3D printed gun reddit

index - fosscad

- About

- Rules

- Where to find files

- Where to source parts

- Rail Kit Vendors

- Index of 3D printed firearms

- List of objects to print before printing firearms

- Beginner Guides and Tutorials

- Fusion 360 & FreeCAD tutorials

- FreeCAD

- Fusion 360

- TinkerCAD

- 3D printing and what it means for you

- Frequently Asked Questions and Approved Submitters

- Comprehensive Ender 3 New User's Guide

- Getting Started

- Printers

- Filaments

- Slicers

- Printing and Troubleshooting

- Further Info

- User Guides

- YouTubers

About

r/fosscad is a subreddit dedicated to the discussion of 3D printed guns and related topics.

Feel free to share your prints, ask questions, ask for help, and encourage others.

We are all here to learn and help!

FOSSCAD is a decentralized cluster of people and bots dedicated to the datalove of open source CAD, CNC, ECM (Electrochemical machining), 3d-Printing, awesomeness and firearms.

As a decentralized community, FOSSCAD has no members or leaders and has many definitions. FOSSCAD is sometimes referred to as The Order of the Third Axis. More definitions to follow. ALL Your CAD are belong to US!

RIP JStark <3

Rules

Keep posts on topic and high quality.

Be civil and don't troll.

Do not encourage, glorify, incite, or call for violence or physical harm against an individual or a group of people.

To combat spam, accounts must be at least 7 days old to post and comment.

Always research your country, state, and local laws before printing or downloading 3D files.

Do not share "3D printing files to produce firearms" per Reddit's content policy.

Do not ask others to print you something or offer to pay for others to print you something.

Where to find files

Per reddits rules, you cannot link directly to STLs or files relating to firearms parts that are regulated such as lowers.

If you are looking for files, load up Google or DuckDuckGo and search for any of the below exact phrases to get you started in the right direction and place

- Deterrence Dispensed - example https://duckduckgo.com/?q=Deterrence+Dispensed&t=h_&ia=web

- CTRLPEWs guide

- AWCY

- AWCY Odysee

- PrintYour2A

- FOSSCAD

- TheGatalog

- Defense Distributed

- Weight Forward & Gun CAD Ideas

- DEFCAD

Where to source parts

Coming soon (but most of the time just GunBroker and eBay)

Rail Kit Vendors

- Aves Rails

- Riptide Rails

Index of 3D printed firearms

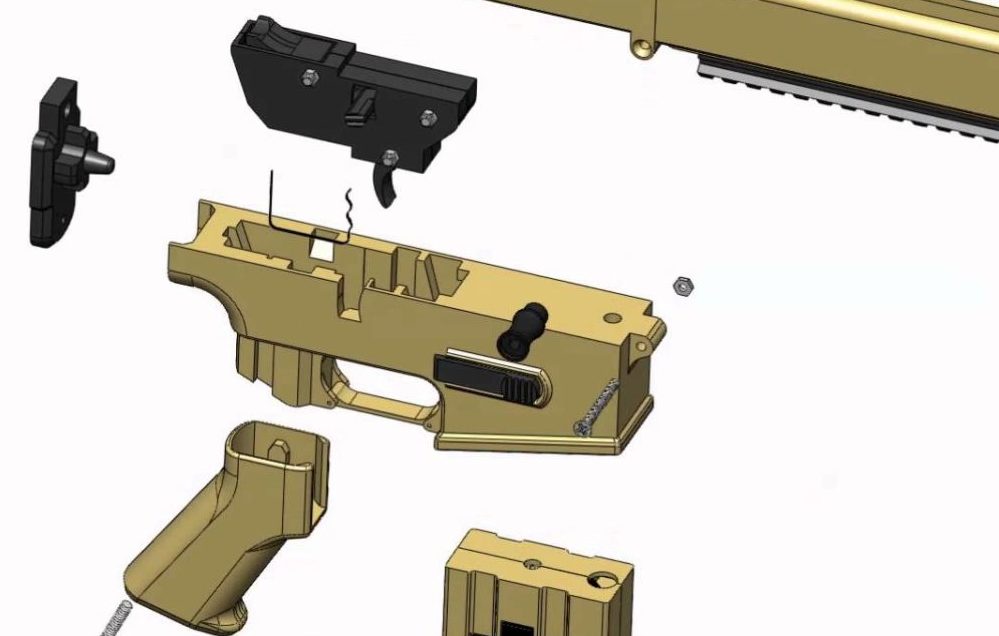

For the purposes of this index:

- Complete firearms are entirely printed/fabricated from basic consumer materials and contain few or no gun parts

- Hybrid firearms use several parts from one or more guns, but are more than just a printable receiver or substantially change the form-factor of the firearm.

- Gun parts are parts manufactured specifically as a firearm component and may be restricted in some jurisdictions

- Machined parts are metal parts that require any modification that can't be done with basic hand tools. Anything that requires special tools or is more complex than cutting to length with a hacksaw or drilling a simple hole with a hand drill is considered "machined".

https://www.reddit.com/r/Gunidex/wiki/index

List of objects to print before printing firearms

Printing these will help you become more familiar with your 3d printer and it's settings. You will want to have your machine and settings dialed in just right so that your future prints will come out perfect and functional.

Bed Leveling https://www.thingiverse.com/thing:2987803

Calibration Cube https://www.thingiverse.com/thing:1278865

Extrusion Test https://www.thingiverse.com/thing:1622868

Benchy https://www.thingiverse.com/thing:763622

Vase to check for z binding https://www. thingiverse.com/thing:72040

thingiverse.com/thing:72040

Baby Yoda for supports https://www.thingiverse.com/thing:4038181

Beginner Guides and Tutorials

Below are some phrases to Google or DuckDuckGo that will help you find popular guides in the 3d printing community that will get you headed down the right path.

- CTRLPEWs guide

- ferret's guide to printing with nylon

Fusion 360 & FreeCAD tutorials

FreeCAD

FreeCAD is an open-source parametric 3D modeler made primarily to design real-life objects of any size.

Website: https://www.freecadweb.org/

- https://youtube.com/c/FreeCADAcademy

- FreeCAD for Beginners pt.1 - UI, Sketching, Constraints, Extruding, and 3D Printing

- FreeCAD for Beginners pt.2 - Parametric Modelling

- FreeCAD for Beginners pt.3 - Importing and Editing .STL Files

- FreeCAD for Beginners pt.4 - Parts, Revolving, and Patterns

- FreeCAD for Beginners pt.5 - The Mirror Tool

- FreeCAD for Beginners pt.

6 - Extruded Text

6 - Extruded Text

Fusion 360

Fusion 360 is a cloud-based 3D modeling, CAD, CAM, CAE, and PCB software platform for product design and manufacturing.

Website: https://www.autodesk.com/products/fusion-360/overview

- Fusion 360 Tutorial for Absolute Beginners

- LEARN FUSION 360 FAST! A Beginner Tutorial - step by step instructions, no prior knowledge required

- Fusion 360 Tutorial For Beginners (QUICK & EASY) + Exporting for 3D Printing

TinkerCAD

Tinkercad is a free, easy-to-use web app that equips the next generation of designers and engineers with the foundational skills for innovation: 3D design, electronics, and coding!

Website: https://www.tinkercad.com

- TinkerCAD - Tutorial for Beginners in 9 MINUTES!

- [How to import an image into TinkerCAD(https://www.youtube.com/watch?v=NN8jvzm7D8s)

- TinkerCAD - Aligning Objects

- Tinkercad for Beginners - Easy 3D Modeling Guide)

3D printing and what it means for you

3D printing is the process of using a computer controlled assembly to move a nozzle along the X(left/right), Y(away from you/toward you), and Z(up/down) axes, through which filament is forced by extrusion and heat and thus transformed from a solid to a melted form. This new form is then layered onto a printer's bed. The heated nozzle assembly, known as a hot-end, moves along the X and Y axis to place a layer of melted plastic. Immediately after the heated plastic has been laid down, it is cooled by a fan or the ambient air temperature. On certain printers, the hot-end moves up one layer height after each layer has been printed and places a new layer on top of the previous one. This is how fused deposition modeling (FDM) 3D printers like the Creality Ender 3 work.

This new form is then layered onto a printer's bed. The heated nozzle assembly, known as a hot-end, moves along the X and Y axis to place a layer of melted plastic. Immediately after the heated plastic has been laid down, it is cooled by a fan or the ambient air temperature. On certain printers, the hot-end moves up one layer height after each layer has been printed and places a new layer on top of the previous one. This is how fused deposition modeling (FDM) 3D printers like the Creality Ender 3 work.

Many individuals in the general firearms community might question the value of 3D printing when there are alternatives like milling 80% finished receivers or even building guns out of hardware materials. The answer to that is that 3D printing offers an ease of access that is unparalleled in the practice; it is the simplest possible way for the average person to obtain a gun. Very little skill is involved in loading data onto a printer and having it make parts, thus ensuring that everyone has the freedom to keep and bear arms. And with its pleasing simplicity and related activity — new designs are being created by the day — legislators everywhere are receiving the message that the people will always be one step ahead of the politicians.

And with its pleasing simplicity and related activity — new designs are being created by the day — legislators everywhere are receiving the message that the people will always be one step ahead of the politicians.

Frequently Asked Questions and Approved Submitters

Check out the FAQ for some answers to common questions and misconceptions regarding 3D printing guns. If you would like to become an approved submitter and contribute to this wiki, please follow the process outlined here.

Comprehensive Ender 3 New User's Guide

While this wiki is a general source of information that caters to users of all 3D printers, a more in-depth guide has been made specifically for the Ender 3 and pertains directly to the gun parts designs that will be printed. If you're an Ender 3 user or plan to be one, use this guide in addition to the resources here in order to successfully start printing.

Getting Started

Read over

https://old.reddit.com/r/3Dprinting/comments/lv818a/purchase_advice_megathread_what_to_buy_who_to_buy/

The 3D printing process is fairly simple and involves these basic steps:

- Get a digital 3D model (by downloading or making one)

- Slice it (use a program to generate instructions for the printer)

- Print it (and troubleshoot it)

- Post-process it (remove support material, clean up areas, etc.

)

)

Use the following information to help you choose a printer, filament and slicer.

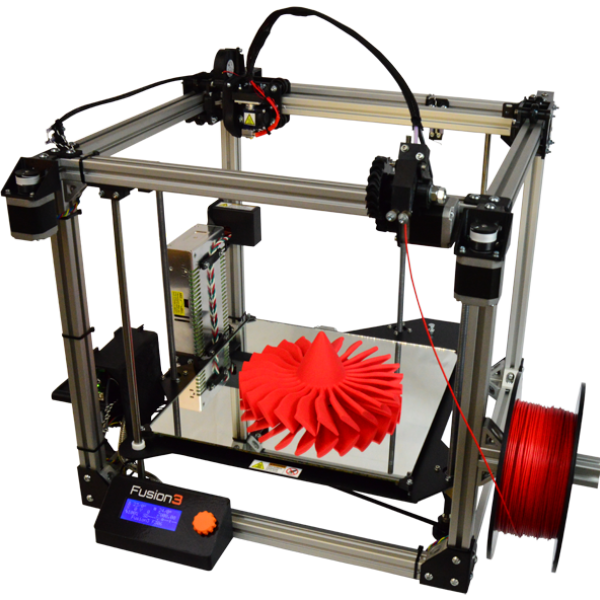

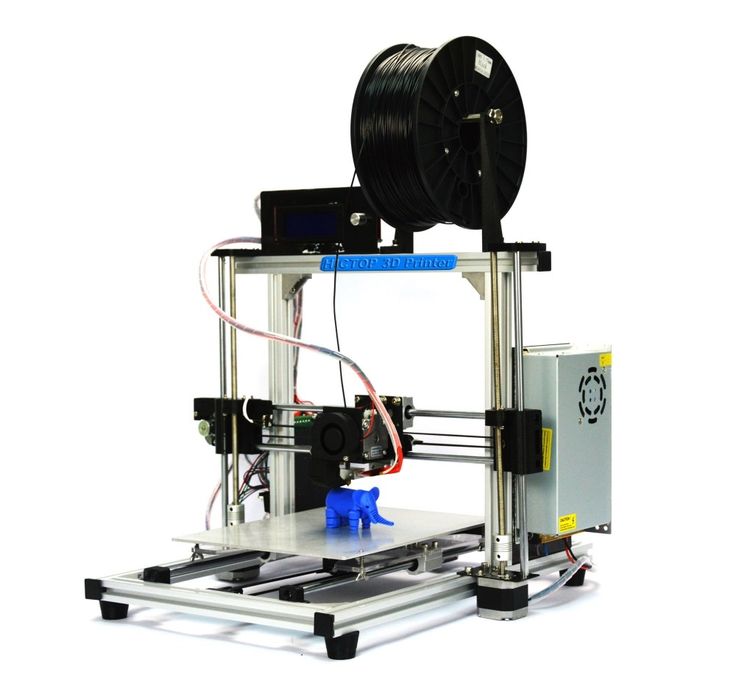

Printers

There are numerous 3D printers available on the market, but only a few are of particular and pertinent value to the hobby. These printers are the Creality Ender 3 and the Prusa i3 MK3S, with the former being the entry level budget model and the latter usually used for higher-end printing. The following is a table with more information about them:

| Price | Item | Description |

|---|---|---|

| $150-$200 | Creality Ender 3 | If you're new to 3D printing and don't intend to print a great variety of items, the Ender 3 is perfect for a beginner. It's generally considered to be the cheapeast "real" 3D printer and can regularly be found around the $175 mark. Most of the lastest 3D printed gun designs are made with the Ender 3 in the mind, so you'll typically never have to worry about a design not being a match for the printer. Most of the lastest 3D printed gun designs are made with the Ender 3 in the mind, so you'll typically never have to worry about a design not being a match for the printer. |

| $160-$230 | Creality Ender 3X | The 3X is an upgraded model of the Ender 3, with its biggest selling point being the tempered glass print bed that comes packaged with it. The glass bed is often touted as the most necessary upgrade part for the stock printer, and the 3X conveniently comes with it. This version also comes with an MK-10 extruder, which reduces the risk of clogging and uneven extrusion. The 3X can occasionally be found on sale for prices as low as the regular Ender 3, so this model is always recommended if it can be purchased at a discount. |

| $180-$250 | Creality Ender 3 Pro | This pro version of the Ender 3 comes with a number of minor improvements, including a larger aluminum extrusion and a better power supply. However, it's conventionally not recommended over the standard model. The improvements do not substantially add to the value of the printer like the 3X. However, it's conventionally not recommended over the standard model. The improvements do not substantially add to the value of the printer like the 3X. |

| $400-$450 | Creality CR-6 SE | Slightly larger build plate 235 x 235 x 250 mm. Auto bed leveling. |

| $350-$450 | Creality CR-10 | Large build plate 300 x 300 x 400mm. Auto bed leveling. |

| $749 | Prusa i3 MK3S | The MK3S is all-around better than all of the Ender 3 models. It prints faster, it has an all metal hot end for printing nylon, it comes with an auto-leveling bed, and a lot more. Additionally, it can be bought already assembled for an extra cost. If you're not printing on a budget and would like a well reviewed and tested 3D printer, then the MK3S is for you. |

Overall, the original Creality Ender 3 is the recommended model to buy, and it will also be used as a reference in this wiki. Moreover, it's supported by our guide that can help even newcomers to the hobby start easily printing.

While there are many more 3D printers not listed here, the ones presented are widely considered the best for 3D printing gun designs.

Filaments

See also: List of 3D printer filaments

Many types of plastics are available for printing. The most popular and affordable (<$13/lb) are PLA, ABS, and PET-G.

- PLA is a bioplastic and is known as a very easy plastic to print. This is because it has one of the lowest levels of "thermal shrink," causing it to have less warping and curling as it cools down. It can even be printed without a heated bed. Strength-wise it does well, especially if it is annealed. It is very rigid and its typical failure mode is relatively sudden breaking. PLA is also not very temperature-tolerant in its unannealed state and as such is unsuitable for prints which may be exposed to high temperatures (like the hot interior of a car in summer, for example).

Nonetheless, PLA and PLA+ is still recommended as the best filament to use for 3D printing gun parts.

Nonetheless, PLA and PLA+ is still recommended as the best filament to use for 3D printing gun parts.

Most 3D printed guns will use PLA+. A popular brand is eSun PLA+. Available on Amazon.

ABS is a very common engineering plastic which has been adapted for 3D printing. It requires ventilation of the room it is printed in due to its unpleasant fume emissions while printing. It is also known for warping if printed outside a stable temperature enclosure. ABS is printed at higher temperatures that are near the threshold of not being printable with PTFE-lined hot ends and requires very hot heated bed temperatures (90°C). That being said, it has a less abrupt failure mode than PLA, is more temperature tolerant, and is stronger by some measures. Finally, you can use acetone to both vapour smooth and weld ABS parts together.

PET-G is the most popular copolyester for 3D printing and basically consists of PET known from plastic bottles + glycol. The addition of glycole increases printability but worsens mechanical/thermal properties.

PET-G usually is more flexible than PLA and ABS and can withstand heat up to ~75°C, which lies right in between the two other plastics. Further properties include a good chemical resistance, high translucency, a shiny surface, and very good layer adhesion. PET-G is available for print temperatures of 210-260°C and requires a heated bed of ~70°C. Part cooling fan can be used but strongly affects layer adhesion in a negative way. One common issue with printing PET-G is its tendency to string, which causes blobs of molten plastic on the nozzle that can drop on the print. This eventually causes uneven surfaces on the printed part. Countermeasures include increased retraction, a steady print speed, a disabled part cooling fan and slight underextrusion.

PET-G usually is more flexible than PLA and ABS and can withstand heat up to ~75°C, which lies right in between the two other plastics. Further properties include a good chemical resistance, high translucency, a shiny surface, and very good layer adhesion. PET-G is available for print temperatures of 210-260°C and requires a heated bed of ~70°C. Part cooling fan can be used but strongly affects layer adhesion in a negative way. One common issue with printing PET-G is its tendency to string, which causes blobs of molten plastic on the nozzle that can drop on the print. This eventually causes uneven surfaces on the printed part. Countermeasures include increased retraction, a steady print speed, a disabled part cooling fan and slight underextrusion.Nylon: Actually polyamide which comes in many different variations (PA6, PA12, PA6/6, etc...). General properties are a very usable balance between stiffness and flexibility, superior layer adhesion and good temperature resistance (~70-180°C).

Some types of nylon require specific build plates (phenolic-paper, garolite or compressed wooden boards, etc...) while others print on a glass bed at room temperature. Part fans should always be turned off as it affects layer adhesion and increases warping. Typical hotend temperatures are 250-270°C, therefore making nylon require a high temperature hot end. Most nylon grades are very susceptible to humidity and need to be stored dry.

Some types of nylon require specific build plates (phenolic-paper, garolite or compressed wooden boards, etc...) while others print on a glass bed at room temperature. Part fans should always be turned off as it affects layer adhesion and increases warping. Typical hotend temperatures are 250-270°C, therefore making nylon require a high temperature hot end. Most nylon grades are very susceptible to humidity and need to be stored dry.

Slicers

See also: List of slicing software

Slicing software takes a 3D model and turns it into instructions for the 3D printer. The instructions are generally exported in GCode, which essentially is a list of locations to move to, the amount of filament to extrude, and so on.

The popular choices for slicing software are:

- Ultimaker Cura: free, open source, highly customisable. Getting Started, Full Manual

- Prusa Slicer (Based on Slic3r). Beginning with Prusa Edition

There are, however, many other options, most of which are discussed in the list of slicing software linked above.

Be sure to check the layer preview to see if it makes sense in your slicer before printing (no unsupported overhangs, no parts missing, etc.)

Printing and Troubleshooting

Files to 3D printable gun parts cannot be linked in this wiki, this subreddit, or anywhere else on Reddit due to the site's recently updated content policy. In addition, specific instructions on how to 3D print gun parts cannot be provided. However, this section can serve as a troubleshooting guide for the printing process itself.

Follow your manufacturer's instructions in setting up your printer and starting your first print. It's a good idea to print a test print first (usually printers come with one). If it succeeds, then you can move onto slicing and printing your own models or some calibration prints. If your first print fails, then you can begin troubleshooting.

By far the most common reason for prints failing is an issue with leveling/tramming:

This visual reference and this video may also help.

Once you have your prints sticking and printing, these guides can help you identify and solve any other issues you're experiencing:

Our Troubleshooting and Calibration wiki page

A Printa Pro PrintaGuide

rigid.ink visual guide

Matterhackers Troubleshooting Guide

Simplify 3D Visual Troubleshooting Guide

Ultimaker Visual Troubleshooting Guide

It's also worthwhile seeking information from the manufacturer of your machine.

If the above suggestions don't solve your issue, then it's time to seek help from the r/fosscad community. Here is what a good help post should have:

A highly descriptive title

Photos of the issue, screengrabs of the layer view in your slicer, screengrabs of the model itself

A description of what the machine was doing as it produced this issue

Your basic settings such as: nozzle and bed temperature, speed, nozzle/line width and later height, the printer you're using and the material you're printing in.

Or better yet, a screengrab of your settings

Or better yet, a screengrab of your settingsAny other information you think could be relevant such as modifications or hypotheses.

The following links are for user guides created by approved submitters. Please ensure that all information therein is correct.

User Guides

If you would like to become an approved submitter and contribute to this wiki, please follow the processoutlinedhere.

YouTubers

- IvanPrintsGuns

- Print Shoot Repeat

- Booligan Shooting Sports

- CTRLPew

- Mr Snow Makes

- AG Cast

- PSR Clips

- P80 Ralph

- The 3D Print General

- SmokieShootShoot

- /r/DIYGuns/

- /r/3DPrintGuns

- /r/GhostGunner

- /r/Gunsmith

- /r/Gunsmithing

- /r/Reloading

- /r/printedguns

- /r/firearms

- /r/guns

- /r/liberalgunowners

Please check out my new subreddit "3D Print Guns" (I have permission from mods) : Firearms

Please check out my new subreddit "3D Print Guns" (I have permission from mods) : FirearmsLooks like you're using new Reddit on an old browser. The site may not work properly if you don't update your browser ! If you do not update your browser, we suggest you visit old reddit .

The site may not work properly if you don't update your browser ! If you do not update your browser, we suggest you visit old reddit .

Press J to jump to the feed. Press question mark to learn the rest of the keyboard shortcuts

Search all of RedditFound the internet!

Firearms

r/Firearms

8 comments

63% Upvoted

View discussions in 2 other communities

About Community

r/Firearms

Discuss firearms, politics, 2nd amendment news. We value freedom of speech as much as we do the right to keep and bear arms. Posts must be somewhat related to firearms and must comply with the Global Reddit Rules.

Created Jul 22, 2010

221k

Armed Citizens

763

Online Now

Similar to this post

r/Firearms

"No on wants to take your guns you paranoid.

..

..94%

290

1d

r/Firearms

Always stay strapped

96%

46

3d

r/Firearms

Best $37 dollars I've ever spent, won a raffle.

93%

114

2d

r/Firearmsnsfw

Reminder to train malfunctions

97%

205

6d

r/Firearms

Thankful to be an American…

74%

512

4d

r/Firearms

Shower thought: the funniest thing about “deer don’t wear...

95%

183

5d

r/Firearms

These people are dumb crazy!!! They just call anyone and...

76%

415

3d

r/Firearms

What do your squirrels carry?

99%

25

5d

r/Firearms

Ah, wouldn’t be surprised if they’ve been doing this for.

..

..96%

107

4d

r/Firearms

Drinking game: go to r/news and take a shot for every...

88%

327

6d

r/Firearms

Never let them take your guns

94%

133

15h

r/Firearms

Sir, there might be something wrong with your EOTech...

98%

117

5d

r/Firearms

these British Amazon reviews for a baseball bat

98%

210

3d

r/Firearmsnsfw

oh you wanna kidnap me? how cute(Girl with a concealed...

98%

99

2d

r/Firearms

We need to talk about your flair...

94%

32

2d

Reddit and its partners use cookies and similar technologies to provide you with a better experience.By accepting all cookies, you agree to our use of cookies to deliver and maintain our services and site, improve the quality of Reddit, personalize Reddit content and advertising, and measure the effectiveness of advertising. By rejecting non-essential cookies, Reddit may still use certain cookies to ensure the proper functionality of our platform.For more information, please see our Cookie Notice and our Privacy Policy .

By rejecting non-essential cookies, Reddit may still use certain cookies to ensure the proper functionality of our platform.For more information, please see our Cookie Notice and our Privacy Policy .

Advertisement

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability.

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

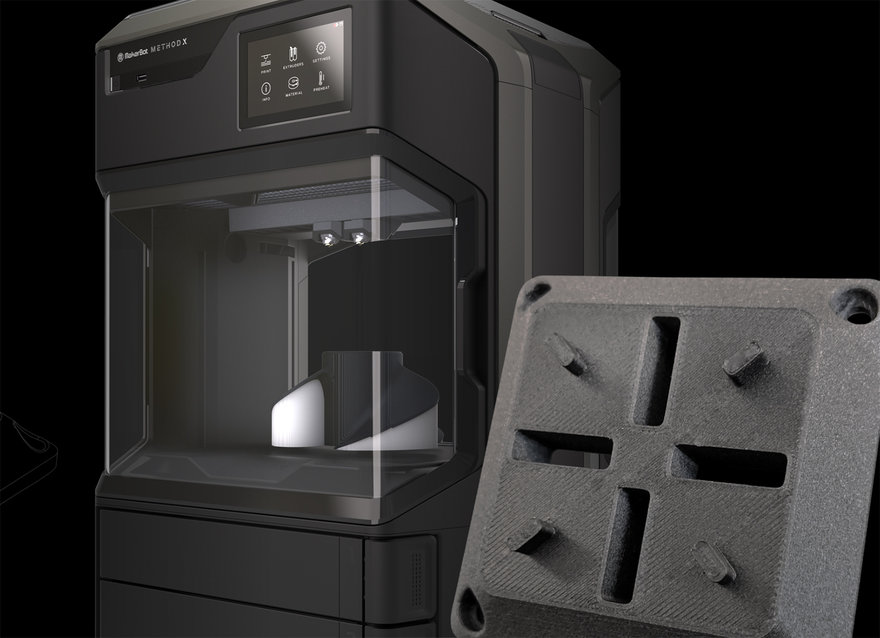

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale production. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas.

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

Custom heads for LEGO men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

3D Printed Chaplain

Chaplain 3D model from Warhammer 40k

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

DC Universe Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

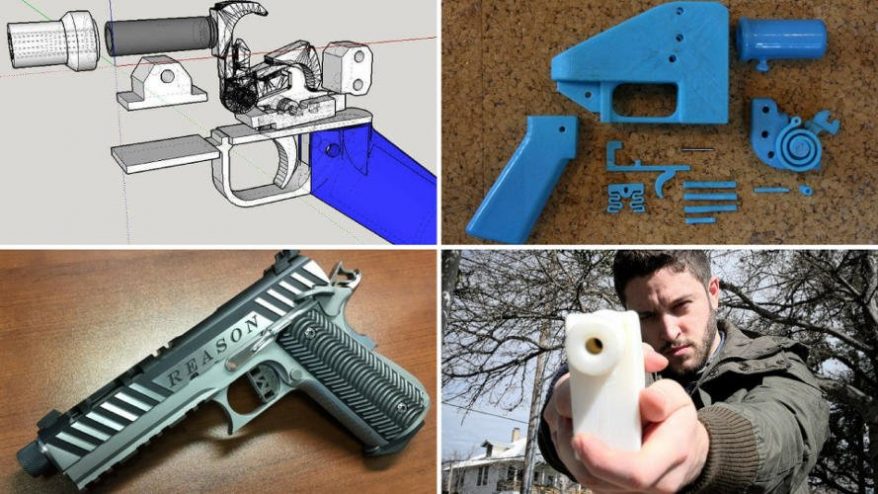

Weapon Seal

Seal of weapons

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer.

The first printed pistol was made on a Stratasys Dimension SST 3D printer.

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a fairly weak .380 ACP round and could only last a dozen rounds at most.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan.

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip.

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0063

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez.

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the strength of the plastic was not enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle.

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts are modeling and posting models and detailed instructions for assembling traction prosthetic hands and fingers in the public domain so that any user can print and make a prosthesis at home.

Simple Traction Hand Model

Production

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased.

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Prototyping

Gas turbine prototyping.

Prototyping by traditional methods is often time-consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing.

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production. After all, the production of traditional stencils with filling in molds took up to 5 weeks, and the 3D printed model is ready by the morning.

Totals

Despite the unethical side of 3D printing, there are still more positive use cases. 3D printers have become indispensable assistants in various industries - from home hobbies to serious industries. With the help of 3D printers, unique products are made that could not be obtained using other machines.

Popularization of 3D printers is a matter of time. But do not forget that 3D printing is just a tool, just like a drill or a hammer. It depends only on the user how it will be used.

Redditor recreated the GTA Online Up-n-Atomizer using a 3D printer

Redditor created the iconic GTA Online Up-n-Atomizer in real life using a 3D printer. This version looks almost the same as the in-game weapon. A whimsical retro-futuristic pistol that looks more like a toy than a real weapon, the 3D printed model looks quite believable.

This iconic weapon is often used against griefers in the game, but its high price means newbies can't afford it. The Up-n-Atomizer does not appear to be a lethal weapon as it simply disables vehicles and launches NPCs (and other players) back without killing them instantly.

The Up-n-Atomizer does not appear to be a lethal weapon as it simply disables vehicles and launches NPCs (and other players) back without killing them instantly.

Reddit user heutemalnicht posted this recently on the r/gtaonline subreddit. In the OP's post (original poster) can be seen with a 3D printed gun with slight color differences from the original in-game weapon.

The Up-n-Atomizer is seen more as a useful tool than a weapon. This is not fatal and can be a great help when players get stuck somewhere. The way these weapons work is very similar to the sonic weapons in other video games such as Saints Row The Third.

It knocks back any vehicles, NPCs or other players in its path. The weapon is designed like a stereotypical raypunk pistol, but its bright blue and neon yellow color makes it look like a child's toy. Players often use this weapon to shoot down Oppressor Mk II griefers.

The in-game price for Up-n-Atomizer is ridiculous. It can be purchased from AmmuNation for $399,000, making it one of the most expensive weapons in GTA Online. However, given its usefulness, most players do not hesitate before buying it.

However, given its usefulness, most players do not hesitate before buying it.

Another Redditor poked fun at Rockstar's recent hostility towards its fans when mods were shut down after receiving DMCA notices. In fact, Take-Two Interactive, the parent company of Rockstar Games, became something of a laughingstock after they decided to sue Hazelight for their It Takes Two game.

So the above comment may seem funny at first, but judging by the way things are, it could easily turn out to be true.

Players can still get in trouble for making these things and then selling them in large quantities. However, this is not something that most players need to worry about.

This isn't the first time someone has recreated the Up-n-Atomizer from GTA Online.