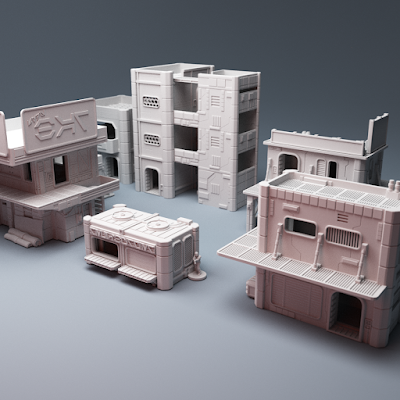

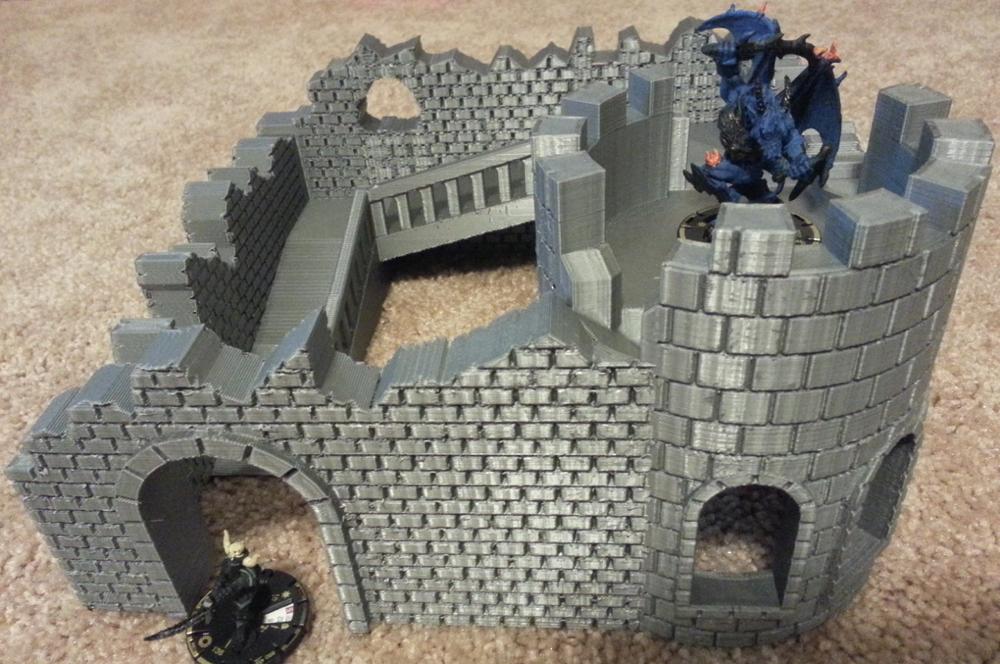

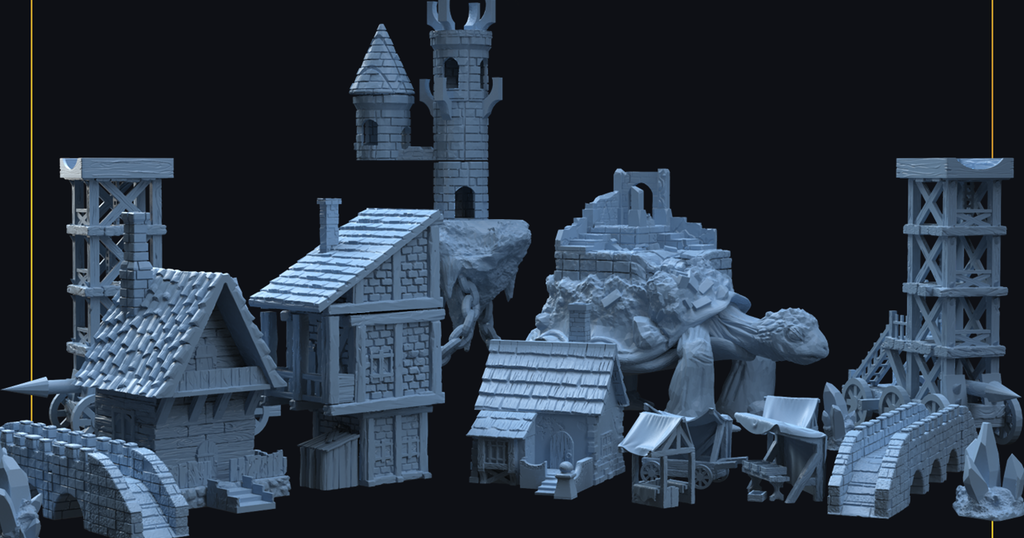

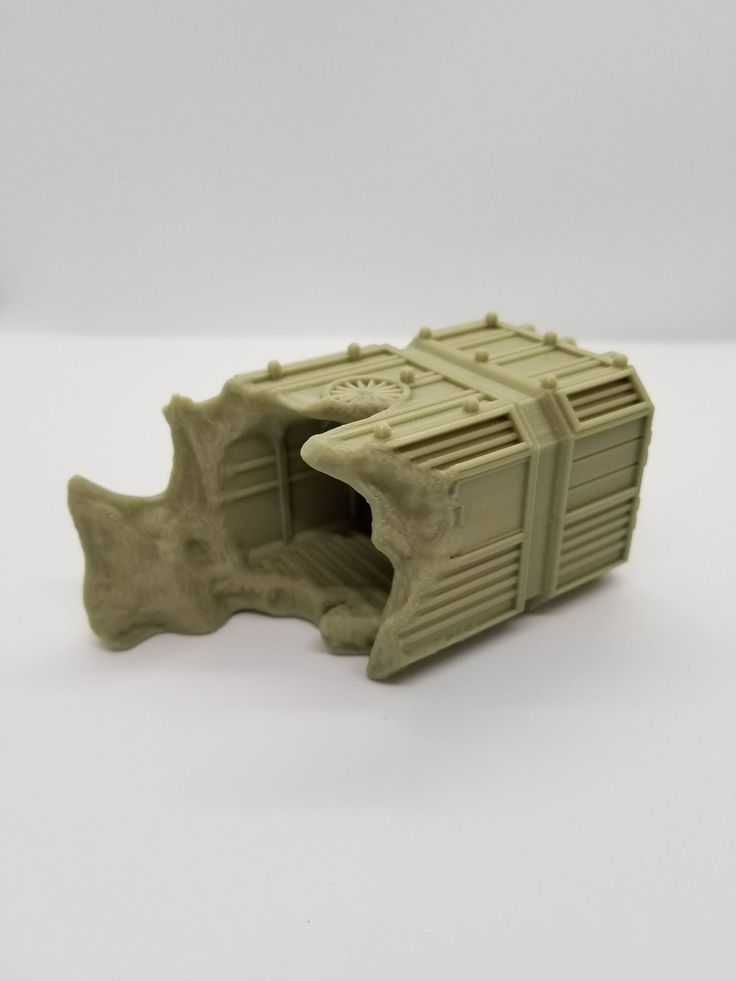

3D printed tabletop terrain

3d Printed Terrain - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Buildings Archives - Infinite Dimensions Games

-

New!

Add to Wishlist

USD $24.

95Add to cart

-

New!

Add to Wishlist

USD $19.95Add to cart

-

Add to Wishlist

USD $18.95Add to cart

-

Add to Wishlist

USD $18.95Add to cart

-

Add to Wishlist

USD $19.95Add to cart

-

Add to Wishlist

USD $12.95Add to cart

-

Bundle Deal!

Add to Wishlist

USD $24.40 Add to cart

-

Add to Wishlist

USD $12.95Add to cart

-

Add to Wishlist

USD $10.95Add to cart

-

Add to Wishlist

USD $10.95Add to cart

-

Add to Wishlist

USD $14.95Add to cart

-

Bundle Deal!

Add to Wishlist

USD $8.97 Add to cart

-

Add to Wishlist

USD $18.95Add to cart

-

Add to Wishlist

USD $14.95Add to cart

-

Add to Wishlist

USD $25.95Add to cart

-

Add to Wishlist

USD $18.95Add to cart

-

Add to Wishlist

USD $12.95Add to cart

-

Bundle Deal!

Add to Wishlist

USD $106.09 Add to cart

-

Add to Wishlist

USD $4.95Add to cart

-

Add to Wishlist

USD $18.95Add to cart

-

Add to Wishlist

USD $4.95Add to cart

-

Add to Wishlist

USD $3.95Add to cart

-

Bundle Deal!

Add to Wishlist

USD $6.93 Add to cart

-

Add to Wishlist

USD $15.95Add to cart

-

Add to Wishlist

USD $5.95Add to cart

-

Add to Wishlist

USD $19.95Add to cart

-

Add to Wishlist

USD $18.95Add to cart

-

Add to Wishlist

USD $29.95Add to cart

-

Add to Wishlist

USD $29.95Add to cart

-

Bundle Deal!

Add to Wishlist

USD $55.90 Add to cart

-

Add to Wishlist

USD $19.95Add to cart

-

Add to Wishlist

USD $29.95Add to cart

Wishlist 0

Continue Shopping

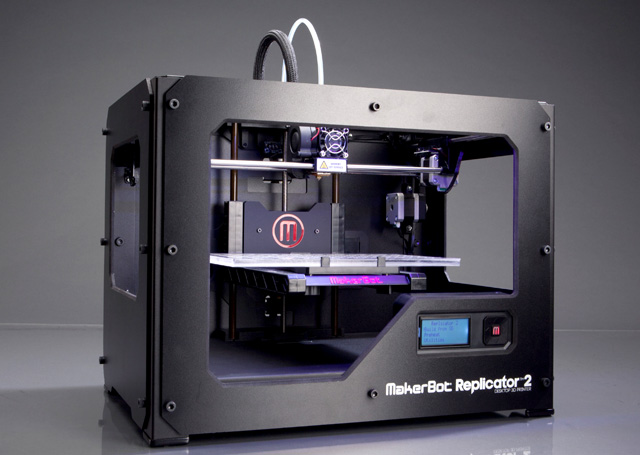

Types of tables for 3D printer

Contents

-

- Print platform materials

- Heated table

- Non-heated table.

- Table surface

- Types of calibration

- Automatic calibration

- manual calibration

- Calibration of a 3D printer table with Cartesian kinematics

- Calibration of the Delta printer 9000 9000

- Print platform materials

The correct calibration of the 3D printer bed, or as it is also called Hot Bed, is very important. The first layer is like a foundation for a house, if the foundation is fragile, then the house will not stand for a long time.

If the plane of the printed surface is uneven, then the model may be partially peeled off or deformed. The first layer may not stick to the printing platform at all, and the result of many hours of printing will not be a neat 3D model, but plastic noodles.

Print failure example

Therefore, it is very important to properly calibrate the table. Printing platforms can be conditionally divided into two types - adjustable and not.

The adjustable table is attached to the printer with spring-loaded screws. It is not rigidly fixed in height and with the help of screws it is possible to calibrate the plane and the gap between the 3D printer table and the nozzle.

Adjusting screw

Unregulated is a printing platform that is rigidly fixed to the printer body. This solution is used in delta printers. Calibrate them only programmatically.

Non-adjustable delta printer table

Print platform materials

The material from which the table is made may vary depending on whether the table is heated or not.

Heated table

There are several types of heating elements for a 3D printer platform - aluminum, textolite, silicone and kapton. Each of them has its pros and cons.

Textolite heater - inexpensive, but fragile and can be strongly bent when heated.

Silicone heater - can not be used alone. Usually used in conjunction with a metal base.

Usually used in conjunction with a metal base.

An aluminum table is expensive, but it heats up more evenly and is less subject to thermal deformation than other platforms.

The Kapton heater is very expensive and cannot be used on its own. Usually glued to a metal base. Can be heated up to 200 degrees.

Types of heated printing surfaces

Most often, an aluminum heating table or a silicone heating pad is used in conjunction with an aluminum plate. Low price, ease of processing and high thermal conductivity make aluminum the most popular material for the manufacture of heated printing tables.

The main advantage of heating the printed surface is to increase the adhesion (adhesion) of the first layer of plastic. If the printer is with a closed case and a heated platform, a “passive thermal chamber” is created inside. Due to this, plastics with high shrinkage do not crack in layers during printing, the adhesion of layers (interlayer adhesion) increases, and internal stress is more evenly distributed during cooling.

But there are also disadvantages - when heated, the metal table expands a little, and since it has nowhere to expand, it begins to bend. For a printing platform up to 200x200 in size, deformation will not be very critical, but for larger tables this becomes a tangible problem.

Each manufacturer of 3D printers with a large printable area solves the problem of deformation of the metal table in its own way. For example, in Raise 3D, the table is fixed along the entire plane with pins at 13 points.

Heated table fixing Raise 3D

Table without heating.

An unheated printable surface is often used in 3D printers designed to work only with PLA and other low temperature plastics. For example - printers for children or large printers with an open case.

An unheated printable surface is often used in 3D printers designed to work only with PLA and other low temperature plastics. For example - printers for children or large printers with an open case.

For example - printers for children or large printers with an open case.

Children's printer with acrylic print bed

Tables without heating are made of aluminum or acrylic. If the table is aluminum, then glass or any other coating should be used on top. Aluminum is a soft metal and even a brass nozzle can scratch or damage it if not properly adjusted.

Heating table with aluminum base and mirror

Acrylic tables are often used in inexpensive 3D printers designed for kids. Acrylic is difficult to damage or break. You can print on an acrylic table without glass or other coating.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Flash Forge |

Table top

In order for the first layer to adhere to the table tightly, different surfaces are used that increase adhesion. It is more convenient to remove the model from the removable surface. If you need to immediately start printing another model, you can simply quickly change from one removable surface to another.

It is more convenient to remove the model from the removable surface. If you need to immediately start printing another model, you can simply quickly change from one removable surface to another.

The most popular table surface is the regular tempered glass or mirror. It is not expensive and available. It is believed that the accuracy class of the mirror is higher, but for small working areas (up to 200x200 mm), ordinary tempered glass is enough.

Glass itself does not hold the first layer well, so various adhesives or stickers are used to increase adhesion.

Ordinary glass can burst from a temperature difference or “crumble”, then the model comes off along with pieces of glass. Good thing it's easy to replace.

A piece of glass came off with model

Sitall glass - in fact, it is ordinary glass with the addition of boron oxide. This makes it stronger than ordinary glass and resistant to temperature changes. But the cost of such glass is much higher than ordinary or tempered glass.

But the cost of such glass is much higher than ordinary or tempered glass.

Sitall glass

Perforated table - mainly used for printing ABS plastic. Thanks to the perforation, the plastic adheres firmly to the print platform. In order for the bottom of the model to turn out to be even in the slicer settings, you need to enable printing on a raft (substrate).

Perforated table used in UP printers!

Stickers - There is a huge variety of stickers for printing platforms. It can be either ordinary masking tape or a specialized surface (rough with an adhesive surface).

The finished model is easier to remove from a flexible substrate than, for example, from glass. With some substrates, the model can be easily removed after the printing platform has cooled down. For some, you need to heat the table and only then tear off the model.

Separately, you can select a variety of compositions that are applied to the surface of the printing platform to increase the adhesion of the first layers. 3D varnishes, 3D adhesives, etc. Probably every 3D maker has his own special recipe for the same composition that almost everything sticks to. It can be BF glue mixed with a solvent or alcohol, ABS diluted in acetone, kvass with sugar, glue stick, etc.

Do not spray varnish or other sprays inside the printer. Glue particles can settle on mechanisms, fans, and even get on electronics. This can lead to damage to the 3D printer. Simply remove the platen surface from the printer and apply the adhesive.

Add to compare

Product added to compare Go

| Manufacturer | Raise3D |

Add to compare

Product added to compare Go

| Manufacturer | Flash Forge |

Add to Compare

Product added to comparison Go

| Manufacturer | Flash Forge |

Calibrations

In addition to choosing the surface of the print platform, it is important to correctly level the plane of the table and set the correct gap between the table and the nozzle. Calibration can be automatic or manual.

Calibration can be automatic or manual.

Printers with large print surfaces, such as the Raise 3D Pro 2 and Pro 2 Plus, are calibrated at the factory. The user only needs to check the gap between the table and the nozzle, because it may go astray during transportation.

Automatic calibration

Automatic calibration is performed using a sensor (optical or contact), which is mounted next to the extruder. The printer checks several points on the print platform one by one and remembers the values. The first layer will be printed correct for the curvature of the table.

You can meet the calibration using a conductive substrate that is placed instead of the printed surface. This method is rare, but still has a place to be. It is commonly used to calibrate 3D printers with delta or delta robot kinematics.

Automatic calibration allows you to quickly and effortlessly level the table. It becomes especially indispensable for printers with delta or delta robot kinematics. Optical sensors "do not see" glass, so for printers with an optical sensor, it is better to use other surfaces of the print platform.

Optical sensors "do not see" glass, so for printers with an optical sensor, it is better to use other surfaces of the print platform.

Some printer models have a menu with hints to help you properly set the platform plane and gap. It is enough to launch the “assistant” and follow the instructions on the screen. This is not exactly automatic calibration, but with such help it becomes much easier for a beginner to correctly calibrate the table.

An example of a 3D printer with automatic calibration is Raise E2. The Raise E2 extruder has a contact sensor to determine the distance between the nozzle and the printed surface. The resulting values help to correct the print height of the first layer. You can calibrate not the entire table, but only the area on which the model will be located.

Manual calibration

Manual calibration is when the user sets the plane of the table and the gap between the table and the nozzle himself. To do this, under the printing platform there are screws or winglets with which you can adjust the height of the printing platform.

To do this, under the printing platform there are screws or winglets with which you can adjust the height of the printing platform.

Calibration screws

The standard gap between the platform and the nozzle, for most printers, should be - 0.1-0.2mm. If there is no set of probes at hand, a standard A4 sheet folded in half can replace it. Before calibration, the print surface (if it is heated) and the nozzle must be heated.

Sometimes manufacturers of 3D printers recommend a gap between the table and the nozzle - 0. Therefore, read the instructions before calibrating.

We will consider the calibration of the two most common kinematics - Cartesian and delta.

Cartesian kinematics is based on the Cartesian coordinate system and the movement of the 3D printer's head along the x, y, z axes.

Printer example with Cartesian kinematics

In deltas, the extruder moves along 3 identical axes using carriages moving along vertical guides. The delta printer can be called a simplified delta robot, but these are still two different kinematics.

The delta printer can be called a simplified delta robot, but these are still two different kinematics.

Example of a printer with delta kinematics

3D printer table calibration with Cartesian kinematics

Different manufacturers may have slightly different calibration instructions. We will consider here the calibration of the printer with standard kinematics.

-

Heat up the table and nozzle. When heated, the metal expands slightly, so the gap between the printing platform and the nozzle may differ between the “hot” and “cold” ones.

-

Through the printer menu, send the table and extruder to the "home" or zero position in all axes. Usually the zero point is the near left corner of the extruder and the top position of the print platform. Be sure to make sure that the 3D printer does not rest the nozzle on the table and does not damage it. If this is the first calibration, use the nuts to lower the table as low as possible.

-

Through the printer menu or manually (for this you need to turn off the motors through the menu), move the extruder so that the nozzle is above the adjusting screw.

-

Use a feeler gauge and adjusting screw to set the gap between the print bed and the nozzle.

-

Repeat all steps for all calibration screws. Usually there are 3 or 4 screws.

-

After aligning the plane above the screws, move the extruder to the center and check the gap. If the gap matches the feeler gauge, then the table plane and platform distance are correctly calibrated.

Delta printer table calibration

Calibrating a delta printer is a very large topic, so here we will only describe the general principles.

The delta printer does not have the x, y and z axes we are used to. Instead, the delta printer has 3 towers - A, B, C, on which the carriages move.

Since the delta table is static, it is calibrated programmatically. The gap is calibrated by 3 points (at the columns) and the lens (center) of the table. The lens can be concave or convex.

The gap is calibrated by 3 points (at the columns) and the lens (center) of the table. The lens can be concave or convex.

Before calibration, check the mechanics of the printer - the belts must be tensioned evenly, there must be no play in the carriages and the effector (the plate to which the extruder is attached). If the belts are loose or uneven, it will be problematic to calibrate the printer.

Some 3D makers check belt tension with a tuner. Evenly tensioned belts will sound the same, but the correct “note” is found empirically.

There are a huge number of programs for delta calibration, but one of two is usually used - Pronterface or Repetier-Host. Using them, you can directly access the printer using special commands and change the values in the firmware.

As auxiliary programs, you can use a virtual calculator and from there transfer the values \u200b\u200binto the firmware or download the finished GCode. They need to specify the parameters of your printer - firmware (usually Marlin or Repetier), diagonal length, circumference, etc. These parameters can be taken from the firmware or measured with a caliper. It is important to specify all the parameters as accurately as possible, otherwise the printer will not be able to calibrate.

They need to specify the parameters of your printer - firmware (usually Marlin or Repetier), diagonal length, circumference, etc. These parameters can be taken from the firmware or measured with a caliper. It is important to specify all the parameters as accurately as possible, otherwise the printer will not be able to calibrate.

First, 3 points are aligned at towers A, B, C, and only then the lens in the center of the table is corrected.

Manual delta calibration is tricky, but it doesn't have to be repeated often. Typically, the printer only needs to be recalibrated after some mechanical parts, belts, or print bed cover have been replaced.

Totals

The calibration process may seem tedious and complicated, but in fact, once you do it yourself, the process will no longer seem so intimidating. In addition, most manufacturers try to help novice users and equip their printers with auto-calibration sensors or try to simplify this process as much as possible with detailed menu prompts.

And a variety of coatings for a printed table will help you find exactly the surface that suits your needs. As practice shows, every 3D maker, novice or experienced, has his own proven way to make the first layer stick tightly.

Don't be afraid to experiment and let every 3D print be successful.

Invented a modular 3D printing table that saves time and consumables / Sudo Null IT News

SLY_G

Popular science 3D printers

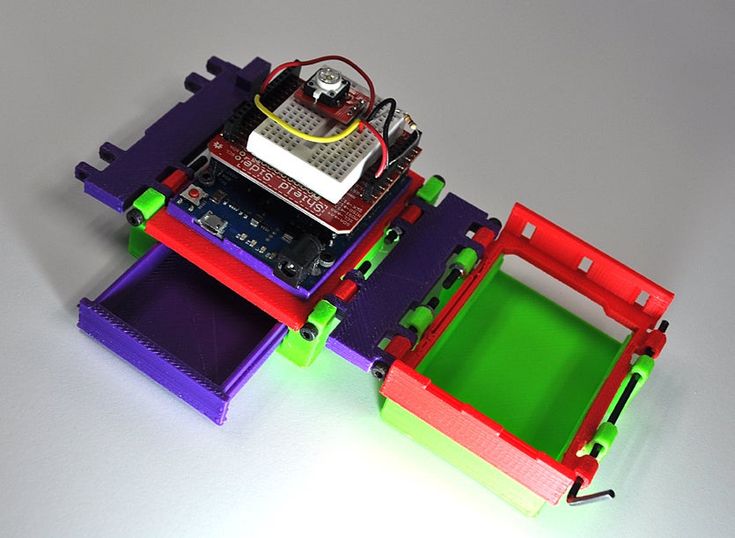

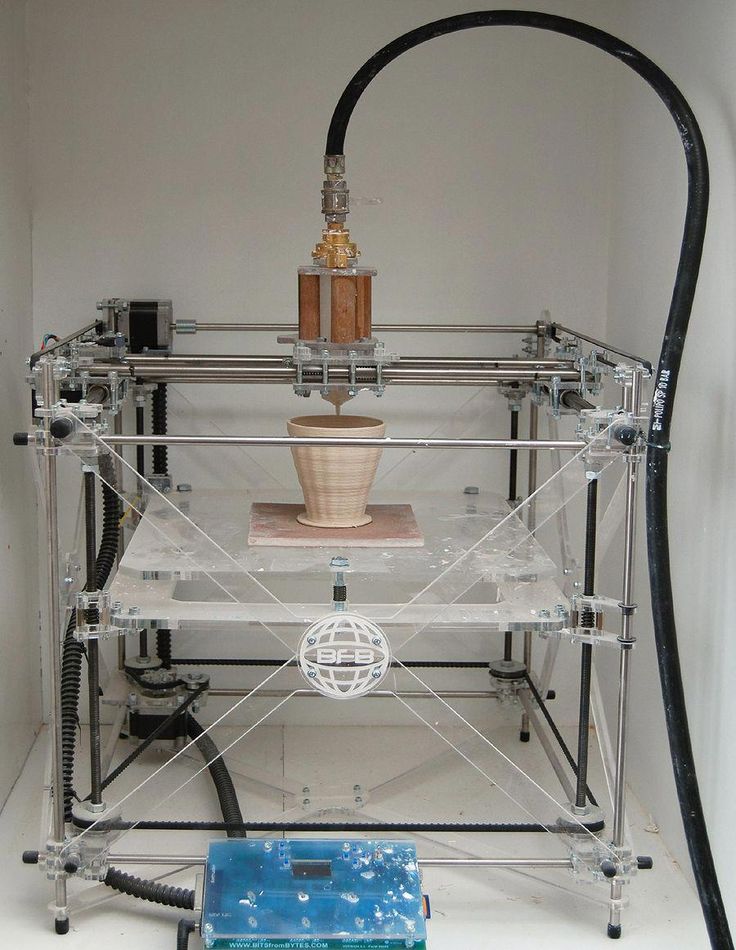

Researchers from the College of Engineering. Viterbi at the University of Southern California has developed a unique 3D printer bed that can dynamically change its surface configuration. Such a table in the future will reduce printing time and material consumption.

Left - printing as on a regular table, with long supports. In the middle is a seal with shortened supports due to the rise of the table parts.

In the middle is a seal with shortened supports due to the rise of the table parts.

Instead of the standard large and flat surface of the printing table, the researchers' prototype uses a composite table consisting of many small plates. Each of them is able to rise on command given by the program that controls the print. The plate raised in height saves the material consumed when printing a similar support. According to engineers, this technology can save about 35% of plastic.

Prof. Yong Chen of Industrial and System Engineering and Ph.D. Yang Xu supervised the work. The results of their research are published in the journal Additive Manufacturing.

Although inexpensive plastic is most often used for printing, support structures such as supports are usually considered waste and thrown away. This contributes to the growing problem of increasing 3D printing waste. In addition, Professor Chen said that he is working with biomaterial printing technologies, in which consumables are very expensive.

95

95 90

90