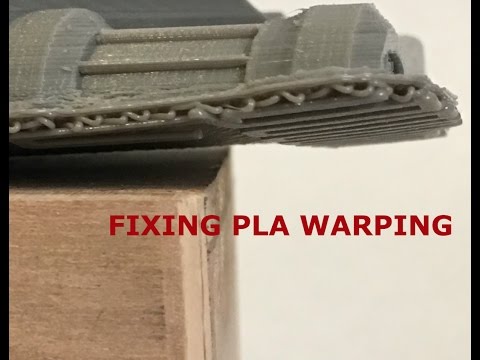

3D print prevent warping

Prevent Warping - You Can Do It

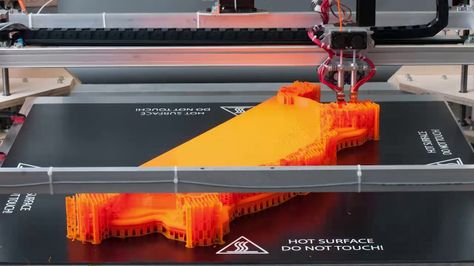

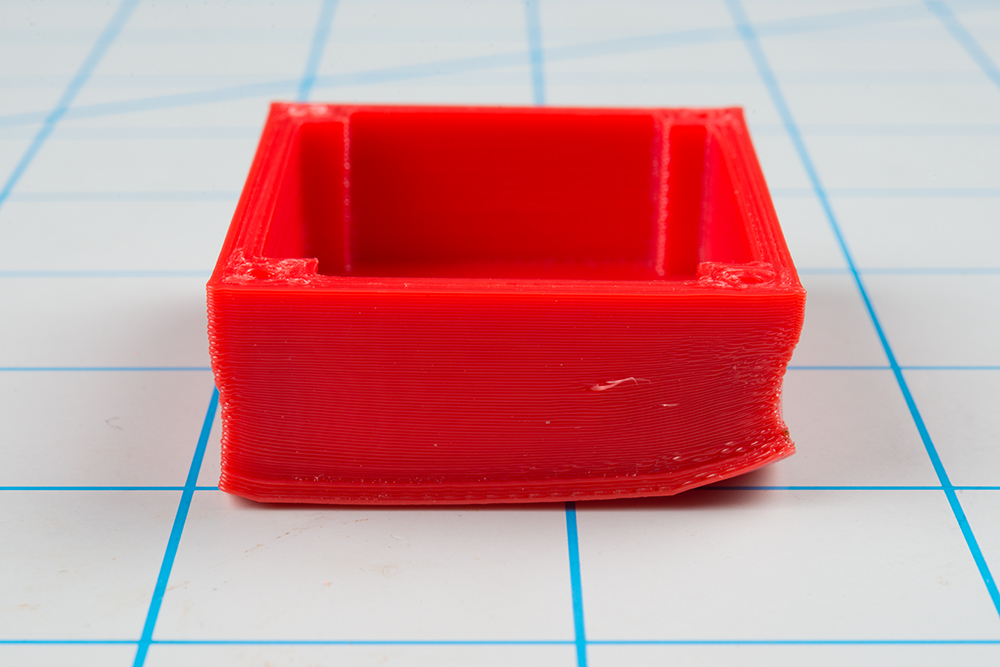

In particular, if you frequently print with materials like ABS and HIPS, over time you will get annoyed by what is known as “warping”. This is an unsightly misprint in which part of the model bulges or warps. In the worst case, the print is completely detached from the bed.

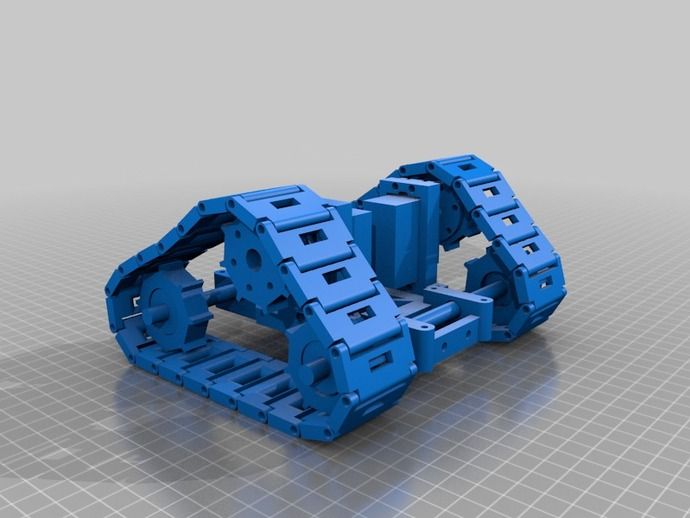

Especially with functional parts, the accuracy of which is of great importance, warping can quickly mess up the entire print. Mostly, models with a large contact surface on the print bed are affected. In this article, you will find out what causes warping and how you can avoid the “warp effect”.

Causes of WarpingWarping occurs due to uneven temperature distribution and the resulting tension in the substrate. Since ABS or HIPS filaments warp more at uneven temperatures than PLA, for example, and tend to shrink during cooling, the warp effect can be observed more frequently with these materials.

If an ABS print is cooled down at room temperature, it can shrink by almost 1. 5%. The larger the print model, the more unevenly it cools, the layers shrink unevenly and parts of the print bulge.

So the reasons for warping mostly have to do with temperature:

- Unevenly heated print bed

- Too fast printing process

- Incorrect location of the 3D printer (for example at the window)

- Incorrect slicer settings

- Contaminated print bed

1. Use a heated bed

A heated print bed keeps the model evenly warm during the printing process by equalising the temperature in the print object. At the same time, it also ensures better bed adhesion. If possible, the bed temperature should be just below the filament softening point, because: The higher the temperature of the bed, the lower the temperature difference in the individual filament layers and the resulting warping. However, be careful not to set the heating bed temperature too high, otherwise you risk plastic deformation of the model and intensification of the warp effect.

However, be careful not to set the heating bed temperature too high, otherwise you risk plastic deformation of the model and intensification of the warp effect.

In addition, always preheat your heating bed and do not print immediately without waiting for a suitable temperature so that the heat can stabilise to some extent. The print bed can even be insulated for optimal heat distribution; temperature-resistant insulation from the automotive sector is very suitable for this.

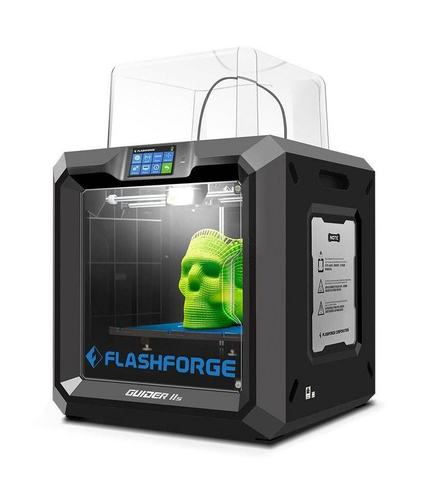

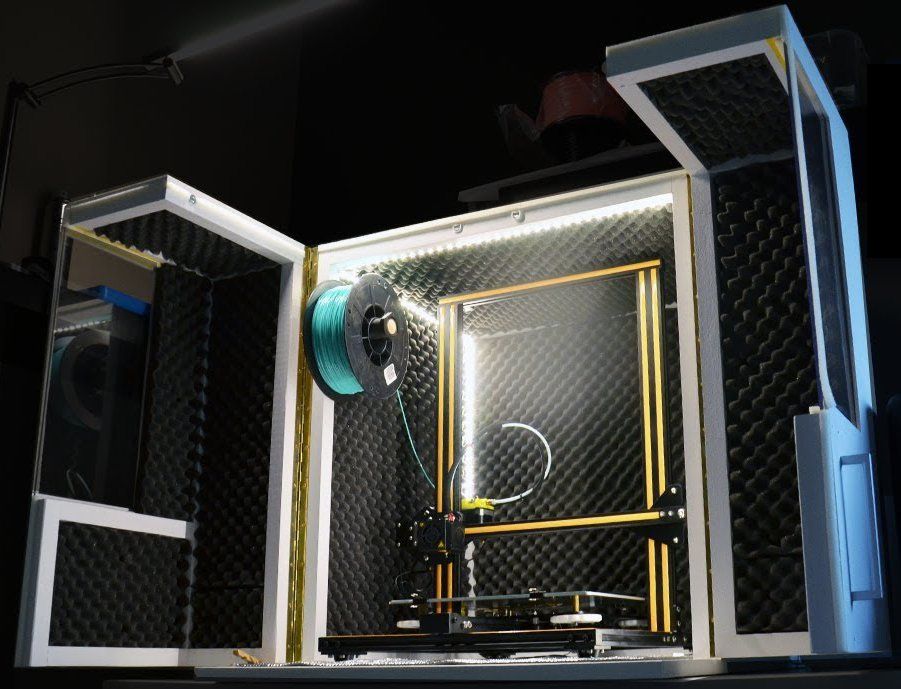

2. Print in an enclosed print chamber

A closed housing keeps the temperature inside the model constant during the entire printing process. When printing with a heated chamber, you should always make sure to keep the doors closed during the printing process so that the heat inside cannot escape. You can find a suitable 3D printer cover in our shop.

3. Choose the right location for your 3D printer

A 3D printer should ideally be set up in a place where there are no drafts. A window seat, in the hallway or next to a door is therefore less ideal, as drafts of air unintentionally cool the print. Basically, you should regulate the room temperature by keeping windows and doors closed as much as possible.

A window seat, in the hallway or next to a door is therefore less ideal, as drafts of air unintentionally cool the print. Basically, you should regulate the room temperature by keeping windows and doors closed as much as possible.

4. Turn off the material fan for the first few layers

To prevent the bottom layers from becoming detached from the build bed, you can turn off or slow down the fan while the first layers are printing. Keep in mind, however, that the melted filament still needs to solidify quickly enough to allow a precise build-up of the layers.

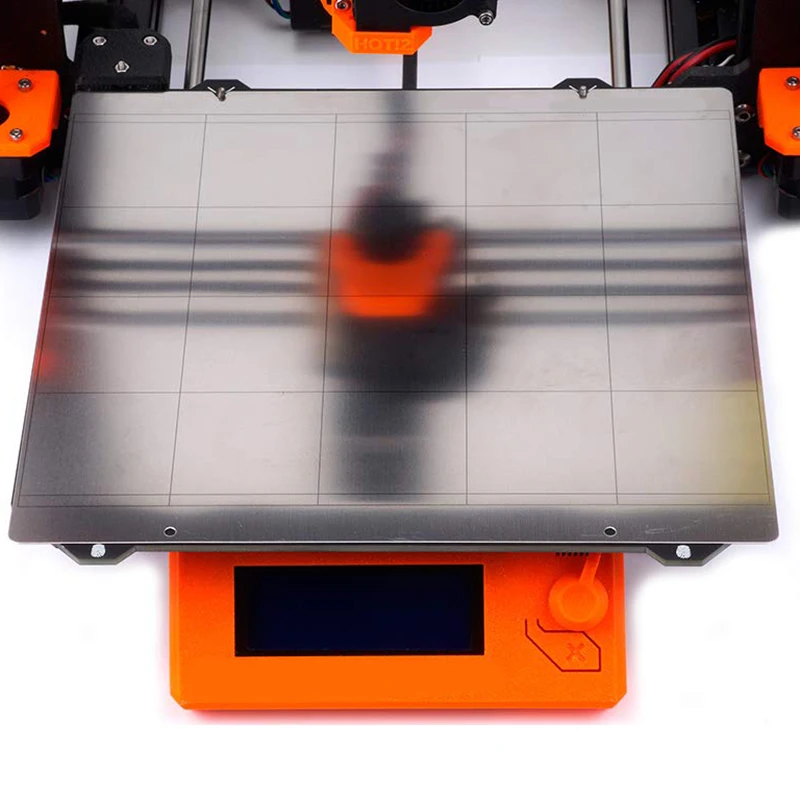

5. Improve bed adhesion with adhesives or a suitable bed surface

As already mentioned, the lack of adhesion of the print to the bed can also lead to warping. To avoid warping your prints, use a build plate with good adhesion or improve your adhesion with adhesives, glue, blue tape, or a print bed coating.

Since most FDM printers are equipped with a glass or aluminium surface and the surfaces are often too smooth for printing thermoplastics, it can be worthwhile to use a flexible plate as a print bed upgrade.

6. Adjust your slicer settings

Not only can the temperature and print bed adhesion affect the bulging of your 3D print, but the wrong slicer settings also have an impact on your print quality.

- Reduce your printing speed

Especially if you have frequent problems with warping, you should try to reduce your printing speed. At the same time, the nozzle temperature should also be reduced accordingly as the extra heat is not heated with this lower flow.

- Use rafts and brims

A raft can help with larger and a brim with smaller components to avoid warping by building up a base layer, the edges of your model are “held” and these warp less. The raft can easily be detached from the model after printing.

7. Thoroughly clean your print bed

If you often have problems with warping or your prints do not adhere to the bed, clean it thoroughly with the cleaning agents provided. Stubborn residues such as glue can be removed with chemical solvents.

Stubborn residues such as glue can be removed with chemical solvents.

If your build platform is uneven or damaged, you should definitely replace it.

8. Use good quality filament

Last but not least, it should be said that you should always use high-quality filaments for successful 3D printing - and always adhere to the material-dependent application instructions. Only a high-quality filament that has been used correctly can achieve a beautiful print result.

What Causes 3D Print Warping and How to Prevent It

3D print warping is a common problem in fused deposition modeling (FDM) that causes parts to deform on the print bed. If you’ve ever noticed that the base of your 3D print is curling up and the corners are unsticking from the build plate, that’s warping. The good news is that there are several tips and tricks to prevent warping and improve your chances of a successful, warp-free 3D print.

What causes 3D print warping?

3D print warping happens when extruded filament layers on the 3D printer build plate cool too quickly and shrink. This causes the plastic material to contract and pull away from the build plate, resulting in warping (or curling, as it is sometimes known).

This causes the plastic material to contract and pull away from the build plate, resulting in warping (or curling, as it is sometimes known).

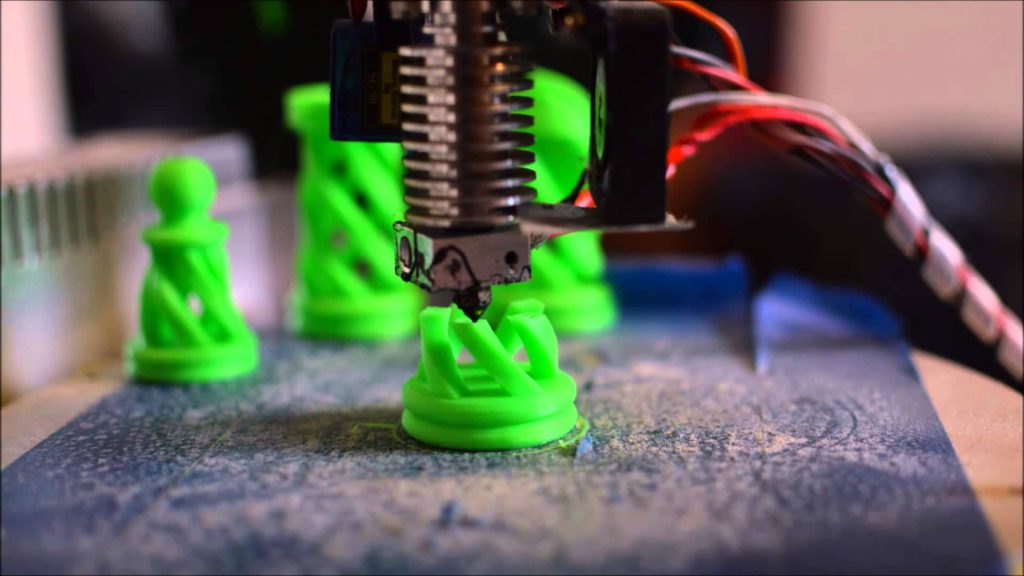

We can understand the problem of warping better if we zoom out a bit and look at the FDM process on the whole. In FDM 3D printing, a heated extruder deposits melted filament onto a print bed. This filament is made from a thermoplastic, a type of material characterized by its ability to melt into liquid form and resolidify when cooled. This means that in the printing process, as each layer is deposited, the filament hardens as it cools, but it also shrinks.

Thermoplastic filament shrinks as it cools; if it shrinks too quickly it can lead to warping

Warping occurs when the cooling process happens too quickly or unevenly and 3D printed layers shrink and pull on less solidified layers, ultimately lifting the first layer off the build platform and causing deformation. Though it is possible to experience warping with any type of 3D printed part, it is more common when 3D printing larger parts or parts with a large surface area. Certain 3D printing filaments are also more prone to warping than others. Typically, materials with a higher printing temperature, like ABS, suffer more from shrinkage because the temperature difference as they cool is more extreme.

Certain 3D printing filaments are also more prone to warping than others. Typically, materials with a higher printing temperature, like ABS, suffer more from shrinkage because the temperature difference as they cool is more extreme.

How to fix 3D printer warping?

Fortunately, the chances of 3D print warping can be mitigated and 3D print outcomes can be improved using a few key techniques.

Bed Adhesion

One effective way to minimize the risk of 3D print warping is to improve your 3D printer’s build plate adhesion. Good bed adhesion will keep your 3D printed part stuck to the build surface and prevent the first layers of the print from curling up as they cool.

Bed adhesion can be achieved in a few ways. For example, there are dedicated 3D printer adhesives that can be applied to the build plate before printing. Many also opt for more DIY adhesives, like glue sticks and hairspray. A third option is tape, which is placed on the build plate surface. Painter’s tape is a popular option because it can be removed easily and the porous texture of the non-stick side keeps filament stuck down.[1] Kapton tape is also commonly used to encourage bed adhesion.

Painter’s tape is a popular option because it can be removed easily and the porous texture of the non-stick side keeps filament stuck down.[1] Kapton tape is also commonly used to encourage bed adhesion.

If you are using adhesives on your 3D printer, be sure that the print surface is clean before and after printing. Glue residue can cause an uneven print surface, potentially impacting calibration and the quality of future prints. It is also a good idea to try a test print if you are using a new adhesive to ensure it keeps the bottom layer of the print down but can also be easily unstuck when the print is done.[2]

An enclosed build chamber can reduce the risk of warping by maintaining a stable print temperature.

Temperature

Because cooling filament too quickly is what causes shrinkage and warping, it is key to control the temperature of your build as much as possible. 3D printer temperatures can be regulated using different methods or a combination of approaches. One of the most effective tricks for improving bed adhesion is to use a heated build plate. Each type of filament will have its own recommended bed temperature for good adhesion—for example, PLA works best with a heated bed at a temperature of between 60 and 70°C, while ABS requires a hotter print bed of between 100 and 120°C.[3]

One of the most effective tricks for improving bed adhesion is to use a heated build plate. Each type of filament will have its own recommended bed temperature for good adhesion—for example, PLA works best with a heated bed at a temperature of between 60 and 70°C, while ABS requires a hotter print bed of between 100 and 120°C.[3]

Using an enclosed print chamber can also help to maintain an ambient temperature throughout the printing process and stop 3D printed layers from cooling too quickly. Many 3D printer models have a built-in enclosed chamber, but those that don’t can still benefit from a DIY enclosure. Other ways to improve temperature consistency in your 3D printer are to adjust cooling fan speed settings (especially for the first layers of a print) and keeping your room temperature as ambient as possible (i.e. keeping cold air out by closing windows).

Brim or Raft

Brims and rafts are tried and true techniques for boosting bed adhesion, especially for ABS and other high-temperature filaments. These 3D print features are added in slicer software right before printing and have several functions.

These 3D print features are added in slicer software right before printing and have several functions.

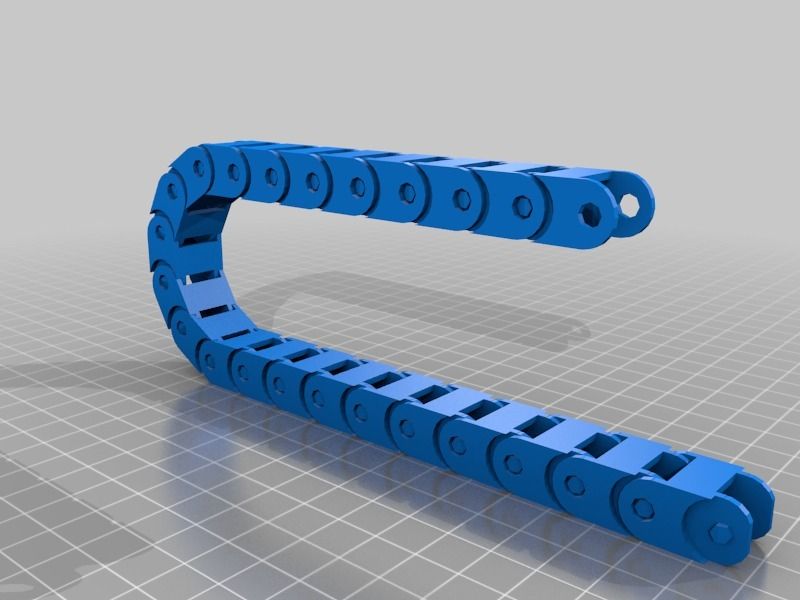

Specifically, a brim is a 3D printed border that connects to and goes around the edges of a 3D printed part. Brims are typically a few millimeters wide and consist only of 1-2 layers. They increase the footprint of the 3D printed part and anchor its edges to the build platform. A raft is similar, only it is also printed under the 3D printed part, acting as a base for it.

Brims and rafts are especially beneficial for 3D printed parts with unbalanced geometries or small footprints, as they can stabilize the print and secure it to the build surface. Both brims and rafts must be removed after printing, either by hand (by peeling them off) or using a tool. Printed parts with brims or rafts may require additional post-processing to achieve a smooth first layer.

3D printed brims can help to anchor the printed part down to the build platform.

Slicer settings

The risk of warping can also be reduced substantially by implementing the right print settings for the first layers of the printed object. Most slicer software programs allow you to adjust the print speed and layer height specifically for the first layer. A slower print speed for the first printed layer of a build will help to ensure that the filament sticks to where it has been deposited and is not pulled by the nozzle as it moves. Choosing a slightly thicker layer height for the first layer can also improve bed adhesion and help reduce any leveling inconsistencies.

Most slicer software programs allow you to adjust the print speed and layer height specifically for the first layer. A slower print speed for the first printed layer of a build will help to ensure that the filament sticks to where it has been deposited and is not pulled by the nozzle as it moves. Choosing a slightly thicker layer height for the first layer can also improve bed adhesion and help reduce any leveling inconsistencies.

Another print setting that can influence warping is fan speed. Fans are built into some FDM 3D printers and ensure the build space does not get too hot. By tweaking fan speeds you can maintain closer control over print cooling. For example, fans can be programmed to turn on only after the first few layers of a print have been deposited. This helps the first layers cool slowly and evenly on the print bed.

Conclusion

3D print warping is a frustrating problem most makers will encounter at some point or another. By following the tips and methods laid out in this article, however, you can ensure good bed adhesion, consistent printing temperatures, and ultimately reduce warping and improve print quality overall.

References

[1] TapeManBlue, 2022. “The Complete Guide to Blue Tape for 3D Printing”. [Internet]

https://tapemanblue.com/blogs/tips-tricks/blue-tape-for-3d-printing [Accessed March 31, 2022].

[2] Ultimaker, November 10, 2020. “Build plate adhesion: How to get your print to stick to the build plate”. [Internet] https://support.ultimaker.com/hc/en-us/articles/360012015680 [Accessed March 30, 2022].

[3] Simplify3D, 2022. “Warping”. [Internet] https://www.simplify3d.com/support/print-quality-troubleshooting/not-sticking-to-the-bed/ [Accessed March 30, 2022].

How to avoid deformation of models when 3D printing

There is nothing “better” than walking away from the printer for a couple of hours and taking a nap, and returning to find this:

Vermicelli. Plastic

Sound familiar? Yes, these are the same “angel hair”, “spaghetti” or “vermicelli” obtained by tearing the model off the desktop. The cause of such a disaster is often the deformation of the layers. Twisting the edges of the model up causes the extruder to catch on the model and simply break or tear it off the platform. Then begins the artistic filling of the environment with plastic thread in the artistic style of Jackson Pollock.

The cause of such a disaster is often the deformation of the layers. Twisting the edges of the model up causes the extruder to catch on the model and simply break or tear it off the platform. Then begins the artistic filling of the environment with plastic thread in the artistic style of Jackson Pollock.

Left: No. 5, 1948. Author: Jackson Pollock. Fiberboard, oil. Price: $140 million

Right: Angel hair, 2013. Author: Ravix. Prusa Mendel printer, ABS plastic. Price: $0

But the charms of deformation don't stop there. What is the easiest way to quarrel two "makers"? Correct answer: ask them which is better - PLA (polylactide) or ABS (acrylonitrile butadiene styrene). ABS - a thing, of course, tempting. This plastic is strong, durable and inexpensive. Polylactide, in general, is also relatively inexpensive, but relatively soft and biodegradable - with all the ensuing consequences. So why are popular devices like the Makerbot Replicator built to print with only polylactide? The environmental friendliness of PLA is a secondary reason, rather a bonus. And the main reason is the low glass transition temperature and minimal shrinkage. It does not require heating to ultra-high temperatures for melting, and when cooled, although it shrinks, losing volume, but not much. In other words, printing with polylactide is easier. But ABS “shrinks” quite noticeably, losing up to 8% of its volume. If you do not control the temperature regime, then you can get curvature and even cracks.

And the main reason is the low glass transition temperature and minimal shrinkage. It does not require heating to ultra-high temperatures for melting, and when cooled, although it shrinks, losing volume, but not much. In other words, printing with polylactide is easier. But ABS “shrinks” quite noticeably, losing up to 8% of its volume. If you do not control the temperature regime, then you can get curvature and even cracks.

In our article, we propose to consider methods for eliminating deformation.

- 1 Use heated platform

- 2 Choose the right adhesion

- 3 Cleanliness is key to good printing

- 4 Height calibration

- 5 You drive more quietly - you will continue

- 6 Don't catch cold on your model

- 7 Turn down the heat

- 8 Reduce the density of model

- 9 Print with liner

- 10 Lugs

- 11 Thresholds

- 12 Thermowalls

Use Heated Bed

Heated Build Bed

This option is offered with many modern 3D printers, and in the case of the RepRap, you can modify it yourself. Let the heating add to the cost of the printer, but it's worth it. Heating the model from below allows you to slow down and even out the cooling process. If small PLA models can be printed without heating, then when printing large objects, a heating element is no longer necessary, since even a slight shrinkage of PLA has a cumulative effect with increasing model dimensions. When printing with ABS plastic, heating is simply necessary, otherwise the rapid shrinkage of the lower layers will lead to deformation of the upper, still hot parts of the model. It is worth paying attention to the uniformity of the platform heating. If the heating is not uniform, then the very first layers, cooling unevenly, can “twist”. Often the glue or tape used to hold the model in place won't even help. The edges will rise, the extruder will hook on the applied layers, and then - "vermicelli".

Let the heating add to the cost of the printer, but it's worth it. Heating the model from below allows you to slow down and even out the cooling process. If small PLA models can be printed without heating, then when printing large objects, a heating element is no longer necessary, since even a slight shrinkage of PLA has a cumulative effect with increasing model dimensions. When printing with ABS plastic, heating is simply necessary, otherwise the rapid shrinkage of the lower layers will lead to deformation of the upper, still hot parts of the model. It is worth paying attention to the uniformity of the platform heating. If the heating is not uniform, then the very first layers, cooling unevenly, can “twist”. Often the glue or tape used to hold the model in place won't even help. The edges will rise, the extruder will hook on the applied layers, and then - "vermicelli".

Choose the Right Adhesion

Kapton is a Great Platform Coating

If the plastic won't adhere to the platform, you're in trouble. Which one is the best - there is no consensus. There are tables made of aluminum, glass (even basalt), steel, titanium. Seasoned RepRapers pray for Kapton, a polyimide film applied to the surface of the platform. By the way, the film can be processed with a fine-grained emery cloth - a rough surface will contribute to the "seizure" with the plastic. Some users spray the surface of the platform with a spray adhesive containing acetone (to set the ABS), or even hairspray!

Which one is the best - there is no consensus. There are tables made of aluminum, glass (even basalt), steel, titanium. Seasoned RepRapers pray for Kapton, a polyimide film applied to the surface of the platform. By the way, the film can be processed with a fine-grained emery cloth - a rough surface will contribute to the "seizure" with the plastic. Some users spray the surface of the platform with a spray adhesive containing acetone (to set the ABS), or even hairspray!

Cleanliness is the key to good printing

If the build platform is covered in dust, plastic will stick to the dust. How this will affect the adhesion of the model to the platform itself hardly needs to be explained. If you are printing with ABS, you can wipe the platform with acetone to dissolve the small pieces left from previous models. Acetone has no effect on polylactide, but you can try Limonene. By the way, the thread should also be kept clean, because the accumulation of dust in the extruder is fraught with all sorts of interesting, but unpleasant consequences. One simple method to clean the filament (if it's already dusty) is to use a foam filter before feeding it into the extruder.

One simple method to clean the filament (if it's already dusty) is to use a foam filter before feeding it into the extruder.

Height calibration

Trying to print a cube with too much initial distance between nozzle and bed

A correctly applied first layer is the cornerstone of successful printing. If the head sits too high above the platform when applying the first coat, the adhesion may be too weak. This problem is solved experimentally: if your model breaks off the platform, try lowering the initial head height in small steps. If the platform is heated, then it makes sense to carry out the calibration in a heated state, because the deformation of the platform during heating can make the “cold” calibration inaccurate.

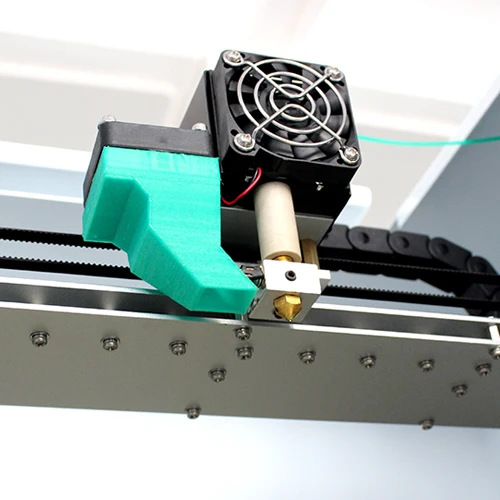

Slower ride - farther you will be

Reducing print speed can reduce model deformation

Yes, unfortunately, 3D printing even small objects takes a lot of time. But in order to increase adhesion to the platform and give the layers extra time to cool evenly, it may be necessary to slow down the printing process. This is especially important when working with PLA, because the polylactide takes a long time to cool down, and the lower layers can undergo deformation under the pressure of the upper layers if they do not have time to pass the glass transition point.

But in order to increase adhesion to the platform and give the layers extra time to cool evenly, it may be necessary to slow down the printing process. This is especially important when working with PLA, because the polylactide takes a long time to cool down, and the lower layers can undergo deformation under the pressure of the upper layers if they do not have time to pass the glass transition point.

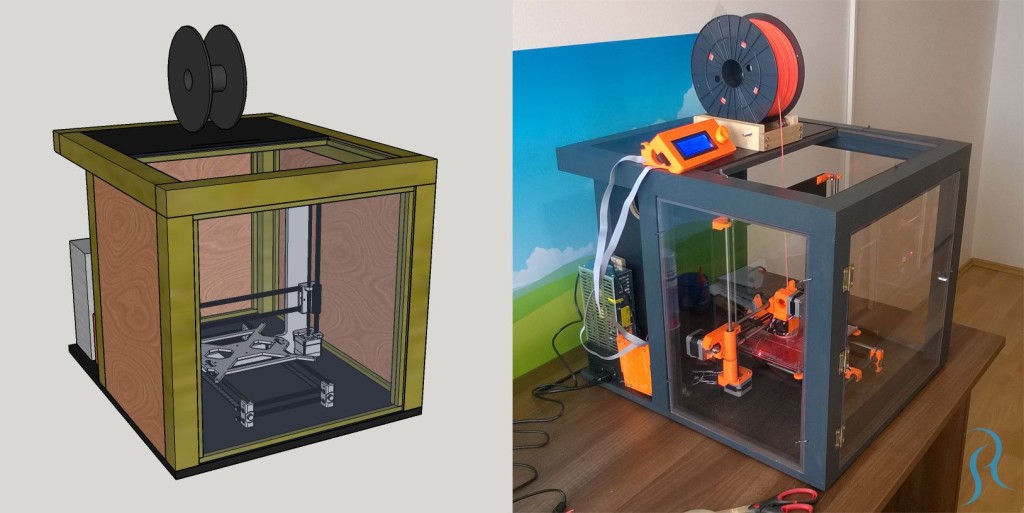

Don't catch cold on your model

Maker Case - a cabinet for 3D printers that prevents drafts

Drafts can have negative consequences not only for real people, but also for plastic ones. A banal draft can lead to uneven cooling of the model - hypothermia on one side, followed by one-sided shrinkage and lopsidedness. No wonder many manufacturers prefer to make closed cases for their printers. In addition, the tightly closed housing helps maintain a high background temperature in the working chamber, which is good when working with ABS plastic. But when printing PLA, you may have to remove one of the panels or open the door (depending on how the case is arranged) to help cool the model faster. Many manufacturers install additional fans on their extruders to blow off the fresh layers of polylactide (we counted three on the PrintBox3D One!). Although, in general, this is a sound idea, it often has the opposite effect, since only one side of the model is blown. In the case of PrintBox3D One, the calculation was made to quickly cool fresh layers - before subsequent layers become a barrier to airflow. And Picaso Builder uses a tricky system of channels built into the extruder to evenly blow the model from above.

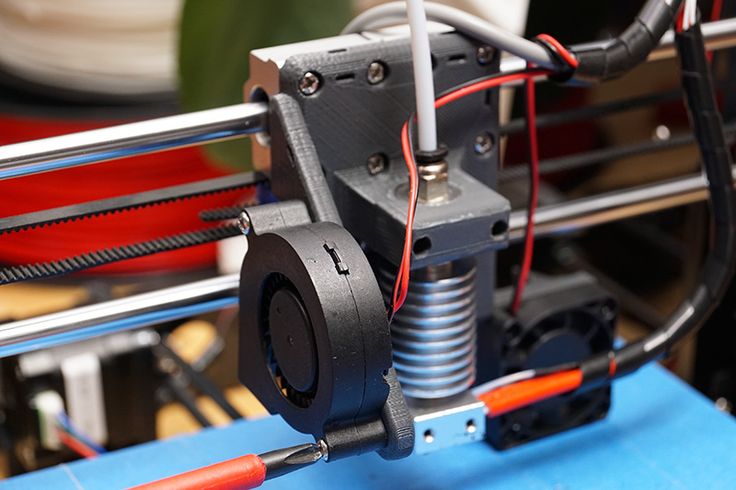

But when printing PLA, you may have to remove one of the panels or open the door (depending on how the case is arranged) to help cool the model faster. Many manufacturers install additional fans on their extruders to blow off the fresh layers of polylactide (we counted three on the PrintBox3D One!). Although, in general, this is a sound idea, it often has the opposite effect, since only one side of the model is blown. In the case of PrintBox3D One, the calculation was made to quickly cool fresh layers - before subsequent layers become a barrier to airflow. And Picaso Builder uses a tricky system of channels built into the extruder to evenly blow the model from above.

Turn down the heat

Not yours. This refers to the temperature of the extruder. The ideal option is to heat the extruder to a temperature slightly above the glass transition temperature of the plastic, so long as the extrusion proceeds normally and the layers “seize” among themselves. After all, the stronger the plastic is heated, the longer it will cool down, and the more noticeable the shrinkage will be. But keep in mind that such experiments can bring additional stress on the extruder mechanism, up to and including damage to it. Yes, the nozzle can get clogged. Be careful.

After all, the stronger the plastic is heated, the longer it will cool down, and the more noticeable the shrinkage will be. But keep in mind that such experiments can bring additional stress on the extruder mechanism, up to and including damage to it. Yes, the nozzle can get clogged. Be careful.

Decrease the density of the model

Various degrees of filling

The model can be homogeneous (solid piece of plastic), hollow (walls on the outside, absolutely nothing inside), or lightweight (seemingly solid, but inside filled with plastic mesh or honeycombs) . The last option has a lot of advantages. This includes savings in materials compared to solid models, good strength compared to brittle hollow models, and, finally, a reduced likelihood of deformation. The logic is quite simple: the larger the surface of the layer in contact (i.e., sticking together) with the platform, and the smaller the volume of plastic in the following layers, the less likely the lower layer is to twist when the upper layers shrink. Add the already described substrates here, and the chances of successful printing increase many times over.

Add the already described substrates here, and the chances of successful printing increase many times over.

Print with a backing

Printing a wheel on a backing

A backing or "raft" is the base of the model, made in the form of a grid. Due to the high porosity, such structures cool quickly and evenly, and then serve as a reliable basis for the present model. The larger and thicker the substrate, the stronger and more reliable it is. Here you already have to find the perfect balance between functionality and material consumption. Many digital modeling programs (such as Skeinforge or ReplicatorG) have built-in underlays.

Lugs

Model with lugs

The problem with underlays is that they can seriously degrade the quality of the bottom layer of the model. After all, all this extra plastic will have to be removed, right? Alternatively, you can print the extensions of the bottom layer (the so-called "lugs") in the most vulnerable places for twisting - for example, in the corners. The lugs will help hold the edges in place until the bottom of the model hardens. After printing, they will be much easier to remove than the backing. The disadvantage of this technique is the need for an additional work surface.

The lugs will help hold the edges in place until the bottom of the model hardens. After printing, they will be much easier to remove than the backing. The disadvantage of this technique is the need for an additional work surface.

Thresholds

Threshold Model

Essentially it is a combination of lining and lugs. The oversized lining is built on with additional objects (“thresholds” or “visors”) whose sole purpose is to hold the lining in place. The most effective method of preventing deformation of the lower layers, but also the most costly in terms of materials. The advantage is the fact that the “thresholds” themselves do not touch the model, and therefore, at the end of printing, only the substrate itself will have to be cleaned from the model.

Thermal walls

A kind of draft control. The idea is based on the construction of thin walls around the model, which keep warm air inside and contribute to a more uniform cooling of the model. In fact, this is an alternative to the closed printer case. The walls themselves can be deformed, but since they are not part of the model, this is not a problem. The downside is the additional consumption of materials.

In fact, this is an alternative to the closed printer case. The walls themselves can be deformed, but since they are not part of the model, this is not a problem. The downside is the additional consumption of materials.

If you have your own tricks, write to us at [email protected]

Go to the main page of the Encyclopedia of 3D Printing

How to Prevent Warp in 3D Printing: The Complete Guide

Warp can cause serious print problems and is often difficult to fix. In some cases, it can even ruin the print completely. That's why it's important to take the time to understand the causes of warp and learn how to prevent it. Keep reading to learn how to prevent 3D printing from warping.

What is buckling and why does it happen in 3D printing?

Warping is one of the most common mistakes in 3D printing. It occurs when the plastic filament cools and contracts at different rates, causing the printed object to deform. This often occurs at the edges of the print, where the filament cools the fastest.

This often occurs at the edges of the print, where the filament cools the fastest.

To prevent warping, it is important to use a heated print plate and place the printer in a temperature controlled room. Also, some materials are less prone to warping than others. For example, PETG and ABS have a higher pour point than PLA, which means they are less likely to warp when cooled quickly. By understanding the causes of warpage and taking steps to prevent it, you can ensure that your 3D prints look their best.

4 main causes of warpage

Why do prints warp? Let's look at some of the most common causes.

1. Temperature difference

This is one of the main causes of warping. When the temperature in the working chamber changes too much, it can cause uneven cooling and contraction, resulting in warpage. For example, if the print cools too quickly, it may warp before it hardens properly. This can be caused by poor ventilation, insufficient fan speed, or using the wrong type of assembly material.

Conversely, if the plate is too hot, the plastic softens and flexes, which also causes deformation.

2. Incorrect adhesion of the base

If the 3D printing does not adhere well to the build plate, it can easily deform when cooled and compressed. This can be caused by several factors, including improper bed alignment, using the wrong type of adhesive, incorrect nozzle height, insufficient extrusion, or not properly cleaning the bed prior to printing.

3. Incorrect slicing settings

The slicing software determines the ideal path the 3D printer should take to create the desired object. This path is calculated based on many factors, including the orientation of the object, the type of material used, and the desired resolution. If any of these settings are incorrect, it may cause the object to warp during printing. In addition, incorrect slicing settings can cause parts of the object to detach from the forms during printing. These delaminations can also lead to warping and inaccuracies in the final object. Therefore, before printing, you need to make sure that all slicing settings are correct.

Therefore, before printing, you need to make sure that all slicing settings are correct.

4. Printing too fast

Printing too fast can cause buckling for several reasons. First, when the extruder moves too fast, the filament can start to curl instead of lying flat. This causes the printed output to curl and may result in poor print quality. Second, if the build plate is not properly heated, the warmer bottom layer can cause the top layers to warp as they cool. Also, printing too fast can cause the plastic to cool too quickly, making it more brittle and prone to warping.

6 ways to prevent buckling

There are several things you can do to minimize the risk of buckling. These include:

1. Designing objects with a high surface area to volume ratio

One of the most important things when creating 3D printed materials is to ensure that they retain their shape even after printing. This is especially important for objects that are subjected to loads or heat, as deformation can lead to serious problems. One way to prevent deformation is to create objects with a large surface area to volume ratio. This means that a 3D object has a large surface area relative to volume. This is often achieved by making the object thinner or by increasing its surface area.

One way to prevent deformation is to create objects with a large surface area to volume ratio. This means that a 3D object has a large surface area relative to volume. This is often achieved by making the object thinner or by increasing its surface area.

Objects with a large surface area to volume ratio are less likely to deform because the forces acting on them are distributed over a larger area. As a result, they can retain their shape even under significant loads or heat. This principle is used in various engineering applications and can be an effective way to prevent warping.

2. Using supports in the printing process

One way to prevent warping is to use supports. Supports are attachment points that hold the structure in place as it cools, preventing it from deforming. In addition, with the help of supports, manufacturers can create parts with more complex shapes and geometries. As such, supports are an essential tool for success in 3D printing.

3.

Control of the cooling process

Control of the cooling process The risk of deformation can be reduced by controlling the cooling process. One way to do this is to use a cooling chamber, which helps regulate the temperature and prevent uneven cooling. Another option is to use materials with different melting points so that they solidify at different rates. By controlling the cooling process, deformation can be prevented and high-quality 3D prints can be obtained.

4. Using the heated build plate

Heated build plate helps prevent the filament from cooling too quickly and shrinking. In addition, the heated plate helps improve adhesion. This is especially important when printing with ABS, which is notorious for being difficult to adhere to the plate. Thus, using a heated plate can be an effective way to prevent deformation and improve the quality of 3D printing.

5. Using a rim or platform

Basically, it's an extra layer that you add to your print to help hold it on the build plate.

These are both layers that are printed around the perimeter of the object. They help keep the object from deforming by providing more surface area for adhesion. The edge is a single layer that is usually removed after printing is complete. A raft is a layered structure that remains attached to an object. It's harder to remove, but it provides a greater level of support.

6. Try changing the printer settings

Change the printer settings so that the outside of the print prints at a higher temperature than the rest of the print. This will help create a stronger bond between the outer perimeter and the platen, which in turn will help prevent warping.

You can try increasing the temperature, slow down the cooling, or even use a fan. These settings depend on the type of media you're using, so it's important to do your research before you start printing. Through trial and error, you will be able to find the ideal settings for your printer and filament combination.