3D scanner london

3D Scanning In London | Cost Effective 3D Scanning

3D scanning in London

can we 3D scan your part?

This is the most common question that we get asked. Generally, the answer is yes; we can 3D scan your part. We offer a mobile 3D scanning service and work in London & the surrounding areas.

You will need to provide us with some basic information. We will need to know the size of the object and what the item is used for. A photo is helpful so that we can get an idea of how detailed the part is. It’s important to know if its load-bearing or if there is any damage to the part. All these questions can usually be answered with a chat over the phone or a brief email.

3D scanning large objects

When 3D scanning large items, we use our handheld mobile scanners. This type of scanner is suitable for objects from the size of a kettle up to a vehicle’s size. This type of scanner is mobile, so we can visit your London site to carry out the 3D scan. It captures very fine details and is perfect for replicating larger objects.

3D scanning small objects

For smaller objects, we use desktop 3D scanners. They are perfect for smaller items and range from around 30mm up to roughly 350mm. These scanners are part of our in house service. Small items are mainly posted out to us. It works well for cogs, clips, jewellery and other small but detailed objects.

Recent 3D Scans

bumper

This is an unedited 3D scan of a ford front bumper. The holes on the bumper are from markers to aid with 3d scanning.

The client wanted to use the data for several different reasons. The main aim was for fixing locations and modifications.

MG Ashtray

A customer took advantage of our 3d scanning services to create a mount for the cars’ main badge to fit the ashtray. We 3d scanned the ashtray and the badge to capture both curves, and we then used our SLA 3d printers to create a mount to create what looked like an OEM badge mount.

Chopper Frame

We used our mobile 3D scanning service for Raw Steel Choppers to digitally scan this rare chopper frame.

One of their customers was asked to reproduce the frame and make any modifications need and the data sent to a CNC company.

death penny

Here we used our desktop scanner for this world war one death penny. The customer wanted to reproduce the coin for so they could have their own copy. The coin was 3d Scanned with our desktop 3d scanner, we then cleaned the data ready for printing. The coin was 3d printed on one our resin printers.

Why Use 3D Scanning...

Advantages of 3D Scanning

Saves time when designing products – If your product design is based on an existing object, then 3D scanning can capture every detail of the part. Providing you with the data to design a matching part that fits perfectly. Or if you are altering a current design, you can use our 3D scan data as a good starting point.

Simplify the prototype process – Our 3D scanning services can reduce the number of prototype cycles needed. You can also compare the 3D scan data between each version. The 3D Scan process will also highlight any design flaws.

Improved Quality Control – You can use the 3D scan data to check the quality of your product. You can also check the scale and stability of the product. It is perfect for the manufacturing process, whether it’s 3d printing, CNC milling or injection moulding, you can spot deviations immediately and rectify them easily.

Re-manufacture parts without CAD Drawings – Want to re-manufacture parts but don’t have the original drawing? By using our 3D scanning services, you can create an exact drawing within hours. By reverse-engineering the scan data, you can design a new product. You can then compare the drawing for the old and new products.

Keeping costs down – All of the above points save time during the designing, prototyping, and manufacturing processes. As we all know, time is money. Utilising our 3D scanning services can make the design process 75% faster, and therefore 75% cheaper!

As we all know, time is money. Utilising our 3D scanning services can make the design process 75% faster, and therefore 75% cheaper!

Already have your scan data? – If you already have your scan data but need it reversed engineered and maybe 3D printed, check out our other services.

Scan to CAD

Our 3D scanning service is ideal for CAD users. We can capture exact detail using our 3D scanners. Then transfer this data into a 3D solid CAD model. 3D scanning is a much faster and more accurate way to collect data. Saving you time and money.

If you work in CAD and want to measure an obsolete part, this can be quite challenging. By using our 3D scanning services, we can create an accurate drawing within hours. This type of data is almost impossible to recreate by hand. We can provide you with accurate 3D scan data for a relatively low cost.

Lost CAD drawings are now a thing of the past. We can provide you with this information from a physical part. If you are ready to find out more about our 3D scanning services to CAD, please get in touch. We are more than happy to travel to your London site.

If you are ready to find out more about our 3D scanning services to CAD, please get in touch. We are more than happy to travel to your London site.

Reverse Engineering

Our 3D scanning services and reverse engineering services work hand in hand. You can utilise the scan data to streamline the manufacturing process.

We will reverse engineer the data. You can design a part to fit on to the original part.

You can also redesign and improve upon the original object and remove design flaws from the original part.

Do you want to make your designing and manufacturing process more accurate and much simpler? Manufacturing better quality and more accurate parts? Then our 3D Scanning Services is the service you need.

If you would like to find out more, please get in touch to discuss your requirements. If you would like us to travel to your London location, please let us know.

Lets Talk

We’re ready for your enquiry. Please fill out the form, and someone will get back to you as soon as possible or give us a call, which ever suits you best.

Name

Phone

Message

Upload

3D scanning and 3D printing studio based in East London

An important part of our work is to work with creative directors. We have 20 years experience of guiding creatives through the 3D world.

Our collaboration with photographers Nick Knight, Daniel Sannwald, Sølve Sundsbø have produced some amazing artwork animations and visual effects. We have worked on album covers, music videos, fashion films, art installations, Bronze sculptures, Stage props and also featured on many magazine covers and editorials.

A peek of the amazing work we have done through the year

Daniel Sannwald for Arena Homme+

Nick Knight x Kanye West for V Magazine

Lane Crawford S/S '13

3d Scanning is a fantastic way to capture objects into the computer using Laser or Structured light techniques.

We have 7 different types of scanning rigs. All of our scanning rigs capture both data and colour.

The most versatile 3D laser scanning & 3D object bureau in Europe for: 3D Laser Scanning, 3D Body scanning, Scaling Statues, 3D Facial scanning, 3D Printing, Mobile high resolution colour 3D body scanning, bespoke 3D Laser Scanning and 3D modeling for film, TV and web applications.

We can turn the scan data into CAD data.

Our work with sculptors and model makers is a game changer. We have been working with sculptors like Nikos Kotziamanis transforming their artwork in a matter of days.

We can scale up or down any object you have.

This also allows for any manipulation of the sculpture in its digital state. We can edit the data to suit its new purpose.

Sculpture /right/ measuring 2.5 meters scaled down to 5 cm.

Images of Brian Clough with Kind permission of Les Johnson FRBS.

http://www.lesjohnsonsculptor.com/

We have a Zcorp Z450 colour 3d printer, this printer prints in plaster, after it is printed the model is quite porous we soak in a choice of infiltrants, for maximum strength we would soak it in Epoxy resin, for speed we would soak it in Super Glue, for moulding we soak it in our secret formula of Wax.

Our Form 1 3D printer uses plastic as its printing material. Objects are much stronger but very hard to manipulate after. It is often used for prototyping and objects that do not require retouching.

We have been involved with 3D printing for a long time. There isn't much we haven't been challanged with. Whatever your project is, just tell us your end goal and we should be able to help you reach it.

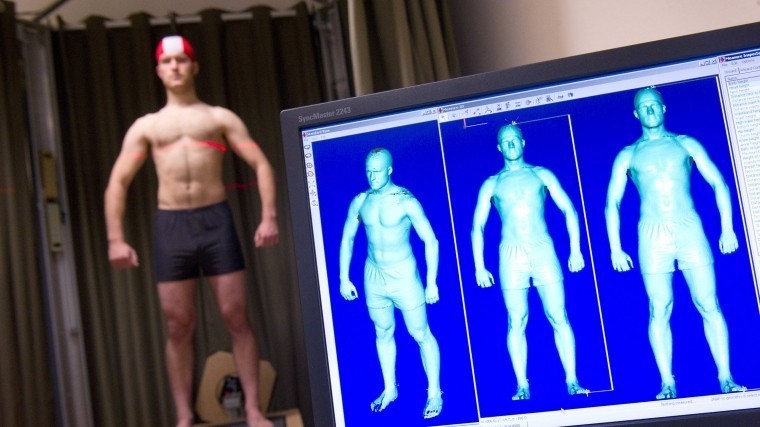

Rapido3D Were the first company to design a full colour whole body scanning solution in the UK, nobody has as much experience in the UK as Rapido3d when it comes to scanning the human form.

Our body scanning rig gives us unlimited positions capturing more data than any other scanning solution available to date.

Non Contact. Non laser solution.

Because it has been specifically designed to digitise human bodies, it's an ideal solution for game development, medical research, animation and cinematic special effects.

Our 3D Full Body Scanner captures a subject's 3D coordinates and high resolution color texture. the results can then be imported into most 3D software eg, 3D Studio Max, Softimage, Kaydara, Maya, Lightwave, OBJ, STL, VRML just to name a few, our colour output is compatible with our new Zcorp Z-450 full colour 3D Printer

the results can then be imported into most 3D software eg, 3D Studio Max, Softimage, Kaydara, Maya, Lightwave, OBJ, STL, VRML just to name a few, our colour output is compatible with our new Zcorp Z-450 full colour 3D Printer

Naomi Campbell

3D scan of an actor and the marble CNC sculpture

Reza Aramesh

3D scan of a model for Diesel

We have been involved with 3D scanning and 3D printing for 20 years. There is no other studio in the uk that is familiar with the technology and as versatile as we are.

Being the studio we are we have worked with top artists from around the world, we help guide creative directors through the medium of 3D scanning and help them visualise their wants.

Texel Portal BX - Texel

Portal to a new reality

Go demo

- Description

- Exploitation

- ON

- Work results

- Contents of delivery

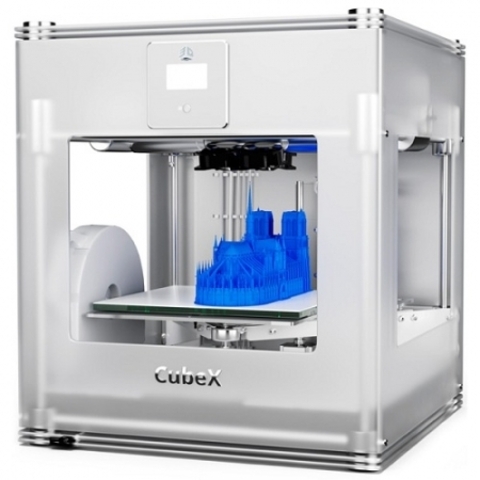

Texel Portal BX is a 3D scanner for color scanning people. Fill out the registration form, start scanning and in 30 seconds you will receive an accurate 3D image of a person in full growth.

Fill out the registration form, start scanning and in 30 seconds you will receive an accurate 3D image of a person in full growth.

Portal BX is more than just a 3D scanner. This is a whole complex, which consists of a high-tech scanner and high-tech software from Texel. While the scanner analyzes a person standing on the platform in 30 seconds, special algorithms are preparing to take over. In just 1 minute in the Texel Cloud, they turn scan results into a realistic 3D model.

The scanner requires minimal human participation - it is enough for him to register in the system, specifying his name and e-mail, where a link to the 3D model will be sent. He will be able to share a link to it with his friends in social networks directly from our cloud. We have automated everything that could be simplified or entrusted to electronics: scanning, data processing, building a 3D model and preparing it for production.

You don't have to figure out how it works - the 3D scanner and software will do everything for you. Texel Portal BX is reliable and completely predictable in operation. As a result, the client will receive an accurate three-dimensional digital model for subsequent 3D printing or integration into other services.

Texel Portal BX is reliable and completely predictable in operation. As a result, the client will receive an accurate three-dimensional digital model for subsequent 3D printing or integration into other services.

Get started as soon as our technician sets up and tests your 3D scanner. Portal BX comes with a powerful computer, a comfortable keyboard with a touchpad, a registration console and a basic repair kit. So that you can create a unique atmosphere at the place of use of the 3D scanner and draw attention to your brand, we will develop an individual design for you and perform customization on an individual project.

Software

We are proud of the science-intensive Texel Cloud software, which was developed by our team of talented computer vision scientists (and this is confirmed by 6 thematic scientific publications). Our software combines several million points into a coherent high-precision 3D model, and you get scan results quickly and spend a minimum of resources. At the same time, faces, shades and textures are preserved, facial expressions, hairstyle and clothes are realistically transmitted.

At the same time, faces, shades and textures are preserved, facial expressions, hairstyle and clothes are realistically transmitted.

To scan complex hairstyles, dark, shiny and very thin elements, we use the best sensors on the market. Even complex details of clothing will look like real ones, and the proportions will remain natural. Once the scan is complete, the 3D copy can be integrated into various services, such as AR/VR systems or a virtual fitting room.

The result of the work is the creation of a 3D copy of a person and its transfer to the digital space. Access to a 3D copy is carried out via a link sent in an e-mail or via SMS.

How do I manage the scan results? Invite your customers to make a reduced 3D copy of them or receive a digital model by mail and from there share the link with friends through popular social networks. You can also integrate a 3D model into other services — AR/VR systems, a computer game, or a virtual fitting room.

Maximum scope of delivery of Texel Portal BX 3D scanner:

- Texel Portal 3D scanner podium - 1 pc.

- Texel Portal 3D scanner columns - 2 pcs.

- Texel Portal 3D scanner control unit - 1 pc.

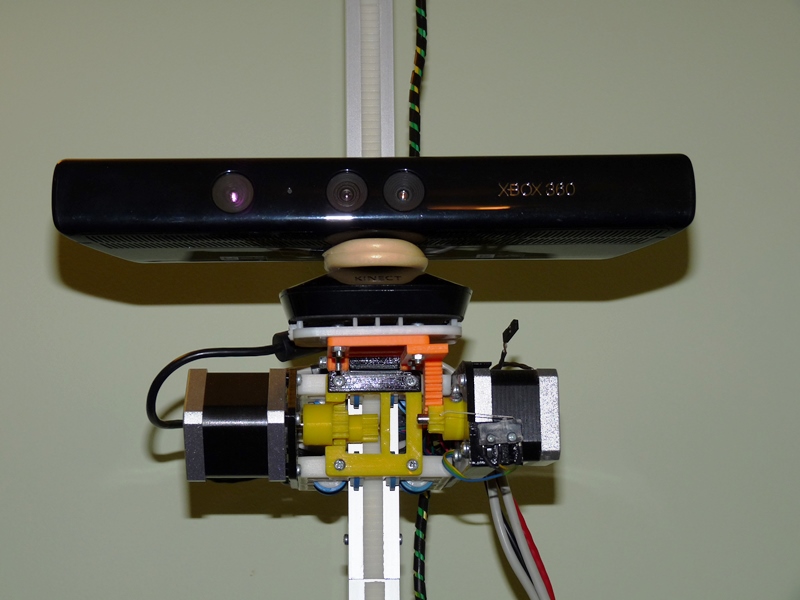

- Sensors (cameras) Asus Xtion Pro Live - 5 pcs.

- Spare parts kit (brackets, connectors, heat shrink tube, hex keys, cable ties, cable-channel links, cable tie, potentiometer, USB-cable for controller firmware).

- Cable, extension and adapter kit (3 network extensions, patchcords, USBcords, power cords, HDMI, VGA, DVI, DisplayPort cables, HDMI-DVI, HDMI-VGA adapters).

- Wi-Fi router TP-Link TL-WR841N - 1 pc.

- Wi-Fi adapters TrendNet TEW-804UB - 2 pcs.

- PC Spare Parts.

Plywood box dimensions: 2410×1550×320 mm.

Net weight: 112.7 kg.

Gross weight: 255 kg (with accessories in box).

Created the most accurate 3D scanner | Jewelry INFO

07/05/2019 03:53 Production

Ukrainian inventor Leonid Nazarenko and his son Denis create a high-precision 3D scanner for jewelers. It has no analogues in the world in terms of price and quality.

It has no analogues in the world in terms of price and quality.

The story of two inventors began about four years ago when they wanted to get high-precision 3D models of small objects, such as coins or figurines. But faced with the fact that the laser scanners available on the market, firstly, are very expensive, and secondly, their accuracy left much to be desired.

The very idea of the scanner was born when Denis Nazarenko was trying to make a model of the statue of Manjushri. “But scanners capable of capturing the smallest details of a model cost at least 17,000 euros and were out of reach for a small company. So we decided to create our own,” the Kickstarter presentation reads.

Who are Nazarenko

In a small office in the town of Vyshneve near Kyiv, father and son set about experimenting. The background allowed them to use deep knowledge from completely different engineering fields.

Leonid Nazarenko began his career at the Antonov plant, which built the world's largest An-225 aircraft. He created models of aircraft from childhood, and then taught schoolchildren to do the same. Leonid had a good understanding of metalworking and a wide range of knowledge in engineering disciplines.

He created models of aircraft from childhood, and then taught schoolchildren to do the same. Leonid had a good understanding of metalworking and a wide range of knowledge in engineering disciplines.

Denis Nazarenko won various competitions in mathematics, physics and computer science. He has been working on software development for many years. And his most famous project is Start Menu X, a convenient alternative to the Windows Start menu, which has been used by many people around the world.

LED vs. Laser

As two engineers found out, the laser projector creates a lot of noise when scanning, which is bad for the quality of the 3D copy. And he has a worthy alternative. The light-emitting diode (LED) beam in combination with good lenses made it possible to achieve noticeably better results.

This photo shows how much noise the laser beam has compared to the LED beam:

Another bonus. This technology does not require expensive projectors and cameras.

This technology does not require expensive projectors and cameras.

Entrepreneurs decided to take their idea to Kickstarter through a partner who lived in Canada. Last spring, they managed to raise over $22,000 to produce their first model, the D3D-s desktop 3D scanner.

According to Denis Nazarenko, who was contacted by the journalist Liga.Tech , together with their father, in a year they assembled and delivered about 10 scanners to investors who supported them with money on a crowdfunding platform. A few pieces are still being finalized.

Fashion for second rings

According to Nazarenko, during this time they managed to find the exact niche for their devices - the American jewelry market. According to him, the tradition of wearing so-called shadow wedding bands is widespread in the States. These are additional rings that spouses order in addition to engagement rings, for example, for a wedding anniversary, and then both of them are worn on the same finger.

In such cases, jewelers need to scan the engagement ring and actually make a replica of it.

Antique ring scanned with D3D-s scanner by D3D-s on Sketchfab

Ukrainian inventors started receiving requests from jewelers and dentists. Such niche demand prompted Nazar and Denis to launch their second Kickstarter campaign - a 3D scanner specifically for jewelers. They launched it a week ago, at the end of June 2019, and have already collected the requested amount - $13,600 out of $15,000. The project was supported by eight people who wanted to get a jewelry scanner. The first supporters will get it for $4000-6000. And in retail, the device will already cost $8,000

“The D3D-s scanner is suitable for both self-employed jewelers and professional teams with experience using ultra-expensive scanners,” the developers note in the project description.

According to Denis Nazarenko, a 5 megapixel camera is installed in the scanner, which is much cheaper than a less accurate 1. 2 megapixel camera designed for laser scanners.

2 megapixel camera designed for laser scanners.

Another innovation is mobility. The scanner also has six directions for movement. This allows you to scan figures of any complexity with a light beam. Scanning is fully automatic. You just need to specify the size and click the button.

“When we created the desktop scanner, we wanted to achieve a resolution that would allow us to scan a coin. As a result, adapting the scanner to the needs of jewelers was not a problem. We have added another axis of rotation and reduced the size of the scanner. We've also upgraded the optics and camera, as jewelers don't need color scanning. We also installed high-precision motors,” the developers of the device say.

The price of the device is much cheaper than analogues. The closest model is B9Scan 350 - will cost almost $15,000. At the same time, even the most expensive laser models (for $50,000) cannot provide such a distance between points as the Ukrainian development - 0.