3D printers seattle

3D Printing Seattle | Forge Labs

3D Printing Seattle | Forge LabsOn-Demand 3D Printing & Manufacturing ServicesWe manufacture parts using the most advanced 3D printing and additive manufacturing technologies on the West Coast. Get instant online quotes for prototypes or production runs, and accelerate your product development with ultra-fast turnaround and next day shipping, anywhere in Washington.

Accelerate Manufacturing With Instant Online Quotes, Cutting Edge 3D Printing & Next-Day Shipping Anywhere in Canada.

Watch Video

Get an Instant Quote

What's Inside Forge Labs

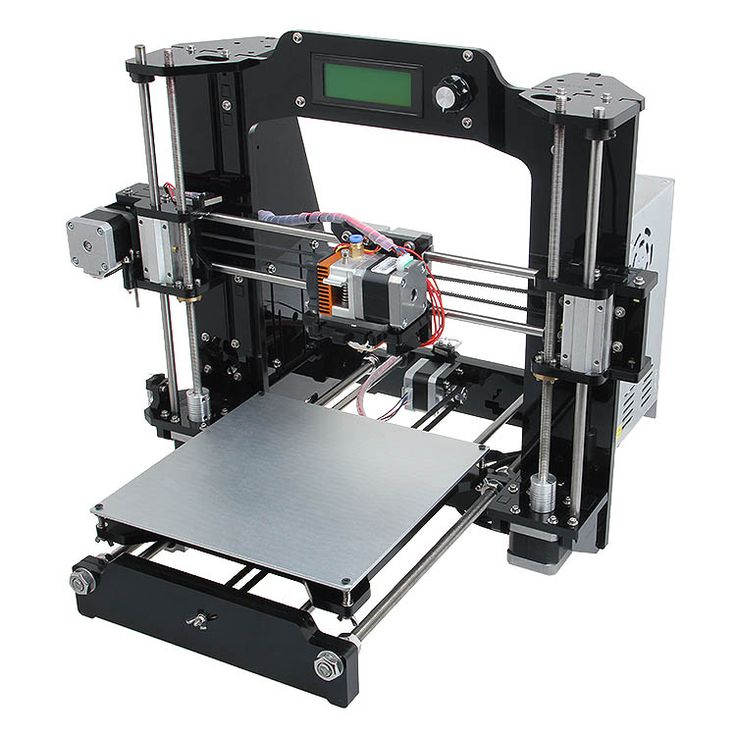

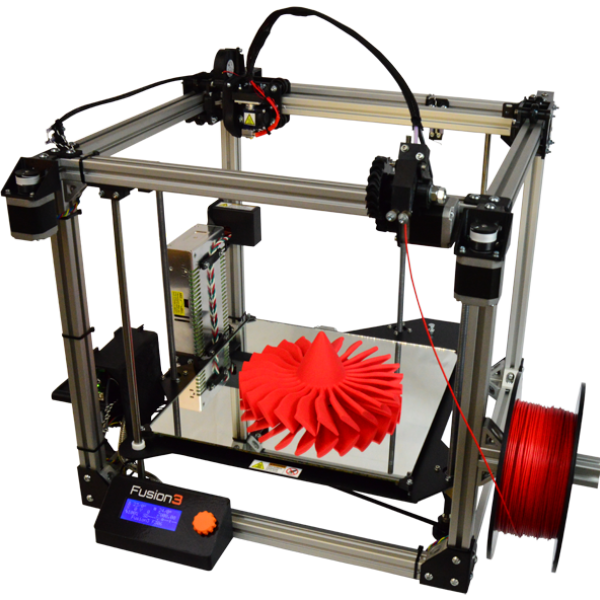

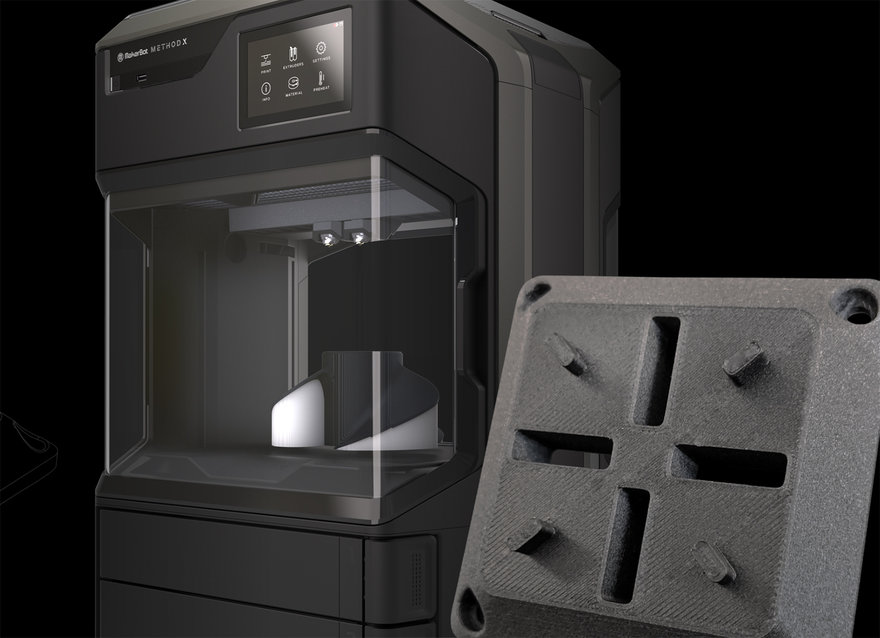

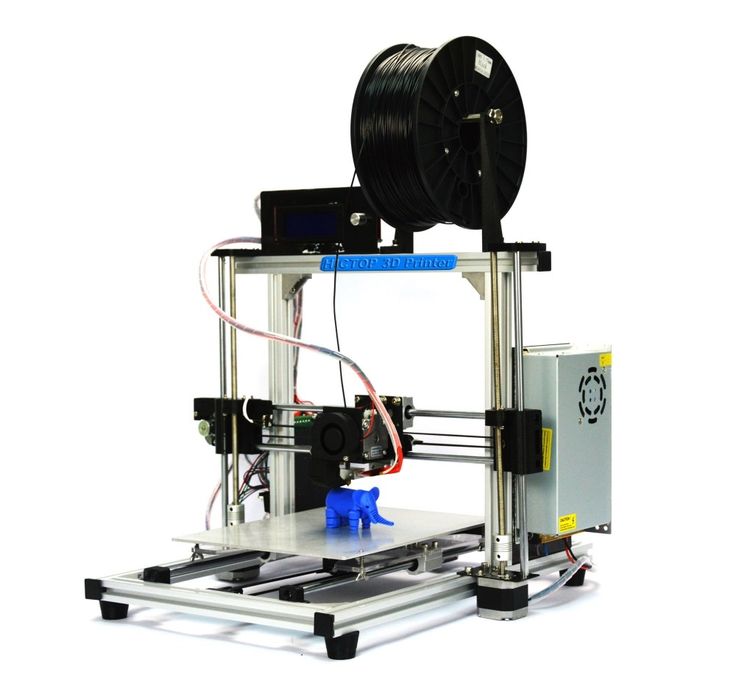

Fused Deposition

Stereolithography

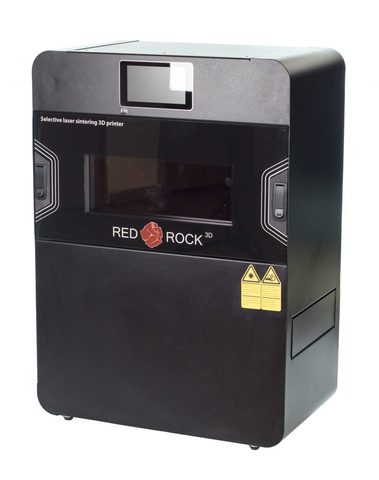

Selective Laser Sintering

Multi Jet Fusion

PolyJet Matrix

Metal Sintering

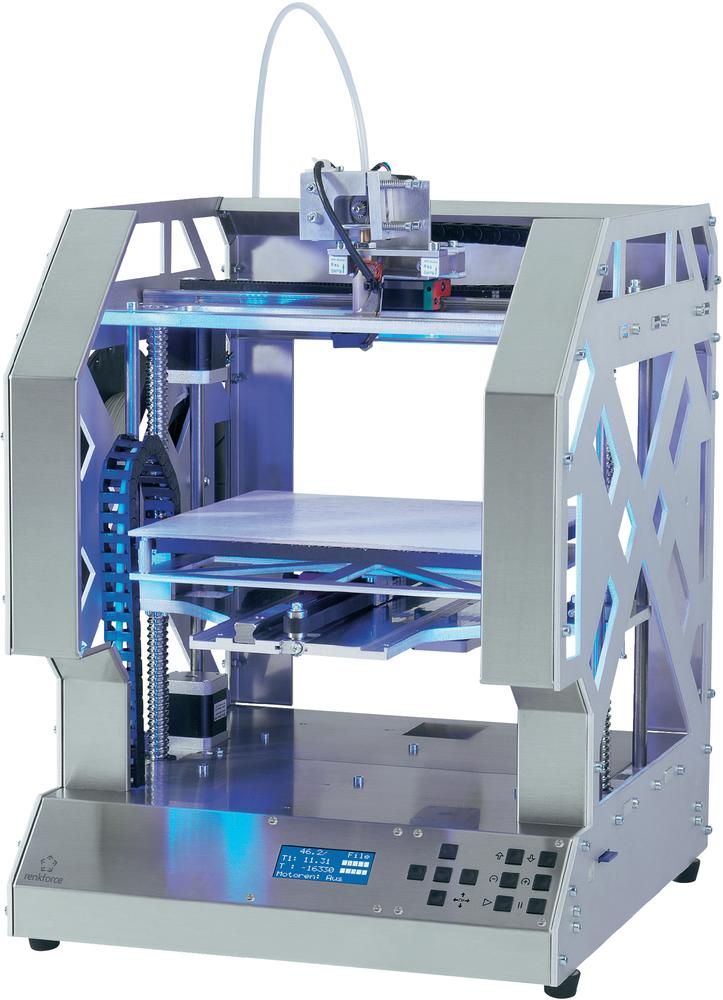

The Most Advanced 3D Printing Technologies On The West Coast

Go from design fully functional 3D printed part in under a week. Get immediate pricing on all major industrial 3D printing technologies using our online quotation platform. Forge Labs supports businesses across Seattle to help them stay ahead of the curve with the latest in 3D printing technologies. Our experienced team of engineers have a proven record with industries in Aerospace, Aviation, and Healthcare. Whatever the challenge, you're in good hands.

From ultra fast prototypes to mid sized production orders of functional end-use parts, we deliver in days, not weeks.

West Coast ManufacturingYour parts are produced on the West Coast by our team of manufacturing experts, using the industry's most advanced 3D printers.

Easy to Use Digital Manufacturing PlatformGet instant quotes in 50+ 3D printing materials and additive manufacturing technologies.

Next Day Delivery Anywhere in WashingtonNext-day shipping anywhere in Seattle, or across the USA. Get your parts where you need them.

Get your parts where you need them.

Simply upload your 3D design, select from our materials and technologies, and place your order. Move quickly from concept to market by leveraging the rapid turnaround time and high production capacity of additive manufacturing.

- We ship next-day, anywhere in Washington State.

- Consistently high quality 3D printing & repeatable parts. Feel confident in your 3D printed manufacturing runs with inspection reports and certificates of conformance.

Trusted by Seattle Engineers & Designers

Explore our 3D Printing Technologies in Seattle

3D Printing Technologies Selective Laser Sintering Fused Deposition Stereolithography PolyJet Matrix Multi Jet Fusion Metal Laser Sintering3D Printing Materials3D Printing MaterialsSeattle's largest selection of 3D printed materials. Choose from 50+ industrial resins, plastics & metals to create everything from functional end-use parts to visual prototypes, concepts and art.

Choose from 50+ industrial resins, plastics & metals to create everything from functional end-use parts to visual prototypes, concepts and art.

View All Materials

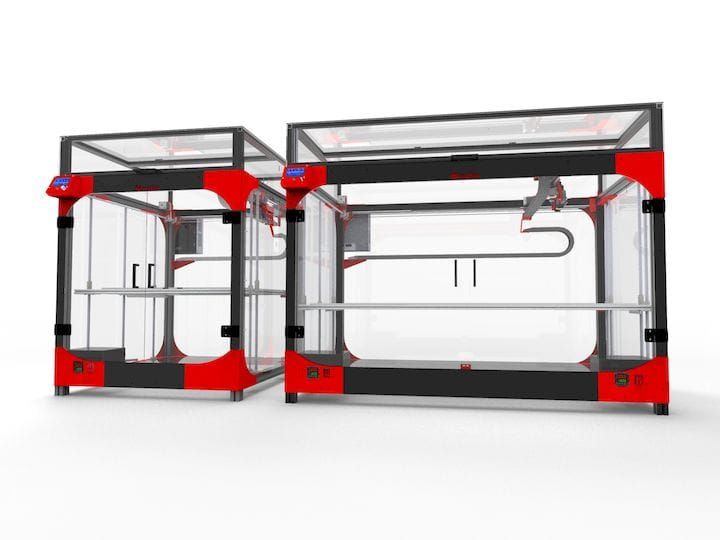

Thermoplastics3D Print large format parts up to 36 x 24 x 36 inches in functional plastics.

Industrial ResinsUltra-High accuracy resins perfect for prototyping or mold making

MetalsMake strong, highly complex, and functional metal parts with DMLS

3D Printing Materials3D Printing MaterialsCanada's largest selection of industrial 3D printing resins, plastics & metals to create everything from functional end-use parts, to visual prototypes, concepts and fine art.

ThermoplasticsPlastics ideal for end-use applications and small to mid sized production runs

Industrial ResinsDetailed, high accuracy and functional parts with the industries leading resins.

Functional metal parts produced with the freedom of additive manufacturing

View All Materials

From prototypes to end-use production

Rapid Manufacturing in Seattle with 3D Printing

Ultra Quick PrototypesGet accurate prototypes in days, and validate even the most demanding designs with 3D Printing. Reduce time to market, test your product, collect objective opinions and raise capital with prototypes that both function, and feel like the final product. Get functional 3D Printed prototypes fast and in the hands of your stakeholders to explore all the market possibilities.

- Get instant online quotes and place orders immediately.

- Automated design for manufacturing feedback on all uploaded CAD files.

- Track your orders and see status updates in real time as they progress.

Manufacture end-use parts in volume for a variety of demanding industries from Aerospace, Automotive to Medical industries using 3D Printing. Compared to traditional methods, additive manufacturing enables higher freedom of designs, greatly reduces production leads times and reduces upfront manufacturing costs.

Compared to traditional methods, additive manufacturing enables higher freedom of designs, greatly reduces production leads times and reduces upfront manufacturing costs.

- Work our team of dedicated application engineers and project managers to optimize your files for production with 3D printing.

- Receive quality inspection reports, certificates of conformance & custom inspection reports available with every order.

Jigs & Fixtures

Medical

Aerospace

Consumer Goods

Architectural

Film & TV

Automotive

End-Use

Industry spotlight

Soaring to New Heights in Aerospace Manufacturing

The Greater Seattle area has been home to some of the most innovative aviation and aerospace companies over the past several decades. Today Washington hosts more than 1,500 aerospace companies creating a highly robust supply chain strengthened further by the recent advances in Additive Manufacturing & 3D Printing. Confidence in 3D printing has increased significantly in the past decade, with more aerospace & aviation engineers exploring 3D printing not only for rapid prototyping but also for manufacturing end-use parts that can be used functional throughout the aircraft. Leveraging the advanced manufacturing capabilities of 3D printing enables aerospace parts and assemblies to be simplified, allowing them to incorporate highly complex geometries that were not previously possible with traditional manufacturing methods.

Confidence in 3D printing has increased significantly in the past decade, with more aerospace & aviation engineers exploring 3D printing not only for rapid prototyping but also for manufacturing end-use parts that can be used functional throughout the aircraft. Leveraging the advanced manufacturing capabilities of 3D printing enables aerospace parts and assemblies to be simplified, allowing them to incorporate highly complex geometries that were not previously possible with traditional manufacturing methods.

Forge Labs supplies Aerospace companies in Washington lightweight, flight-ready interior aircraft parts using high performance materials that meet the demanding needs of the American Aerospace & Aviation industry. Our high performance 3D printed materials allow for rapid and more affordable customization options, in a variety of thermoplastics, composites and metals. Aerospace designers and engineers are able to leverage the design freedom granted by 3D printing to introduce more customization and produce lighter, better, stronger parts even faster than before. Together with our strict quality control process, material certifications we are able to consistently provide the Aerospace industry with repeatable, high performance parts that improve the assembly process, reduce production time, costs and time to market.

Together with our strict quality control process, material certifications we are able to consistently provide the Aerospace industry with repeatable, high performance parts that improve the assembly process, reduce production time, costs and time to market.

Read More

Get instant online quotes for both prototypes and production runs using the most advanced 3D printing and additive manufacturing technologies on the West Coast. Accelerate production development with ultra fast part turnaround and next day shipping anywhere in the United States.

Extrusion Multi-JetGet an Instant Quote

What's Inside Forge Labs

The Most Advanced 3D Printing Technologies On The West CoastGo from digital design to fully functional 3D Printed part in under a week. Get immediate pricing on all major industrial 3D printing technologies using our online quotation platform. Forge Labs supports businesses across Seattle to help them stay ahead of the curve with the latest in 3D printing technologies. Our experienced team of engineers have a proven record with industries in Aerospace, Aviation, and Healthcare. Whatever the challenge, you're in good hands.

Forge Labs supports businesses across Seattle to help them stay ahead of the curve with the latest in 3D printing technologies. Our experienced team of engineers have a proven record with industries in Aerospace, Aviation, and Healthcare. Whatever the challenge, you're in good hands.

From ultra fast prototypes to mid sized production orders of functional end-use parts, we deliver in days, not weeks.

Easy to Use Digital Manufacturing PlatformGet Instant Quotes in 50+ 3D Printing Materials and Additive Manufacturing Technologies.

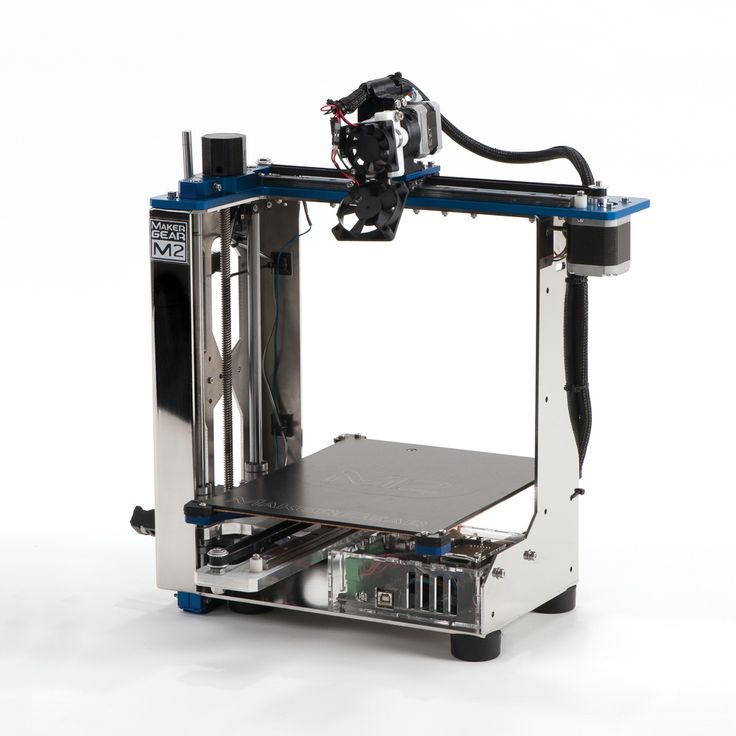

Fully Equipped West Coast ManufacturingYour parts are produced by our team of manufacturing experts, using the industry's most advanced 3D printers.

Next Day Delivery Anywhere in WashingtonNext-day shipping anywhere in Seattle, or across the USA. Get your parts where you need them.

Get an instant quote

Our Seattle 3D Printing Capabilities

Simply upload your 3D design, select from our materials and technologies and place your order. Move quickly from concept to market by leveraging the rapid turnaround time and high production capacity of Additive Manufacturing.

- We ship next-day, anywhere in Washington State.

- Highest quality, repeatable 3D Prints. Feel confident in your 3D Printing manufacturing runs with inspection reports and certificates of conformance with every order.

Trusted by Seattle Engineers & Designers

3D Printing TechnologiesSeattle's most powerful 3D printing technologies

Selective Laser Sintering (SLS) Fused Deposition (FDM) Stereolithography (SLA) PolyJet Matrix (PJM) Multi Jet Fusion (MJF) Metal Laser Sintering (DMLS)View All 3D Print Technologies

3D Printing MaterialsSelect from 50+ industrial resins, plastics & metals.

Plastics ideal for end-use applications and small to mid sized production runs

Industrial ResinsDetailed, high accuracy and functional parts with industrial resin 3D printing.

MetalsFunctional metal parts produced with the freedom of additive manufacturing

View All 3D Print Materials

From prototypes to end-use production

Rapid Seattle Manufacturing Services with 3D PrintingUltra Quick PrototypesGet accurate prototypes in days, and validate even the most demanding designs with 3D Printing. Reduce time to market, test your product, collect objective opinions and raise capital with prototypes that both function, and feel like the final product. Get functional 3D Printed prototypes fast and in the hands of your stakeholders to explore all the market possibilities.

- Get instant online quotes and place orders immediately.

- Automated design for manufacturing feedback on all uploaded CAD files.

- Track your orders and see status updates in real time as they progress.

Manufacture end-use parts in volume for a variety of demanding industries from Aerospace, Automotive to Medical industries using 3D Printing. Compared to traditional methods, additive manufacturing enables higher freedom of designs, greatly reduces production leads times and reduces upfront manufacturing costs.

- Work our team of dedicated application engineers and project managers to optimize your files for production with 3D printing.

- Receive quality inspection reports, certificates of conformance & custom inspection reports available with every order.

Jigs & Fixtures

Medical

Aerospace

Consumer Goods

Architectural

Film & TV

Automotive

End-Use

Industry Spotlight

Aerospace Manufacturing

The Greater Seattle area has been home to some of the most innovative aviation and aerospace companies over the past several decades. Today Washington hosts more than 1,500 aerospace companies creating a highly robust supply chain strengthened further by the recent advances in Additive Manufacturing & 3D Printing. Confidence in 3D printing has increased significantly in the past decade, with more aerospace & aviation engineers exploring 3D printing not only for rapid prototyping but also for manufacturing end-use parts that can be used functional throughout the aircraft. Leveraging the advanced manufacturing capabilities of 3D printing enables aerospace parts and assemblies to be simplified, allowing them to incorporate highly complex geometries that were not previously possible with traditional manufacturing methods.

Today Washington hosts more than 1,500 aerospace companies creating a highly robust supply chain strengthened further by the recent advances in Additive Manufacturing & 3D Printing. Confidence in 3D printing has increased significantly in the past decade, with more aerospace & aviation engineers exploring 3D printing not only for rapid prototyping but also for manufacturing end-use parts that can be used functional throughout the aircraft. Leveraging the advanced manufacturing capabilities of 3D printing enables aerospace parts and assemblies to be simplified, allowing them to incorporate highly complex geometries that were not previously possible with traditional manufacturing methods.

Forge Labs supplies Aerospace companies in Washington lightweight, flight-ready interior aircraft parts using high performance materials that meet the demanding needs of the American Aerospace & Aviation industry. Our high performance 3D printed materials allow for rapid and more affordable customization options, in a variety of thermoplastics, composites and metals. Aerospace designers and engineers are able to leverage the design freedom granted by 3D printing to introduce more customization and produce lighter, better, stronger parts even faster than before. Together with our strict quality control process, material certifications we are able to consistently provide the Aerospace industry with repeatable, high performance parts that improve the assembly process, reduce production time, costs and time to market.

Aerospace designers and engineers are able to leverage the design freedom granted by 3D printing to introduce more customization and produce lighter, better, stronger parts even faster than before. Together with our strict quality control process, material certifications we are able to consistently provide the Aerospace industry with repeatable, high performance parts that improve the assembly process, reduce production time, costs and time to market.

Read More

Get started with us

Frequently Asked Questions

Simply upload your 3D design, select from our materials and technologies and place your order! We all common 3D CAD formats including STL, OBJ, SLDPRT, Parasolid and more!

Yes, we have an expert team of in-house 3D modelers with expertise in reverse engineering services of existing 2D drawings, physical products & concepts.

Absolutely! Give us a call and we would be happy to discuss your project and make material recommendations.

We ship using using next day service to ensure you get your parts as soon as they are ready. Parts are delivered anywhere in Seattle and Washington area via FedEx typically within 1 business day.

There is no minimums and no maximum parts. Order as many parts as you need without worrying about warehousing.

The average turnaround time for most parts & technologies is between 2-5 business days. Metal parts can often take longer up to 10 business days, whereas plastic parts can be done as quick as the next business day.

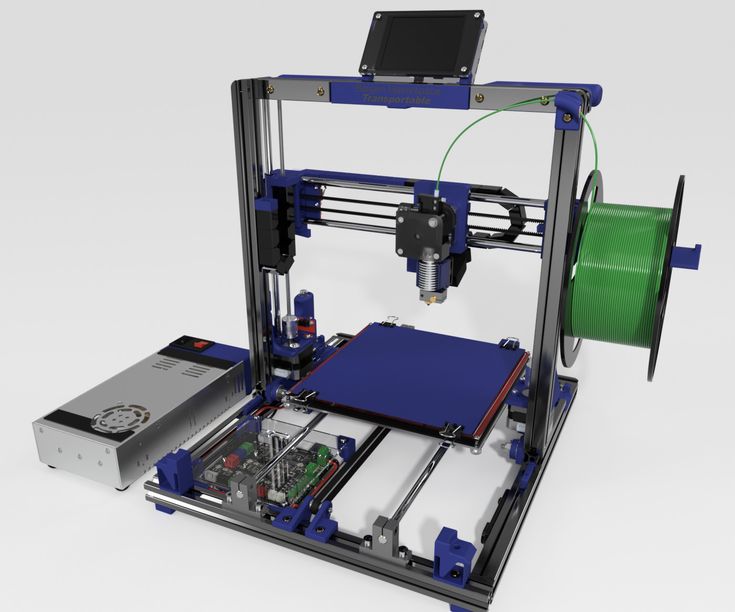

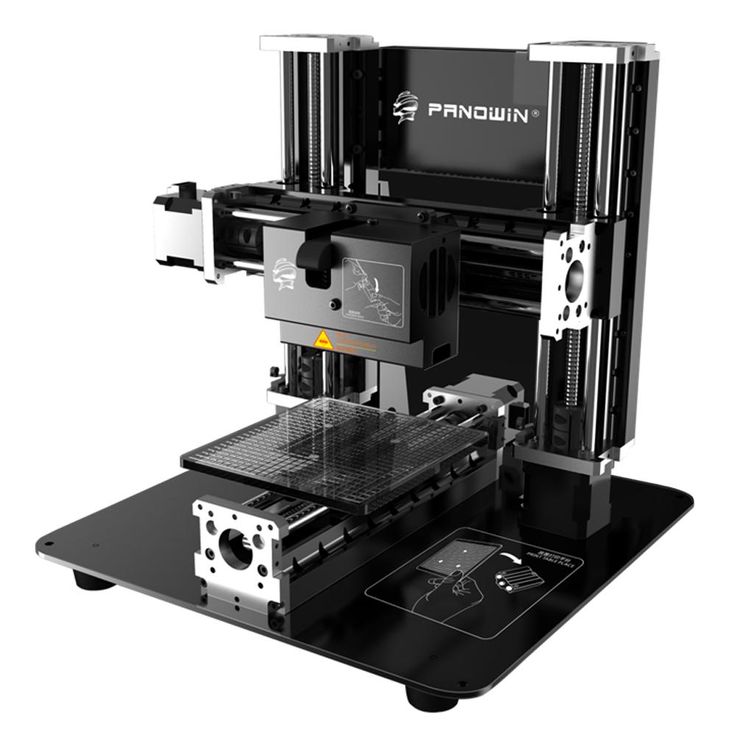

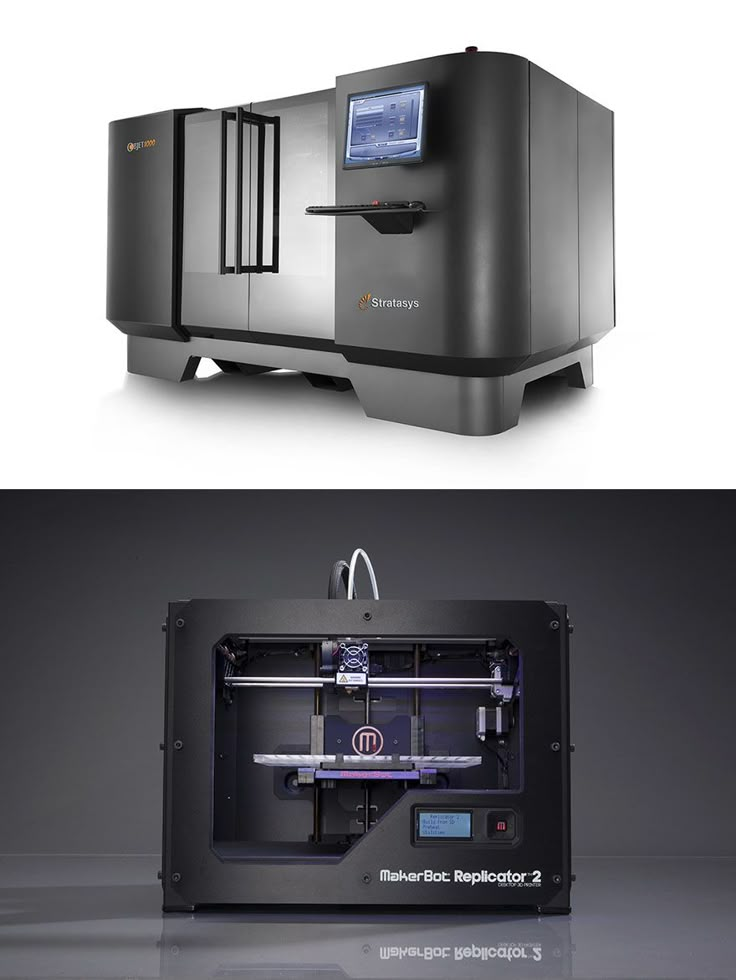

Forge Lab's Fused Deposition Modeling 3D Printers are made by Stratasys, our Stereolithography (SLA) machines are by 3D Systems, and our Powder Bed Fusion and Direct Metal Laser Sintering Machines are made by EOS & HP.

View more FAQ

Start Manufacturing parts today

Upload your 3D model to get started

STEP | STP | SLDPRT | STL | IPT | 3DXML | PRT | SAT files

All uploads are secure & confidential

Frequently Asked Questions

Learn how Seattle's most innovative industries are using 3D Printing and digital direct manufacturing to support their rapid prototyping and on-demand production needs. From Aerospace and Automotive to fine art and film, Forge Labs' 3D Printing services serve a wide range of industries.

From Aerospace and Automotive to fine art and film, Forge Labs' 3D Printing services serve a wide range of industries.

Yes, we have an expert team of in-house 3D modelers with expertise in reverse engineering services of existing 2D drawings, physical products & concepts.

Absolutely! Give us a call and we would be happy to discuss your project and make material recommendations.

We ship using using next day service to ensure you get your parts as soon as they are ready. Parts are delivered anywhere in Seattle and Washington area via FedEx typically within 1 business day.

There is no minimums and no maximum parts. Order as many parts as you need without worrying about warehousing.

The average turnaround time for most parts & technologies is between 2-5 business days. Metal parts can often take longer, whereas plastic parts can be done as quick as next day.

Forge Lab's Fused Deposition Modeling 3D Printers are made by Stratasys. Our Stereolithography (SLA) machines are by 3D Systems. Powder Bed Fusion and Direct Metal Laser Sintering Machines are made by EOS & HP.

Powder Bed Fusion and Direct Metal Laser Sintering Machines are made by EOS & HP.

See our full FAQ page for more

Start 3D Printing today

Upload your 3D model to get started

STEP | STP | SLDPRT | STL | IPT | 3DXML | PRT | SAT files

All uploads are secure & confidential

3D Printing Service Seattle, WA | Instant Quotes Online

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.

9/5

9/5 Over 313 customers are satisfied with our 3D printing service.

“Ara is very responsive and went the extra mile to make sure the result is perfect. Really appreciated!”

“Very fast printing and very accommodating. Didn't have the colour I was looking for, but got it same day and printed that evening. Excellent communication!”

“This is my first "large" 3d printed object. I have to say, the quality is far better than I expected. The speed and shipping of the product was top notch. I will definitely be 3d printing more things in the future! ”

“Thanks for quickly making parts, they look beautiful.”

“Fantastic quality and an excellent attention to detail”

“Fast and quality prints, from a knowledgeable and friendly printer. Would recommend to a friend and use again. Thanks! ”

Thanks! ”

“Excellent job. The GF material behaves extremely well for my testing. The prototypes were all clean and looked perfect. ”

“Prints were top notch and packaged neatly.”

“Easy to submit project, and professional communication and printing. Good job!”

“We received compliments from our customer printing files at 100 micron.”

“As always, a pleasure to do business with.”

“Project came out great, thank you for the extra pieces.”

“Thanks for re-printing the ones with voids! The parts look great!”

“Very good quality. Parts sizes where exact as ordered”

“Great to work with. Easy communication, fast shipping. ”

“Great Communication and service, fast turnaround, and high quality prints!”

“Great printer! Quality exceeded my expectations and communication was A++.”

“Prints are great, just what I needed. Thanks!”

“Thanks for doing 2nd! I wasn't sure if the inner tie would print well and since it only worked once will not try that again. ”

”

“They work, good dimensions, very strong.”

“Quick and solid service. Highly satisfied”

“Great print and great service as always. Thanks a lot.”

“Absolutely wonderful. I'm so impressed with the quality of print, speed of arrival and great communication process...and VERY GOOD price per part. Your service is now my sole source for 3D printing needs. ”

“I've run out of feedback. Orders are always high quality and done quickly.”

“Provider is very helpful with ideas, and provides feedback on what is working and what isn't. I have paid a bit more to use them again, and local pick-up is very helpful for efficiency and cost.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Seattle, WA

Everett, WA Marysville, WA Redmond, WA

Kirkland, WA Sammamish, WA Shoreline, WA

Bellevue, WA Seattle, WA Mount Vernon, WA

Renton, WA

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Seattle's second tallest skyscraper to receive 3D printed façade fixtures

News

Walters & Wolf plans to use 150 3D printed mounts to mount the translucent façade on the new Rainier Square Tower, the second tallest building in Seattle, Washington.

Rainier Square Tower will be located next to the original Rainier Tower, designed by renowned architect Minoru Yamasaki. Yamasaki's most famous project was the towers of the World Trade Center in New York, which were destroyed in the 2001 attacks. The skyscraper in Seattle is interesting due to the tapering shape of the base, reminiscent of a pedestal. The new 58-story building will be located almost back to back, will sparkle with a glass facade and rise to two hundred and sixty meters, which will make it the second tallest skyscraper in Seattle after the 76-story Columbia Center. In addition, the headquarters of Amazon will be located here.

Panels and fasteners for the translucent façade are to be supplied by Walters & Wolf, which is facing a major problem. One of the walls of the building, as seen in the illustrations, has a curved shape like a slope. As a result, one hundred and forty V-shaped aluminum fasteners from twenty centimeters to half a meter long are required to install panels on this side of the skyscraper. For each floor, the fixtures have not only their dimensions, but also their shape, which greatly complicates the production.

For each floor, the fixtures have not only their dimensions, but also their shape, which greatly complicates the production.

After being turned down by several contractors due to the complexity of the order, Walters & Wolf turned to local digital manufacturing office 3Diligent for help, offering two options - either die casting or 3D printing of the finished products. 3Diligent produced several prototypes for comparative testing, after which Walters & Wolf settled on 3D printed options, explaining the choice for higher accuracy and structural strength. The elements are not required to be able to withstand ultra-high loads, but they must adhere well to the silicone sealant, and here the somewhat rough surface of 3D printed products only plays into the hands.

It is not specified which 3D printing technology is used in the production of fasteners: 3Ddiligent has at its disposal additive installations for selective laser sintering and deposition, direct laser deposition and inkjet printing technologies. Most likely, the last option was used, which involves the construction of layers of metal powders using jet heads that apply a binder. After printing, the blanks are heat treated to remove the binder, sinter metal particles, and relieve internal stresses. Work on the new skyscraper is expected to be completed next year.

Most likely, the last option was used, which involves the construction of layers of metal powders using jet heads that apply a binder. After printing, the blanks are heat treated to remove the binder, sinter metal particles, and relieve internal stresses. Work on the new skyscraper is expected to be completed next year.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected]

Follow author

Follow

Don't want

4

More interesting articles

9

Subscribe to the author

Subscribe

Don't want

In the village of Aisha, Zelenodolsk district of Tatarstan, work is underway to build thirty-four houses using the...

Read more

5

Subscribe to the author

Subscribe

Don't want

The World Nuclear Association (WNA) has published a report on the application of advanced manufacturing technologies. ..

..

Read more

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci...

Read more

How 3D printers work | RBC Trends

Trends

TV channel

Newspaper

Pro

Investments

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Conferences

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

What can be printed on a 3D printer and when will this service be available to everyone? Answers to these questions are being sought by Nikolai Dubinin, host of the Industry 4.0 YouTube channel

Why 3D printers are needed

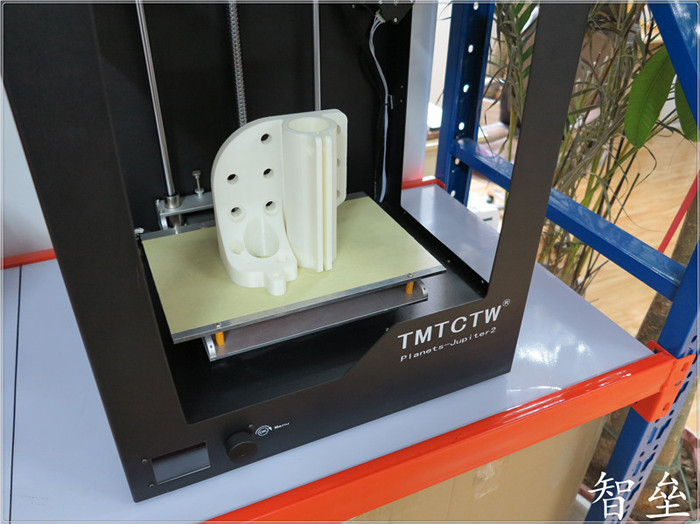

This is an individual approach to objects that can be printed at any time. Such a printer can reproduce any detail that can fit in it. You can print from plastic - hard and soft, as well as from rubber and composites.

Such a printer can reproduce any detail that can fit in it. You can print from plastic - hard and soft, as well as from rubber and composites.

Business Why

A good example of the benefits of 3D printers is a baby skull printed for a hospital. It is used for planning operations in neurosurgery. On such a skull, the doctor trains to operate on the child so that he spends as little time as possible on the operating table.

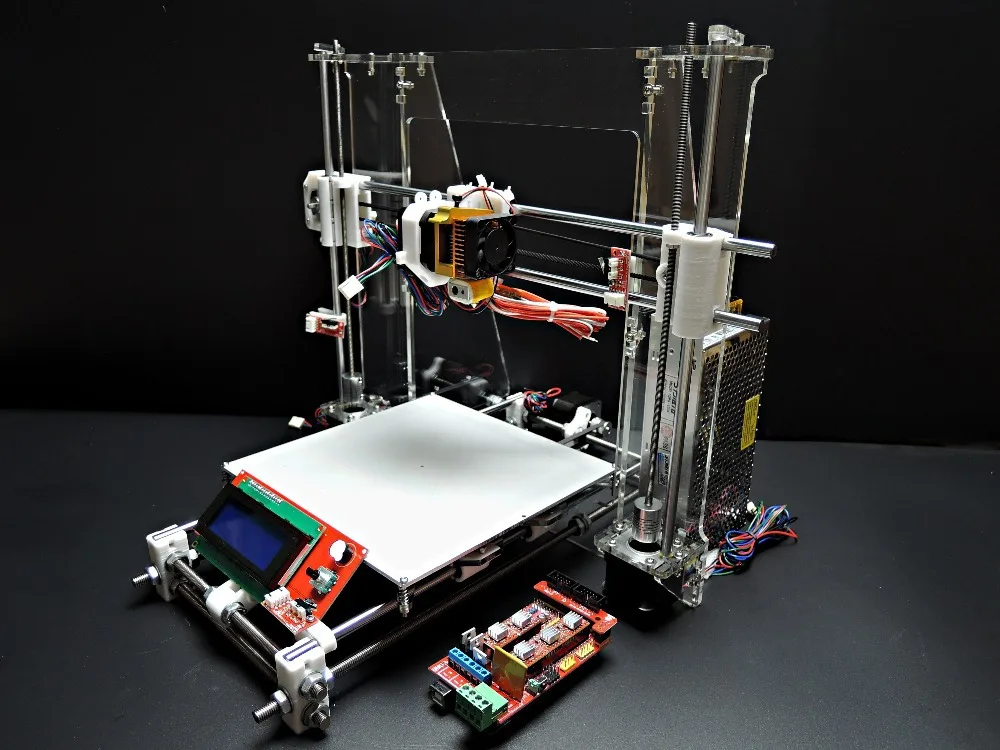

To print complex parts, such as a human skull, simple physics is not enough: the part will not have time to cool down and will “go” during the printing process. Therefore, a support structure is needed, which is printed by the second nozzle of the printer. That is, the main material comes from one nozzle, the temporary support material or the second color comes from the second. When necessary, they switch and do not interfere with each other. After the complex figure has been printed, the support material is simply dissolved.

Who buys 3D printers

The main buyer is a business: designers, engineers, architects, advertisers, doctors. Schools also buy printers.

Schools also buy printers.

In Russia, the leader in the production of 3D printers is Picaso 3D. In America, Ultimaker is in first place in terms of popularity.

What 3D Printer Inks Are Made Of

There is a wide range of materials used to make filament for printing. There are even biodegradable plastic threads. They are produced by a complex chemical reaction from cane and corn. Biodegradable plastic has a sufficiently high strength, it is easy to store and is not harmful to the environment. True, a part made of such a material is short-lived - in five to ten years it will need to be printed again.

Why 3D printing is not yet widespread

Now the development of 3D printing is limited by high-speed capabilities - until printers can print goods as quickly as machine tools and press machines produce them. At the moment, 3D printing is a small-scale and medium-scale production. On the other hand, if we talk about a series, then there is no point in printing - it is better to create a mold that can easily make 10-20 thousand pieces of parts.