Are 3d printed houses safe

Are 3D printed houses safe?

Right after the fascination on what a 3D printed house actually is sets in, one of the first questions we’re asked is, “ok, but are 3D printed homes safe?”

3D printed homes are similar to traditionally built concrete houses in a variety of ways. Concrete is completely sound and has been used in architecture for centuries. It is still an excellent building material today for many modern structures. In fact, concrete walls are safer than many other common building materials!

It’s important to remember that 3D printed houses need to meet local state laws and regulations. In other words, these homes are required to be up to code in order to live in, like any other home. Safety is always the top priority.

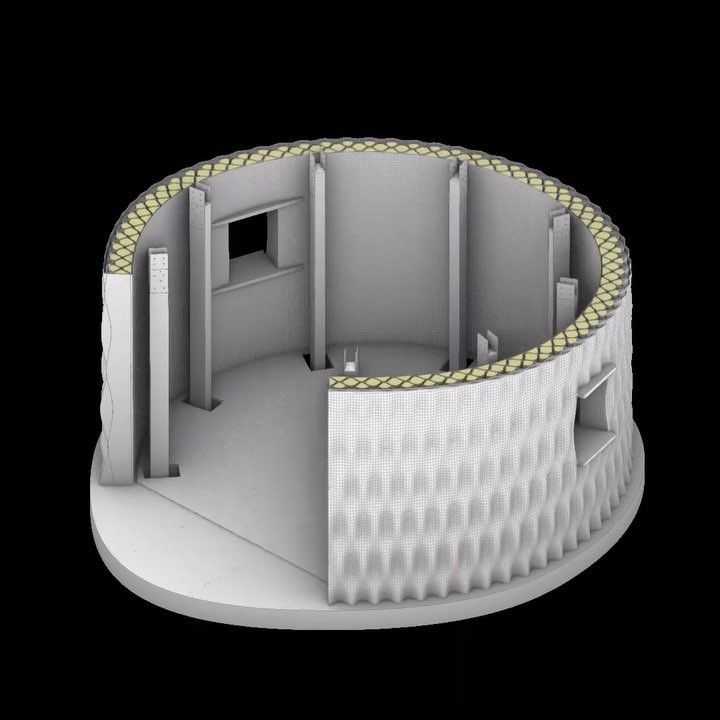

Let’s familiarize you with how these houses are built. You’ll feel a lot more confident once you understand how it’s structurally sound.

How is a home 3D printed?

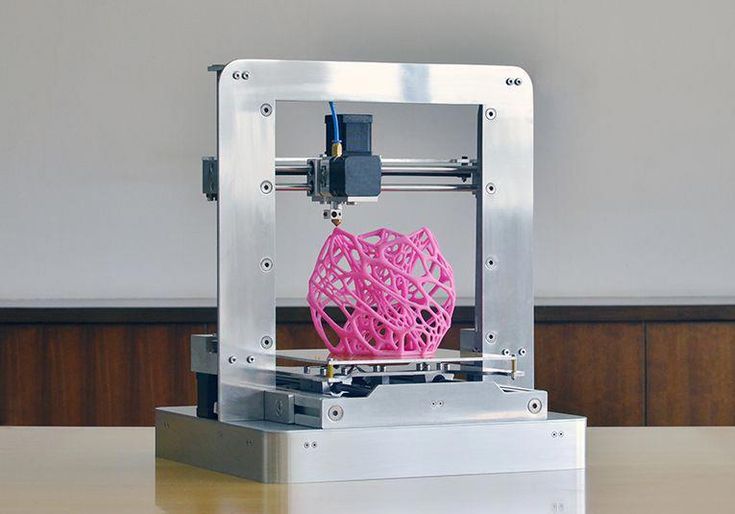

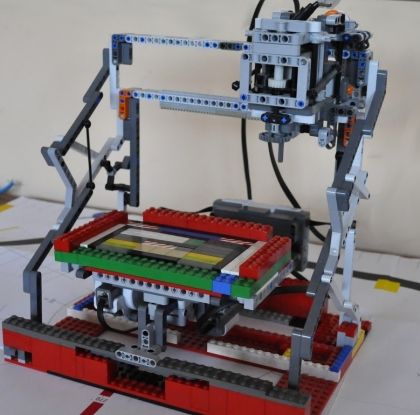

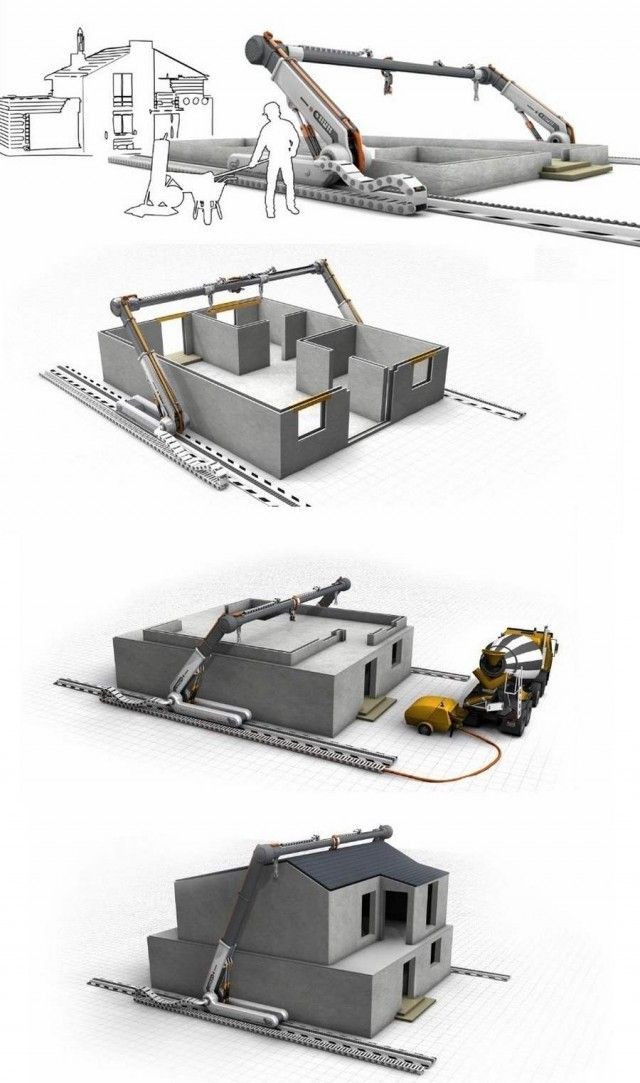

We have developed 3D printers to extrude concrete mixture with ideal consistency and a controllable drying factor. These are two important factors that allow SQ4D to continually stack layers of cementitious mix and retain dimensional accuracy, while allowing the concrete to flow smoothly.

Many outside factors can influence drying time, stacking, and flowability. Being in full control of your mix is extremely important for consistent concrete mixes – this is why we mix our concrete on-site, on-demand.

Once the workers set the machine to print, our system extrudes the concrete according to the floorplan.

It’s safer because there’s less to go wrong and less direct exposure to the silica in the wet concrete.

Did you know?

Concrete produces little waste. Building a 3D printed concrete house is not only SIGNIFICANTLY

more environmentally friendly than other modern houses, but also that much cooler to live in.

3D printed concrete walls vs. wood: Which is safer?

Wood has been standard in residential construction for years now, but it is weaker than most concrete mixes and easily damaged. Concrete constructed houses might sound unusual to some, but it’s been used all throughout history, for thousands of years.

Concrete constructed houses might sound unusual to some, but it’s been used all throughout history, for thousands of years.

It’s very prevalent in Florida, Europe, and high wind areas. In fact, the Pantheon is over 1,800 years old and was built with concrete! Both wood and concrete are safe and completely legal, but did you know that concrete is the safer of the 2?

Many outside factors can influence drying time, stacking, and flowability. Being in full control of your mix is extremely important for consistent concrete mixes – this is why we mix our concrete on-site, on-demand.

Once the workers set the machine to print, our system extrudes the concrete according to the floorplan.

Here’s why concrete is thought to be safer:- Concrete is not vulnerable to the elements the way wood is. For example, concrete is far more resistant to fire and pests.

- Our concrete is handled by a machine.

Less handling means less work related injuries and direct exposure to the material when it’s wet.

Less handling means less work related injuries and direct exposure to the material when it’s wet. - Our concrete has been compression tested to 6000+ psi, making it far more durable than wood.

- Wood is susceptible over time, whereas concrete is a lot more resistant to aging issues like mold.

Does that mean my house will survive the nuclear apocalypse?

Whoa, whoa, whoa, slow down there! A 3D house is definitely strong and durable, but it’s not the modern-day answer to a bunker.

Between the concrete and special pre-engineered truss system, a 3D house is safe enough to withstand a lot of additional force.

In other words, you can trust your 3D printed concrete to withstand:

- Fires

- High-speed winds

- Extreme temperatures (blizzards and extreme summer heat)

- Earthquakes

- Floods or droughts

But — a cement house is still a house. It’s still mostly aboveground, has windows, and is influenced by a majority of factors.

We can’t predict all that can go wrong, and we are a firm believer in respecting Murphy’s law when it comes to forces beyond our control (e.g. mother nature). So in the event of a serious natural disaster, we recommend you follow protocol and evacuate for your safety.

How are 3D printed house legal?!

Sounds too good to be true, huh? 3D printed houses are the result of years of technological experimentation and engineering innovation. While our industry is growing tremendously, we’re proud to say that we’re at a point where we can print 3D houses safely, and even exceed local code and housing regulations.

That’s right, these structures must meet the same safety standards and expectations as any other house. The fact that we are able to build houses at a lower cost with what used to be “the more expensive choice” is incredible! We hope you decide to come live the dream with us by living in ours!

SQ4D is working on printing houses all over the nation. Are you signed up for our mailing list? Make sure you don’t miss out on the next build near you.

Are you signed up for our mailing list? Make sure you don’t miss out on the next build near you.

Are 3D Printed Homes Safe By Modern Standards? — urdesignmag

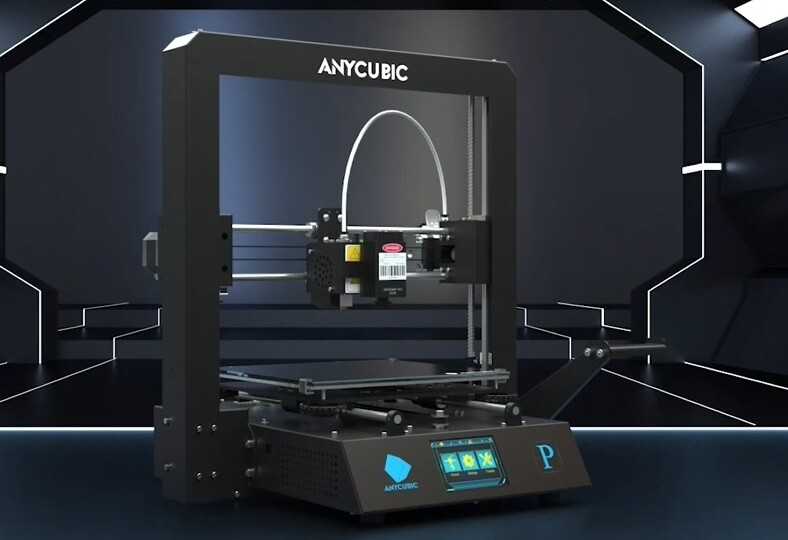

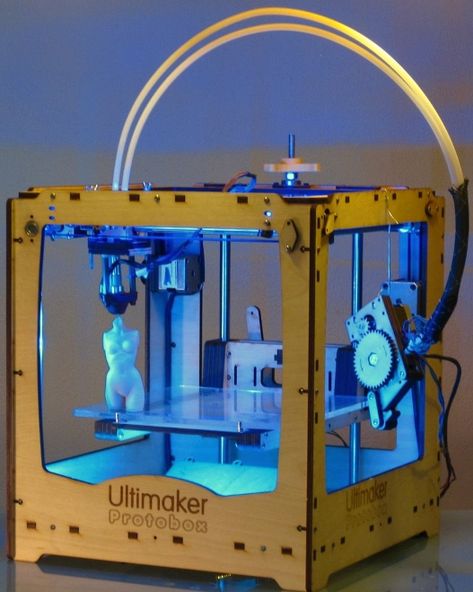

3D printing technology has become a staple in many aspects of modern production, including the construction industry. Homes that once took months or years to build are easily constructed using 3D printers in mere days or weeks, and though these properties are not considered the norm yet, it is likely that in the years to follow, their versatility will only increase homeowners’ willingness to move into these modern dwellings.

April 30, 2021 marks a milestone for 3D printing worldwide as the first time occupants have moved inside of a 3D printed property. Though highly practical, modern, and efficient, many still pose the question, are 3D printed homes safe?

3D Printed Homes Reportedly Safer Than Traditional Options

Many sources and builders alike have made claims that 3D printed homes aren’t just safer, but more durable and last longer than traditional built dwellings. They are carefully constructed with climate control, natural disasters, and inclement weather conditions in mind during the planning process.

They are carefully constructed with climate control, natural disasters, and inclement weather conditions in mind during the planning process.

The question of safety standards is easily traced back to 2014. In China, a printing architecture firm by the name of Winsun, planned and erected the first functioning 6-story apartment building while also making frontpage news that they have managed to print 10 functional homes in just one day. As of the year 2020, this same company has made claims that they have constructed at least 15 houses with fully functioning interiors. However, the question many ask is whether these same buildings are safe?

Each 3D printed property is constructed from eco-friendly yet highly durable materials that are guaranteed to remain twice as strong as traditional concrete and wood. Namely, these materials are sand as well as construction rubble from other projects. The printer can form these materials into something wholly durable and fully recyclable.

No Building Codes Exist As Of Yet

One of the biggest pitfalls of 3D printed homes is that there are no set standard building codes or procedures that manufacturers must adhere to. That means many of the purportedly safe printed dwellings aren’t ready to receive their first occupants. The government must make it a priority to establish guidelines for the plumbing, electrical, structural integrity, and overall safety of these modern properties. Unfortunately, 3D printed homes are hardly a viable alternative to traditional homes without government regulations.

Though the Chinese company, Winsun, has purportedly manufactured many such homes, they do not allow for insight into their building processes. This also means that the safety of their construction projects is forever called into question and their properties remain unoccupied as of right now.

The Longevity Of 3D Printed Homes

Traditional homes can last up to 100 years or more with proper maintenance, and as few as 20 or 30 years without maintenance. Most companies that currently print homes using 3D technology claim that their properties can for certain survive up to 60 years as long as they are maintained and constantly occupied.

Most companies that currently print homes using 3D technology claim that their properties can for certain survive up to 60 years as long as they are maintained and constantly occupied.

The integrity of the manufactured homes also depends on the materials used. Many companies opt for concrete-based mixes, however, if timber frames are also incorporated into buildings, it can significantly decrease their safety and longevity.

The Conclusion

Though highly creative, affordable, and environmentally-conscious, the lack of established safety standards call into question the integrity of 3D printed homes. They are ideal short-term dwellings, but whether they truly stand the test of time remains to be seen.

Comments

comments

3d printingHouses

The world's first 3D printed house

June 21, 2016

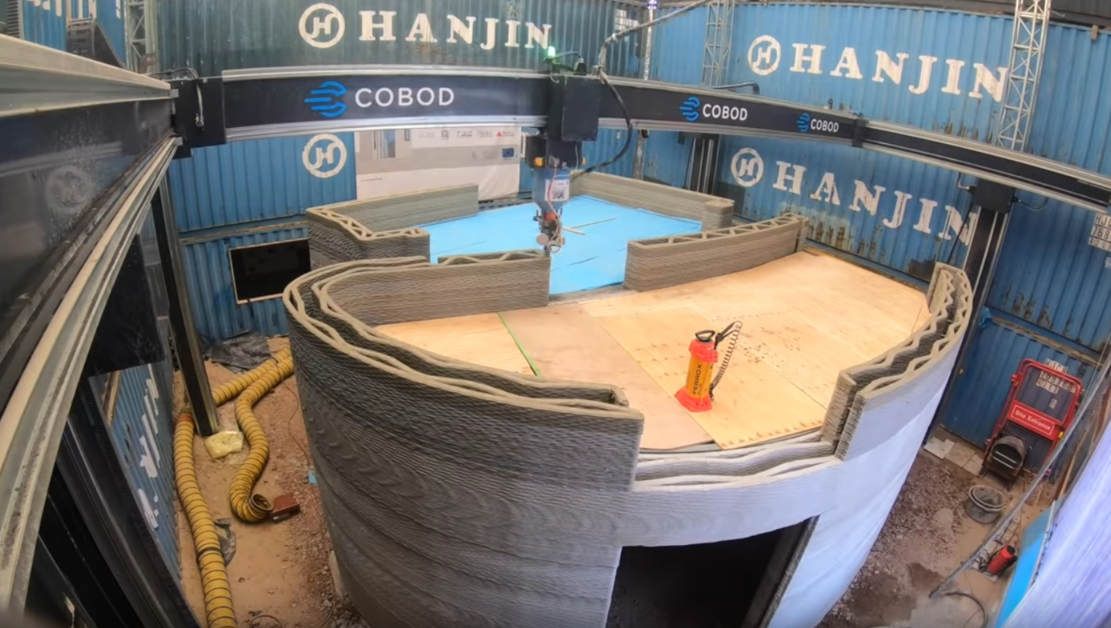

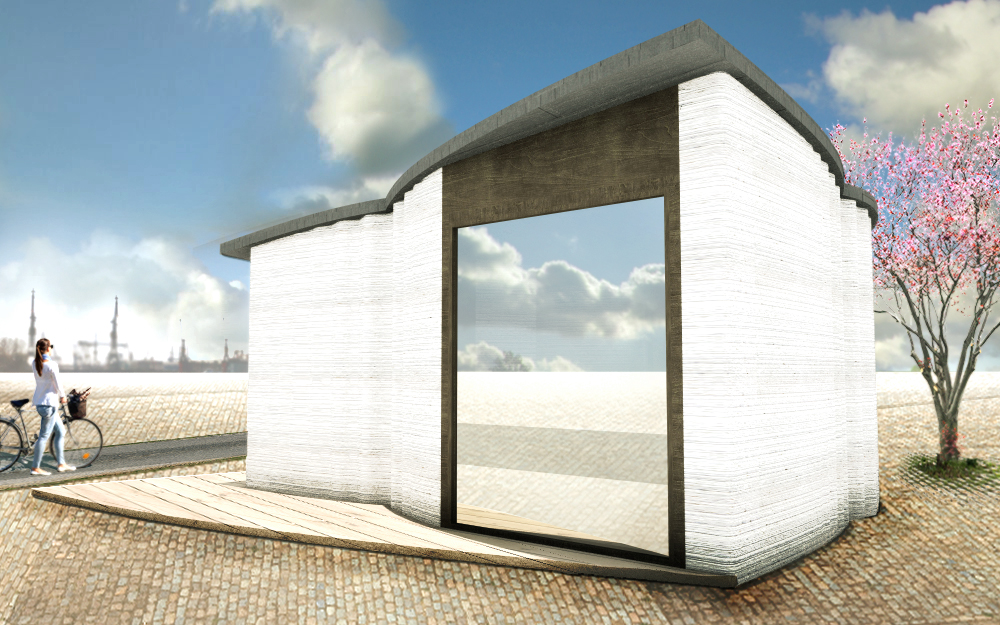

The world's first 3D printed building has appeared in the capital of the United Arab Emirates. It was erected in the city center near the Dubai International Financial Center.

A 250,000 square meter one-story office building was erected in the city center near the Dubai International Financial Centre. It has electricity, telecommunications, water supply and an air conditioning system.

Construction using new technology cost $140,000. This is about 50% cheaper than the same building erected in the traditional way.

Construction team consisted of 19 people. One monitored the work of a 3D printer, eight assembled a house from printed elements, the rest carried out engineering communications. The creation of the office building took 17 days, another two days were spent on decorating the premises inside.

For construction, a 3D printer 6 m high, 37 m long and 12 m wide is used. Workers only need to install the rails along the contour of the future house and the 3D printer structure, the rest will be done by the computer.

The robot moves along the rails, spreading concrete until the house is completed. It remains for builders to install windows and doors in prepared openings.

0

- VKontakte

- Odnoklassniki

- Copy link

Add to the elected

900

9004Popular new buildings

Show more

also read all articles

ratings

11/29/2022

Top-5 of available new buildings near the MCD-5

In the summer of the capital, the authorities of the new line MTsd-5, which will connect Domodedovo and Pushkino. Of course, real estate market specialists expect an increase in demand in this regard...

Of course, real estate market specialists expect an increase in demand in this regard...

ARCHITECTURE AND DESIGN

0003

Five interiors based on the principles of the Bauhaus

History's most famous art and design school, Bauhaus' was founded in Germany in 1919 and, although it closed just over a decade later, it still...

TRENDS

24.11.2022

Prices for new premium-class buildings fell by 14% over the year

Surprisingly, the premium segment has become the only class among the capital's new complexes, where the price tag has decreased over the year. So, according to...

7 amazing things you can 3D print

August 16 Technology

Real food, living heart, rice eco-house and other useful "printouts" that can solve the world's problems.

1. Human organs

Scientists can now print skin, kidneys, liver tissue, heart and a number of other organs. True, while they are usually smaller than real ones, and therefore suitable only for clinical trials or surgical practice. But in the future, they should seriously help in the fight against various diseases. For example, they want to use 3D skin as a means for healing wounds. And full-fledged printed hearts or kidneys can shorten the queue for donor organs and save more lives: hundreds of thousands of people need transplants every year.

But in the future, they should seriously help in the fight against various diseases. For example, they want to use 3D skin as a means for healing wounds. And full-fledged printed hearts or kidneys can shorten the queue for donor organs and save more lives: hundreds of thousands of people need transplants every year.

3D organs are created from real living cells, either from adult stem cells or from a sample taken directly from a person. They play the role of ink, which the printer heads put on an organic or synthetic base. The correct shape, texture and tissue layers are programmed based on the results of the scan - this ensures maximum copy accuracy. The main challenge facing scientists now is to find an opportunity to create organs that can function inside the body: to contact the nervous and circulatory systems and perform their tasks correctly.

2. Bones and cartilage

Illustration: Phonlamai Photo / Shutterstock And here they are already being used by surgeons in real life. For example, 3D implants are used to replace femurs. There are also successful examples of transplantation of printed bones of the skull and cartilage of the auricle. The next step in the application of this technology may be the replacement of small damaged areas right inside the person. Such a 3D printing method, according to the researchers, will speed up the process and save in cases where speed of reaction is critical, for example, in the treatment of bone cancer.

For example, 3D implants are used to replace femurs. There are also successful examples of transplantation of printed bones of the skull and cartilage of the auricle. The next step in the application of this technology may be the replacement of small damaged areas right inside the person. Such a 3D printing method, according to the researchers, will speed up the process and save in cases where speed of reaction is critical, for example, in the treatment of bone cancer.

3D printers also come in handy in dentistry. They simplify the process of creating crowns, bridges and prostheses: the specialist does not need to select sizes manually - the model is formed and printed on the basis of images of the oral cavity. They can also be used as temporary implants to help patients get used to their new teeth and make sure they fit well in their mouths. The technology is safe: special photopolymer resins are used for printing. They are strong, retain an aesthetic shade for a long time and do not irritate the mucous membrane.

3. Prostheses

Arms, legs and other parts of the body. Due to the simplified manufacturing process, 3D prostheses cost less and are created faster. In the standard scheme, you first need to make a cast of the remaining part of the patient's limb, then cast a trial version from plaster, then try it on, correct inaccuracies, and only then proceed to create the finished product. In the 3D version, it is enough to collect measurements, correct the model on the screen and print it.

However, these prostheses do not necessarily have a purely cosmetic function. 3D hands with touch control, that is, a reaction to body signals, or with a vibrational response to touching objects already exist. In addition, it is easier to replace a printed artificial limb after wear with a similar one by re-creating it according to the saved layout.

3D prostheses can be used for more than just humans. For example, in Australia, an artificial leg for a dog was created on a printer.

The speed and cost of producing 3D prostheses is a chance for many children: conventional options are rendered useless too quickly due to the active growth of the child. And a printed model can be created even for a one-year-old patient who is just learning to move: scientists from Lincoln University have already presented such a development.

4. Food

Brands use 3D printers to model future products or create unusual shapes for everyday food. Creative serving options are also used in some restaurants. In 2016, an entire restaurant was temporarily opened in London, the menu of which consisted entirely of dishes obtained using 3D technology.

But choosing the look isn't the only benefit of 3D food printing. Due to the possibility of virtual programming of the composition, the dishes created by the printer are easy to adjust to the desired nutritional value: control the calorie content, the amount of proteins, fats, carbohydrates, fiber, vitamins. This will make life easier for people who are on a strict diet for medical reasons. Also, the printer will allow you to cook the usual food, but from budget ingredients. For example, to form a fish fillet from seaweed. This, in theory, should help solve the problem of world hunger.

This will make life easier for people who are on a strict diet for medical reasons. Also, the printer will allow you to cook the usual food, but from budget ingredients. For example, to form a fish fillet from seaweed. This, in theory, should help solve the problem of world hunger.

In the future, 3D printers could make eating more ethical. For example, they will make it possible to stop killing animals for the production of meat products. One of the alternative options here is the creation of meat entirely based on plant components.

Another way is to form "ink" for a 3D printer from a meat sample taken from an animal by biopsy. A device for printing using this technology was created at the Moscow State University of Food Production (MGUPP). True, for a 3D printer to be able to make a whole steak from a tiny piece of fabric, it takes several months. First, the sample is cultured in a bioreactor. When there are enough cells, they begin to form the base - from ingredients of plant origin. After that, animal and vegetable “ink” are alternately applied to it. As a result, the product retains both taste and texture.

After that, animal and vegetable “ink” are alternately applied to it. As a result, the product retains both taste and texture.

The MGUPP 3D printer is capable of printing not only meat, but also, for example, chocolate or dough. University researchers plan to experiment with the technology further to expand their product range.

5. Clothing and footwear

Illustration: asharkyu/ShutterstockMany brands produce 3D printed items. For example, Nike printed the upper part of the sneaker, and Adidas made the midsole. Dresses by Dutch designer Iris van Herpen, sewn using this technology, are regularly worn by celebrities. Austrian Julia Koerner also works with the printer - accessories that she created in collaboration with costume designer Ruth Carter, worn by Angela Bassett in the movie "Black Panther".

Fashion 3D printing expands the creative possibilities of designers, allowing for futuristic shapes that are difficult to achieve with conventional sewing methods. However, this is not the main advantage of the technology. A 3D printer reduces resource consumption: a thing or its element immediately appears in the right size - no extra shreds and threads remain. In addition, 3D fabric requires less water to make than cotton, and it can also be quickly created from recycled or recycled materials. In the future, the printing of things can destroy fast fashion, allowing you to create them piece by piece, ideally suited to the parameters and requests of the client.

However, this is not the main advantage of the technology. A 3D printer reduces resource consumption: a thing or its element immediately appears in the right size - no extra shreds and threads remain. In addition, 3D fabric requires less water to make than cotton, and it can also be quickly created from recycled or recycled materials. In the future, the printing of things can destroy fast fashion, allowing you to create them piece by piece, ideally suited to the parameters and requests of the client.

6. Laboratory instruments

Printed instruments, due to the speed and cost of production, can help in research in poor countries. Now there are several projects that create budget microscopes for diagnosing malaria in Tanzania.

3D technology makes science accessible to amateurs too. For example, Australian researchers have developed a microscope attachment for a smartphone and made the files available to the public: anyone who has a printer can create such a device.

.jpg)