Austin 3d printing shop

3D Printing Service for Austin, Texas

CapabilitiesCustom Online 3D Printing ServiceTexasAustin

High Quality Austin, Texas 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Austin, Texas 3D Printing Service: 3D Prototypes and Production Parts

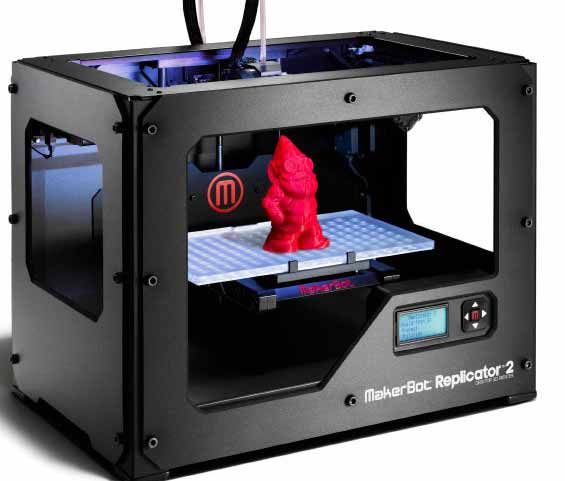

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

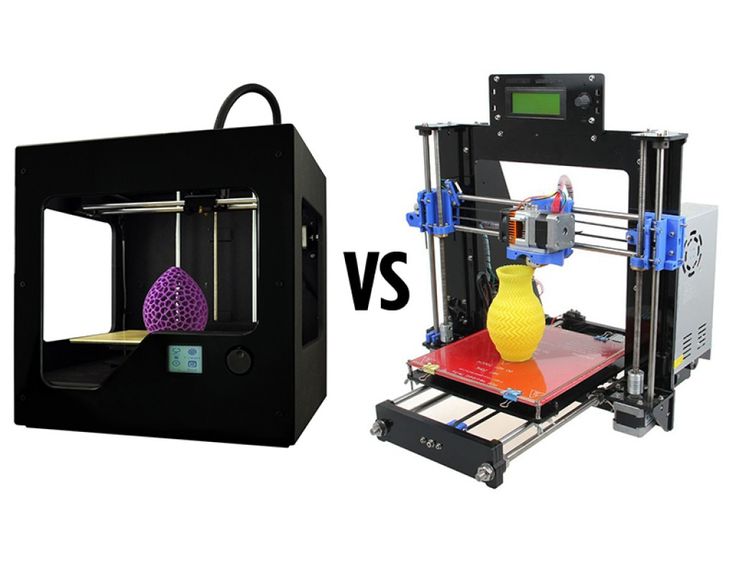

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

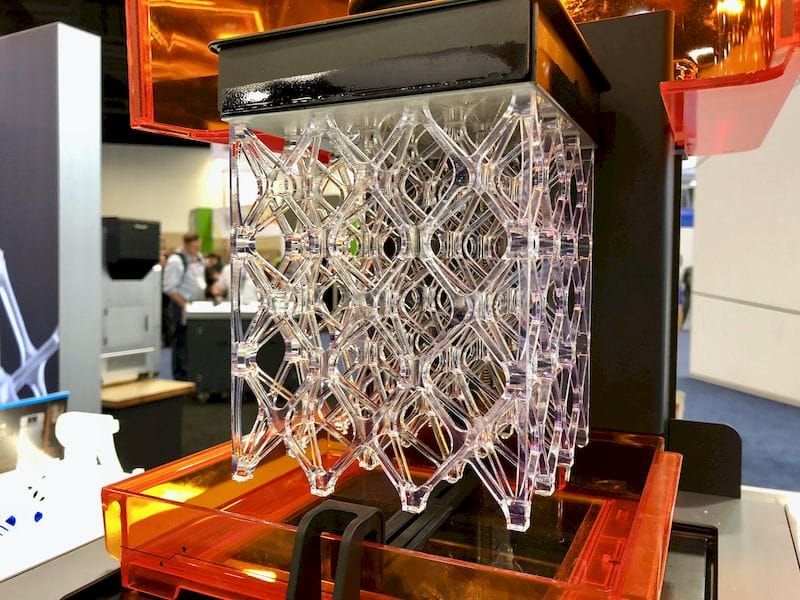

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

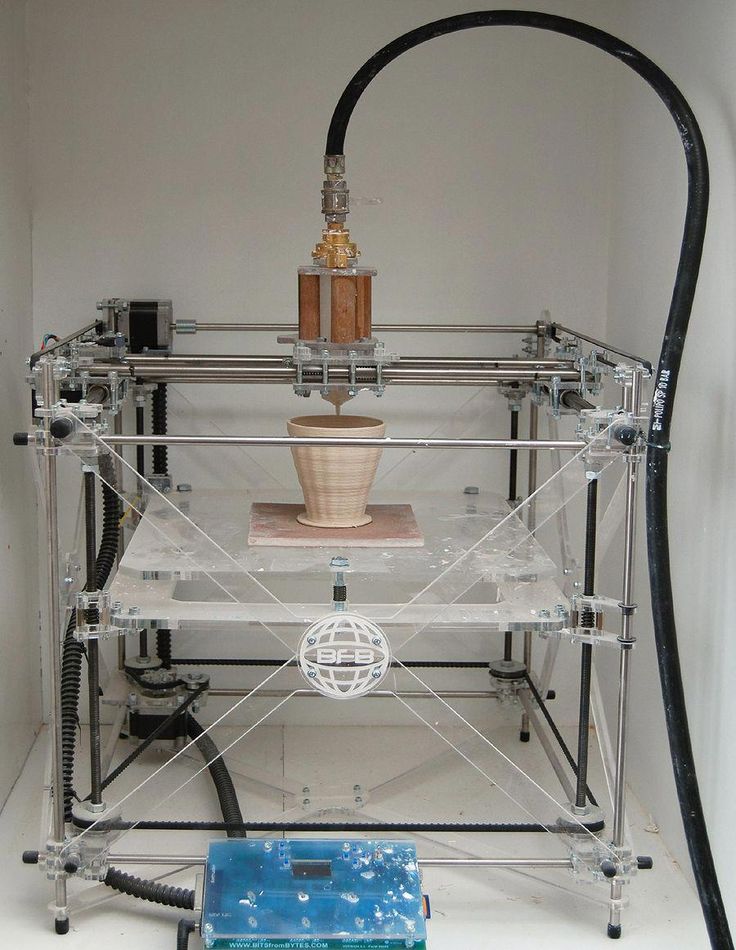

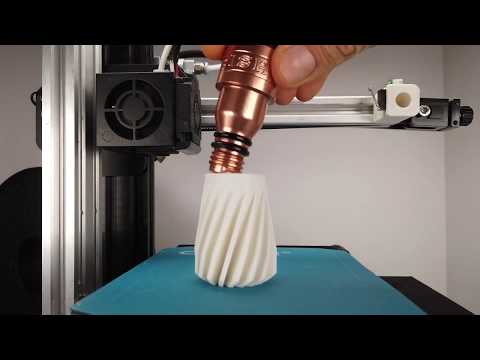

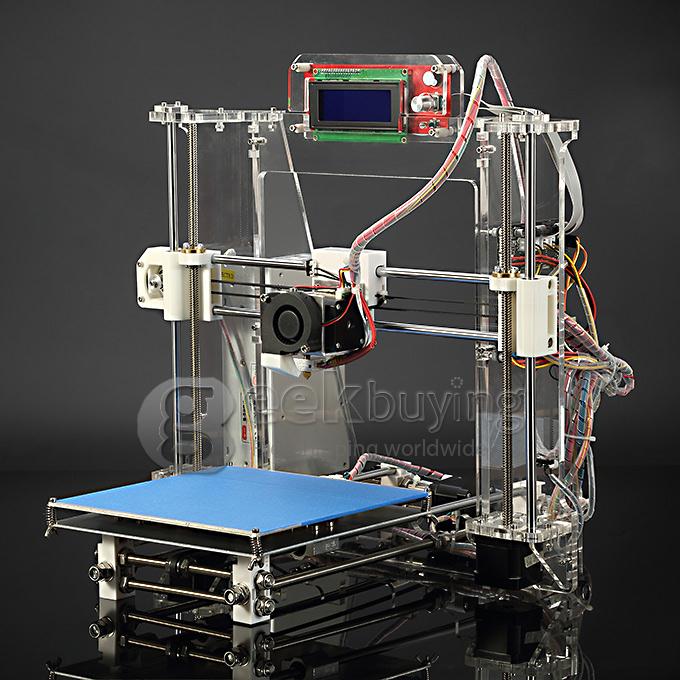

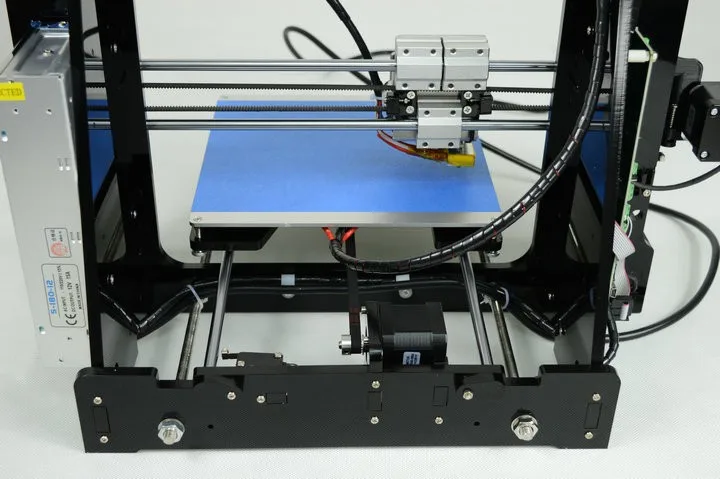

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Austin, Texas

San Antonio

TexasCollege Station

TexasWaco

TexasFort Worth

TexasCorpus Christi

TexasArlington

TexasGrand Prairie

TexasIrving

TexasDallas

TexasAbilene

TexasGarland

TexasPlano

TexasTyler

TexasFrisco

TexasMcKinney

TexasLaredo

TexasShreveport

LouisianaOdessa

TexasBrownsville

TexasLubbock

Texas

Ready to start making custom 3D printed parts?

3D Printing Service Austin, TX | Instant Quotes Online

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

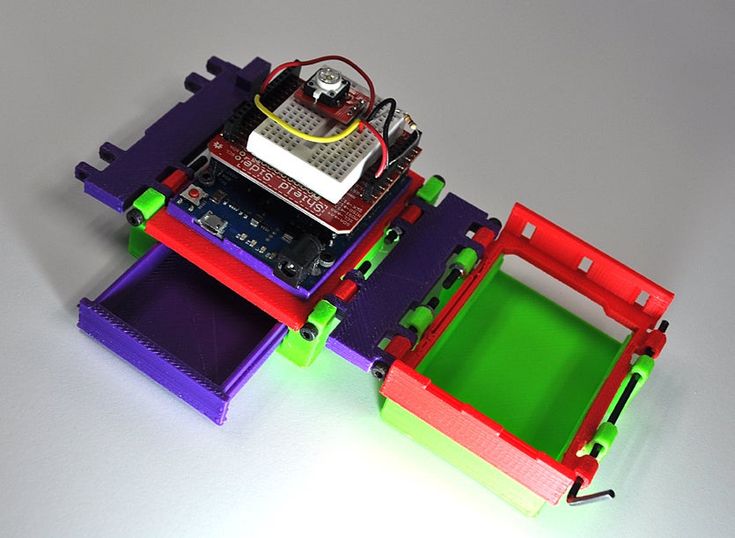

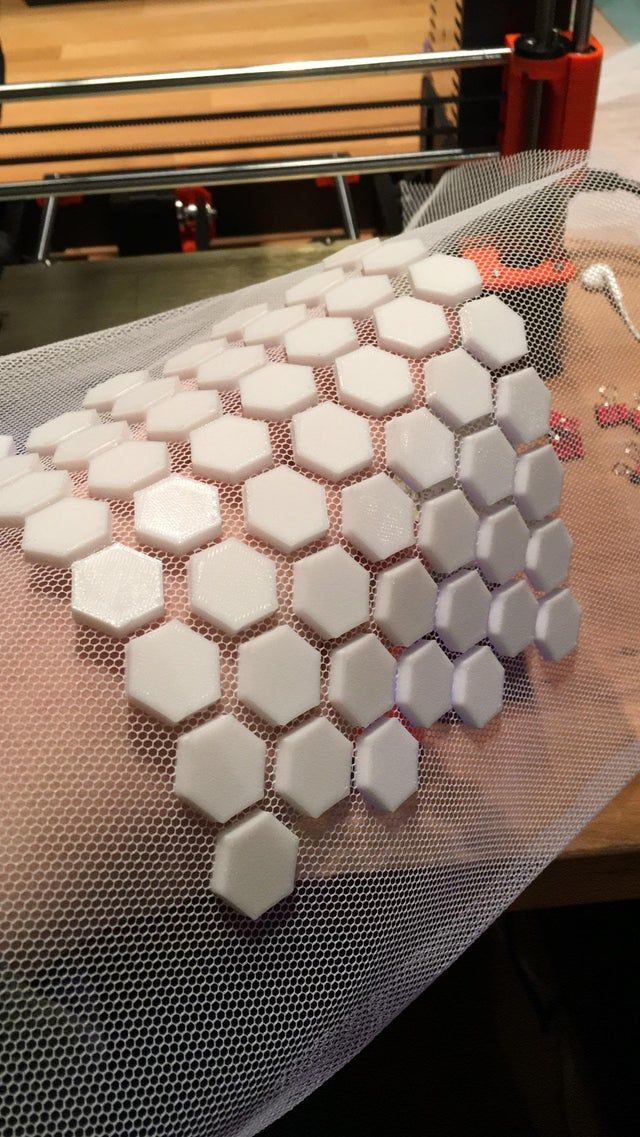

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

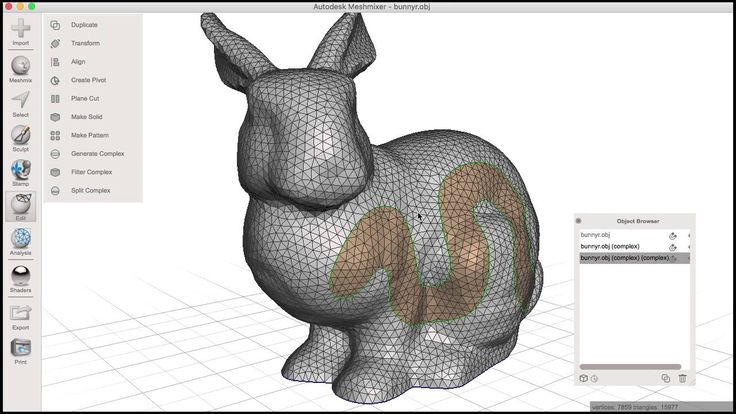

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 128 customers are satisfied with our 3D printing service.

“Great turn around time and patience to provide the best quality print possible. Do recommend using them and will in the future.”

“Great service with quick turnaround time, will use again.”

“Great communication and speed on the job! Highly recommend!”

“thank you for your attention to detail, surface finish and wall thickness are generously wonderful. Much appreciated!”

“The print was a good quality and the turnaround time was quite fast”

“Super easy to work with! Responded very quickly, fixed a file within minutes that I had not submitted correctly, and communicated every step of the way. Would highly recommend! ”

“Smooth printed parts, great communication. ”

“Fast turn around, good communication, and lovely print quality :)”

“Excellent job! Will definitely use again. A+”

“Amazing turn around time and very friendly and helpful. Would use again anytime.”

“Great parts! Fast service! Sent me photos of the printed parts a day or two after I ordered. ”

”

“Good communication and print quality. Also fast! ”

“Print is fantastic - exactly what I was looking for!”

“The order was completed much faster than I anticipated and came out great. Awesome customer service, almost instant responses to everything.”

“Excellent all around. Great communication and attention to detail.”

“Such a fast turn around time, despite the fact that it was a holiday weekend and I was doing late night shopping. The print came out looking great and Joe even offered to drill out the screw holes to make sure they where large enough. Thanks for the great work! ”

“I couldn’t wait to get home to place it. Fits good, just a little gap, but likely a measurement issue based on what I found online to provide you. ”

“Definitely worth having anything printed here. Great quality and service. ”

“Excellent quality & communication. Highly recommended.”

“Speedy turnaround and excellent communication. Great experience all around!”

“Great prints and service. Highly recommend.”

Highly recommend.”

“Great prints, did not expect they would be this good!”

“The parts came in excellent condition and in the expected time. ”

“Nice print quality and it was done very fast! Highly recommended!!!”

“Great quality, quick service, all around awesome.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Austin, TX

San Marcos, TX New Braunfels, TX Austin, TX

Cedar Park, TX Pflugerville, TX Round Rock, TX

Georgetown, TX San Antonio, TX Killeen, TX

Temple, TX

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Startup Icon raised $207 million to build houses using 3D printing - Services on vc.

ru

ru Image credit: ICON, Lake/FLATO Architects

264 hits

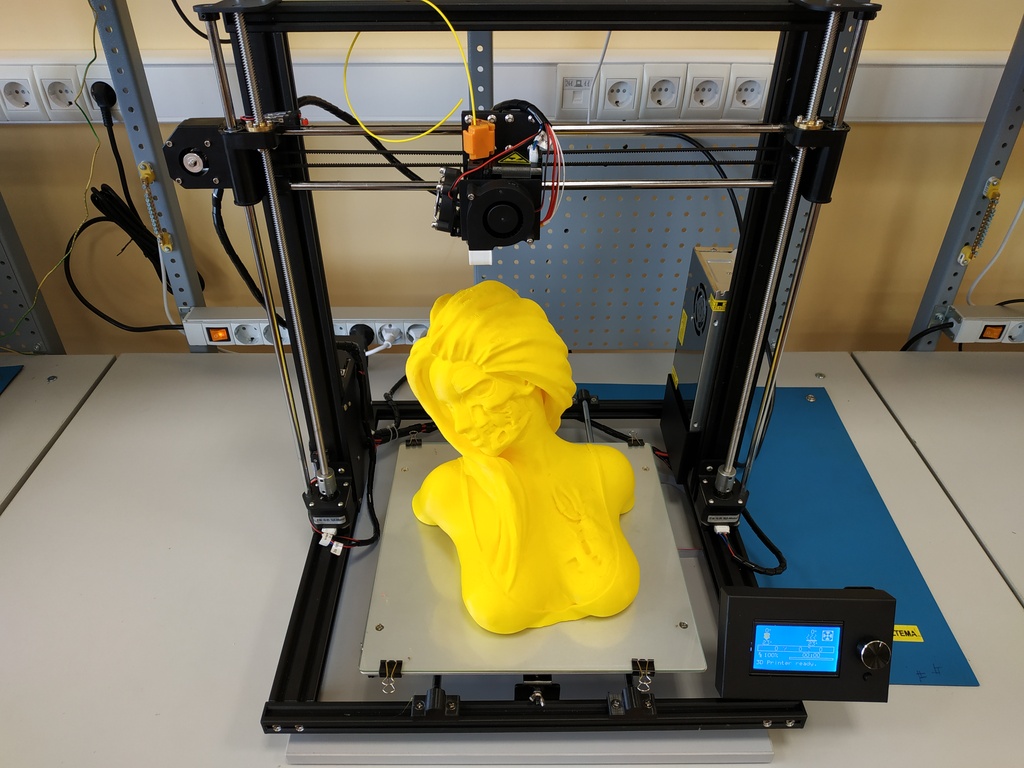

Startup Icon from Austin, Texas is developing innovative building technologies . In particular, the company creates houses using 3D printing. In addition to private residences for sale, project prints housing for the homeless and low-income people, together with NASA, is developing building systems for creating future infrastructure on the Moon and Mars, and also creating barracks for the military department in Texas.

Earlier this week, the company announced that it had raised $.207 million in its Series B funding round. US VC firm Norwest Venture Partners led the round, along with several major investment funds. The total amount of project financing thus increased to $266 million.

ICON was founded by at the end of 2017, and in March 2018 presented its first 3D printed house at the SXSW media festival in the USA. The area of the house was about 33 square meters. meters, it took about 48 hours to print. Concrete was chosen as the print material because, according to company co-founder and CEO Jason Ballard, is "one of the most sustainable materials on Earth."

The area of the house was about 33 square meters. meters, it took about 48 hours to print. Concrete was chosen as the print material because, according to company co-founder and CEO Jason Ballard, is "one of the most sustainable materials on Earth."

According to TechCrunch, the company has 3D-printed more than two dozen houses and structures for the US and Mexico in three years using the 3D printer. About half of these houses are designed to accommodate the homeless or the extremely poor.

The company entered the private housing market in early 2021 with two 3D homes for sale in Austin. Two more houses from the same series should go on sale on August 31st.

Vulcan 9 system0041 Image credit: iconbuild.com

ICON recently introduced the Vulcan , a patented "next generation" building system, as well as the new Exploration house series. The first house in this series, House Zero , is designed and optimized specifically for 3D printing. The startup says Vulcan's technology makes it possible to build "sustainable, energy-efficient" homes faster than traditional building methods. Vulcan can print homes up to 270 square meters, Ballard said.

The startup says Vulcan's technology makes it possible to build "sustainable, energy-efficient" homes faster than traditional building methods. Vulcan can print homes up to 270 square meters, Ballard said.

The CEO of ICON also claims that since the inception of the company, its revenue has been growing by 400% almost every year. Over the past year, the startup has tripled its team to 90,007 over 100 employees.

The company plans to invest in new funding to further create homes with its technology, provide housing assistance to the homeless or those affected by natural disasters, and develop building systems to create habitats on the Moon and Mars with NASA.

About 3D printing and 3D printing of clothes and shoes

About 3D printing and 3D printing of clothes and shoes | project news 3DPulse.Ru3d pulse.ru

Our new report "Construction 3D printing in Russia" is published

Our report "Construction 3D printing in Russia" collects information about domestic companies and start-ups that produce. ..

..

Vladimir Viktorovich Molodin (SIBSTRIN): "The idea [of printing with polystyrene concrete] appeared three years ago, and it took 30 years to get there."

Interest in 3D construction printing is growing rapidly around the world, with most of the developed 3D printers working with...

Mass 3D printing of individual houses: reality or utopia? - public study by Techart group

In its public survey, Techart explores whether 3D printing can bring something really new to the construction industry...

Victor Mann (RUSAL): "In Russia, additive manufacturing is one of the most dynamically developing industries"

RUSAL is a leading company in the global aluminum industry and the largest aluminum producer with a low carbon footprint. Her...

"3D Printing in the Oil and Gas Industry: Incentives and Constraints" - Techart Group Public Study

Techart Consulting Group published a study analyzing the current state and development prospects. ..

..

Current news

Clothes, shoes, accessories

Asics launches the ACTIBREEZE sandal, its first 3D printed shoe

The new shoe debuted at the World Championships in Athletics, July 15-24 in Oregon, where they were worn...

Clothes, shoes, accessories

Osprey introduces the innovative UNLTD backpack series with 3D printed suspension elements

The production of innovative elements using Carbon DLS technology was provided by OECHSLER.

Clothes, shoes, accessories

Chinese researchers develop a new method for 3D printing smart electronic clothing

Researchers from Zhejiang University develop a new method for 3D printing electronic circuits using liquid...

Clothes, shoes, accessories

Sennheiser Launches IE 600 Metallic 3D Printed Earphones

The new earphones are 3D printed using amorphous zirconium and will be available from March 8th.

Clothes, shoes, accessories

VAUDE Unveils TPU Backpack Prototype with 3D Printed Hanging System

The German outdoor brand has unveiled the world's first Novum 3D backpack made from mono-TPU material and fully wearable...

Clothes, shoes, accessories

Youtuber 3D printed his own pair of inexpensive TPU Crocs

Canadian YouTuber Austin Hartley designed and printed his own pair of Crocs on a regular desktop...

Clothes, shoes, accessories

ECCO offers the market 3D printed tooling for the development of new shoe models

Molds for molding soles are a significant cost element in the development of new shoe designs. ECCO decided...

Clothes, shoes, accessories

3D printing started to be used at the Souvenirs section of Krasnoturinskaya IK-3

It was decided to combine new technologies with manual labor at the souvenir production section of the Krasnoturyinsky IK-3, according to the website.