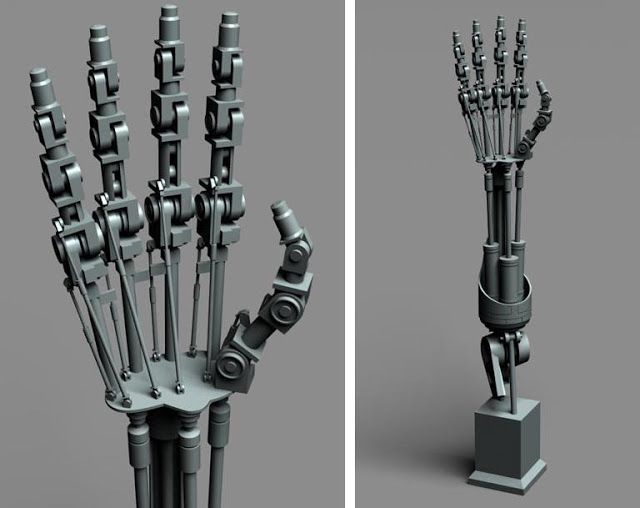

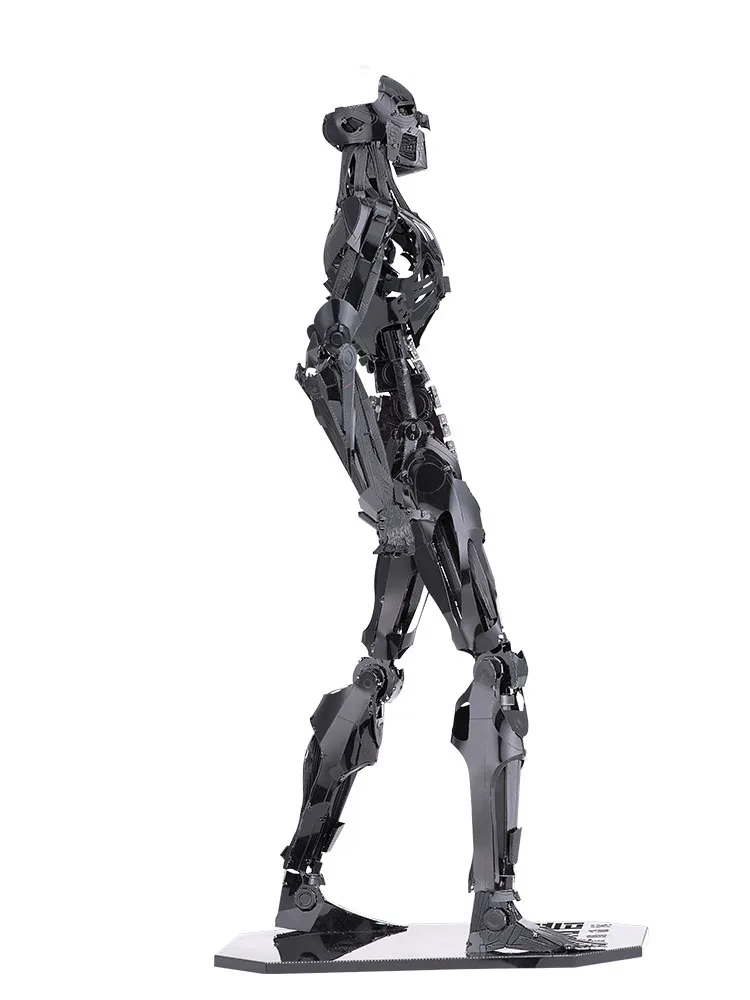

3D printed terminator hand

3D Printed Functional Terminator Hand

Explore how Anthony Williams, our April Hacker of the Month, designed his 3D printed mechanical Terminator hand replica.

Rhonda Grandy

April 6, 2017

For the most part, we all know that you can make some really cool stuff thanks to 3D printing. Anthony Williams, our April Hacker of the Month, makes cool stuff and takes it to the next level by creating awesome videos during his design, printing, and building process. His most recent endeavor: a working mechanical Terminator hand replica.

Video of the assembly and control of the Terminator hand

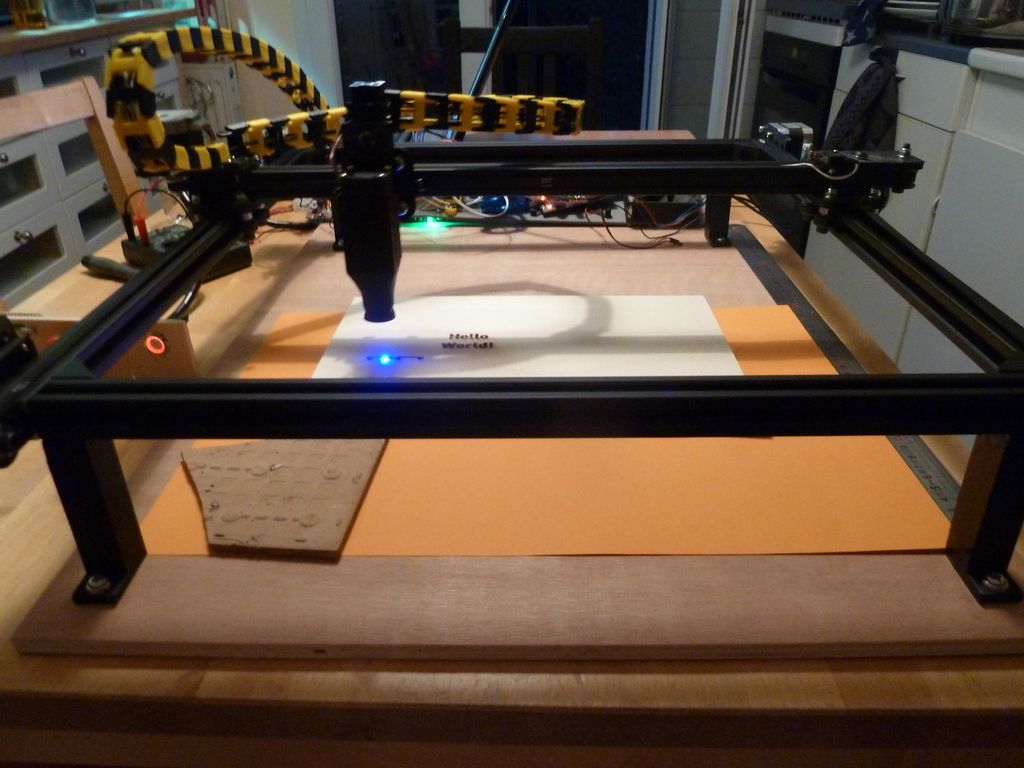

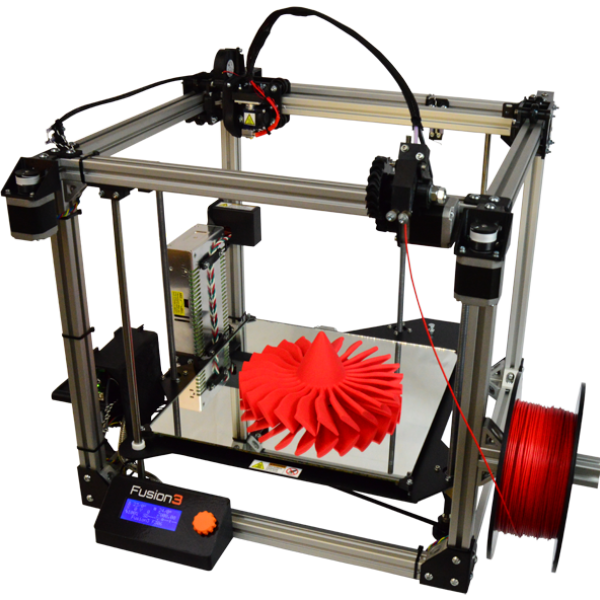

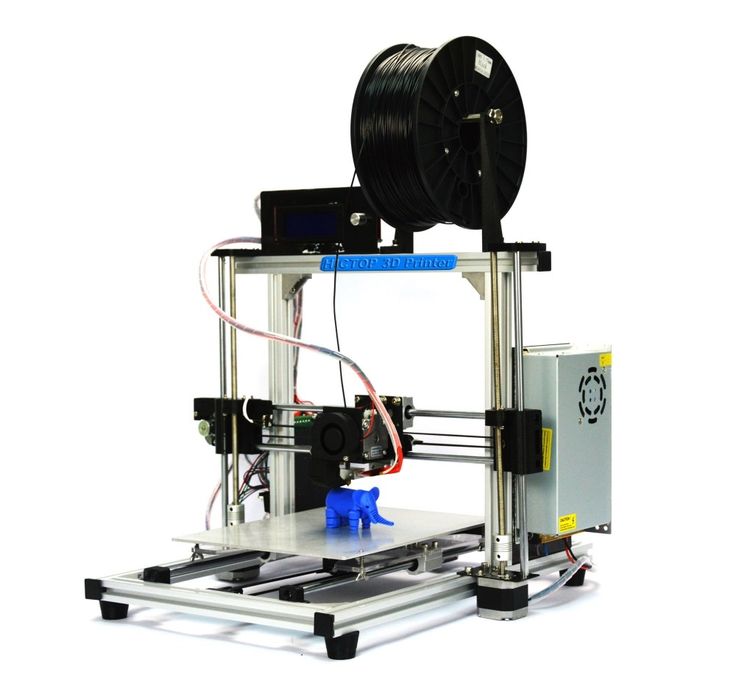

Williams, a 3D animator and modeler from Johannesburg, South Africa, first heard about 3D printing in the early 90's and dreamed of owning one ever since. With improvements in the technology that now dominates most of our lives, and the fact that 3D printers are more affordable than ever, he decided it was time to invest in one. Just over a year ago, he purchased the Ultimaker 2.

"As a maker and inventor, I always wanted to be able to hold my 3D creations as I do with woodwork or metalwork, so it seemed logical to own a 3D printer," explained Williams, adding that, "when it arrived, it was the unboxing of a new set of skills."

Printing away on the Ultimaker 2

As we've probably all experienced when discussing 3D printing, a few misconceptions are usually brought up by people that have not experienced the capability of the machines. Some of these misconceptions tend to be that they are slow, can only use plastic, and that they are small. Williams has the perfect response to debunk the nonbelievers:

"People said 3D printing was slow, but something that would have taken me hours or days to craft by hand was now appearing in front of my eyes in minutes! People also say, 'Ah yes, but it’s just plastic and brittle,' but my answer is, does it matter? It’s a prototype, don’t be too fussy, you can make a mold and make hundreds if you want. One other misconception I had was that 3D printers are small, so what can you really make? Most things we use in daily life are small enough to fit in your hand. Many things are made of many small parts, so I learned that size is not really an issue."

One other misconception I had was that 3D printers are small, so what can you really make? Most things we use in daily life are small enough to fit in your hand. Many things are made of many small parts, so I learned that size is not really an issue."

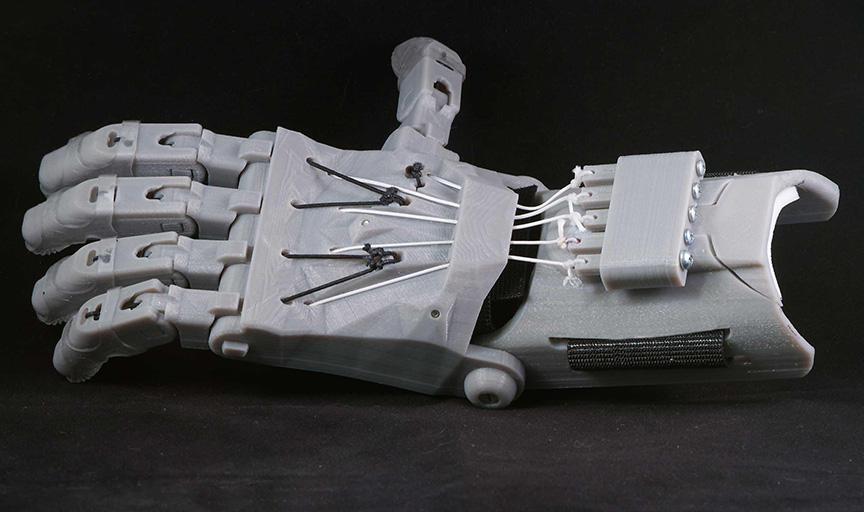

Terminator hand being controlled by a single wire

Not only is his above answer to 3D printing criticism the perfect justification, his mechanical Terminator hand replica is solid proof that anything is possible with 3D printing.

He had been wanting to build a Terminator hand since he first saw the original movie. Williams is a big fan of 70's, 80's, and 90's movie prop designers. "In the early 90’s, I tried to make a steel version by hand that could be used as an arm extension for turning hot coals. The result is pretty ugly and heavy, so I shelved the idea," said Williams, "but after getting my 3D printer, I realized it was possible to build it properly, using a similar lever method to what they used in the first movie. "

"

"I decided that it must be a working mechanical replica, and the fingers should open and close using only five strings, which could be operated by the user via a base control system , or via a lever in a future e-NABLE design that I will be working on," said Williams.

The early 90's attempt of the hand made of steel

By using levers, all joints on the fingers move evenly, and open and close with a single wire. In the closed position, the fingers “lock” due to the leverage angles, thus granting it to carry loads with very little effort. "The next step is to improve and strengthen the design and share it with the e-Nable community," stated Williams. The Terminator hand and mechanics would definitely be an excellent (and welcome) addition to the e-NABLE fleet.

Video of the design process

Williams used ABS filament to make the printed components of the hand because it is strong and you can use acetone to do some post-processing finishing. "I used ABS so that I could solvent weld the pieces easily using acetone," he explained, adding that "acetone can also be painted on in a thin layer after a light sanding to weld the surface layers and achieve a nice glossy finish. The trick is to not use too much, and to let it dry thoroughly between layers. I only paint it once or twice max."

"I used ABS so that I could solvent weld the pieces easily using acetone," he explained, adding that "acetone can also be painted on in a thin layer after a light sanding to weld the surface layers and achieve a nice glossy finish. The trick is to not use too much, and to let it dry thoroughly between layers. I only paint it once or twice max."

"My 3D printer literally helps me daily," raved Williams, "it’s brilliant for things like key-rings, gate remote covers or figurines, but also for very useful things like adjustable reflectors I designed to “zig zag” my security sensor beam around my house, or bubble & valve systems for my pond, or a pool broom connector for my sister." Williams clearly knows that the potential uses of a 3D printer are unlimited.

"In my opinion, 3D printers are an essential tool for any 3D artist or designer. New software and tools are making it easier for anyone with little or no 3D knowledge to start creating, so I would love it if every child was taught a basic 3D program and given access to a printer," said Williams. We definitely agree.

We definitely agree.

To check out more of Williams' cool projects, visit his YouTube channel Ants in Africa.

Want to be our next Hacker of the Month? Email [email protected], and tell us about your 3D printed creation - you could be featured in our next newsletter. Hacker of the Month wins 3 free spools of PRO Series PLA or ABS filament to further their pursuit of 3D printing greatness.

Free STL file Terminator Arm with container・Object to download and to 3D print・Cults

Gland Connector 19mm

€1.05

Emergency stop button for 3 phase manual motor starter

€1.26

AC MOTOR FAN 30 mm Shaft

€3.02

Micro SD Card Puller

Free

Laser Air Assist Nozzle for 33x33 mm laser diode housing.

Free

Dacia Duster master key button

Free

MK8 Extruder part cooling 30mm fan mount.

Free

X Wing Kit

Free

Best 3D printer files of the Art category

Cute Flexi Print-in-Place Skeleton

€2.96

Tiny Arcade ornament

Free

The Joyful Yell

Free

Other festive cache pot

Free

Up Cycle Spool Planter

Free

Deactivated

attack on titan

€8

Best sellers of the category Art

Baby Crystalwing Dragon, Cinderwing3D, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

€4.01

Cute Flexi Print-in-Place Frog

€1.96

Bearded Dragon Articulated Toy, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3. 41

41

Biting dragon

€3

ZOU GHOST - GHOST WITH LEGS

€2.88

Biting Archaeopteryx

€3

Rose Dragon, Valentine's Day, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

€4.07

CUTE FLEXI PRINT-IN-PLACE CROCODILE

€2.96

Flexi Print-in-Place Astronaut

€2.96

Articulated axolotl

€3.50 -15% €2.98

Funny Skull Mask for Halloween

€1.26

Cute Flexi Print-in-Place Sloth

€2.96

Cute Flexi Print-in-Place T-Rex Dinosaur

€2.96

Cute Flexi Print-in-Place Circus Elephant

€2.96

Flexi Print-in-Place Foot

€1. 96

96

Flexi Print-in-Place Brachiosaurus Dinosaur

€2.96

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

New generation 3D printed prosthetic hand

Archive

which performs the function of a prosthesis.

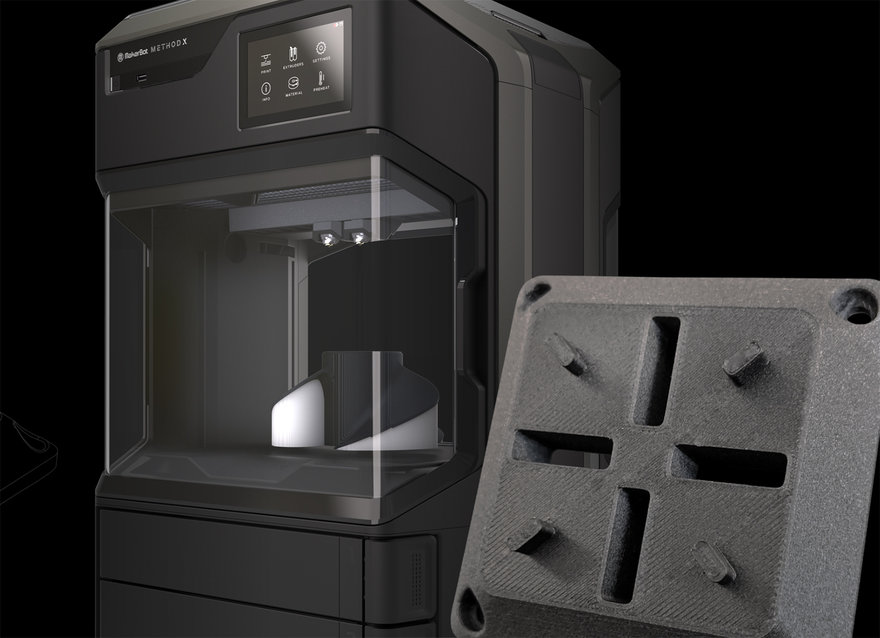

This exhibit is living proof of the high level of modern 3D printing. You have probably already read the news about how 3D printing devices help in the medical field and prostheses printed on such devices surprise patients less and less. Very soon, robotic arms will be recreated on 3D printers in a couple of minutes, making life easier for people with disabilities.

This exhibit is living proof of the high level of modern 3D printing. You have probably already read the news about how 3D printing devices help in the medical field and prostheses printed on such devices surprise patients less and less. Very soon, robotic arms will be recreated on 3D printers in a couple of minutes, making life easier for people with disabilities. As for the "Terminator Hand", it also testifies in favor of the fact that a technological breakthrough greatly affects the life of a modern citizen by saving time, money and materials.

“Modern 3D printers mostly use only one consumable and this greatly limits their capabilities. You can create complex geometric shapes, but they will still remain in a passive state. A prototype prosthetic arm was created to showcase the future of 3D printing. We want to make the recreated 3D models more functional to serve humanity. It would be much easier if a 3D printer could print a mobile phone with a touchscreen and chips,” said Professor Richard Haig, leader of the 3DPrinting Research Group.

So far, this prosthetic arm is just a working exhibit. But modern 3D printing has already provided some lucky ones with prostheses. For example, the Robohand project, the details of which can be found on this page. The creator of this Robo-arm has posted the CAD files on the Internet and now anyone can download them.

The Unsealed Terminator Arm is an improved version of the Robo Arm. Professor Haig hopes that soon he will be able to establish, if not mass, then at least local production of this prosthesis. We hope that very soon this device will be available to everyone.

Article prepared for 3DToday.ru

Follow author

Follow

Don't want

Even more interesting articles

7

Subscribe to the author

Subscribe

Don't want

So, you are thinking about the possibility of making money on 3D printing. How realistic is this? Quite, although the way...

How realistic is this? Quite, although the way...

Read more

3

Subscribe to the author

Subscribe

Don't want

Recently, cloud-based 3D printing services have been developing. This concept allows the implementation of...

Read more

3

Subscribe to the author

Subscribe

Don't want

Today, more and more RepRap 3D printers based on modeling technology appear on the market ...

Read more

what 3D printers can do. "Paper"

August 22, 2014

The first person with a 3D-printed bionic prosthesis and the author of the open-source InMoove robot project talk about how fablabs will help people.

Gaël Langevin

Author of the French open-source project InMoove

— The InMoov project appeared in 2012 when I bought a 3D printer. My wife was against this purchase and kept saying: why do you need it, they say, you will print some little rabbits on it only. However, something more came up. InMoov is a robot project that is 95% is 3D printed and can be reproduced by anyone at home. Since this is an open-source project, there are already about 120 clones in the world: there is one in Russia, Spain, Germany, and so on. The bottom line is that we can create such a robot and program it as we please. The project started with the fact that I printed a hand, which consists of palms and fingers, and posted the project on the Internet. There appeared a lot of people who became interested in it, and the hand project was printed 80 thousand times. Then I launched the My Robot Labor project, the main task of which was to make this hand function like a human one.

My wife was against this purchase and kept saying: why do you need it, they say, you will print some little rabbits on it only. However, something more came up. InMoov is a robot project that is 95% is 3D printed and can be reproduced by anyone at home. Since this is an open-source project, there are already about 120 clones in the world: there is one in Russia, Spain, Germany, and so on. The bottom line is that we can create such a robot and program it as we please. The project started with the fact that I printed a hand, which consists of palms and fingers, and posted the project on the Internet. There appeared a lot of people who became interested in it, and the hand project was printed 80 thousand times. Then I launched the My Robot Labor project, the main task of which was to make this hand function like a human one.

Photo: www.inmoov.fr

At the stage of creating the shoulders, head and eyes, we can make the robot move its arms, find objects with its eyes. One day Nicolas Huche called me and asked if we could work together. When we started working, I continued to improve my robot.

One day Nicolas Huche called me and asked if we could work together. When we started working, I continued to improve my robot.

InMoov is a 95% 3D printed robot project that can be reproduced by anyone at home. Since this is an open-source project, there are already about 120 clones in the world

As a result, we created a new hand - I'm sure this hand of the new generation. Fingers work with the help of a special mechanism and two sensors that are attached to the living part of the hand. Sensors convert muscle impulses into electrical impulses, and with the help of them, the fingers receive commands, thanks to which a person can squeeze and unclench his fingers. Now Gael and I are working on sensory sensors so that the robot can feel the compression of objects. Perhaps the sensor will be located on the tip of the finger and vibrate, like on a mobile phone, so that you can feel how much the object is compressed.

Nicolas Huchet

Enthusiast who 3D printed his own hand

Photo: gamemag.

ru

ru — I live in Rennes, France. When I was 18, I worked as a mechanic. Once I had an accident, after which my arm was amputated. Since then, I have been using a myoelectric prosthesis that is controlled by my hand. I was a little disappointed in his work, because he is not at all like the ones we see in the films. But I was lucky, because in France, myoelectric prostheses are paid for by the insurance company. I lived with him for a couple of decades, but then I saw that there are new, more advanced prostheses. However, as they say in France, if something is very expensive, then it is worth a whole hand.

I saw a 3D printer and asked the employees: is it possible to design and print such a robotic arm as in the Terminator movie? And they answered me "yes"

One day I stumbled upon fab labs, the peculiarity of which is that they are open to absolutely everyone, not just engineers.