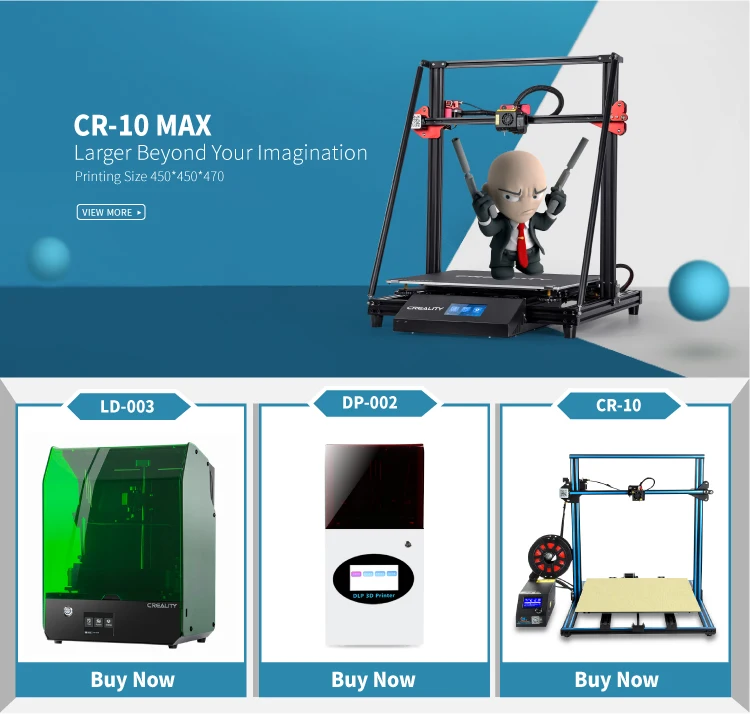

Alibaba 3d printers

Alibaba and Tronxy 3D Sued Over 3D Printer Fire Death

3D printing news News Alibaba and Tronxy 3D Sued Over 3D Printer Death in San Fransisco

Published on June 14, 2022 by Madeleine P.

According to court documents from San Fransisco, the parents of Calvin Yu, who died in a fire caused by a 3D printer in 2020, are suing both the 3D printer manufacturer, Tronxy 3D, and Alibaba. The fire occurred when a Tronxy X5SA 24V 3D printer overheated and caused a fire when it ignited the couch. This caused fatal injuries in Calvin Yu. Now his parents are seeking damages from the two companies under a number of complaints including negligence and product liabilities concerning printer defects and failure to warn.

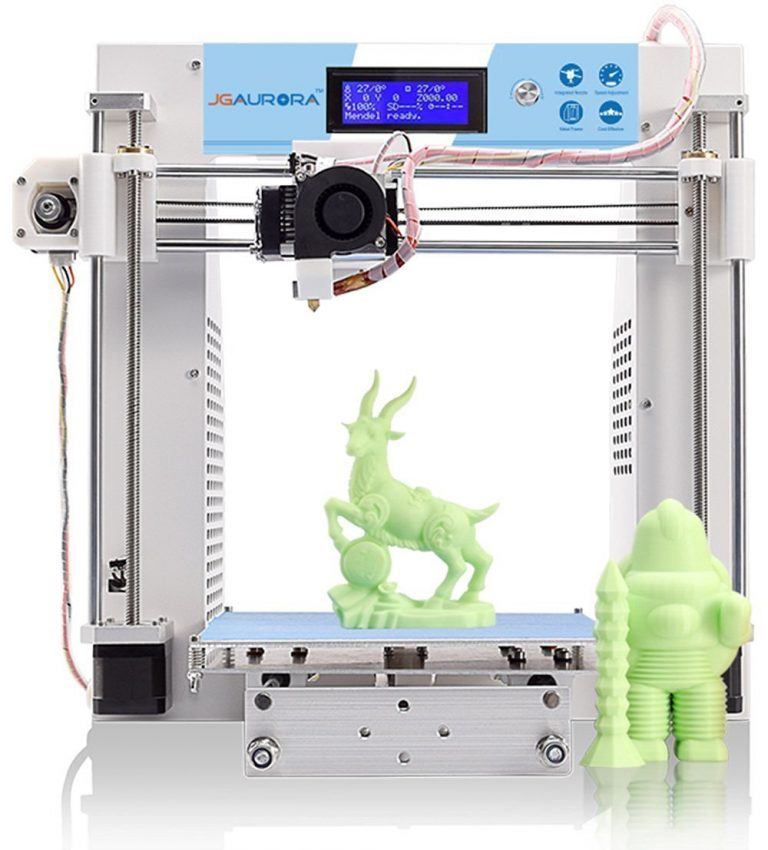

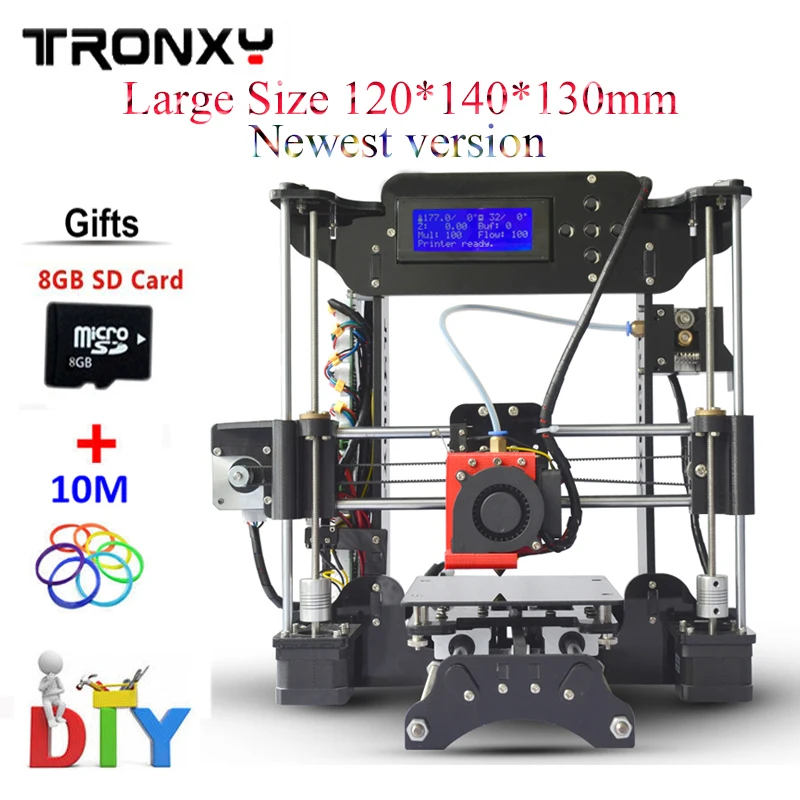

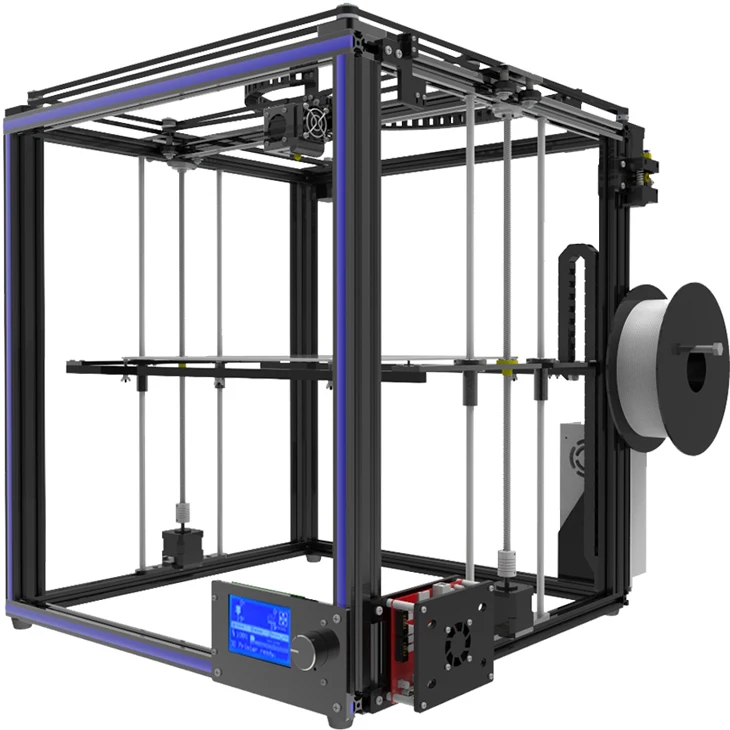

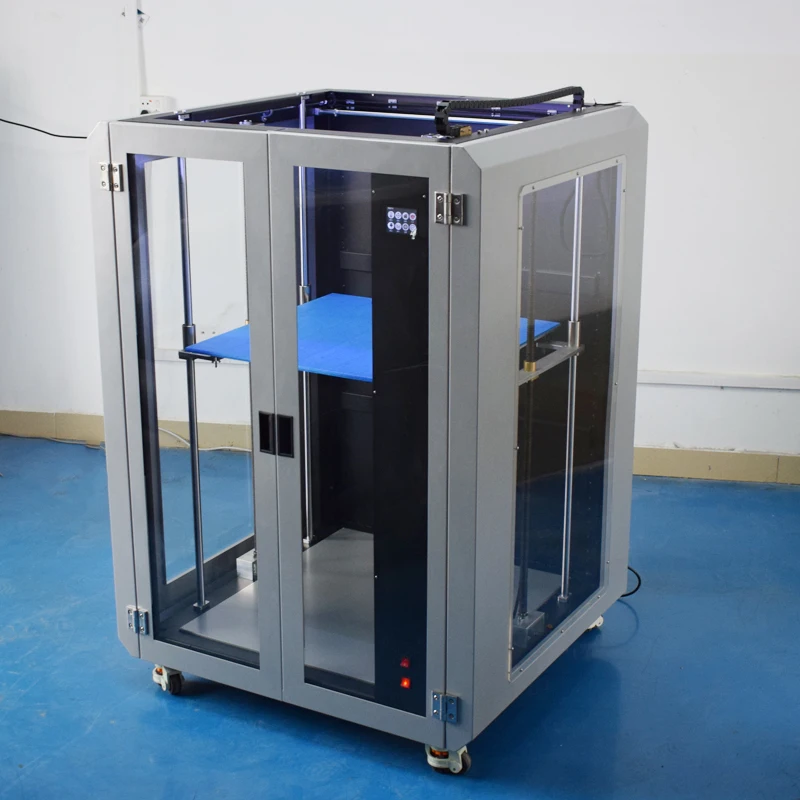

You have probably at least heard already of Alibaba, the multinational technology company specializes in e-commerce, retail, internet and technology, among other things. Most importantly in the case of this lawsuit, the company also own AliExpress, an online retail service based in China, similar to Amazon and popular for its worldwide free shipping and low prices. Meanwhile, Tronxy 3D is a popular Chinese manufacturer of 3D printers including DIY options. They focus primarily on FDM, LCD and ceramic printers. In this case, the fire was caused by a Tronxy X5SA 3D printer, one of the more popular models which is available from only $280.00 and which was bought from AliExpress.

A Tronxy X5SA 24V 3D Printer caused the fire when it overheated (photo credits: Tronxy)

The Yus’ Case for Damages Against Tronxy and Alibaba

In the court documents, it was noted that the San Fransisco Fire Department did find that the direct cause of the fire was the 3D printer which was plugged into an outlet when it overheated. They also concluded that Calvin Yu’s death was a result of thermal injuries caused by the supposedly defective 3D printer. Hoi Kwong Yu and Janice Yu are now seeking damages as they claim that 3D printer was being used as intended and thus was defective and malfunctioned. They also place the blame on Alibaba and Tronxy for not sufficiently warning them of potential dangers or properly checking the machine. The documents note that, “[The] Defendants…had a duty to warn Decedent Calvin Yu about the defects in, and the dangers associated with, use of the Tronxy X5SA 24V 3D printer of which they were aware, or in the exercise of ordinary care, should have been aware, at the time the printer left the Defendants’ control.”

The documents note that, “[The] Defendants…had a duty to warn Decedent Calvin Yu about the defects in, and the dangers associated with, use of the Tronxy X5SA 24V 3D printer of which they were aware, or in the exercise of ordinary care, should have been aware, at the time the printer left the Defendants’ control.”

In fact, according to users on Reddit, this could have been caused by a previously known issue with Tronxy printers where thermal runaway protection, or essentially protection system that prevents a printer to heat up uncontrollably, was disabled. This was discovered by Angus Deveson from Maker’s Muse who subsequently notified the company. The company did apparently respond and updated the firmware for all 3D printers to enable it. However, this 3D printer was potentially bought before this could be done as according to the court documents, it was bought on November 9th, 2019 and Maker’s Muse published an update on November 19th, 2019. Though it should be noted that this is speculation in this specific case.

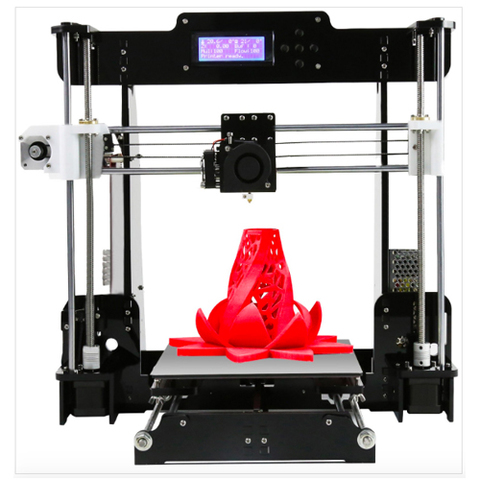

Tronxy 3D printers are available on AliExpress

Moreover, the court documents name strict liability (failure to warn) as one of the complaints. They note that “Defendants…knew or should have known of the Tronxy X5SA 24V 3D printer’s propensity to overheat and catch fire.” Suggesting that this could have played a role. This is increasingly a common issue not just with stores directly selling goods, but for retail services like Alibaba and Amazon, who have been found to often be on the hook for liabilities relating to projects that they have sold. The issue became so large for Amazon as it faced complaints over third-party sales that the company implemented a new policy last year which stated that it would pay customers up to about $1000 when a third-party causes property damager or personal injury. To our knowledge, Alibaba has no such policy, but the precedent is clear.

Regardless, it is important to consider that even with at home desktop 3D printers, there are potential dangers. According to the CDC, users should be mindful of potentially potentially in harmful materials, being in contact with hazardous materials as well as the risk of static, fire or even explosions. While these are by no means common, even beginners with “easy-to-use” 3D printers should ensure that they are aware of safety features and know how to implement them. These measures will help minimize the potential for risk or death while using machines which ultimately are not toys. We will keep watch for any updates on this developing story. In the meantime, you can read the court documents as uploaded by The Register for Yu v. Alibaba Group HERE.

According to the CDC, users should be mindful of potentially potentially in harmful materials, being in contact with hazardous materials as well as the risk of static, fire or even explosions. While these are by no means common, even beginners with “easy-to-use” 3D printers should ensure that they are aware of safety features and know how to implement them. These measures will help minimize the potential for risk or death while using machines which ultimately are not toys. We will keep watch for any updates on this developing story. In the meantime, you can read the court documents as uploaded by The Register for Yu v. Alibaba Group HERE.

What do you think of Yu v. Alibaba Group? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Cover Photo Credits: © Frank Schulenburg / CC BY-SA 4. 0

0

3D Printing News Sliced: Alibaba, EA, Amazon, Telescope Prime

This week’s edition of Sliced, the 3D Printing Industry news digest features additive manufacturing trade fair updates, 3D printed body armour and game controllers for people with disabilities.

We also cover Amazon, Alibaba, Desktop Metal, MakerBot, Stratasys, Allevi, Cadbury, Carbon, DiManEx, SLM Solutions, DSM, Arburg, Prusa Research and more.

Additive manufacturing trade fairs

From 16 to 21 September, international trade fair EMO Hanover will gather industry leaders of metal processing. German metal 3D printer manufacturer SLM Solutions will present in-booth lectures and metal AM demonstrations at hall 9 booth I06. The lectures will highlight SLM applications in aerospace, automotive, energy, toolmaking, medical and dental industries. There will be live SLM demonstrations of 3D printing. The highlights are a rocket engine with an integrated functional cooling structure and the first AM series turning tool for the cutting industry.

Another upcoming trade fair is K 2019 which focuses on the plastics and rubber industry. K 2019 will be held in Düsseldorf, Germany between 16 and 23 October 2019.

Under the theme of ‘Bright Science. Brighter Living’, global materials producer DSM is exhibiting at hall 6, booth 11. We will see 3D printing applications of DSM’s family of high-performance thermoplastic elastomers Arnitel in non-pneumatic tires, car tail light enclosure and athletic footwear. On top of showcasing its latest purpose-led innovations, DSM will also share insights on customized production for automotive OEMs.

Meanwhile at hall 6 booth A13, German injection molding systems manufacturer Arburg will exhibit its new 3D printing techniques and new projects. Eight injection molding machines Allrounders and the Freeformer polymer 3D printer will be on the Arburg stand. The applications cover prototyping and end-use production for automotive, electronics, construction and medicine industries. Arburg will also introduce its newest effort in circular economy – arburgGREENworld. This programme consists of four pillars: “Green Machine”, “Green Production” and “Green Services” relate to offers for customers whereas “Green Environment” relates to Arburg’s internal processes. Its new digital product and service portfolio arburgXworld will debut at the K as well.

Arburg will also introduce its newest effort in circular economy – arburgGREENworld. This programme consists of four pillars: “Green Machine”, “Green Production” and “Green Services” relate to offers for customers whereas “Green Environment” relates to Arburg’s internal processes. Its new digital product and service portfolio arburgXworld will debut at the K as well.

Cars, underwater scooters and body armor

Electric car manufacturer Lightyear has launched a sustainable car prototype with more than sixty 3D printed interior parts. Lightyear collaborated with Dutch cloud-based additive manufacturing supply chain platform DiManEx to supply the parts through its extensive network of partners. Depending on the complexity and post-processing, DiManEx managed to supply parts within 4 to 10 days. Production of Lightyear starts next year.

Verashape, a Polish 3D printer manufacturer, has prototyped power supply parts for SEACRAFT, a recreational and technical diving underwater scooter. Verashape’s FFF printer VSHAPER PRO+ enables manufacturing of batteries of different capacities on the spot. Other than developing the electric cells of appropriate efficiency, the company also 3D printed the templates that fix the position of cells during welding.

Verashape’s FFF printer VSHAPER PRO+ enables manufacturing of batteries of different capacities on the spot. Other than developing the electric cells of appropriate efficiency, the company also 3D printed the templates that fix the position of cells during welding.

The American Army Research Laboratory has devised a method to produce strong but lightweight ceramic body armor from a 3D printer. Researchers reinvented a direct ink writing 3D printer such that multiple materials can be extruded out of a single nozzle. Two syringes containing distinct, viscous ceramic slurries are connected to a custom-made auger and print head. Controlling ratio of extrusion materials, this 3D printing method is able to produce parts with a gradient which is impossible with traditional ceramic forming techniques. The ability to attach multiple materials onto a single armor plate greatly enhances its performance compared to those based on one material only. This direct ink writing method can be applied to other fields such as biomedical implants.

This direct ink writing method can be applied to other fields such as biomedical implants.

Expanding the 3D printing business network

For business, we see a number of partnerships announcements between 3D printing companies this week.

Xometry, an on demand manufacturing marketplace has joined global B2B e-commerce platform Alibaba.com’s U.S. B2B ecosystem as a Co-Marketing Sponsor. The B2B ecosystem initiative was launched to help small and medium-sized businesses (SMBs) access the $23.9 trillion eCommerce industry. Through AI algorithms, Xometry will connect Alibaba.com’s business buyers to its Partner Network of over 3,000 SMBs. Exclusive deals on Xometry’s on-demand manufacturing services, including 3D printing, CNC machining, sheet metal fabrication, and injection molding will also be provided Alibaba. com customers.

com customers.

Italian 3D printer manufacturer Nexa3D is expanding its North American channel sales with the help of 3D printer reseller Dynamism. Nexa3D makes ultrafast SLA 3D printers for professionals and businesses, such as the NXE400 and Varseo XL. Founded 22 years ago in the U.S., Dynamism offer Nexa3D’s technology to its global additive manufacturing customer network.

Nexa3D’s NXE400 printer. Photo via Nexa3D.Polish 3D printer and filament manufacturer Omni3D has gained its first German reseller. Other than Factory 2.0 Production System, the German reseller will also offer two 3D printers that will debut this year, Omni 500 LITE and Factory 2.0 NET. Omni3D also finalized a contract with Swedish online retailer 3D Prima in May. Now, Omni3D printers are available in 15 countries, including Russia, India, Australia and New Zealand.

Citing unfavourable market conditions, Saudi Arabian chemicals company SABIC has called off a specialty chemicals venture with Swiss materials R&D company Clariant. The companies share an interest in 3D printer filaments with SABIC producing FFF filaments and Clariant producing high-grade polymer filaments. A merger between SABIC’s specialties business and Clariant’s high performance materials segment was in discussion. However, the Swiss firm reported a net loss of $101 million for the first six months of 2019 and is shelving its specialty chemicals business. In a disclosure to the Saudi stock market, SABIC said it would revisit discussions on the merger with Clariant once conditions are improved.

The companies share an interest in 3D printer filaments with SABIC producing FFF filaments and Clariant producing high-grade polymer filaments. A merger between SABIC’s specialties business and Clariant’s high performance materials segment was in discussion. However, the Swiss firm reported a net loss of $101 million for the first six months of 2019 and is shelving its specialty chemicals business. In a disclosure to the Saudi stock market, SABIC said it would revisit discussions on the merger with Clariant once conditions are improved.

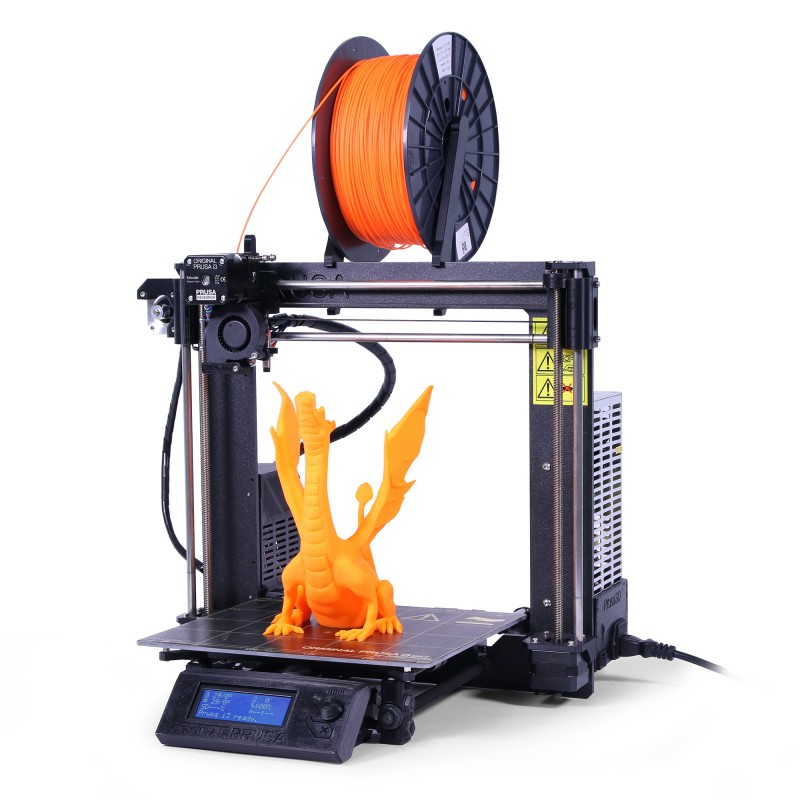

Awarding winning open source 3D printer manufacturer Prusa Research recently celebrated the sale of over 130,000 3D printers since its founding in 2012. Traditionally focused on FFF devices, Prusa Research expanded its offerings into the SLA market last year. Without distributors, Prusa Research directly delivers 80% of its 3D printer sales as assembly kits, and let customers build the machine at home. According to the estimation by Wohlers Associates, 591,079 desktop 3D printers have been sold in 2018. Prusa Research has gained a 10.1% market share by selling 59,776 3D printers last year.

Prusa Research has gained a 10.1% market share by selling 59,776 3D printers last year.

New metal 3D printing filament

German 3D printing materials manufacturer BASF 3D Printing Solutions has launched Ultrafuse 316L, a metal-polymer composite for FFF 3D printers. Like its previous generation Ultrafuse 316LX, the new metal composite filament is designed to print stainless steel metal parts for prototypes and metal tooling. This highly flexible and strong material can be processed on any conventional open-material FFF 3D printer.

First adopter of Desktop Metal Studio System

The University of Sheffield and global engineering solutions firm Weir Group have become the first UK adopters of Desktop Metal’s Studio System. In the Netherlands, mechanical engineering company AWL-Techniek was the first to install the Desktop Metal Studio System+ in the Benelux region. This office-friendly metal 3D printer is designed for small-batch rapid prototyping. The University of Sheffield adds the Studio System to its collection of machines which already includes powder bed fusion and blown powder methods. Weir will be using its Studio System to prototype, test and commercialize components and tooling for Mining and Oil & Gas customers. AWL-Techniek plans to this system to produce robot grippers and welding fixtures, as well as supporting its R&D activities.

In the Netherlands, mechanical engineering company AWL-Techniek was the first to install the Desktop Metal Studio System+ in the Benelux region. This office-friendly metal 3D printer is designed for small-batch rapid prototyping. The University of Sheffield adds the Studio System to its collection of machines which already includes powder bed fusion and blown powder methods. Weir will be using its Studio System to prototype, test and commercialize components and tooling for Mining and Oil & Gas customers. AWL-Techniek plans to this system to produce robot grippers and welding fixtures, as well as supporting its R&D activities.

For 3D scanners, awarding winning 3D scanning and imaging device provider FARO has launched its first colour structured light scanner Cobalt Design. The 3D scanner is specifically developed for design applications and is ideal for scanning complex surfaces, especially highly detailed organic shapes. Combined with FARO’s recently introduced RevEng software platform, Cobalt Design enables full field scanning of small to medium objects, a best in class speed to accuracy combination, full colour digitization and workflow acceleration.

Combined with FARO’s recently introduced RevEng software platform, Cobalt Design enables full field scanning of small to medium objects, a best in class speed to accuracy combination, full colour digitization and workflow acceleration.

New 3D software features, platforms and research projects

MakerBot announced new features and updates for MakerBot Cloud, its cloud-powered 3D printing desktop software. After the updates, MakerBot Cloud is integrated with major design software, such as Solidworks, Autodesk Fusion 360, and Autodesk Inventor. Users can now scale, rotate, and arrange their models on the build plate, as well as adjust the characteristics of the model for faster draft print or slower high surface quality print. The new movable purge tower feature for the METHOD printer optimizes printer build volume. The new feature also includes monitoring and viewing prints in real-time via the onboard camera of a MakerBot 3D Printer.

MakerBot Cloud interface. Image via MakerBot.

Image via MakerBot.German 3D software developer CADENAS has introduced 3D model search engine 3Dfind.it. Specifically geared to the technical sector, 3Dfind.it features nearly 900 catalogs in architecture, engineering and electronic products. Different native and neutral CAD formats are available to download, such as Autodesk, Revit, SOLIDWORKS and ArchiCAD. On top of simple text searches, 3Dfind.it also enables parametric text search, 3D shape search, 2D sketch search and color search.

Amazon 3D scanned bodies in its Real World Image Study to learn about diversity among body shapes in New York City. The study is run by Body Labs, a startup producing detailed 3D body models for shopping and gaming that Amazon acquired in 2017. In exchange for a $25 gift card, volunteers got their bodies 3D scanned and photographed in everyday attire and form-fitting clothes. While the exact kind of research was not specified, the company promises it will use its data exclusively for internal product research and not for marketing purposes.

Training young innovators with 3D printing

Automated manufacturing platform 3D Hubs has held the 3D Hubs Student Grant 2019 competition. Applicants were challenged to solve a real-life problem in the following five categories with 3D printing: Product design, Robotics, Sustainability, Transportation, Healthcare. Around 200 submissions from over 100 universities around the world were received. The winner of each category received $1000 to further develop their projects as well as technical support from 3D Hubs to turn their idea into a real product using 3D Hubs’ 3D printing services.

3D Hubs Student Grant 2019 Healthcare category winner ReCleft. Photo via 3D Hubs.Manufacturing association SME and major 3D printer manufacturer Stratasys have announced the winners of their co-sponsored three-day 2019 Additive Manufacturing Competition. The 2019 challenge required participants to make a functional end-of-arm tool in a simulated real-life manufacturing robotics scenario involving a full-production sedan assembly line. Among the 47 competing teams, three high school and three college teams received top honors for their designs. The winning high school teams received scholarships from the SME Education Foundation, and postsecondary participants were given a one-year subscription for Tooling U-SME classes and RAPID + TCT conference passes.

Among the 47 competing teams, three high school and three college teams received top honors for their designs. The winning high school teams received scholarships from the SME Education Foundation, and postsecondary participants were given a one-year subscription for Tooling U-SME classes and RAPID + TCT conference passes.

Carbon, the Silicon Valley-based start-up behind Digital Light Synthesis (DLS) hosted Kode With Klossy, a free coding camp founded by Karlie Kloss for teenage girls. The custom curriculum included Kode With Klossy instructor trainings as well as a panel with Carbon’s female leaders. Afterwards, the students learnt about Carbon’s Lattice Engine that created the adidas 4D midsoles. Through an interactive live print demo, the students learned about Carbon’s software-controlled materials, watched the printing process in real time, and received their very own 3D printed bracelet.

To educate students on regenerative medicine, U.S. 3D bioprinting company Allevi has started the Allevi Academy. The Allevi Education Curriculum walks students through CAD design, 3D printing and strategies for tissue engineering. Students will run experiments like making small blood vessels in a gel using Allevi’s bioprinters and bioinks. Recently, teachers at a high school in Pennsylvania implemented Allevi’s curriculum. As a relatively new product offering, Allevi Academy plans to expanding to other U.S. schools and universities and hopefully globally.

The Allevi Education Curriculum walks students through CAD design, 3D printing and strategies for tissue engineering. Students will run experiments like making small blood vessels in a gel using Allevi’s bioprinters and bioinks. Recently, teachers at a high school in Pennsylvania implemented Allevi’s curriculum. As a relatively new product offering, Allevi Academy plans to expanding to other U.S. schools and universities and hopefully globally.

Like a box of chocolates

This week we see 3D printing being creatively applied to make sweets, assistive gaming devices, designer lighting collection and statues.

British multinational confectionary brand Cadbury has launched its first-ever milk chocolate 3D printer to celebrate World Chocolate Day. In collaboration with 3P Innovation, Cadbury has installed the prototype in Melbourne to produce milk chocolate charms. Using a multi-lane approach, the machine produces eight chocolates at a time. Tightly controlling conditions of the chocolate, Cadbury managed to temper the chocolate which prior 3D printers failed. Tempering is essential to ensure a smooth, delicious and evenly-coloured chocolate. Two Dairy Milk chocolate charms cost $8 AUD (around $5 USD) or four will cost $15 AUD ($10 USD).

Tempering is essential to ensure a smooth, delicious and evenly-coloured chocolate. Two Dairy Milk chocolate charms cost $8 AUD (around $5 USD) or four will cost $15 AUD ($10 USD).

In Vancouver, digital games developer Electronic Arts (EA) hosted an assistive technology buildathon. As part of the Makers Making Change initiative, the buildathon connects volunteer makers to people with disabilities. Around 150 EA employees 3D printed open-source gaming switches and buttons that can be used with adaptive controllers for people with disabilities. Local gamers attended the event to provide building advice and help test the new devices and controllers. Switches with a variety of sizes and types were built, enabling gamers to use devices that best match their body shape, strength, dexterity, and overall abilities.

Amsterdam design label Freshfiber has unveiled 3D printed lighting collection for homes, restaurants, and hotels. Named Fold, Flux and ZooM, the lamps feature elements such as interlocking spiral and smooth geometric curves. Created with 3D printing and finished by hand, Freshfiber created unique and premium lighting with nylon and steel. Freshfiber Lighting pre-orders will start shipping by the end of September.

Named Fold, Flux and ZooM, the lamps feature elements such as interlocking spiral and smooth geometric curves. Created with 3D printing and finished by hand, Freshfiber created unique and premium lighting with nylon and steel. Freshfiber Lighting pre-orders will start shipping by the end of September.

Make3d.in, an Indian 3D printer manufacturer, made a 6-feet statue in 24 hours. The statue is to commemorate Mr. Brahmaiah Bollineni, a virtuous leader in an Indian village who recently passed away. For the printing process, Make3d.in used a total of fifteen Pratham 3.0 and Pratham 5.0 desktop 3D printers. The whole process from design, printing to painting was done in 4 days.

3D printing powered space exploration

Polish scientists Aleksy Chwedczuk and Jakub Bochiński have created the first parametric open-source DIY telescope project Telescope Prime using 3D printed parts. The telescope model consists of three main parts:

– The main parabolic mirror with a diameter of 20 cm

– Raspberry Pi microcomputer with touch display and camera

– 3D printed parts for fixing both the camera and the mirror.

Polish 3D printing service provider Sygnis New Technologies participated in the project by adjusting 3D models of the parts and 3D printing the end product.

Ascent Aerospace has invested in a Large Scale Additive Manufacturing (LSAM) machine from Thermwood Corporation. The LSAM machine has a 10 ft x 40 ft build area. A wide variety of materials such as ABS, nylon and polycarbonate are compatible with this 3D printer. Ascent will use the LSAM machine for large-scale printed composite tooling of layup molds, masters, drilling fixtures and vacuum holding fixtures.

Ascent’s LSAM machine. Image via Thermwood.The 3D printing powered Kleos Scouting Mission launch period has been extended to October 2019. Since January 2018, Luxembourgian satellite company Kleos Space has sent six Low Earth Orbit satellites on scouting missions for defence with U.S. aerospace company Rocket Lab’s 3D printed rocket engines. While the satellites are ready for launch at first opportunity, Kleos is using the extra time to develop their second generation satellites to deliver enhanced coverage.

Subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter for all the latest additive manufacturing news.

Find your next opportunity on 3D Printing Jobs.

Industrial revolution. Part 3. $1000 3D Printer / Sudo Null IT News Today I will tell you about the existing 3D printers and how using the website www.alibaba.com you can order and produce almost anything in China!

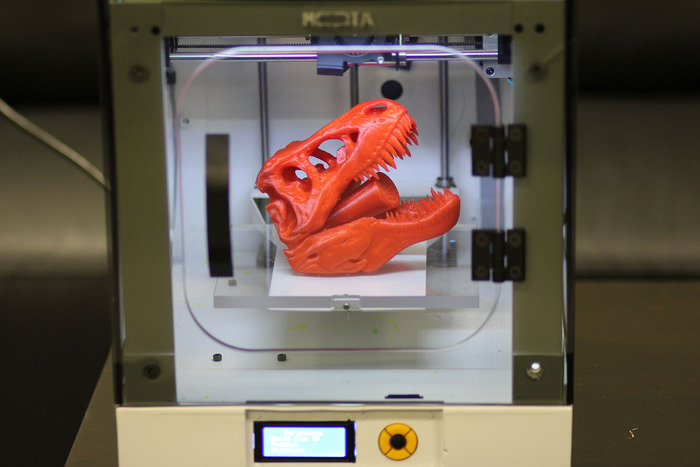

On the grounds of a former Brooklyn brewery, Bre Pettis and his team of engineers build the MakerBot, the first 3D printer under $1,000! Unlike inkjet printers, instead of ink, MakerBot builds objects by extruding a layer of molten plastic (ABS Plastic) 0.33 mm thick. Just 5 years ago, you couldn't get anything like this for less than $125,000.

At the production site, you can see 100 boxes of MakerBots lined up and ready to go to their customers. So far, 500 MakerBots have been sold and, with each copy sold, there are more and more ideas about its possible use. For example, instead of a conventional head that extrudes liquid plastic, one could create a cutting head by turning a printer into a sawing machine for wood, metal, or just ice cubes for drinks!

For example, instead of a conventional head that extrudes liquid plastic, one could create a cutting head by turning a printer into a sawing machine for wood, metal, or just ice cubes for drinks!

MakerBot is designed for making plastic parts based on a 3D model file. Do you want to create a gear? Create a gear model and print it on the printer! Want to change a product you already have? Scan it (Researchers at the University of Cambridge have developed a technology that allows you to create a 3D file by rotating an object in front of a webcam), tweak it in a 3D designer like Google SketchUp, and upload it to ReplicatorG. Within minutes, you will have a new physical object.

With other tools, you can do even more! For example, the $18,000 ShopBot PRSalpha machine will allow you to create wooden products the size of a front door. Or you can buy yourself a smaller rig for $1,500 from buildyourcnc.com. If you work with metal, try the $2000 machine. And if you're into electronics, design your board with CadSoft Eagle and then you can build it in Advanced Circuits.

The same applies to laser, plasma and water machines. Using this approach, you can create anything from jewelry to car chassis. To be honest, tens of thousands of people do just that. We've already seen the DIY boom with T-shirts and mugs, and then with Etsy, a marketplace for handcrafted items (Etsy generated about $200 million in sales last year). Now the do-it-yourself boom is moving into more complex applications such as 3D plastic modeling and open source electronic equipment such as the groundbreaking Arduino project.

With these tools, individuals can produce products that were previously available only to full-fledged producers. In addition, over the past few years, Chinese manufacturers have learned to process small orders more efficiently, allowing them to produce almost anything at almost any production scale.

First of all, the maturity and web orientation of business in China led to this situation. Chinese factories are accepting more and more orders via the Web, communicating with customers via email, and accepting payments via credit cards or PayPal, a convenient alternative to bank transfers, letters of credit, etc. In addition, the economic crisis has forced companies to look for custom orders with higher margins.

In addition, the economic crisis has forced companies to look for custom orders with higher margins.

To dive into the new world of opportunities that Chinese factories provide, visit Alibaba.com, the largest directory of Chinese manufacturers and suppliers. On it, using the usual search, you can find the suppliers you need and then through the Instant Messaging system to find out if they can do what you need. Alibaba's instant messaging system contains an online translator from English to Chinese so that people can communicate in their own language. Usually the answer comes within a few minutes: “we can’t do this” or “we can do it and here’s how you can order” or “we already did something similar and here’s how much it will cost.”

Alibaba CEO Jack Ma calls it C to B (consumer to business). This is a new type of trade that is ideal for entrepreneurs in the DIY movement. “If we support companies to do smaller cross-border operations, the profits can be big, because in this case, unique goods will be produced, and not “junk goods,” Ma says. Since its founding in 1999, Alibaba has become a $12 billion company with 45 million registered users worldwide. The company's $1.7 billion IPO in 2007 was the largest since Google. Over the past three years, companies doing business through Alibaba have created more than 1.1 million jobs in China, Ma said.

Since its founding in 1999, Alibaba has become a $12 billion company with 45 million registered users worldwide. The company's $1.7 billion IPO in 2007 was the largest since Google. Over the past three years, companies doing business through Alibaba have created more than 1.1 million jobs in China, Ma said.

Very close to shanzhai. The term "shanzhai", which translates from Chinese as "thug", usually refers to a thriving business of counterfeit electronics, or, as shanzhai.com defines it, it is "a supplier who does business without following traditional rules and regulations, which often leads to innovative and unusual products or business models. But interestingly, these same suppliers are the catalysts for the manufacturing side of the industrial revolution, responding quickly and flexibly to any wishes of micro-entrepreneurs. The rise of shanzhai's business practices "offers a new approach to economic recovery based on connecting small companies more closely with each other," said Tom Igoy, lead developer of the open source computing platform Audrino. “What happens if you apply this approach to the manufacturing world? We'll see soon!"

“What happens if you apply this approach to the manufacturing world? We'll see soon!"

To be continued…

3D printing trends that could boost profits in 2022

3D printing is becoming popular these days because it takes the printing process to the next level. It has become an integral part of many industries and is loved by designers for the value it provides as an efficient way to prototype new products. Given the growing popularity of 3D printing, this article will highlight industry trends that will increase profits in 2022.

Content

3D Printing Market Potential

Popular 3D Printed Items in 2022

Bottom Line

3D Printing Market Potential

is expected to grow at a compound annual growth rate (CAGR) of 22.1% between 2021 and 2030. In addition to these optimistic trends, specialist firms in the industry have also predicted a CAGR of 27% for the 3D printing market, reaching a market turnover of $115 billion by 2030.

This rapid growth is mainly due to the increased use of 3D printing in prototyping, tooling and design in the manufacturing and industrial fields. This is due to the growing demand and more flexible features offered by various modern 3D printers.

In addition, the expansion of 3D printing applications in many other areas such as healthcare, consumer products and education is likely to become an even greater driver of the 3D printing industry. And as 3D printers become more affordable and widely available, their use is no longer limited to the traditional manufacturing sector, but is slowly expanding to include home and home use.

Popular 3D printed items in 2022

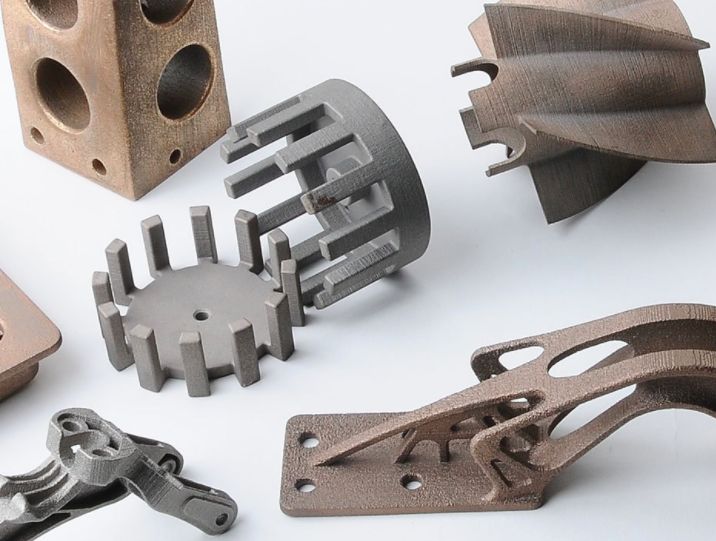

Industrial products

The development of 3D printed industrial products is mainly driven by the growth of the metal 3D printing industry, which has a CAGR of 22.9% from 2021 to 2030 with a market value of $22.6 billion .

Metal 3D printing applications are centered around manufacturing processes such as prototyping, tooling, and creating functional parts for the automotive, aerospace, defense, healthcare, consumer electronics, and construction industries. The Asia-Pacific region is the market that is expected to grow the most over the next 5-10 years, given the industrial and construction needs of emerging markets.

The Asia-Pacific region is the market that is expected to grow the most over the next 5-10 years, given the industrial and construction needs of emerging markets.

The growth of the 3D metalworking industry is largely due to the fact that the 3D printing process is much faster than the traditional production of parts. This is especially true for some unique items made to specification, such as custom made gears and shafts. 3D printing offers both flexible and customized industry solutions as the designs, sizes and shapes to be printed can be easily customized with the appropriate software.

And of course, while metal printers may require a large initial investment, metal 3D printers these days start at a much more economical price, but are still capable of promising high durability and high performance.

Fortunately, for those businesses that may find it difficult to make an initial investment, there is a good alternative to getting into the industrial goods 3D printing business. That is, by hiring a 3D printing service to have your desired 3D printed products delivered straight to your door. Such highly specialized options often provide not only flexibility in terms of metal 3D printing material, but also versatility in terms of 3D printing technologies.

That is, by hiring a 3D printing service to have your desired 3D printed products delivered straight to your door. Such highly specialized options often provide not only flexibility in terms of metal 3D printing material, but also versatility in terms of 3D printing technologies.

Medical products

The dental industry is the most prominent specialization in the field of medicine that uses 3D printing technology. 3D printers are used to produce various dentures. The dental 3D printing market is expected to more than double within five years, to $7.9 billion in 2027 from the current estimated market size of $3.1 billion.

Three major factors that have contributed to this growth include: the rise of cosmetic dentistry in line with growing global disposable income, the growing concerns of tooth loss among an aging world population, and the fact that 3D printing in dentistry can help improve the overall speed, performance and quality of denture equipment.

The current average market price for a dental 3D printer is typically around $3,000 per set according to industry experts. However, in the wholesale world, costs are affected not only by volume, but also by the launch of innovative, low-cost technologies, such as the introduction of LCD-based 3D printers. Wholesale dental-grade LCD 3D printers can cost as little as half the average market price, or even well below that.

However, in the wholesale world, costs are affected not only by volume, but also by the launch of innovative, low-cost technologies, such as the introduction of LCD-based 3D printers. Wholesale dental-grade LCD 3D printers can cost as little as half the average market price, or even well below that.

Fashion & Accessories

The exclusivity and customization of 3D printing make it a good alternative for the fashion industry. Among all kinds of fashion products, jewelry stands out as the most suitable item for 3D printing, partly due to the rapid growth of the jewelry market worldwide, with a CAGR of 12.1% between 2019 and 2026. But it is also related to that 3D printers meet the needs of jewelry designers.

Through the use of computer-aided design software, 3D printers can significantly reduce the reliance on the labor-intensive manual process of producing complex jewelry designs. In addition, the precision 3D printing technology ensures optimal precision and detail, which meets the requirements of such jewelry production technologies as engraving and filigree. All in all, this means that 3D printing has made jewelry manufacturing more cost-effective and offers an efficient and time-saving solution to the needs of designers.

All in all, this means that 3D printing has made jewelry manufacturing more cost-effective and offers an efficient and time-saving solution to the needs of designers.

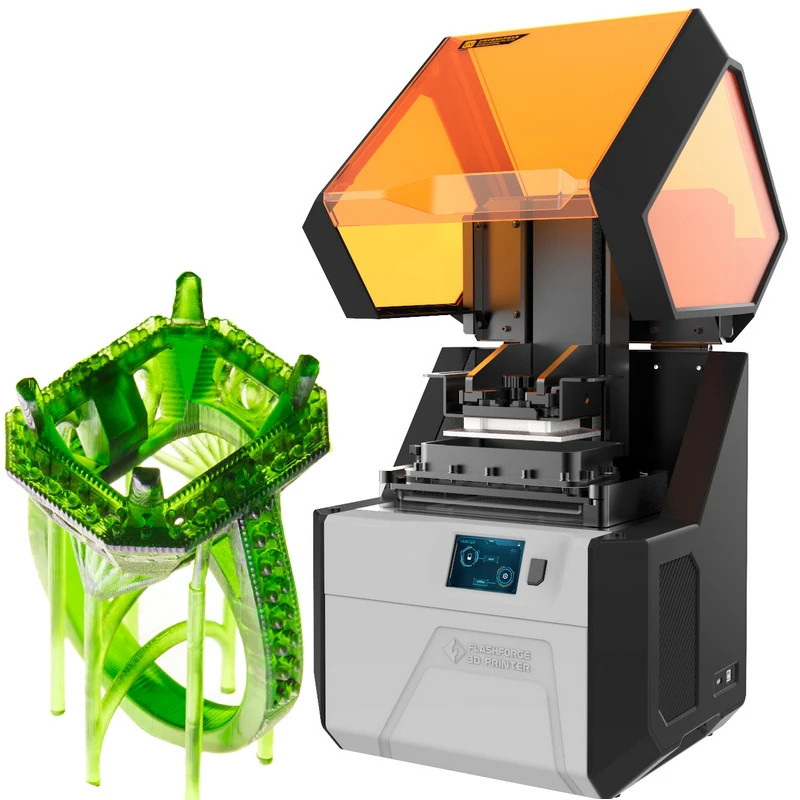

Similar to dental 3D printers, resin printers are most suitable for jewelry 3D printing, and the advent of liquid crystal 3D printing technology has opened up more opportunities for low-cost jewelry 3D printers, for example, this model which is similar to the one in the picture below.

Bottom line

Overall, 3D printers offer a unique solution for many industries around the world, and this will drive the growth of the 3D printing machine and service market. For those interested in entering this market, there are three key products to look out for in order to gain a competitive edge: Industrial, Medical, and Fashion. And the good news is that advances in 3D printing technology have reduced investment opportunities, especially at the wholesale level, making 3D printers more affordable for businesses large and small alike.