed natural and organic shapes with great texturing. It is a great alternative to Maya and 3Ds Max when it comes to the price of the license.

Arnold

If your 3D models require high quality, super realistic renders in complex environments, Arnold is the answer to your needs. This Autodesk software was designed just for that. It supports plugins for Maya, 3Ds Max and other 3D software to allow you to render highly detailed images thanks to advanced ray-tracing tools.

This Autodesk software was designed just for that. It supports plugins for Maya, 3Ds Max and other 3D software to allow you to render highly detailed images thanks to advanced ray-tracing tools.

Revit

This is a very powerful software for architecture engineering which involves planning, designing, construction, building solutions, and infrastructure. Clearly aimed for architects and construction designers, Revit is capable of conceptual design; its 3D parametric modeling allows for detailed documentation, and can also provide high-quality 3D visualizations.

Inventor

Another product from Autodesk is well known in the CAD software world. Inventor is designed especially for the production of mechanical parts. It is capable of both 2D and 3D design, as well as photorealistic renders. Autodesk Inventor has a great set of tools, some of which are aimed to decrease the weight of your design, which is crucial in automotive and aerospace manufacturing.

It is capable of both 2D and 3D design, as well as photorealistic renders. Autodesk Inventor has a great set of tools, some of which are aimed to decrease the weight of your design, which is crucial in automotive and aerospace manufacturing.

Powermill

Autodesk is a leader for a reason. It keeps up with the latest 3D innovations and realizes it’s not only about 3D models staying in virtual reality. 3D technologies are constantly evolving and allow your 3D model to become a solid reality with 3D printing. This is exactly why Powermill was developed.

Dedicated to a growing industry of Additive Manufacturing, this 3D software allows you to apply strategies for 3- and 5- axis subtractive and additive manufacturing. Powermill claims to be an expert in CAM (Computer Aided Manufacturing) programming, allowing for the creation of molds, controlling 5-axis machining and programming CNC machine tools.

An overview

- TinkerCAD

- Type: 3D modeling

- Used for: Simple creations

- Price: Free

- Platform: Doesn’t apply

- AutoCAD

- Type: CAD

- Used for: 2D drawings, documentation, complex and large 3D models, mechanical parts

- Price: $1,610/ year

- Platform: Windows and iOS

- Maya

- Type: 3D modeling

- Used for: High quality renders, animations, simulations, texturing

- Price: $1,545/ year

- Platform: Widows, iOS and Linux

- 3Ds Max

- Type: 3D modeling

- Used for: Detailed 3D content for games, product visualizations, environments, and effects for films

- Price: $1,545/ year

- Platform: Windows

- Fusion 360

- Type: CAD

- Used for: Product design, engineering and simulating tests, CAM

- Price: $495/ year

- Platform: Windows and iOS

- Mudbox

- Type: 3D modeling

- Used for: 3D design of characters, concepts, environments, content creation

- Price: $80/ year

- Platform: Windows, iOS and Linux

- Arnold

- Type: Rendering

- Used for: Renders of highly complex scenes, lightning

- Price: $630/ year (pack licenses available)

- Platform: Windows, iOS and Linux

- Revit

- Type: CAD

- Used for: Architectural designs, MEP engineering, structural and reconstruction design

- Price: $2,310/ year

- Platform: Windows

- Inventor

- Type: CAD

- Used for: 3D mechanical designs, sheet metal, electrical, tube and pipe designs, assemblies

- Price: $1,985/ year

- Platform: Windows

- Powermill

- Type: CAD

- Used for: CAM programming, CNC machine optimization, 3- and 5- axis programming

- Price: Contact Autodesk for pricing

- Platform: Windows

Which software do you choose?

As you can see we covered a wide range of 3D software. From TinkerCAD for absolute beginners, through professional CAD and 3D modeling software for game and film design, industrial design to powerful tools designed for CNC machining and Additive Manufacturing. Ask yourself, what are my needs? The table above listing the main applications of each software should help you to decide which Autodesk software is the best for you. If you are a student, don’t forget to check Autodesks educational license.

From TinkerCAD for absolute beginners, through professional CAD and 3D modeling software for game and film design, industrial design to powerful tools designed for CNC machining and Additive Manufacturing. Ask yourself, what are my needs? The table above listing the main applications of each software should help you to decide which Autodesk software is the best for you. If you are a student, don’t forget to check Autodesks educational license.

You can always start learning 3D modeling and CAD software with our free tutorials. From Autodesk software, we prepared for you Inventor, Fusion 360 and 3Ds Max tutorials. Don’t wait any longer, start 3D modeling today!

Whichever Autodesk software you choose, most of them allow for your 3D parts to be moved from virtual to solid reality. How? Thanks to 3D printing! If you have any questions about that, you can contact our 3D printing experts, who can advise you on 3D technologies and materials. When your 3D model is ready, it’s as easy as uploading your 3D file to our online 3D printing service!

Did you enjoy this article? Subscribe to our Newsletter.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

3 Useful 3D Printing Apps for Fusion 360

Additive Assistant tool for Fusion 360

You've probably already explored the 3D printing capabilities of Fusion 360, and if not, you're missing out. From FFF printing to metal powder additive manufacturing, Fusion 360 tools are evolving at a rapid pace, with even more new features coming towards the end of the year. Today, we're sharing three useful 3D printing apps available on the Autodesk App Store to help you take your additive manufacturing work to the next level.

Fusion 360 FFF Post Configurator

Download here

What it is: is an application that allows you to create and configure FFF post processors.

Who: for anyone who wants to customize their device settings for printing with preset custom messages.

How it works: you can easily load custom settings for printer platform temperature, heat-up timeout, fan speed and other options. Since the result of the configurator is a traditional JavaScript post-processor, advanced users will be able to modify it.

Addition: Check out the application's tutorial for more useful information about its features.

Autodesk Netfabb® for Autodesk® Fusion 360™

Download here

What it is: If you want to seamlessly transfer Fusion 360 models to Netfabb, this app will make the process as easy as possible. In addition, with it you will be able to send all print settings to Netfabb and Netfabb Simulation, including printer selection, support data and placement of parts on the platform.

To whom: Of course, this application is for those who already have a Netfabb subscription. However, if you are using Fusion 360 and want to take your AM work to the next level, Netfabb is the perfect companion tool, providing many advanced features and capabilities for AM. Imagine that you started setting up metal powder printing with the Fusion 360 Additive build extension and manually edited the supports in Netfabb. With this application, you can easily transfer all your data from one program to another.

However, if you are using Fusion 360 and want to take your AM work to the next level, Netfabb is the perfect companion tool, providing many advanced features and capabilities for AM. Imagine that you started setting up metal powder printing with the Fusion 360 Additive build extension and manually edited the supports in Netfabb. With this application, you can easily transfer all your data from one program to another.

Addition: If you want to learn more about Netfabb, visit the product page on our website and don't forget to watch the video below.

Additive Assistant Tool

Download here

What it is: We've been saving the best for last. Additive Assistant Tool allows you to analyze models without leaving Fusion 360: the application analyzes overhang angles, potential distortion and stability problems, can determine the size of the part, and also talk about the impact of its production on the environment.

How it works: Download the application, select the object you want to analyze, and the tool will automatically highlight problem areas that need your attention or need to be changed before being sent to print.

For whom: Any specialist will confirm that the human factor does not disappear with age and experience. The Additive Assistant Tool is a must for anyone new to additive manufacturing in order to understand what pitfalls to avoid, as well as advanced users. Often there are situations when 3D printing is used to create a prototype, and in the future the real product will be produced in a completely different way. In these situations, the Additive Assistant Tool will help ensure that the part prints with as few problems as possible.

Addition: The Additive Assistant Tool is useful if you need to determine where to add supports and modify part geometry to avoid deformation. The application gives a clear visualization of problem areas, which allows you to quickly eliminate them. The tutorial will help you learn more about the features of the app.

The tutorial will help you learn more about the features of the app.

Now that you have three powerful aces up your sleeve, it's time to get to work with Fusion 360 and put it to the test. We hope our tips will help you to significantly improve your projects. Join the official Fusion 360 VKontakte user community to stay up to date with the latest news about your favorite product.

Posted on 08 May 2021 2021-05-08 10:52:00

Preparing models for 3D printing within a single Autodesk Netfabb product

Before moving on to get acquainted with the declared program, let's say a few words about 3D printing.

3D printing is the process of creating three-dimensional objects on a 3D printer by printing material in layers based on a designed 3D model.

The Autodesk Netfabb program was created to prepare and simulate the 3D printing process, this article describes its main features.

- Geometry creation

There are two ways to get a model into Netfabb to prepare it for 3D printing: creating geometry directly in the complex using Fusion 360 cloud CAD or importing from other programs.

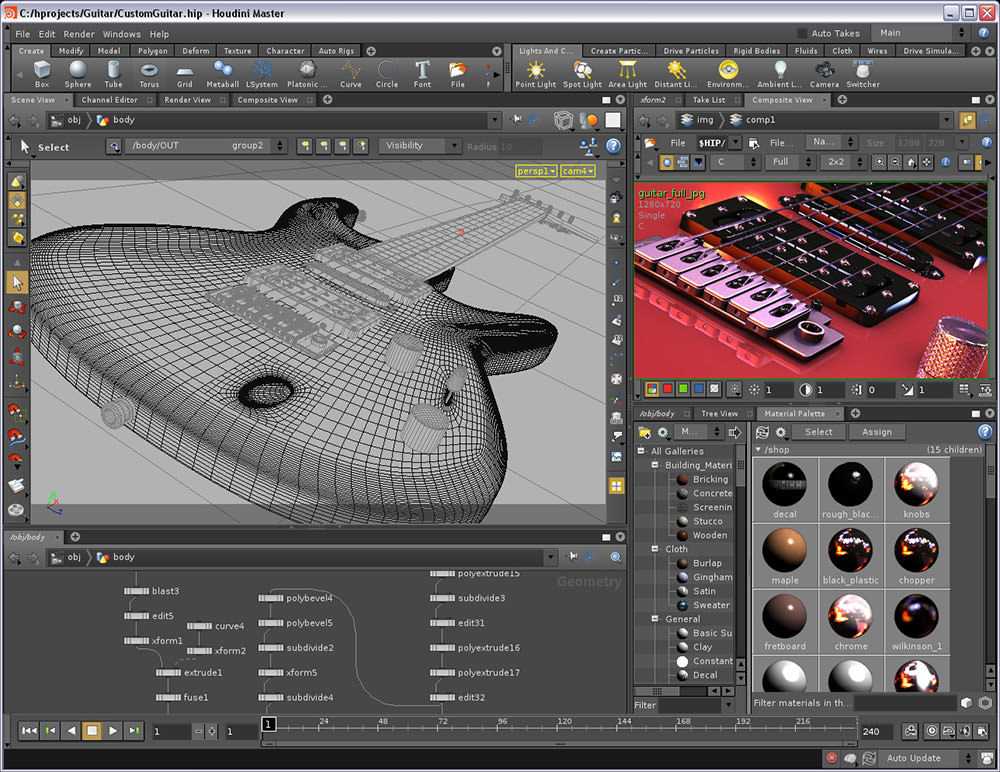

Fusion 360

The Ultimate and Premium versions already include Fusion 360, the Standard version must be purchased separately. With Fusion 360, the user has extensive modeling capabilities: free, surface, solid, parametric, mesh - as well as analysis and calculation tools, built-in Generative Design technology and CNC production preparation tools.

Import

More often than not, Autodesk Netfabb imports models. Design results from conventional CAD are uploaded to Autodesk Netfabb for further work. Here are some examples of CAD files supported by Netfabb directly in source format: Autodesk Inventor, Catia, Rhino, NX, ProEngineer, Autodesk Alias, and others. Geometry from other programs can be easily imported into Autodesk Netfabb using one of the many popular neutral file formats supported by the product, a partial list of which can be seen in the picture above.

Geometry from other programs can be easily imported into Autodesk Netfabb using one of the many popular neutral file formats supported by the product, a partial list of which can be seen in the picture above.

As for neutral file formats, their undoubted advantage is the support for many different 3D systems. But the downside of this popularity is that each program handles them differently, which can lead to various errors or inaccuracies when importing geometry. Of course, such geometry must be corrected before being sent to print. Autodesk Netfabb allows you to do this both manually and largely automatically.

Netfabb got direct access to Autodesk cloud storage and collaboration. The user shares a link that opens through the browser, and in any corner of the planet, another user will see the design solutions of colleagues.

- Optimization methods

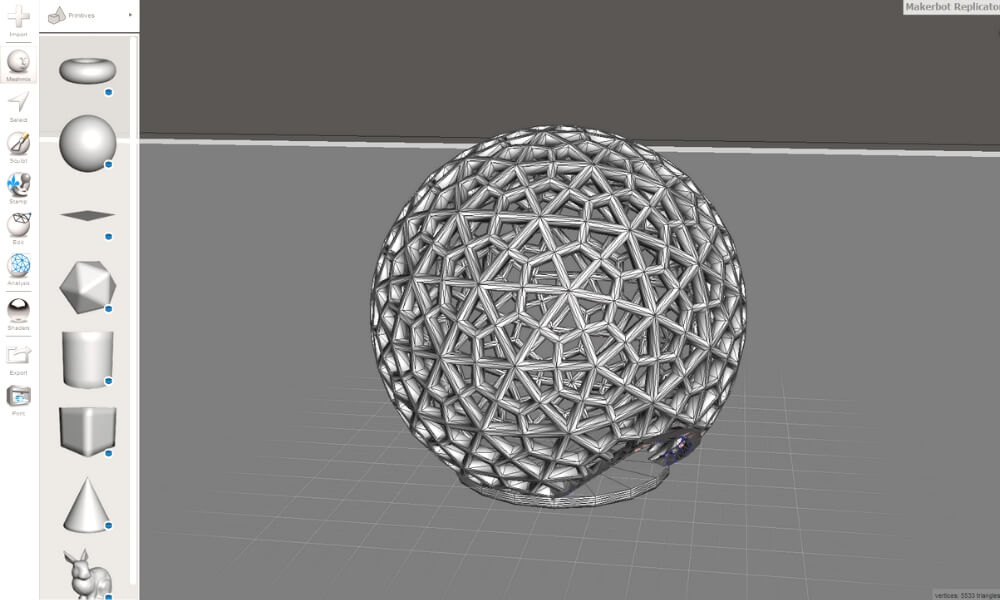

- Lattice structures

The main and most common optimization method is based on the fact that the internal volume of the model is filled with lattice structures. The concept of lattice structures is quite extensive, they can be both compounds of simple elements, and surface elements and their combinations. There are a number of built-in fill structure types, and there is an editor that allows you to generate new structure types. As a result, the model is lightened, the internal volume is filled with a weightless, but at the same time strong lattice, which is printed faster than monolithic volumes.

The concept of lattice structures is quite extensive, they can be both compounds of simple elements, and surface elements and their combinations. There are a number of built-in fill structure types, and there is an editor that allows you to generate new structure types. As a result, the model is lightened, the internal volume is filled with a weightless, but at the same time strong lattice, which is printed faster than monolithic volumes.

- Optimized Variable Density Lattice Structures

Netfabb also includes functionality to optimize a model with a lattice internal structure, resulting in the model becoming a system of shells of variable thickness, filled with lattice structures of variable density, optimized for the loads acting on the design model. Thus, the model is not only optimized for weight, but also provides the necessary strength within the specified limits.

- Topology optimization

Optimization is based on the Autodesk Nastran solver, which calculates and removes zones in the design part that do not contribute to the required strength, which makes it possible to lighten the final design.

- Generative Design

The user sets the general parameters of the designed part: search areas for a constructive solution, obstacle areas, fixed elements and zones, etc. In the given parameters, the program itself will suggest several forms of parts. The user will be able to choose the optimal form that meets the necessary requirements. This method calculates in Fusion 360.

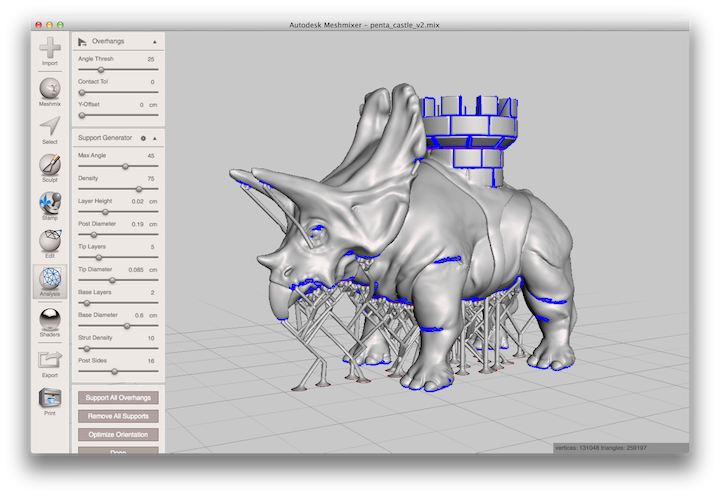

- Preparing to print model

- Part location

Autodesk Netfabb automatically selects the optimal position of the part in the workspace of the selected printer. The user sets the criteria for the optimal location of the model and the settings for its allowable change, after which the program will offer several optimal options, and the user will be able to choose the most suitable one.

- Creation of supports

The program can automatically create a support system of different types, for different technologies. Supports are edited for different requirements, and parts can be automatically updated as the position changes. Finely customized support types can be saved as a template for later use in other projects.

Supports are edited for different requirements, and parts can be automatically updated as the position changes. Finely customized support types can be saved as a template for later use in other projects.

- Automatic packing

Used when it is necessary to maximize the load on all equipment in production, increase the print speed and the number of manufactured parts. With this functionality, the working space of the printer is filled as densely as possible with a multitude of simultaneously printed parts. In doing so, Autodesk Netfabb will automatically enforce user-specified restrictions and seeding rules

- Extensive machine library

Autodesk Netfabb is connected to a large number of machines. The program knows almost all the most common machines on the market - this applies to the working space and the printing technology used. If, nevertheless, the used machine is not in the library, the user can set its parameters manually.

- Trajectory Fine Tuning Utility

Any 3D printer is essentially a CNC machine, but only with an additive tool. The utility offered by Autodesk Netfabb allows you to edit control programs for the printer in a visual form at a low level, including using the built-in programming language - LUA Scripts.

- Print analysis

3D printing, especially from metals, is a very expensive and time-consuming process, during which the user may encounter a number of problems:

- inaccurate 3D printing;

- fragility of materials;

- repeated adjustment of models and unsuccessful attempts to print;

- errors are detected too late.

To eliminate these problems, the Netfabb Simulation module is designed, which:

- simulates printing from metals;

- predicts possible problems;

- visualizes strains and stresses;

- compensates for deformations;

- protects the printer from damage.

Learn more